Ground and underground combined coal and coal-bed gas co-mining method for low-permeability coal bed group

A technology of coalbed methane and low air permeability, applied in underground mining, mining fluid, surface mining, etc., can solve the problems of low coal seam permeability, high cost, and long investment recovery period, so as to improve coal mining efficiency, reduce outburst risks, The effect of low gas content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

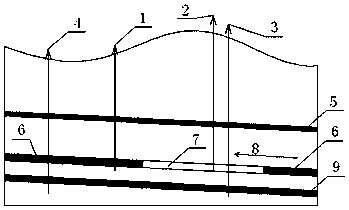

[0024] Such as figure 1 As shown, a method for co-mining coal and coalbed methane in the upper and lower wells of a low-permeable coal seam group comprises the following steps:

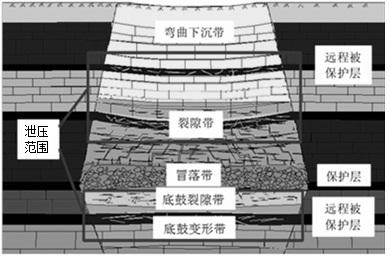

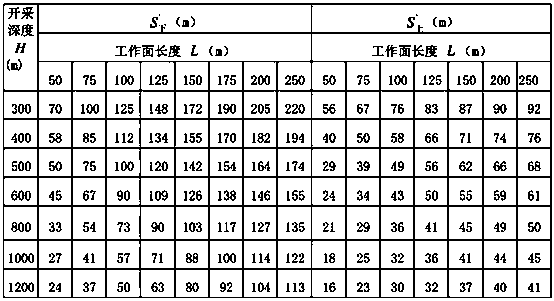

[0025] (1) The protective layer (safety layer) is mined first. When the protective layer is mined, negative pressure extraction of CBM is carried out through mining wells. The mining wells are arranged within the range of 40-50m from the return airway. The well spacing is controlled within the range of 80-200m, and the distance and well spacing from the mining well to the return airway are reasonably set according to the actual gas content of the coal seam and the frequency of gas exceeding the limit. For areas with high coalbed methane pressure, ground fracturing is used to drain underground wells, surface drilling, fracturing the protective layer, release the pressure of coalbed methane in the area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com