Thin-specification X65 steel-grade pipeline steel of single-stand steckel mill and rolling method

A furnace coil mill and thin gauge technology, which is applied to the rolling process of thin gauge X65 steel grade pipeline steel in a single stand furnace coil mill, and the field of rolling technology, can solve the problems of quick stop, poor shape, poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

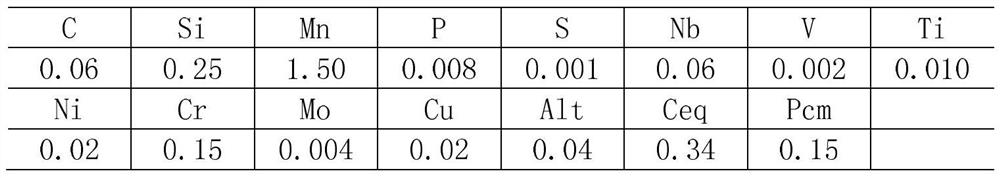

[0020] A thin specification X65 steel grade pipeline steel for a single-stand furnace coil mill, the composition of the steel is

[0021]

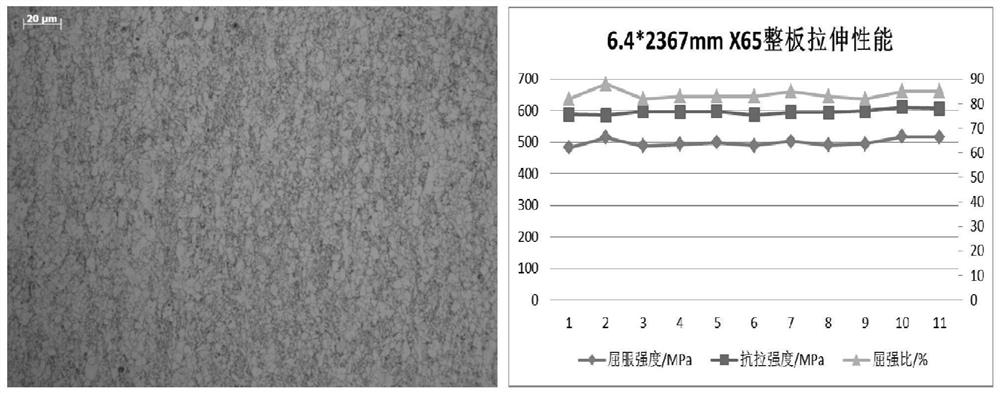

[0022] A single-stand furnace rolling mill thin gauge 6.4 × 2367mm X65 steel grade pipeline steel rolling process, billet thickness 150mm, rolling piece length 165m, the rolling process requirements are as follows:

[0023] 1) The tapping temperature is 1210°C, the temperature uniformity is 2°C, and the temperature of the coiling furnace before and after the rolling mill is set at 930°C;

[0024] 2) There are 11 rolling passes, 4 passes for rough rolling and 7 passes for finish rolling. The reduction rate of the penultimate pass is 19.5%, and the reduction rate of the last pass is 12.4%;

[0025] 3) The rolling temperature in the second stage is 1020°C, the thickness of the billet to be heated in the second stage is 45mm, and the temperature control time is 20-25s;

[0026] 4) The rolling speed of the middle pass of finishing rolling ...

Embodiment 2

[0030] A thin specification X65 steel grade pipeline steel for a single-stand steckel rolling mill, the composition of the steel is as follows by weight percentage:

[0031]

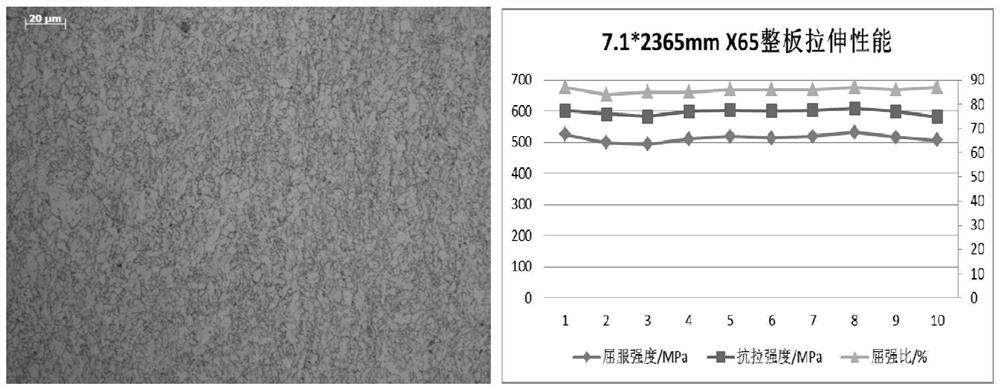

[0032] A single-stand furnace rolling mill thin gauge 7.1 × 2365mm X65 steel grade pipeline steel rolling process, billet thickness 150mm, rolling piece length 160m, the rolling process requirements are as follows:

[0033] 1) The tapping temperature is 1200°C, the temperature uniformity is 4°C, and the temperature of the coiling furnace before and after the rolling mill is set at 930°C;

[0034] 2) There are 11 rolling passes, 4 passes for rough rolling and 7 passes for finish rolling. The reduction rate of the penultimate pass is 18%, and the reduction rate of the last pass is 12%;

[0035] 3) The rolling temperature in the second stage is 1020°C, the thickness of the billet to be heated in the second stage is 48mm, and the temperature control time is 20-25s;

[0036] 4) The rolling speed of the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com