Patents

Literature

83results about How to "Reduce oven time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid lining material of medium-frequency induction furnace and furnace building method thereof

ActiveCN102617164ACounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairCooking & bakingGranularity

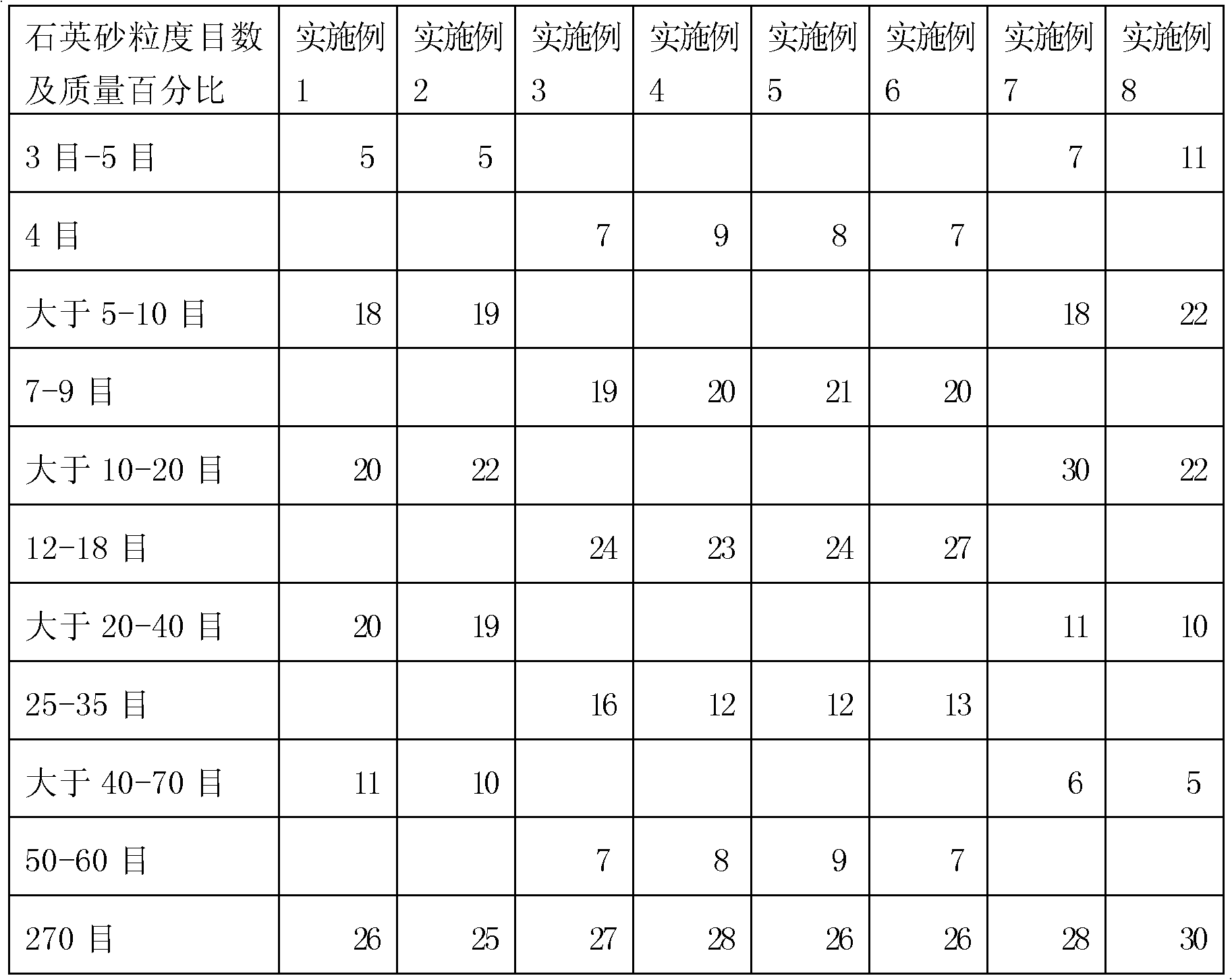

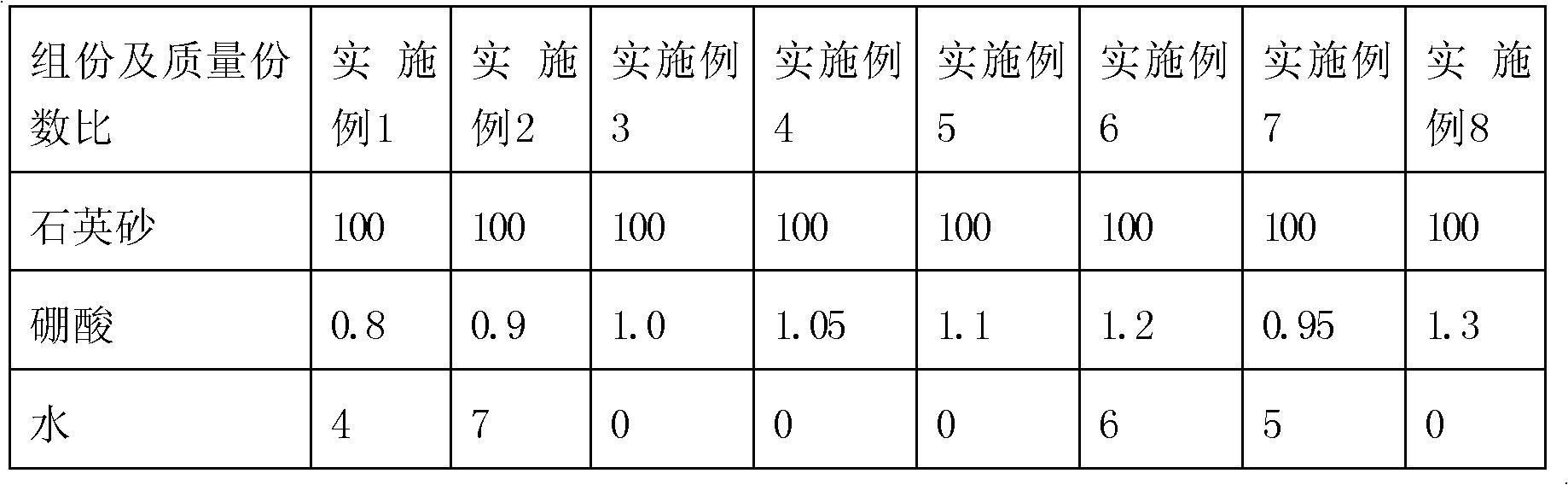

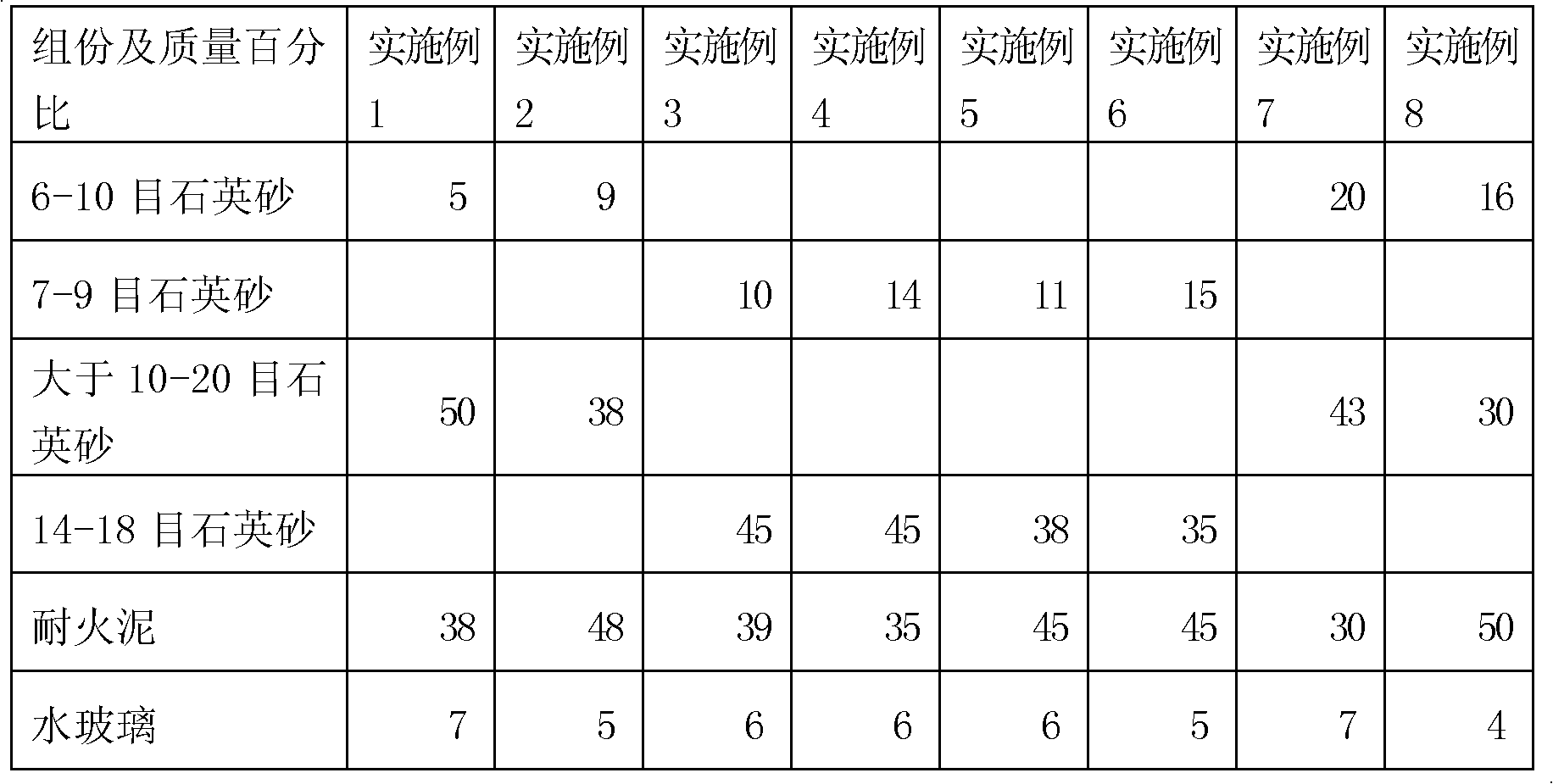

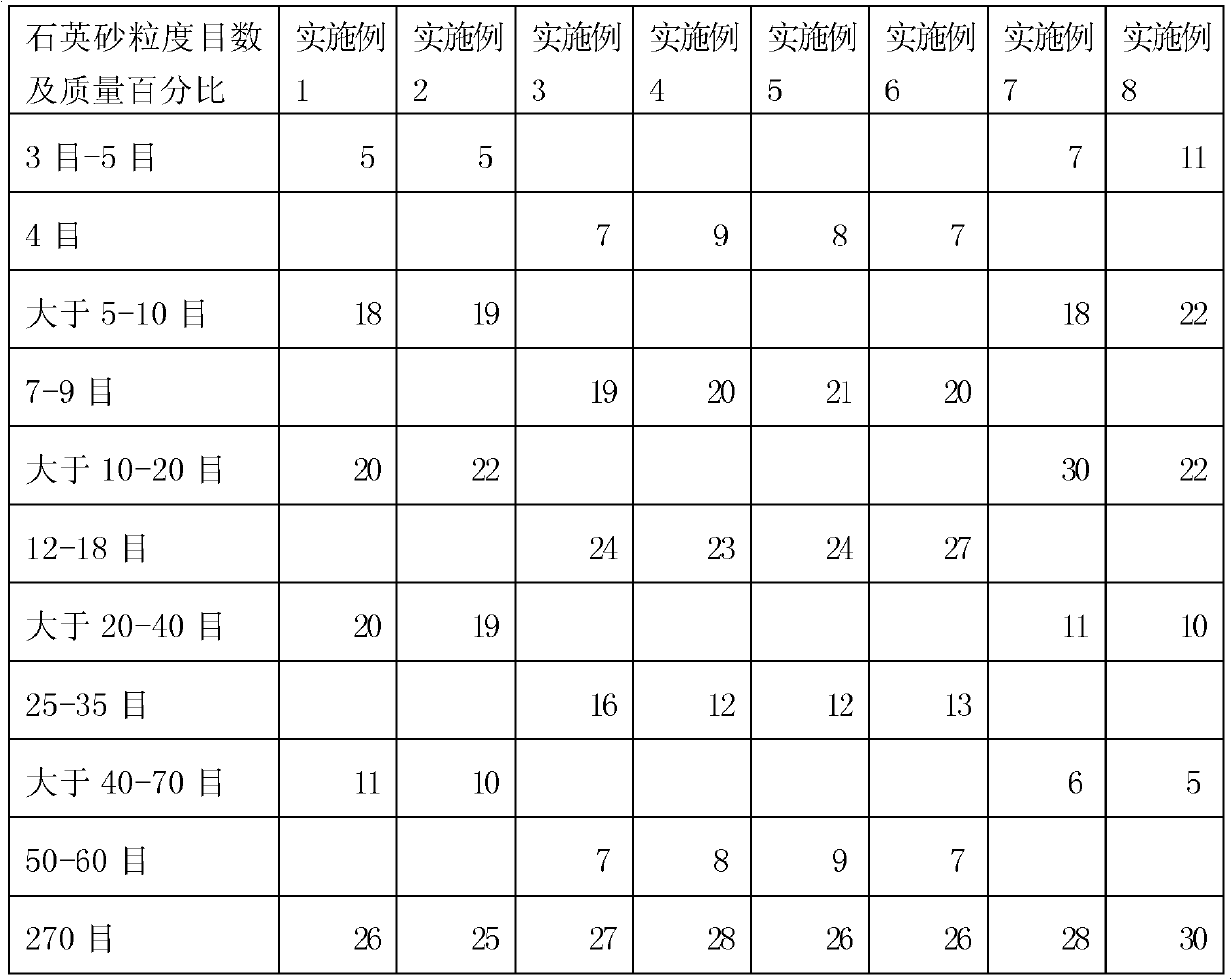

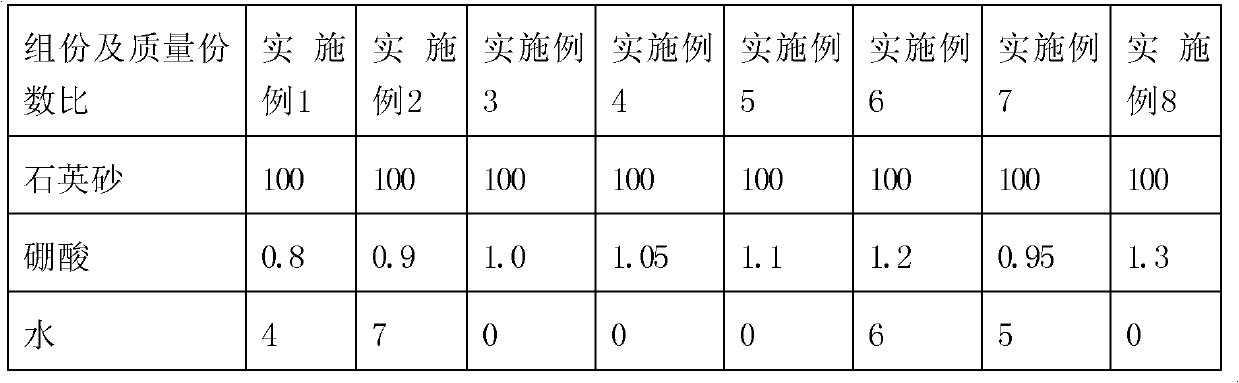

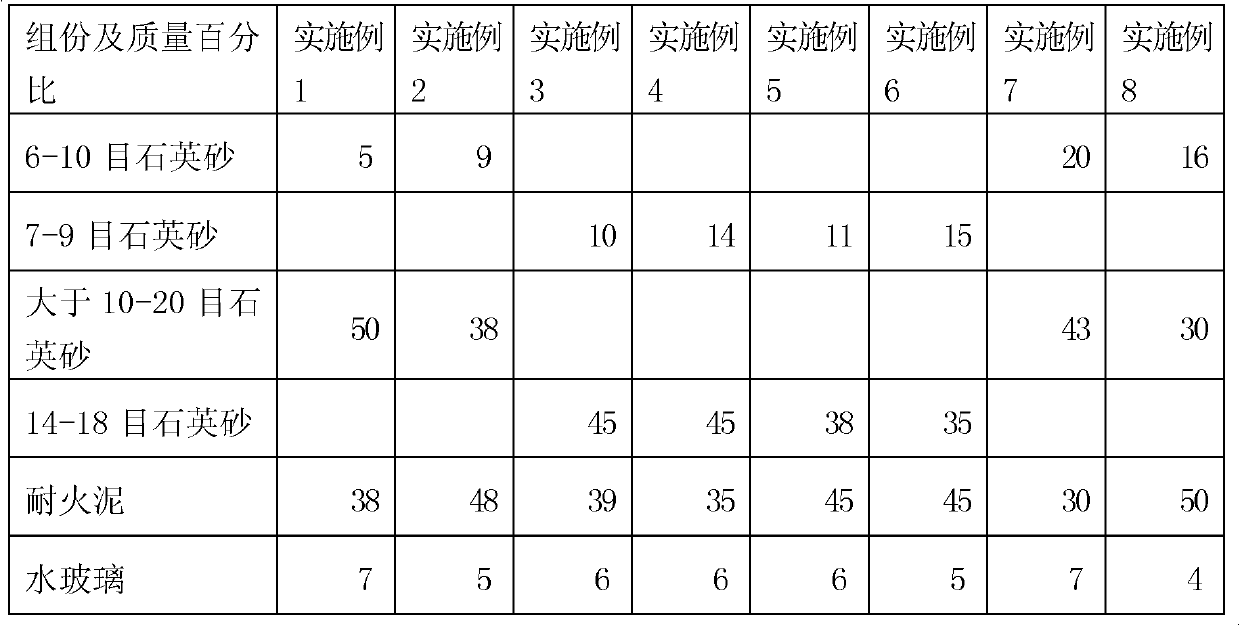

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

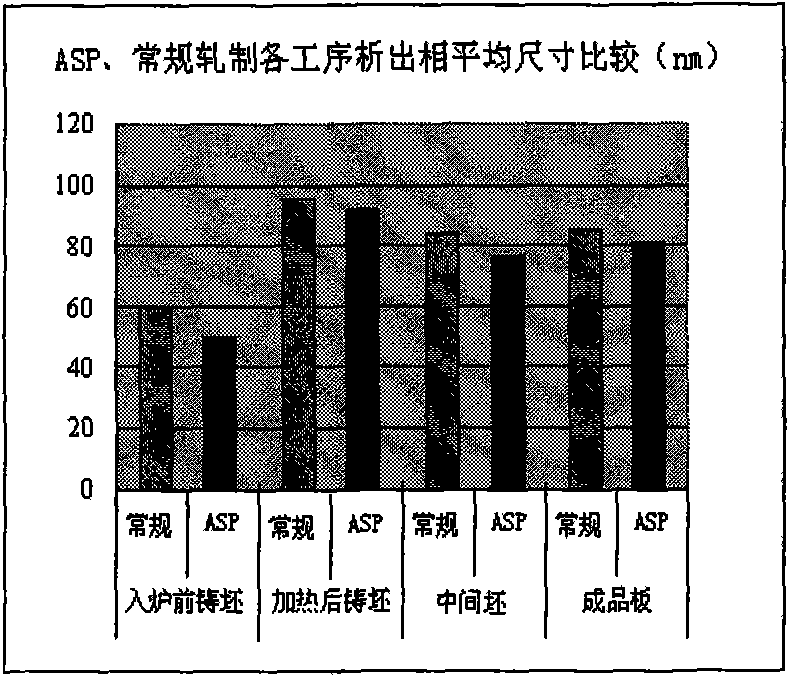

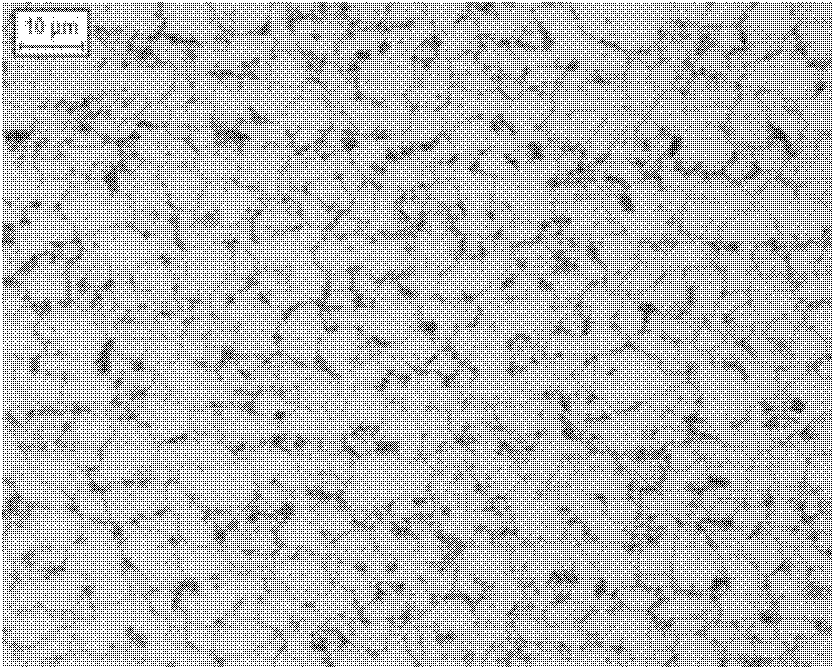

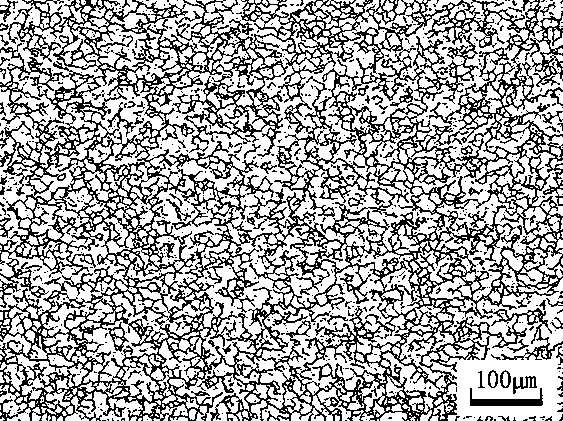

Thick-specification high-tenacity X70 acicular ferrite pipe line steel and manufacturing method thereof

ActiveCN101684539AGreen and efficient production process requirementsRaise the furnace temperatureTemperature control deviceMetal rolling arrangementsLine tubingHigh pressure

The invention discloses thick-specification high-tenacity X70 acicular ferrite pipe line steel and a manufacturing method thereof. The thick-specification high-tenacity X70 acicular ferrite pipe linesteel comprises components as follows in percentage by weight: C: 0.03%-0.06%. Si: 0.15%-0.25%, Mn: 1.55%-1.75%, P: 0.012%-0.020%, S: less than or equal to 0.003%, Cu: 0.20%-m0.35%, Nb: 0.06%-0.08%, Ti: 0.01%-0.02%, AIs: less than or equal to 0.05%, and Mo: 0.20%-0.30%. The manufacturing process of the thick-specification high-tenacity X70 acicular ferrite pipe line steel is characterized in thatcontinuous casting speed is 1.2-1.8m / min; casting temperature of plate blanks is above 550 DEG C; the temperature is raised to 1100-1250 DEG C and kept for 80-120min; the roughing delivery temperatureis 920-1080 DEG C; the finish rolling delivery temperature is 760-880 DEG C; the cooling speed is 10-30 DEG C / s; and the coiling temperature is 450-570 DEG C. The thick-specification high-tenacity X70 acicular ferrite pipe line steel meets and is superior to the performance requirement of API 5LX70 acicular ferrite pipe line steel; meanwhile, the thick-specification high-tenacity X70 acicular ferrite pipe line steel has excellent HIC resistance and is suitable to tick-specification large-caliber high-pressure gas transmission pipelines which requires to be continuously enlarged.

Owner:ANGANG STEEL CO LTD

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

Quick-drying explosion-proof castable and producing process thereof

The invention discloses a castable used for an industrial furnace lining and a producing process thereof, and particularly relates to a quick-drying explosion-proof castable used for an industrial furnace lining and a producing process thereof. The producing process comprises four steps of raw material purchasing and testing, burdening, mixing and packaging. The producing process of the invention has the advantages of realizing quick-drying (rapid hardening) and fast stripping of the castable, and rapid baking without burst or explosion. With greatly shortened construction time and baking time, production pace is speeded up, a large quantity of energy is saved, emission of carbon dioxide and nitrogen oxide is significantly reduced and economic and social benefits are prominent.

Owner:LUOYANG KECHUANG NEW MATERIAL CO LTD

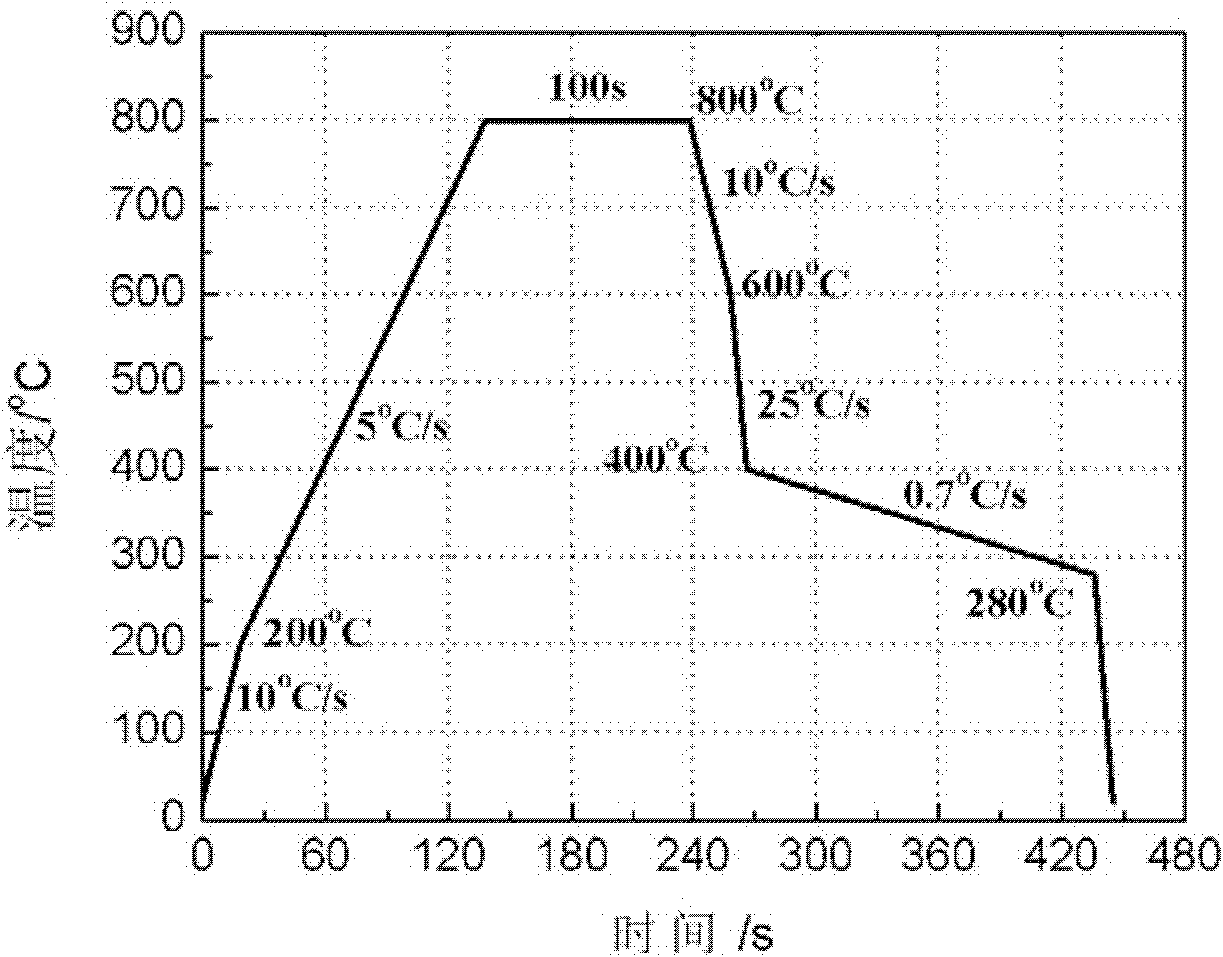

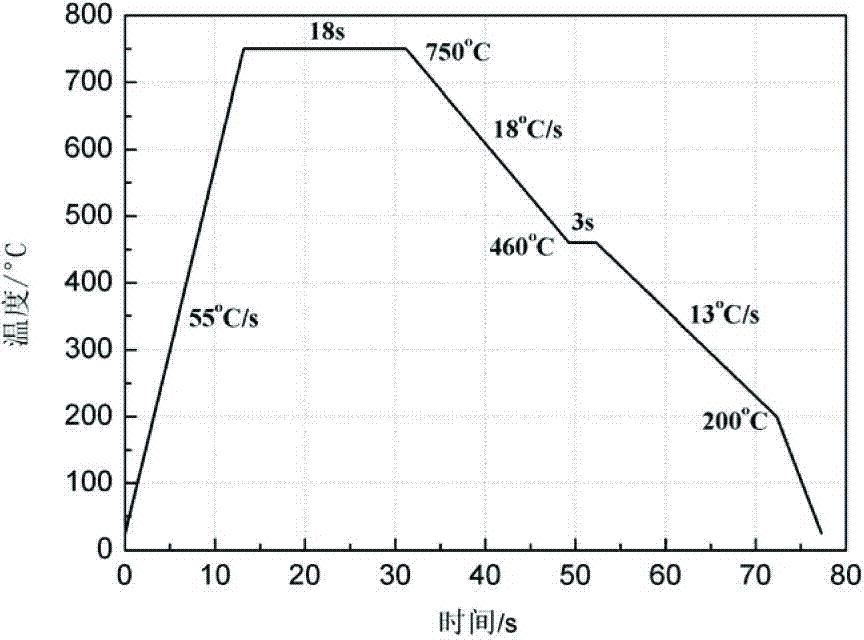

Continuous annealing process of cold rolling low alloy high-strength steel plate with yield strength at grade of 420 MPa

ActiveCN102492823BReduce heatingReduce oven timeFurnace typesHeat treatment process controlSheet steelChemical composition

Owner:SHANGHAI BAOYI CAN MAKING CO LTD

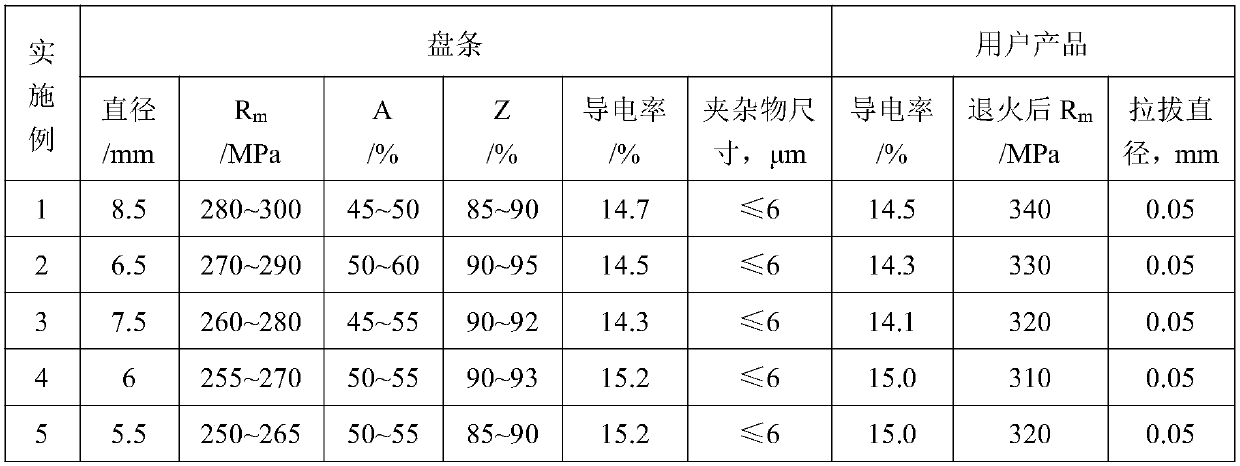

Production method of steel wire rod for very fine copper-clad steel wire

InactiveCN107675068AKeep Steel PureComply with chemical composition requirementsSteelmakingManganese

The invention discloses a production method of a steel wire rod for a very fine copper-clad steel wire. The production method comprises the following steps of a steelmaking procedure and a controlledrolling procedure, wherein the steelmaking procedure comprises the following steps of 1) molten iron pretreatment; 2) converter steelmaking; 3) argon blowing; 4) RH refining: controlling the mass content of carbon in molten steel to be smaller than or equal to 0.003 percent, the mass content of free oxygen to be smaller than or equal to 15ppm and the mass ratio of manganese and sulfur to be Mn / S larger than or equal to 10; and 5) continuous casting; and the controlled rolling procedure comprises the following steps of 6) heating, wherein a temperature of a heating section is 1050-1150 DEG C, atemperature of a heat balance section is 1150 plus / minus 50 DEG C, and a section temperature difference is smaller than or equal to 30 DEG C; 7) roughing; 8) finishing: a temperature of an inlet of afinishing mill is 900 plus / minus 15 DEG C, and a temperature of an inlet of a reducing sizing mill is 890 plus / minus 10 DEG C; and 9) cooling control: controlling cooling on a Stelmor cooling controlline, wherein a laying temperature of a laying machine is 890 plus / minus 10 DEG C, and the average cooling rate is 0.5-1.5 DEG C / s. The steel wire rod produced by the method has especially good colddrawing performance and higher conductivity and meets the requirements for the steel wire rod for the very fine copper-clad steel wire by electronic products including mobile phones.

Owner:武汉钢铁有限公司

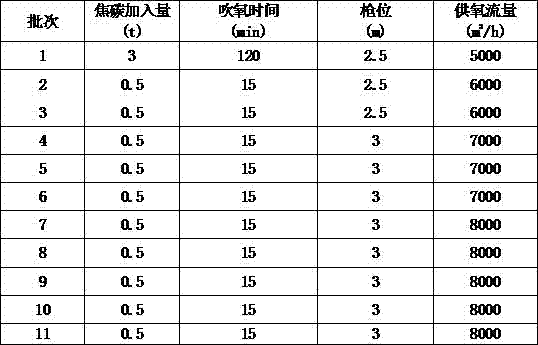

Converter baking method performed after 120t converter replaces furnace lining refractory material

InactiveCN107419052AShorten oven timeImprove lining lifeManufacturing convertersNitrogen gasCombustion

The invention discloses a converter baking method performed after a 120t converter replaces a furnace lining refractory material. The method comprises the following steps that (1), eight tons of coke and one ton of waste wood are added into the converter before converter baking is performed, and the wood is ignited; (2), an oxygen lance is fed for blowing oxygen, and after the wood is ignited, the coke is added into the converter in batches from a stock bin at the top of the converter; (3), the oxygen flow is controlled, specifically, the flow is set as 5000 m<3> / h before the oxygen lance is fed, and the flow is adjusted to 8000 m<3> / h according to the combustion situation; (4), the position of the oxygen lance is controlled, specially, the height between the oxygen lance and the top face of the coke in the converter is 2.5 m before blowing, twenty minutes later, the position of the oxygen lance is raised, and the temperature of a furnace lining maintains being raised uniformly; (5), bottom blowing is controlled, and specifically a bottom blowing device is started to blow nitrogen gas; (6), converter baking is finished, specially the temperature of the furnace lining in the later period of converter baking reaches 780-820 DEG C, converter baking is finished, and hot metal is charged for converting immediately after the oxygen lance is lifted. By means of the converter baking method, the temperature is raised at a uniform speed in the converter baking process, natural water and crystal water in the furnace lining refractory material are removed completely, the furnace lining is tight in combination after converter baking, the hearth temperature reaches the design requirement, the converter baking time is shortened, and the service life of the furnace lining is prolonged.

Owner:XINJIANG BAYI IRON & STEEL

Hot-rolled edge quality control method for low-temperature and high-magnetic-inductance oriented silicon steel

ActiveCN109590339AImprove edge qualityReduce the degree of oxidationMetal rolling arrangementsProfile control deviceSlip coefficientQuality control

The invention discloses a hot-rolled edge quality control method for low-temperature and high-magnetic-inductance oriented silicon steel. The control method comprises the steps of in the process of heating the low-temperature and high-magnetic-inductance oriented silicon steel by a heating furnace high-temperature section, controlling an air-fuel ratio of an upper secondary heating section to an upper soaking section of the low-temperature and high-magnetic-inductance oriented silicon steel to be less than or equal to a first preset value, and controlling an air-fuel ratio of a lower secondaryheating section to a lower soaking section of the low-temperature high-magnetic-inductance oriented silicon steel to be less than or equal to a second preset value, wherein the first preset value isgreater than the second preset value; reducing the temperature of the heating furnace high-temperature section by 10-20 DEGC; and performing three pass of rough rolling on the low-temperature and high-magnetic-inductance oriented silicon steel by a first vertical roll and a second vertical roll, wherein the rolling speed in each pass in rough rolling is controlled at 2.6-4.8 m / s, and the best slope matching speed and backward slip coefficient between the vertical rollers E2 and R2 in each pass. The hot-rolled edge quality control method solves the technical problem of high occurrence rate of 'cake brittleness' defect at the edge of the strip.

Owner:武汉钢铁有限公司

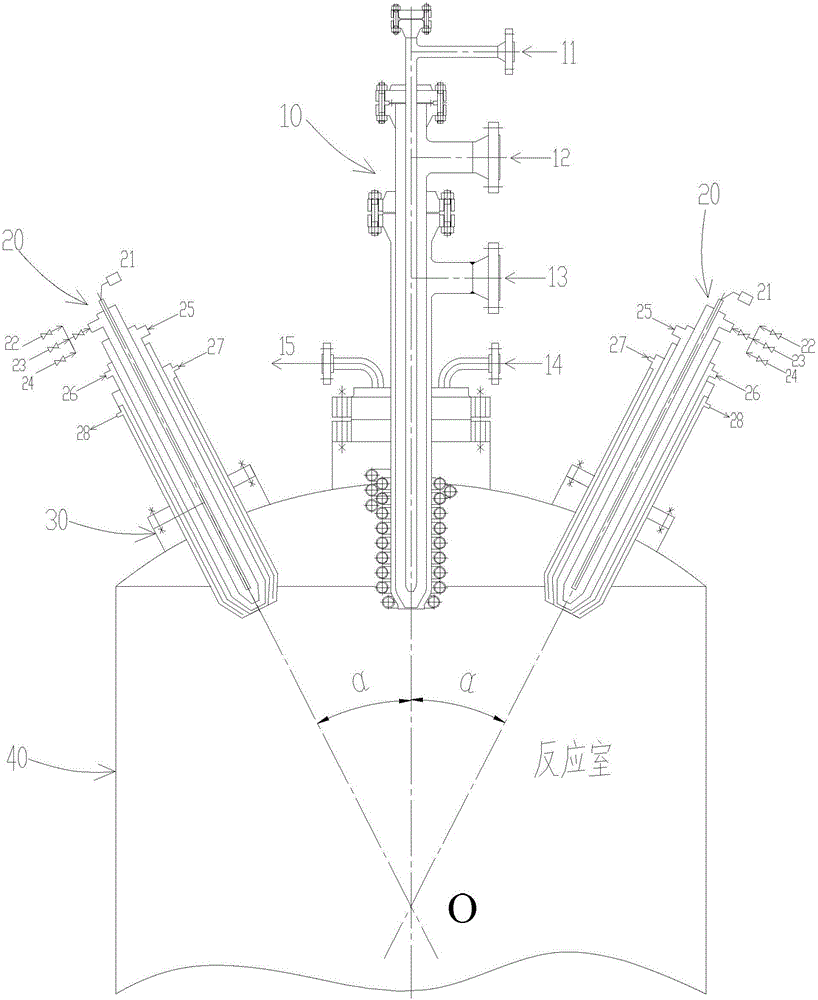

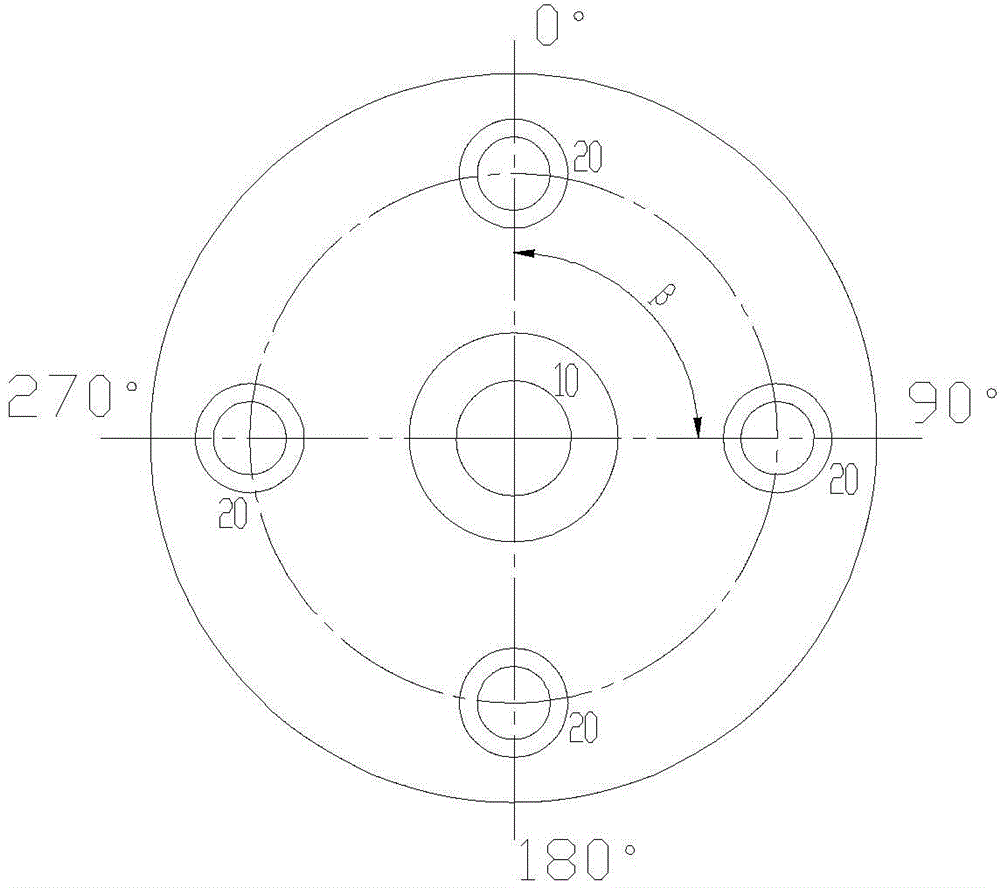

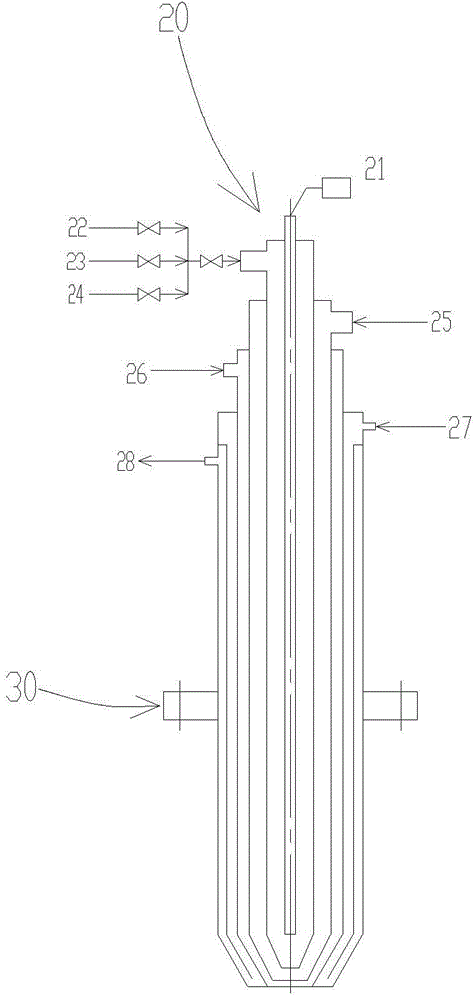

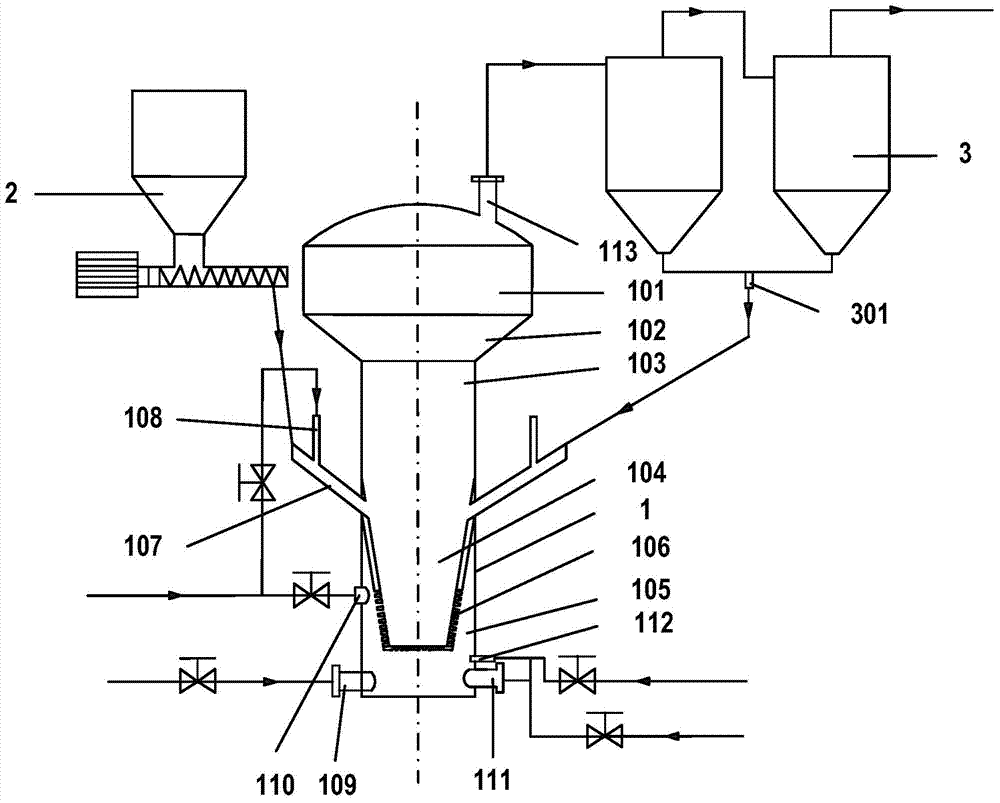

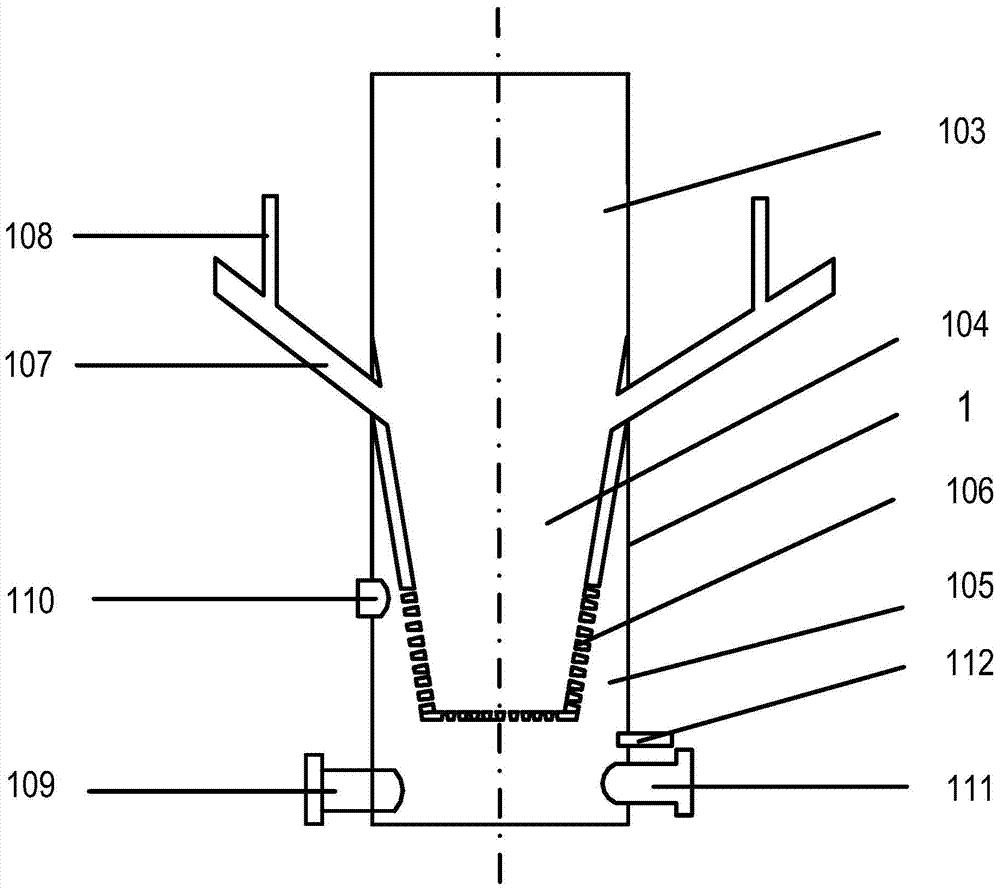

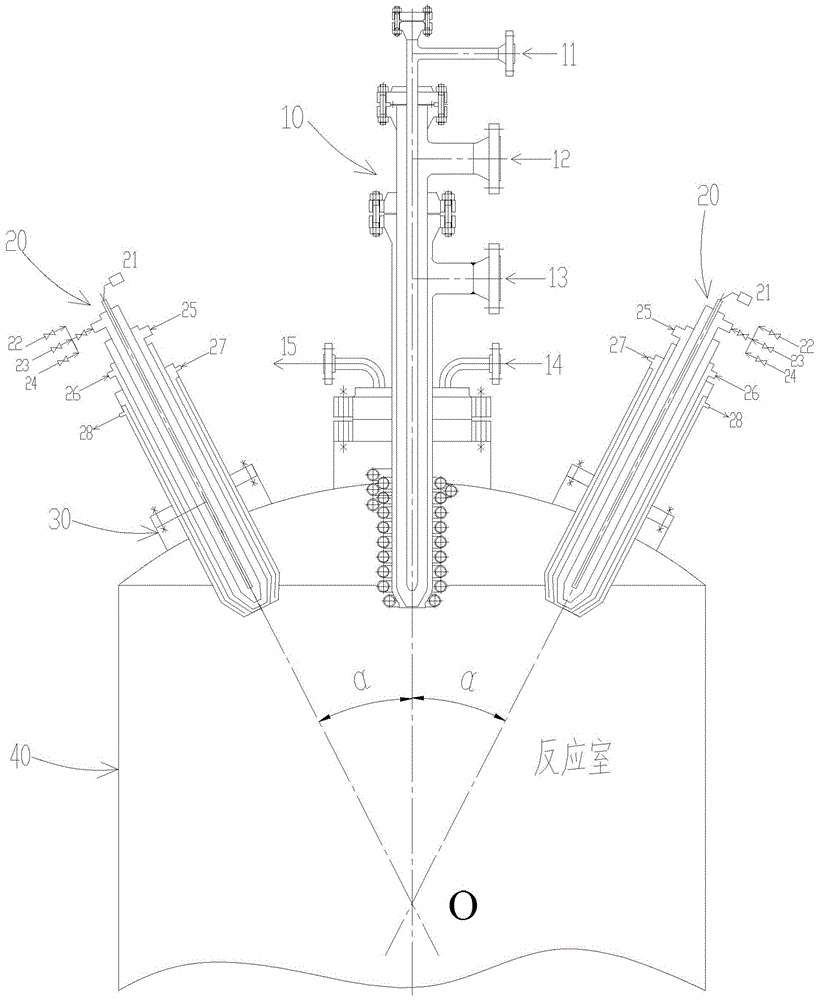

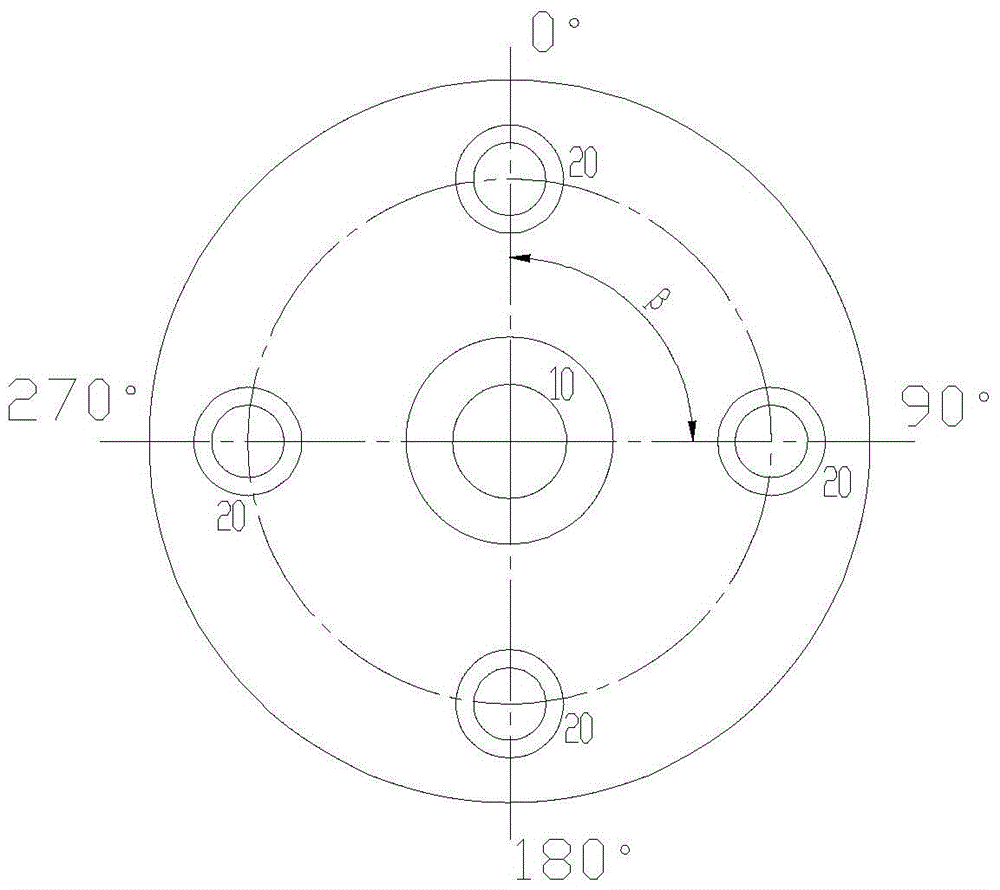

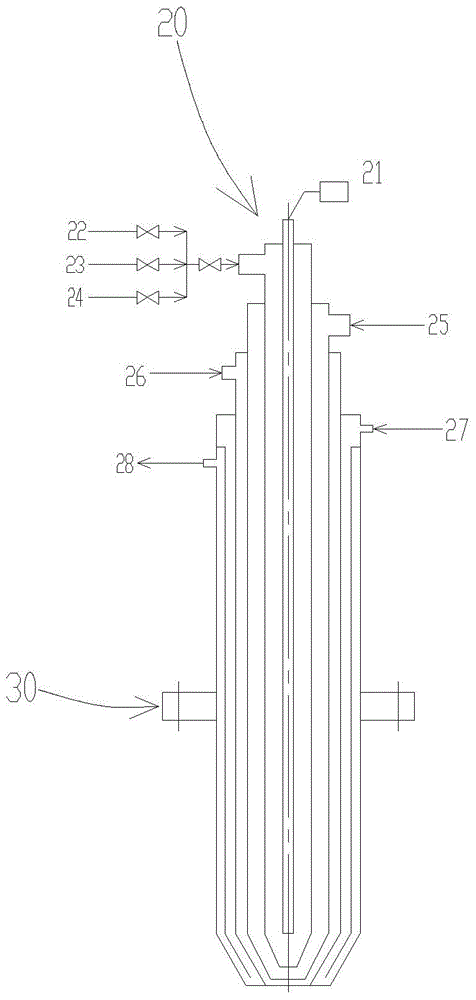

Gasification device with multiple burners and coal gasification technology

InactiveCN104403695AAchieving pressurized gasificationImprove responseGasification apparatus detailsGranular/pulverulent flues gasificationProcess engineeringControl valves

The invention discloses a gasification device with multiple burners and a coal gasification technology. The gasification device comprises a gasification furnace reaction chamber, a main burner, which is arranged on the center of the top of the gasification furnace reaction chamber, and auxiliary burners, which are arranged on the periphery of the main burner. The auxiliary burners are provided with a plurality of connection channels and also provided with control valves for switching the connection channels between the ignition working mode and the technological material feeding mode. The provided technical scheme can shorten the furnace warming time, and achieves the stable operation of gasification device in a long term.

Owner:SANY GRP

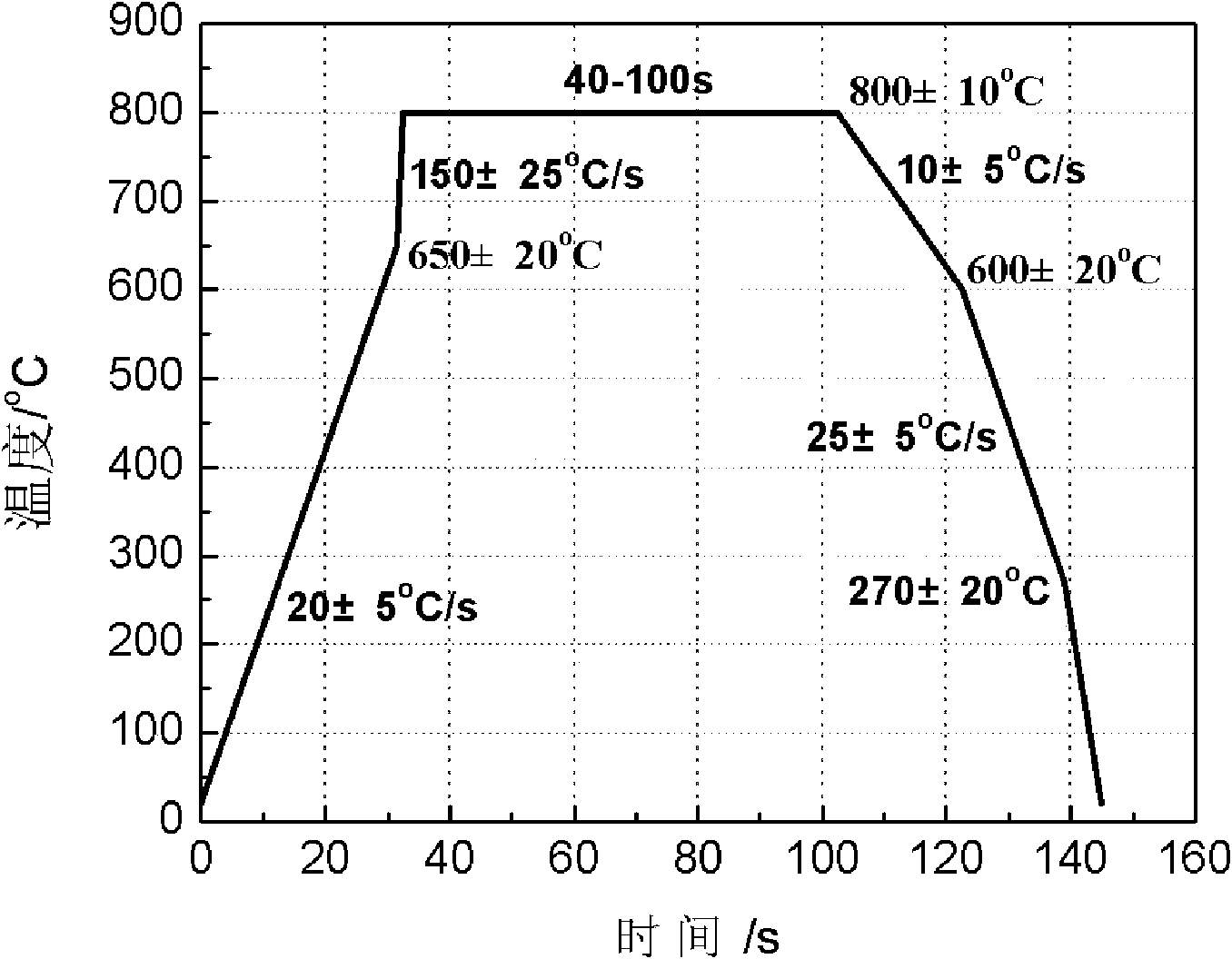

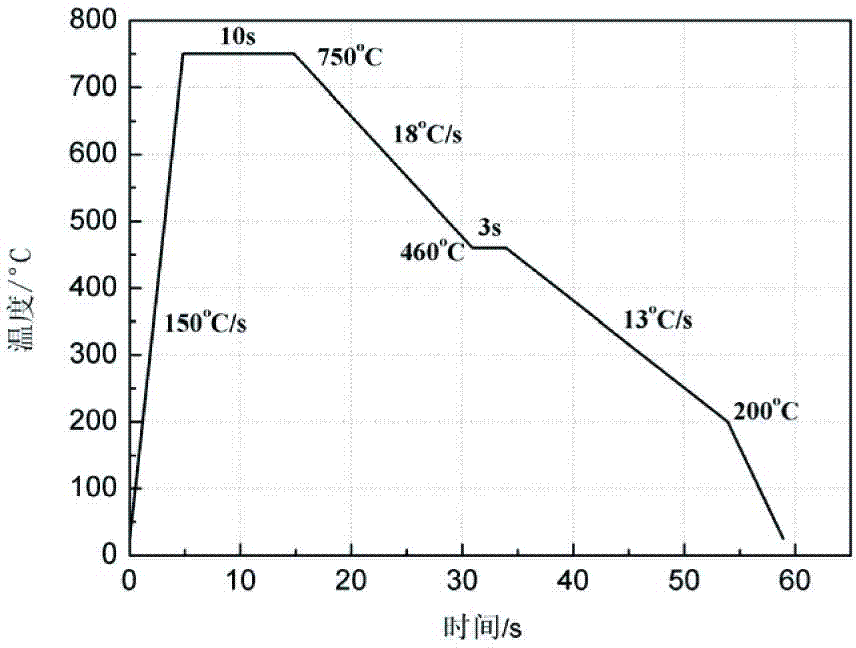

Process for performing continuous annealing on low-carbon aluminum killed steel belt

ActiveCN102808068AReduce heating effectShorten the timeFurnace typesHeat treatment furnacesReduction rateChemical composition

The invention discloses a process for performing continuous annealing on a low-carbon aluminum killed steel belt. The low-carbon aluminum killed steel belt comprises the following chemical components in percentage by weight: less than or equal to 0.04 percent of C, less than or equal to 0.02 percent of Si, less than or equal to 0.28 percent of Mn, less than or equal to 0.045 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.003 percent of N, and the balance of Fe and inevitable impurities; the low-carbon aluminum killed steel belt is subjected to cold rolling and then is subjected to continuous annealing, and the reduction rate of the cold rolling is controlled to be 70 to 80 percent; the continuous annealing process comprises the following steps of: 1) heating, namely heating from room temperature to 750+ / -10 DEG C at the speed of 150+ / -5 DEG C / s; 2) soaking, namely soaking at the temperature of 750+ / -10 DEG C for 5 to 15s; 3) rapidly cooling, namely cooling to 460+ / -10 DEG C at the speed of 18+ / -2 DGE C / s; 4) soaking, namely soaking at the temperature of 460+ / -10 DEG C for 2 to 5s; 5) slowly cooling, namely cooling to 200+ / -10 DGE C at the speed of 13+ / -2 DEG C / s; and 6) spraying water to cool to room temperature. The mechanical property of a continuous annealing steel plate which is produced by the method is kept almost unchanged, the continuous annealing time is shortened, and the energy consumption is reduced.

Owner:SHANGHAI BAOYI CAN MAKING CO LTD

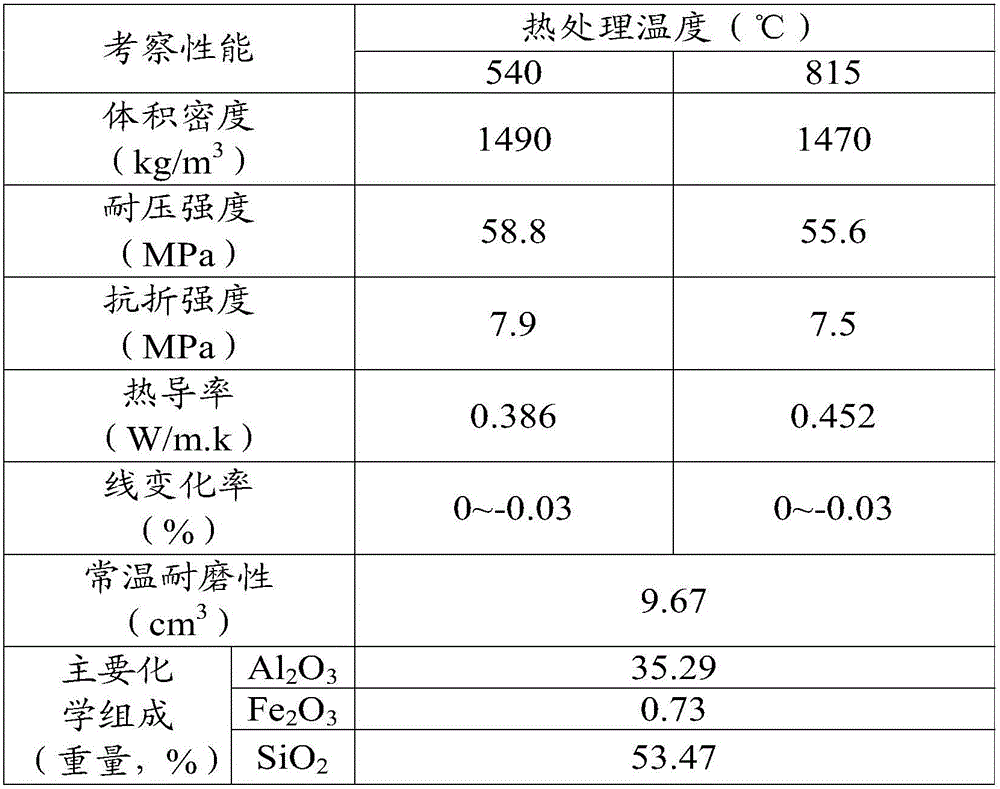

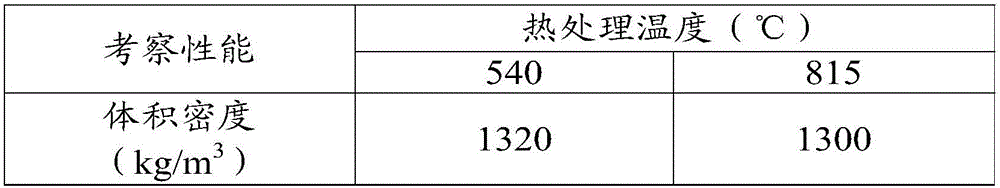

Heatproof and wear resistant lining material

The invention provides a heatproof and wear resistant lining material, and belongs to the field of petrochemical engineering. The heatproof and wear resistant lining material is mainly composed of a base material and additives. The base material comprises 55 to 70% of aggregate, 10 to 15% of powder, and 20 to 30% of bonding agent. The additives comprise a composite additive and explosion-proof fibers. The using amount of explosion-proof fibers is 0.05 to 0.1% of the total weight of lining material. The using amount of composite additive is 0.2 to 0.7% of the weight of base material. The lining material has a high temperature rising speed under baking, the curing time is shortened, and the lining material has the advantages of high early strength, heatproof and wear resistant properties, and strong bonding force.

Owner:DALIAN JINZHOU JINAN REFRACTORINESS CO LTD

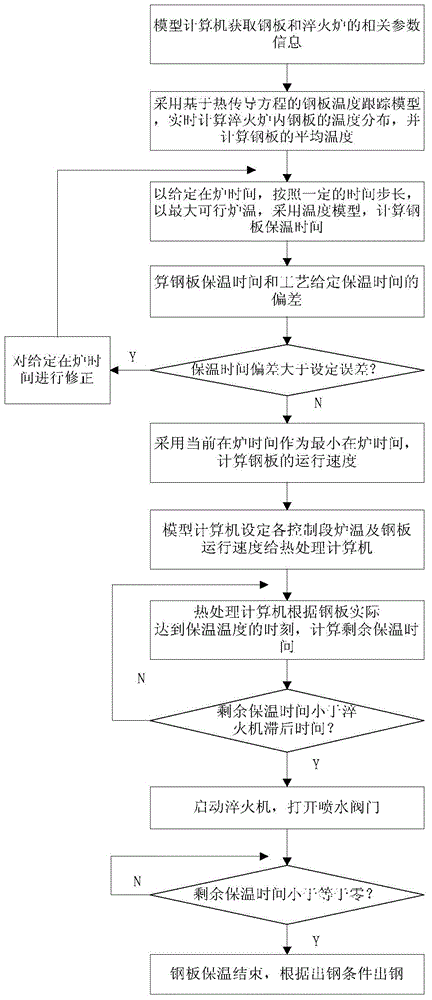

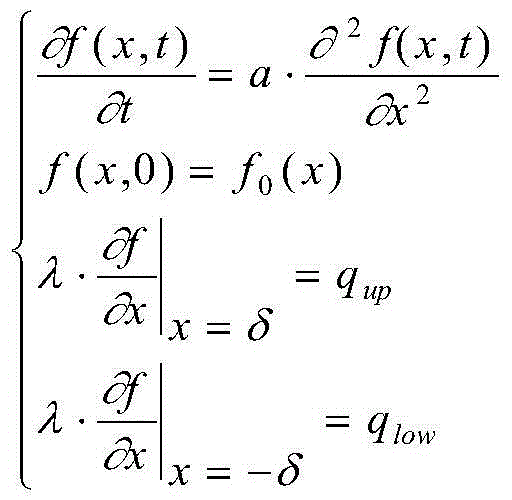

In-furnace time control method for thick steel plate heat treatment

ActiveCN106191411AIncrease productionReduce oven timeFurnace typesHeat treatment process controlSheet steelTime control

The invention relates to an in-furnace time control method for thick steel plate heat treatment. According to the control method, a modeling computer is used for tracking a model through the given temperature, a quenching furnace is operated at the highest feasible temperature, and the shortest in-furnace time of steel plates is estimated and computed; and before the steel plate heat preservation temperature is reached, the steel plate heat preservation time is computed through an estimating method, a quenching machine is started in advance so that the delay time of steel plate tapping can be shortened, and the steel plates are discharged out of the furnace in the shortest time on the premise that the requirements for the heat preservation temperature and the heat preservation time are met. The problems that in the traditional thick steel plate heat treatment process, steel plate tapping is delayed and the heat treatment efficiency is low are solved.

Owner:BAOSHAN IRON & STEEL CO LTD

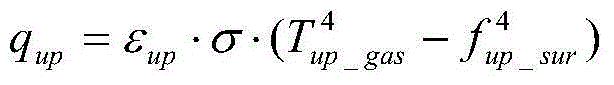

Process for producing titanium tetrachloride in fluidizing chlorination furnace by using artificial rutile

The invention discloses a process for producing titanium tetrachloride in fluidizing chlorination furnace by using artificial rutile. The process includes five steps of: furnace baking, control of feeding, control of chlorination, tail gas slagging and cyclone dust collection. According to the process, the preparation of titanium tetrachloride by using the fine-sized artificial rutile is achieved, and meanwhile the collection and recycle of the artificial rutile in dust slag which is not completely reacted are also achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

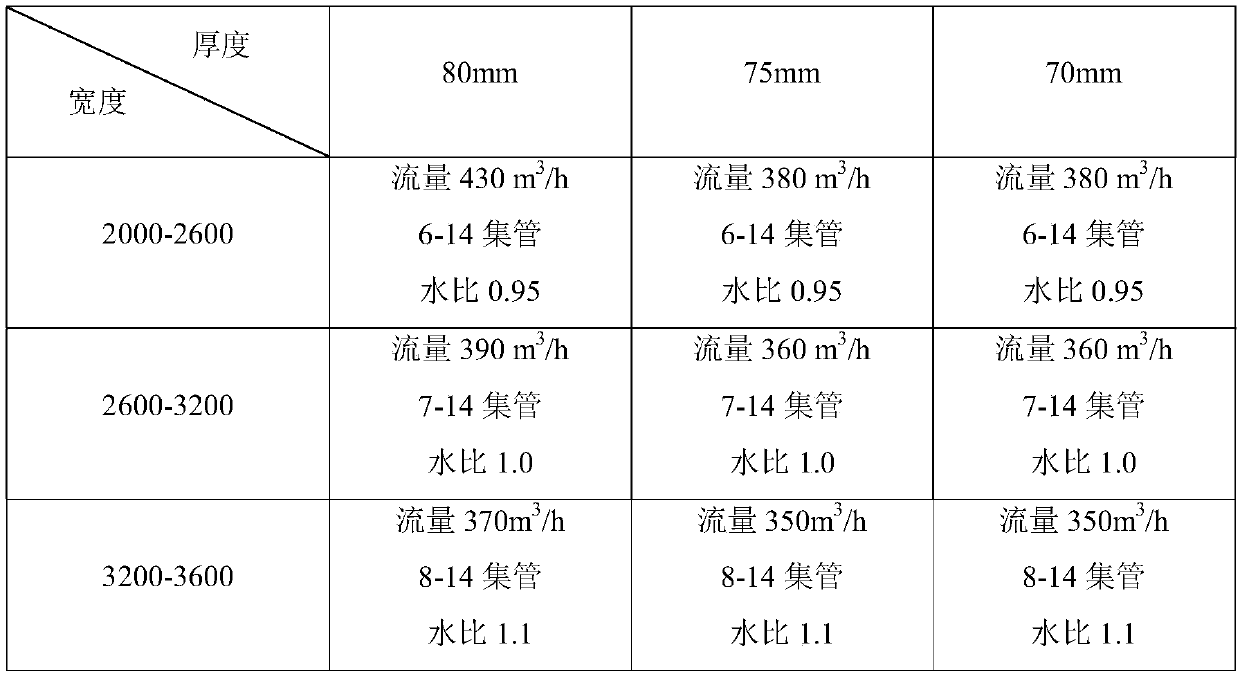

High-formability boron-containing steel with tensile strength higher than or equal to 320 MPa and production method

The invention discloses high-formability boron-containing steel with tensile strength higher than or equal to 320 MPa. The high-formability boron-containing steel is prepared from the following components in percentage by weight (wt%): 0.03-0.07% of C, 0.01-0.3% of Si, 0.4-0.9% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, less than or equal to 0.006% of N, 0.0005-0.003% of B, and 0.03-0.08% of Ti. A production method comprises the following steps: continuously casting to form blank after smelting; heating in stages; roughly rolling; performing fine rolling; performing laminar cooling; and rolling. The high-formability boron-containing steel has yield strength of 250-350 MPa, tensile strength of 320-460 MPa, and ductility higher than or equal to 32%; moreover, cast blank does not need to cut corner after being unloaded if a secondary cooling water ratio is not reduced and N content is not strictly limited; and hot rolling can be directly performed, so that a product defect rate can be controlled to be lower than 0.5%.

Owner:武汉钢铁有限公司

Production method of crack arresting steel for container ship

ActiveCN110076196ALarge amount of depressionAccurate and effective production processTemperature control deviceWork cooling devicesSheet steelUltra fast

The invention discloses a production method of crack arresting steel for a container ship. Billets having different cross sections are selected for rolling according to different finished product widths, the rolling pass is reduced, and the reduction in pass is increased; as for planning arrangement, according to the characteristics that the rolling mode is special and the rolling frequency is slow, the time in a furnace is shortened through blank positions in a heating furnace, execution of a heating technology is ensured, and the surface quality is ensured; the heating process ensures the uniformity of a plate slab in the thickness direction; a rolling technology uses a full longitudinal rolling or full horizontal rolling manner as many as possible, and the effective compression ratio isincreased; and in order to refine grains, the intermediate billet is subjected to ultra-fast cooling, different cooling technologies are set according to specifications, and a finished steel sheet cooling technology is determined. A stable production technology for accurately and effectively producing the crack arresting steel can be realized, the stability of the production technology of the crack arresting steel meets the batch industrial production, the mechanical properties, the product quality stability and various indexes meet the standard requirement, and the production process is easyto control.

Owner:NANJING IRON & STEEL CO LTD

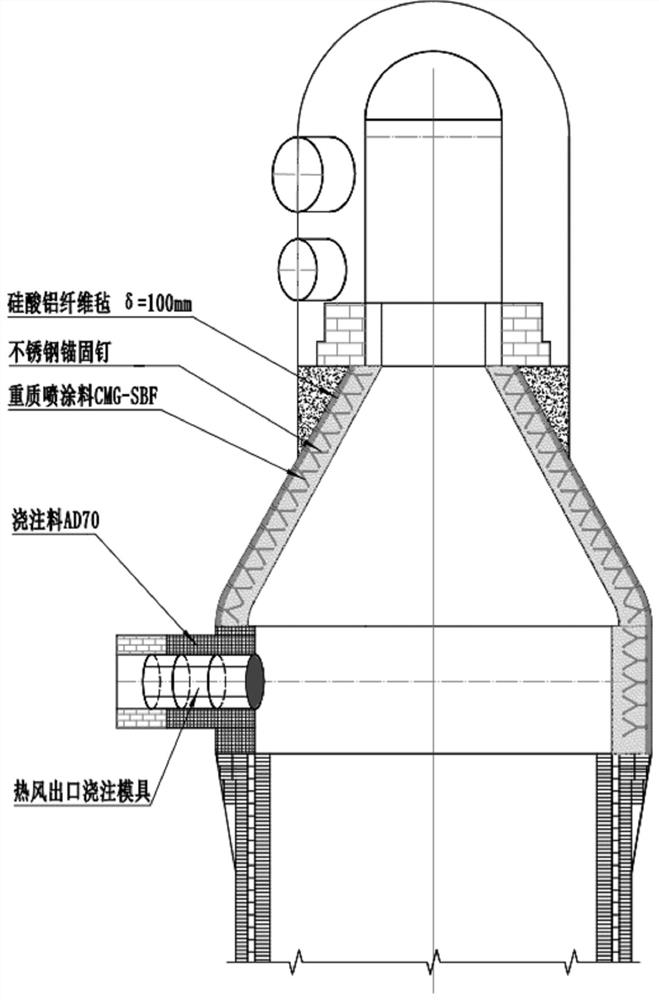

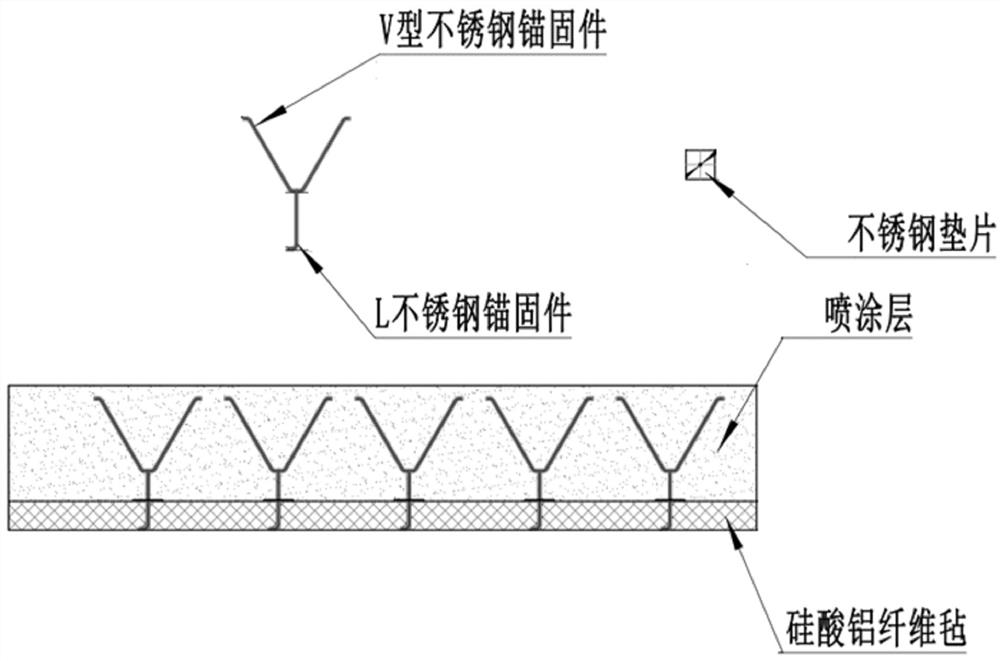

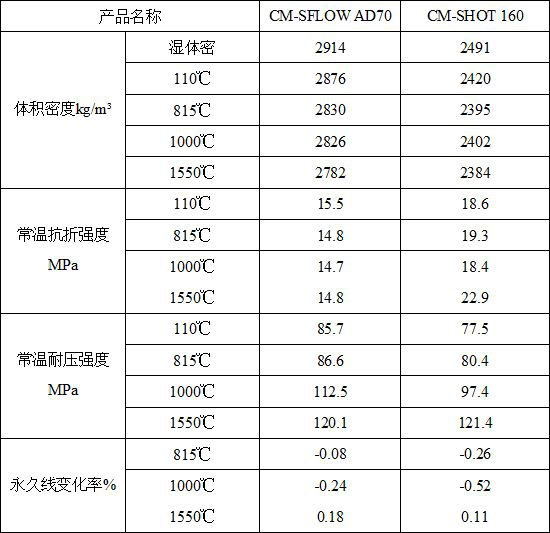

Corundum-mullite low-cement self-flowing castable and method for repairing hot air outlet of top-combustion hot blast stove by using corundum-mullite low-cement self-flowing castable

ActiveCN112390632AExtended service lifePlay a protective effectLinings repairBlast furnace detailsHot air ovenMetallurgy

The invention discloses a corundum-mullite low-cement self-flowing castable and a method for repairing a hot air outlet of a top combustion hot blast stove by using the same, and belongs to the technical field of amorphous refractory materials. The castable consists of the following components in parts by weight: 5-15 parts of tabular corundum 5-3mm particles, 51-5 parts of tabular corundum 3-1mmparticles, 5-15 parts of tabular corundum 1-3mm particles, 5-15 parts of andalusite 5-3mm particles, 5-15 parts of andalusite 3-1mm particles, 2-10 parts of andalusite 1-3mm particles, 10-20 parts ofbrown fused alumina 200-mesh powder, 1-10 parts of brown fused alumina 325-mesh powder, alumina micro-powder, kyanite, a binding agent, 96 silica powder, a water reducing agent, an explosion-proof agent and an additive. The excellent use performance of the material and a complete and rapid construction method matched with the material can be used for rapidly repairing the problem part, ensuring the subsequent service life of the part and assisting an iron-making system to rapidly reproduce.

Owner:大连科萌工程材料有限公司

Black-body radiation energy-saving coating and preparation method thereof

InactiveCN109181375ARaise the temperature gradientHigh thermal efficiencyAlkali metal silicate coatingsChemical industryHigh absorptionBlack body

The invention relates to a black-body radiation energy-saving coating and a preparation method thereof. The coating contains the following components in parts by weight: 30-50 parts of sodium silicate, 5-15 parts of water, 5-10 parts of ferric oxide, 10-20 parts of copper oxide, 3-10 parts of chromium oxide, 5-10 parts of aluminium oxide, 0-5 parts of cerium oxide, 1-10 parts of cobalt oxide, 0-5parts of lanthanum oxide, and 0.5-1.5 parts of dispersing agent. According to the invention, radiation heat transfer is enhanced by utilizing the characteristics of high absorption, high heat accumulation, high radiation and high heat release of a black-body material, so as to reduce radiation heating energy consumption, reduce fuel consumption, and improve the thermal efficiency of boiler pipes,petrochemical cracking furnaces and coking ovens, and further achieve the aim of energy conservation.

Owner:吴丰容

Method for fast exchanging hydrogen after urgency purging of bell-type furnace

ActiveCN103451408AReduce oven timeReduce oxidationFurnace typesHeat treatment furnacesSurface oxidationHydrogen exchange

The invention provides a method for fast exchanging hydrogen after the urgency purging of a bell-type furnace. The method comprises the following steps: manufacturing a simulating heating cover signal plug; programming a fast hydrogen exchange program of an annealing control computer; setting nitrogen purging time and heating cover ignition time to 0, and setting hydrogen exchange time to 12 minutes; controlling furnace atmosphere O2 to be less than 1; when the hydrogen is fast exchanged, firstly disassembling a cooling cover signal plug, connecting the simulating heating cover signal plug, and then starting a heating program to automatically carry out hydrogen exchange according to the set time; and after the hydrogen exchange is finished, disassembling the simulating heating cover signal plug, connecting the cooling cover signal plug, and continuously cooling. According to the method provided by the invention, the integral hydrogen exchange process only needs 30 minutes; the surface oxidation of a steel plate can be effectively reduced, the surface quality of the steel plate can be enhanced, and the second annealing repair of an oxidized steel plate can be avoided; the energy resources are greatly saved, and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

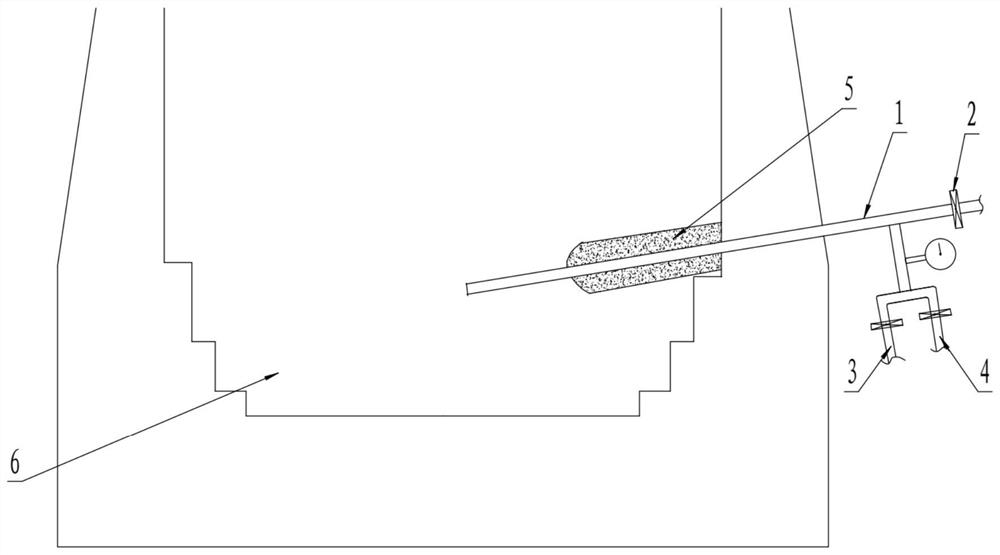

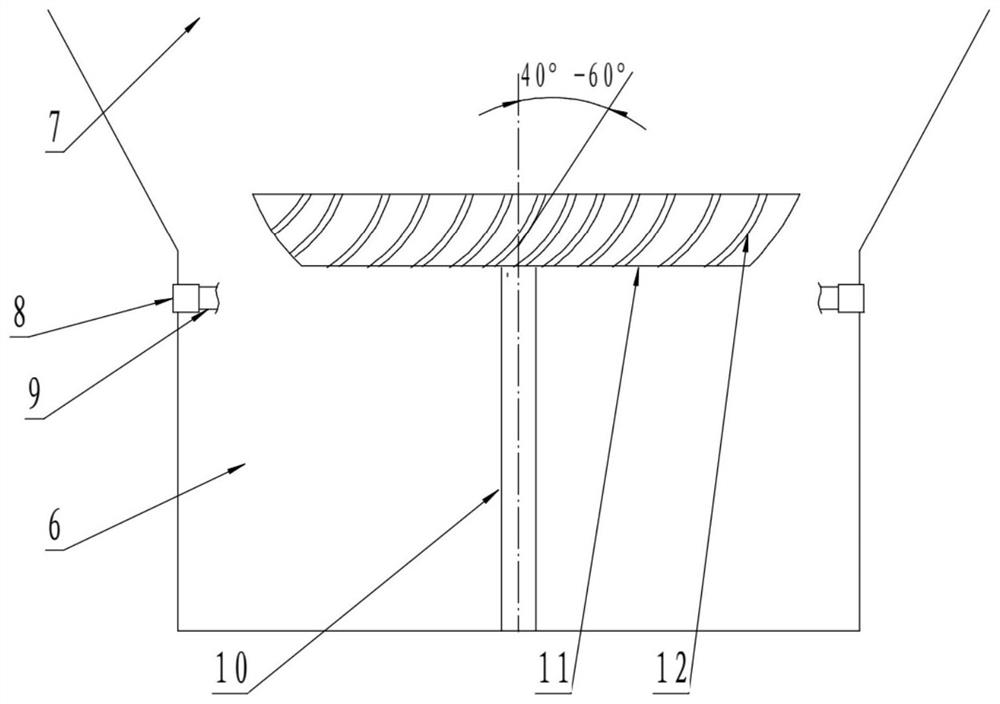

Production method suitable for directly installing furnace and heating steel slab with high-quality carbon structure

The invention discloses a production method suitable for directly installing furnace and heating a steel slab with high-quality carbon structure. The method adopts front-end heavy reduction to carry out a casting blank tissue regulation and control technology, a soft reduction technology of solidification tail-end position uncertainty and a hot roll gap reconstruction technology on an existing continuous casting machine to produce a continuous casting slab with a high-quality high-grade carbon structure (45 steel ) after the slab is subjected to continuous casting, the slab is directly installed the furnace for hot rolling, composition segregation with a smaller slab can reduce the time of the component diffused uniformly in the furnace, so that the heating time of the slab is further shortened to meet the requirement for direct installing and heating of the slab; the expansion of the medium axis crystal area of the slab reduces the cohesion and segregation in 1 / 2 of thickness of inclusion and the component, so that the performance of the produced steel plate is uniform.

Owner:中普(邯郸)钢铁有限公司

Heating method capable of reducing depth of decarburized layer of GCr15 bearing steel

InactiveCN107460301AStop the spreadReduce thicknessFurnace typesHeat treatment furnacesHeating timeStage ii

The invention discloses a heating method capable of reducing depth of a decarburized layer of GCr15 bearing steel. The heating method comprises the following steps of: preserving the heat of steel billets for 30 minutes at a temperature of 500-600 DEG C in a heat preserving furnace; feeding the steel billets into a step beam type heating furnace to heat in four stages, wherein the temperature at a pre-heating stage is 850-1020 DEG C, a temperature at a heating stage I is 1100-1190 DEG C, heating time of the heating stage I is greater than 35 minutes, a temperature at a heating stage II is 1180-1220 DEG C, a temperature at a uniform-heating stage I is 1180-1220 DEG C, a temperature at a uniform-heating stage II is 1170-1210 DEG C, and heating time from the heating stage II to the uniform-heating stage II is greater than 130 minutes; introducing oxygen gas in a heating process, wherein oxygen gas flow at the pre-heating stage is 80000-90000 m<3> / h, oxygen gas pressure at the pre-heating stage is 8-9 bar, oxygen gas flow at the uniform-heating stage is 140000-150000 m<3> / h, and oxygen gas pressure at the uniform-heating stage is 14-15 bar. The method effectively shortens the heating time, and reduces the depth of the decarburized layer.

Owner:NANJING IRON & STEEL CO LTD +1

Multi-burner gasification device and coal gasification process

InactiveCN104403695BAchieving pressurized gasificationImprove responseGasification apparatus detailsGranular/pulverulent flues gasificationProcess engineeringControl valves

Owner:SANY GRP

Heat treatment process of low alloy high-strength steel with yield strength of 690 MPa

The invention provides a rapid heat treatment process of low alloy high-strength steel with yield strength of 690 MPa. The contents of alloy elements in the steel (percentage by weight) are as follows: the content of Mn (Manganese), Cr (Chromium), Ni (Nickel), Cu (Copper) and Mo (Molybdenum) is 2.05-2.6% while the content of Nb (Niobium) and Ti (Titanium) is 0.045-0.085 %. The heat treatment is carried out through rapid heating and quenching; and the method comprises the steps of heating the steel to 960 DEG C at a heating speed of no more than 50 DEG C / min, wherein the austenitizing heat preservation time is 3-5 minutes; and then hardening the steel to the room temperature at a cooling speed of 30-300 DEG C / s. The rapid heat treatment process of the low alloy high-strength steel with yield strength of 690 MPa, provided by the invention, has the following advantages that: the heating and heat preservation time of the heat treatment is reduced through increasing the heating speed and preserving the heat for a short time at a higher austenitizing temperature while the mechanical property of the steel is assured to the benefit of saving energy consumption and improving the productionefficiency; and references can be also provided to the heat treatment of low alloy high-strength steels with other strength levels.

Owner:LAIWU IRON & STEEL GRP

Method for heating special steel with low-heat-value blast furnace coal gas

ActiveCN103451335AGood flame rigidityImprove temperature uniformityBlast furnace detailsHeat treatment furnacesSocial benefitsEconomic benefits

The invention relates to a method for heating special steel with low-heat-value blast furnace coal gas, belonging to the technical field of industrial furnaces. According to the method, an air / coal gas double-heat-accumulation combustion control mode, a sequential cutoff combustion control mode, an alternate cutoff combustion control mode and an air / coal gas double-heat-accumulation vertical partition type heat accumulation type burner are used in a special steel heating furnace, thus realizing the technological requirements that the special steel is slowly heated at in-furnace low temperature and is prevented from oxidation and decarburization at high temperature. According to the invention, the method provided by the invention breaks the heating method that the special steel heating furnace can only use high-heat-value coal gas as fuel, improves the product quality and yield, reduces the fuel consumption, widens the air / coal gas double-heat-accumulation application range, and has great economic benefits, social benefits and environmental benefits.

Owner:BEIJING SHOUGANG INT ENG TECH

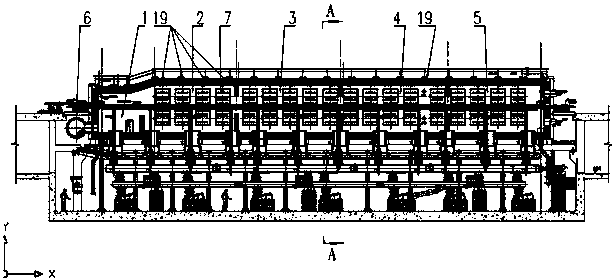

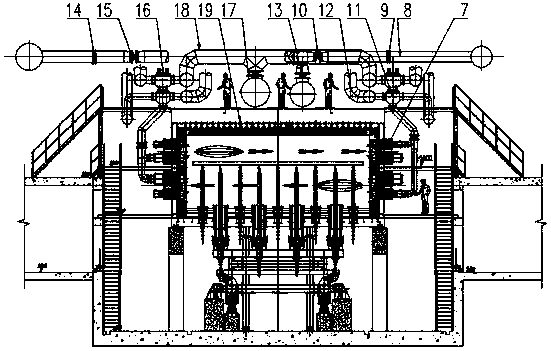

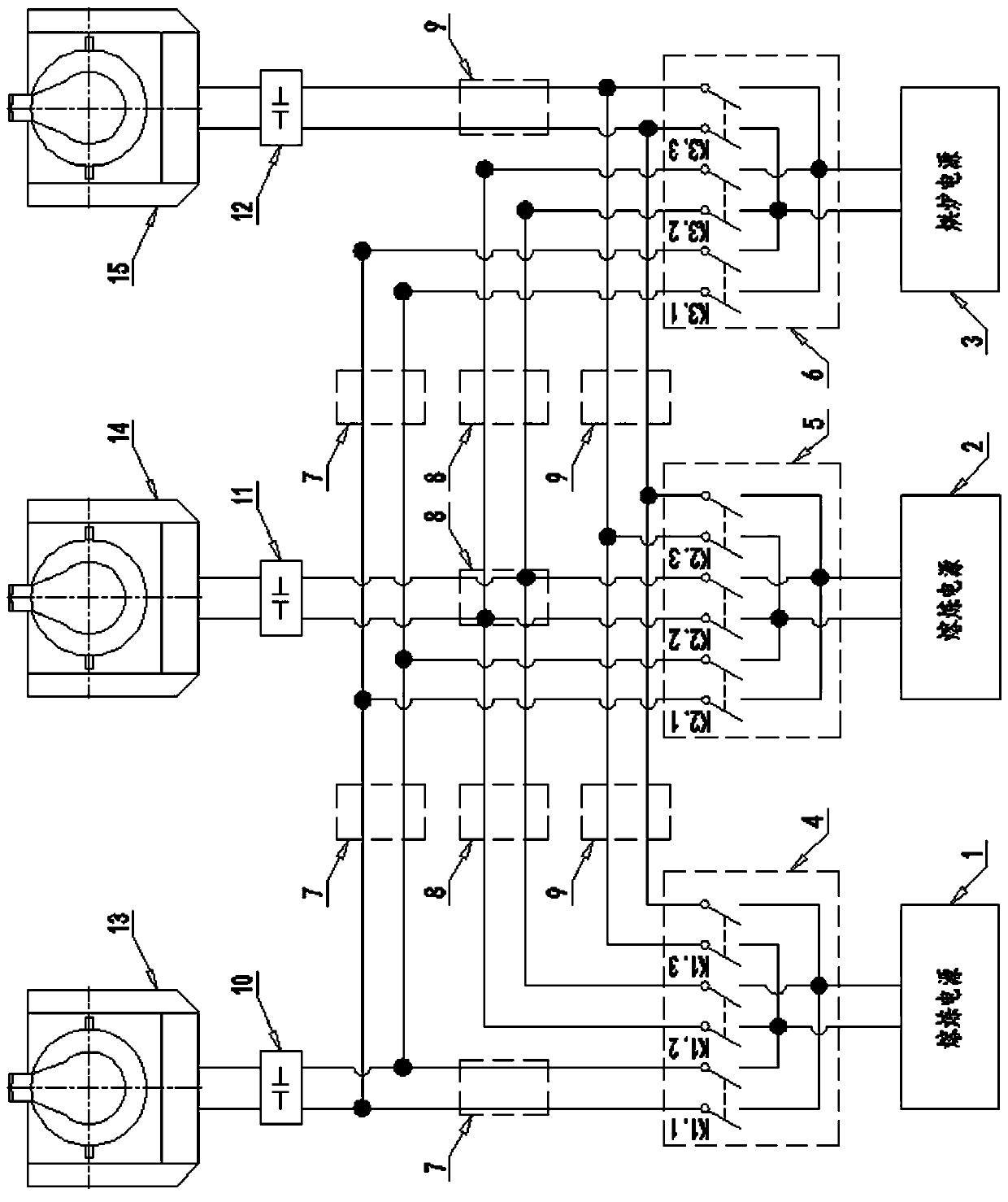

Two-power three-furnace production device with function of baking oven

PendingCN109539794AReduce oven timeSimple structureCharge treatment typeFurnace typesCapacitanceCapacitor

The invention relates to the technical field of smelting furnaces, in particular to a two-power three-furnace production device with a baking oven. The production device with an oven is characterizedin comprises three smelting furnaces, three capacitor banks, three busbar sets, three change-over switches and three power supplies, the three power supplies are connected to the input ends of the three change-over switches respectively, each of the output ends of the three change-over switches are is provided with three gears, and each of the three gears of each change-over switch is connected toeach of power interfaces of the three smelting furnaces through a busbar set and a capacitor bank. According to the device, the production efficiency can be improved, the drying efficiency can be improved, and the baking time of the baking oven can be saved.

Owner:杭州四达电炉成套设备有限公司

Production method of tempering high-strength steel suitable for directly installing and heating pressure container

The invention discloses a production method of tempering high-strength steel suitable for directly installing and heating a pressure container. According to the method, the steel for the high-qualitypressure container (07MnMoVR, 07MnNiVDR and 07MnNiMoDR) is produced by front-end large pressing on an existing continuous casting machine by adopting casting blank tissue regulation and control technology, solidification tail end position indetermination soft pressing down technology and hot roll gap reconstructing technology, and after the slab is subjected to continuous casting, the slab is directly put in a furnace for hot rolling, the uniform component segregation of the slab can be reduced, the time of the slab in the uniform component of the furnace can be reduced, the heating time of the slab is shortened, and the requirement for direct loading and heating of the slab is met; the equiaxial crystal zone of the plate is reduced, so that the agglomeration and segregation of inclusionsand components at the position of one-half thickness are reduced, and the performance of the produced steel plate is uniform.

Owner:中普(邯郸)钢铁有限公司

Method for heating sporadic cold steel billets

InactiveCN102399971AReduce oven timeReduce consumptionFurnace typesHeat treatment furnacesProduction lineMetallurgy

The invention provides a method for heating sporadic cold steel billets, wherein a heating mode of burning steel twice is adopted. The method comprises the following steps of: feeding the cold steel billets in the middle of a plate blank in the process of furnace charging, wherein the planned rolling thickness of the plate blank is more than or equal to 4.0mm; heating the plate blank fed with the cold steel billets and other normal steel billets together to 700 DEG C, then discharging and hoisting the steel billets out of a line by using a resmelting roller; and then carrying out normal furnace charging, heating and rolling on the steel billets which are hoisted out of the line and the other hot steel billets with same specification. According to the method disclosed by the invention, the purposes of shortening the time in furnace of the steel billets and stabilizing the steel burning quality are achieved without additionally increasing any equipment, changing the characteristic that in the continuous casting and rolling production line, the steel billets are directly conveyed for hot charging and influencing normal furnace charging and tapping of subsequent hot steel billets and by using a technological method for reasonably arranging a furnace charging sequence and carrying out secondary heating, therefore not only sporadic contracts can be fulfilled rapidly, but also the coal gas consumption is reduced, and accidents can be prevented from happening.

Owner:ANGANG STEEL CO LTD

Rapid furnace opening method

ActiveCN114134263AShort timeImprove efficiencyBlast furnace detailsProcess efficiency improvementHot blastChemistry

A rapid blow-in method comprises the following steps that (1) an air supply pipeline is pre-buried in an iron notch; (2) the main channel is filled with ramming mass and coke powder; (3) baking the furnace; (4) selecting a furnace opening material; (5) nitrogen cooling; (6) charging with wind; (7) hot air ignition; and (8) quickly introducing coal gas. The method has the beneficial effects that the consumed time is short, the efficiency is high, and the environmental protection and safety problems are reduced; the oven adopts a helical blade hot air shunting table for uniformly shunting hot air, so that the oven baking time is greatly shortened; coke and firewood mixed loading facilitates air supply, facilitates rapid ignition and combustion, makes space for descending of the upper furnace burden, and facilitates rapid loosening of the stock column. Charging with wind has a remarkable effect on drying coke and moisture of a charging material, the blow-in total coke ratio can be reduced by 200-300kg / t, and the phenomenon of material collapse and suspension in the blow-in process of the blast furnace is reduced; and clay gun tapping is omitted during tapping of the iron notch embedded air supply pipeline, so that the tapping time is shortened, and the tapping efficiency is improved. Compared with the conventional technology, the method provided by the invention can shorten the blow-in time by 8-12 hours.

Owner:德龙钢铁有限公司 +1

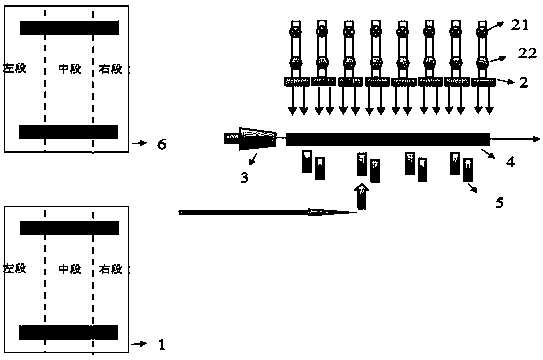

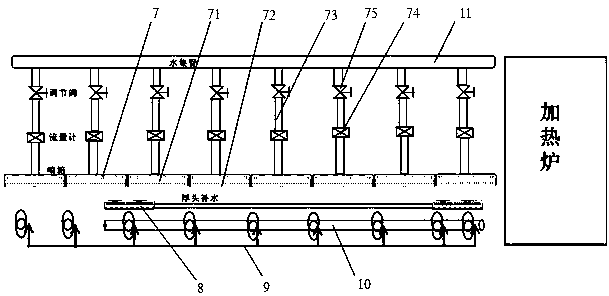

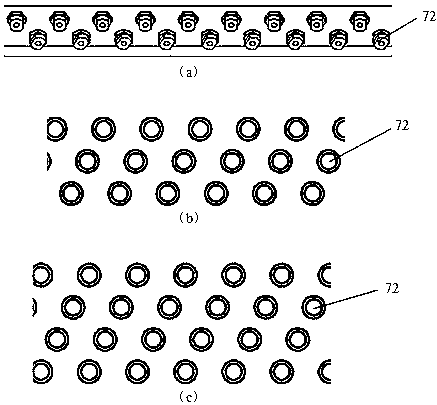

Steel pipe offline quenching production device and method

ActiveCN109423541AStable flowUniform cooling effectFurnace typesHeat treatment process controlSpray nozzlePressurized spray

The invention discloses a steel pipe offline quenching production device and method. The production device comprises an external spray cooling device and an internal spray cooling device, the internalspray cooling device performs internal axial flow injection cooling on a rotating steel pipe, the external spray cooling device performs external spray pressurized spray cooling on the rotating steelpipe (10), the external spray cooling device comprises a direct spray cooling device (7), a steel pipe thickened end oblique spray cooling device (8) and a pressing wheel water supplementing device (9), the direct spray cooling device comprises a plurality of spray boxes, the front end of each spray box is provided with multiple rows of nozzles, the rear ends of the spray boxes are connected withwater inlet pipes, flow meters and flow regulating valves are installed on the water inlet pipes, the flow meters and the flow regulating valves are connected with controllers, the steel pipe thickened end oblique spray cooling device comprises a spray box, the front end of the spray box is provided with multiple rows of nozzles, a plurality of inner cavities are arranged in the spray box, each inner cavity is connected with a water inlet pipe, a flow meter and a flow regulating valve, and an angle is formed between the spray box of the oblique spray cooling device and the spray boxes of thedirect spray cooling device.

Owner:BAOSHAN IRON & STEEL CO LTD

Acid lining material of medium-frequency induction furnace and furnace building method thereof

ActiveCN102617164BCounteract bad effectsCounteracts boric acid to reduce adverse effectsLinings repairPhysical chemistryEngineering

The invention relates to an acid lining material of a medium-frequency induction furnace and a furnace building method thereof. Components of a furnace body lining material comprise that proportion of quartz sand and boric acid is 100: 0.8-1.3 by mass percentage. The quartz sand comprises 5% to 11% of quartz sand with granularity of 3-5 meshes, 18% to 22% of quartz sand with granularity larger than 5-10 meshes, 20% to 30% of quartz sand with granularity larger than 10-20 meshes, 10% to 20% of quartz sand with granularity larger than 20-40 meshes, 5% to 11% of quartz sand with granularity larger than 40-70 meshes and 25% to 30% of quartz sand with granularity of 270 meshes by weight. Materials of a furnace collar and a furnace nozzle comprise 5% to 20% of quartz sand with granularity of 6-10 meshes, 30% to 50% of quartz sand with granularity larger than 10-20 meshes, 30% to 50% of fire clay and 4% to 7% of water glass. The acid lining material and the furnace building method can prolong effective service life of an acid lining and shorten furnace baking time by improving the lining material and the furnace building process.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

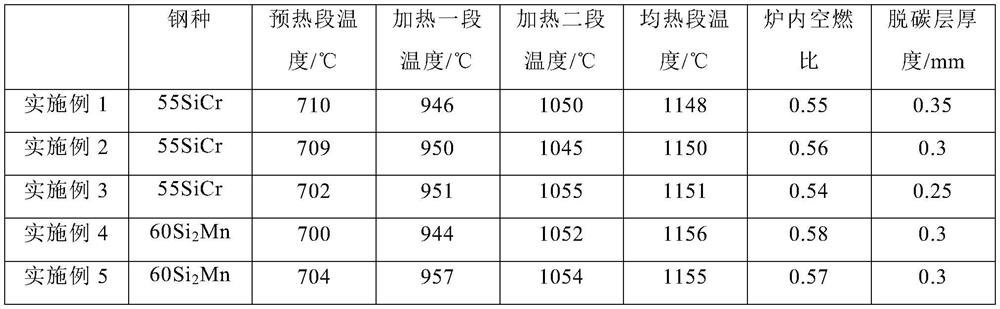

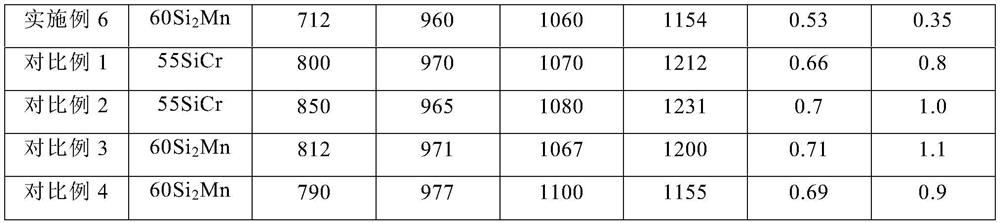

Cogging method for reducing surface decarburization depth of medium-high carbon steel blank

PendingCN114405991AShorten the timeReduce oven timeWork cooling devicesWork heating devicesHigh pressure waterHeating furnace

The invention provides a cogging method for reducing the surface decarburization depth of a medium-high carbon steel blank, which comprises the following steps: calculating the number N = T / t of bloom blanks in a heating furnace according to the heating time T required for the bloom blanks to meet the rolling conditions and the time t for rolling each bloom blank; the bloom blank is added into a heating furnace provided with a preheating section, a first heating section, a second heating section and a soaking section to be heated, then high-pressure water with the pressure larger than or equal to 20 MPa is used for descaling the bloom blank, and the bloom blank is rolled after descaling; a small square billet obtained after rolling is subjected to water cooling through a multi-section water cooling device, the surface temperature of the small square billet is reduced to 570-630 DEG C, and finally the small square billet is conveyed to a cooling bed to be subjected to air cooling; the multi-section water cooling device is composed of a plurality of groups of nozzles which are arranged at intervals and can adjust water volume, each group comprises a plurality of nozzles, and the plurality of nozzles in each group are arranged on the periphery of the small square billet. The time of the blank at high temperature is shortened, and the thickness of a decarburized layer is reduced.

Owner:ZHANGJIAGANG RONGSHENG SPECIAL STEEL CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com