Patents

Literature

463results about How to "Reduce heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

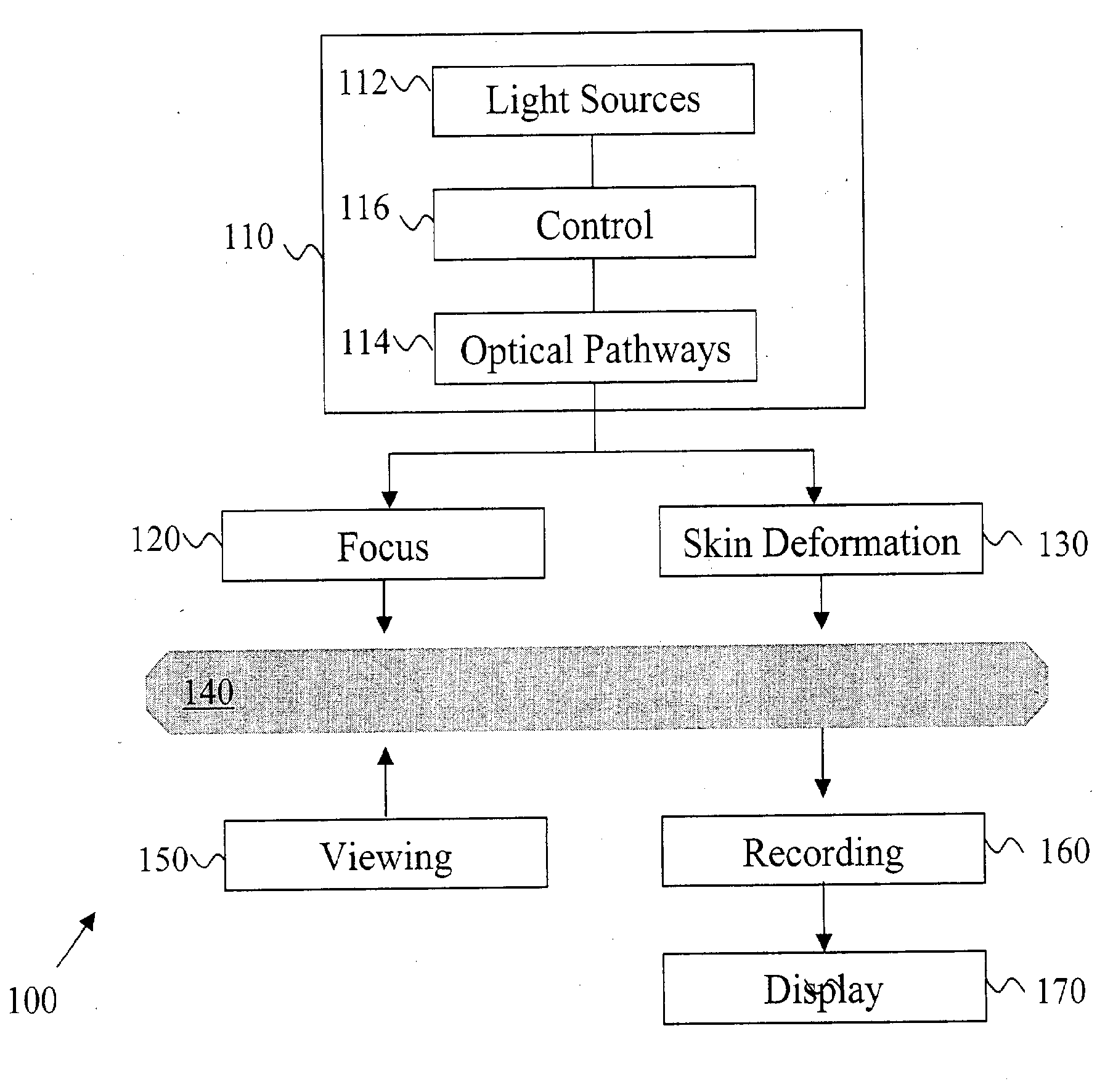

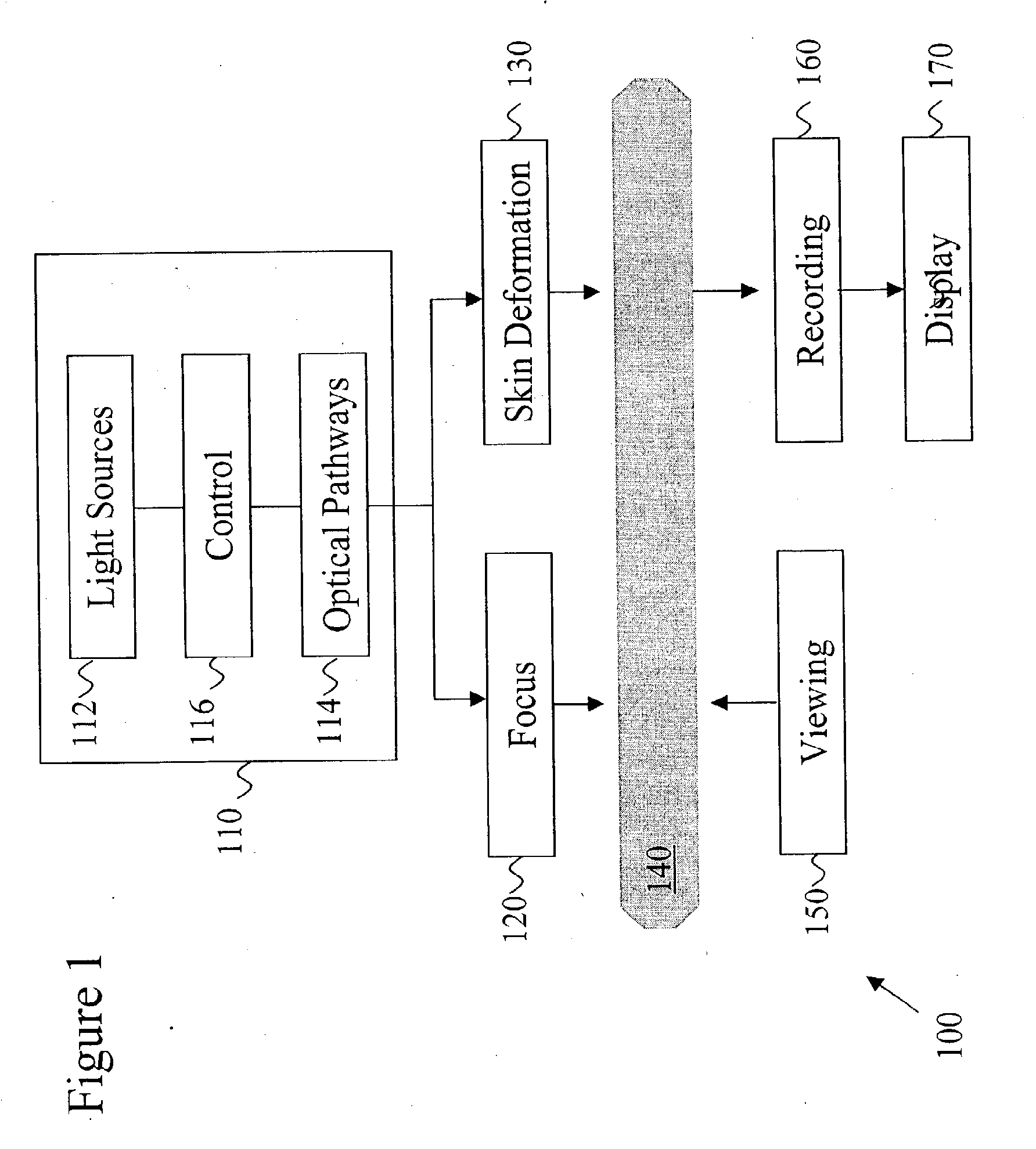

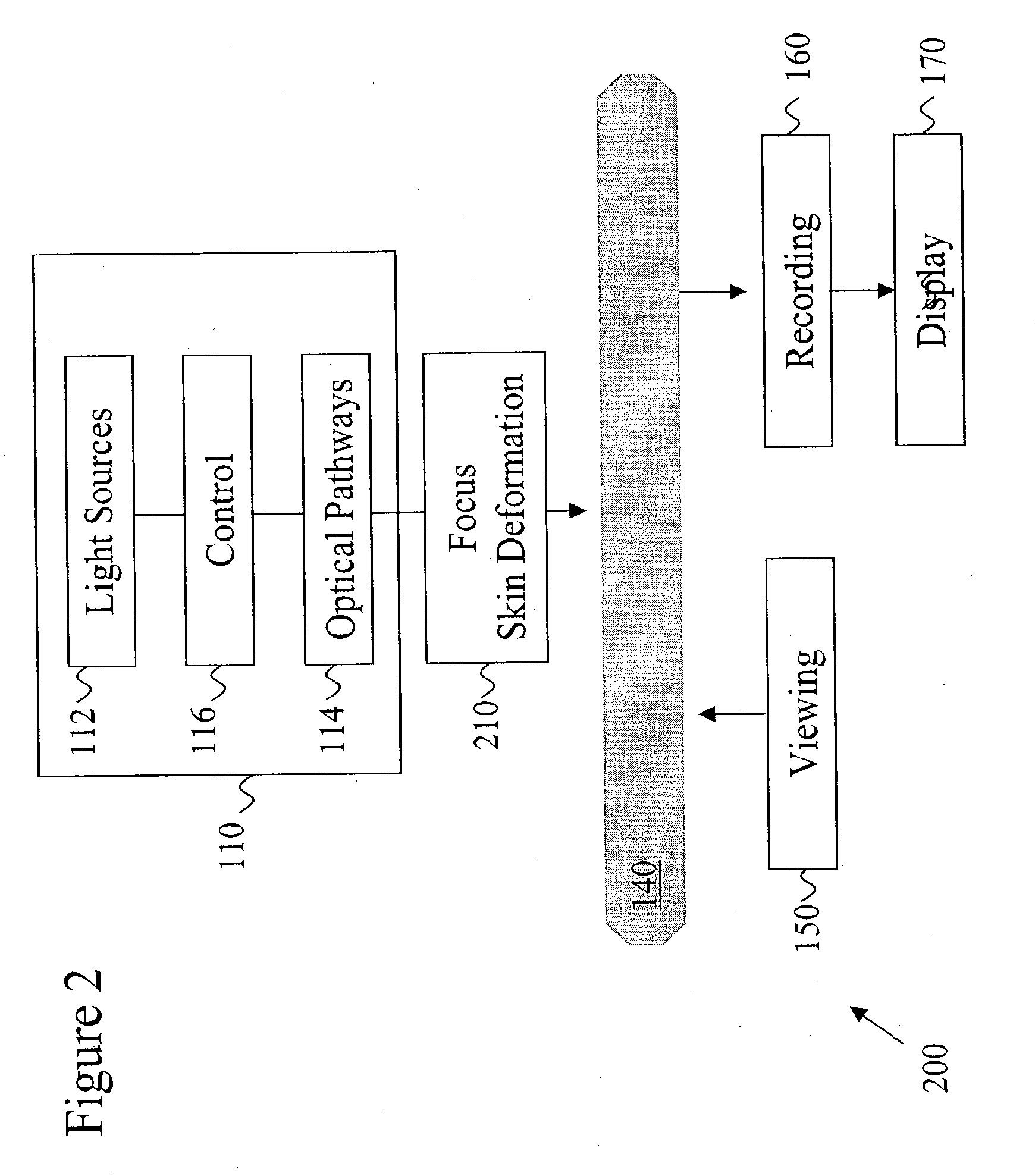

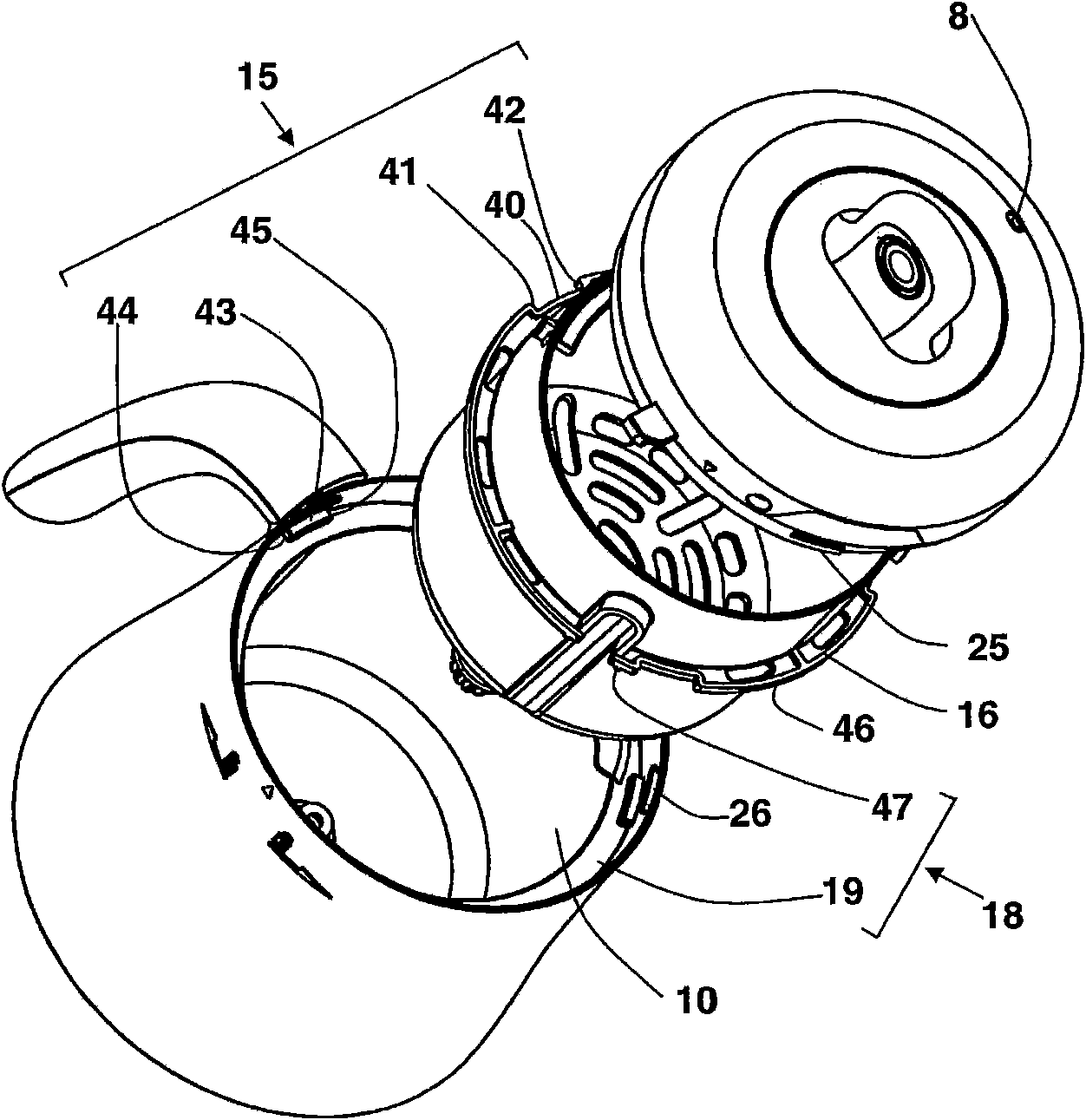

Dermatological Apparatus and Method

InactiveUS20090118720A1Reduce heatReduce heatingSurgical instrument detailsTherapeutic treatmentLaser light

A dermatological laser apparatus in accordance with the present invention may comprise a plurality of laser light sources, a corresponding plurality of optical delivery pathways, and a focusing system. The dermatological laser apparatus may also comprise a control system for controlling the operation of the plurality of laser light sources to generate a broad range of therapeutic treatment patterns on or within a layer of skin.

Owner:RELIANT TECH INC

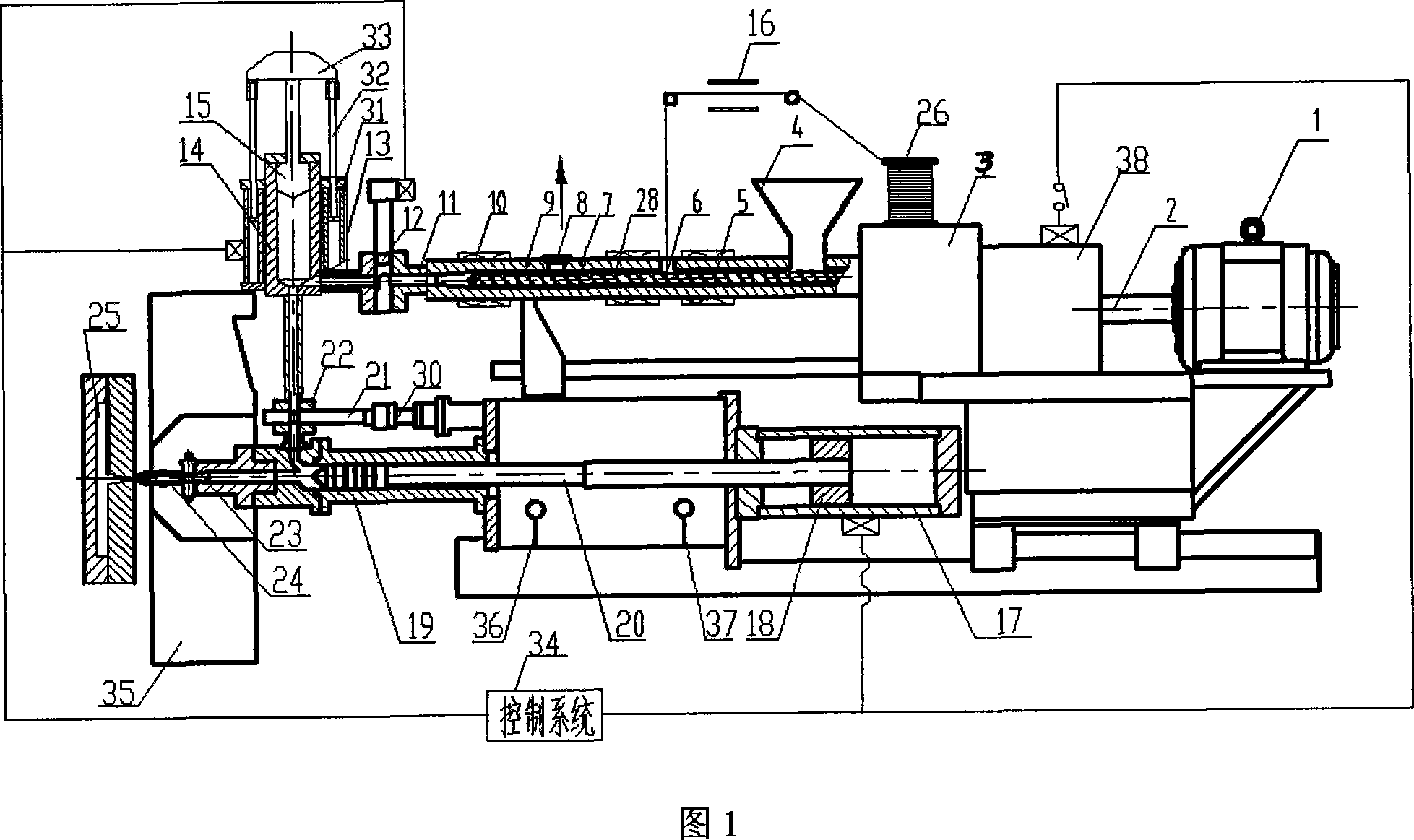

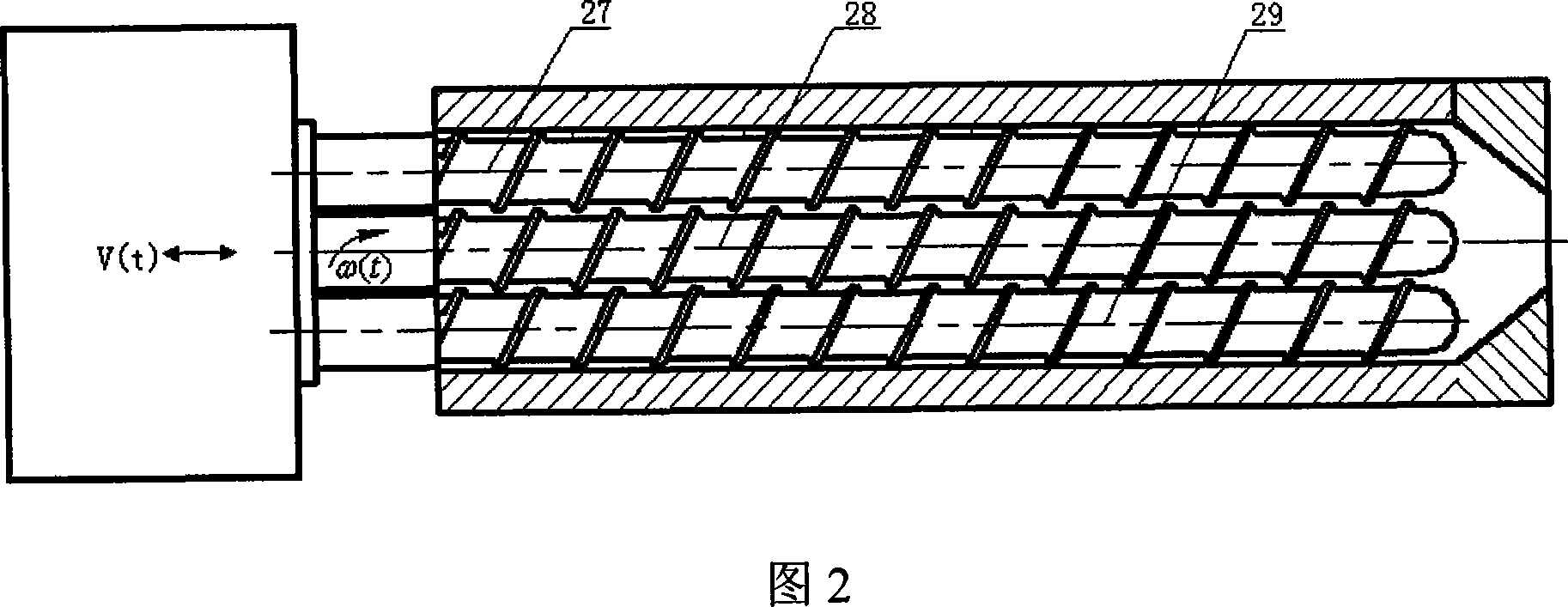

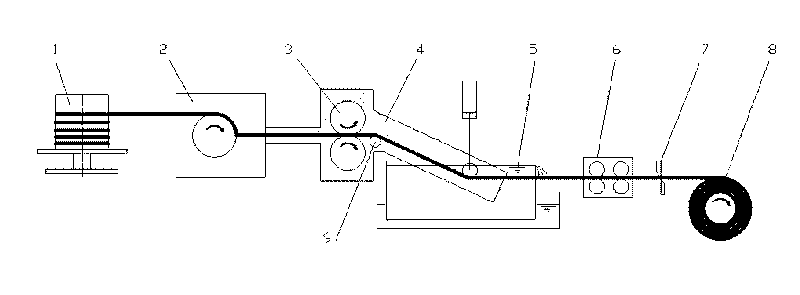

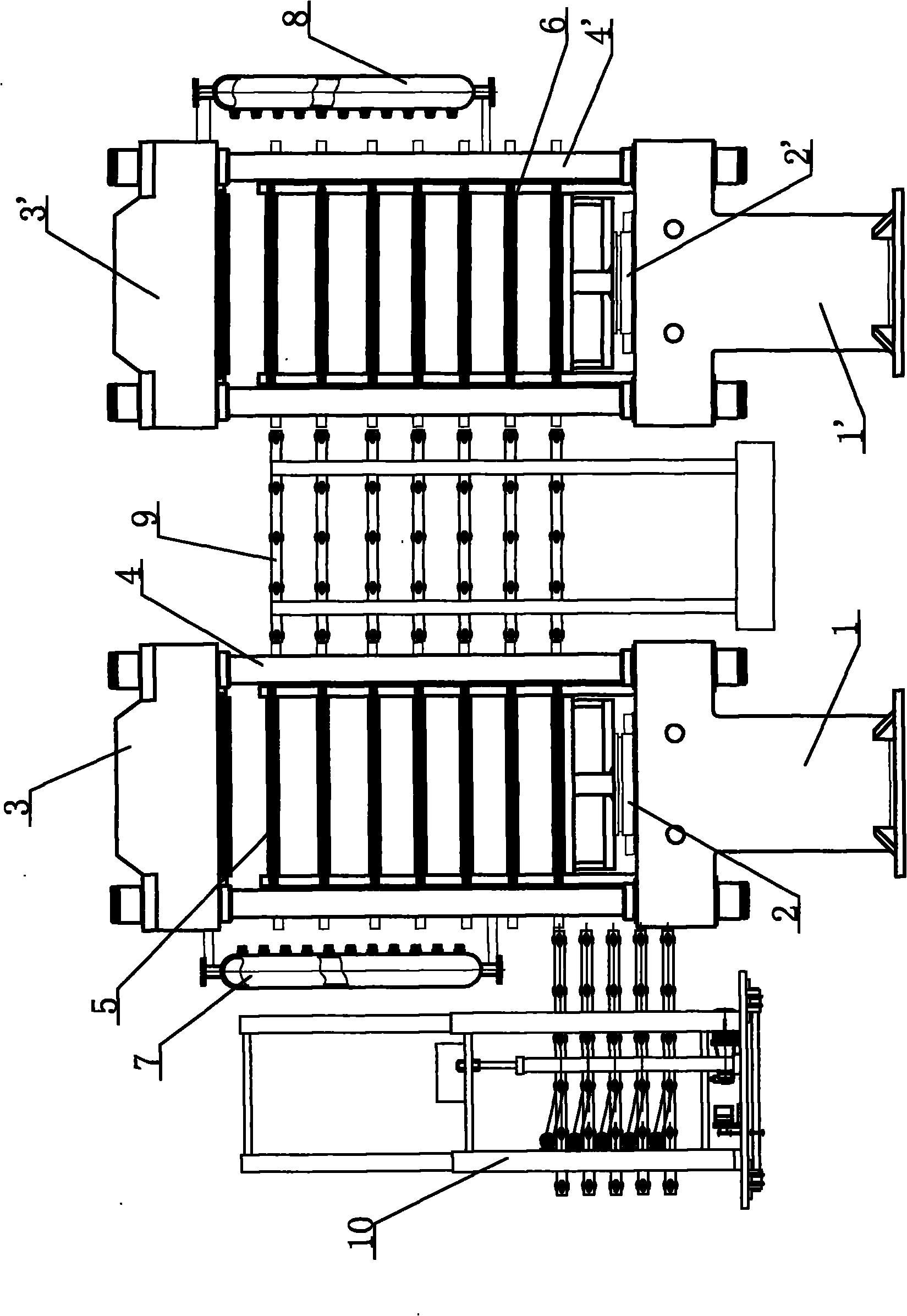

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

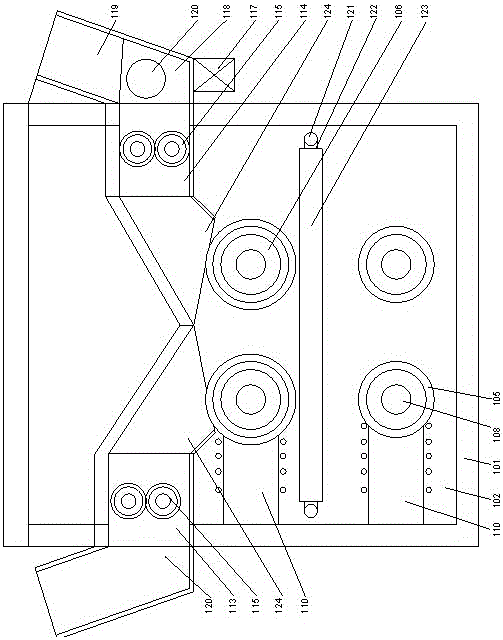

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

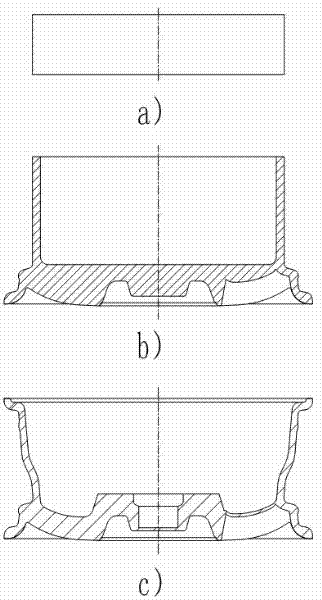

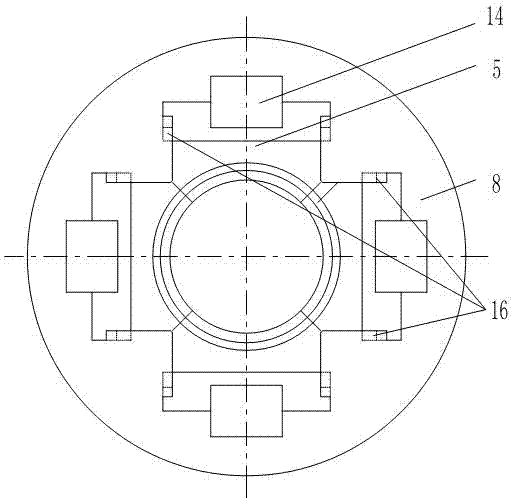

Combined plastic forming method of automobile hub and matching forming mold of automobile hub

InactiveCN102179664AReduce manufacturing costReduce investmentShaping toolsExtrusion diesAlloyEngineering

The invention discloses a combined plastic forming method of an automobile hub and a matching forming mold of the automobile hub. The method comprises the following steps of: 1, forming the automobile hub by using light-alloy blanks through a set of forming mold at two steps under the condition of constant temperature, wherein the forming mold is provided with a split lower mold, two upper extrusion male molds and two upper bulging male molds, and the upper extrusion male molds and the upper bulging male molds are sequentially matched with the split lower mold; 2, matching the blanks in the mold by using the upper extrusion male molds and the upper bulging male molds during forming; 3, pre-forming a spoke part of the hub and the lower part of a rim by adopting an extrusion process; 4, forming the upper part of the rim into a hollow pipe blank; and 5, matching the upper bulging male molds with the lower mold and forming a pre-formed part formed in the step 1 into the hub through the extrusion process. Equipment disclosed by the invention has a simple structure, the deformation resistance of each-step process is lower, the mold size and the equipment tonnage are effectively reduced,the production efficiency is improved, and the production cost is lowered.

Owner:HENAN UNIV OF SCI & TECH

Smelting method of low-carbon aluminium killed steel with low silicon content

The invention relates to a smelting method of the low-carbon aluminium killed steel with a low silicon content, belonging to the steelmaking technical field of the metallurgy industry. The technical scheme in the invention is as follows: before blast furnace vanadium-containing molten iron enters the steelmaking process, the processes of vanadium extraction and silicon removal are performed, the steelmaking process adopts the semi-steel smelting process, low-silicon pre-melted composite refining slag is added in molten iron during the slag-stopping tapping process, the deoxidizing process andthe alloying process for pre-deoxidation; after molten iron enters the ladle furnace (LF) refining process, the conventional mode for preparing white slag through electrode heating is not adopted, white slag is rapidly prepared by covering a cover for heat preservation and using aluminum powder as a deoxidizer in the reducing atmosphere of argon stirring; then calcium treatment and argon soft blowing are performed, the thermodynamic and dynamical conditions of the silicon kickback of molten steel are inhibited under the premise of ensuring the refining quality; and after the argon soft blowing of molten steel is completed, molten steel enters the continuous casting process. By adopting the method, the Si element qualification rate of the low-silicon and low-carbon aluminium killed steel is up to more than 98%; and as the refining electrode heating process is not adopted, the method is characterized by low energy consumption, environmental protection and low production cost.

Owner:HEBEI IRON AND STEEL

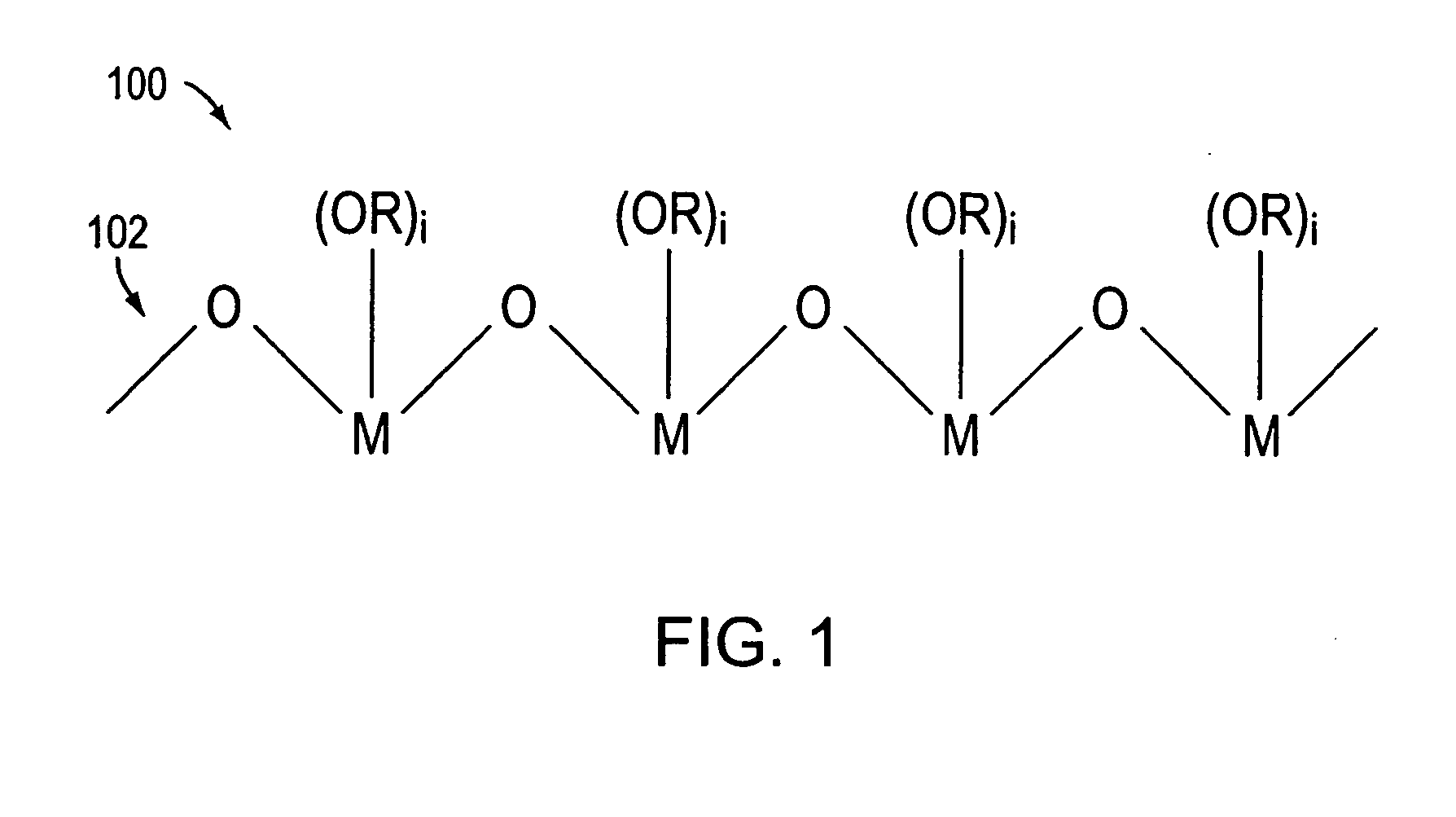

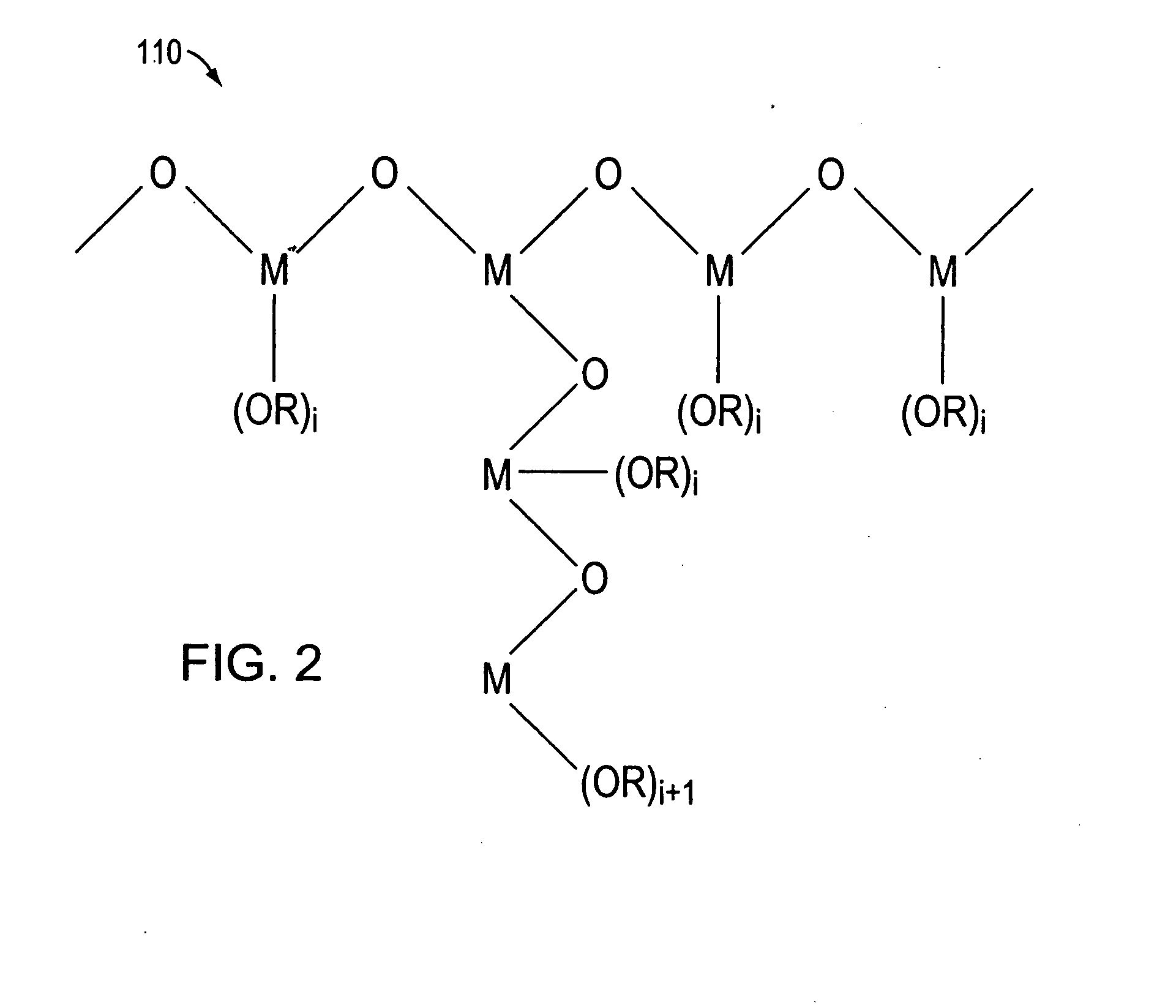

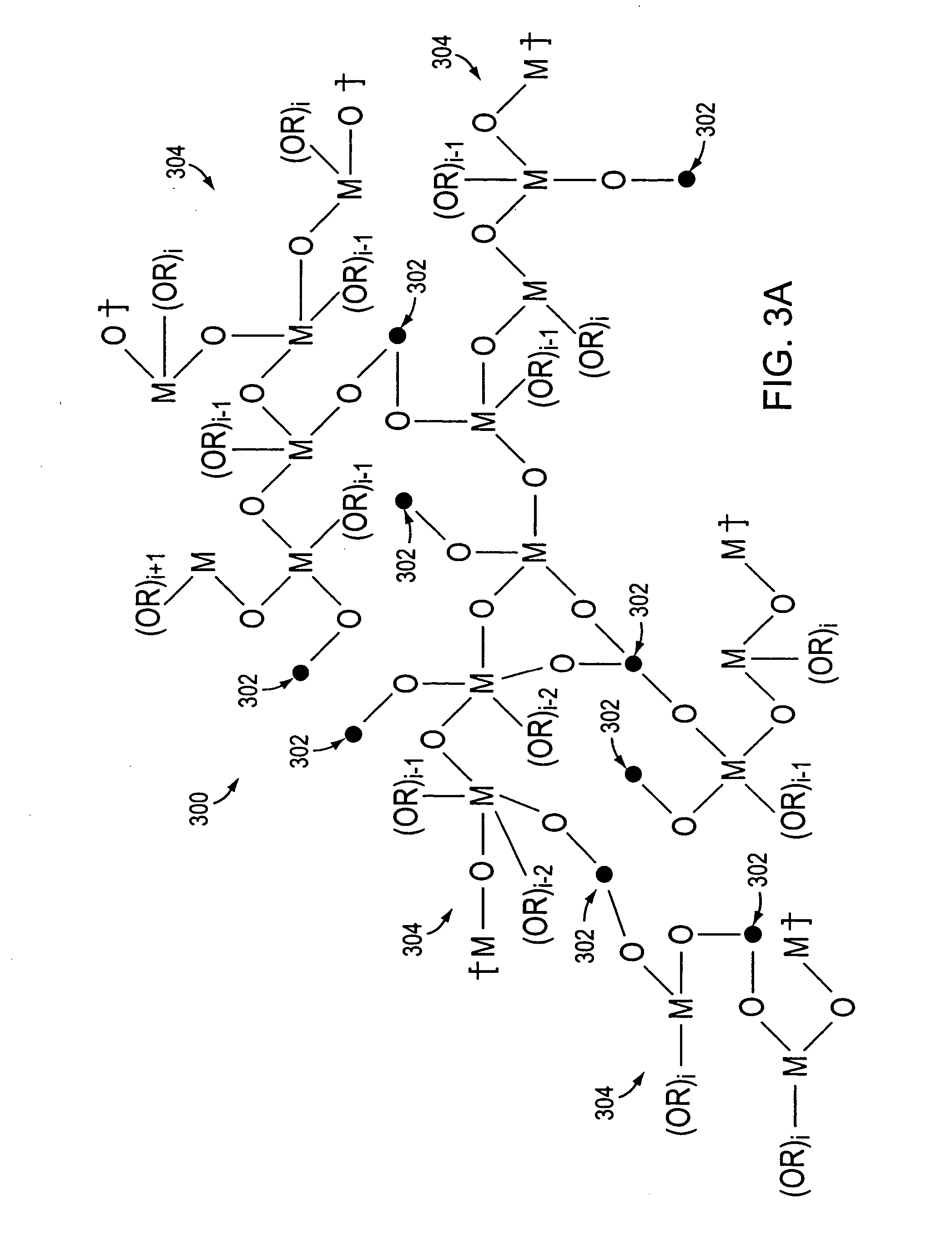

Low temperature interconnection of nanoparticles

InactiveUS20050019414A1Improve performanceEasy to manufacturePowder deliveryHeavy metal active ingredientsNanoparticleOptoelectronics

A polymeric linking agent enables the manufacture of photovoltaic cells on flexible substrates, including, for example, polymeric substrates. Photovoltaic cells may be fabricated by a relatively simple continuous manufacturing process, for example, a roll-to-roll process, instead of a batch process.

Owner:CHITTIBABU KETHINNI +1

Continuous extrusion and continuous rolling process method and production line used for producing oxygen-free copper strip billet

ActiveCN101712050ARealize continuous productionReduce heatingMetal rolling arrangementsProduction lineShielding gas

The invention belongs to the field of copper processing, relating to the process method of the production of copper strip material, and in addition, relating to a copper strip material continuous extrusion and continuous rolling device. The invention provides a continuous extrusion and continuous rolling method used for producing oxygen-free copper strip billet, comprising the following steps: taking the oxygen-free copper rod as a raw material to carry out continuous extrusion to obtain the copper slabs; utilizing the heat generated in extrusion to carry out continuous hot rolling on the copper slabs; and cooling the copper bandlets after hot rolling, discharging to obtain the copper strips, wherein protective gas is adopted to protect the space between the extrusion outlet and the cooling inlet. The invention combines the advantages of low content of oxygen of the upper-draw process, great deformation of the continuous extrusion method and good performance of hot rolling method; the product has the advantages of low content of oxygen, compact organization, fine grains and excellent comprehensive performance; and the process method has the advantages of short flow, less heating and annealing processes, energy saving and environmental protection and the like.

Owner:大连康丰科技有限公司

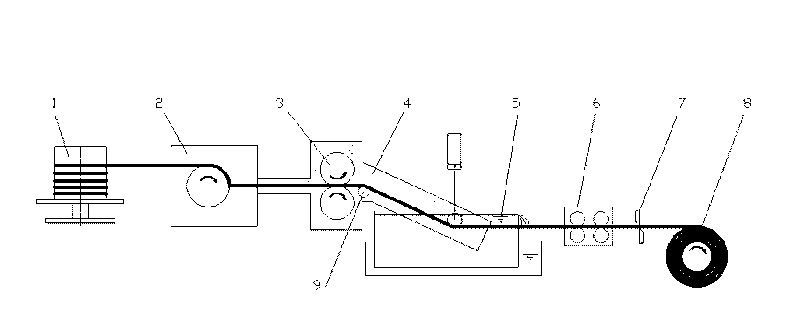

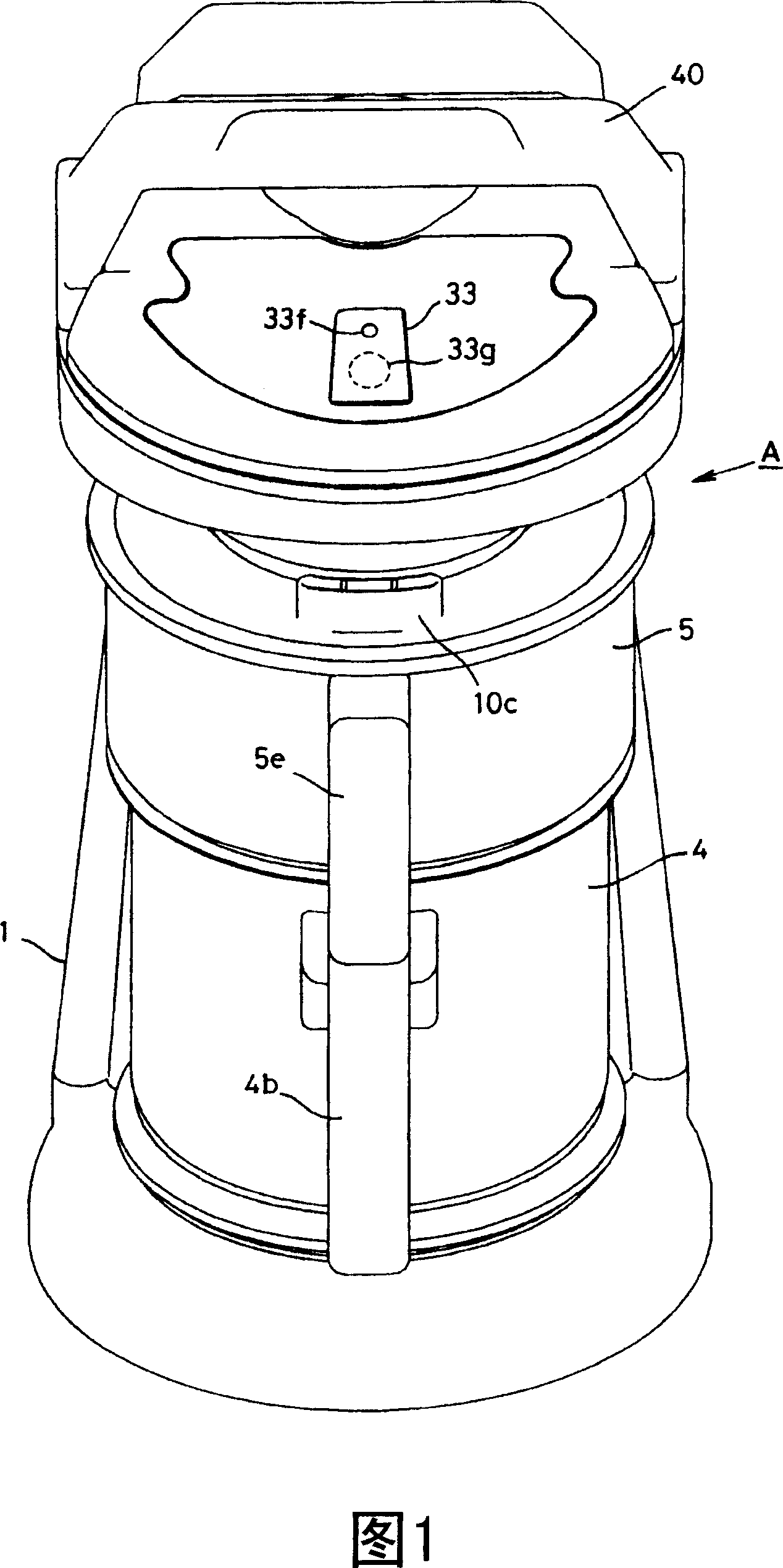

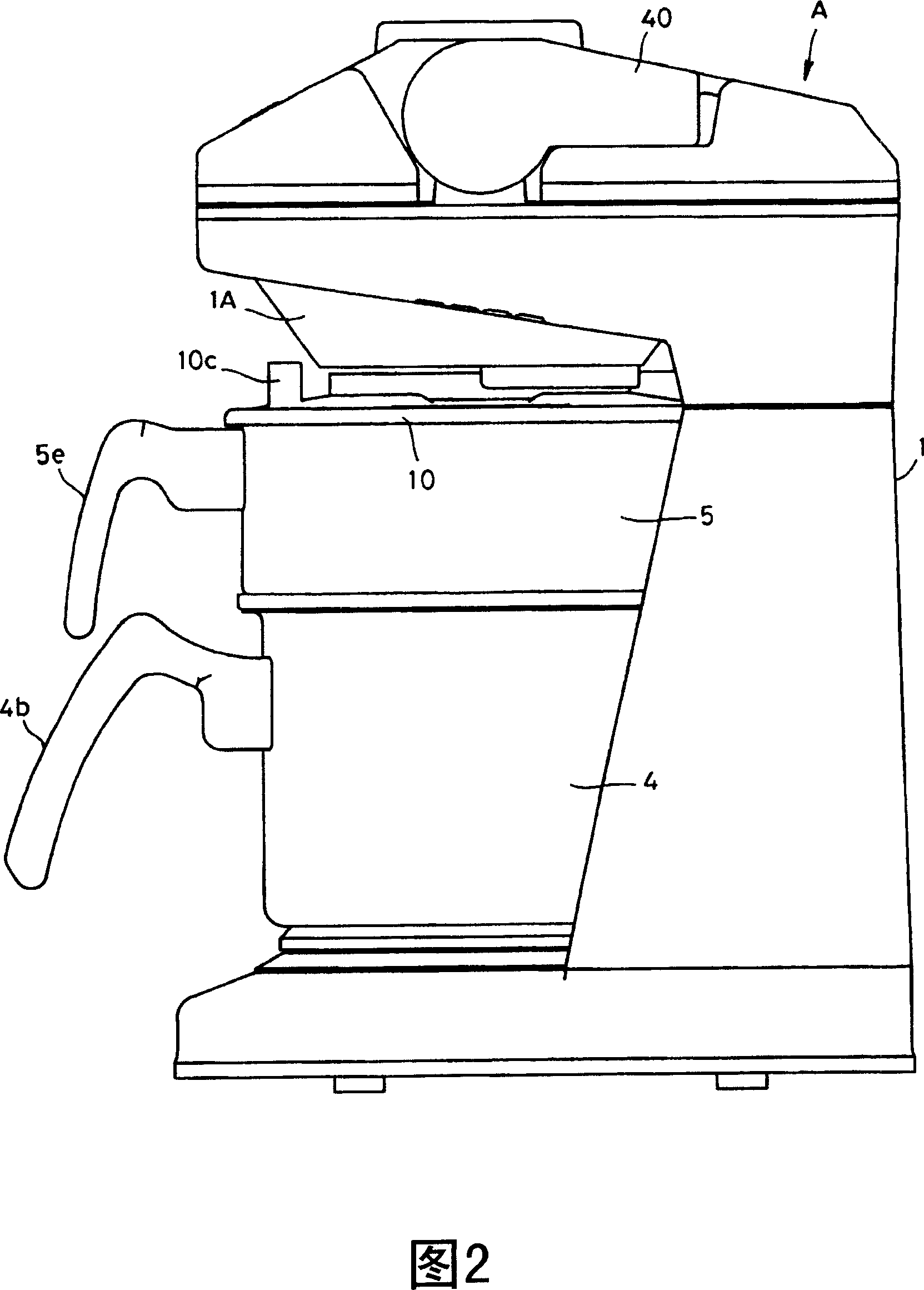

Liquid food cooking method and cooking device

InactiveCN1973738AImprove qualityGuaranteed air tightnessBeverage vesselsFood preparationProper timeFood material

The invention provides an apparatus and method for cooking liquid food, which comprises a heating mechanism, a pressure vessel heated by the heating mechanism, a extracting vessel having a connected pipe extending from the bottom of a receiving-filtration mechanism into the pressure vessel and arranged on an opening of the pressure vessel for sealing the opening, a disintegrator inserted into the inner of the extracting vessel. The extracting vessel is filled with food material and cooking water, then the disintegrator is turned on for smashing the food material in the cooking water left in the extracting vessel. After smashed, the food material is heated by boiled cooking water for extracting available component. Stop heating by the heating mechanism in proper time after extracting, then filtrate the extracting liquid form the extracting vessel using the filtrating mechanism, pump the extracting liquid to the pressure vessel for reclaiming employing the pressure decline, caused by heating stop, though the connected pipe.

Owner:YAMAMOTO ELECTRIC

Method for liquid phase selective hydrogenation of C3 hydrocarbons

ActiveCN101139242ASimple processReduce energy consumptionHydrocarbon by hydrogenationChemistryHydrocarbon

The present invention discloses a selective hydrogenation method for a liquid phase of a carbon fractionation, which relates to a selective hydrogenation method to prepare propylene by propine and or propadiene included in the carbon fractionation from the tower top of depropanization in the manufacturing process for propylene. The method is that: the carbon fractionation is firstly mixed with hydrogen, and then the mixture enters a reaction device from the top of the reaction device; after being made with the selective hydrogenation reaction, the heat material from the bottom of the reaction tower (the mixture between the liquid and the gas) does not take the heat exchange process, and directly enters an air-liquid separated pot to be separated. The air-phase part enters a condensator arranged on or on the upper part of the separated pot; the liquid after being condensed is taken as a product to be inducted; the non-condensed air-phase part discharges or is sent to a fuel air-tube net or the entrance of the second section or the third section or the fourth section of a compressor; the pressure inside of the reaction device is adjusted by controlling the temperature in the consensator or by controlling the air-phase flow for the discharging.

Owner:CHINA PETROLEUM & CHEM CORP +1

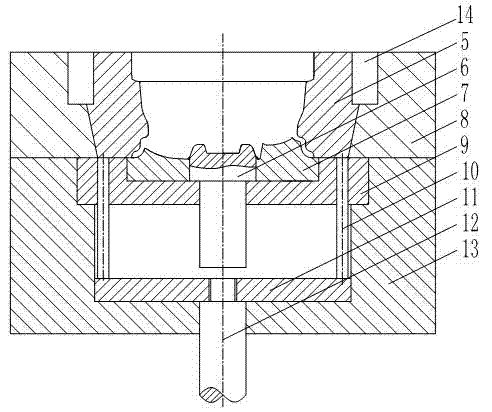

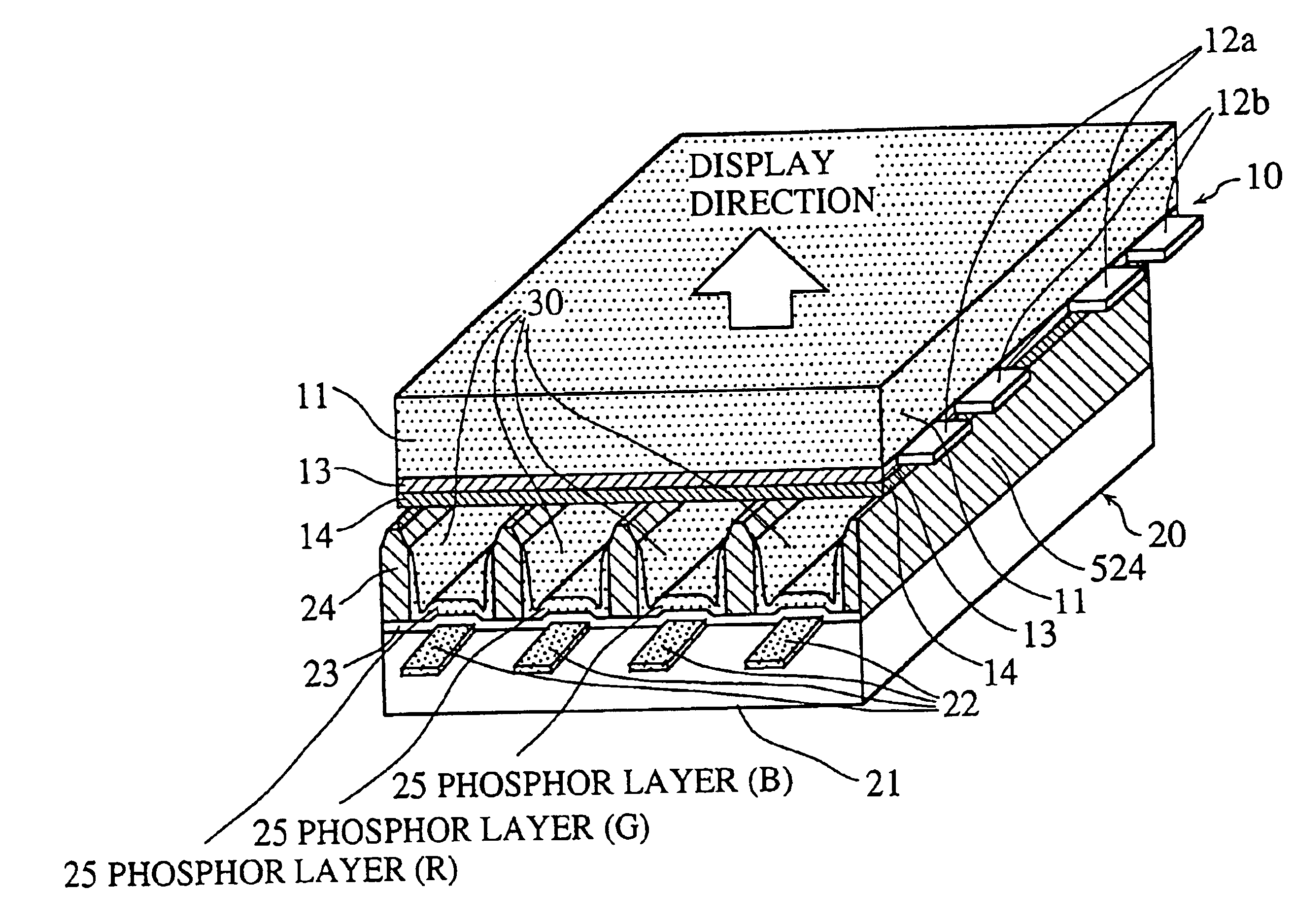

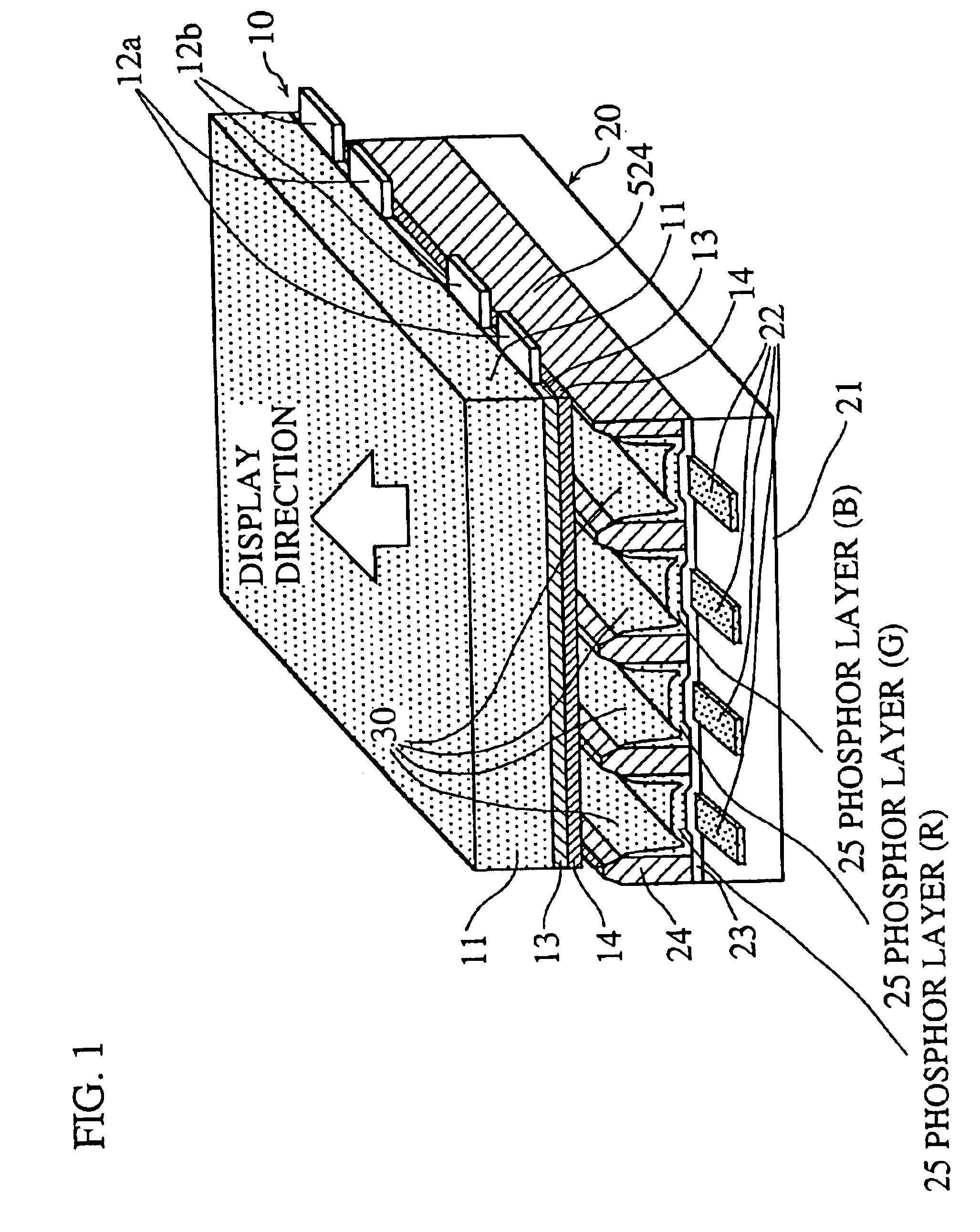

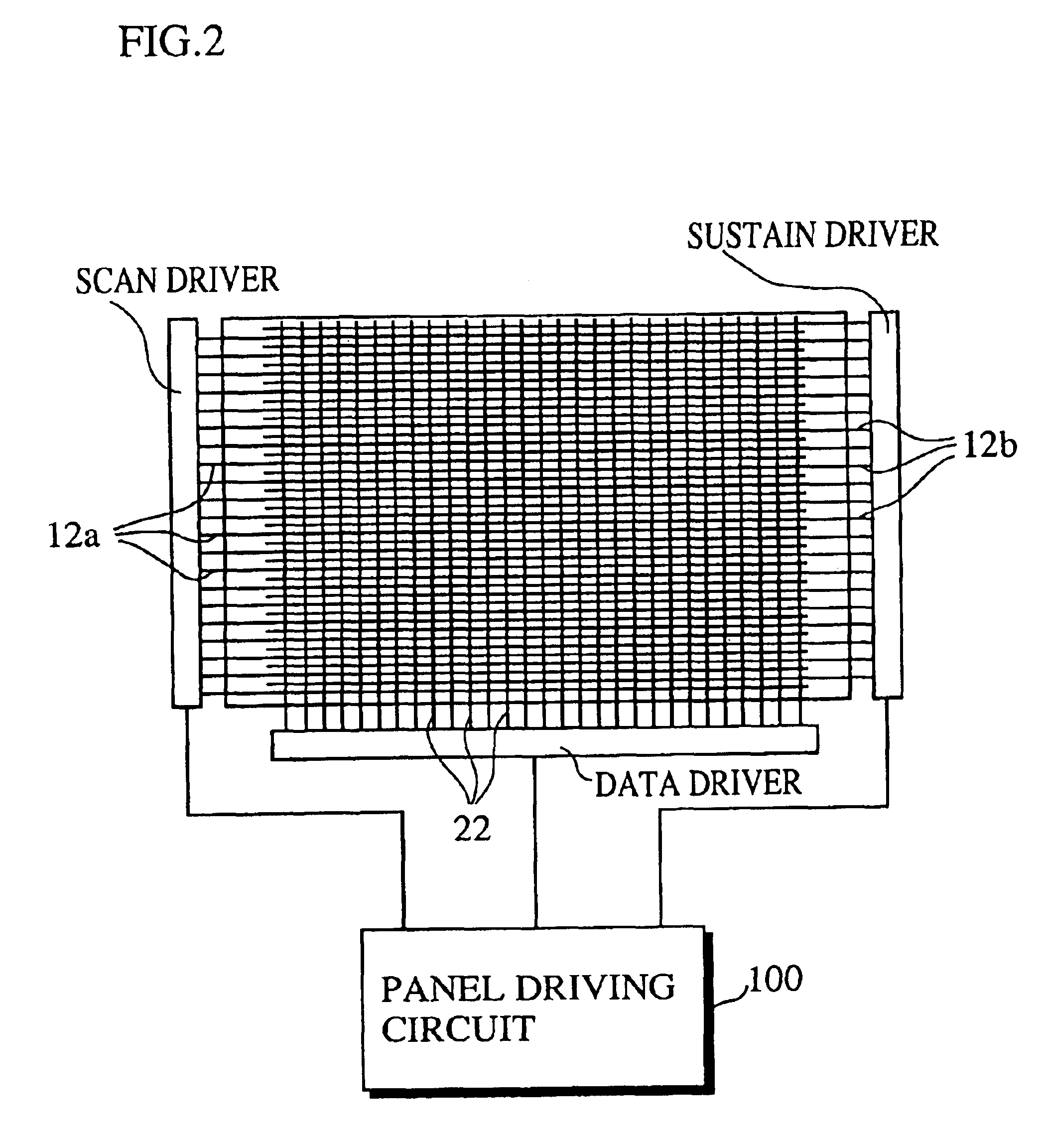

Highly productive method of producing plasma display panel

InactiveUS6860780B2Inhibit deteriorationHigh light-emitting efficiency and color purityAddress electrodesSustain/scan electrodesPhosphorEngineering

A method for producing a plasma display panel that has a front substrate and a back substrate disposed to face each other. A pre-baking phosphor layer containing a phosphor and an organic binder is formed on at least one of surfaces of the front substrate and the back substrate that are to face each other. A sealing material that softens with heat is applied to the peripheral region of at least one of the surfaces of the front and back substrates that are to face each other. The front and back substrates are disposed to face each other in a stack. The front and back substrates are heated to burn out the organic binder while supplying a dry gas containing oxygen to an internal space that is formed between the front and back substrates.

Owner:PANASONIC CORP

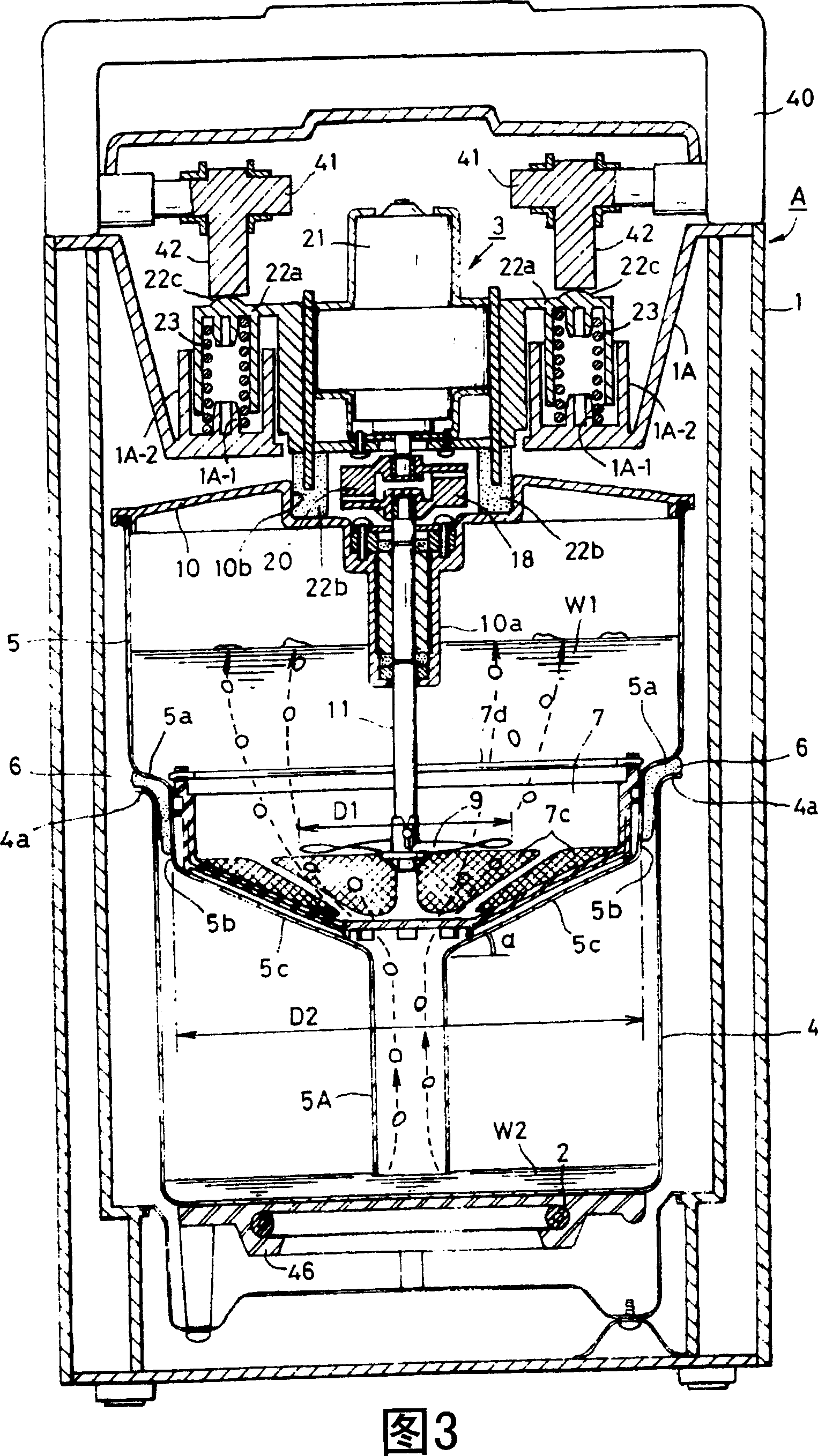

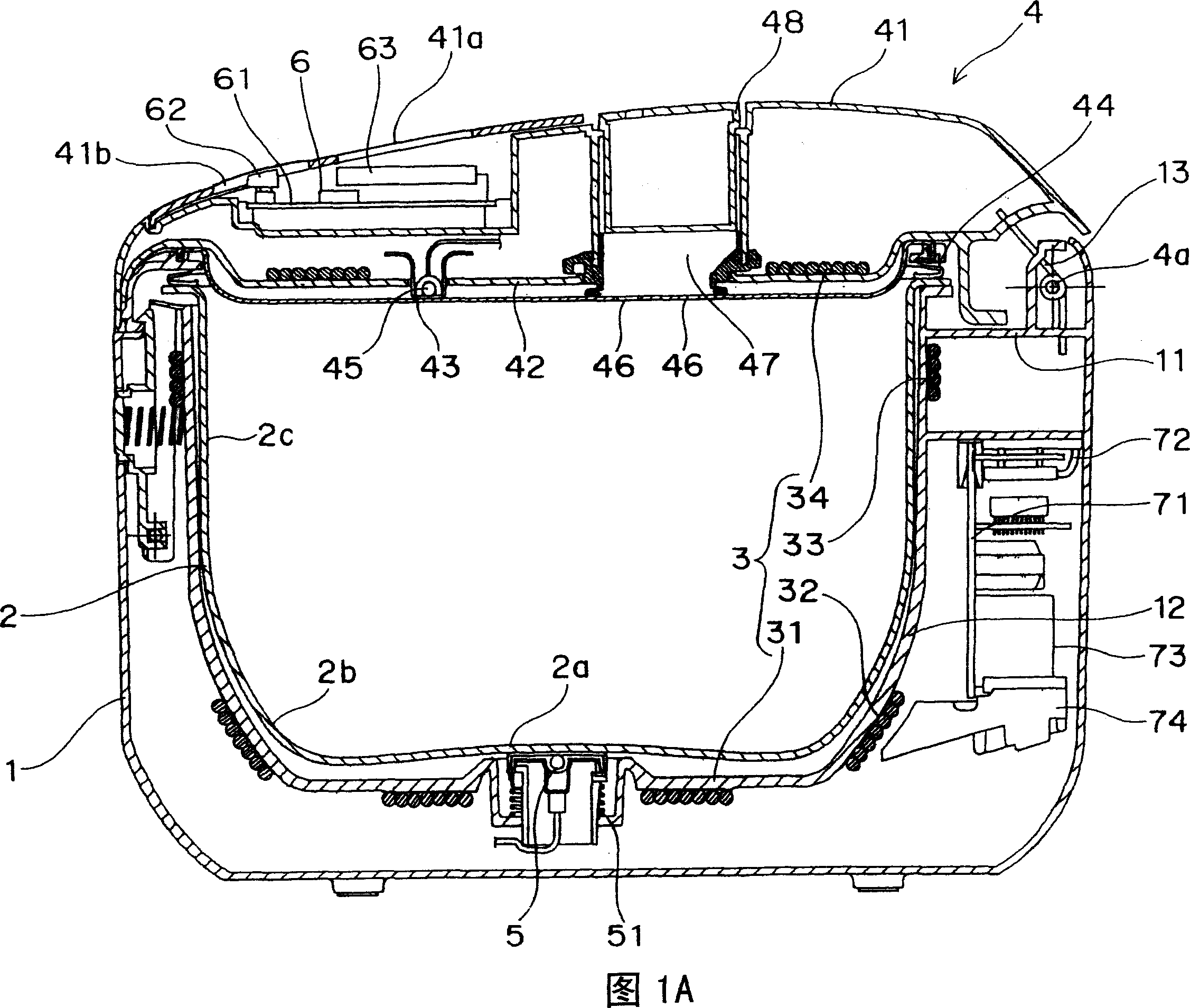

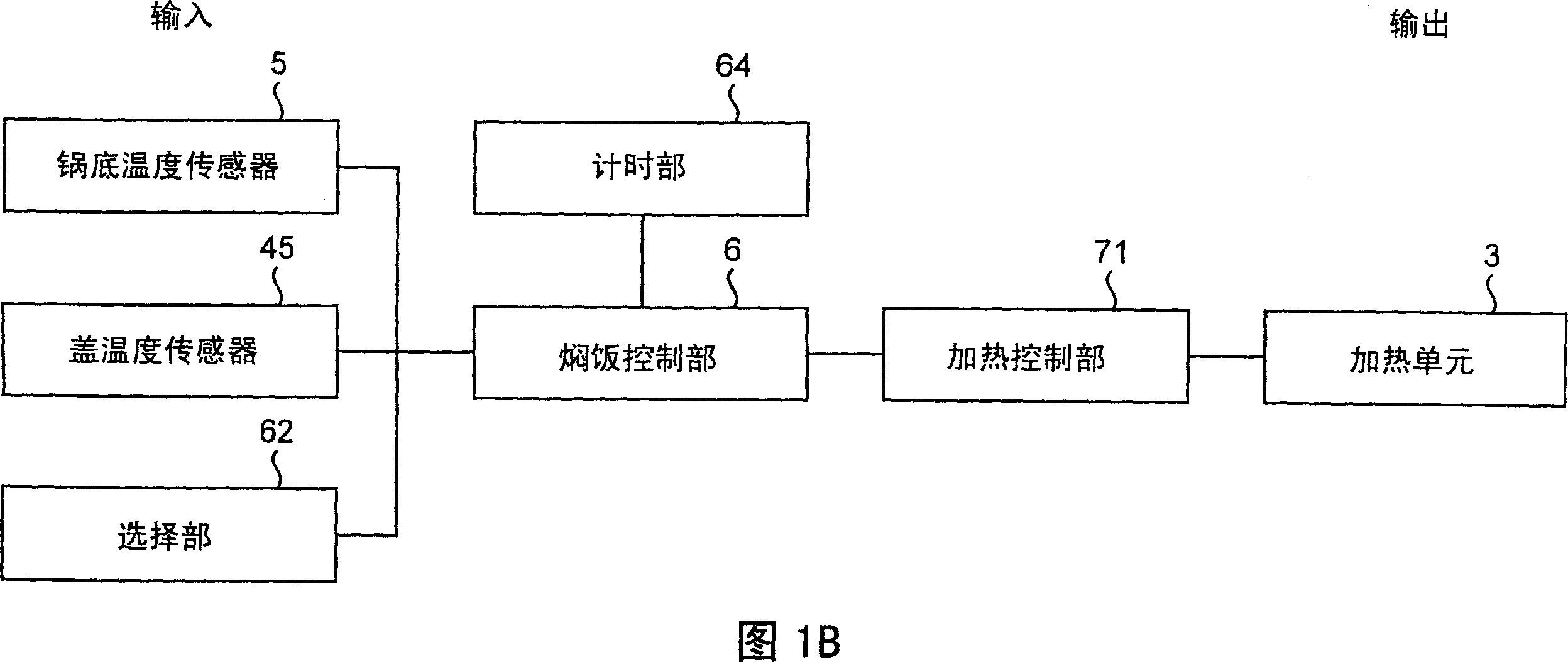

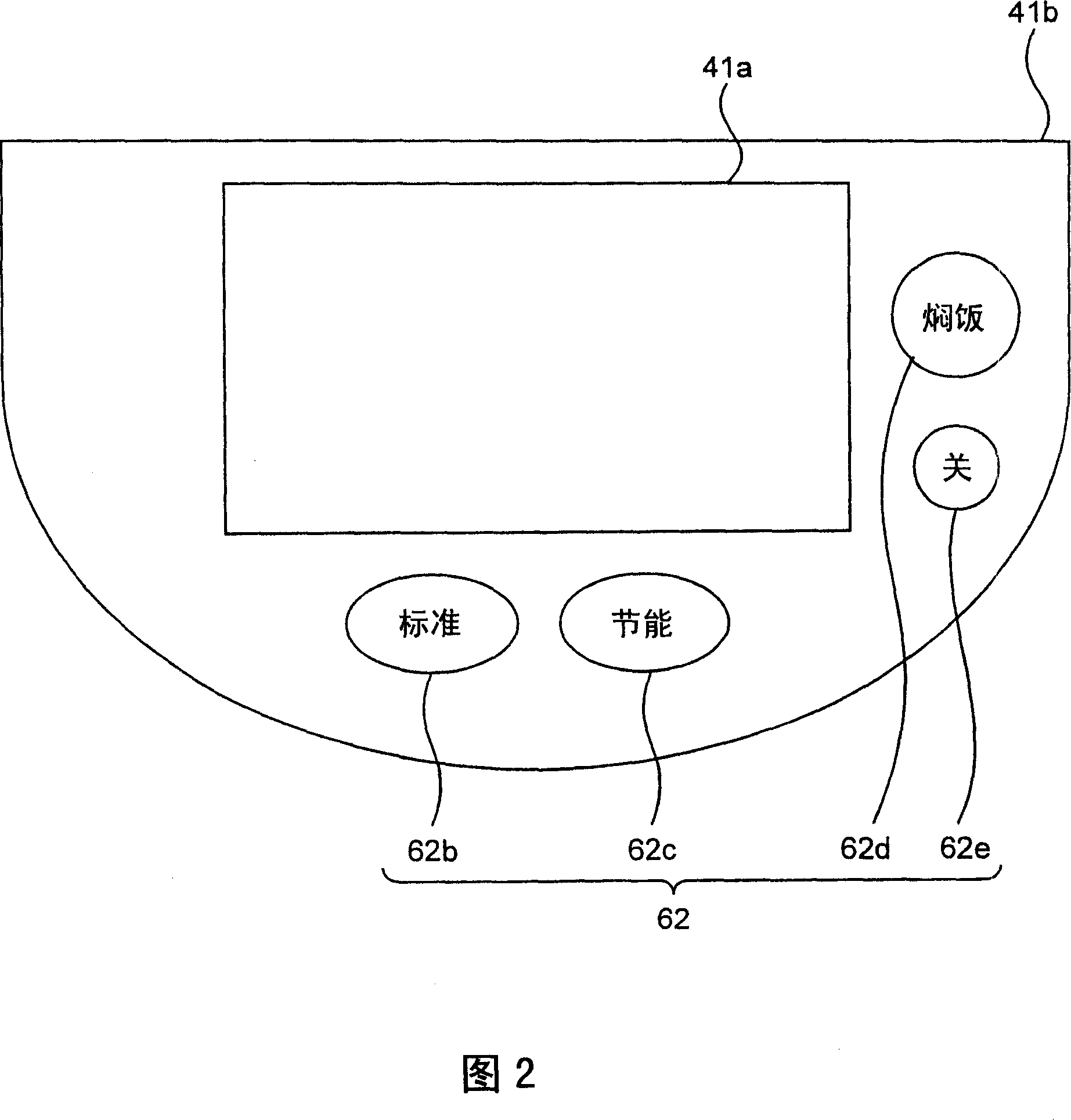

Electrical rice cooker

ActiveCN1943483ANo need to extend cooking timeShorten the soaking timeCooking vesselsProcess engineeringHeat control

The invention provides an electric rice cooker. The rice cooker has a pot housed inside the rice cooker body, an openable lid covering the upper opening of the pot, a bottom heating device for heating the bottom of the pot, a pot temperature detection unit for detecting the temperature of the pot, and a pot bottom control unit. The heating control part of the pot heating operation of the heating device, the rice stewing mode input part inputting any one of the rice stewing modes including the standard rice stewing mode and the energy-saving rice stewing mode, and the stewing rice mode input part according to the input. The rice mode and the detected temperature control the pot heating device to implement the rice cooking process. When the stewed rice control unit inputs the energy-saving stewed rice mode from the stewed rice mode input unit, in the soaking process, the pot heating device is controlled so that the detected temperature reaches a prescribed temperature within a prescribed time; after the prescribed time, The heating control unit is controlled to stop the heating operation of the pan heating device.

Owner:PANASONIC CORP

Production process of copper-silver alloy profile

The invention relates to a production process of a copper-silver alloy profile. The production process comprises the following steps that (1) high-purity cathode copper and pure silver are used as raw materials, the high-purity cathode copper and the pure silver are molten in a melting device after being preheated and dried, and a copper rod is upwards pulled through a traction unit; (2) a copper-silver alloy profile blank is prepared through a continuous extrusion unit; (3) drawing is carried out; and (4) slitting is carried out. The copper-silver alloy profile produced through the process is high in purity, low in oxygen content and high in conductivity and surface quality, and the process is short in procedure and efficient and saves energy.

Owner:金川文化发展(江苏)有限公司

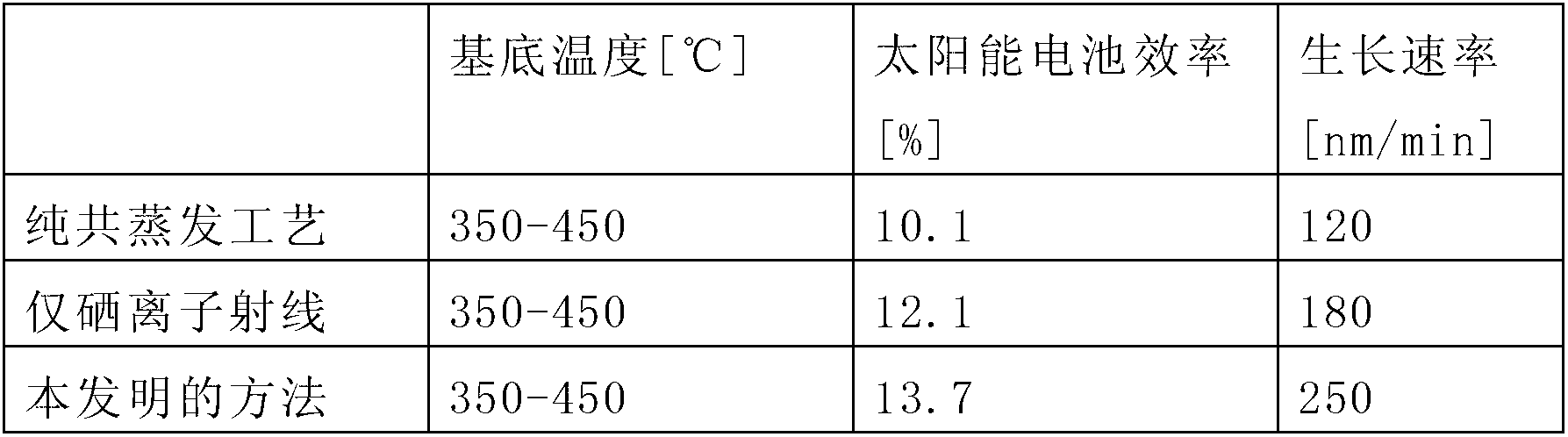

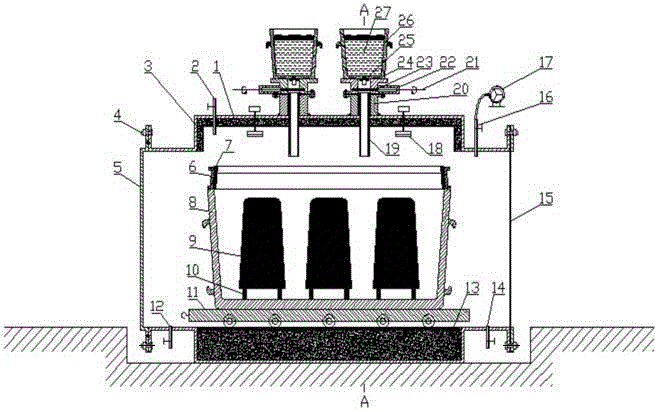

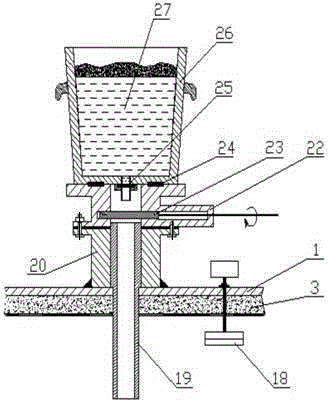

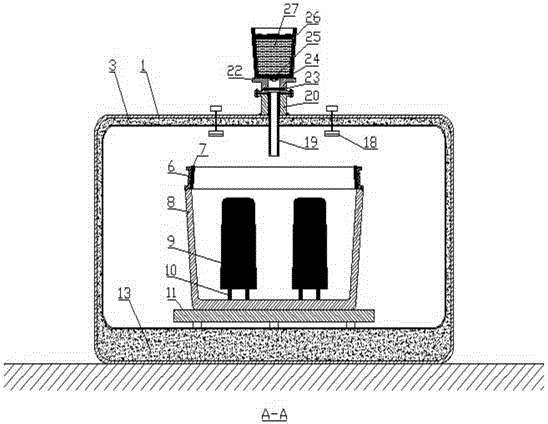

Method and device for producing a semiconductor layer

InactiveCN102763230AImprove efficiencyIncrease productionFinal product manufactureVacuum evaporation coatingWide beamSemiconductor package

The invention relates to a method and a device for producing a semiconductor layer. The problem addressed is that of increasing the deposition rate of the layer constituents and significantly improving the efficiency of a resulting solar cell. At the same time, the material costs are intended to be reduced. The problem is solved by virtue of the fact that, in a vacuum chamber, metal evaporator sources release Cu, In and / or Ga or the chalcogenide compounds, the latter are focused as metal vapour jets onto the substrate, and Se and / or S emerge(s) in an ionized fashion from a chalcogen low-energy wide-beam ion source and this beam is focused onto the surface of the substrate in such a way that it overlaps the metal vapour jets. A device for carrying out the method is described.

Owner:OC3 AG

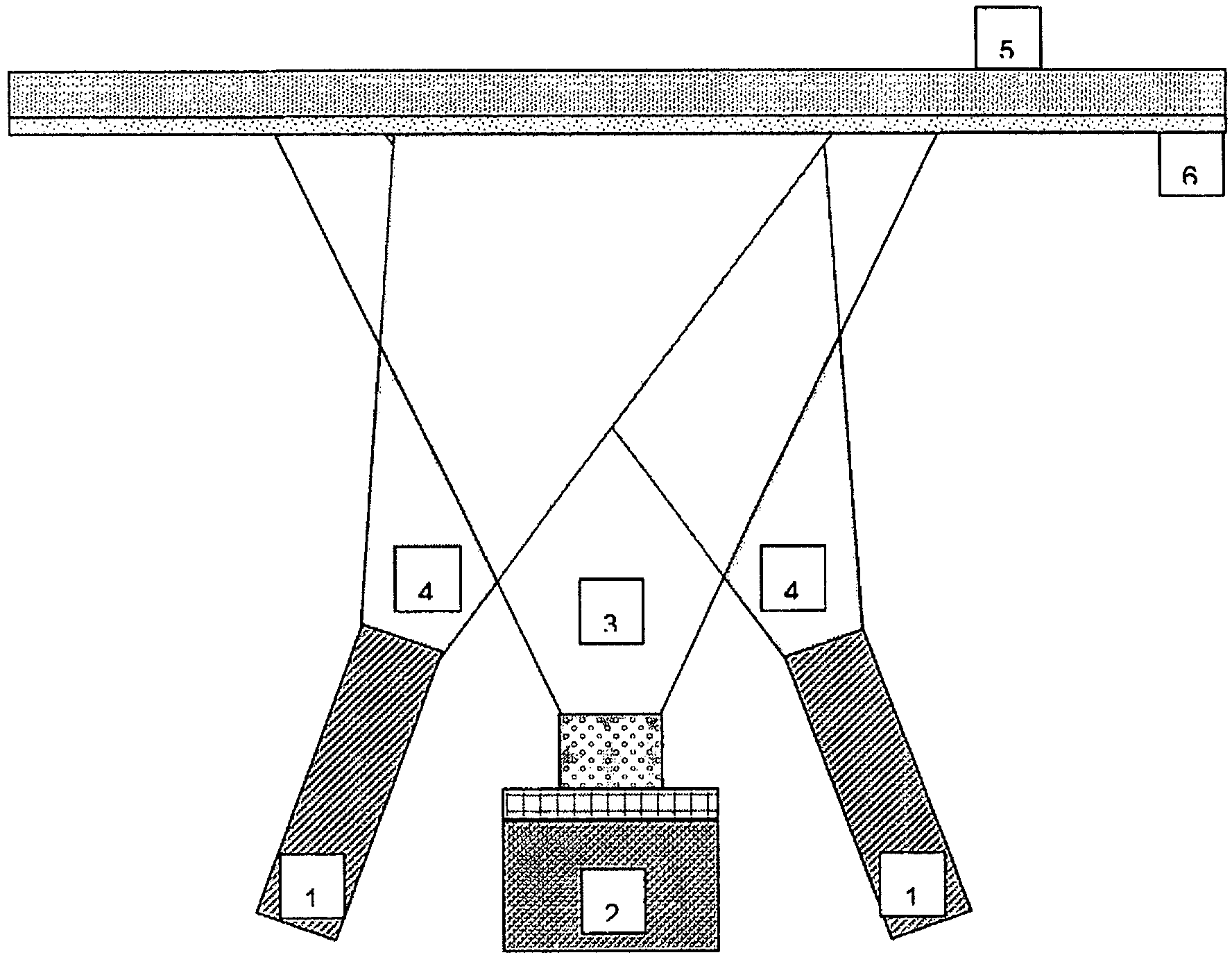

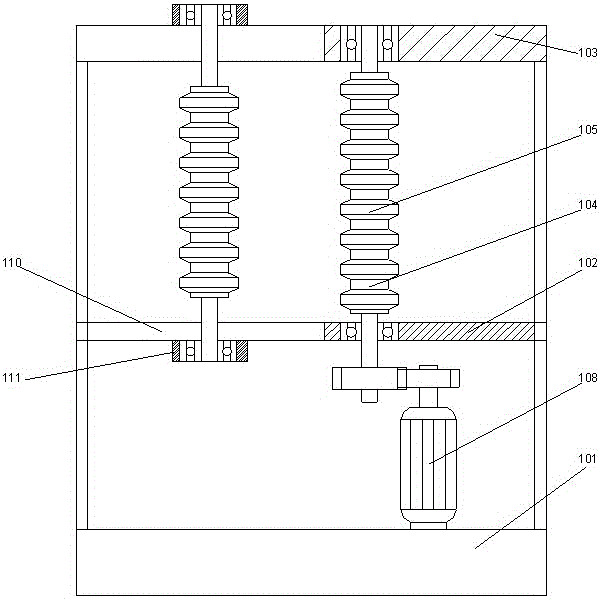

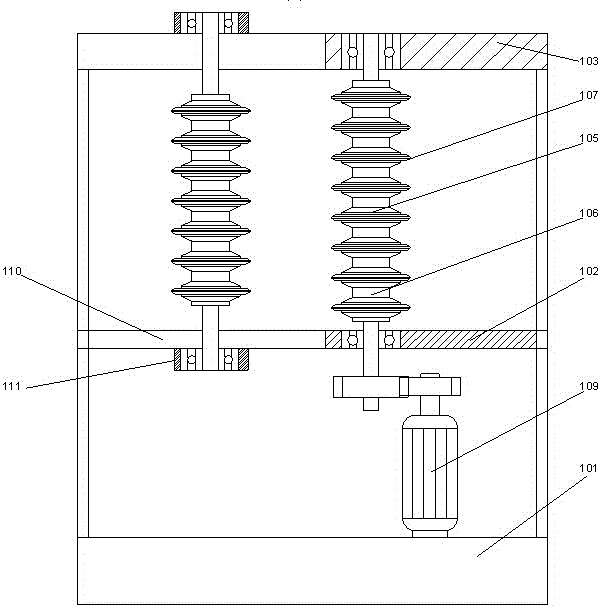

Multi-core reducing multi-ladle co-casting method and device for casting large composite steel ingots

The invention discloses a multi-core reducing multi-ladle co-casting method and device for composite casting large composite steel ingots. The multi-core reducing multi-ladle co-casting method comprises the steps of selecting core blanks, regulating the temperatures of the core blanks, re-removing scales on the surfaces of the core blanks, assembling the core blanks and ingot molds, reducing oxide scales on the surfaces of the core blanks, casting and compositing and cooling composite ingots. The device adopted by the method comprises a tank body, a reducing gas inlet, a heat preservation layer, bolts, a bin door, risers, heat insulation plates, the steel ingot molds, the core blanks, shims, a trolley, an inert gas inlet, a bottom heat insulation layer, an exhaust port, an explosion-proof end cap, a vacuum exhaust valve, a vacuum pump, circulating fans, riser bricks, casting channels, sealing valve rods, sealing valve bodies, sealing valve plates, sealing asbestos, sliding nozzles and steel ladles. Large and ultra-large molded steel ingots which cannot be produced by means of an orthodox casting method can be manufactured. The steel ingots manufactured by means of the multi-core reducing multi-ladle co-casting method and device has the advantages of being low in production cost, high in solidification speed, small in internal segregation, even in components and high in finished product rate.

Owner:佛山市金禾精密模具有限公司

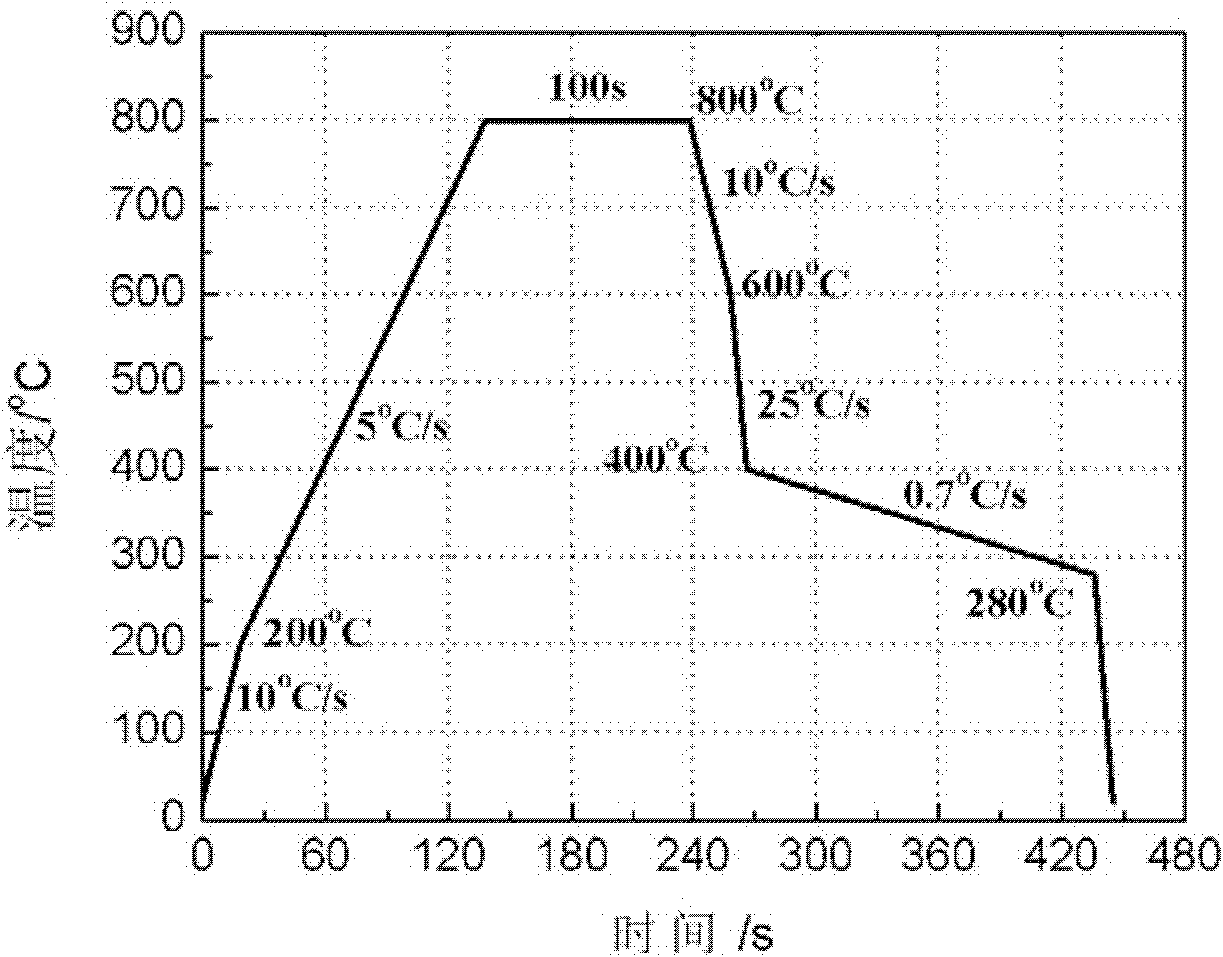

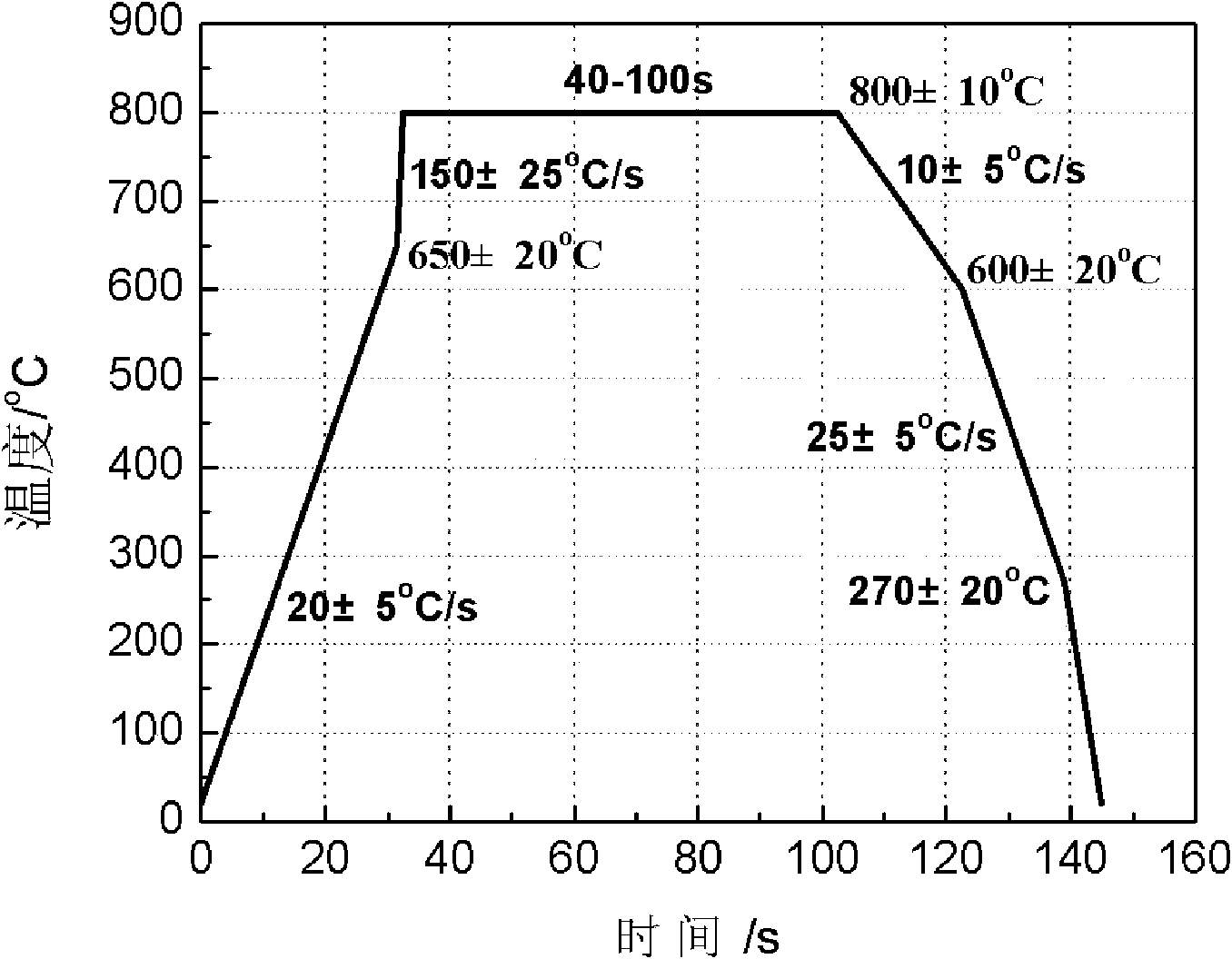

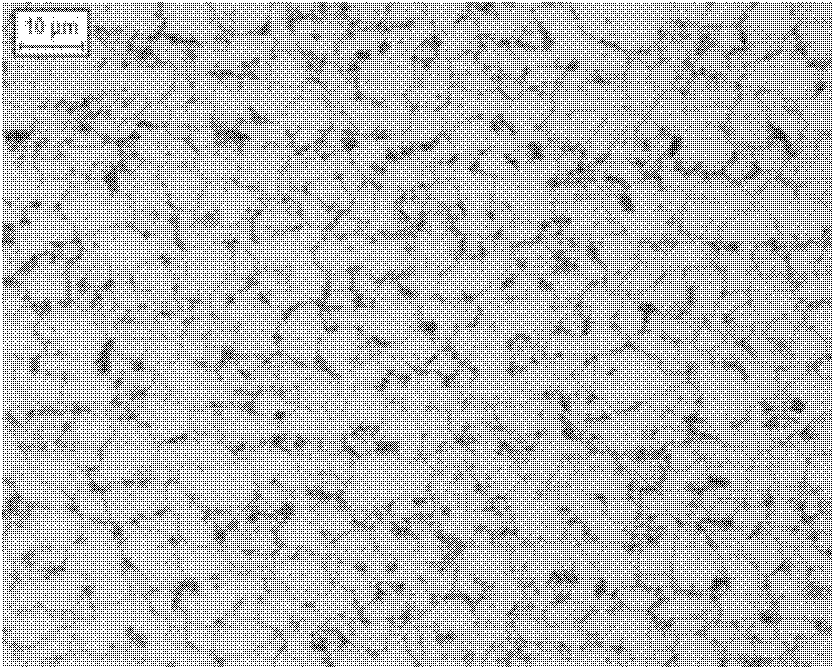

Continuous annealing process of cold rolling low alloy high-strength steel plate with yield strength at grade of 420 MPa

ActiveCN102492823BReduce heatingReduce oven timeFurnace typesHeat treatment process controlSheet steelChemical composition

Owner:SHANGHAI BAOYI CAN MAKING CO LTD

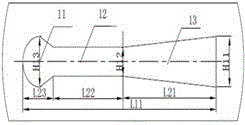

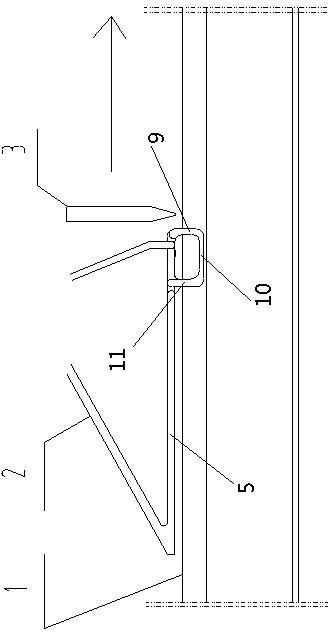

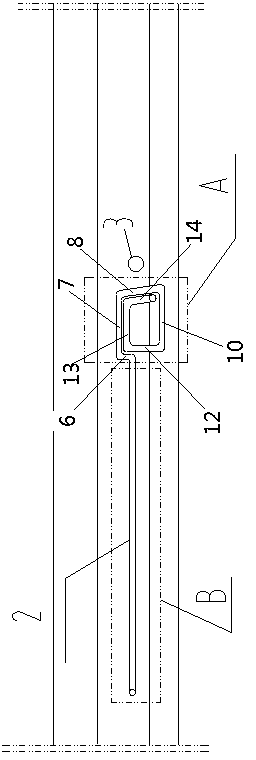

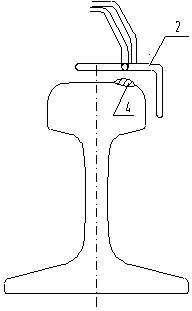

Induction heater and method for realizing non-preheating cladding of alloy on steel rail by using same

InactiveCN103132008ASave energyExtended heating rangeMolten spray coatingHeat transmissionMiniaturization

The invention discloses an induction heater which comprises a heating zone 1 and a heating zone 2, wherein the heating zone 1 is divided into two heating surfaces; a first heating surface is shaped like a trapezoid without the bottom; a second heating surface is a U-shaped one; the two lateral sides of the trapezoid-shaped heating surface are connected with the U-shaped heating surface; and an included angle is formed between the first heating surface and the second heating surface. When the induction heater is used to perform alloy cladding on a steel rail, preheating does not need to be performed in advance, so that on the premise of the same steel rail cladding speed, heat energy required by the method is only one third or less of the prior art; and meanwhile, the method lays a foundation for miniaturization of a generator or even construction without the aid of a rail car. By performing detailed analysis on structure phase change and heat transmission of a steel rail in the cladding process, the invention breaks through the theory that the steel rail must be preheated prior to welding for the first time, and presents that the steel rail can be directly subjected to alloy cladding without being preheated while generation of martensite can be avoided. The technology disclosed by the invention is put forward for the first time at home and abroad.

Owner:CHENGDU ZHONGGUI TECH CO LTD

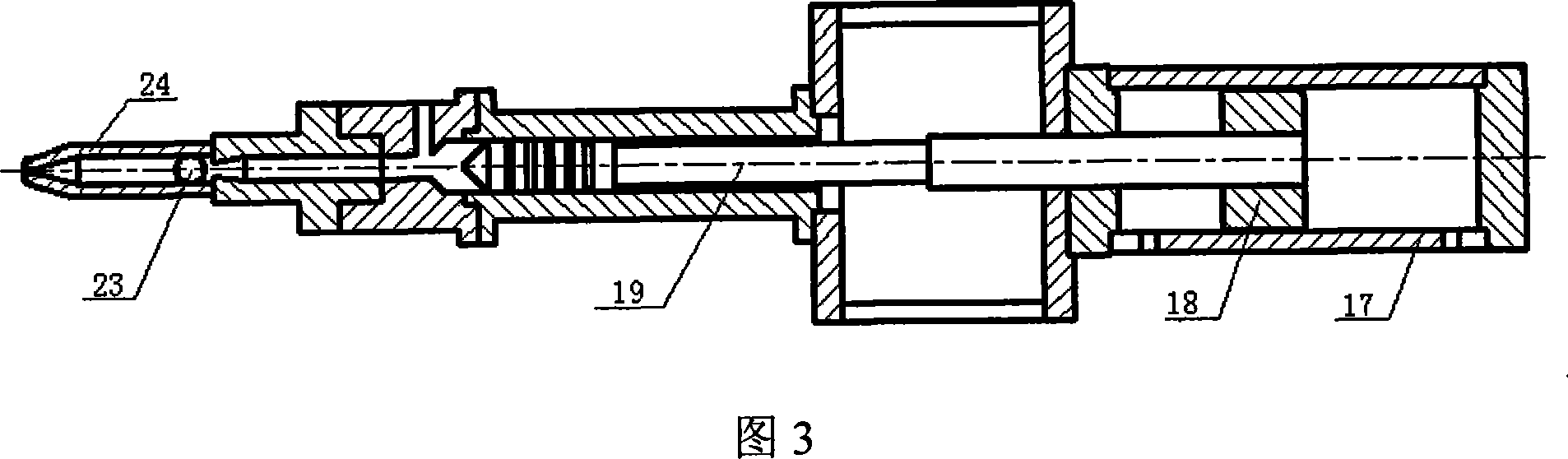

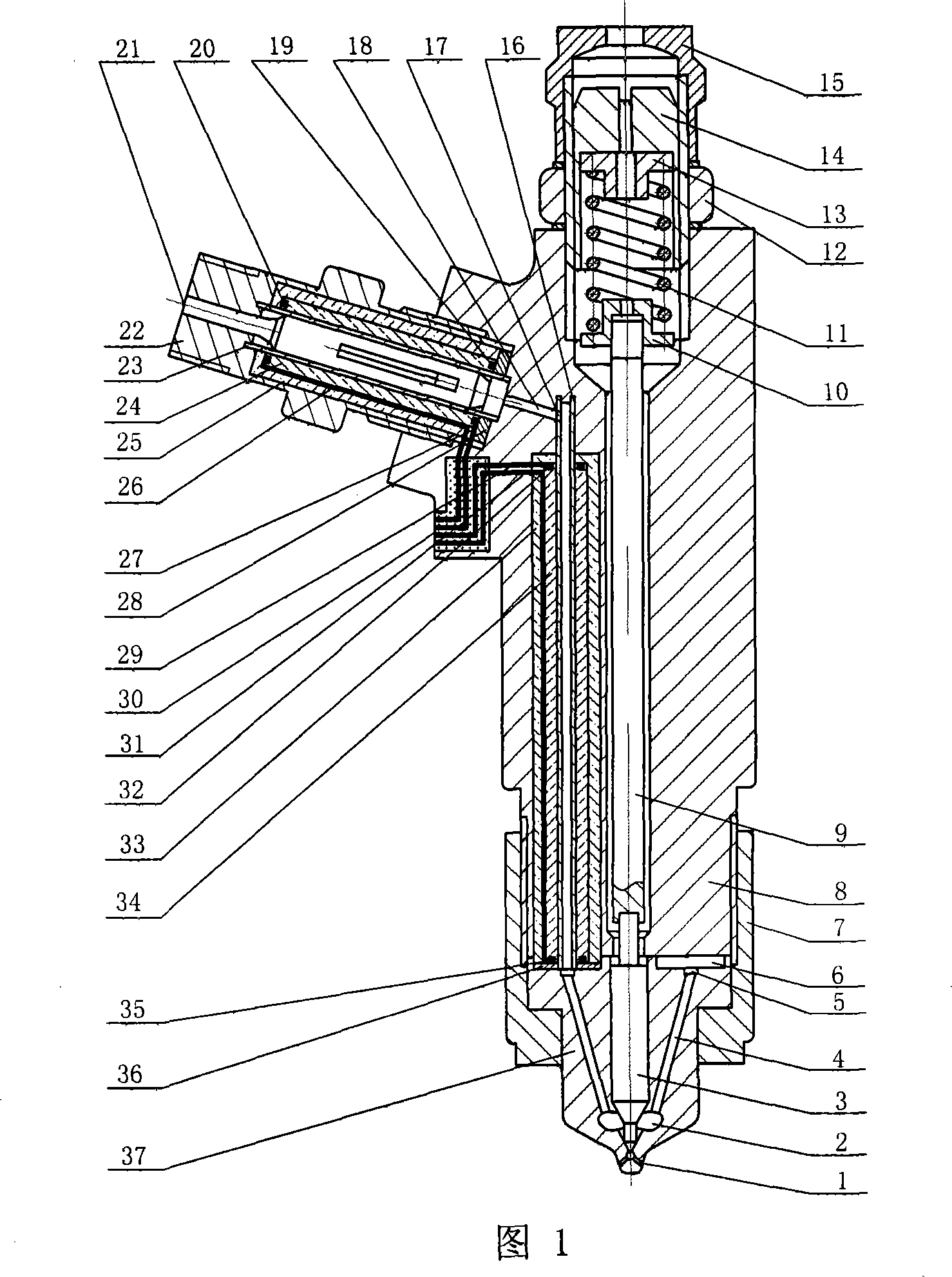

Fuel injector with built-in positive temperature coefficient ceramic heating material

InactiveCN101122271AReduce heatingEasy to sprayFuel injection apparatusMachines/enginesBoiling pointEngineering

An oil injector, inside which a positive temperature coefficient ceramics heating material is arranged, mainly comprises an injector needle valve, an injector needle valve body, an injector body, an injector tappet, an injector pressure-adjusting spring, a round heat transfer pipe inside the injector body, positive temperature coefficient heating ceramics inside the injector body, an insulated jacket inside the injector body, a round heat transfer pipe inside an oil inlet bolt, positive temperature coefficient heating ceramics inside the oil inlet bolt, an insulated jacket inside the oil inlet body, and so on. Positive temperature coefficient heating ceramics is arranged inside the oil inlet bolt and the oil injector, heats the diesel oil with a self-controlling temperature via the heat transfer pipes, and is insulated through the insulated jacket. The invention provides an oil injector used for diesel heating at the self-controlling temperature during the coal start and warm-up courses. The heating temperature will not exceed the boiling point of diesel oil. Less heating is needed, and the heating is quicker, so the diesel emission can be effectively improved and the cold-start performance can be promoted.

Owner:CHINA JILIANG UNIV

Production technology of high-purity and high-conductivity oxygen-free copper strips

The invention relates to a production technology of high-purity and high-conductivity oxygen-free copper strips. The technology comprises the following steps: 1, high-purity copper melting; 2, updraft continuous casting of copper rods; 3, production of copper strip blanks through a continuous extruding set; 4, face milling of the copper strip blanks; 5, rolling through adopting a cold rolling unit; 6, copper strip plate shape straightening and control; 7, annealing; 8, cleaning passivation; and 9, cutting. The high-purity and high-conductivity oxygen-free copper strips produced in the invention have the advantages of high copper content, low oxygen content, high electricity conduction performance, high plastic processing performance and high plate shape quality, and the technology has the advantages of short flow, high efficiency and energy saving.

Owner:泰州麒润电子有限公司

Polyurethane foam special for automobile seat and preparation method

Polyurethane foam special for an automobile seat is prepared by the following raw materials of, by weight ratio, 90-95 parts of 2-3 types of polyether polyol, 0.2-0.6 part of 2-3 types of amine catalysts, 1-2 parts of hard bubble silicone oil, 1-2 parts of cell openers, 2-5 parts of foaming agents, 1-2 parts of chain extenders, 20-25 parts of diphenylmethane diisocyanate (MDI) and 20-25 parts of toluene diisocyanate (TDI). A preparation method includes putting the raw materials into an A raw material bucket and a B raw material bucket of a foaming machine, then using the foaming machine to pour the raw materials in the A raw material bucket and the B raw material bucket into a mould according to the weight ratio of the raw materials, mixing the raw materials in the mould for 3-5 minutes and performing demoulding to obtain the polyurethane foam. The polyurethane foam can be prepared at the normal temperature, the working process is simple, and the polyurethane foam is energy-saving, environment-friendly and good in quality.

Owner:SUIZHOU HONGDE POLYURETHANE

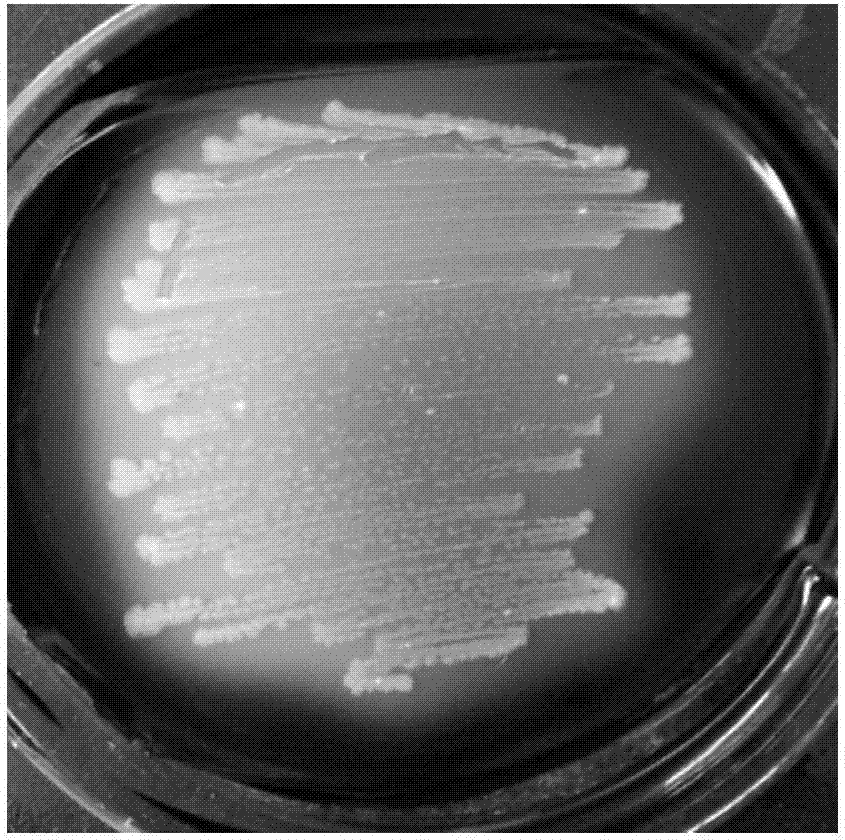

Microbial agent for quickly degrading and reducing organic waste and application thereof

ActiveCN107988099ARelieve pressureHigh waste reduction rateBio-organic fraction processingBacteriaMicrobial agentWaste treatment

The invention provides a microbial agent for quickly degrading and reducing organic waste and an application thereof. The microbial agent is prepared by mixing bacillus subtilis, the preservation number of which is CGMCC No. 14052, bacillus amyloliquefaciens, the preservation number of which is CGMCC No. 14053, bacillus subtilis, the preservation number of which is CICC No. 10210 and bacillus sp,the preservation number of which is CICC No. 10829. The application comprises the following steps: mixing the microbial agent with a carrier rice bran, wherein the microbial agent is attached to the carrier rice bran; carrying out filter pressing treatment on screened organic waste; and inputting the organic waste after filter pressing treatment into a reaction cabin, inputting the carrier rice bran with the microbial agent; and intermittently stirring the mixture to react for 12-24h, wherein kitchen waste can be reduced by over 90%. The microbial agent provided by the invention treats the organic waste on the spot from source, so that the organic waste treatment pressure can be alleviated greatly.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

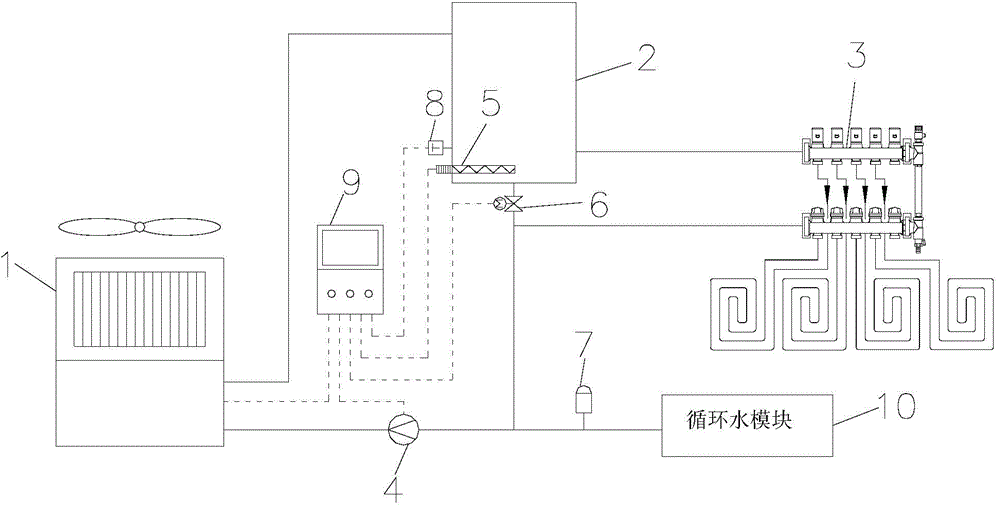

Air source heat pump floor heating system

InactiveCN104132386ALarge heat capacityReduce the frequency of start and stopLighting and heating apparatusEnergy efficient heating/coolingElectricityExpansion tank

The invention discloses an air source heat pump floor heating system which comprises a circulating water module, an air source heat pump, a heating water tank, a tail end floor heating module, a water pump, an electric heating module, an electromagnetic valve, an expansion tank, a temperature sensor and a controller. An inlet of the circulating water module is connected with the expansion tank, the expansion tank is connected with an inlet of the water pump, an outlet of the water pump is connected with an inlet of the air source heat pump, and an outlet of the air source heat pump is connected with an inlet of the heating water tank. According to the air source heat pump floor heating system, the frequency of the adopted water pump can be automatically adjusted according to the probability of indoor opening, the main engine starting and stopping frequency caused in the circumstance of the large heating capacity of an indoor low load device can be easily reduced, the speed of decreasing of the overall water temperature can be reduced in a defrosting mode, the floor can be heated more rapidly in the primary heating period of a floor heating system, waiting time of users is shortened, and the pressure of the system cannot be reduced in the circumstance that outside water pressure is insufficient.

Owner:QUANTUM ENERGY TECH SUZHOU

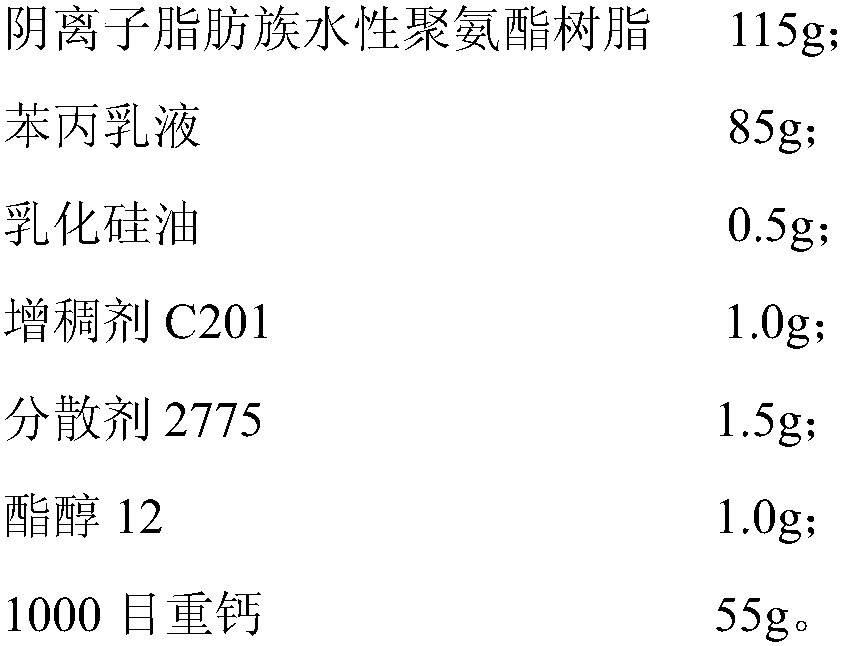

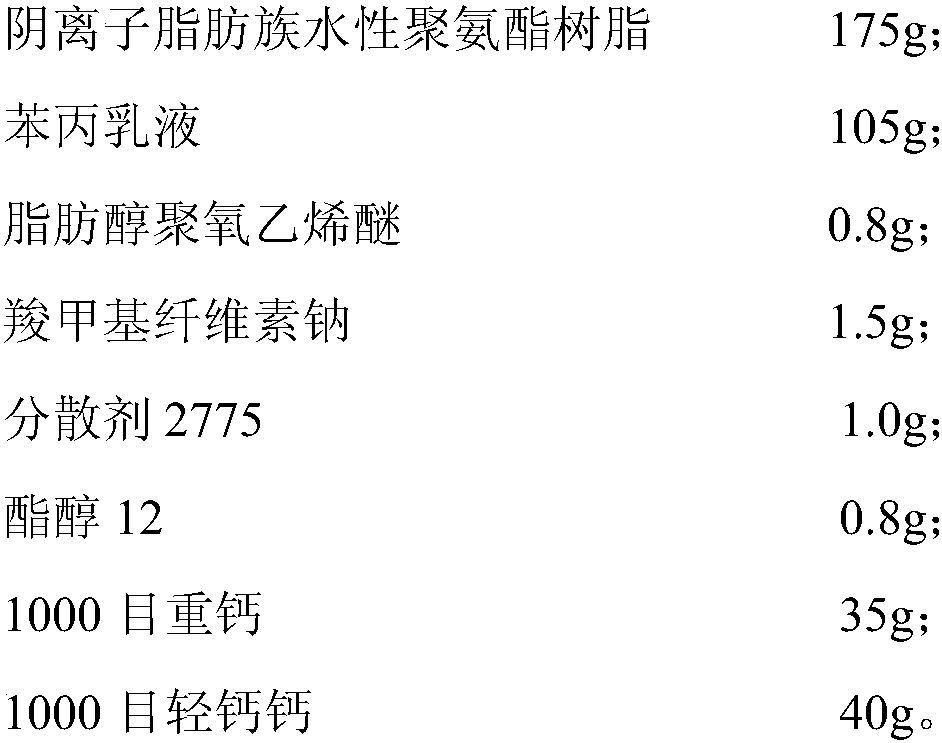

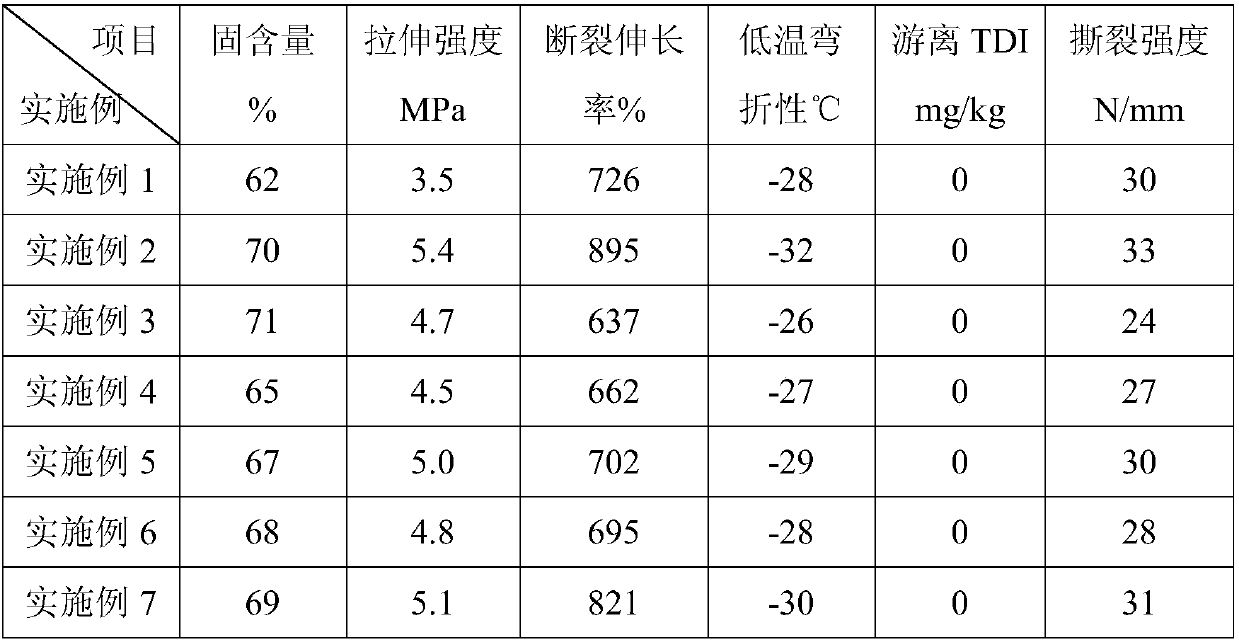

High-elongation waterborne polyurethane waterproof coating and preparation method

InactiveCN107858087AThe production process is simpleReduce energy consumptionPolyurea/polyurethane coatingsEmulsionPolymer science

The invention provides a high-elongation waterborne polyurethane waterproof coating which is prepared from the following components in percentage by mass: 15-60% of waterborne resin component, 10-55%of waterborne emulsion component, 0.5-4% of coalescing agent, 0.1-3% of antifoaming agent, 0.5-4% of thickening agent, 0.5-4% of dispersing agent and 10-40% of filler. The invention solves the problemof the prior art that a large amount of diisocyanate is applied and consequently the hard segment content is excessively high and the obtained polyurethane is very crisp and has poor low-temperaturebending property and low elongation at break, and provides a preparation method for preparing a high-elongation waterborne polyurethane waterproof coating at a room temperature of 15-35 DEG C.

Owner:山东鑫达鲁鑫防水材料有限公司

No-pollution waste and old wire recovery device

ActiveCN105976945AReduce environmental pollutionReduce oxidationBasic electric elementsElectronic waste recyclingEngineeringMechanical engineering

The invention discloses a no-pollution waste and old wire recovery device, and the device comprises a support, a wire core peeling apparatus and a smashing separation apparatus, wherein the wire core peeling apparatus and the smashing separation apparatus are disposed on the support. The support is also provided with a bottom plate, and the top of the support is provided with a top plate. The wire core peeling apparatus and the smashing separation apparatus are respectively located between the bottom plate and the top plate. The wire core peeling apparatus comprises a wire core separation apparatus and a wire core cutting apparatus. The wire core separation apparatus comprises a first roller group disposed between the top plate and the bottom plate, and a first drive apparatus disposed below the bottom plate. The first roller group comprises two parallel rollers, and the two parallel rollers form a cable conveying cavity for conveying a cable. The first drive apparatus is used for driving one roller to rotate. According to the invention, the device employs the wire core peeling apparatus and the smashing separation apparatus, achieves the peeling and smashing of a plastic wire, and achieves the reuse of the plastic skin and a metal wire core.

Owner:黎清弟

Production technique for phosphor copper strip for electrical purposes

The invention relates to a production technique for a phosphor copper strip for electrical purposes. The production technique comprises the first step of introduction of a copper bar onto a tractor unit with high-purity cathode copper as a raw material, the second step of continuous extrusion of a copper strip blank, the third step of cold rolling, the fourth step of annealing, the fifth step of finish rolling, the sixth step of cleaning and passivation, and the seventh step of splitting. The produced phosphor copper strip for electrical purposes has high purity, low oxygen content, high electric conduction and high surface quality. The technique is short in process, high in efficiency and capable of saving energy.

Owner:惠州市一电电池技术有限公司

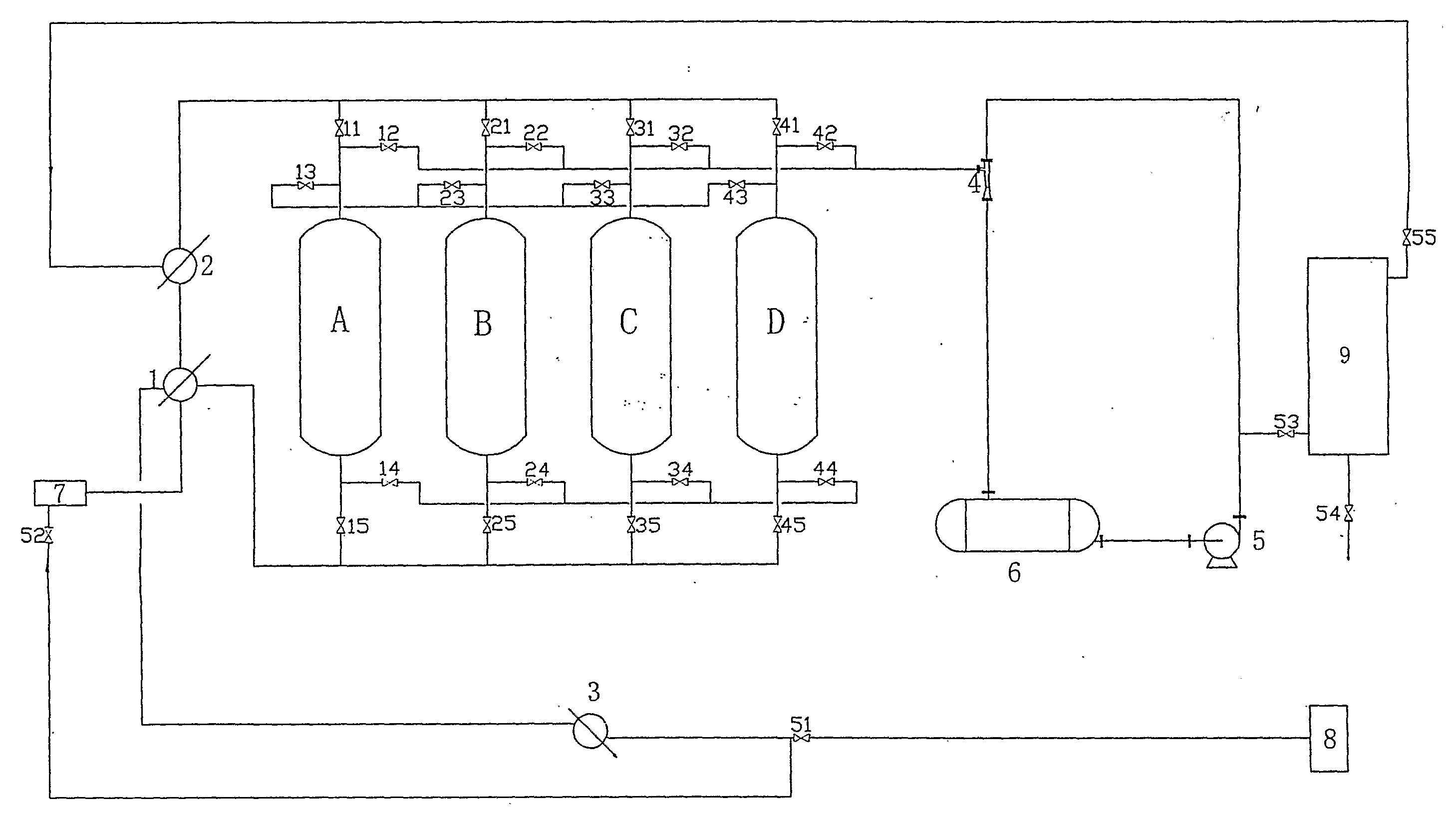

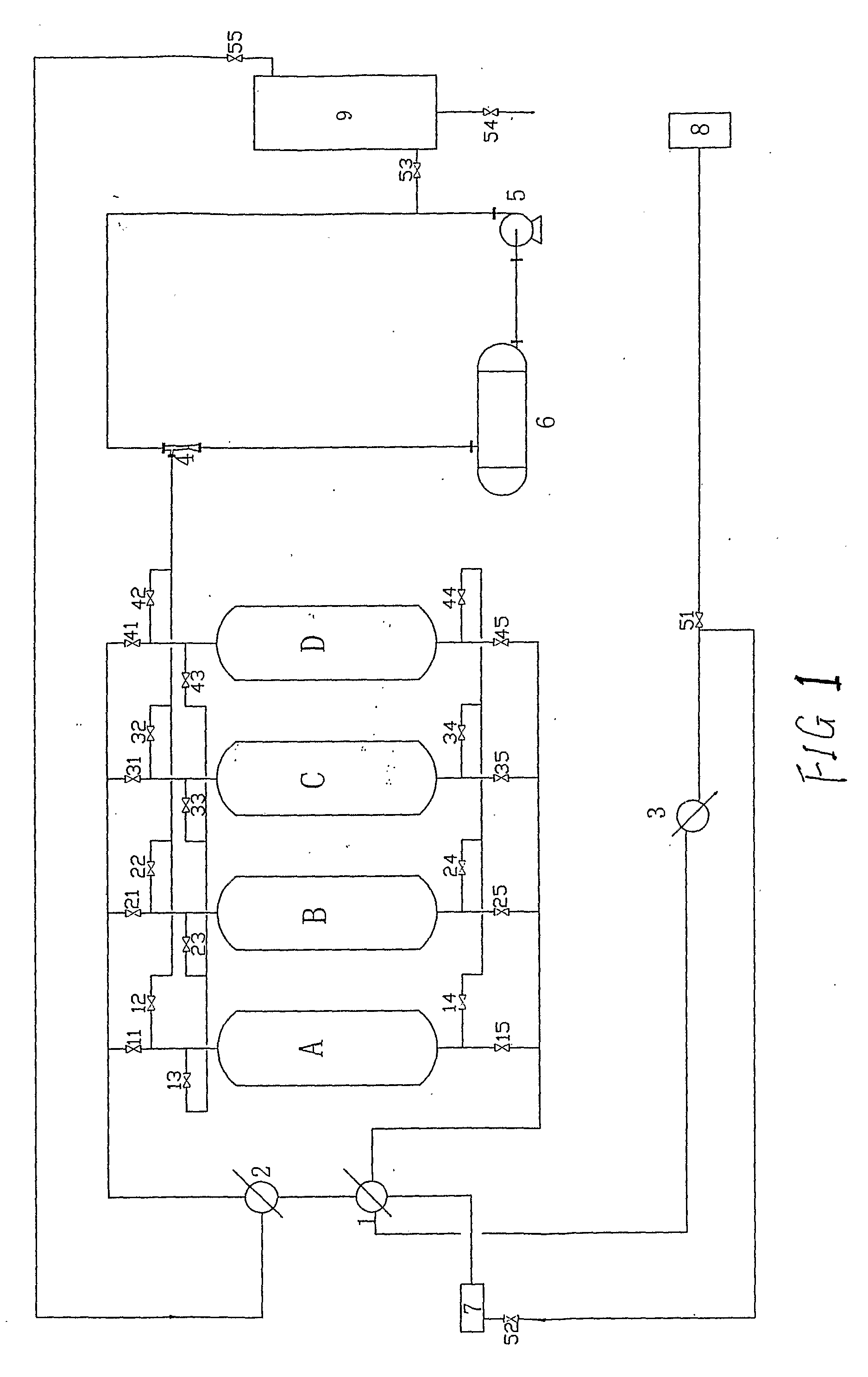

Method of anhydrous Ethanol Production Using Circulation by Multiple Towers Alternation

InactiveUS20080245653A1Reduce heatingSmall surface areaSolid sorbent liquid separationAlcoholic beverage preparationAnhydrous ethanolSorbent

The present invention relates to a method of anhydrous ethanol production using circulation by multiple towers' alternation, the procedure includes the steps of heating, adsorption, internal circulation, vacuum suction, washing and resolving etc. The method can prolong the life of adsorbent, reduce the heat exchanger's surface, cooling water, the equipment investment and energy consumption, provide high ethanol recovery rate and high dehydration, and protect environment.

Owner:ZHONG YALING

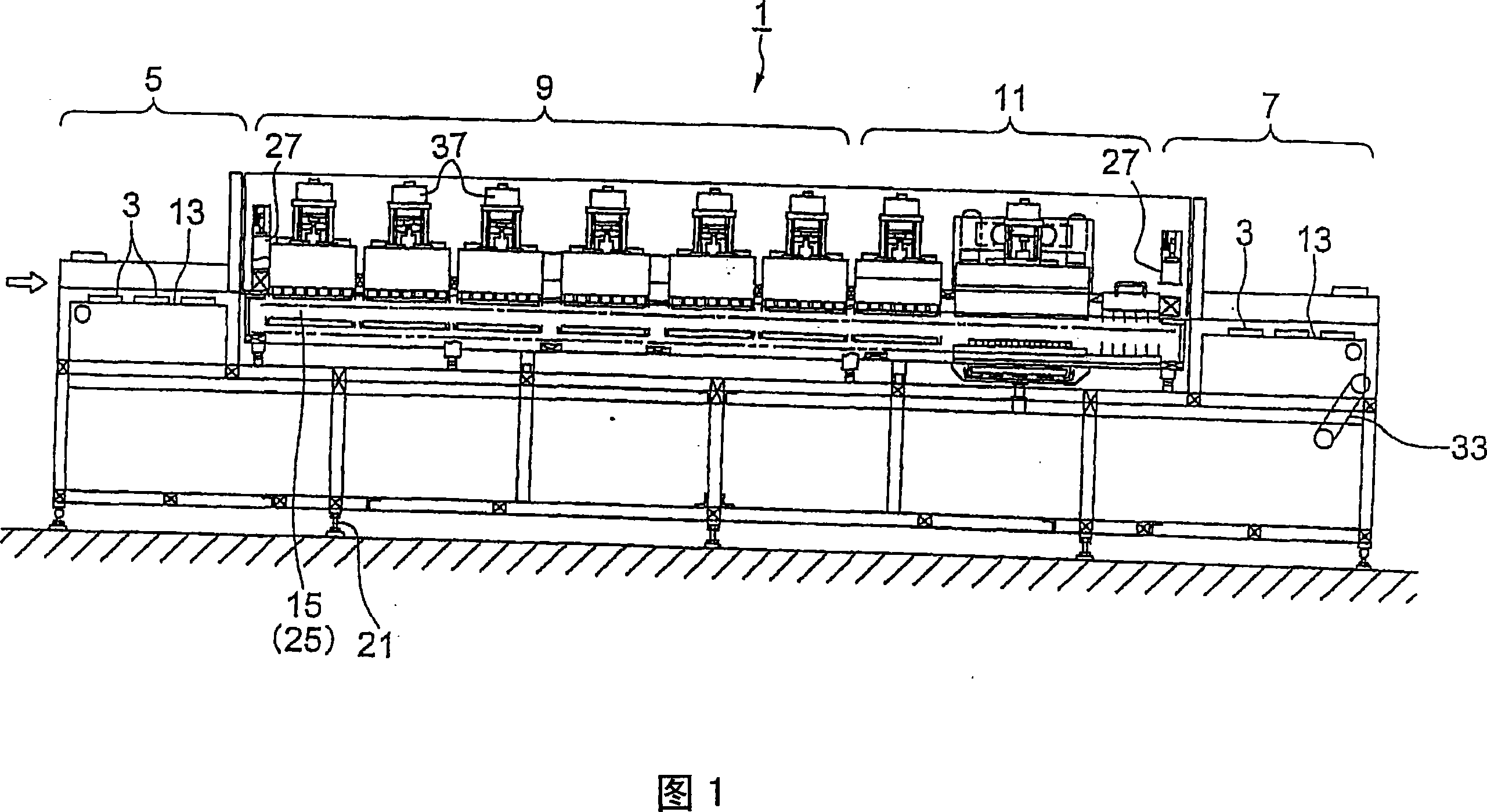

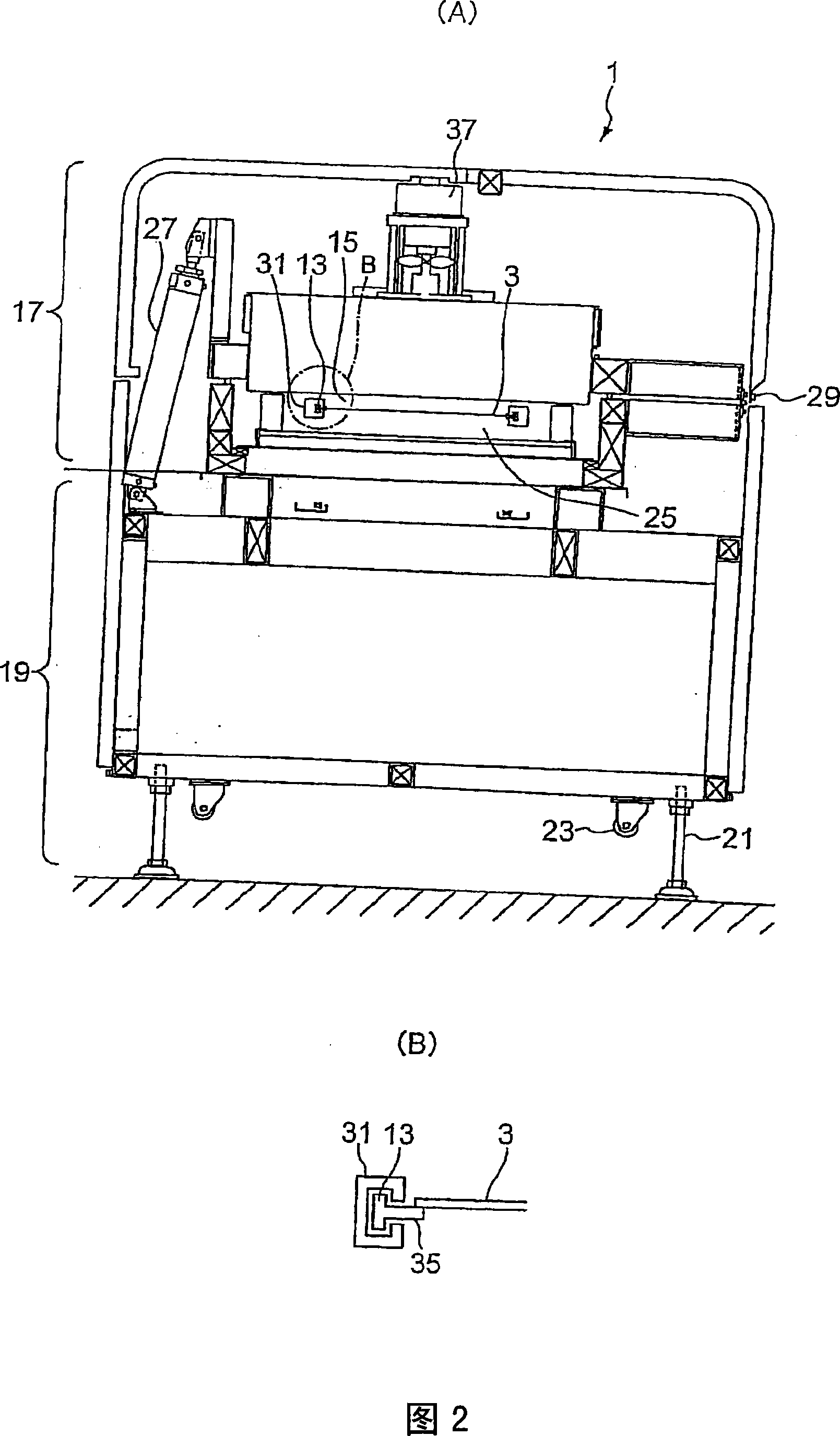

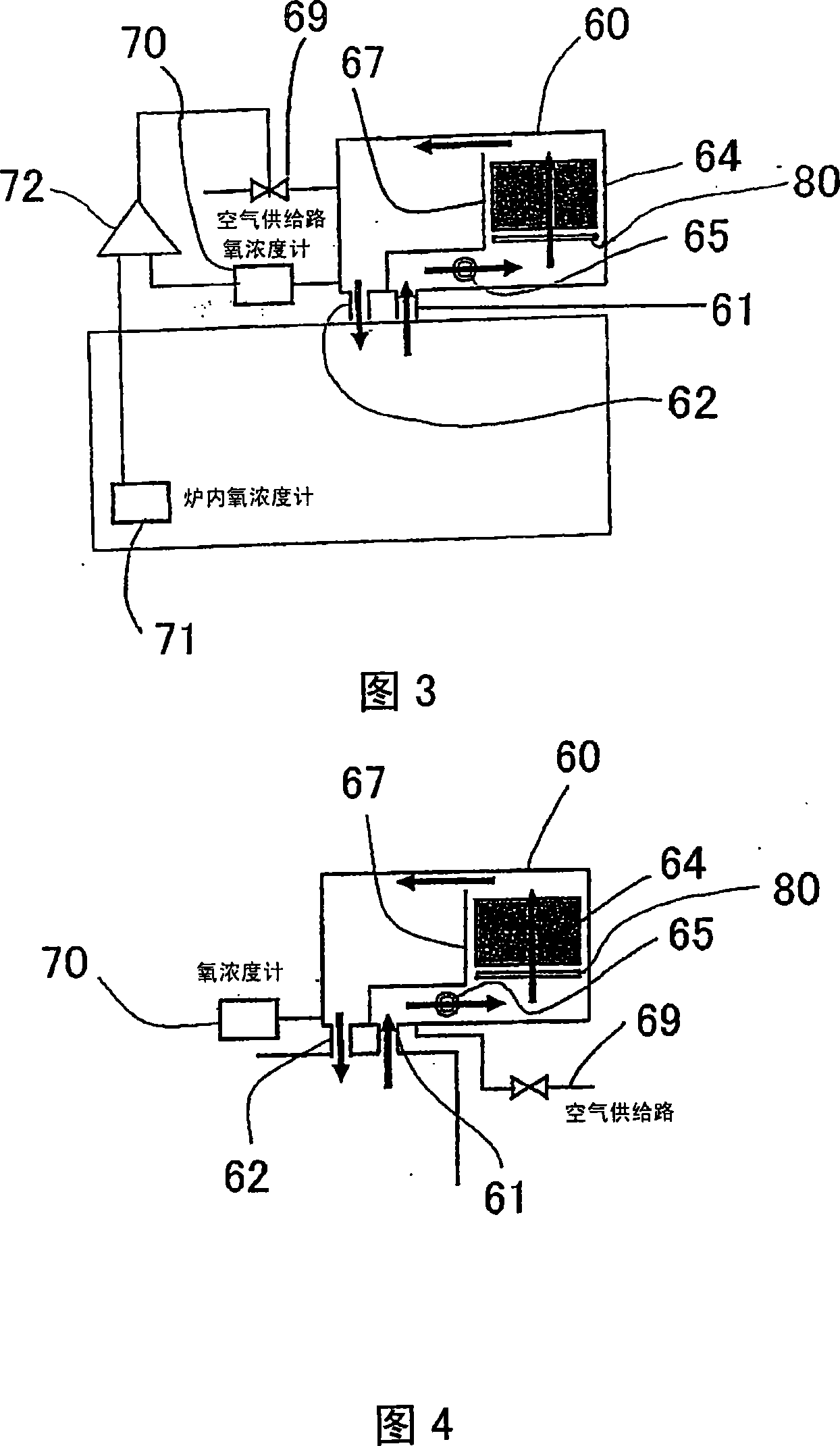

Reflow furnace

InactiveCN101085487AOxygen concentration controlImprove controllabilityHeating appliancesPrinted circuitsProduct gasElectronic component

The present invention provides a reflow furnace which can control temperature of heating chamber without special cooling device, and reduce heating amount of heating chamber with flux component contained in the heated ambient gas burned efficiently. The reflow furnace comprises: carrier device to carry a printed circuit board with electronic components mounted thereon; a heating chamber to heat through an ambient gas the printed circuit board carried therein to solder the electronic components on a surface of the printed circuit board; and an ambient gas purification equipment including a retrieving device to retrieve a part of the ambient gas containing vaporized flux component when soldering, a heating device to heat the retrieved ambient gas to a desired temperature, an oxidation catalyst to burn the flux component contained in the heated ambient gas, a control device to control an oxygen concentration in a high temperature gas after being burned, and a returning device to return the high temperature gas with the oxygen concentration controlled after being burned to the heating chamber.

Owner:TAMURA FA SYST

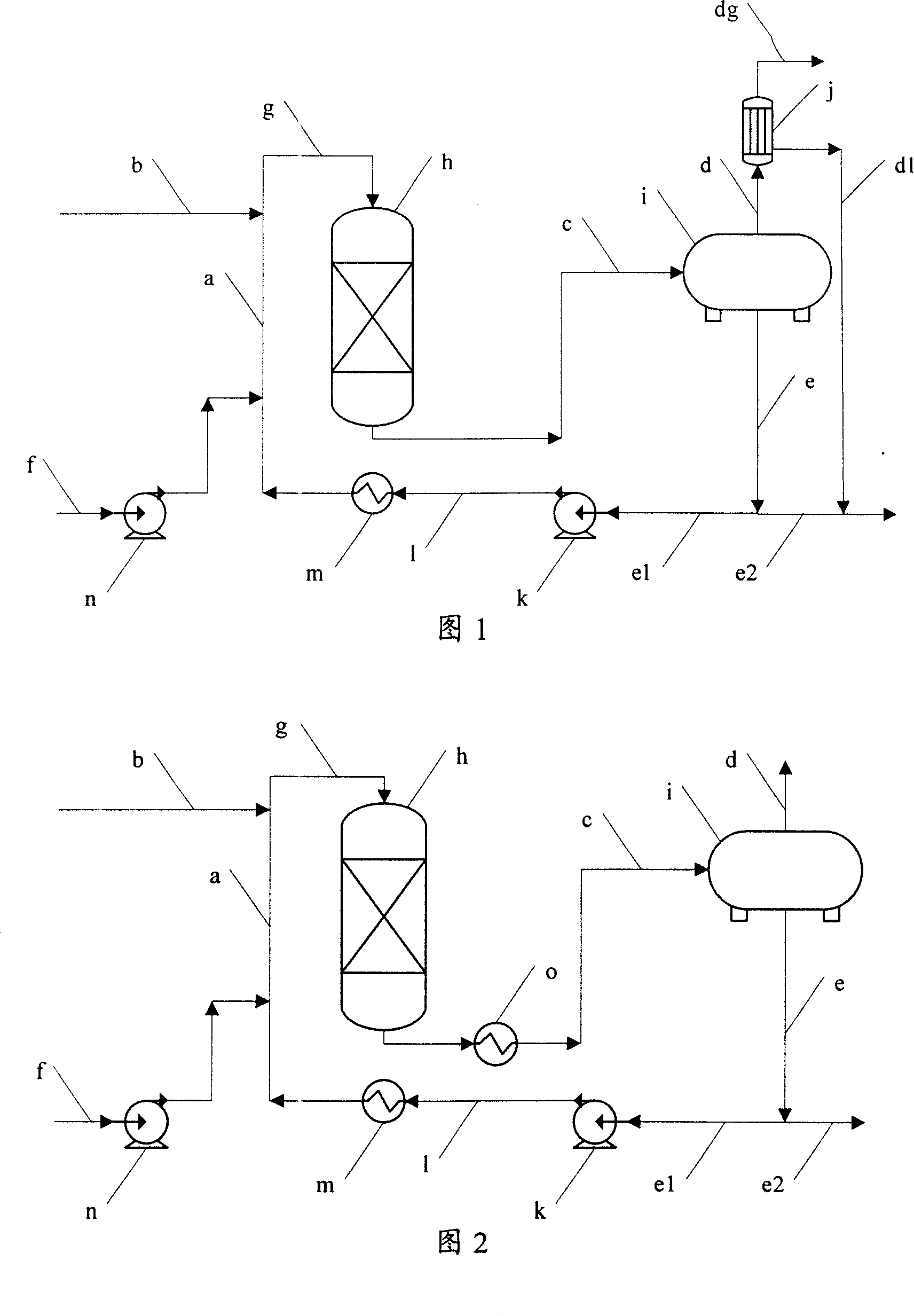

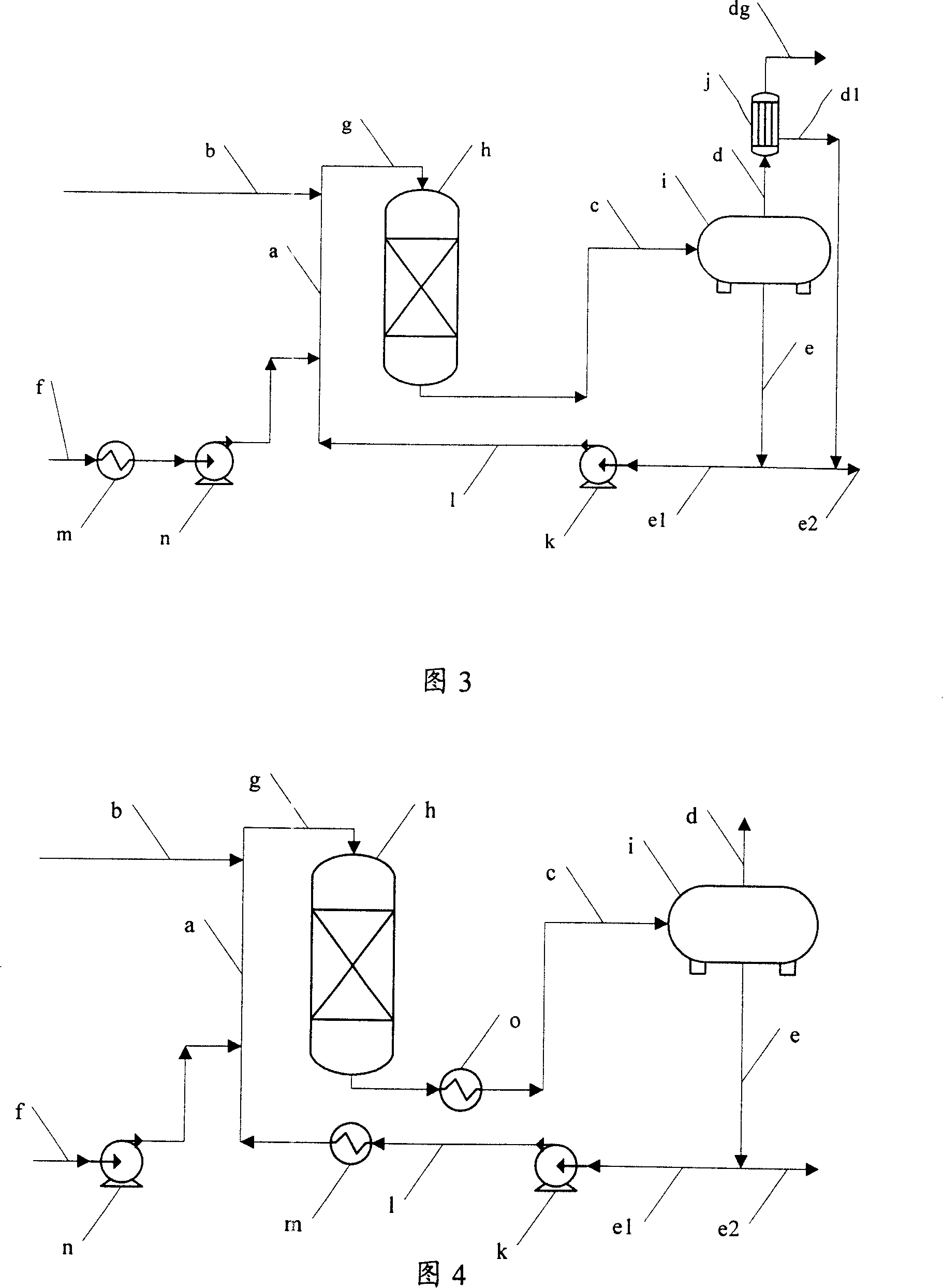

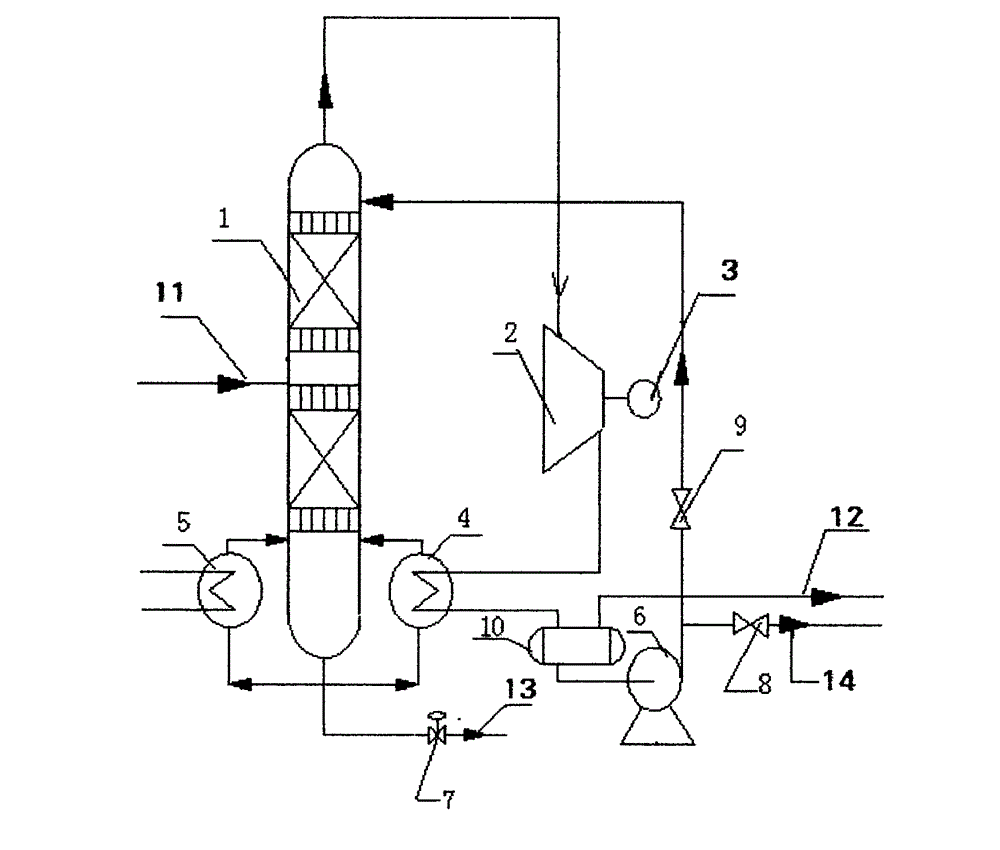

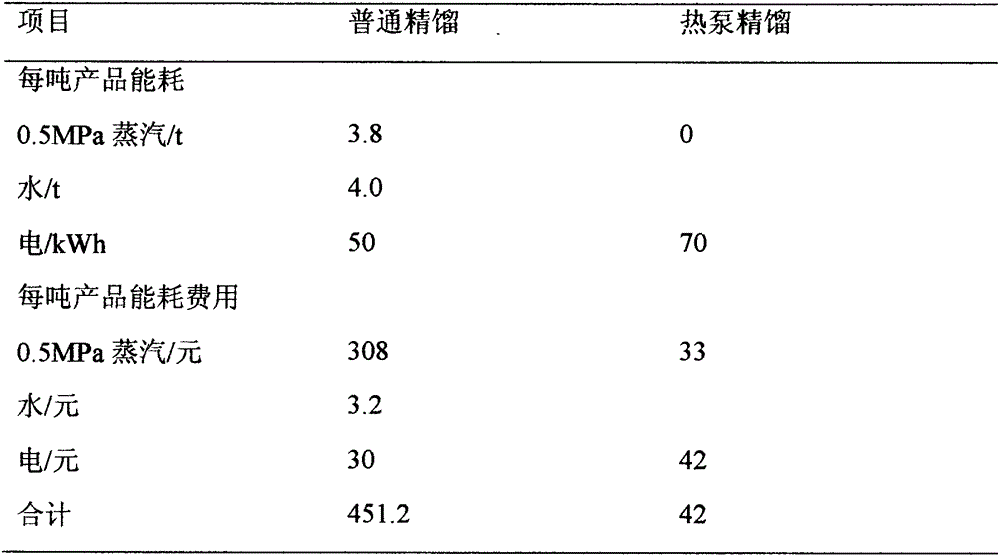

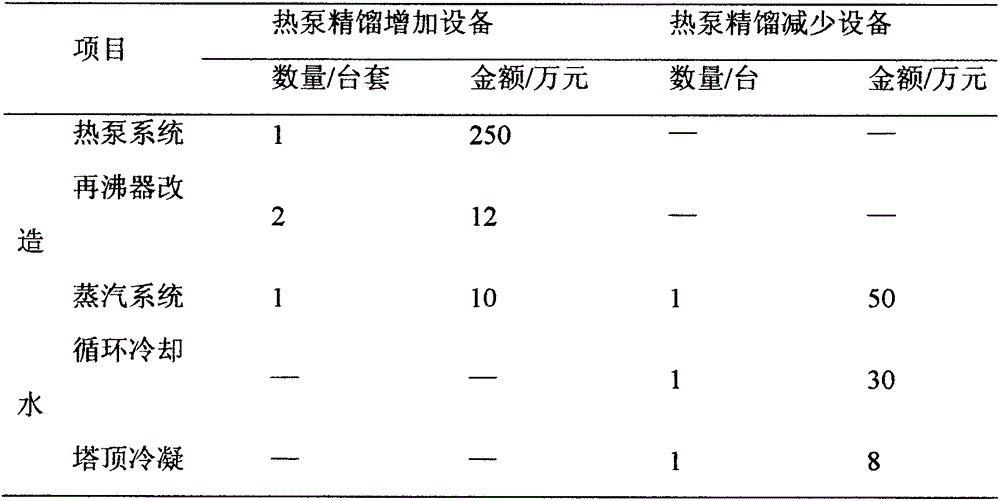

Process and device for distilling and separating isoamylol isomeride by heat pump

InactiveCN102875329AReduce heatingSave heatOrganic compound preparationChemical industryRefluxReboiler

The invention relates to a process and a device for distilling and separating isoamylol isomeride by a heat pump. The device comprises a distilling tower, the heat pump, a reboiler, a buffer tank, a driving heat exchanger and a reflux pump. The distilling tower is provided with a tower top vapor phase port and a tower top discharge outlet, the tower top vapor phase port is hermetically connected with an inlet of the heat pump through a pipeline, the reboiler is provided with a shell pass inlet, a shell pass outlet, a pipe pass inlet and a pipe pass outlet, the shell pass inlet is hermetically connected with the heat pump through a pipeline, the pipe pass inlet of the reboiler is hermetically connected with a tower bottom of the distilling tower, the pipe pass outlet is connected with a vapor phase port on the lower portion of the distilling tower through a pipeline, and the shell pass outlet is connected with the buffer tank. The bottom of the buffer tank is provided with a liquid phase discharge outlet which is connected with an inlet of the reflux pump. An outlet of the reflux pump is divided into two material flows, one is connected with a tower top reflux port of the distilling tower through a pipeline, and the other one is used as discharge on the tower top.

Owner:山东凯利生物科技有限公司

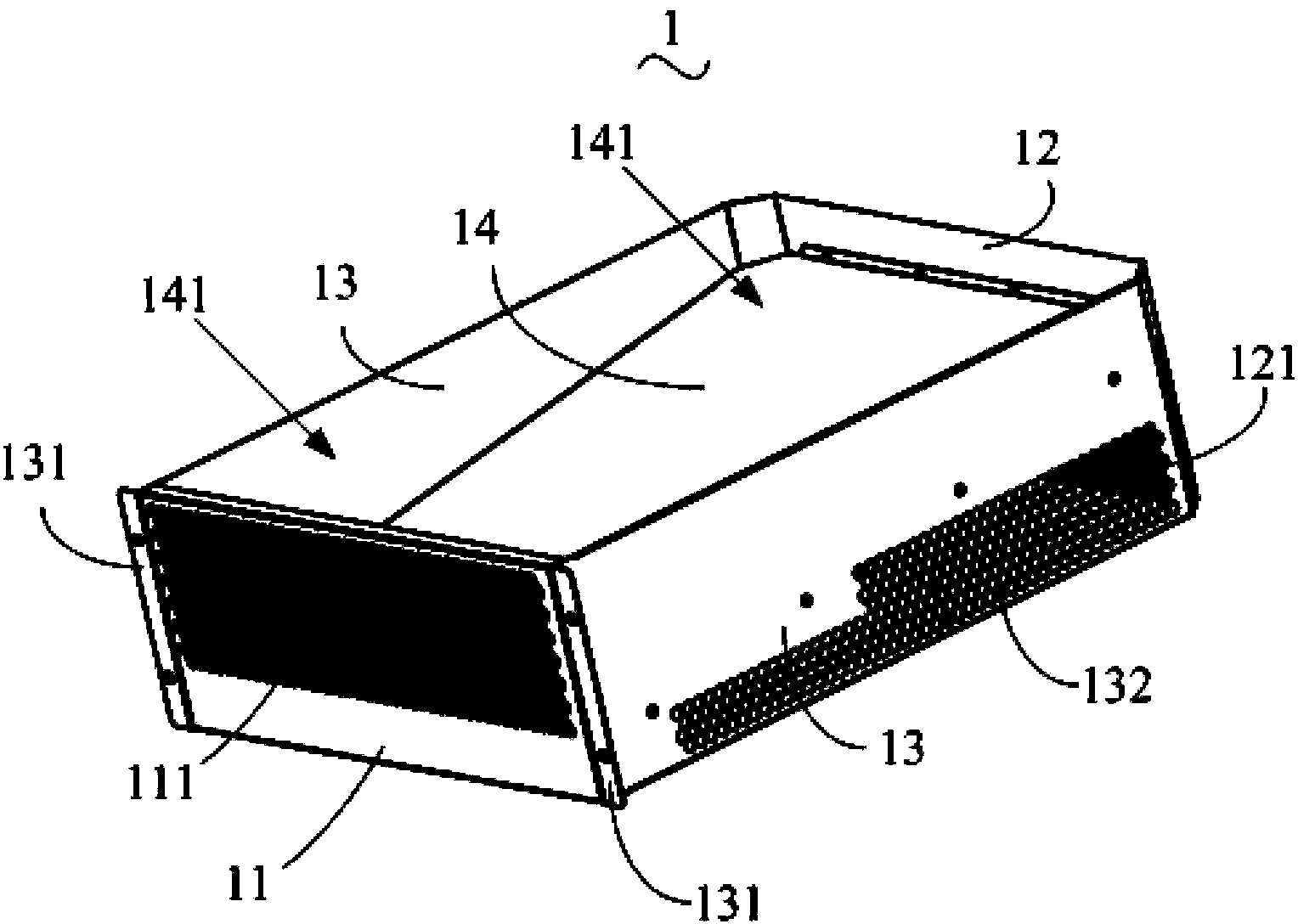

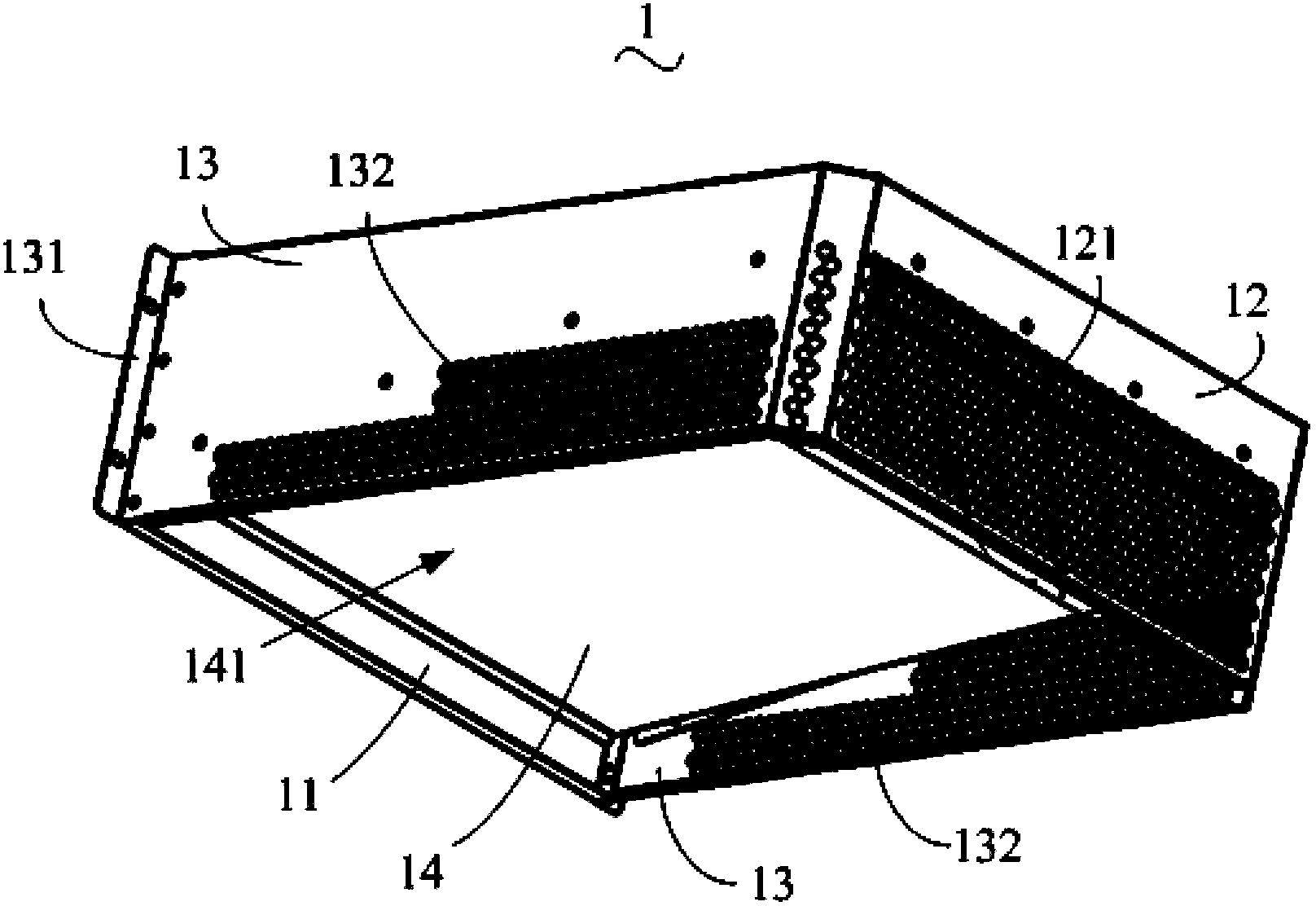

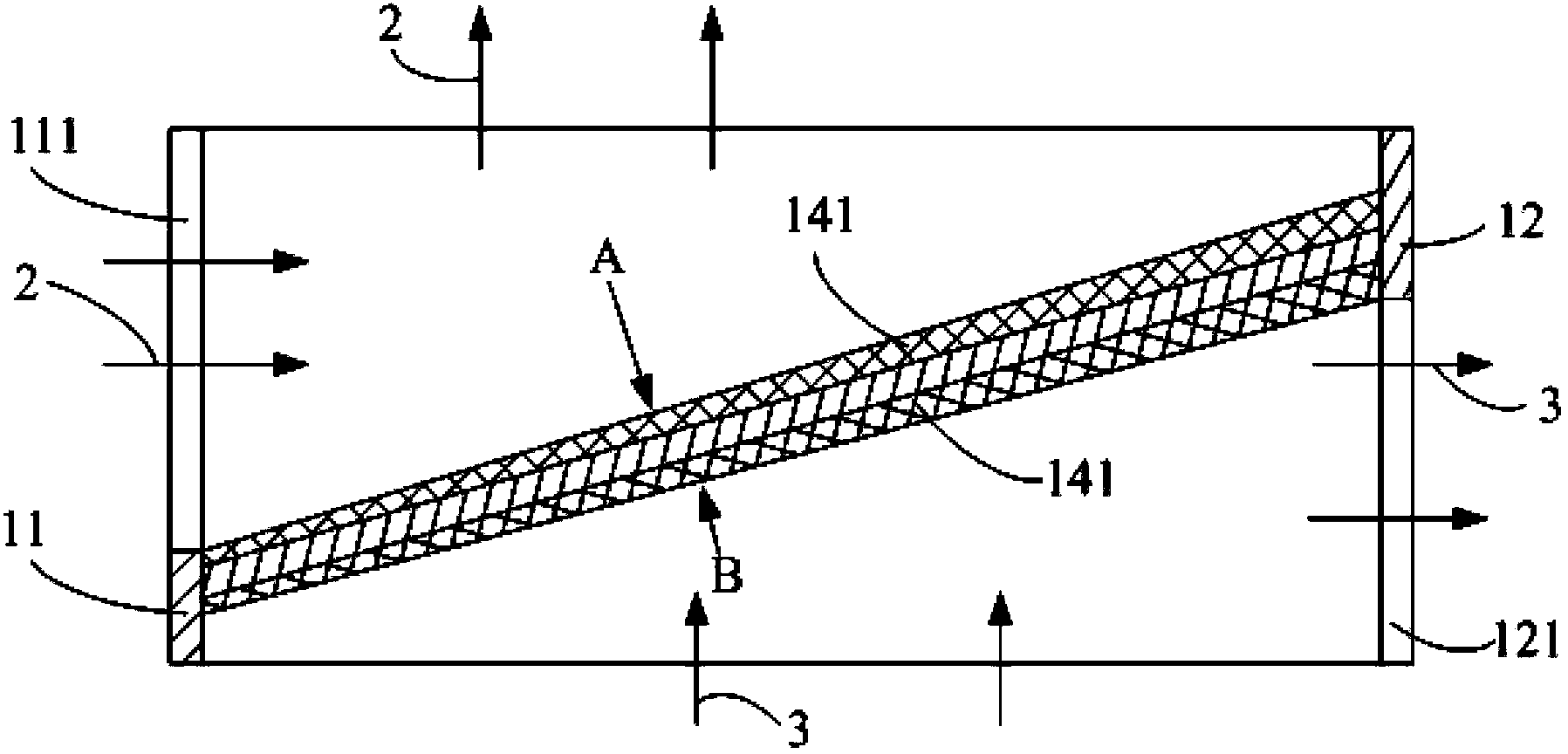

Air guide insertion box for forced air cooling type machine cabinet and forced air cooling type machine cabinet

ActiveCN104349649AReduce heatingAvoid heatingModifications for standard racks/cabinetsThermal insulationForced-air

Disclosed are an air deflecting subrack for a forced air cooling cabinet, and forced air cooling cabinet, the air deflecting subrack comprising a front vertical plate having vent holes, a back vertical plate having vent holes, two side vertical plates having lugs, and an air deflecting transverse plate configured to isolate the wind area; the front vertical plate, the back vertical plate, the two side vertical plates, and the air deflecting transverse plate are fixedly connected integrally so as to differentiate and deflect the cold and hot airflows at the two sides of the air deflecting transverse plate; and the surface of the air deflecting transverse plate is provided with a thermal insulation layer made of thermal insulation material. The present invention has better heat dissipation and good sound absorption effects.

Owner:ZTE CORP

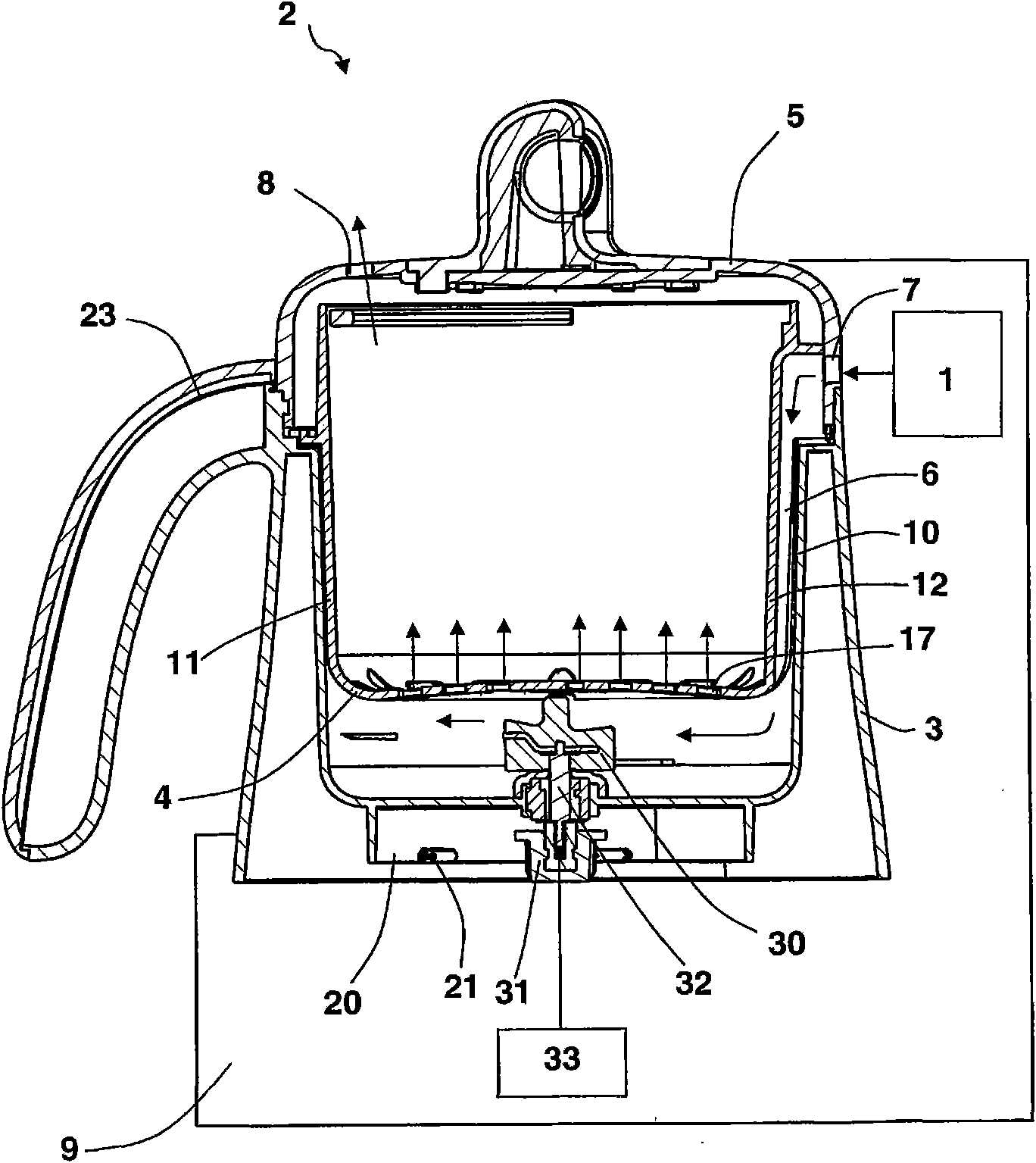

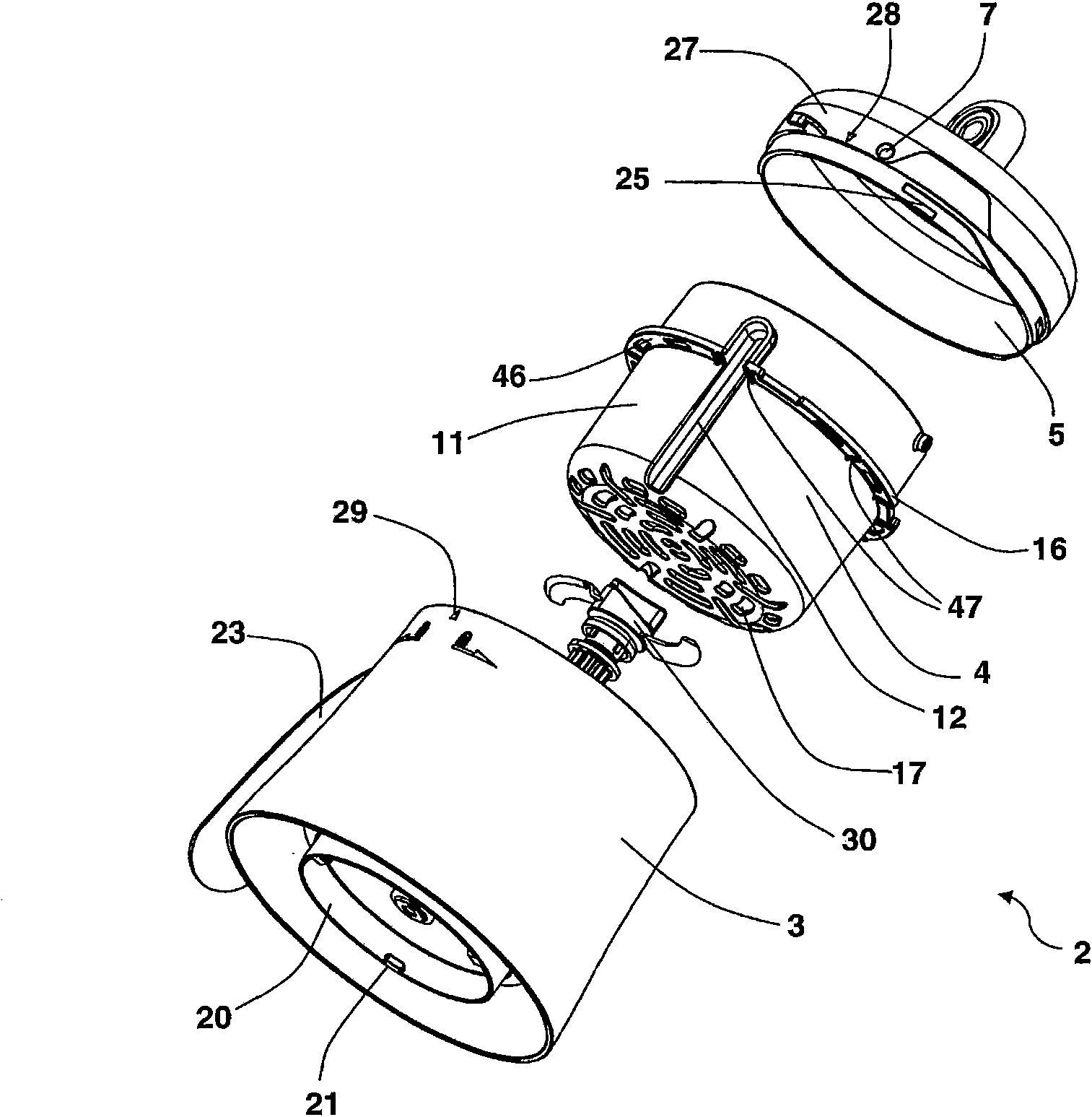

Apparatus for the steam preparation of foodstuffs

InactiveCN101646372ALow costCooks evenly and quicklySteam cooking vesselsEngineeringMechanical engineering

Owner:SEB SA

Method for making special PVC (polyvinyl chloride) floor

The invention discloses a method for making a special PVC (polyvinyl chloride) floor, which comprises the following steps: 1. transferring heat conduction oil into a heating plate of a hot press to keep the heating plate at constant temperature; 2. automatically feeding a die, a PVC floor material and a die clamper together to a workbench; 3. lifting a master cylinder in the hot press to apply pressure; 4. repressing; 5. keeping constant pressure; 6. lowering the master cylinder in the hot press; 7. automatically feeding the die and the material together onto a workbench plate of another cold press; 8. keeping the workbench plate of the cold press at constant temperature by using a cold water machine; 9. lifting the master cylinder in the cold press to apply pressure; and 10. lowering the master cylinder in the cold press to complete the whole production process of the special PVC floor. The method for making a special PVC floor disclosed by the invention has the advantages of high efficiency, high safety, environmental protection and energy saving, and does not use a boiler.

Owner:东莞进力机械科技有限公司

Process for manufacturing end plate for use in pretensioning method prestressed concrete pipe pile

The invention discloses a production method of end plate for pretensioned prestressed concrete pile. Crewel polytype horizontal centrifuge casting-stamping technology is applied in the method. Firstly, regular waste steel, silicon iron, manganese iron by measuring are enclosed into electric cooker with the certain proportion and melt; secondly, residue is cleaned after molten steel is regular by measuring and it is casting in Crewel polytype horizontal centrifuger; thirdly, cast is cooled to 920DEG C-980DEG C and demould starts, and cast is transmitted in forcing press to died and pierced, where the piercing temperature is not less than 780DEG C; finally, it is machined furthermore by the user demand after cast is cooled in stack. The invention is provided with short flow, simple equipment and low cost so on.

Owner:MAANSHAN HUAKE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com