Patents

Literature

53results about How to "Large amount of depression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

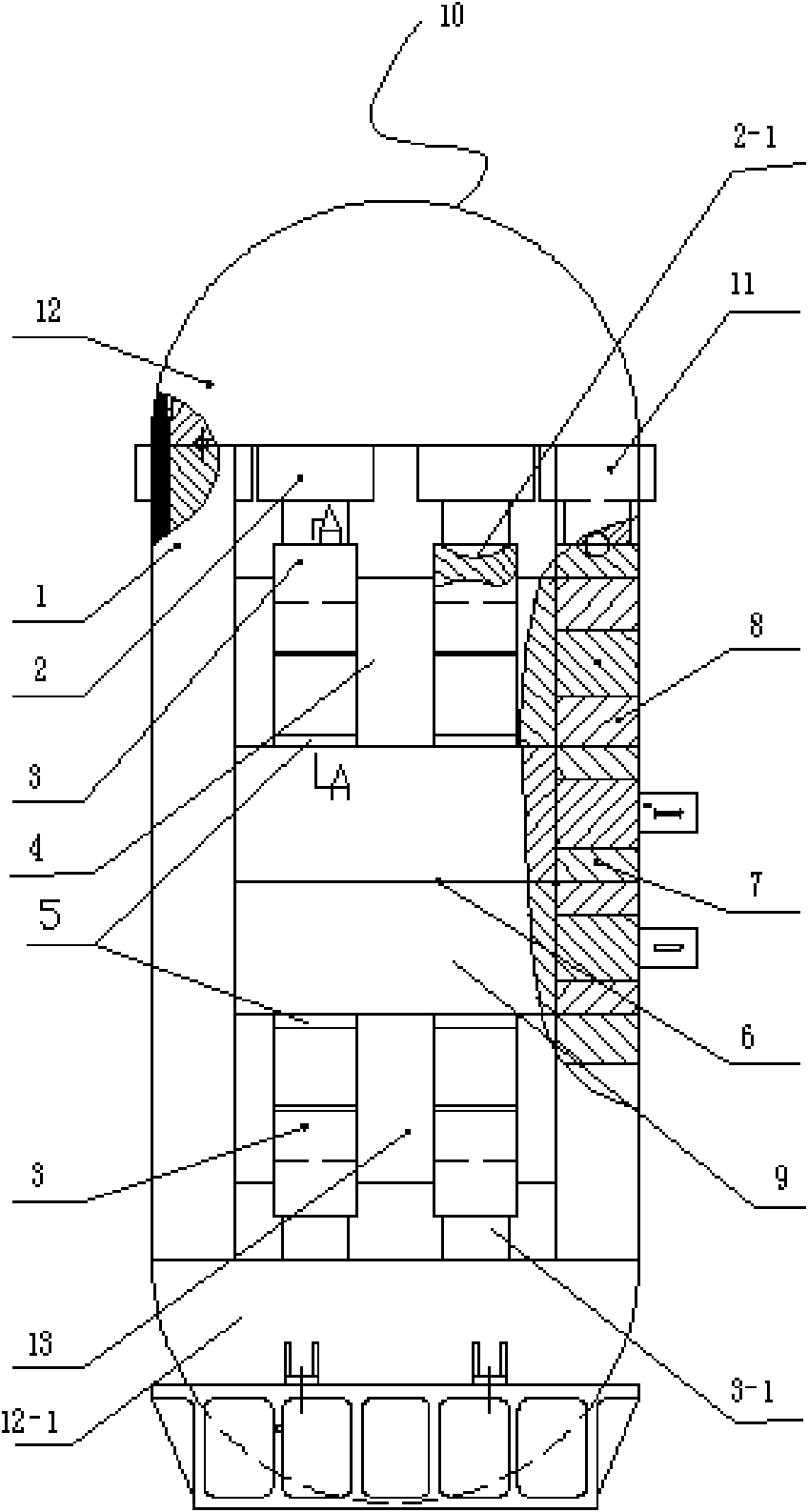

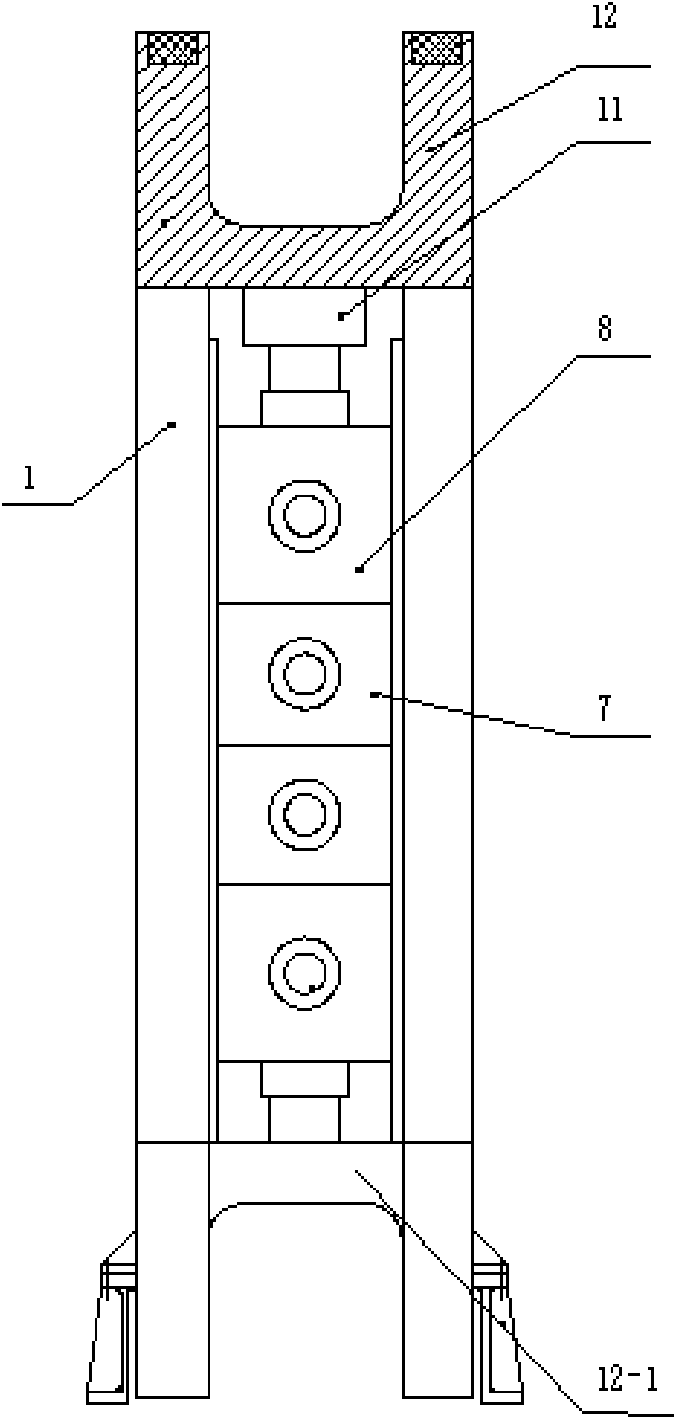

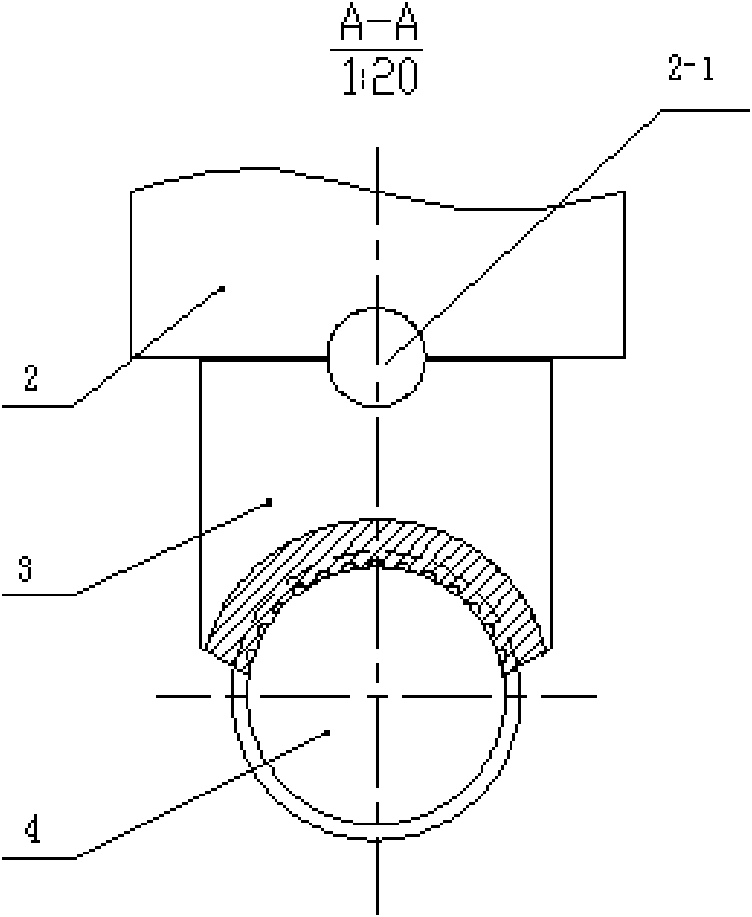

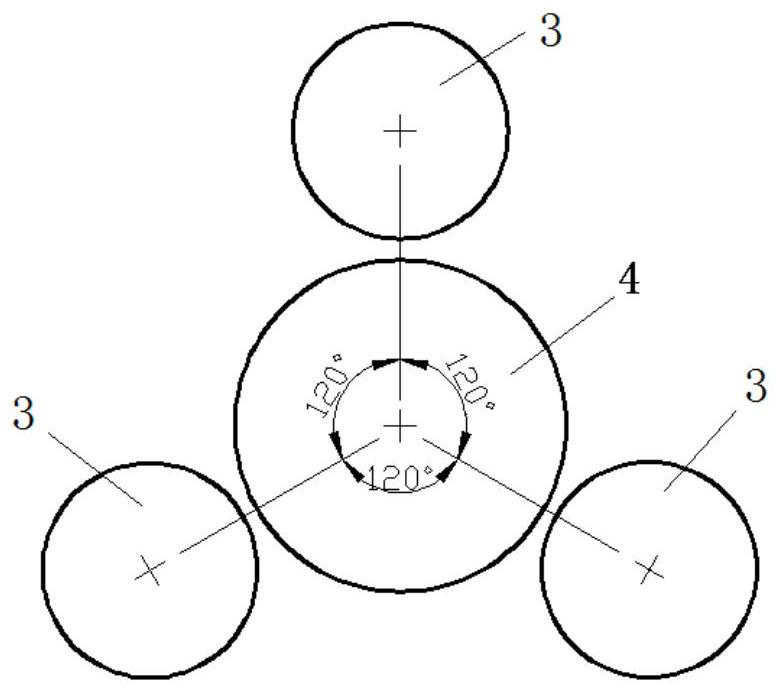

Sheet rolling mill with hydraulic screwdown on support roll

ActiveCN101658862AIncrease the amount of each pressLow costMetal rolling stand detailsCounter-pressure devicesSteel platesWork roll

The invention relates to a sheet rolling mill with a hydraulic screwdown on a support roll. The mill is characterized in that a frame is a horizontal rectangular columnar frame, both sides of an upperbeam of the frame is provided with a journal hydraulic screwdown of an upper support roll, a bearing pedestal and two rectangular columns of a working roll and the support roll form two horizontal frames of the mill, hydraulic screwdown of one or two support rolls which are fixed in the middle of the upper beam of the horizontal frame press a cylindrical surface of the support roll body by a hydrostatic semicircular block, a hydrostatic semicircular block with a bearing is supported in the position of a lower support roll which is the same as that of the upper support roll, the bearing is fixed on a lower beam of the frame. The mill has the following advantages: the position and pressure of the hydraulic screwdown of the journal and the roll body are regulated by a sensor to greatly reduce elastic deformation of the support roll during working, and can realzie rolling of the accurate-sized steel plate and increase percent reduction under the condiiton of reducing number and diameter of the supprt rolls and diameter, thus reducing cost and enhancing efficiency.

Owner:朱勉学

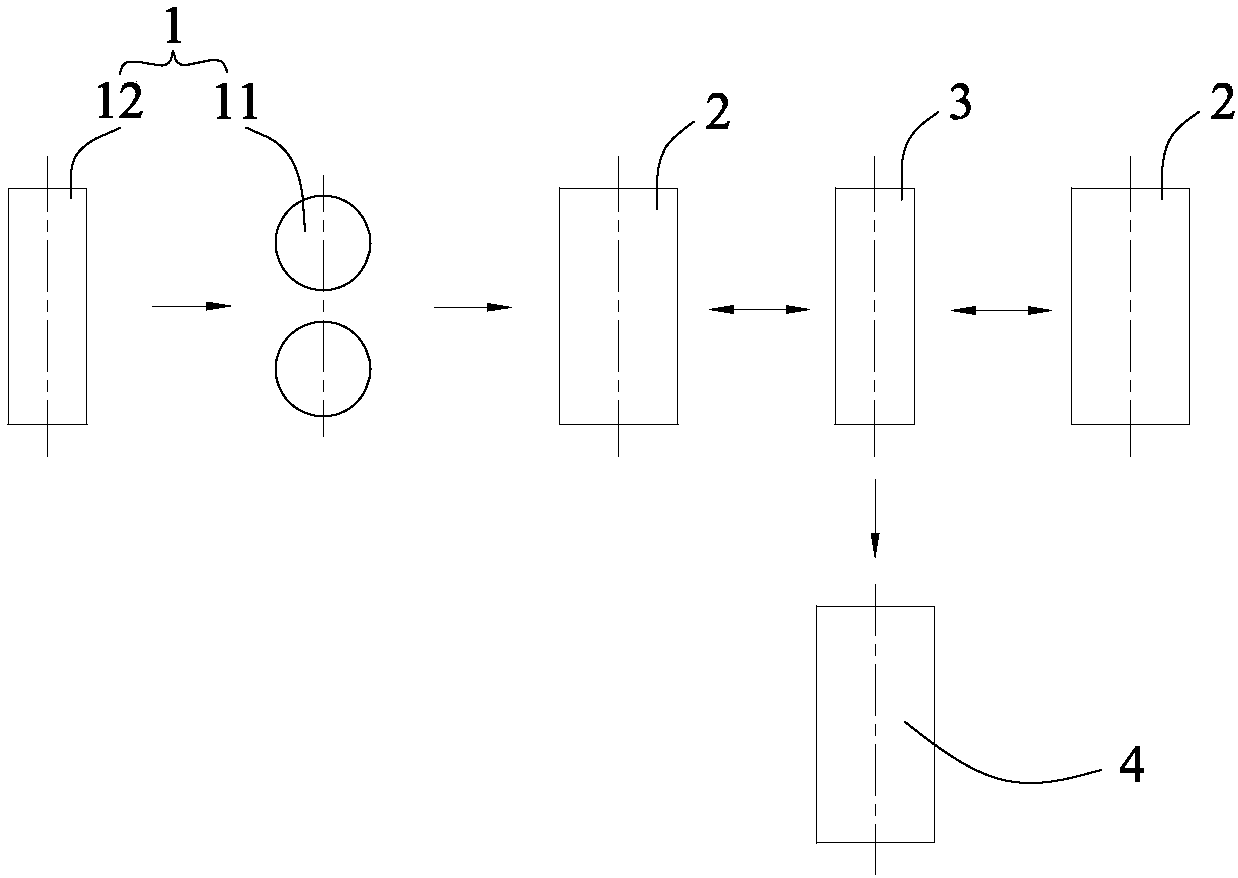

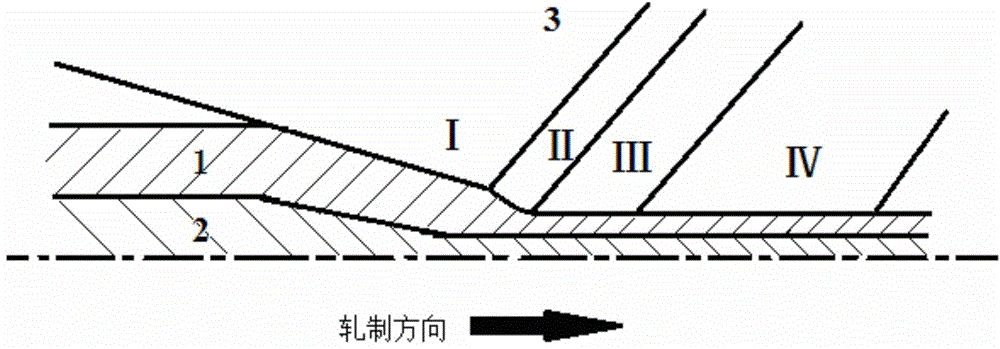

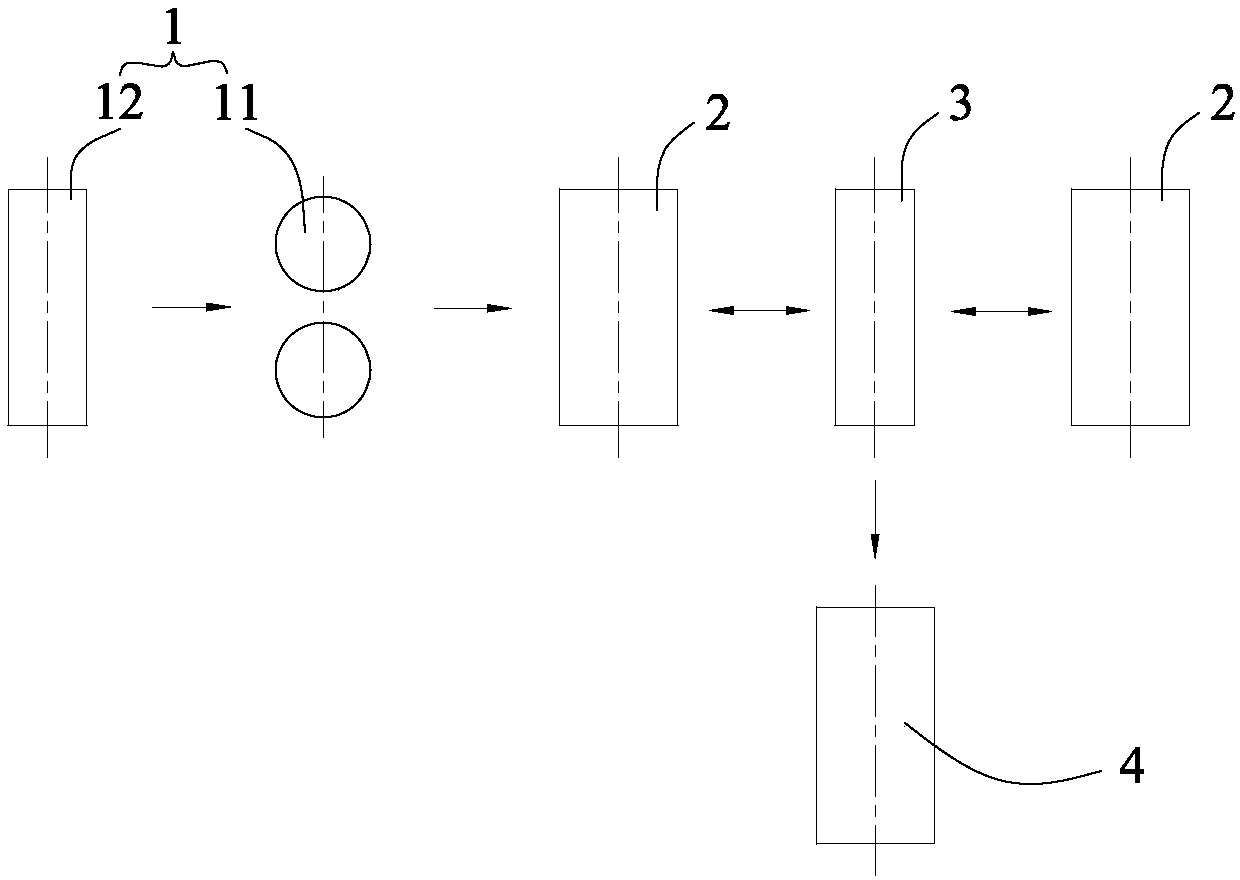

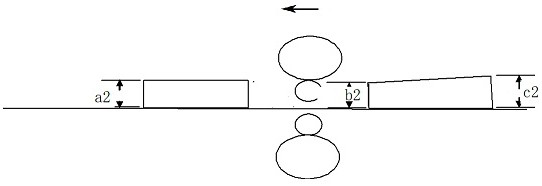

Method for performing two-pass rolling on thickness variable strips

ActiveCN104338748ACorrection of shapeLarge amount of depressionRoll mill control devicesMetal rolling arrangementsEngineeringMechanical engineering

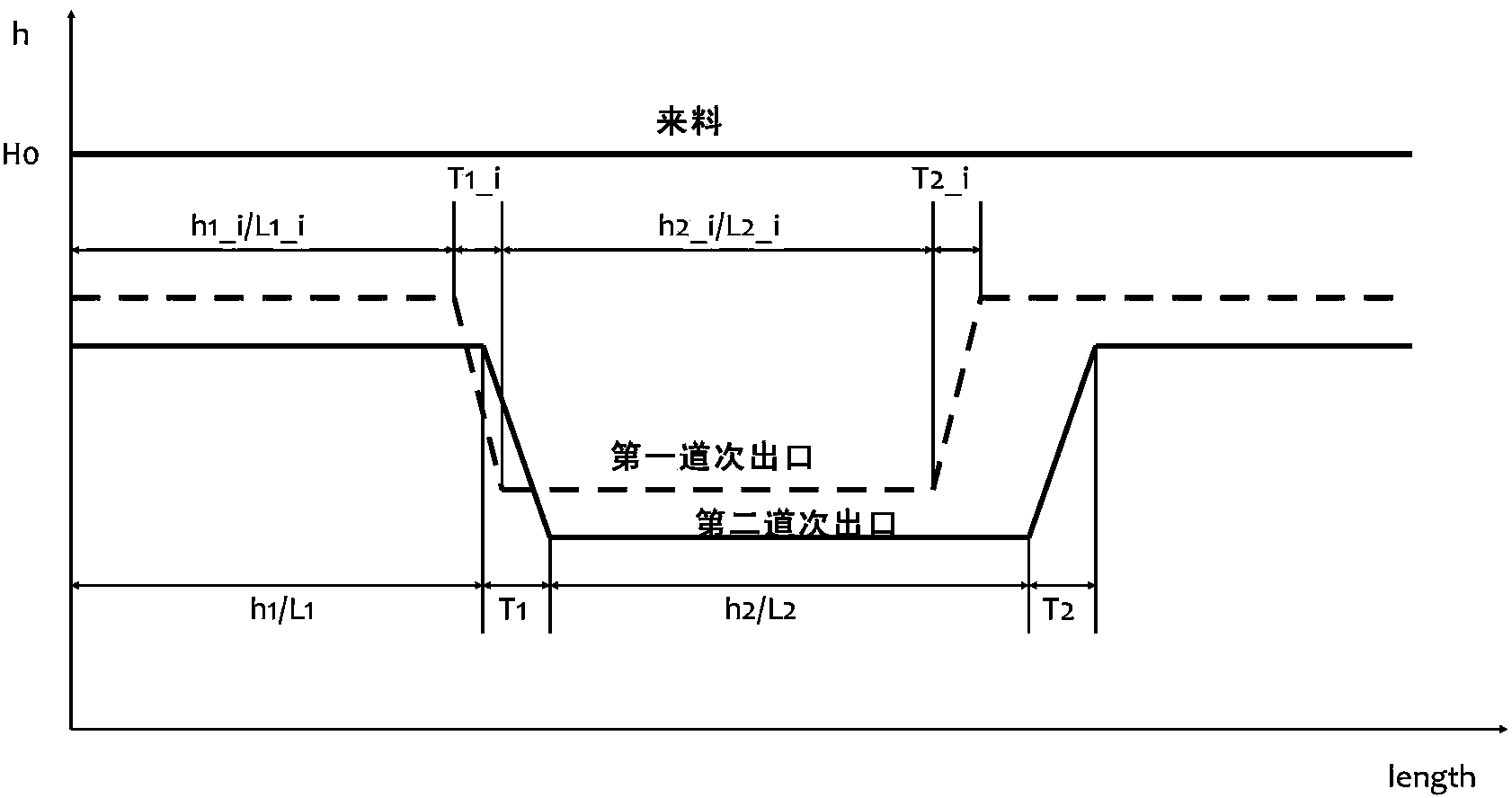

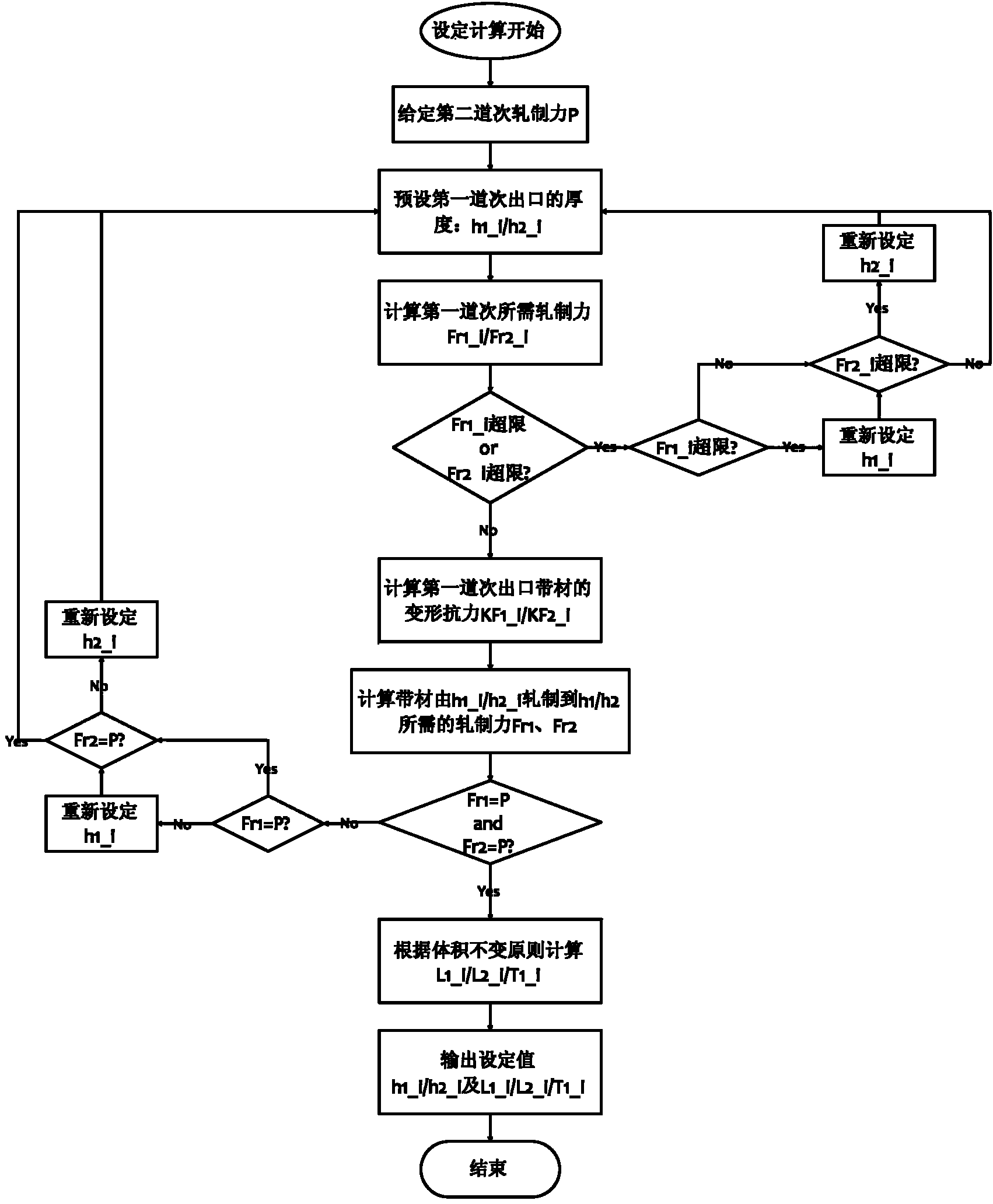

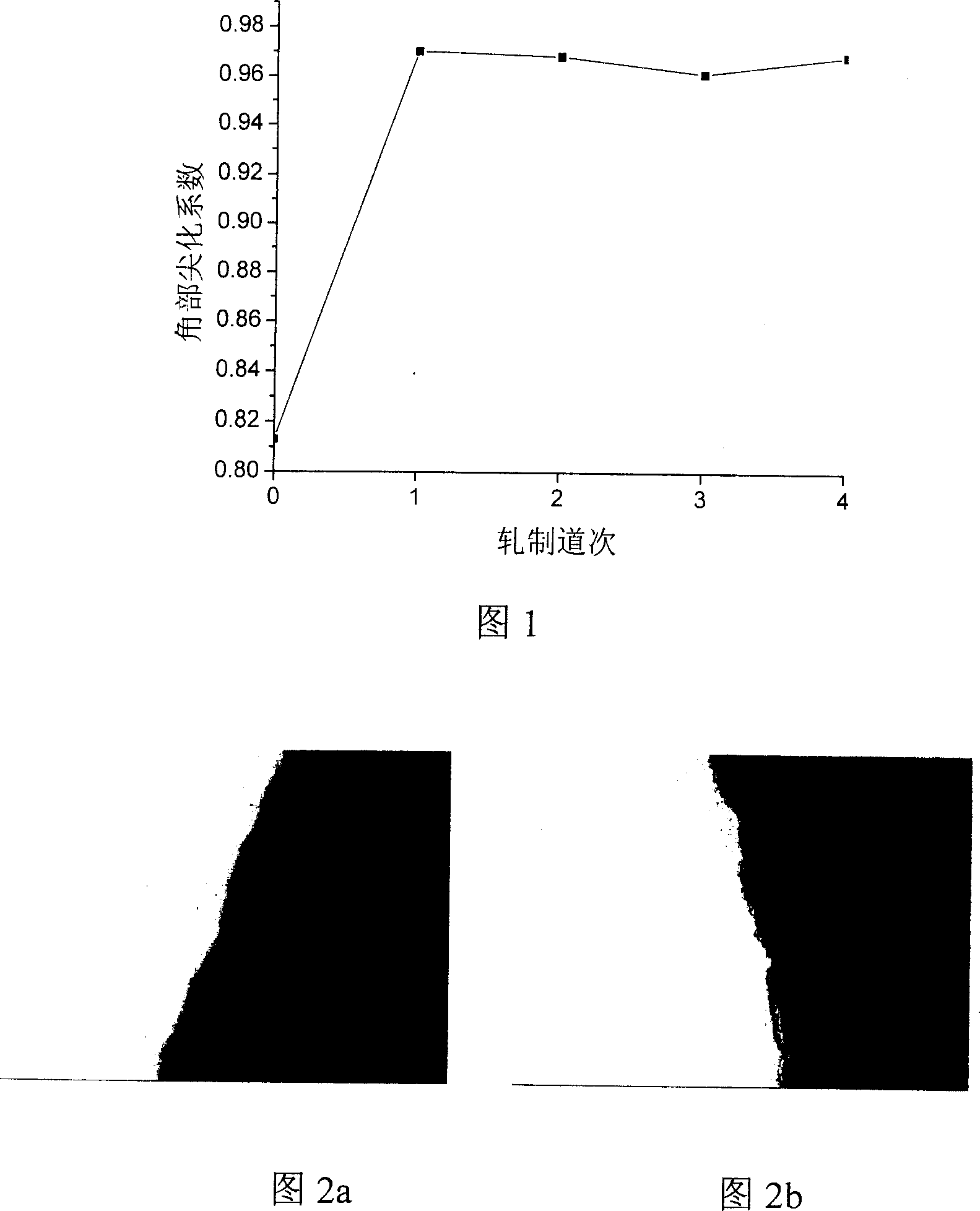

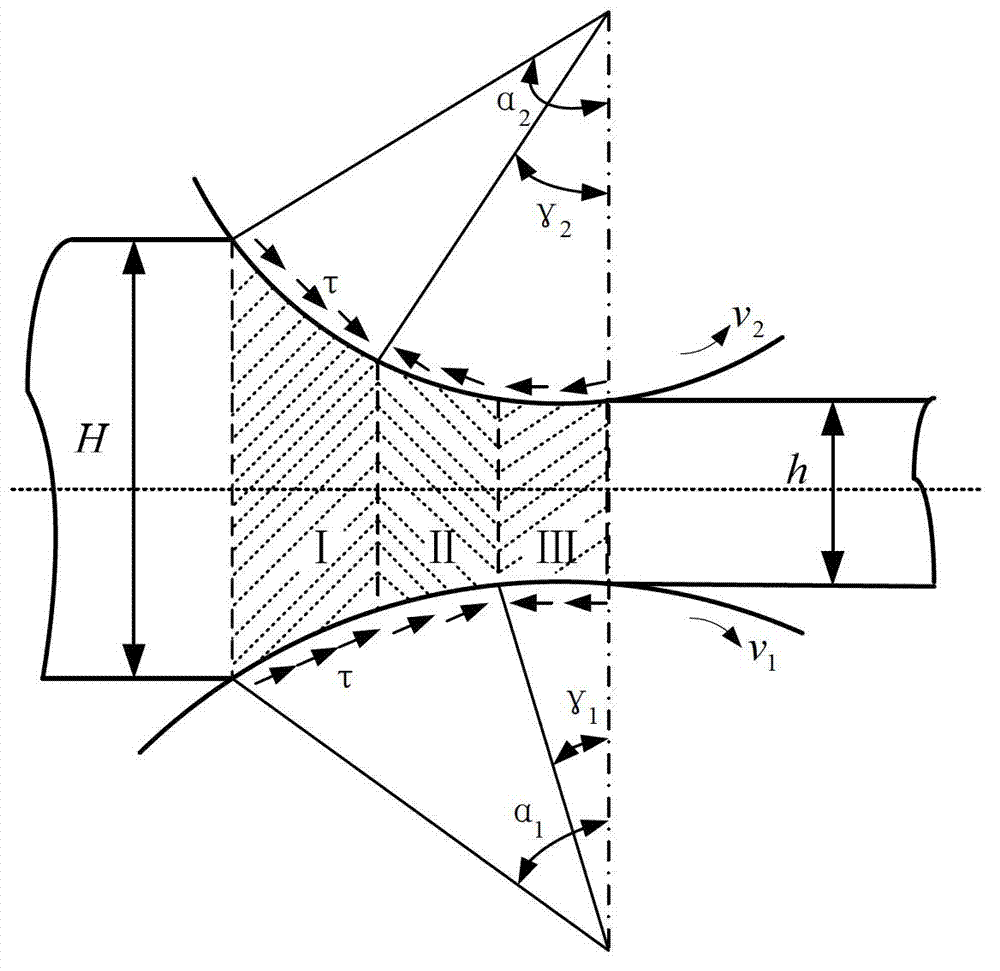

A method for performing two-pass rolling on thickness variable strips includes calculating rolling reduction required by a first pass and the length of each section; presetting a target rolling force P<SET> of a second pass; supposing outlet thickness h1_i and h2_i of the first pass, and calculating parameters such as a rolling force and rolling power required by the first pass; if the parameters exceed the capacity of a rolling machine, returning to reset the parameters; calculating deformation resistance KF1_i and KF2_i of a first-pass outlet strip according to outlet thickness of the first pass; calculating a second-pass rolling force Fr1 and Fr2 required for rolling the strip from h1_i and h2_i into hi and h2, judging whether Fr1 and Fr2 are equal to the target rolling force P<SET> of the second pass, resetting h1_i and h2_i if Fr1 and Fr2 are not equal to the target rolling force P<SET> of the second pass, and performing returning again; calculating corresponding outlet length. According to the method for performing two-pass rolling on thickness variable strips, by means of two-pass rolling, large rolling reduction is achieved without increasing rolling capacity; a constant rolling force manner is used for the second pass so that the shape of the strips is corrected.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-groove rolling method for high speed wire bar intermediate rolling train

InactiveCN101152654AImprove work rateImprove productivityRoll force/gap control deviceTemperature control deviceReduction rateWire rod

The invention discloses a non-groove rolling method for high speed wire rod roughing mill group and mainly solves rolling technical problem of the high speed wire rod roughing mill group. The non-groove rolling method comprises two pass non-groove rolling, four pass non-groove rolling or six pass non-groove rolling; the ratio of height and width of the rolling component is 0.90 to 1.58, reduction rate of pass is 15 percent to 45 percent, rolling temperature is 1000 celsius degree to 1100 celsius degree, the adaptation range of blank is 120*120mm to 180*180mm, and the absolute spread coefficient range is 0.25 to 0.45. The invention adopts a pass-free flat roller to replace a rough rolling pass roller of the prior art and realizes non-groove rolling of the high speed wire rod roughing mill group. The invention aims to provide the non-groove rolling method for the high speed wire rod roughing mill group adopting the flat roller to replace the rough pass roller, meanwhile, decreasing production cost, improving product quality and productivity of the mill and expanding the adaptation range of blank.

Owner:BAOSHAN IRON & STEEL CO LTD +1

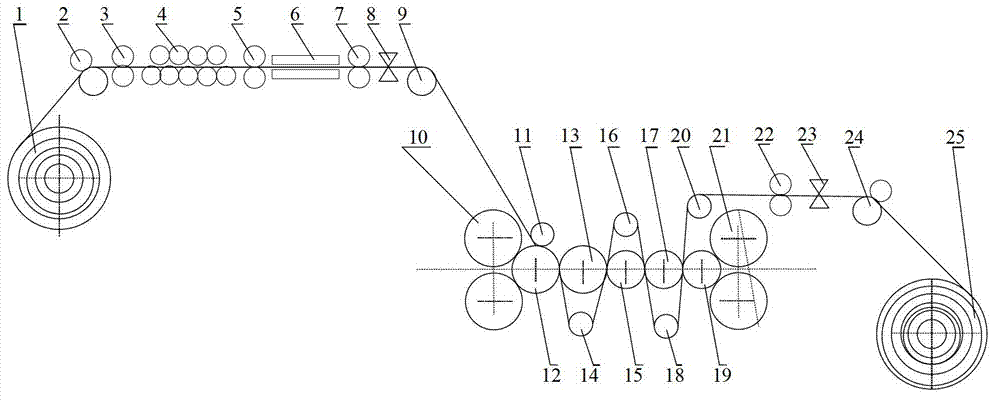

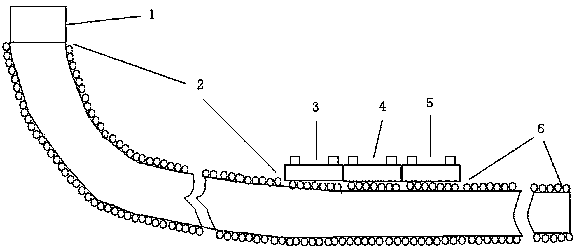

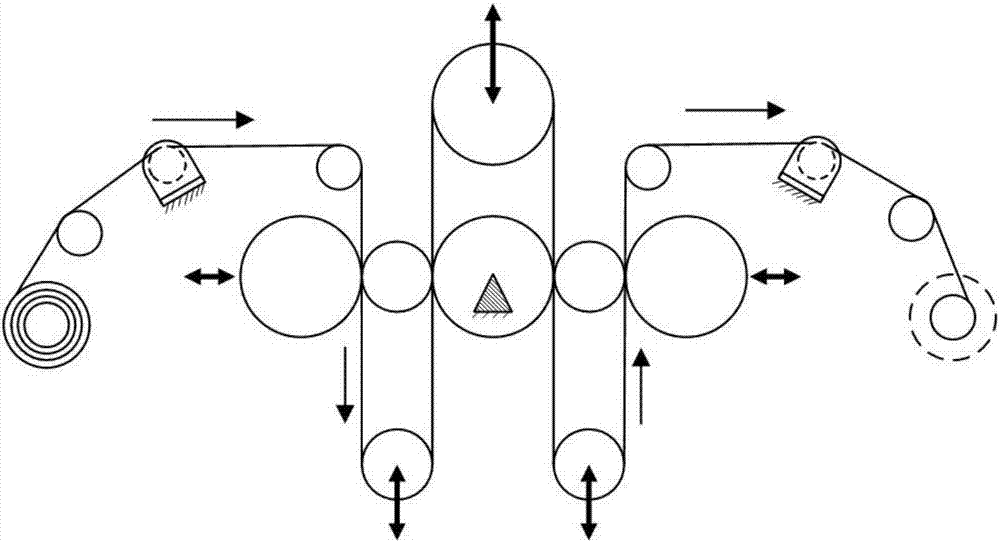

Continuous asynchronous rolling device of magnesium alloy sheet strip coil

InactiveCN102773255AStable rolling tensionRealized strip rollingMetal rolling arrangementsEngineeringEnergy consumption

The invention relates to a continuous asynchronous rolling device of a magnesium alloy sheet strip coil and belongs to the field of magnesium alloy materials. The continuous asynchronous rolling device conducts decoiling on the magnesium alloy strip coil through a decoiling device, the magnesium alloy strip coil enters a flattening machine to be flattened through a tension pinch roller and enters a strip coil preheating device through the tension pinch roller after being corrected to be heated to preset temperature, feeding material thickness is measured through a thickness gauge, then the strip coil enters a continuous asynchronous rolling machine for rolling, the rolled strip coil passes through the thickness gauge to measure thickness of a finished product and enters a rolling machine to be rolled through the tension pinch roller, and the whole coiling rolling is achieved after stable rolling tension is finished. The continuous asynchronous rolling device has the advantages of reducing rolling pressure and rolling torque, reducing energy consumption, increasing gate transformation quantity, improving rolling efficiency and the like, thereby being favorable for rolling production of strip coils of magnesium alloy which is hard to deform.

Owner:UNIV OF SCI & TECH BEIJING

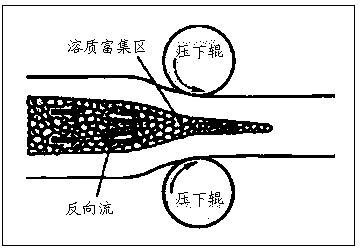

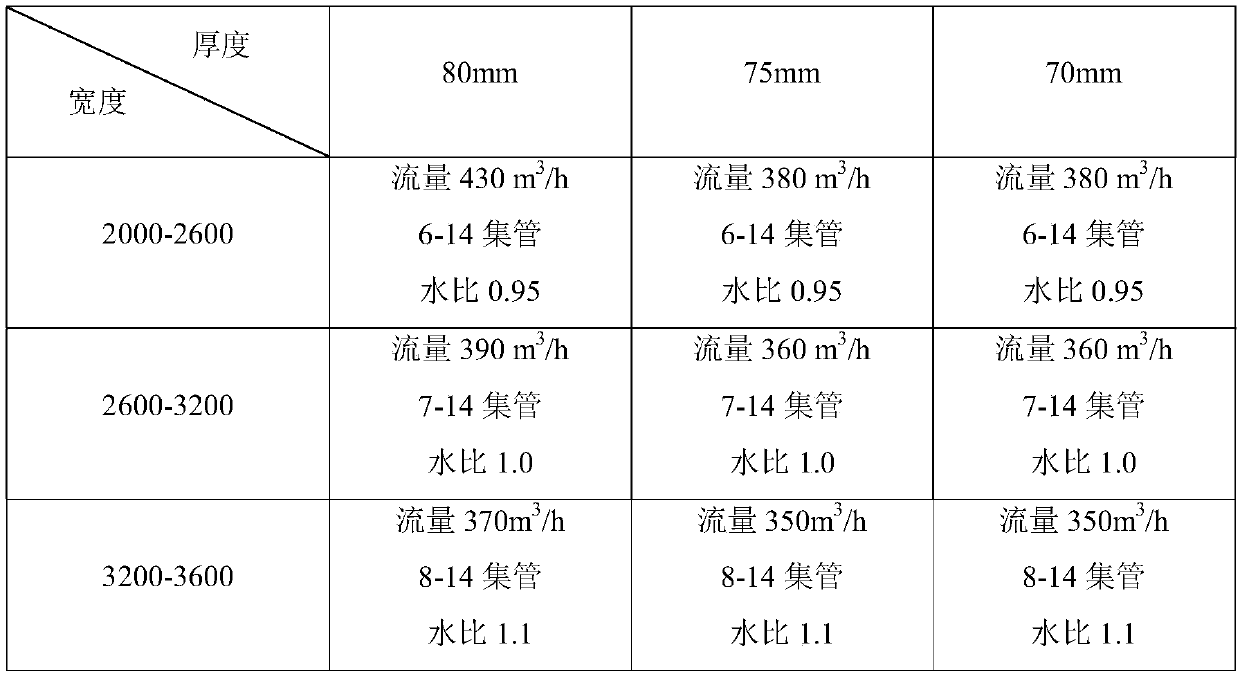

Phosphorus-containing steel slab continuous casting method

The invention provides a phosphorus-containing steel slab continuous casting method, wherein the phosphorus content of molten steel is equal to or greater than 0.02%. The phosphorus-containing steel slab continuous casting method comprises the following steps: carrying out low superheat degree control on molten steel, wherein the superheat degree range of molten steel in a tundish is 15-25 DEG C;adopting strong cooling for cooling a crystallizer, wherein the water flow velocity of the wide face of the crystallizer is 9.5-10.5 m / min, and the water flow velocity of the narrow face of the crystallizer is 13.0-14.0 m / min; carrying out deviation control on a plurality of continuous casting machine roll gaps in a sector section, and carrying out deviation control on the roll gap precision of zero section to fourth sections according to the range of + / -0.5 mm; carrying out negative deviation control on the roll gap precision of fifth section to the section before soft reduction according tothe range of -0.5 mm to 0 mm; carrying out positive deviation control on the roll gap precision of the section subjected to soft reduction according to the range of 0.3+ / -0.3mm; and carrying out deviation control on the roll gap precision of the section after soft reduction according to the range of + / -0.5mm. With adoption of the phosphorus-containing steel slab continuous casting method, generation of segregation of p at a grain boundary is effectively reduced, generation of segregation of p at a casting blank center is also reduced and an excellent phosphorus-containing steel slab is obtained.

Owner:SHOUGANG CORPORATION

Low alloy structural steel with low cost and thick specification and production method thereof

The invention discloses low alloy structural steel with low cost and thick specification. The low alloy structural steel comprises the following components by weight percent: 0.17%-0.20% of C, 0.15%-0.30% of Si, 0.35%-0.55% of Mn, less than or equal to 0.025% of P, less than or equal to 0.01% of S, less than or equal to 0.008% of N, and the rest of Fe and inevitable impurities. A production method of the structural steel comprises the following steps: (1) continuous casting to obtain billet; (2) soaking the cast billet; (3) high-pressure descaling, and finish rolling, wherein the sum of reduction rates of F1 and F2 is greater than or equal to 98% and is less than or equal to 105%, and F1 and F2 cooling water amount is 70%-80% of normal water amount, F3 or F4 is nominal, and the outlet temperature is 840-870 DEG C; (4) setting the laminar flow cooling speed to be 40-83 DEG C / s, the coiling temperature to be 540-570 DEG C, and the head coiling temperature to be 580-600 DEG C; (5) cooling. The production method disclosed by the invention basically eliminates phenomena such as mixed crystal and cold bending cracking, has good coiling shape, and is suitable for being widely applied to the field of steel production.

Owner:武汉钢铁有限公司

Heavy reduction technology for improving center segregation and center porosity of super-thick slabs

The invention discloses a heavy reduction technology for improving center segregation and center porosity of super-thick slabs. The heavy reduction technology is characterized in that the oil cylinder pressure of hydraulic cylinders on three sectorial sections of solidification tail ends of the continuous casting slabs ranges from 1800KN to 2500KN; and according to the solidification characteristics of steel types, the superheat degree of molten steel is controlled between 10-35 DEG C, the casting speed of a casting machine is controlled between 0.6 meter / minute and 1.0 meter / minute, the specific water flow of a secondary cooling zone is controlled between 0.4 and 0.6 liter / kilogram, large pressure is applied to one sectorial section to achieve the reduction of 5.0-12.0 millimeters, and the other two sectorial sections are slightly pressed to achieve reductions of 2-3 millimeters. The heavy reduction technology can be implemented to improve the quality of the super-thick slabs which further can be used for substituting for static ingots to produce super-thick steel plates with the thickness of 100millimeters and more, and the heavy reduction technology can achieve the high production efficiency and is environment-friendly.

Owner:新余钢铁股份有限公司

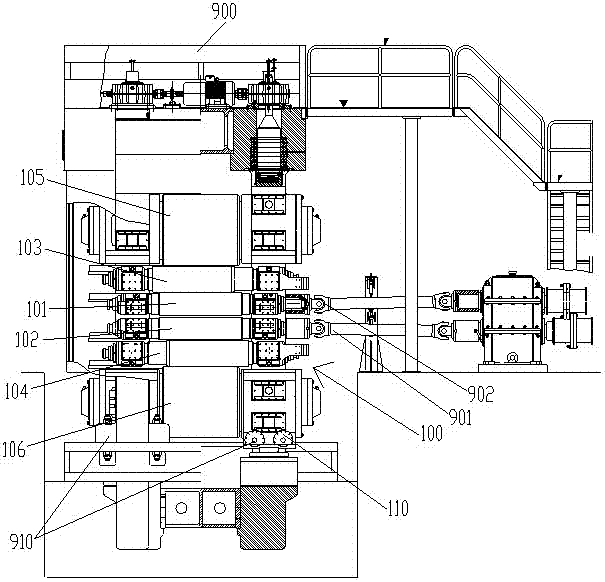

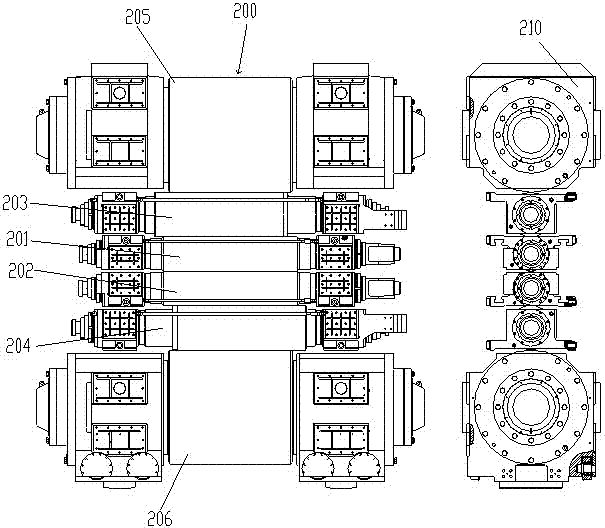

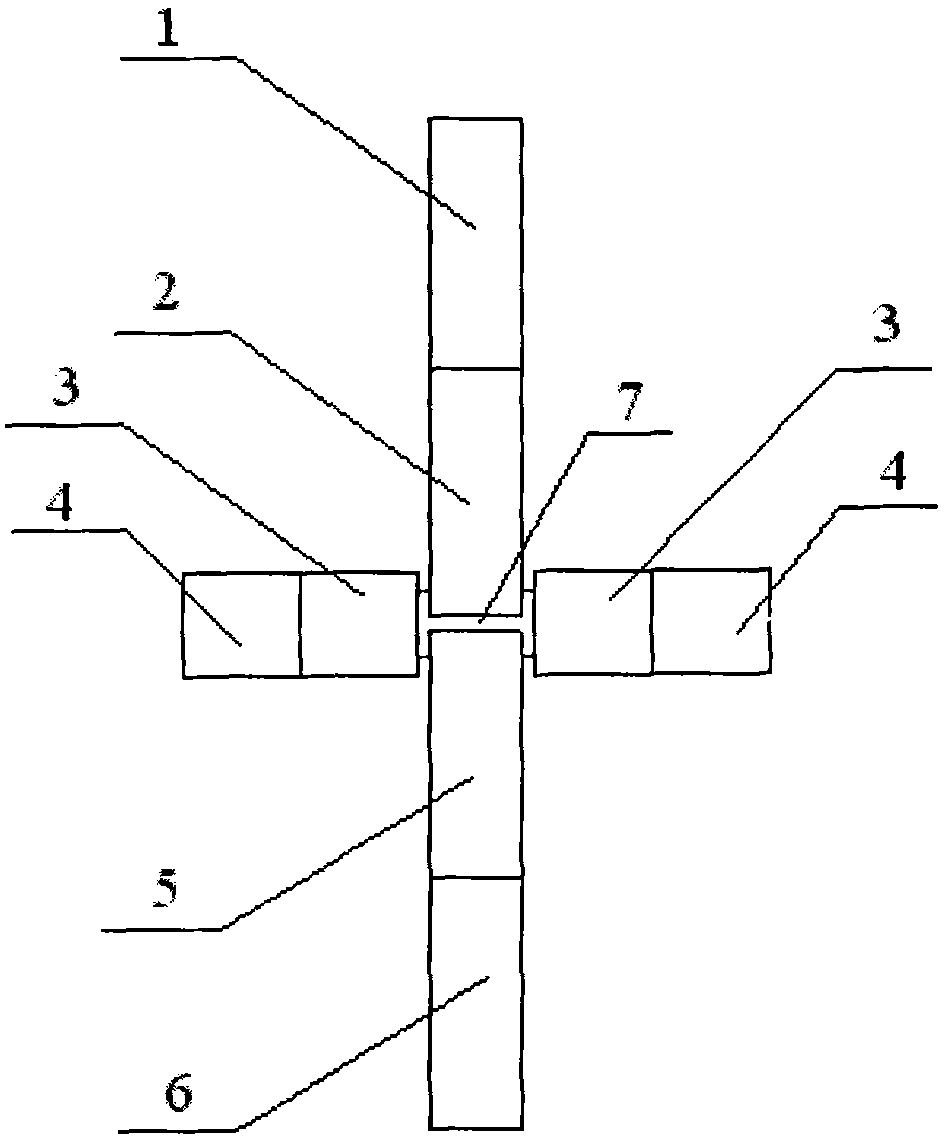

Production system for H-shaped steel

ActiveCN107695094ASmall elongation coefficientImprove biteMetal rolling arrangementsStrip millMaterials science

The invention provides a production system for H-shaped steel. The production system comprises a rough rolling unit, X-hole-shaped universal rolling mills, edging mills and an H-hole-shaped universalrolling mill. The rough rolling unit is used for rolling continuous casting billets for producing the H-shaped steel into intermediate billet materials first. Each X-hole-shaped universal rolling millcomprises two second horizontal rolls and two second vertical rolls, and an X-shaped rolling hole is formed between each two second horizontal rolls and the corresponding two second vertical rolls. When the intermediate billet materials rolled by the rough rolling unit enter the X-shaped rolling hole of each X-hole-shaped universal rolling mill, the corresponding two second horizontal rolls rollwebs of the billet materials, then the corresponding two second horizontal rolls and the corresponding two second vertical rolls roll the webs and flanges of the billet materials, and X-shaped billetmaterials are rolled. The X-shaped billet materials obtained after rolling of the X-hole-shaped universal rolling mills enter the edging mills, and the edging mills roll the flanges of the X-shaped billet materials to adjust the width of the flanges. The H-hole-shaped universal rolling mill is used for rolling the X-shaped billet materials rolled by the edging mills into the H-shaped steel.

Owner:刘庚申 +1

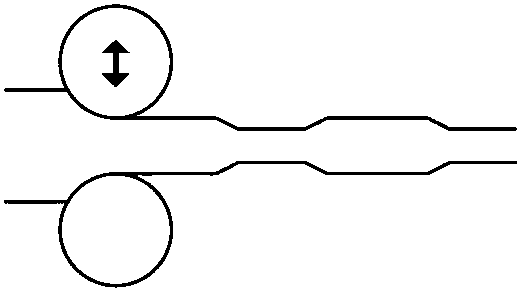

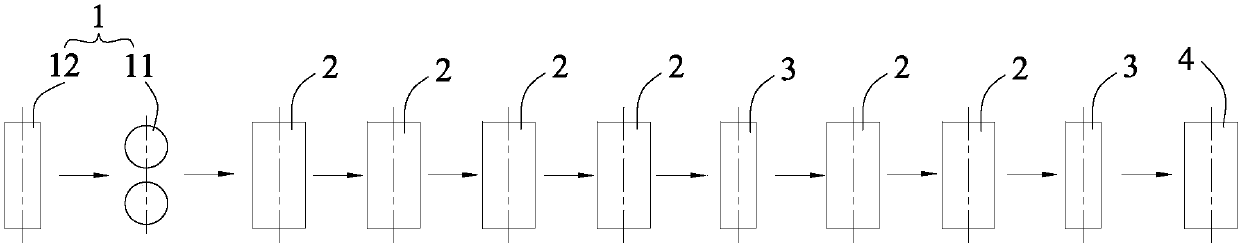

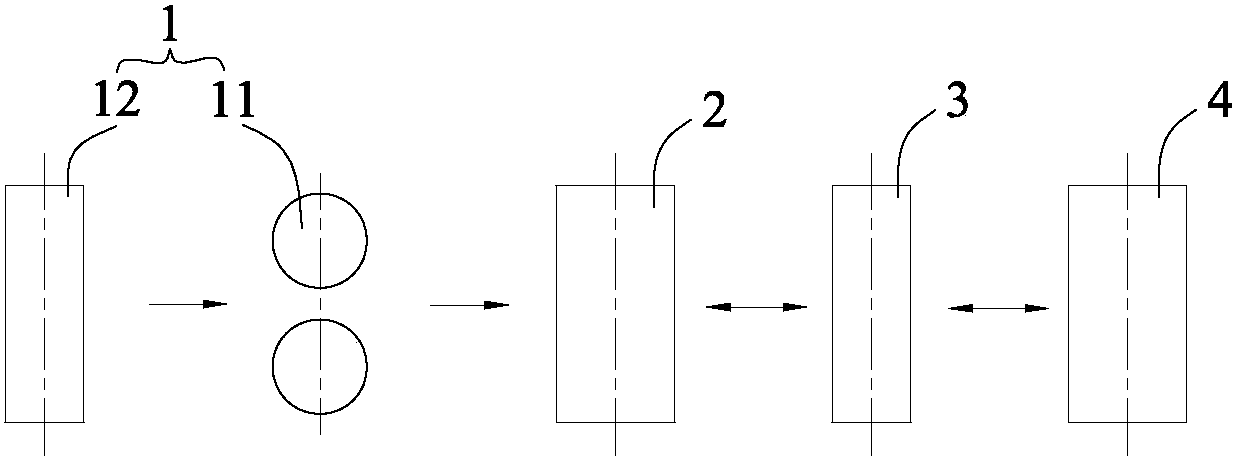

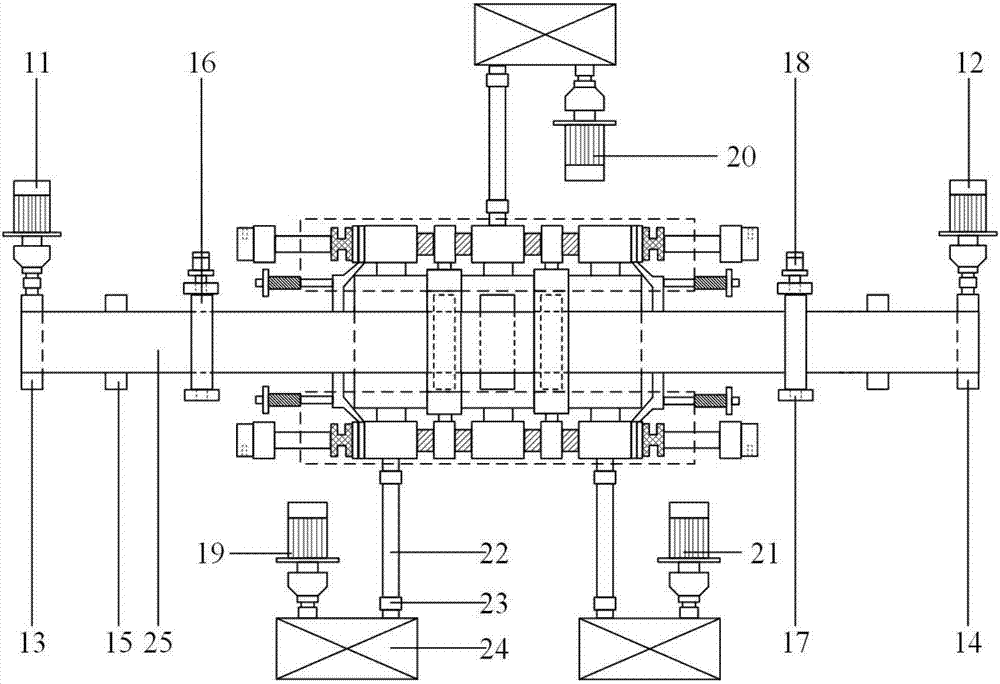

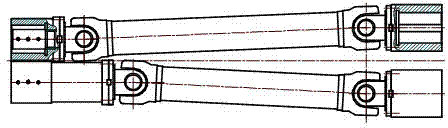

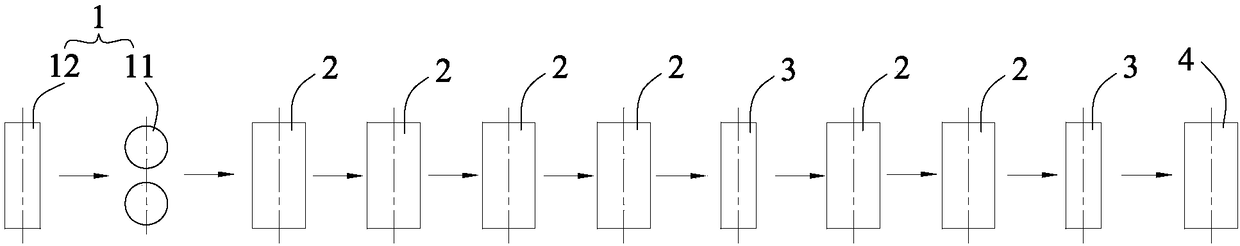

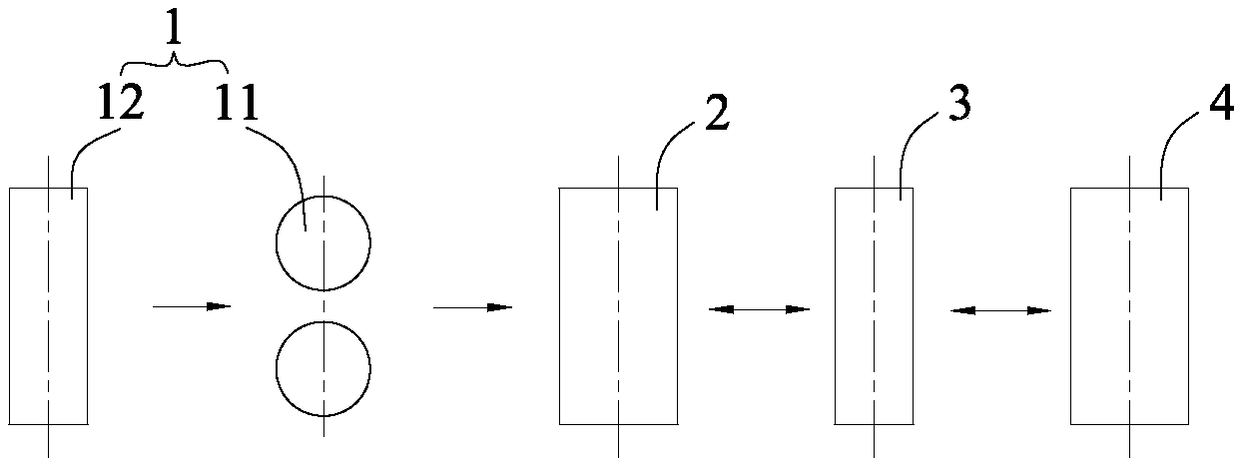

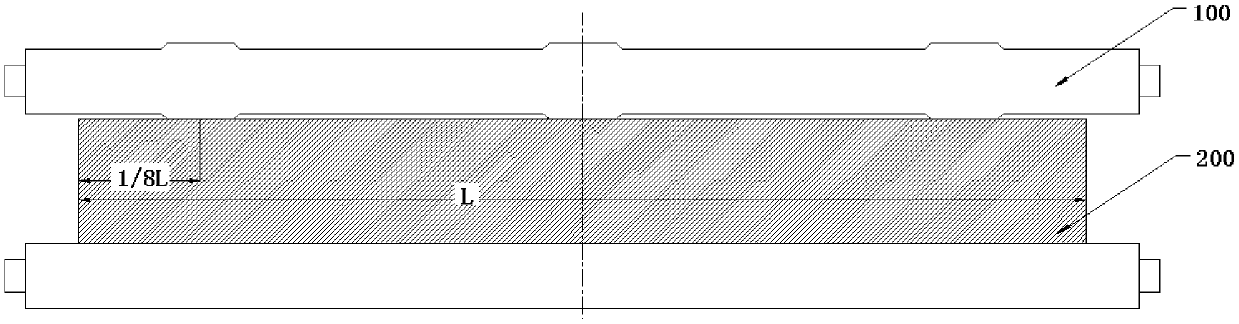

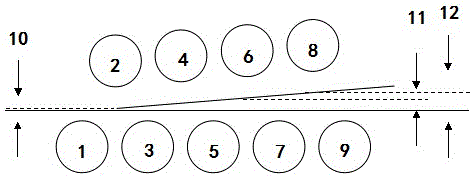

Thin belt material single-rack continuous mill and implementation method

ActiveCN106944479AImprove rolling production efficiencyLarge amount of depressionRoll force/gap control deviceTension/compression control deviceEngineeringMechanical engineering

The invention discloses a thin belt material single-rack continuous mill and an implementation method. The thin belt material single-rack continuous mill is provided with a plurality of work rollers which have the same or different diameters. The work rollers include drive rollers and driven rollers. Multi-pass asynchronous rolling or asynchronous and synchronous rolling is implemented by controlling the linear speeds of the drive rollers. Along with the increase of the rolling pass number, the linear speeds of the rollers are sequentially increased in the rolling direction, and the last pass can adopt either asynchronous rolling or synchronous rolling. When synchronous rolling is adopted, the roller diameters of the last two rollers are the same, and the linear speeds of the rollers are the same. The thin belt material single-rack continuous mill and the implementation method have the beneficial effects that multi-pass continuous rolling is realized in a single rack, larger rolling reduction can be realized in one rolling length, the rolling production efficiency of an ultra-thin belt is improved, equipment investment and occupied space are reduced, and meanwhile the production, operation and maintenance expenses are reduced accordingly; and the transverse rigidity of the rollers can be improved, the transverse thickness deviation of a rolled piece is small, and the plate shape quality of products can be improved.

Owner:NORTHEASTERN UNIV

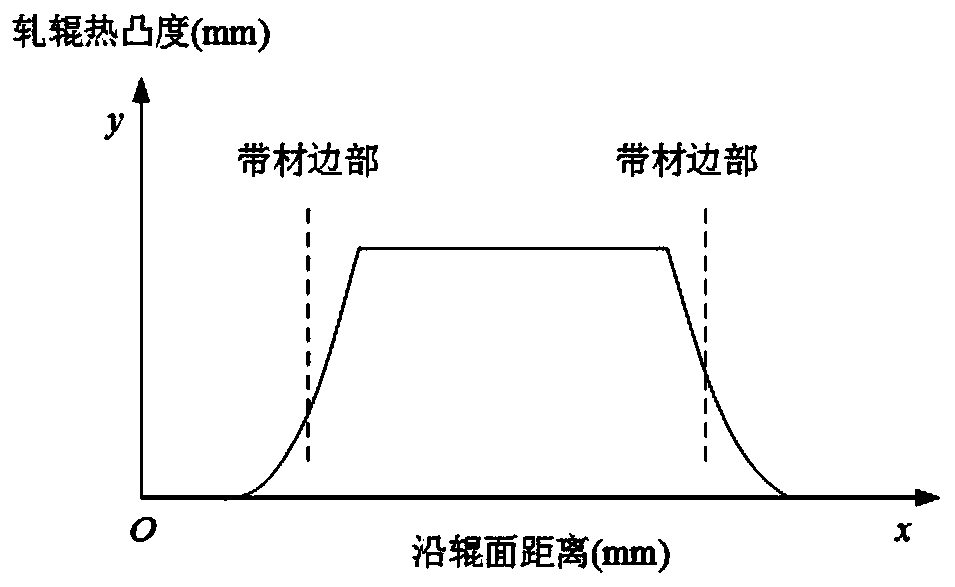

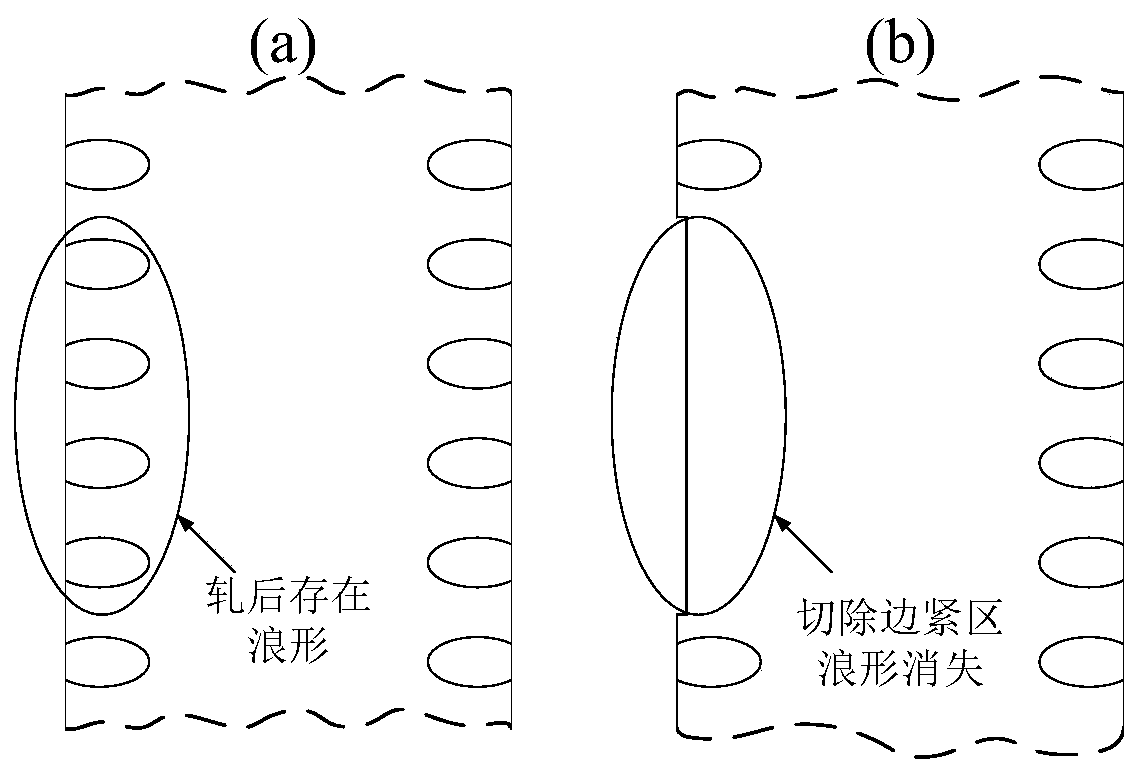

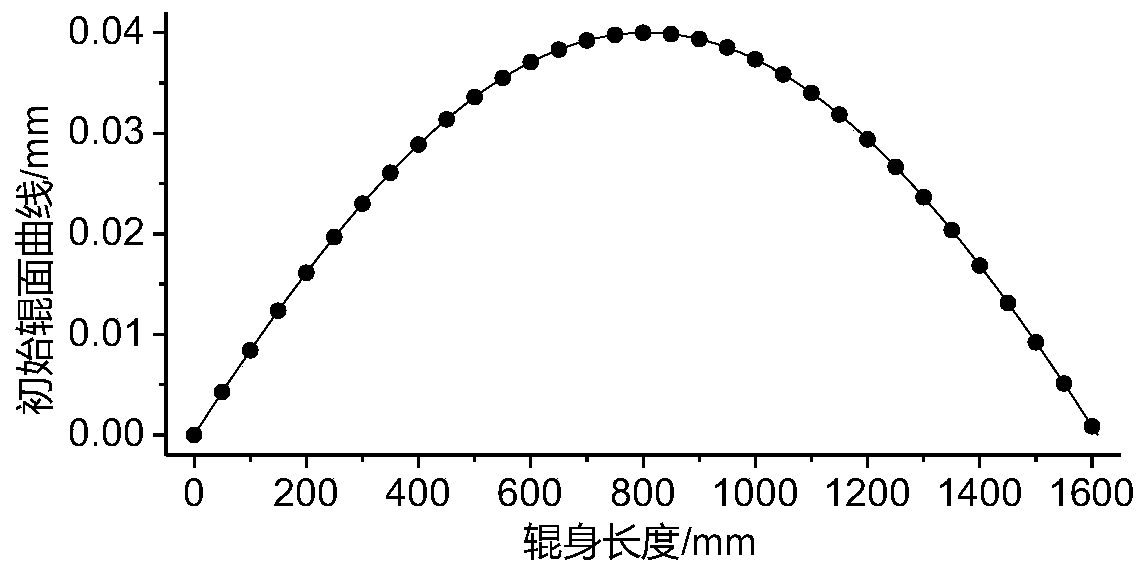

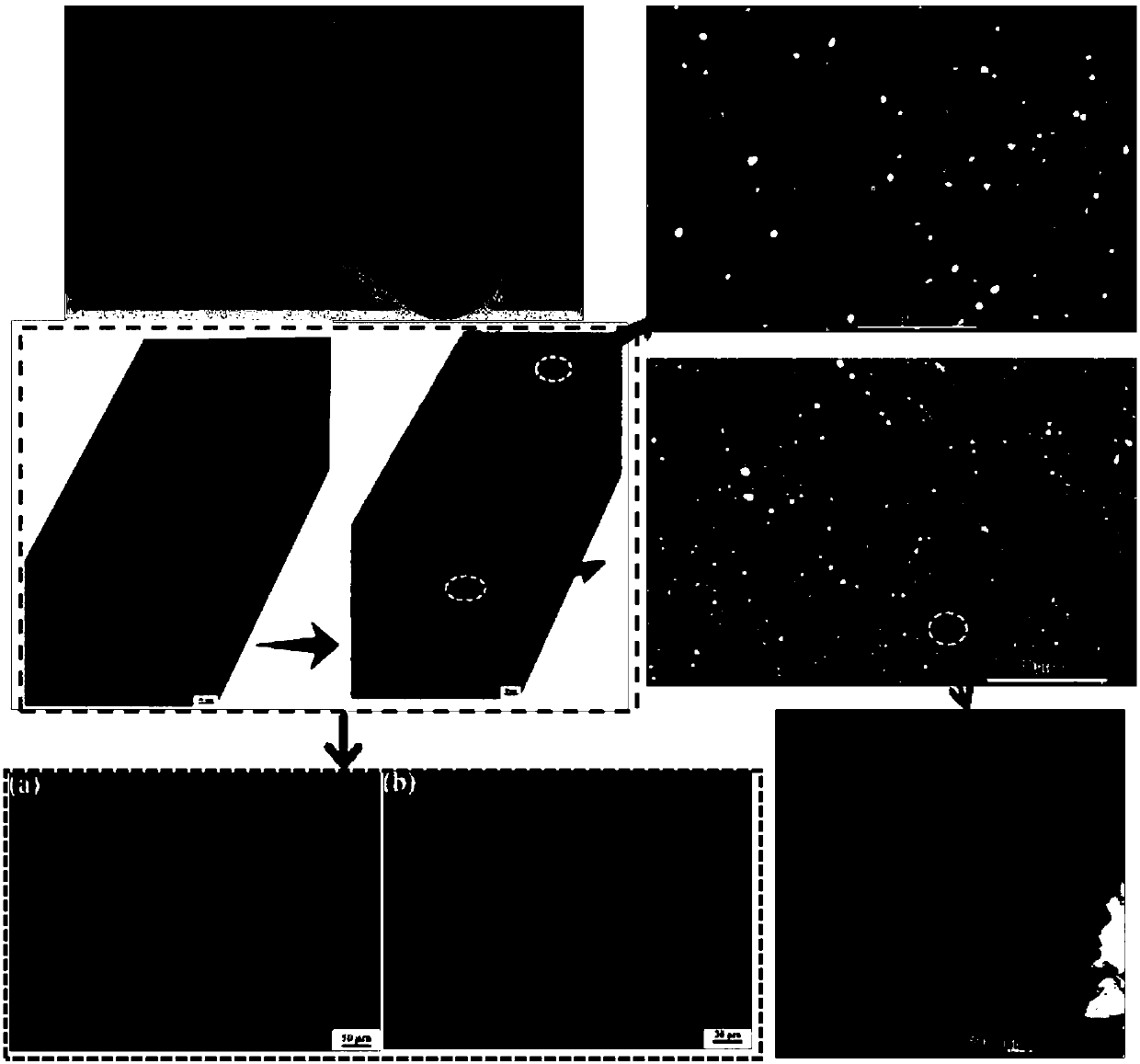

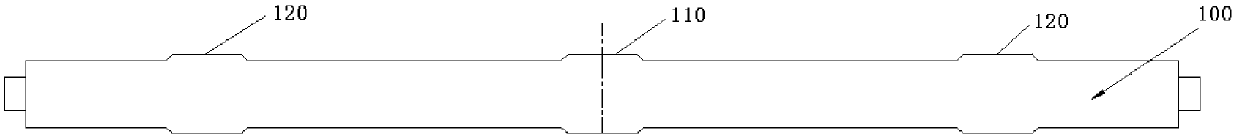

Working roller roller shape design method for relieving edge tightness and rib wave plate shape defects generated after extremely-thin belts are rolled

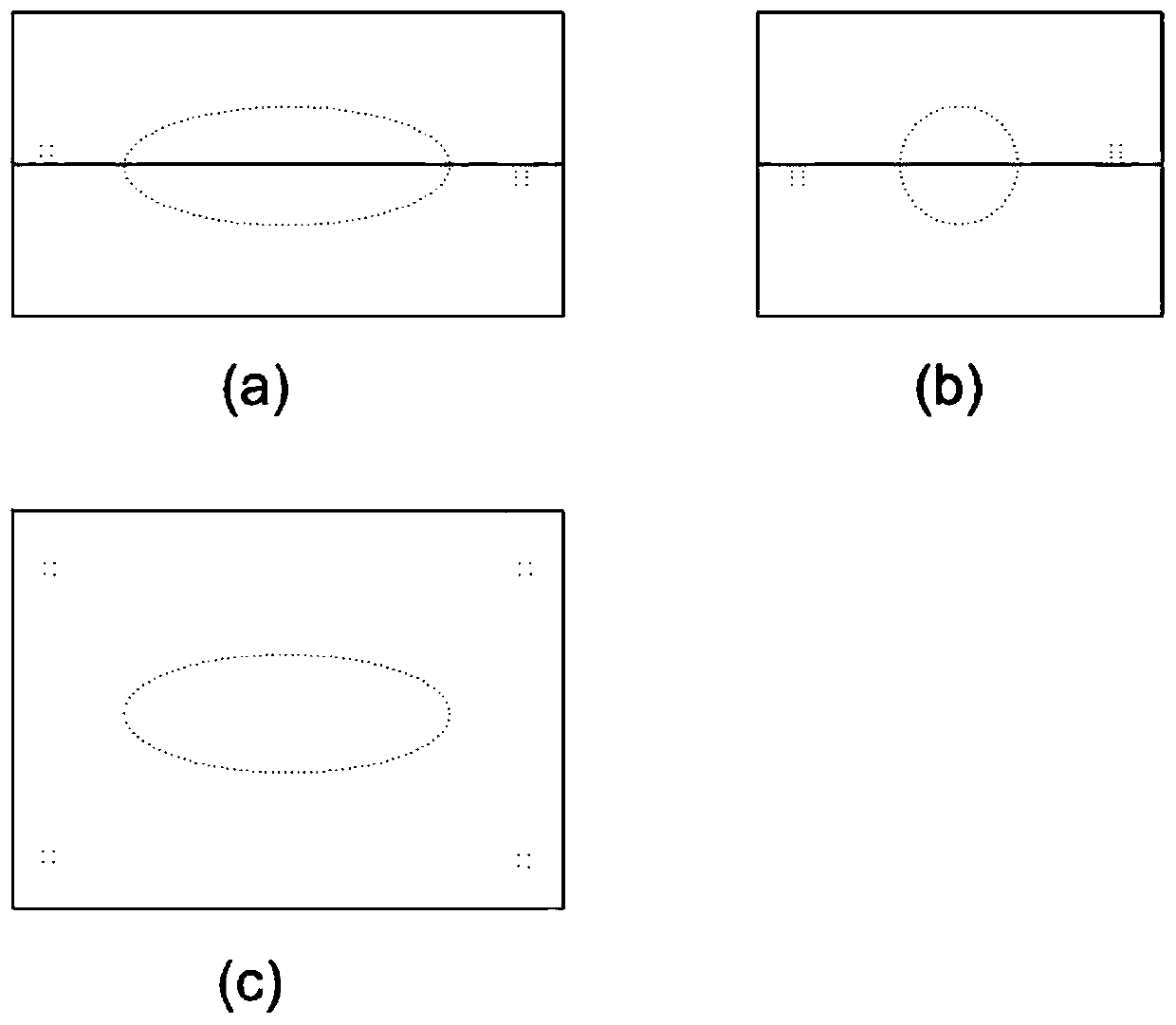

ActiveCN109967529ALarge amount of depressionImprove defectsRollsMetal rolling arrangementsDistribution characteristicEngineering

The invention provides a working roller roller shape design method for relieving edge tightness and rib wave plate shape defects generated after extremely-thin belts are rolled, and belongs to the technical field of plate and belt calendering. The method includes the steps that firstly, the plate shape conditions of 20 or more reels of rolled extremely-thin belts are statistically analyzed, the distribution characteristics of the edge tightness and rib wave plate shape defects of the rolled extremely-thin belts are obtained, then the length of a roller body of a working roller of a rolling mill and the widths of inlets of the extremely-thin belts in production are defined, and new roller shape protruding region positions are determined; and finally the use condition of the initial roller shape of the working roller is defined, and new roller shape middle roller shape curves are designed according to the initial roller shape of the working roller. Parameters of all the sections of curves of the roller shape are determined mainly according to the length of the roller body of the working roller of the rolling mill, the widths of the inlets of the extremely-thin belts, the plate shapeconditions of the rolled extremely-thin belts and the initial roller shape of the working roller. By means of the method, the edge tightness and rib wave plate shape defects generated after the extremely-thin belts are rolled can be effectively relieved, waste generated thereby is reduced, and the rolling yield of the extremely-thin belts is increased.

Owner:UNIV OF SCI & TECH BEIJING

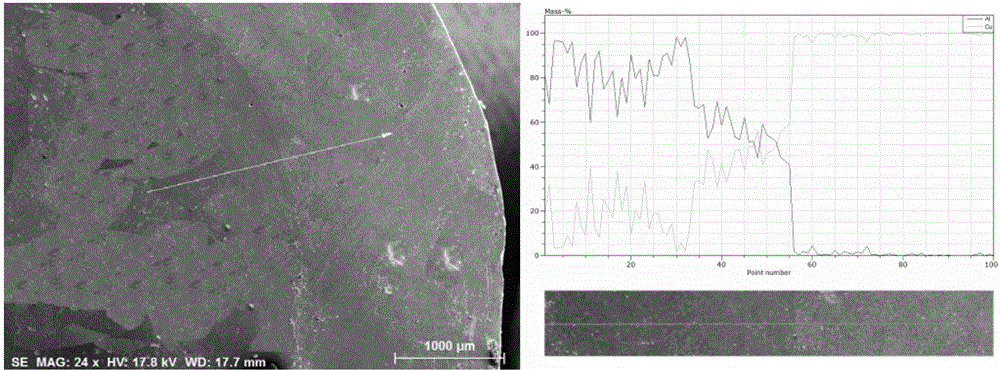

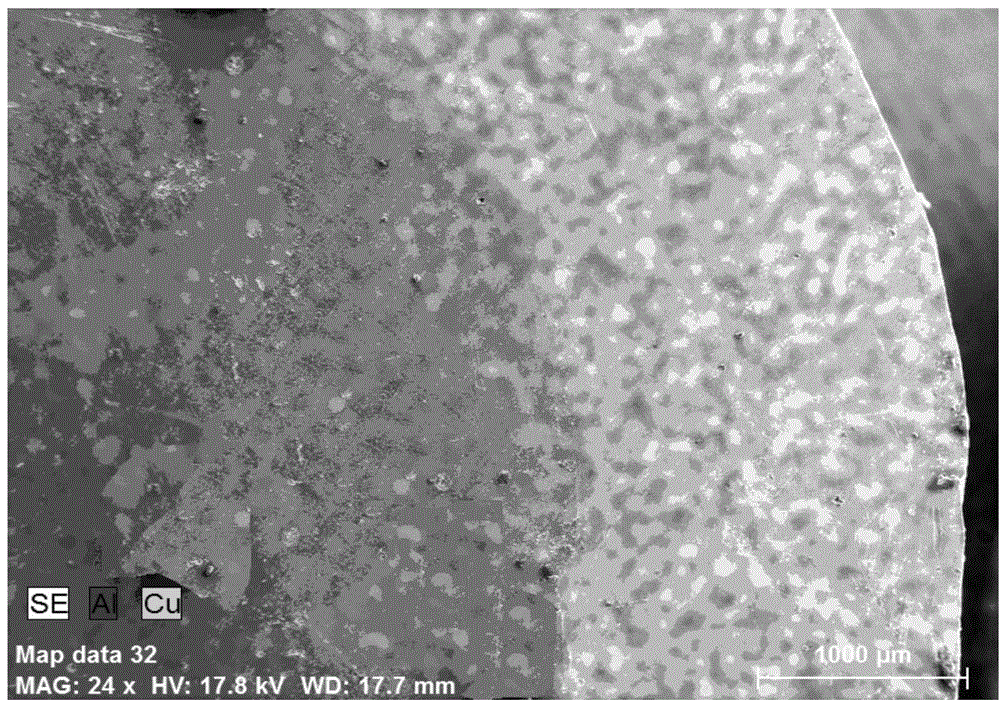

Preparation method for double-metal compound wire

InactiveCN105710154AWide range of adaptationLarge amount of depressionMetal rolling arrangementsSurface finishingAluminium

The invention relates to a preparation method of a bimetal composite wire, belonging to the field of bimetal composite wire preparation. In this method, two metal pipes and bars of different materials are surface-treated and nested together, and then the pipes and bars nested together are rolled by a three-roller planetary rolling mill, so that the pipes and bars are combined together. , to obtain a bimetallic composite billet; the bimetallic composite billet is rolled again with a multi-stand Y rolling mill or a vertical roller mill, and rolled into a bimetallic composite wire rod with a diameter of 4.5-5.5mm; The metal composite wire is drawn and processed to prepare a bimetal composite wire with a diameter of 0.5 mm to 3 mm. A series of bimetallic composite wires such as titanium-clad copper bimetallic composite wires, titanium-clad steel bimetallic composite wires, and copper-clad aluminum bimetallic composite wires can be prepared. The bimetallic composite wires obtained by this method have high bonding strength between the two metals. The production equipment is simple, flexible and low in cost.

Owner:有研科技集团有限公司

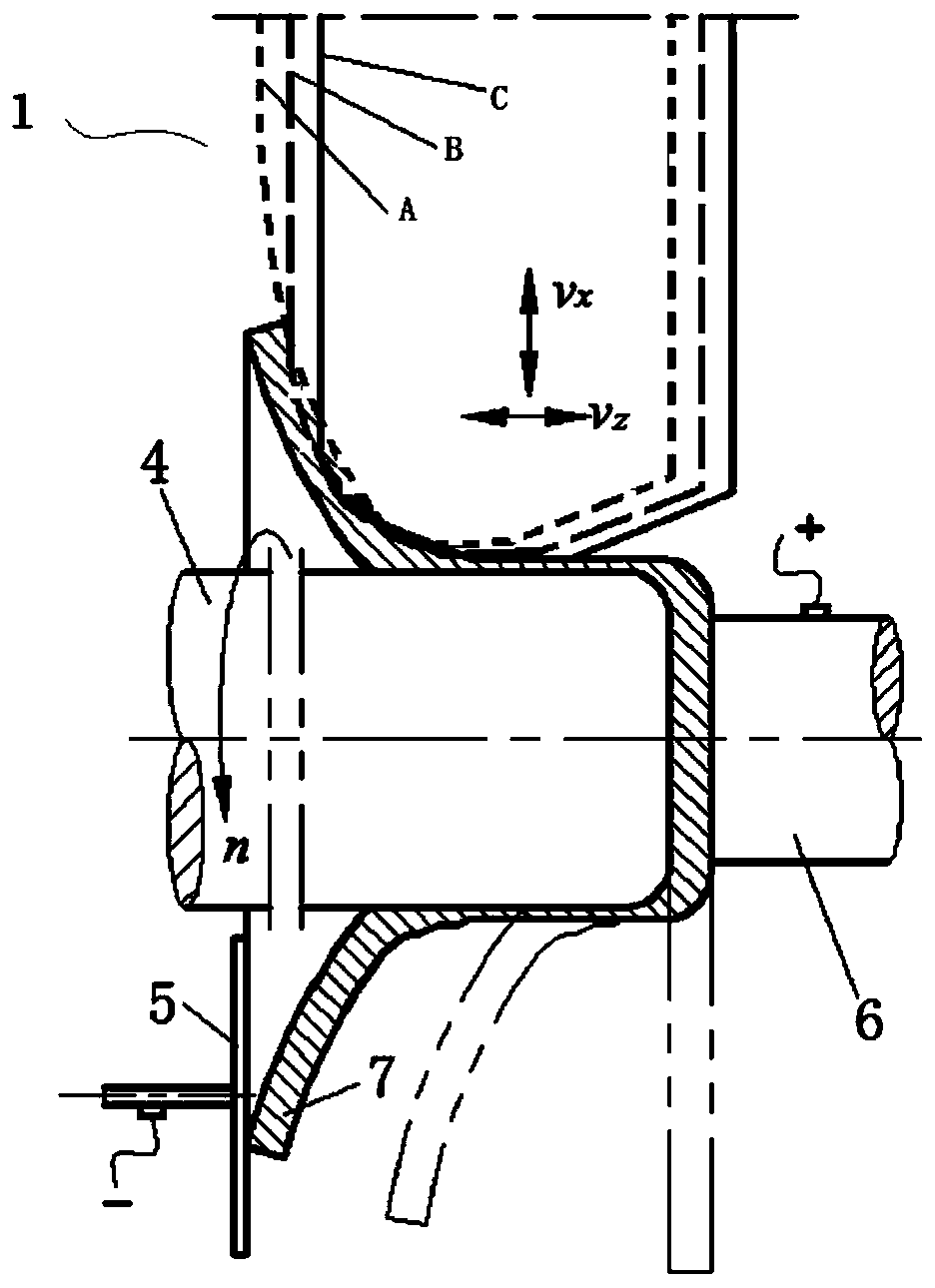

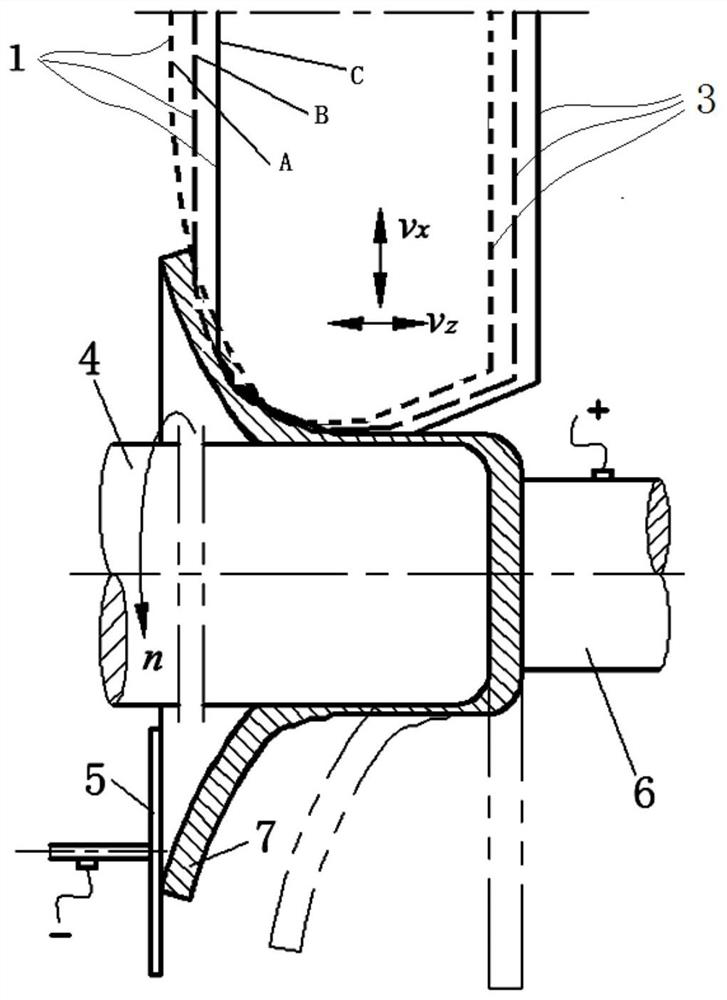

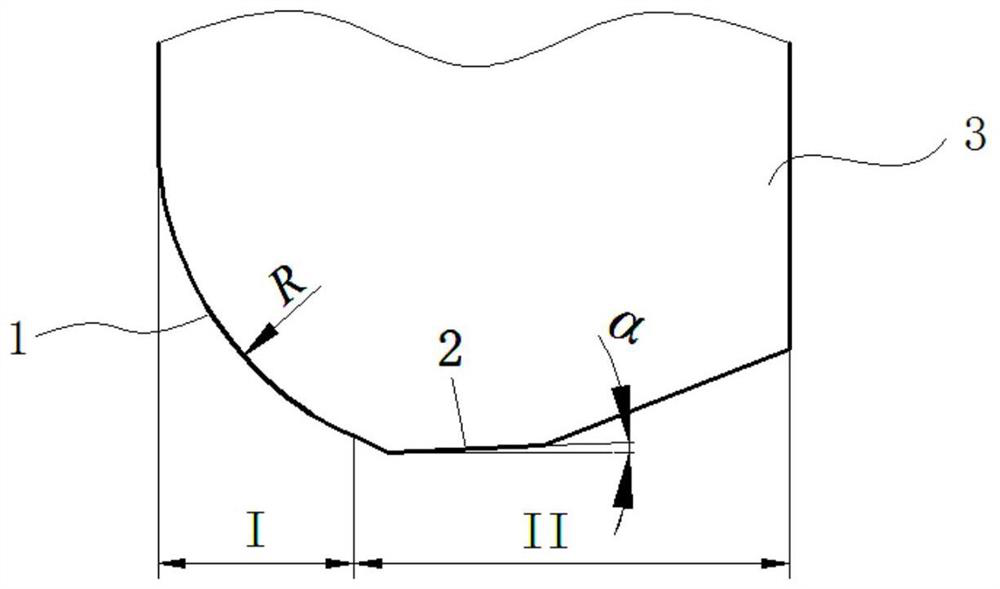

Deep-cup-shaped thin-wall part current auxiliary composite spinning forming device and method

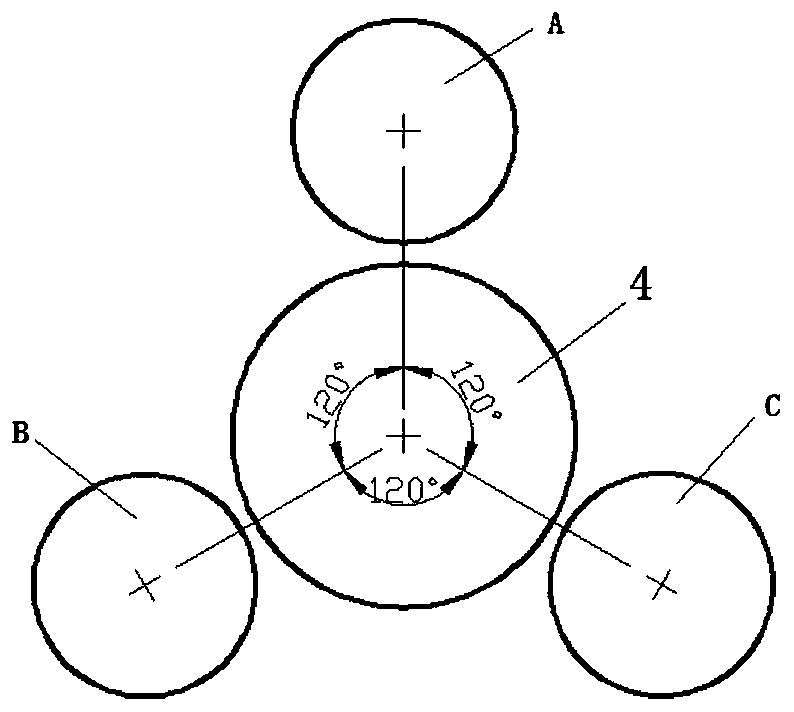

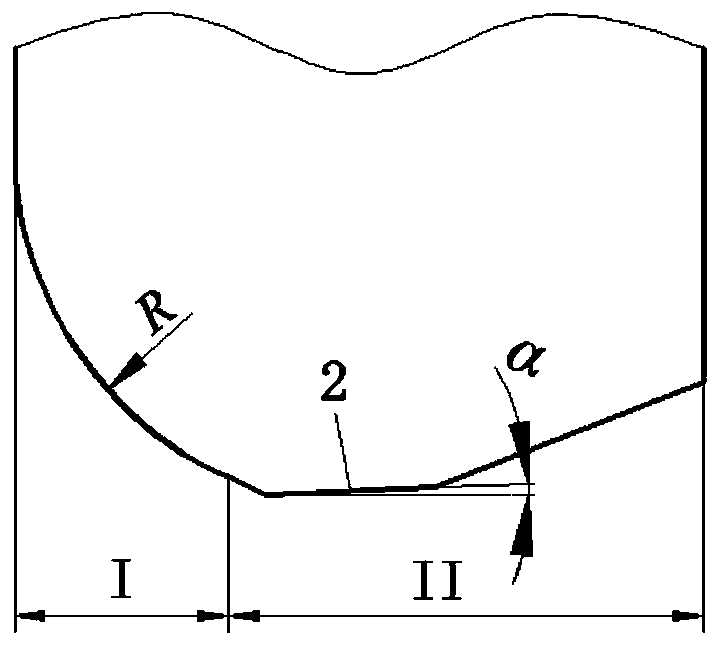

ActiveCN111408650ALarge pass reductionReduce spinning passesShaping toolsHollow articlesEngineeringMaterials processing

The invention discloses a deep-cup-shaped thin-wall part current auxiliary composite spinning forming device and method. The device comprises a spinning core die, a tailstock and a plurality of spinning rollers distributed on the circumference of the spinning core die at equal intervals. The spinning rollers are arranged in a staggered manner in the axial direction and the radial direction of thespinning core die. The spinning surfaces of each spinning roller comprise a deep drawing spinning surface, a flowing spinning segment and a shaping spinning surface. The deep drawing spinning surfaces, the flowing spinning segments and the shaping spinning surfaces of all the spinning rollers are distributed in a staggered mode in the axial direction and the radial direction of the spinning core die. In the spinning process, arc-shaped surface shapes and structures of the spinning rollers for deep drawing and spinning are different, so that the spinning rollers focus on exerting pressure to different portions of a blank respectively in each rotation period of the spinning core die, the pass reduction is increased, the spinning pass is reduced, the production efficiency can be improved, andthe defects that the material processing process is discontinuous, finally workpieces are hardened and materials are broken and cannot be used are reduced.

Owner:SOUTH CHINA UNIV OF TECH

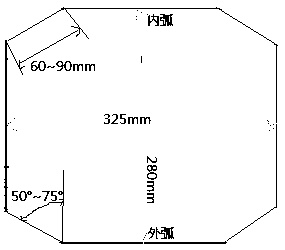

Continuous casting process capable of relieving internal quality defects of bearing steel bloom

The invention discloses a continuous casting process capable of relieving internal quality defects of bearing steel boom. The continuous casting process adopts a large chamfering crystallizer, a chamfering angle of the obtained large chamfered continuously cast bloom is 50-75 degrees, and length of a chamfered inclined surface is 60-90 mm. The adopted following pressing-down process is as follows: at a pressed-down start point position, central solid fraction fs is 0.55-0.65, and pressing-down amount is 1.0-2.0 mm; at a second pressing-down roller, central solid fraction fs is 0.65-0.75 and pressing-down amount is 3.0-5.0 mm; at a third pressing-down roller, central solid fraction fs is 0.75-0.85, and pressing-down amount is 2.0-4.0 mm; at a fourth pressing-down roller, central solid fraction fs is 0.85-0.95, and pressing-down amount is 2.0-3.0 mm; and at a fifth pressing-down roller, central solid fraction fs is 0.95-1.0, and pressing-down amount is 0-2.0 mm. The continuous casting process reduces casting, rolling and pressing-down force in a casting blank pressing-down process, and improves pressing-down efficiency, so that the effects of stably controlling quality defects such as center segregation, V-shaped segregation, central loosening and hole shrinkage of the bearing steel boom are achieved.

Owner:XINGTAI IRON & STEEL

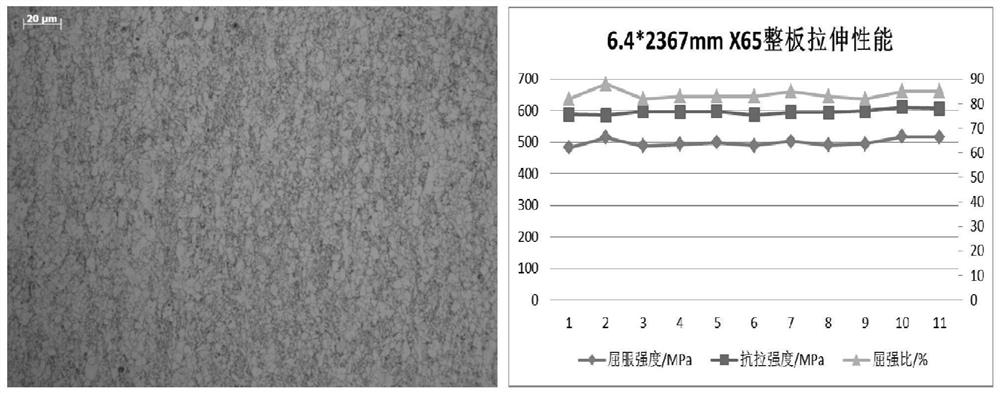

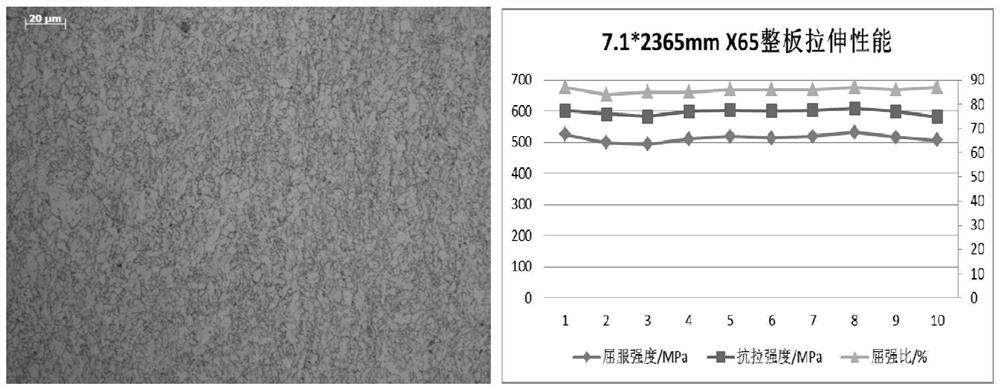

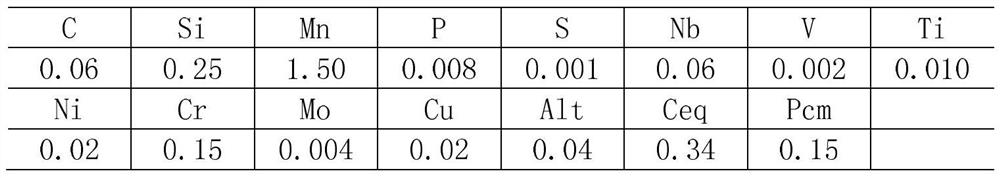

Thin-specification X65 steel-grade pipeline steel of single-stand steckel mill and rolling method

InactiveCN111790754AImprove temperature uniformityImprove the uniformity of mechanical propertiesTemperature control deviceTension/compression control deviceLine tubingRolling mill

The invention discloses thin-specification X65 steel-grade pipeline steel of a single-rack steckel mill and a rolling method. The steel is composed of the following components in percentage by weight:0.03 to 0.07 percent of C; 0.10 to 0.30 percent of Si, 1.30 to 1.70 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.0050 percent of S, 0.040 to 0.060 percent of Nb, less than or equal to 0.10 percent of V, 0.006 to 0.020 percent of Ti, 0.10 to 0.25 percent of Cr, less than or equal to 0.30 percent of Ni, less than or equal to 0.10 percent of Mo, less than or equalto 0.10 percent of Cu, 0.015 to 0.050 percent of Al and the balance of Fe and impurities. According to the rolling method, a blank with the thickness of 150 mm is used for producing the thin-specification pipeline steel plate with the finished product specification of (6-8) mm X65 grade. By controlling the tapping temperature, the coiling furnace temperature, the second-stage initial rolling temperature, the rough rolling final pass reduction rate, the final rolling speed, ACC cooling and the like, the thin-specification X65 steel-grade pipeline steel plate with the performance and the plateshape meeting the requirements is obtained, the productivity and the yield of a rolling mill are improved, and the performance percent of pass is high.

Owner:NANJING IRON & STEEL CO LTD

Production method of crack arresting steel for container ship

ActiveCN110076196ALarge amount of depressionAccurate and effective production processTemperature control deviceWork cooling devicesSheet steelUltra fast

The invention discloses a production method of crack arresting steel for a container ship. Billets having different cross sections are selected for rolling according to different finished product widths, the rolling pass is reduced, and the reduction in pass is increased; as for planning arrangement, according to the characteristics that the rolling mode is special and the rolling frequency is slow, the time in a furnace is shortened through blank positions in a heating furnace, execution of a heating technology is ensured, and the surface quality is ensured; the heating process ensures the uniformity of a plate slab in the thickness direction; a rolling technology uses a full longitudinal rolling or full horizontal rolling manner as many as possible, and the effective compression ratio isincreased; and in order to refine grains, the intermediate billet is subjected to ultra-fast cooling, different cooling technologies are set according to specifications, and a finished steel sheet cooling technology is determined. A stable production technology for accurately and effectively producing the crack arresting steel can be realized, the stability of the production technology of the crack arresting steel meets the batch industrial production, the mechanical properties, the product quality stability and various indexes meet the standard requirement, and the production process is easyto control.

Owner:NANJING IRON & STEEL CO LTD

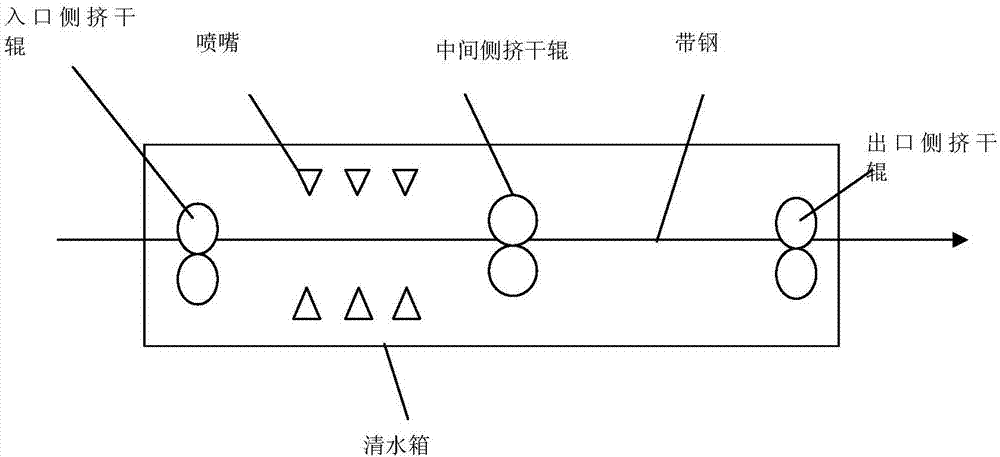

Method for cleaning segment defect treatment in stainless steel cold rolling acid pickling process

The invention provides a method for treating defects in the cleaning section in the pickling process of stainless steel cold rolling. The method for treating defects in the cleaning section in the pickling process of stainless steel cold rolling includes: in the final cleaning process, using at least three The rollers clean the steel strip, and the three groups of rollers are respectively an entrance-side squeezing roller, a middle-side squeezing roller and an exit-side squeezing roller, wherein the material of the exit-side squeezing roller is polyurethane rubber. The invention eliminates the defect that the rubber is pressed into the binary ethylene-propylene rubber roller during use, which leads to a decrease in product quality and a short service life of the roller.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

Ten-gate holeless rod continuous rolling process

InactiveCN108296283AImprove the annual operating rateImprove productivityTemperature control deviceRollsReduction rateStrip mill

The invention discloses a ten-gate holeless rod continuous rolling process, and belongs to a metal rolling process. The ten-gate holeless rod continuous rolling process is characterized in that hole rollers in previous ten gates of rod continuous rolling are replaced by flat rollers; hole rolling of rods in the previous ten gates is replaced by holeless rolling; holeless rolling in the previous ten gates is adopted to roll the rods; the rolling parameters are as follows: the rolling height-width ratio is 0.90-1.8; the reduction rate in each gate is 20%-60%; the rolling temperature is 950 DEG C-1100 DEG C; the height*width range of blanks is 150 mm*150 mm-165 mm*165 mm; the absolute broadsiding coefficient range is 0.18-0.45; holeless rolling of the rods in the previous ten gates is realized; the production cost is reduced; the product quality and the utilization rate of a rolling mill are improved; and the application range of the blanks is widened.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

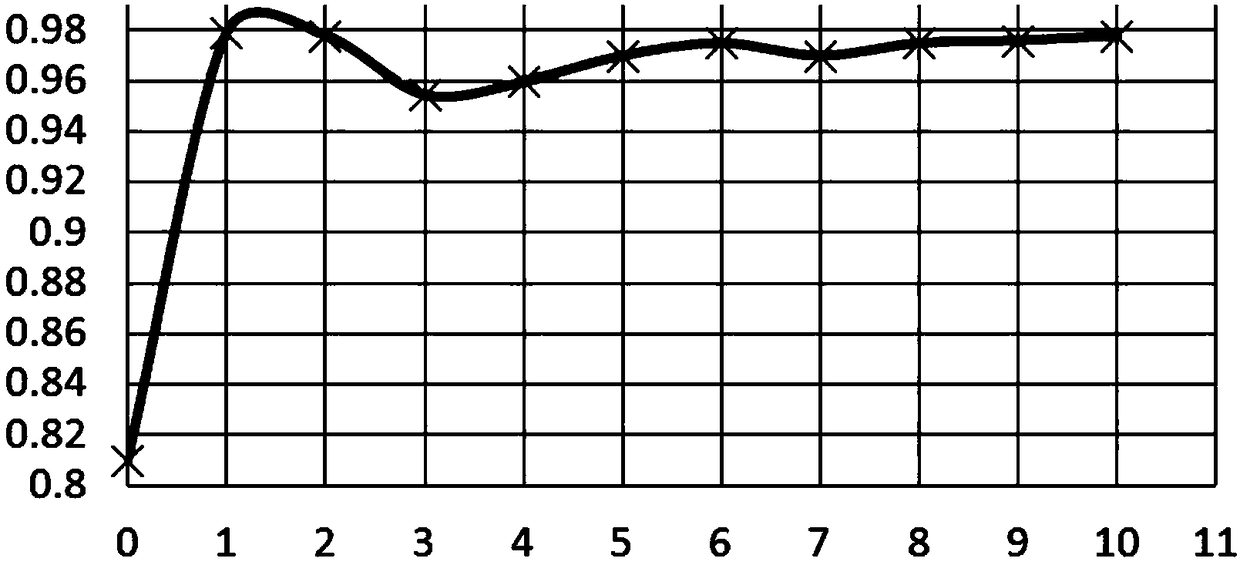

Short-flow rolling preparation process of high-strength and high-plasticity AlN/AZ91D magnesium base composite material plate

ActiveCN107747071AQuality improvementHigh quality and high performanceMagnesium matrix compositeIngot

The invention relates to a short-flow rolling preparation process of a high-strength and high-plasticity AlN / AZ91D magnesium base composite material plate; solid solution and water quenching processesof a cast ingot before rolling are formulated; subsequent rolling and annealing processes are optimized; and a set of cold rolling process for preparing a high-strength and high-plasticity magnesiumbase composite material rolled plate is provided. The cold rolling process is high in reduction in pass, few in annealing times among passes and short in annealing time, and can realize industrial short-flow preparation. In particular, through the patent technology, namely the optimal ratio of solid solution process parameters to water quenching process parameters to rolling process parameters toannealing process parameters, the edge cracking problem in the cold rolling process is solved when the high-strength and high-plasticity cold-rolled plate is obtained, and finally, the high-quality and high-performance magnesium alloy composite material cold-rolled plate can be obtained with high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

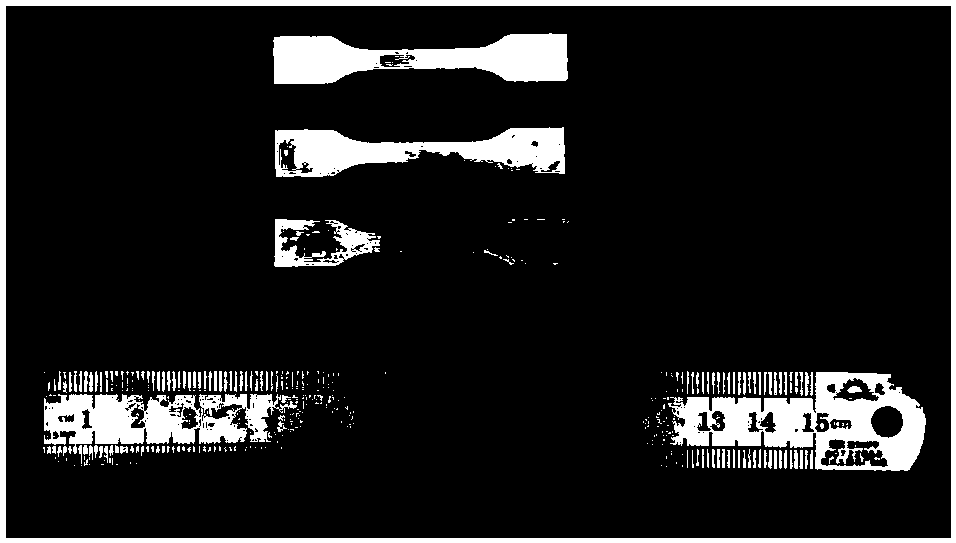

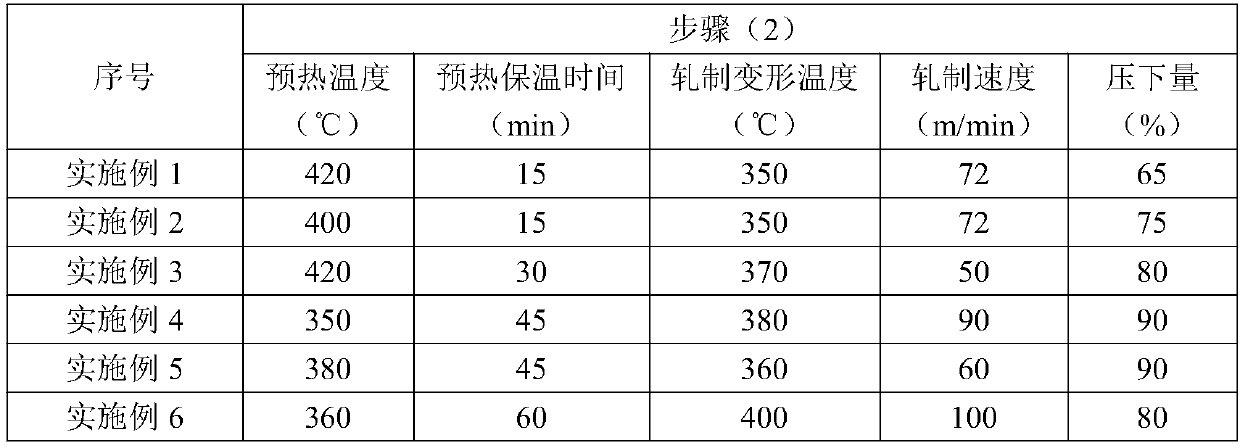

Rough rolling process and method for preparing high-strength high-ductility magnesium alloy sheet

InactiveCN110404966AIncrease rolling speedLarge amount of depressionMetal rolling arrangementsHigh intensityUltimate tensile strength

The invention discloses a rough rolling process for preparing a high-strength high-ductility magnesium alloy sheet. In the rough rolling step, the rolling speed of each rolling pass is controlled to be 50-100 m / min, and the rolling reduction of each rolling pass is controlled to be 60%-90%. The invention further discloses a method for preparing the high-strength high-ductility magnesium alloy sheet. The method comprises the rough rolling process. According to the rough rolling process and method for preparing the high-strength high-ductility magnesium alloy sheet, the rolling speed is high, the rolling reduction is large, the average grain size of a magnesium alloy slab obtained after the rough rolling step is less than or equal to 20 microns, the magnesium alloy sheet manufactured after subsequent warm rolling is good in rolled plate shape, and in the case of the magnesium alloy sheet, the yield strength is larger than or equal to 220 MPa, the tensile strength is larger than or equalto 290 MPa, and the elongation percentage is larger than or equal to 15%.

Owner:BAOSHAN IRON & STEEL CO LTD

Cold rolling unit system and implementation method thereof

InactiveCN102078880BExtended service lifeLow costMetal rolling stand detailsMetal rolling arrangementsUnit systemEngineering

The invention relates to the field of strip steel processing, and discloses a cold rolling unit system and an implementation method thereof. According to the cold rolling unit system and the implementation method thereof provided by the invention, when a first working roll of a first roll system is used to phi370 millimeters and cannot be reused, the first working roll can be subjected to secondary quenching, and a reformed second roll system is used as a second working roll for continuous operation. When a second middle roll of the reformed second roll system is used to phi450 millimeters and cannot be reused, the second middle roll can be subjected to secondary quenching, and the first roll system is used as a first middle roll for continuous operation. When the diameter usage range of the working roll is enlarged to be between 400 and 340 millimeters and the usage range of the middle roll is enlarged to be between 485 and 415 millimeters, the service lives of the working roll and the middle roll are prolonged, the old is changed into the new, and the production cost is reduced.

Owner:佛山市高明基业冷轧钢板有限公司

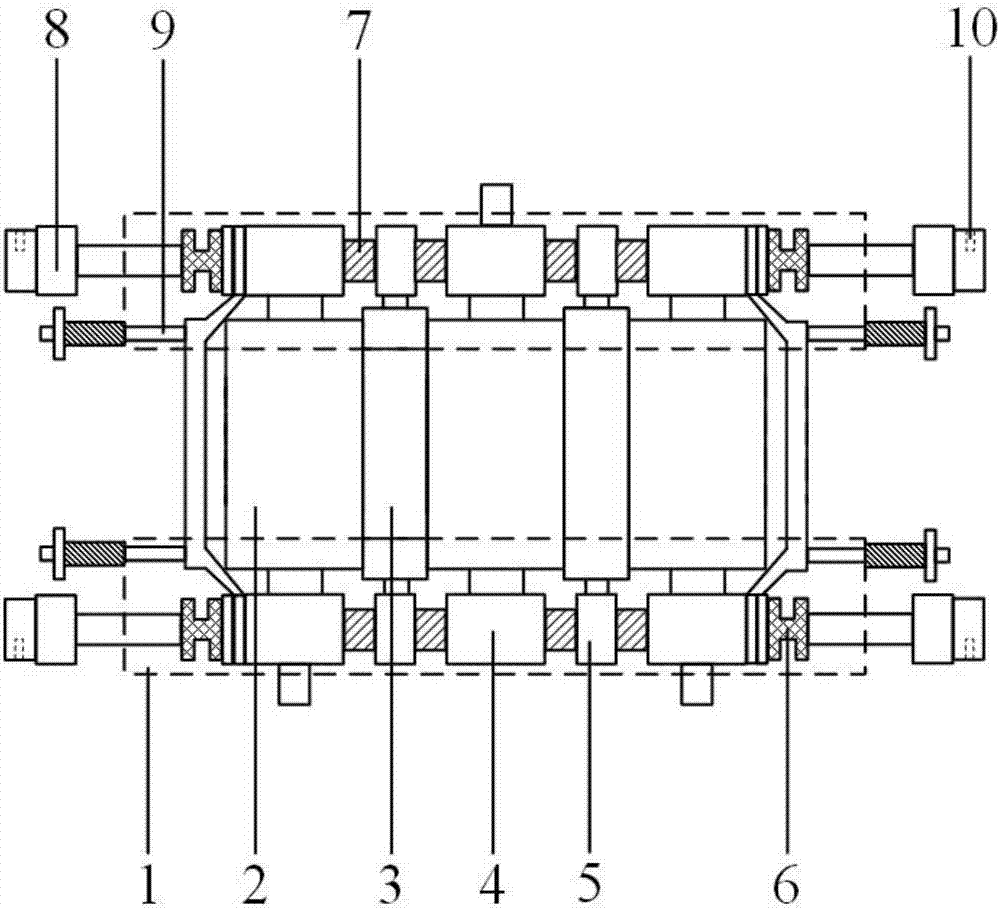

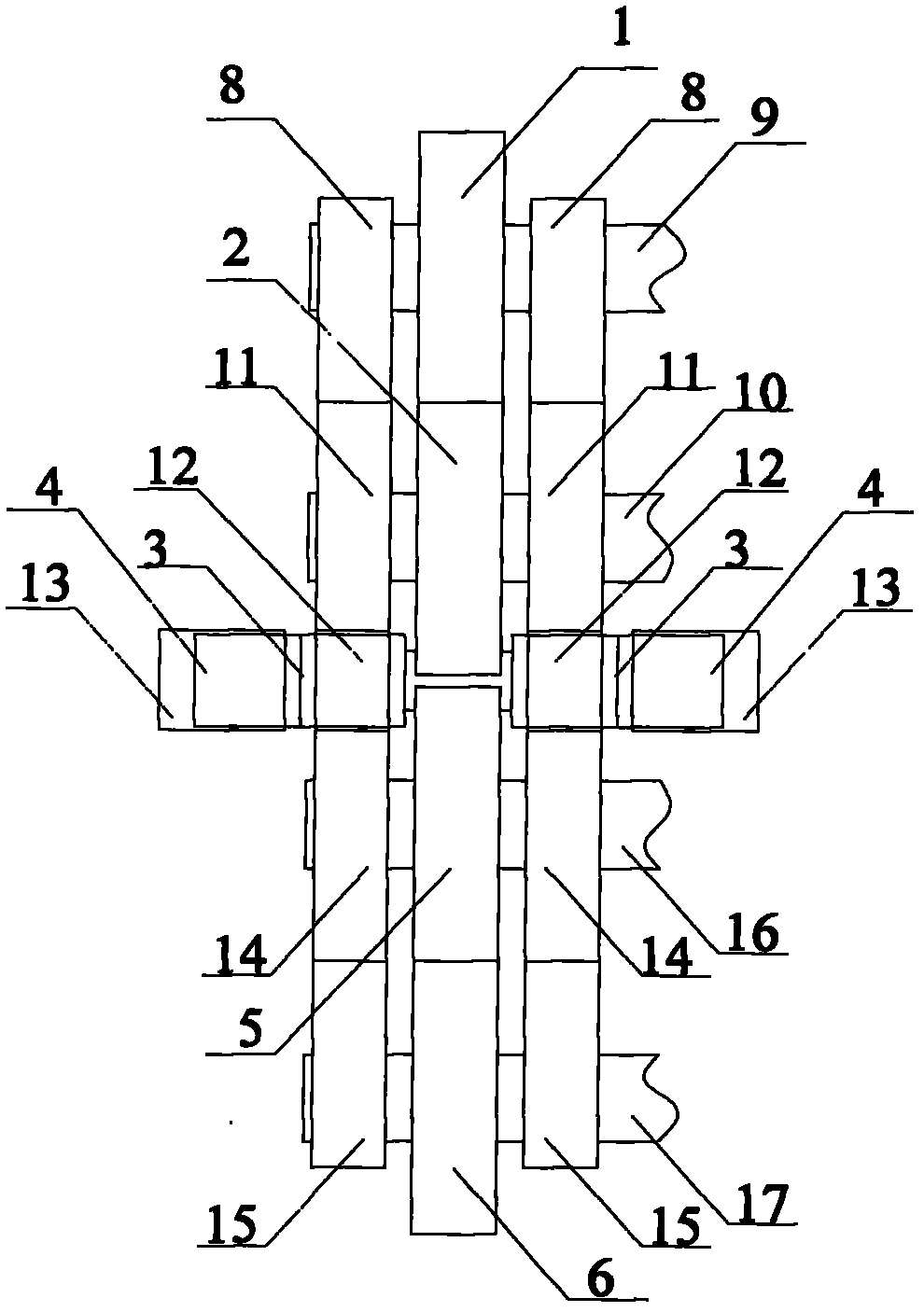

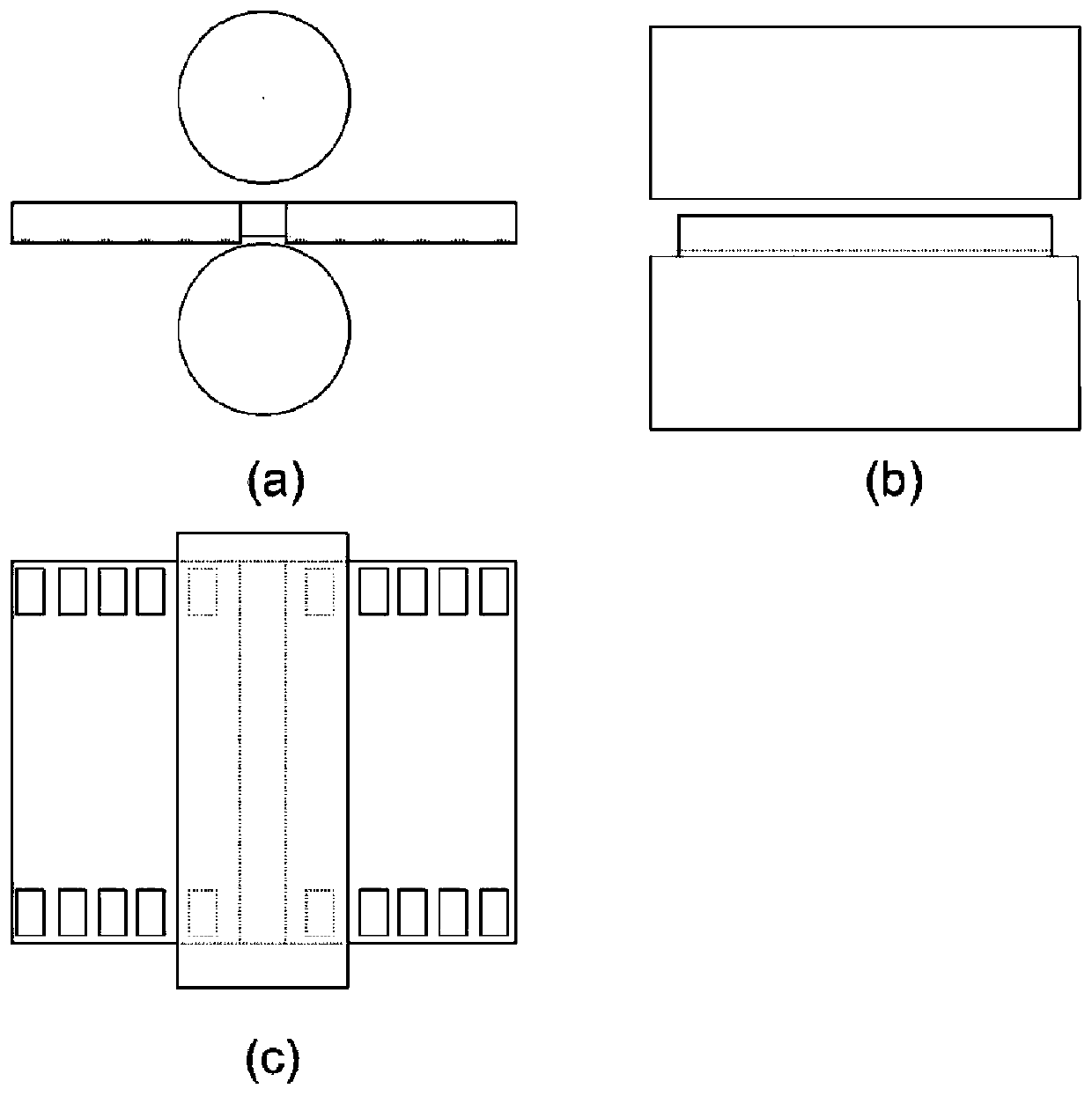

Universal mill type

InactiveCN102125933AImprove rolling forcePrecise size controlMetal rolling stand detailsMetal rolling arrangementsEngineeringHigh intensity

The invention relates to a universal mill type, which belongs to the technical field of structural steel hot-rolling devices. The universal mill type adopts an eight-roller structure. Two horizontal supporting rollers, namely an upper horizontal supporting roller and a lower horizontal supporting roller, are arranged beside two horizontal working rollers. The upper horizontal supporting roller is positioned right above the upper horizontal working roller, and the lower horizontal supporting roller is positioned under the lower horizontal working roller. The centers of the four horizontal rollers are in a straight line. Two supporting rollers are separately arranged outside two vertical working rollers, and the centers of the four vertical rollers are in a straight line. The roller diameter of each supporting roller is longer than or equal to the roller diameter of each working roller in contact with the supporting roller. When the mill of the invention is used, the mill allows relatively large rolling reduction, makes the dimensional control of rolled pieces more precise and the rolling to high-strength structural steel easier, realizes the rolling control and the cooling control more easily, is beneficial to improvement of product precision, reduces the rolling pass, reduces production cost, enhances the performance of the structural steel, better realizes the rolling of the structural steel made of high strength materials, meets use requirements of users, and promotes energy conservation and environmental protection.

Owner:SHANDONG IRON & STEEL CO LTD

H-beam production system

InactiveCN107695094BSmall elongation coefficientImprove biteMetal rolling arrangementsRolling millFlange

The invention provides a production system for H-shaped steel. The production system comprises a rough rolling unit, X-hole-shaped universal rolling mills, edging mills and an H-hole-shaped universalrolling mill. The rough rolling unit is used for rolling continuous casting billets for producing the H-shaped steel into intermediate billet materials first. Each X-hole-shaped universal rolling millcomprises two second horizontal rolls and two second vertical rolls, and an X-shaped rolling hole is formed between each two second horizontal rolls and the corresponding two second vertical rolls. When the intermediate billet materials rolled by the rough rolling unit enter the X-shaped rolling hole of each X-hole-shaped universal rolling mill, the corresponding two second horizontal rolls rollwebs of the billet materials, then the corresponding two second horizontal rolls and the corresponding two second vertical rolls roll the webs and flanges of the billet materials, and X-shaped billetmaterials are rolled. The X-shaped billet materials obtained after rolling of the X-hole-shaped universal rolling mills enter the edging mills, and the edging mills roll the flanges of the X-shaped billet materials to adjust the width of the flanges. The H-hole-shaped universal rolling mill is used for rolling the X-shaped billet materials rolled by the edging mills into the H-shaped steel.

Owner:刘庚申 +1

Low-carbon silicon steel strip for cold rolling and producting process thereof

The invention discloses a mild low-carbon low-silicon hot-rolled steel strip for cold-milling and producing technique, its chemical components: C 0.02-0.09%, Si 0.01-0.10%, Mn 0.20-0.60%, P 0.005-0.04% and S 0.005-0.04%, produced by calm steel link-casting process. Adopt 90-ton oxygen convertor top-bottom compound blowing smelting, steel package through blowing Ar gas, and less silicon and proper Al wire to deoxidize the liquid steel, adopt medium package inserted water gap protection residue to cast, the height of the liquid surface of the liquid steel controlled above 100mm, two cooling being weak cooling system.

Owner:LIANYUAN IRON & STEEL GROUP CO LTD

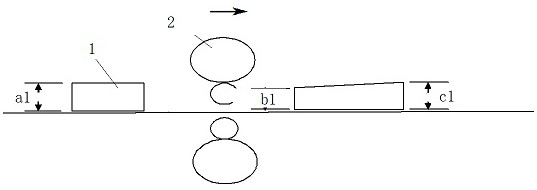

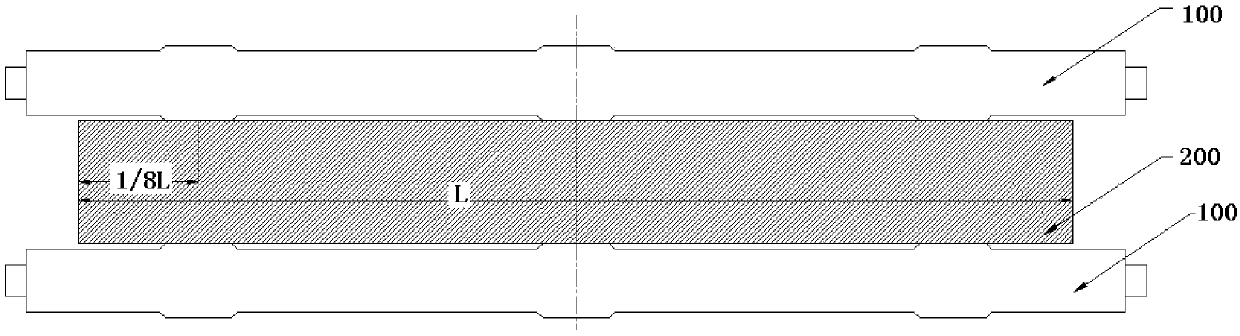

Differential-thickness rolling method for medium-thickness plate

InactiveCN113042526ALarge amount of depressionLarge amount of deformationRoll mill control devicesMetal rolling arrangementsSteel platesFirst pass

The invention relates to a differential-thickness rolling method for a medium-thickness plate, and belongs to the technical field of production of medium-thickness plates in the metallurgical industry. According to the technical scheme, the number of passes of differential-thickness rolling is even, the first pass of differential-thickness rolling adopts the mode that the reduction rate is gradually increased, the thicknesses of a steel plate rolled by the first pass of differential-thickness rolling in the length direction are different, the upper surface of the steel plate has a certain gradient, the thinner end of the steel plate is engaged into the second pass of differential-thickness rolling, and in the second pass of differential-thickness rolling, the reduction rate is also gradually increased, the steel plate with the upper surface having the certain gradient is rolled into a flat plate with the consistent thickness in the length direction, and so on until the last pass of differential-thickness rolling. The method has the beneficial effects that low-pressure engagement and high-pressure steel throwing can be realized through differential-thickness rolling, so that the rolling reduction of the steel plate is greatly increased, the deformation of the core part of the steel plate is increased, the deformation is promoted to spread deep into the core part of a rolled piece, the performance of the steel plate is improved, the number of rolling passes can be reduced, and the rolling efficiency is improved.

Owner:HANDAN IRON & STEEL GROUP +1

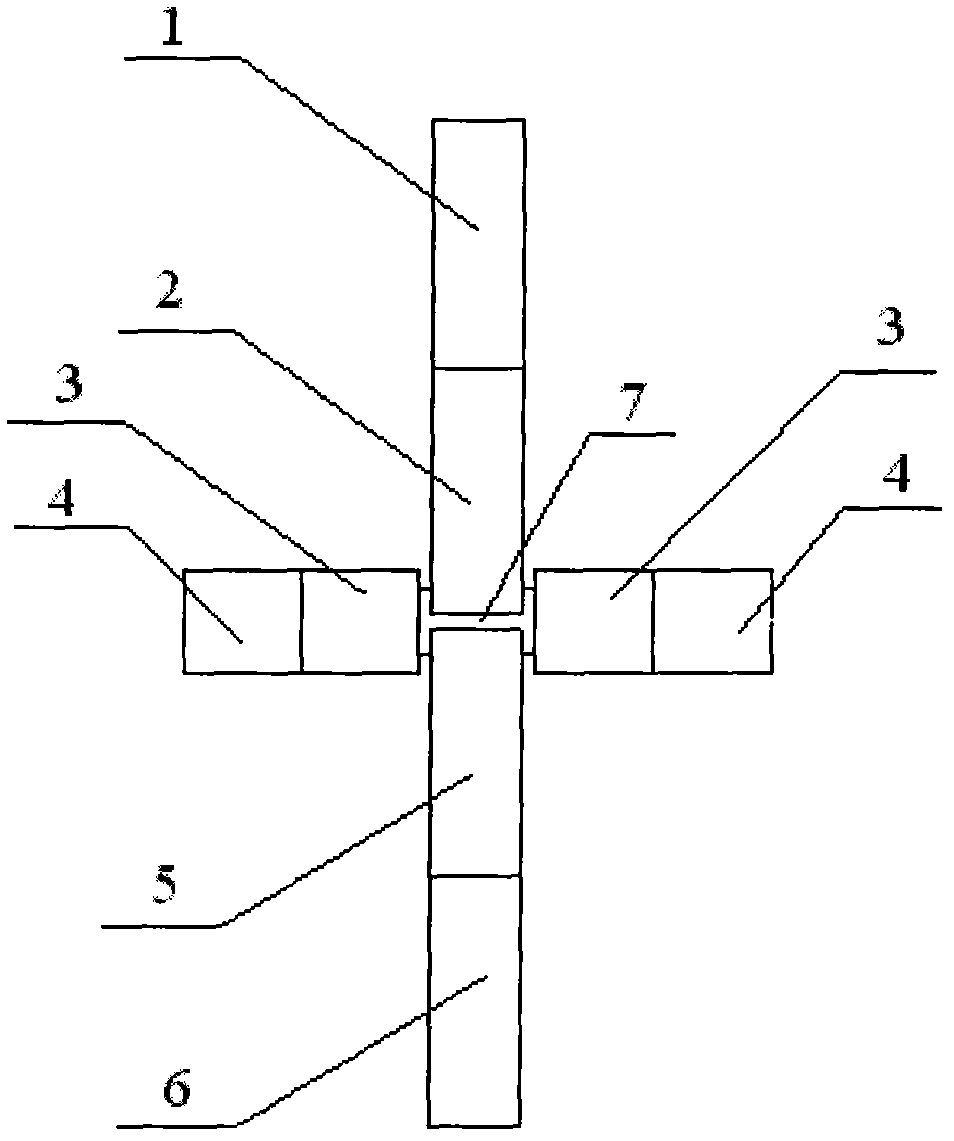

Convex foot roller for continuously casting plate blank and method for improving center segregation and porosity of continuously cast plate blank

The invention belongs to the technical field of the production of plate blanks, and particularly discloses a convex foot roller for continuously casting a plate blank and a method for improving the center segregation and porosity of the continuously cast plate blank. The method aims at solving the problems how to weaken the center segregation of the continuously cast plate blank and lighten the center porosity of the continuously cast plate blank. The convex foot roller for continuously casting the plate blank comprises a roller body and a bulge structure, wherein the bulge structure is arranged on the roller body; the bulge structure comprises an intermediate bulge arranged in the middle of the roller body and two lateral bulges symmetrically arranged on the roller body. The method for improving the center segregation and porosity of the continuously cast plate blank comprises the following steps of carrying out pressing-down treatment on the continuously cast plate blank entering a secondary cooling zone by adopting a pulling-straightening machine with the convex foot roller. The convex foot roller for continuously casting the plate blank can be used for pressing down the continuously cast plate blank in a targeted manner in the form of a solidification zone during a solidification last phase; molten steel containing an enriched segregation element in the continuously cast plate blank is effectively stopped from flowing to accordingly weaken the center segregation and meanwhile, the solidification contraction amount of the continuously cast plate blank is compensated to lighten the center porosity of the continuously cast plate blank.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

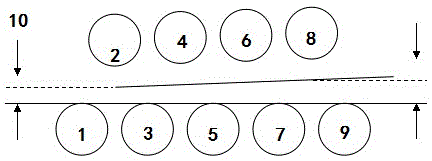

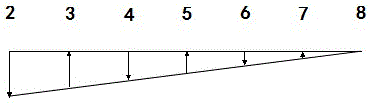

Cold straightening process for improving straightening capability through reduction of number of working rolls of straightener

ActiveCN105107873AIncrease the amount of cuttingExtended Straightening CapabilitiesWork rollEngineering

The invention discloses a cold straightening process for improving the straightening capability through the reduction of the number of working rolls of a straightener. In the step of the first pass large plastic deformation straightening, the number of the working rolls actually performing straightening is determined; one or two upper working rolls on the outlet side do not perform straightening; roll gaps of the inlet and the outlet are set; and the roll gap of the inlet is calculated according to a secondary model and based on a condition that a steel plate plastically deforms by 80%. In the step of the second pass small plastic deformation straightening, all the working rolls perform straightening; the roll gap of the inlet is calculated according to the secondary model and based on a condition that the steel plate plastically deforms by 65%; and the roll gap of the outlet is designed to be the thickness of a plate to be straightened. According to the invention, through the reduction of the number of the working rolls actually performing straightening on the outlet side of the straightener, the load of the straightener is reduced, the rolling reduction of the inlet of the straightener is increased, the maximum bending curvature of the steel plate is increased, the straightening capability of the straightener is enhanced, and the straightening qualified rate of the steel plate is improved.

Owner:NANJING IRON & STEEL CO LTD

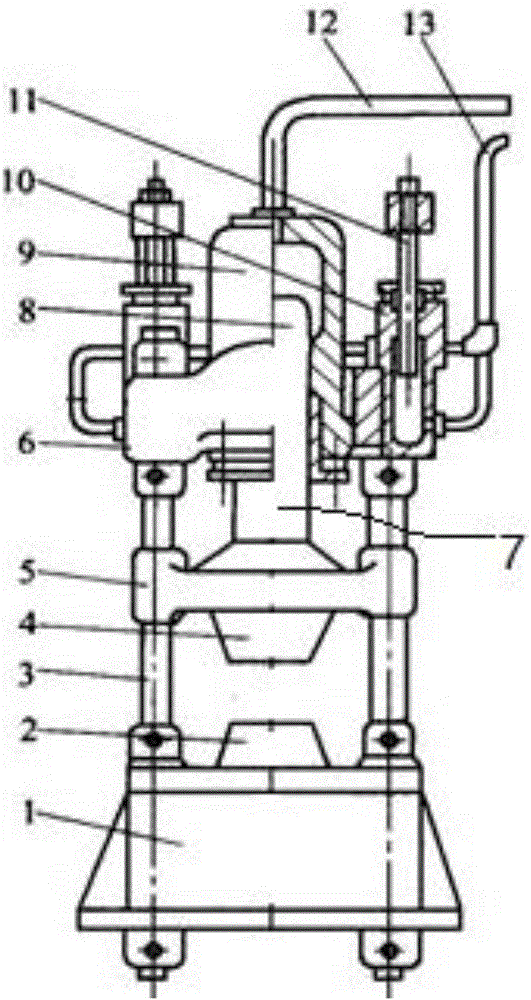

Hydraulic forging device for vehicle spare parts

InactiveCN106694774AQuality improvementHigh forging pressureForging press drivesWorking environmentIndustrial engineering

A hydraulic forging device for vehicle spare parts comprises a fixed system and a movable system. The fixed system comprises a lower cross beam, stand columns, an upper cross beam, a working cylinder and a return cylinder; the movable system comprises a movable cross bar, a working plunger and a return plunger; the stand columns and a lower anvil is installed at the upper end of the lower cross beam, the movable cross beam is installed between the lower cross beam and the upper cross beam, and an upper anvil is installed on the movable cross beam and located above the lower anvil; the working cylinder is installed at the upper end of the upper anvil, the plunger is installed in the working cylinder, a first pipeline is installed at the upper end of the working cylinder, and the return cylinder is installed on the side of the working cylinder; and the return plunger is installed at the upper end of the return cylinder, and a second pipeline is installed on one side of the return cylinder. According to the hydraulic forging device for the vehicle spare parts, hydraulic pressure is adopted to replace the impact force during hammer forging, a larger forging pressure can be provided, the pressing quantity of blank deformation is large, and the depth of forging penetration is large so that the interior quality of a forged piece can be improved; the overall structure is simple, vibration and noise of the forging device during forging are small, and the working environment is improved.

Owner:SHANGHAI METALSA AUTO PARTS

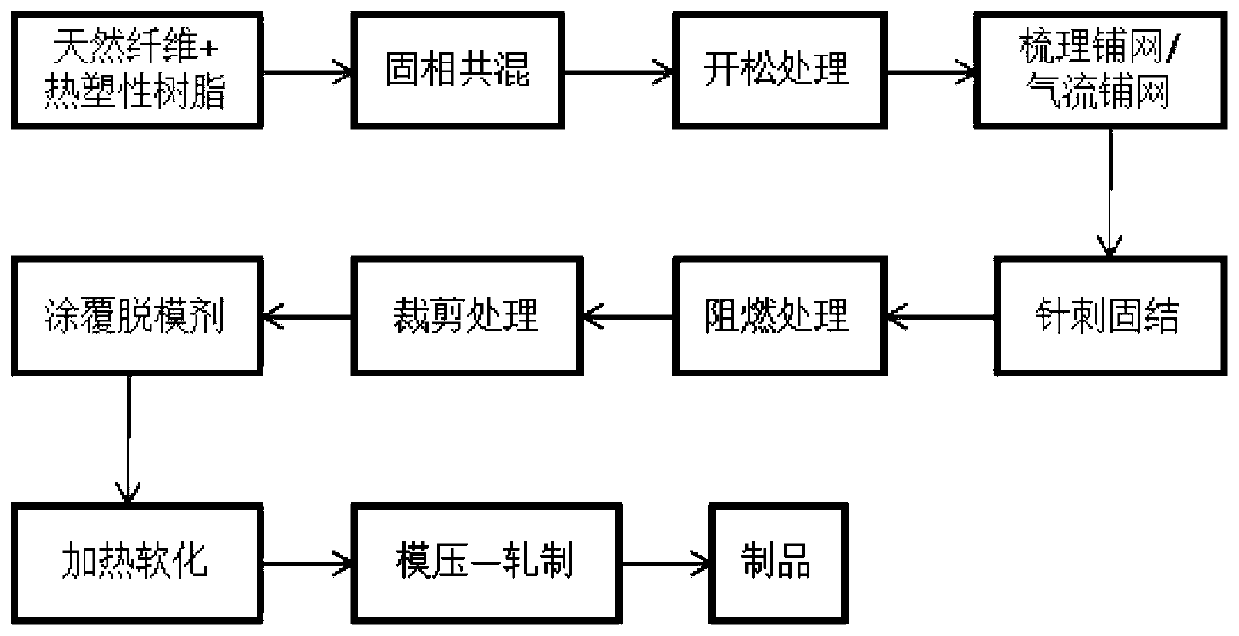

A molding-rolling compound molding process method of natural hemp fiber reinforced composite material

ActiveCN109291607BReduce consumptionIncrease productivityLamination ancillary operationsLaminationNylon 66Nylon 6

Owner:JILIN UNIV

A current-assisted composite spinning forming device and method for deep cup-shaped thin-walled parts

ActiveCN111408650BAvoid cumbersomeDiscontinuous production processShaping toolsHollow articlesSpinningMaterials processing

Owner:SOUTH CHINA UNIV OF TECH

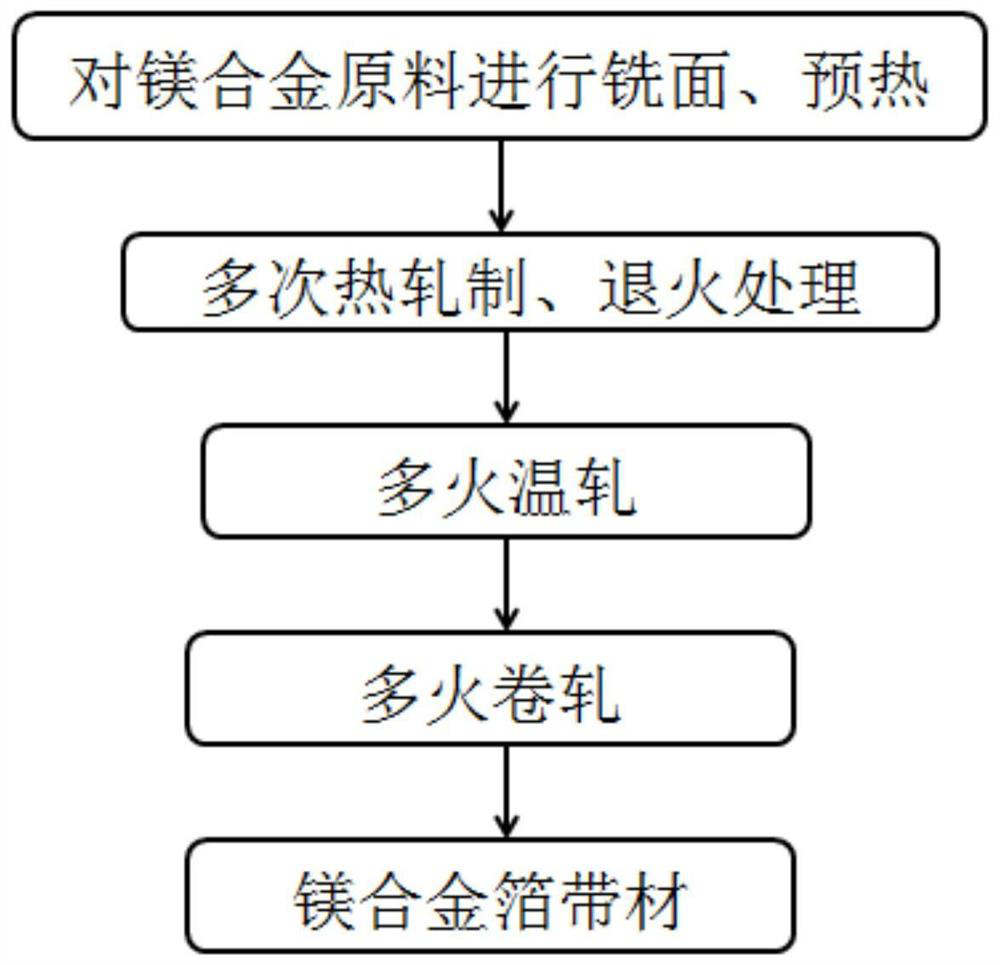

A kind of preparation technology of magnesium alloy foil strip

ActiveCN110607493BImprove deformation abilityDeformation stress reliefMetal rolling arrangementsMetallurgyMagnesium alloy

The invention discloses a preparation technology of a magnesium alloy foil belt material. The preparation technology of the magnesium alloy foil belt material includes: performing face milling treatment and preheating on magnesium alloy raw materials; preforming repeated hot rolling and annealing treatment; preforming repeated warm rolling, and circulating the annealing treatment process for multiple times; and performing annealing treatment, circulating the cold rolling process for multiple times, and obtaining the magnesium alloy foil belt material. The provided preparation technology realizes the rolling, and the thickness of the magnesium alloy foil belt material obtained by adopting the preparation technology reaches 0.06-0.1mm.

Owner:CHANGSHA ADVANCED MATERIALS IND RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com