Operating method of powder material packing scale

A technology of powder materials and working methods, which is applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of uncontrollable powder quantitative supply, affecting packaging work efficiency, low packing density of materials, etc., and achieves bagless packaging. Pollution, efficiency improvement, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

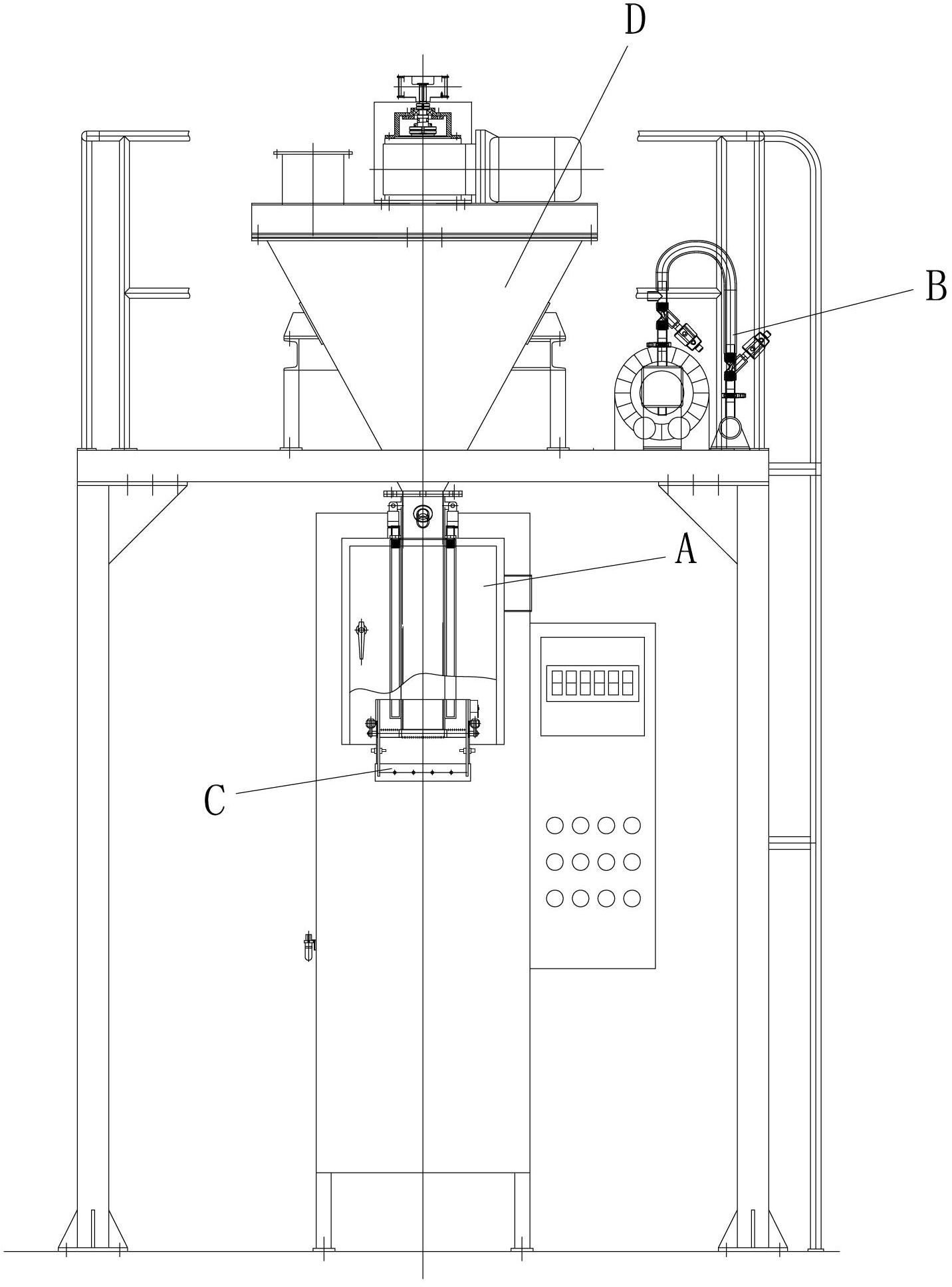

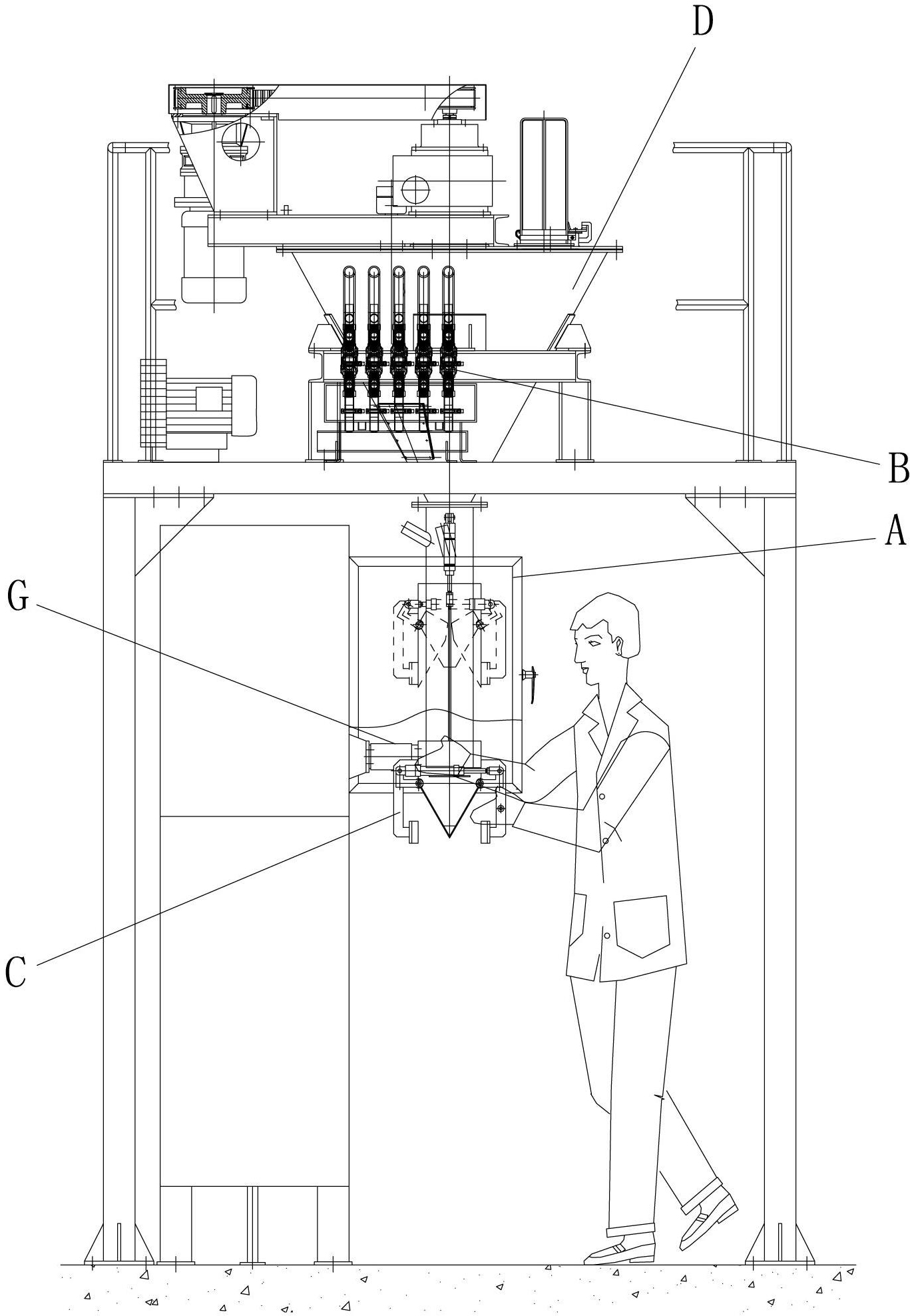

[0022] See Figure 1-9 , the packaging scale of the present embodiment includes: a degassing and unloading device A arranged on the bottom outlet of the hopper D, and an air extraction nozzle connected to the degassing and unloading device A for providing degassing and blowing and blocking gas sources Blow combination valve B, bag clamping mechanism C located at the bottom of degassing and unloading device A.

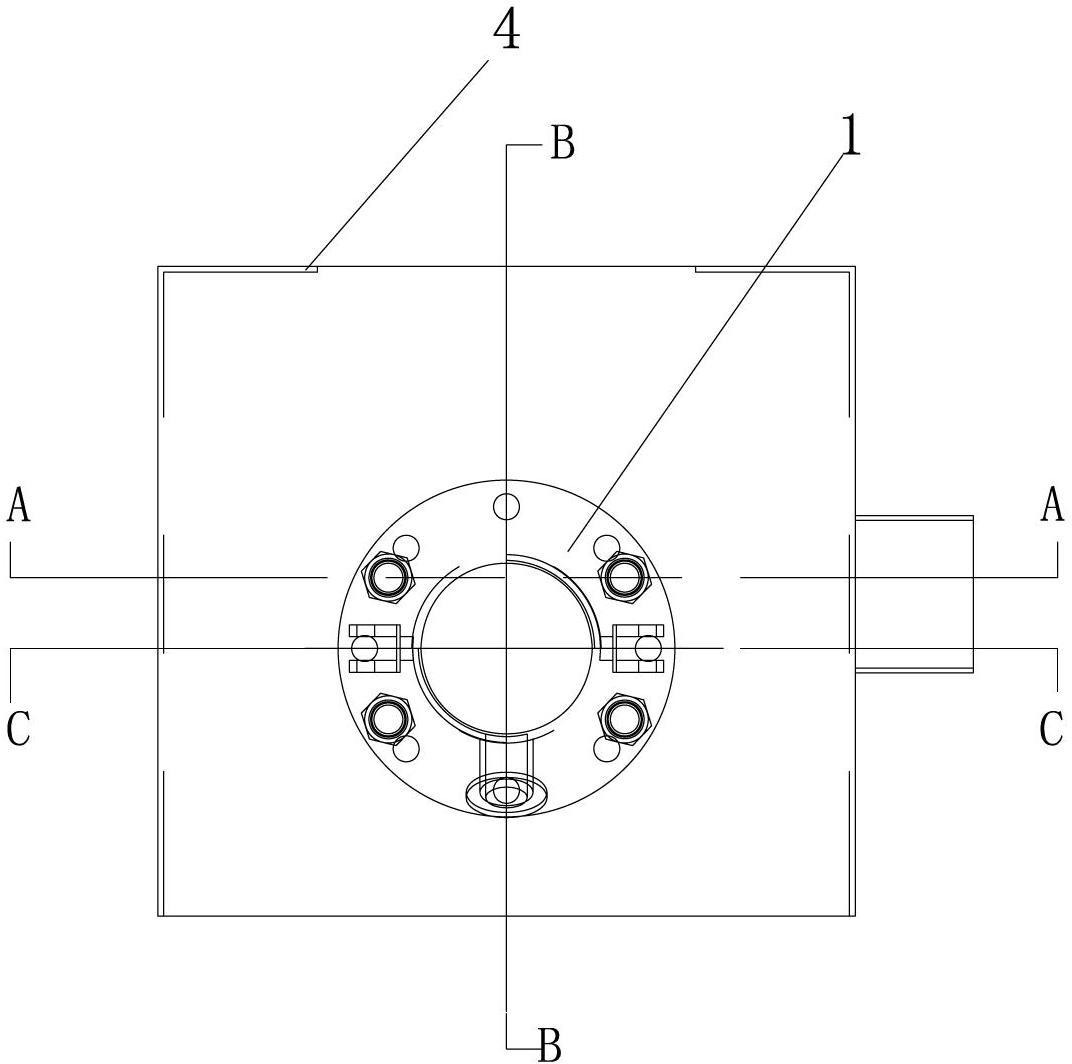

[0023] The degassing and blanking device A comprises: a blanking cylinder 1, the inner wall of the blanking cylinder 1 is provided with a cylindrical inner filter element, and the outer wall of the blanking cylinder 1 is provided with a The interface 2 communicated with the gap between them; the interface 2 is connected with the combined valve B of air extraction and injection.

[0024] A plurality of outer filter cores 3 are evenly distributed around the lower barrel 1; the ports on the top of the outer filter cores 3 are connected to the combination valve B for air e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com