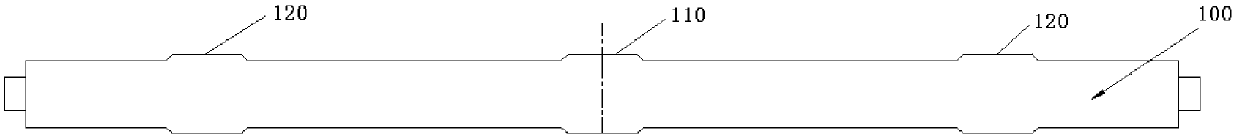

Convex foot roller for continuously casting plate blank and method for improving center segregation and porosity of continuously cast plate blank

A slab continuous casting and foot roll technology is applied in the field of slab production to achieve the effects of improving the reduction effect, reducing the center porosity and reducing the stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The above-mentioned method for improving the segregation and porosity of the continuous casting slab center was applied to a 230mm×1850mm slab continuous casting machine in a steel factory.

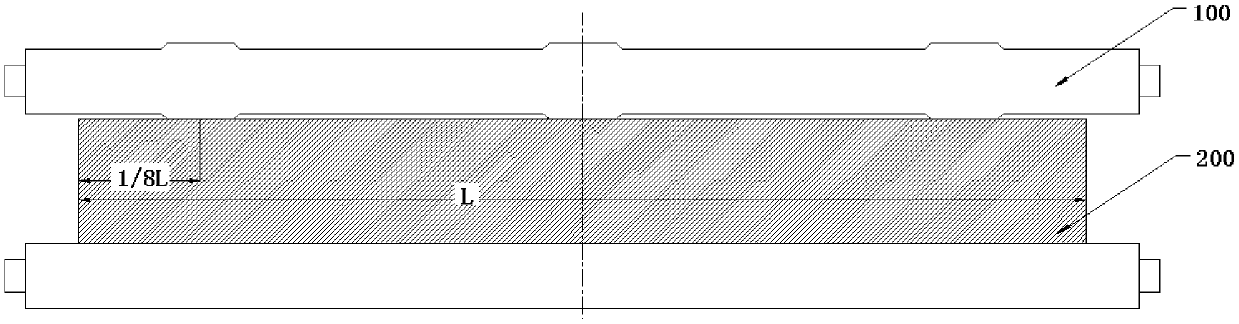

[0038] Such as figure 2 As shown, the continuous casting slab 200 entering the secondary cooling zone is subjected to reduction treatment by using a tension leveler; the tension leveler includes an upper foot roll and a lower foot roll, and the upper foot roll is any one of the above-mentioned slabs Convex footed rolls for continuous casting, the lower footed rolls are flat footed rolls;

[0039] Among them, there are 5 pulling and leveling machines for pressing;

[0040] In the drawing direction, the length of the middle protrusion 110 and the length of the side protrusions 120 of the upper foot rolls of each drawing and straightening machine are all successively reduced, and the length of the middle protrusion 110 of the first upper foot roll is 220mm, and the adjacent The len...

Embodiment 2

[0044] The above-mentioned method for improving the segregation and porosity of the continuous casting slab center was applied to a 230mm×1850mm slab continuous casting machine in a steel factory.

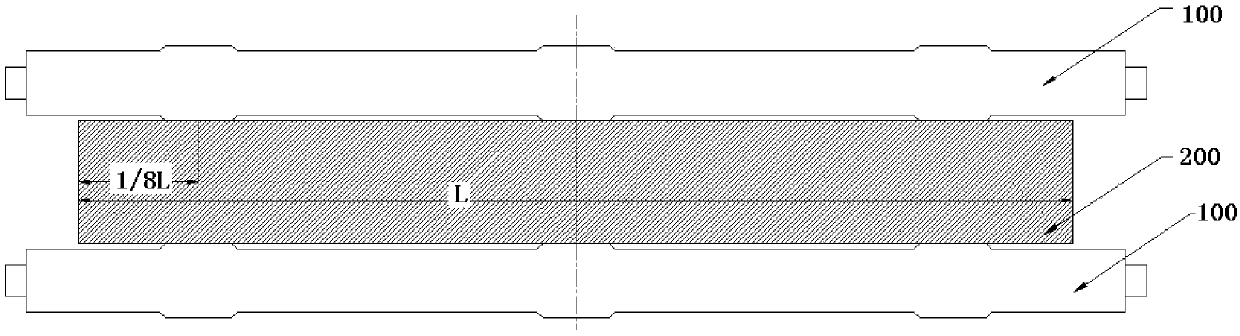

[0045] Such as image 3 As shown, the continuous casting slab 200 entering the secondary cooling zone is subjected to reduction treatment by using a tension leveler; the tension leveler includes an upper foot roll and a lower foot roll, and the upper foot roll and the lower foot roll are any The above-mentioned convex foot roll for slab continuous casting;

[0046] Among them, there are 5 tension levelers for pressing, and the upper edge of the raised structure on the lower foot roller is kept level with the upper edge of the flat roller at the front end of the secondary cooling zone;

[0047] In the drawing direction, the length of the middle protrusion 110 and the length of the side protrusions 120 of the upper and lower foot rolls of each drawing leveler decrease successively; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com