Patents

Literature

91results about How to "Increase nucleation point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diphase stainless steel and manufacturing method thereof

The invention discloses a diphase stainless steel, which comprises the following components in percentage by weight: less than or equal to 0.05 percent of C, 0.2 to 1.0 percent of Si, 0 to 2.0 percent of Mn, 22 to 27 percent of Cr, 0 to 2.0 percent of W, less than or equal to 0.1 percent of S, less than or equal to 0.03 percent of P, 0 to 0.003 percent of B, more than 0 and less than or equal to 0.2 percent rare earth of which the Ce content is more than 50 percent, and the balance of Fe and inevitable impurities, wherein a casting blank of the diphase stainless steel comprises over 60 percent of isometric crystal. A method for manufacturing the diphase stainless steel comprises the following steps of: performing smelting, die casting or continuous casting to form the casting blank, wherein the thickness of a steel die is more than 30 mm during the die casting to ensure that the cooling velocity of the steel is more than 10 DEG C per minute, and in the process of the continuous casting, the degree of superheating of the casting is between 30 and 100 DEG C, and the casting speed is over 1.2 meters per minute; putting the casting blank into a heating furnace, heating the casting blank to the temperature of between 1,100 and 1,250 DEG C, performing heat preservation on the casting blank, and then forging or hot-rolling the casting blank to a required thickness; and annealing and pickling a steel plate or a plate coil after forging or hot-rolling, and controlling the annealing temperature to be between 1,000 and 1,100 DEG C. The diphase stainless steel has high corrosion resistance and high hot-working performance, and can be widely applied in the fields of petroleum, chemical industry, papermaking, marine engineering and the like in rigorous corrosion environments.

Owner:BAOSTEEL SPECIAL STEEL CO LTD +1

Abrasion-resistant steel for low-alloy ultra-high strength engineering machine and preparation method thereof

The invention belongs to the technical field of iron-base alloy and particularly relates to abrasion-resistant steel for a low-alloy ultra-high strength engineering machine and a preparation method thereof. The abrasion-resistant steel comprises, by mass, 0.20-0.40% of C, 0.40-0.90% of Si, 0.8-2.0% of Mn, 1.00-2.50% of Cr, 0.30-0.60% of Mo, V<=0.08%, Ti<=0.04%, S<=0.004%, 0.004-0.008% of P, B<=0.002%, 0.002-0.005% of N and the balance Fe and inevitable impurities. The abrasion-resistant steel combines reasonable chemical components and a large deformation rolling process, has the advantages of being low in alloy element content, strong in strength, good in toughness, low in cost, good in abrasive resistance and the like, and is suitable for engineering machines, mining equipment, cement equipment and the like.

Owner:CENT IRON & STEEL RES INST

Preparation method of boron-containing structural steel

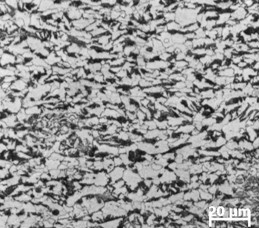

InactiveCN102080179AImprove performanceSimple rolling process and cooling processTemperature control devicePearliteChemical composition

The invention discloses a preparation method of boron-containing structural steel. The boron-containing structural steel comprises the following chemical components by weight percent: 0.08-0.20% of C, 0.10-0.30% of Si, 0.80-1.50% of Mn, no more than 0.010% of P, no more than 0.010% of S, 0.0008-0.0030% of B and the balance of Fe and inevitable impurities. The preparation method comprises the following specific steps: heating to 1175-1225 DEG C for austenitization, and then performing multipass rolling, wherein the deformation temperature is between the austenitic recrystallization region and austenitic unrecrystallization region and the austenite-ferrite two-phase region; and then cooling to 600-660 DEG C at a cooling rate of 1-10 DEG C / s, and then performing air cooling. The boron-containing structural steel prepared by the method provided by the invention mainly contains ferrite, bainite and a small amount of pearlite. The structural steel has the advantages of uniform structure, fine grain and good strength and toughness.

Owner:NANJING IRON & STEEL CO LTD

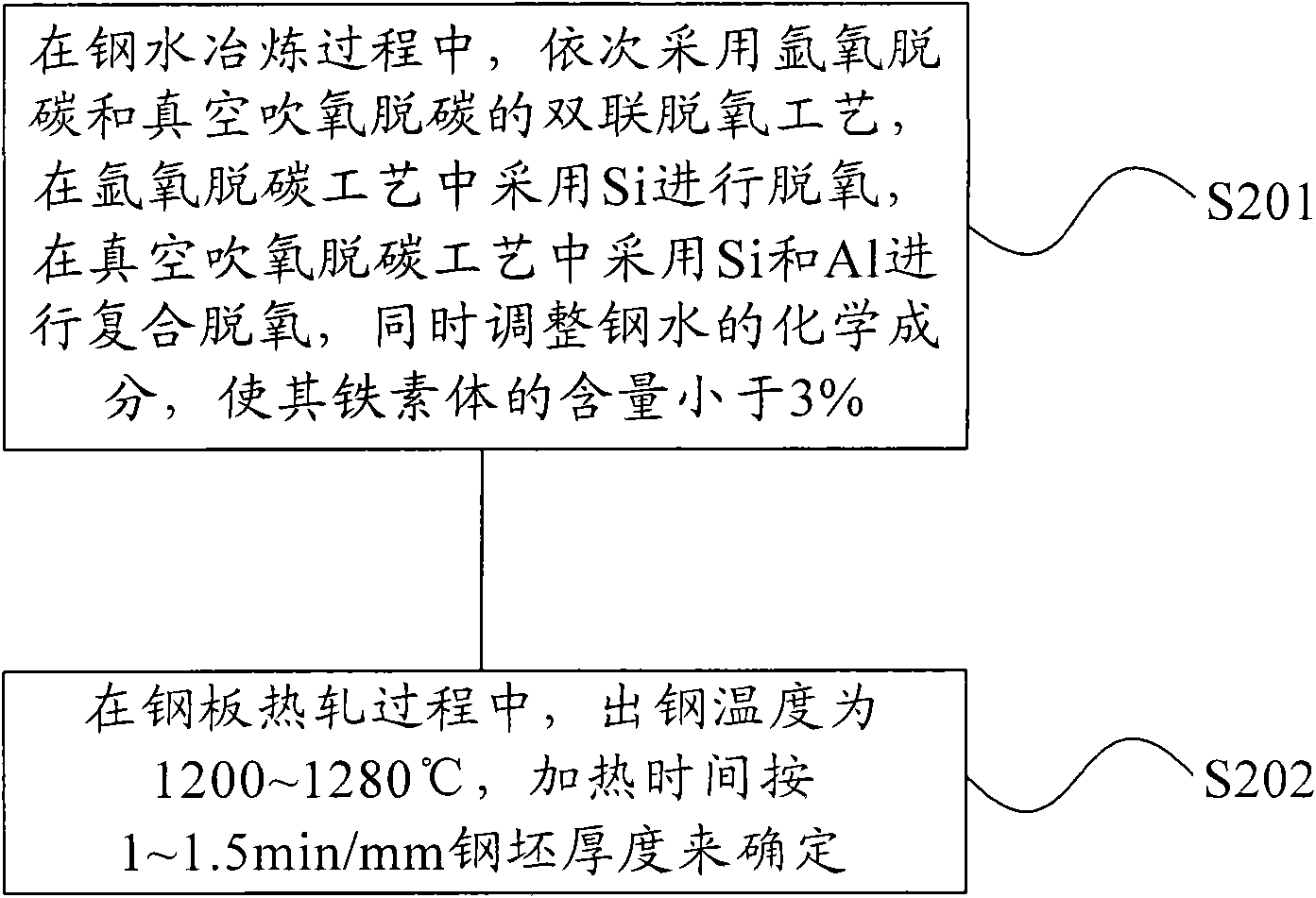

Austenitic stainless steel plate and manufacture method thereof

The invention provides an austenitic stainless steel plate which is composed of the following chemical compositions in percentage by weight: less than or equal to 0.03% of C, 0.3-1.0 % of Si, 0.8-2.0% of Mn, less than or equal to 0.003% of S, less than or equal to 0.03 % of P, 16.0-20.0% of Cr, 10.0-14.0% of Ni, 1.0-3.0% of Mo, less than or equal to 0.08% of N, less than or equal to 0.004% of O, 0.005-0.01% of optional Ca and / or 0.001-0.003 % of optional B and the balance of Fe and other inevitable impurities, wherein the weight percentage of Ni, Mn, N, C, Cr, Mo and Si also satisfies that the content of ferrite delta in the steel plate is less than 3%. Correspondingly, the invention also provides a manufacture method of the austenitic stainless steel plate. By the technical scheme, the austenitic stainless steel plate of the invention has good surface quality and does not have the surface defects, such as liner scale, inclusion, peeling, crazes and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

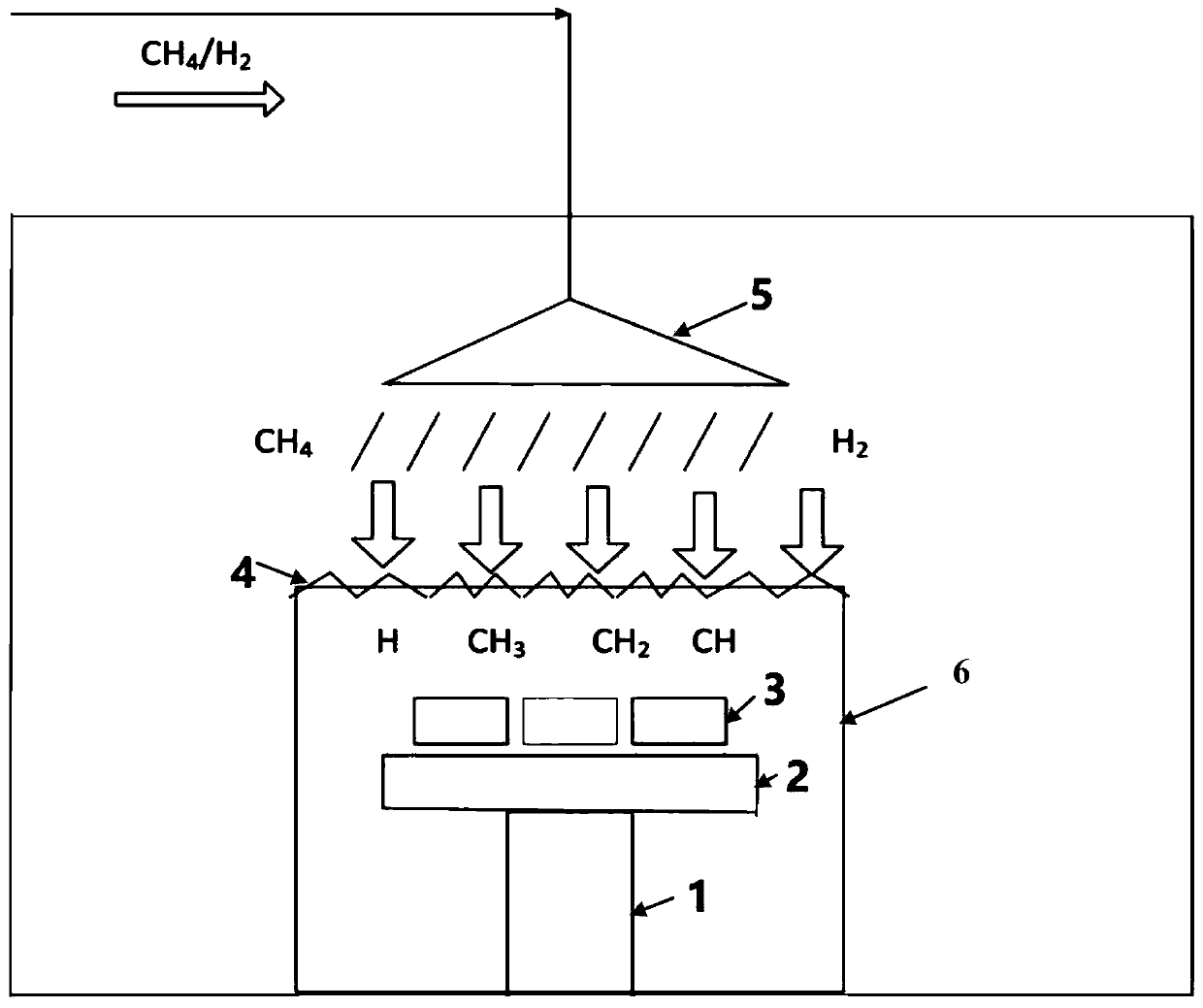

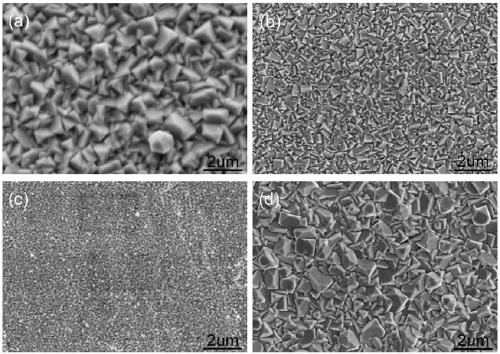

Gradient diamond and graphite composite self-lubricating antifriction engineering ceramic coating and preparation method thereof

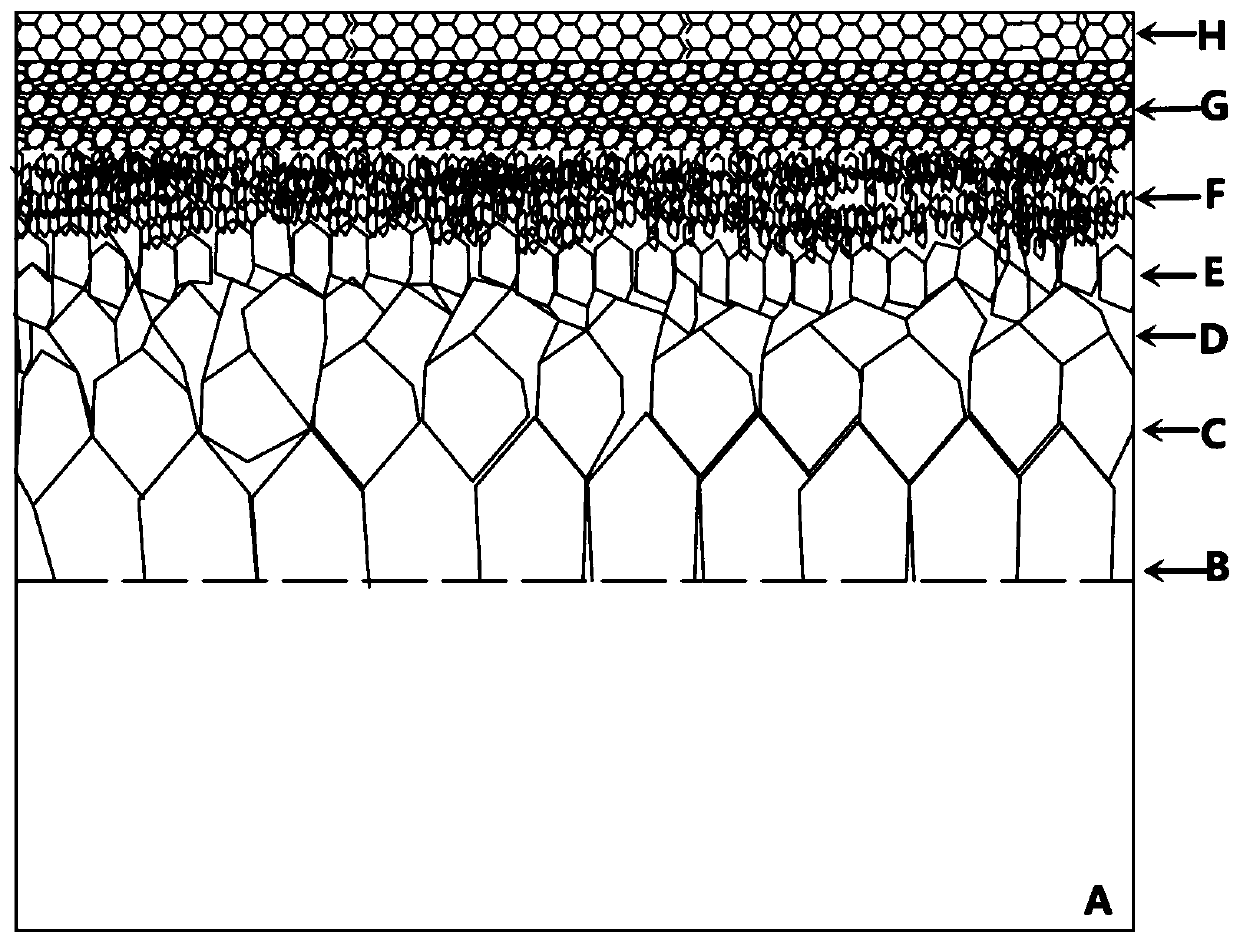

ActiveCN110205604AGood internal stepped growth structureImprove toughnessChemical vapor deposition coatingCeramic coatingWear resistant

The invention provides a gradient diamond and graphite composite self-lubricating antifriction engineering ceramic coating and a preparation method thereof, and belongs to the field of full-ceramic bearing self-lubricating wear-resistant coatings. The coating is sequentially composed of multiple stages of size-progressive diamond coatings and multiple graphite coatings from the surface of an engineering ceramic substrate to the outside; each stage of the size-progressive diamond coating comprises multiple micro-crystal diamond coatings, multiple sub-micron-crystal diamond coatings and multiplenanocrystal diamond coatings; and the diameters of crystal grains of diamonds in every two adjacent diamond coatings are stepwise decreased from the surface of the engineering ceramic substrate to the outside. The gradient diamond and graphite composite self-lubricating antifriction engineering ceramic coating is prepared through a hot filament chemical vapor deposition method. The coating is a first-stage stepwise-changed or multistage stepwise-changed micron / submicron / nano-diamond and graphite coating, the internal toughness and the surface hardness of the coating are improved, and the bonding strength of graphite and diamond coatings or the diamond coatings and the engineering ceramic substrate is enhanced. Under the limiting conditions, the durability is good, and the self-lubricatingproperty is stable.

Owner:SHENYANG JIANZHU UNIVERSITY

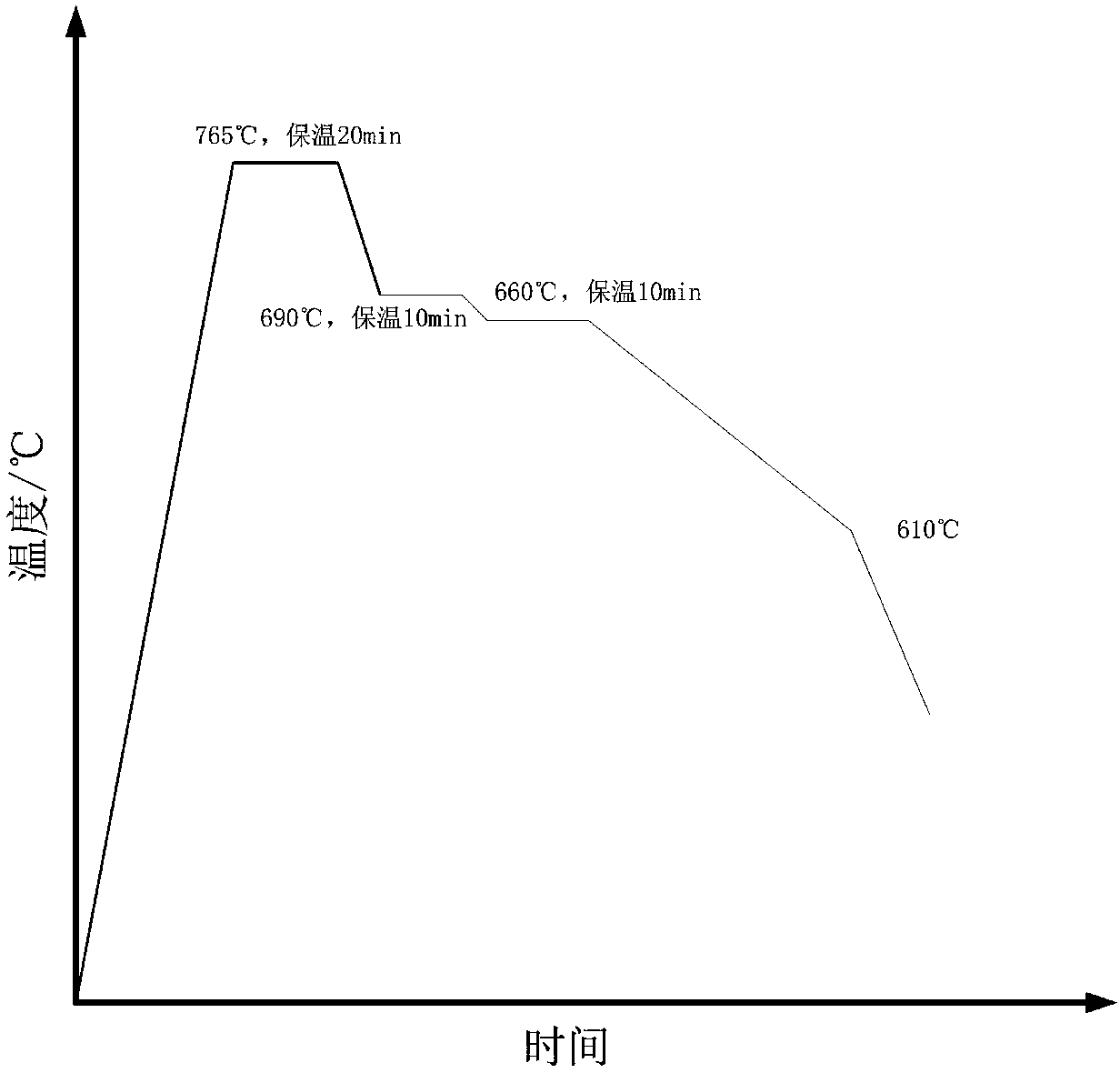

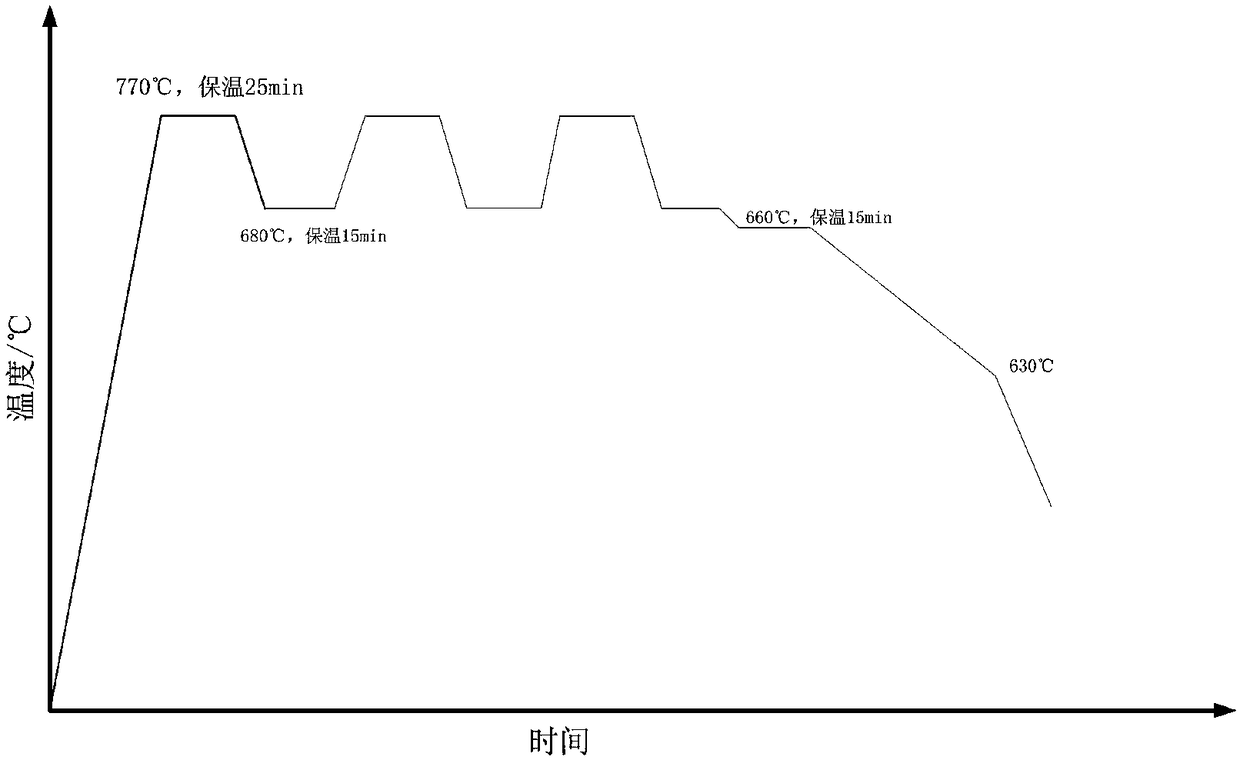

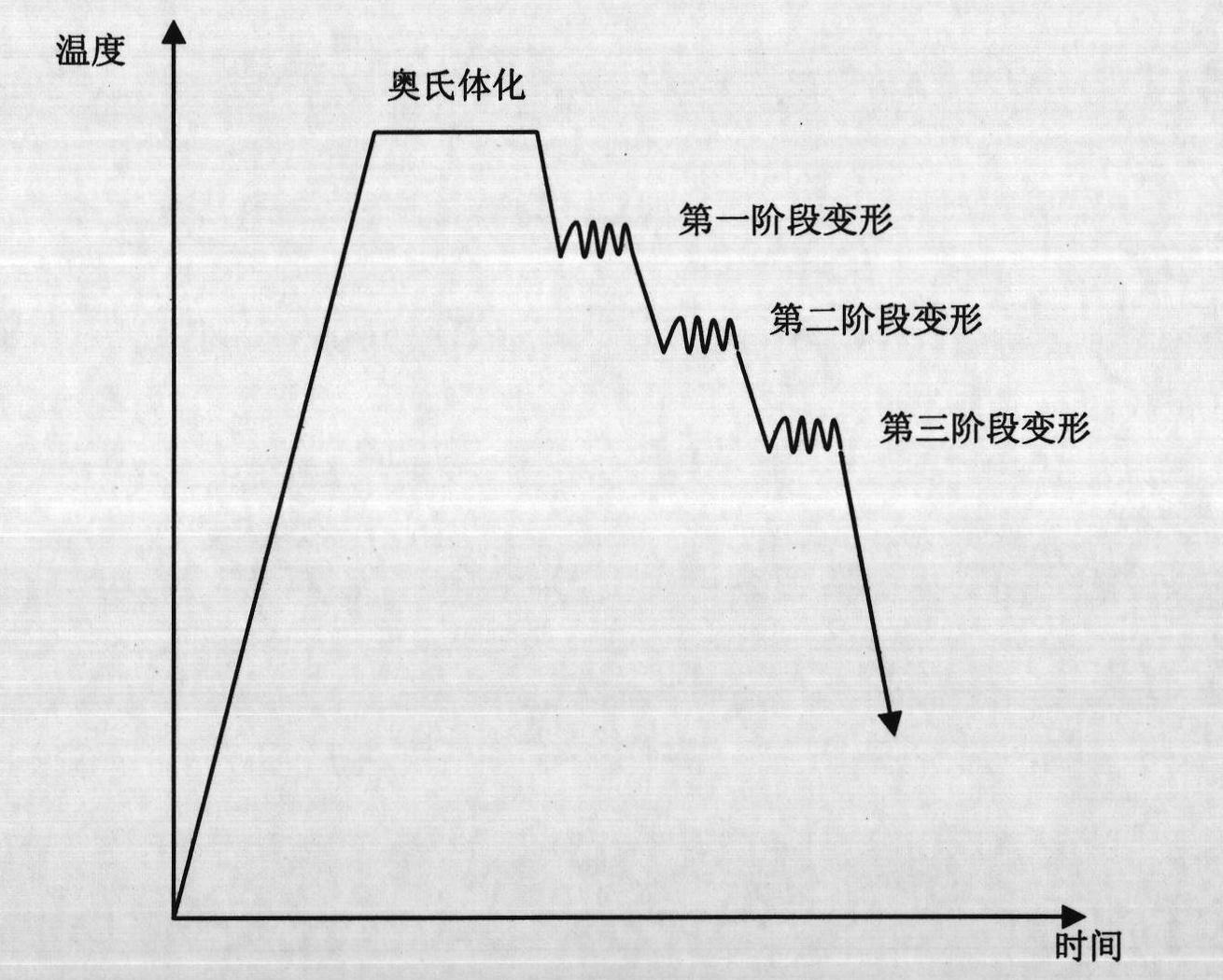

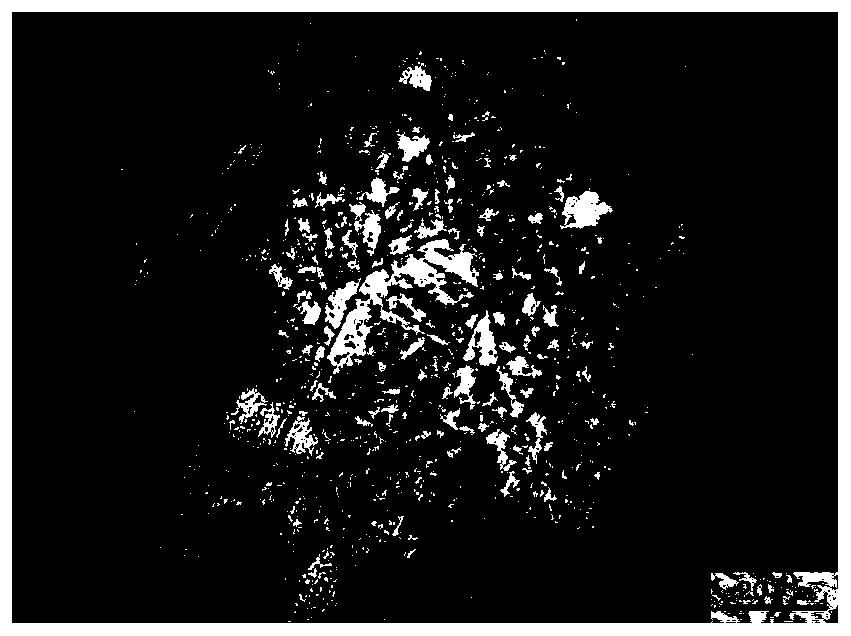

Quick spheroidizing annealing process of bearing steel tubes

InactiveCN108300843AFast spheroidizationReduce solubilityFurnace typesHeat treatment furnacesDouble phaseRoom temperature

The invention provides a quick spheroidizing annealing process of bearing steel tubes. The quick spheroidizing annealing process comprises the following steps: 1), heating the bearing steel tubes until Ac1 reaches 20 DEG C to 30 DEG C or above, and keeping a temperature for 20 minutes to 30 minutes; 2), cooling the bearing steel tubes subjected to heat insulation at a first time until Ar1 reaches10 DEG C to 30 DEG C or below, and keeping the temperature for 10 minutes to 20 minutes; 3), repeatedly carrying out the step 1) and the step 2), and performing circulating heat treatment for many times on the bearing steel tubes subjected to heat insulation at a second time; 4), cooling the bearing steel tubes subjected to heat treatment for many times along with a furnace to 680 DEG C, and keeping the temperature for 10 minutes to 20 minutes; 5), cooling the bearing steel tubes subjected to heat insulation in the step 4) along with the furnace to 610 DEG C to 650 DEG C; and 6), performing air cooling on the bearing steel tubes subjected to furnace cooling to a room temperature. Isothermic spheroidizing treatment, that is, circulation austenitizing and isothermic spheroidizing processes,on the bearing steel tubes in a double-phase area is carried out repeatedly, thinner sheet carbide formed in cooling of austenite is re-dissolved, precipitated and separated on undissolved carbide particles, and thicker sheet carbide is crushed to realize quick spheroidizing, and the spheroidizing annealing time is shortened at the same time.

Owner:JIANGSU FANLI STEEL TUBE

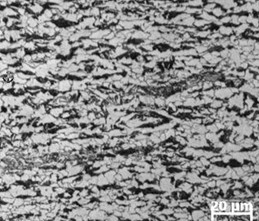

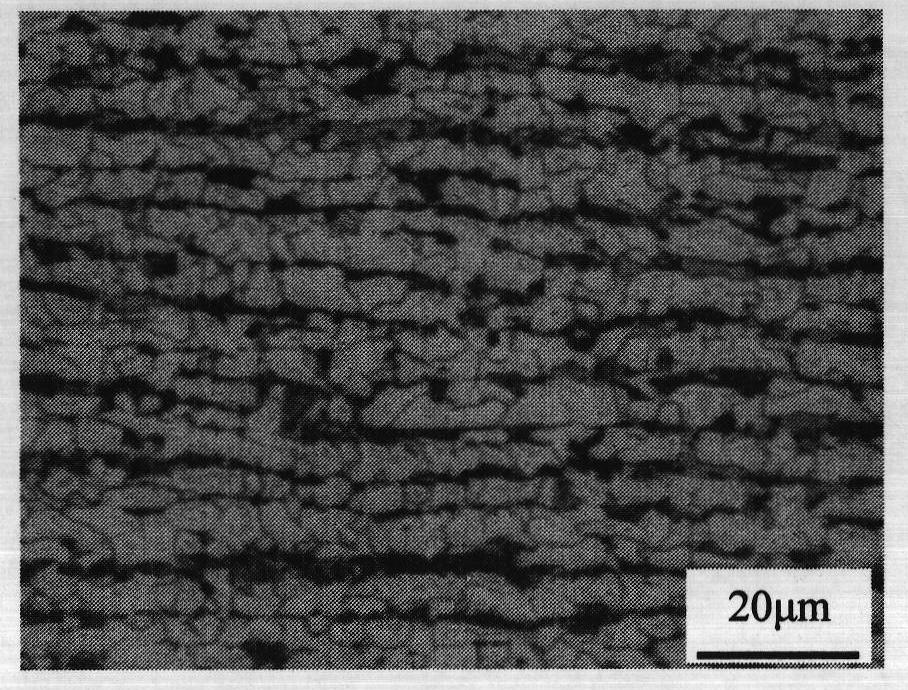

Method for making ultrafine grained steel

InactiveCN102011045AGrain stabilizationInhibition of inverse phase transitionRoll mill control devicesMetal rolling arrangementsMass storageManganese

The invention discloses a method for making ultrafine grained steel, comprising the steps of: heating carbon steel to a temperature of 1200-1240DEG C to carry out austenization, wherein the carbon steel contains 0.02-0.20% of carbon and 0.40-1.60% of manganese by mass fraction; controlling to roll by using an austenite recrystallization area and an austenite non-recrystallization area; performing another deformation near an Ar3 temperature by combining the deformation induced ferrite transformation technology so as to restrain the reverse transformation from the ferrite to the austenite after twice transformation, accumulate mass storage energy of the second transformation, increase the nucleation points of the ferrite, and promote the increase of the volume fraction of the ferrite; and finally cooling to a temperature of 600-650DEG C at a cooling speed of 1-10DEG C / micron for air cooling. The ferrite grain dimension of the prepared ultrafine grained ferrite steel is less than 3.0 microns. The manufacturing method of the ultrafine grained steel does not need large deformation and ultrafast cooling process, and has small mill load and simple process; and the obtained room-temperature ultrafine ferrite grains are stable.

Owner:NANJING IRON & STEEL CO LTD

Environment-friendly monocrystalline silicon piece texturing liquid and preparation method thereof

InactiveCN105113009AEffective control of surface tensionImprove surface propertiesAfter-treatment detailsBetaineGlycerol

The invention discloses environment-friendly monocrystalline silicon piece texturing liquid. The environment-friendly monocrystalline silicon piece texturing liquid is characterized by being prepared from, by weight, 0.5-1 part of sodium hydroxide, 3-5 parts of additives, 2-4 parts of sodium citrate, 0.5-1 part of dodecyl dimethyl betaine, 0.2-0.4 part of coco fatty acid diethanol amide, 0.01-0.02 part of konjac glucomannan, 1-2 parts of glycerin, 0.1-0.2 part of polysorbate-80 and 80-100 parts of water. By means of the environment-friendly monocrystalline silicon piece texturing liquid, the consistency and the repeatability of the texturing technology are effectively improved, and the density of the texturization surface is increased, so that the efficiency of a solar cell is improved, and the production quality is improved; IPA is not contained, environmental protection and human health are facilitated, the main raw materials are easy to degrade, residues in the environment do not exist, pollution does not exist, and the environment-friendly monocrystalline silicon piece texturing liquid is green and environmentally friendly.

Owner:CHINALAND SOLAR ENERGY

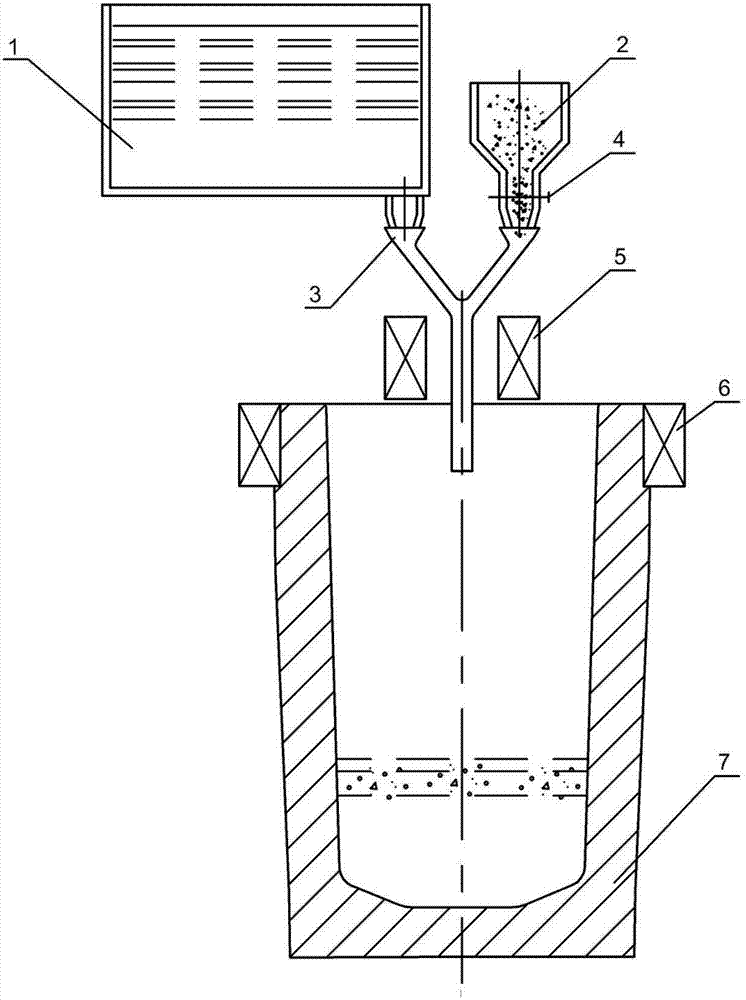

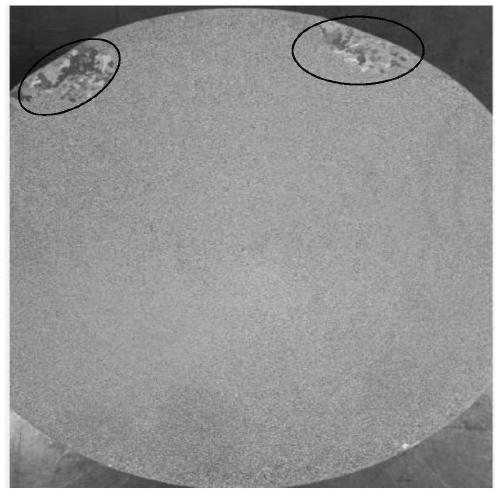

Method for manufacturing large ingot through electromagnetically-controlled self-inoculation treatment

The invention relates to a method for manufacturing a large ingot through electromagnetically-controlled self-inoculation treatment. The method comprises the steps as follows: (1) a Y-shaped double-phase conveying nozzle is adopted for molten metal casting, and an electromagnetic device I is arranged on the outer side of the straight section of the double-phase conveying nozzle; an electromagnetic device II is arranged on the outer side of an ingot mold riser; (2) an ingot mold and the double-phase conveying nozzle are preheated before casting; (3) argon shielding is performed during casting, an inoculant is added when the liquid level of molten metal rises to 1 / 2-2 / 3 of the height of an inner cavity of the ingot mold, meanwhile, the electromagnetic device I is started, and the electromagnetic device II is started when the liquid level of molten metal rises to the height of the ingot mold riser line; and both the electromagnetic device I and the electromagnetic device II run at the low frequency; (4) after casting is completed, the electromagnetic device I is shut down, the electromagnetic device II s adjusted to run at the intermediate frequency from the low frequency, and heat insulation is performed on the ingot mold riser part by the aid of the Joule heating effect of the intermediate-frequency magnetic field until the ingot is solidified. With the method, the solidification structure of the steel ingot can be refined, the center segregation can be reduced, the center porosity can be reduced, and thus the inner and outer quality of the ingot can be improved.

Owner:UNIV OF SCI & TECH LIAONING

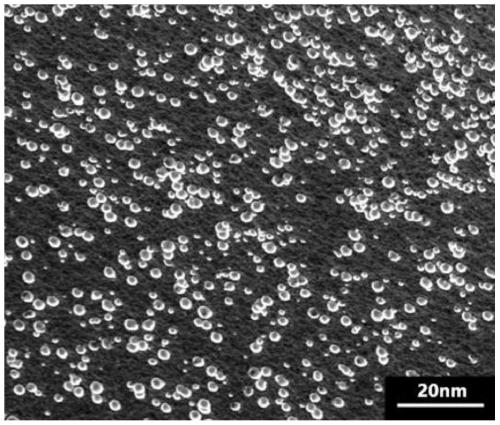

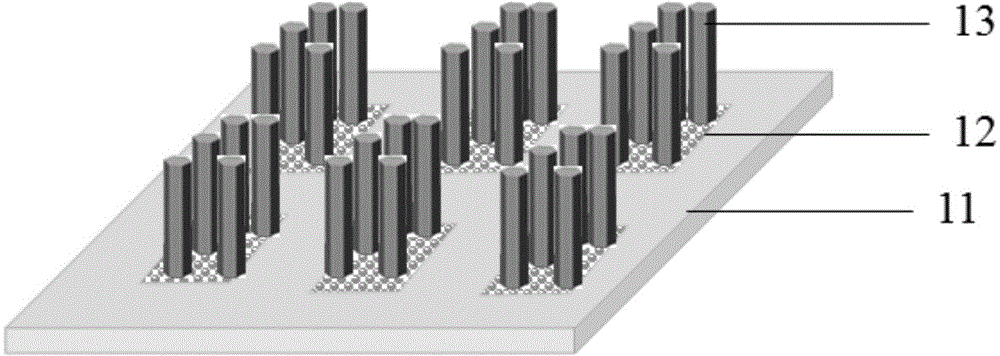

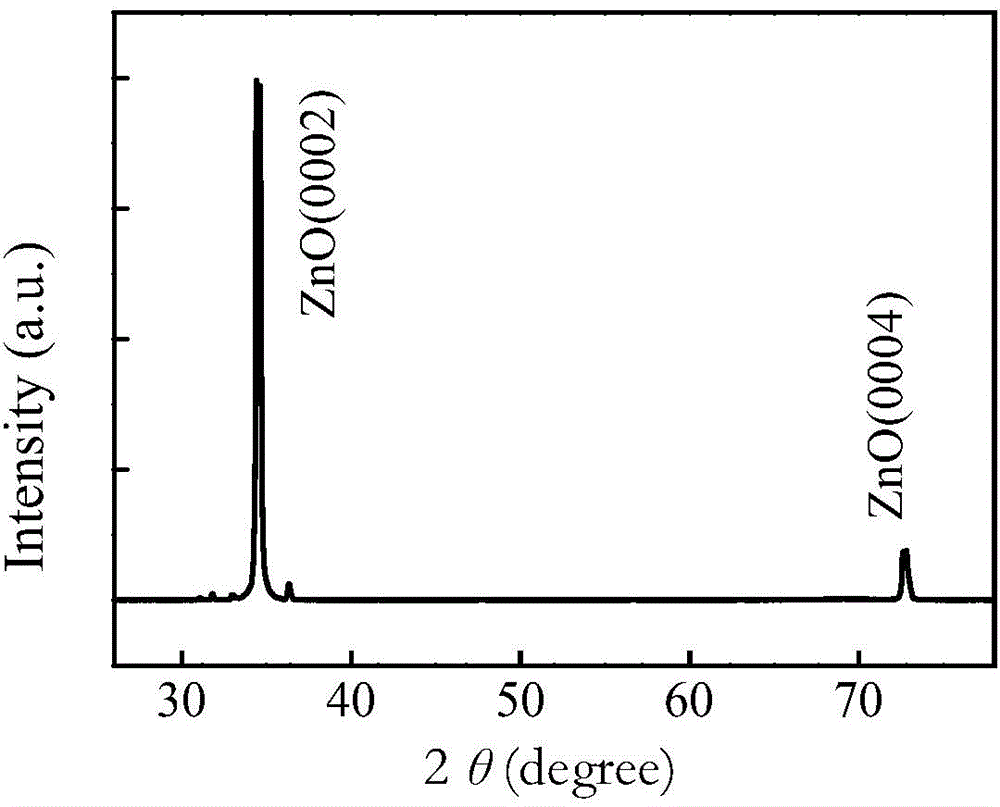

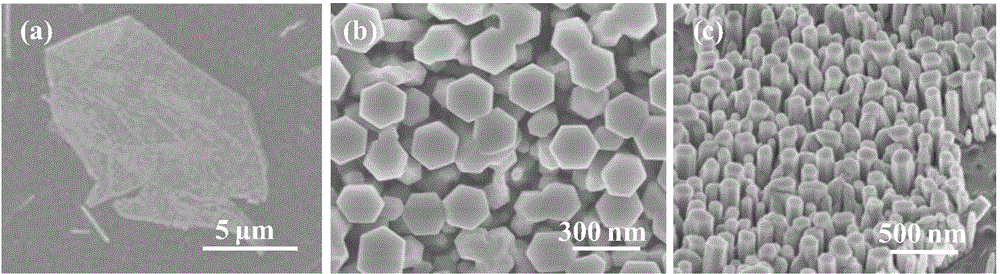

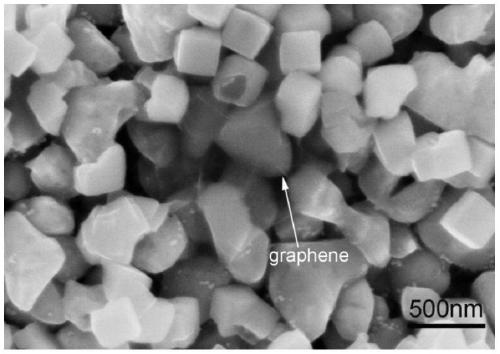

ZnO grading nanoarray on graphene substrate and preparation method and application thereof

InactiveCN104894640AIncrease nucleation rateIncrease nucleation pointPolycrystalline material growthFinal product manufactureCvd grapheneThermal conductivity

The invention discloses a ZnO grading nanoarray on a graphene substrate and a preparation method and application thereof. A graphene nanosheet substrate and grading ZnO nanoarray on the graphene nanosheet substrate area included. The grading ZnO nanoarray on the graphene nanosheet substrate is grown without catalytic CVD graphene. The invention also discloses the preparation method and application of the grading ZnO nanoarray. Compared with the prior art, the invention has the advantages of no need of deposition metal catalyst and deposition of other nucleation layer; and the prepared ZnO nanoarray can be transferred to a flexible substrate as well as to a high thermal conductivity substrate, and is conducive to the preparation of efficient, flexible, high-performance ZnO-based devices.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

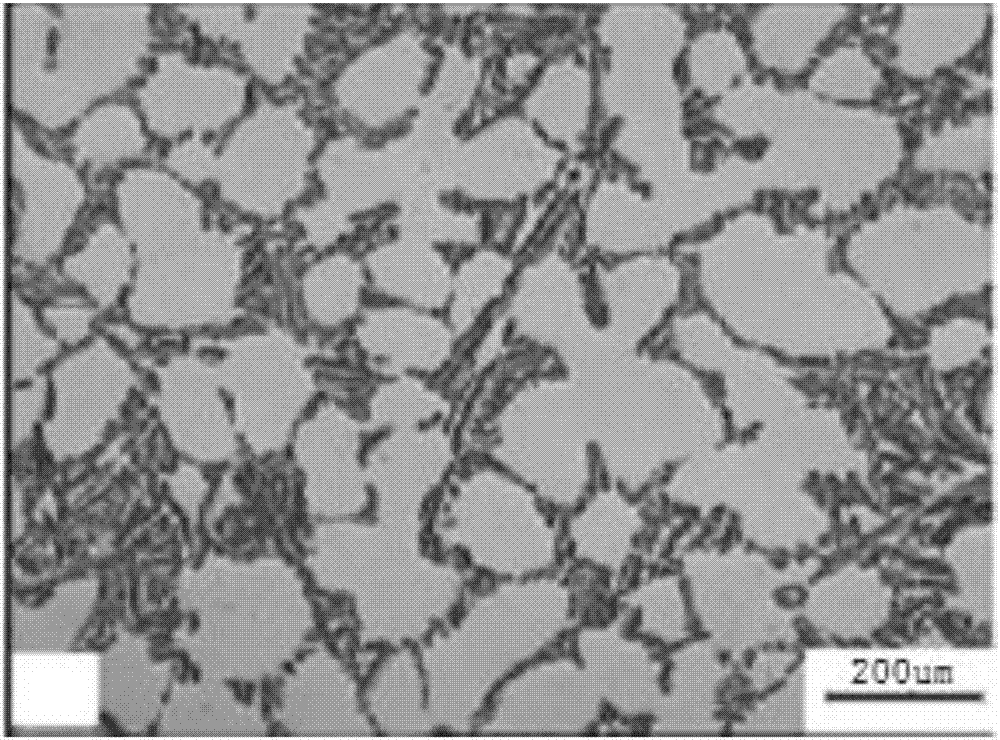

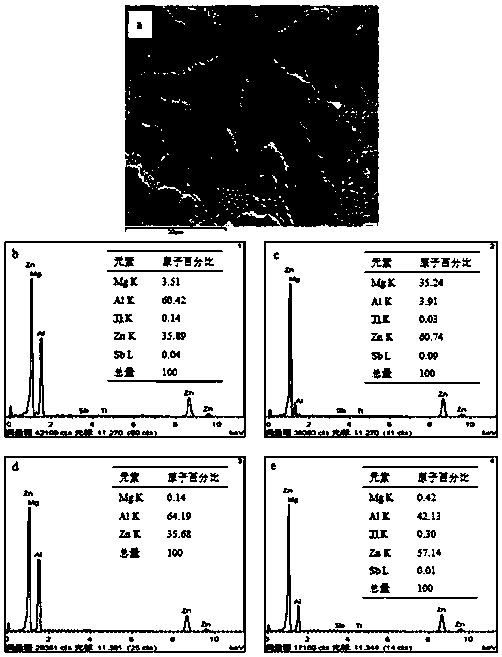

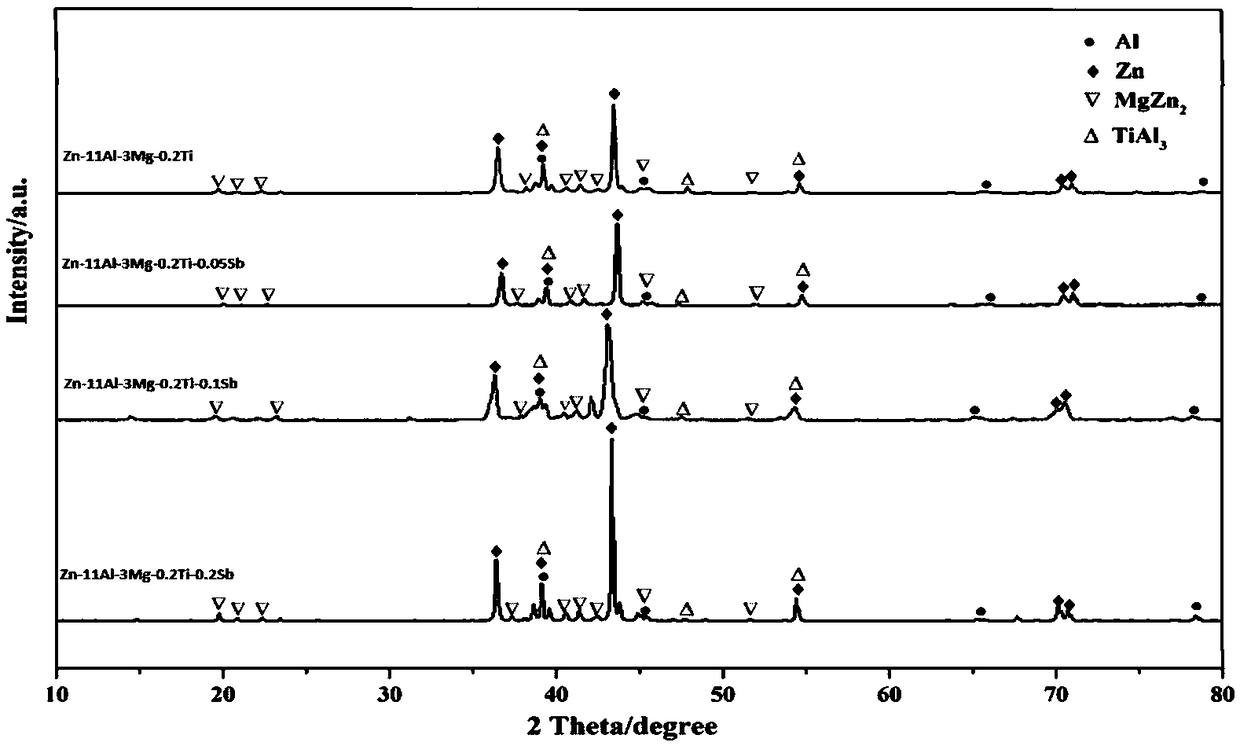

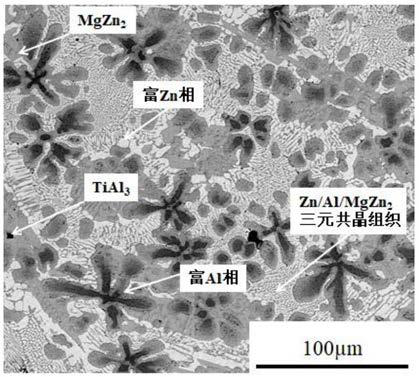

Titanium and antimony-containing hot dipping zinc plating aluminum magnesium alloy and preparation method thereof

ActiveCN108977695AReduce lossIncrease nucleation pointHot-dipping/immersion processesTitaniumNucleation

The invention relates to the field of anticorrosion of steel and iron materials, in particular to a titanium and antimony-containing hot dipping zinc plating aluminum magnesium alloy and a preparationmethod thereof. The alloy is prepared from Zn, Al, Mg, Ti and Sb elements in percentage by mass: 10.0 to 12.0 weight percent of Al, 2.5 to 3.5 weight percent of Mg, 0.1 to 0.2 weight percent of Ti, 0.1 to 0.2 weight percent of Sb and the balance of Zn. Through the addition of Ti and Sb elements in the zinc aluminum magnesium alloy, the flowability of the zinc liquid is enhanced; the zinc loss isreduced; meanwhile, the nucleation points of an aluminum-rich phase are increased; the aluminum-rich dendrite arm length is shortened, so that the crystal grain tissues of the aluminum-rich phase arerefined; the layer sheet space of the eutectic tissues is reduced, so that the eutectic tissues become fine and compact; the comprehensive performance of the alloy is effectively improved; the anti-scratch performance and anti-corrosion performance of the hot dipping zinc plating aluminum magnesium alloy are finally improved; meanwhile, big zinc patterns can be promoted to be formed on the surfaceof the plating layer; the appearance decorative performance of the plating layer is improved.

Owner:UNIV OF JINAN

Aluminum alloy ingot and production technology thereof

The invention provides an aluminum alloy ingot. The aluminum alloy ingot comprises an aluminum ingot and aluminum plate waste, wherein the mass ratio of the aluminum ingot to the aluminum plate wasteis 4:1-10:1. The invention further provides a production technology of the aluminum alloy ingot. The production technology comprises the following steps that (1) raw materials are smelted, wherein thealuminum ingot and the aluminum plate waste are placed into a smelting furnace for smelting; (2) primary refining and slagging-off are carried out in an upper furnace body; (3) the mixture is put into a lower furnace body for refining and slagging-off; (4) sampling is performed, the content of Si and Mg in molten aluminum is adjusted by adding magnesium ingots and silicon ingots, and step (3) andstep (4) are repeated until the content of each chemical element in the molten aluminum reaches a target value; (5) gas and slag are removed, and the molten aluminum is purified; (6) the molten aluminum is cast into an aluminum bar, and Al-Ti5-B0.2 wires are added in the casting process; (7) high-temperature annealing is carried out; and (8), the head and tail portions of the aluminum bar are cutoff after being discharged from the furnace and cooled. According to the aluminum alloy ingot, the defects of coarse grains and feather-shaped crystals on the edge of the ingot are reduced.

Owner:苏州铭恒金属材料科技有限公司

Method for preparing phenolic foam containing expanded graphite

The invention discloses a method for preparing phenolic foam containing expanded graphite. According to the method, firstly, polyacrylic acid is adopted to modify expanded graphite; secondly, gamma-epoxy propoxy propyl trimethoxy silane is adopted to modify expanded graphite so that silane modified expanded graphite alkene can be prepared; finally, phenolic resin containing expanded graphite is prepared through reaction between phenol and paraformaldehyde, and phenolic foam is further prepared. By means of the method, the defects that the mechanical property of phenolic foam is poor, fragility is large, and dreg falling occurs frequently can be effectively improved, the mechanical property of phenolic foam is improved, and phenolic foam has a wider application prospect range.

Owner:JIANGNAN UNIV

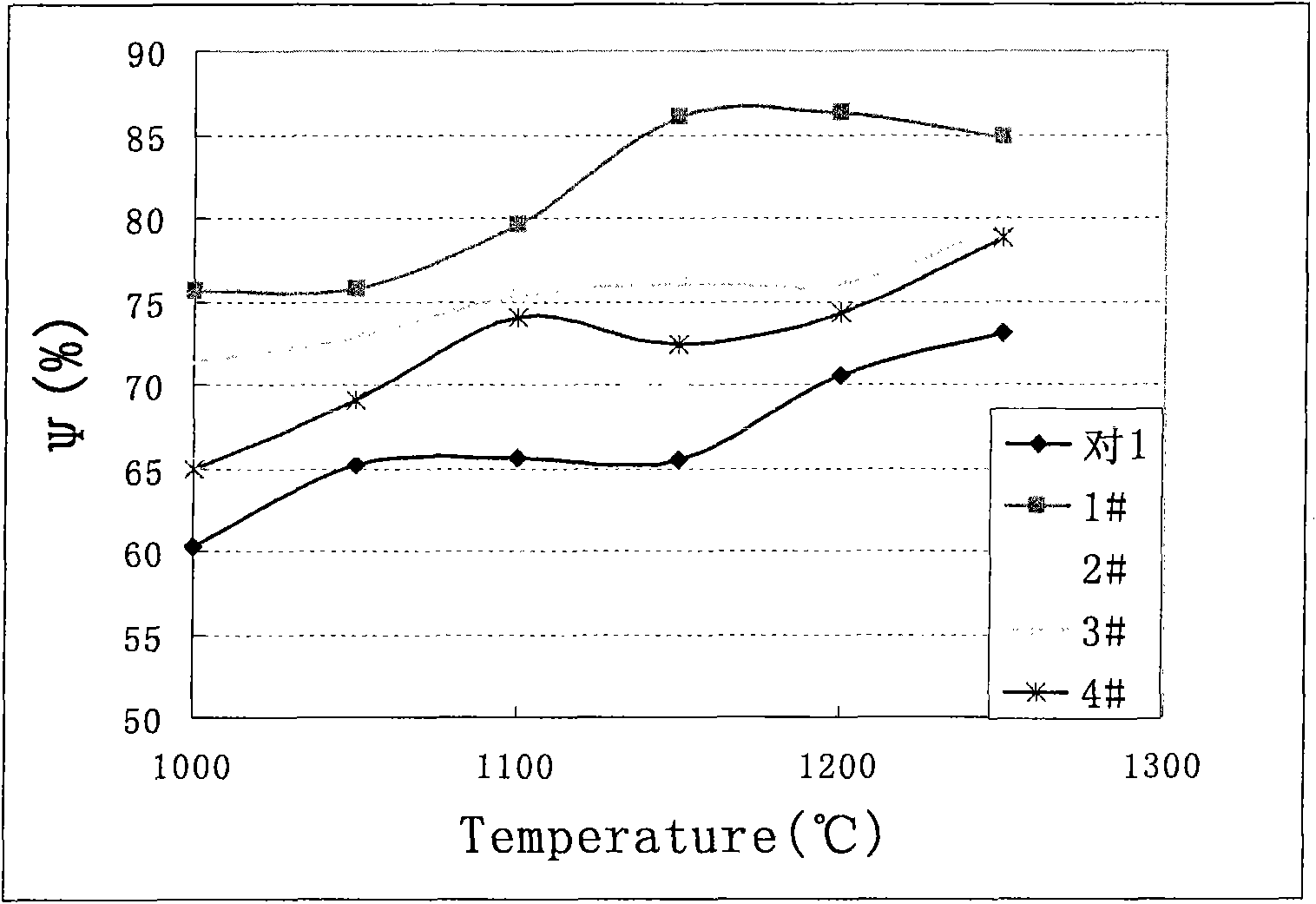

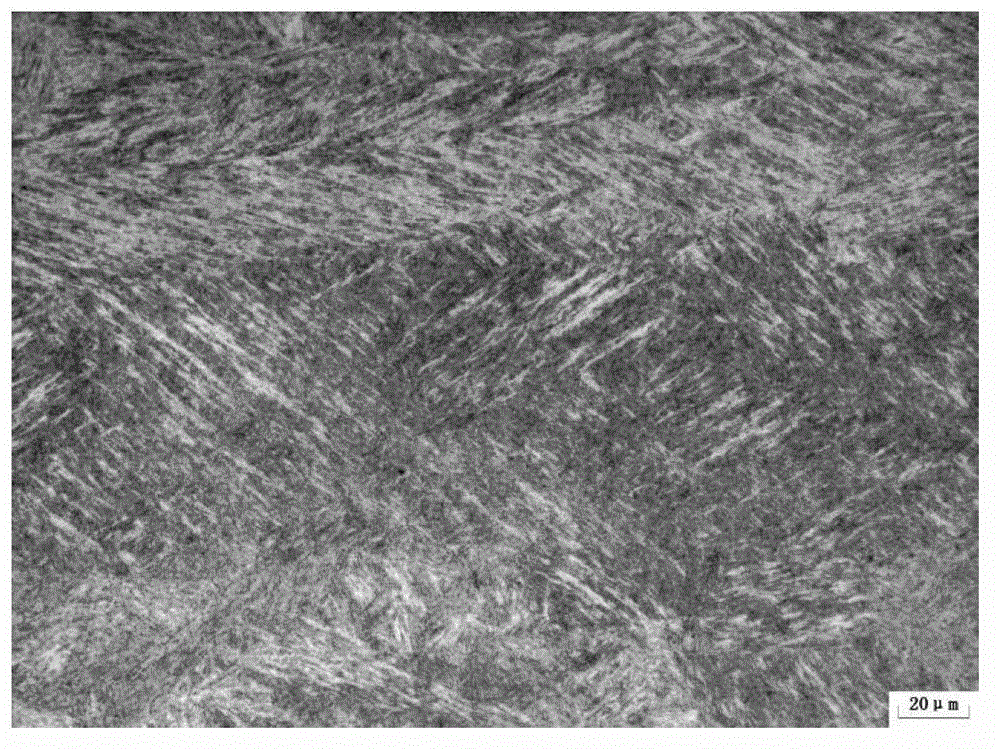

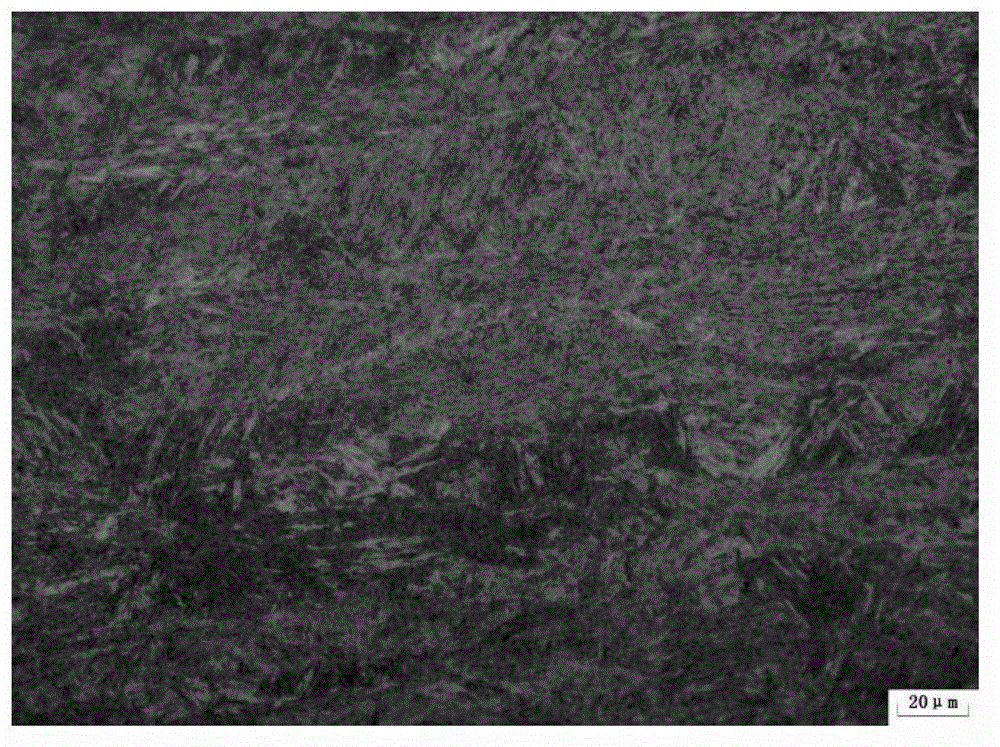

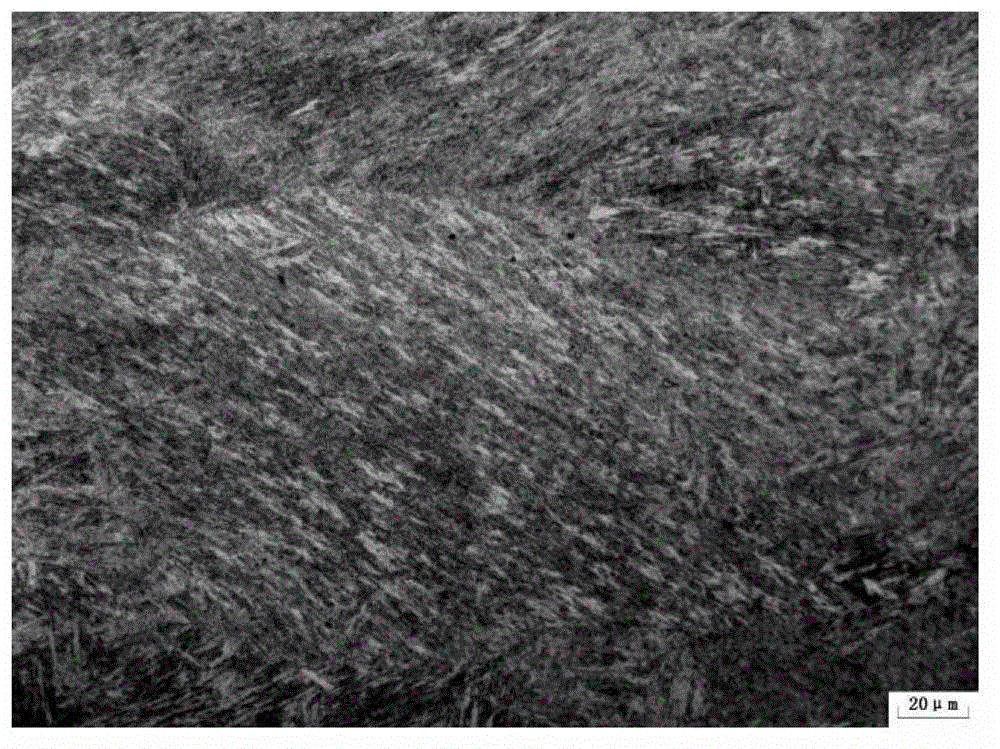

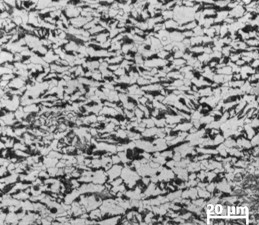

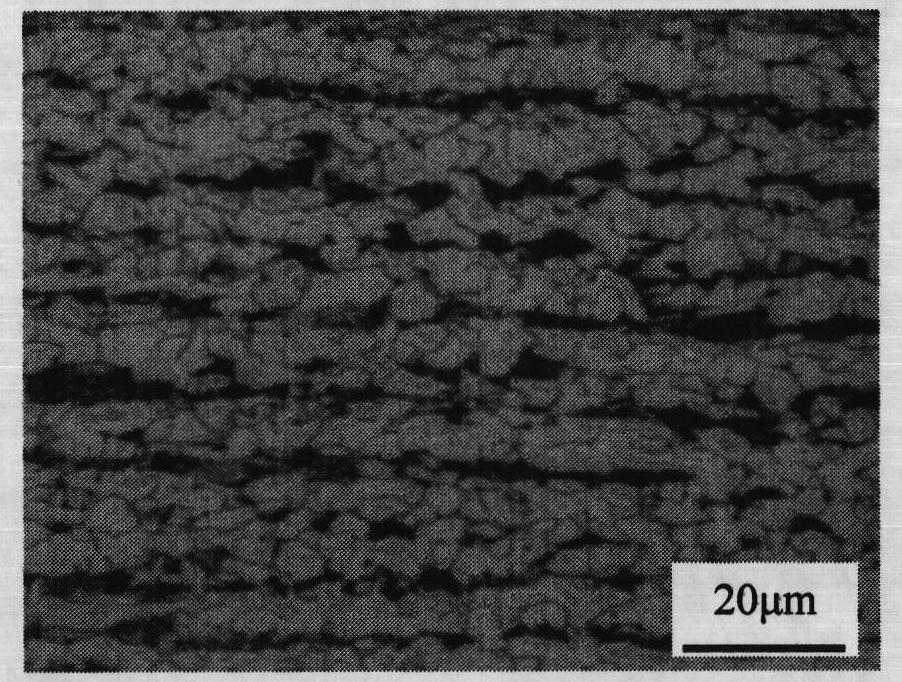

Rolling process of improving 38CrMoAl steel rolling state structure

InactiveCN110180893AImprove uniformityRefined grain sizeTemperature control deviceMetal rolling arrangementsMetallurgyNucleation

The invention discloses a rolling process of improving a 38CrMoAl steel rolling state structure. The rolling process is characterized by comprising the following steps of 38CrMoAl steel blank selection, steel blank heating, steel blank rough rolling, steel blank medium rolling, steel blank finish rolling and steel cooling. The rolling process of improving the 38CrMoAl steel rolling state structurehas the following advantages that a relatively low final rolling temperature is controlled, so that the surface temperature of a rolled piece is lower than a temperature of a core portion in the process, the steel core portion obtains a relatively large compressive stress in the rolling process, the structure uniformity is greatly improved, and crystal grains are further refined; the final rolling temperature is lowered to be close to the actual critical phase change point Ar3, a phase change from gamma to alpha is promoted, and a nucleation site of ferrite is increased, so that a structure morphology of a product is ferrite and pearlite structures in a balanced state; and the rolling process is green and environmentally friendly, does not pollute the environment, is capable of lowering the cost and increasing the benefit and particularly has important significance of controlling the online structure and the performance of medium-low carbon alloy structural steel.

Owner:XINING SPECIAL STEEL +1

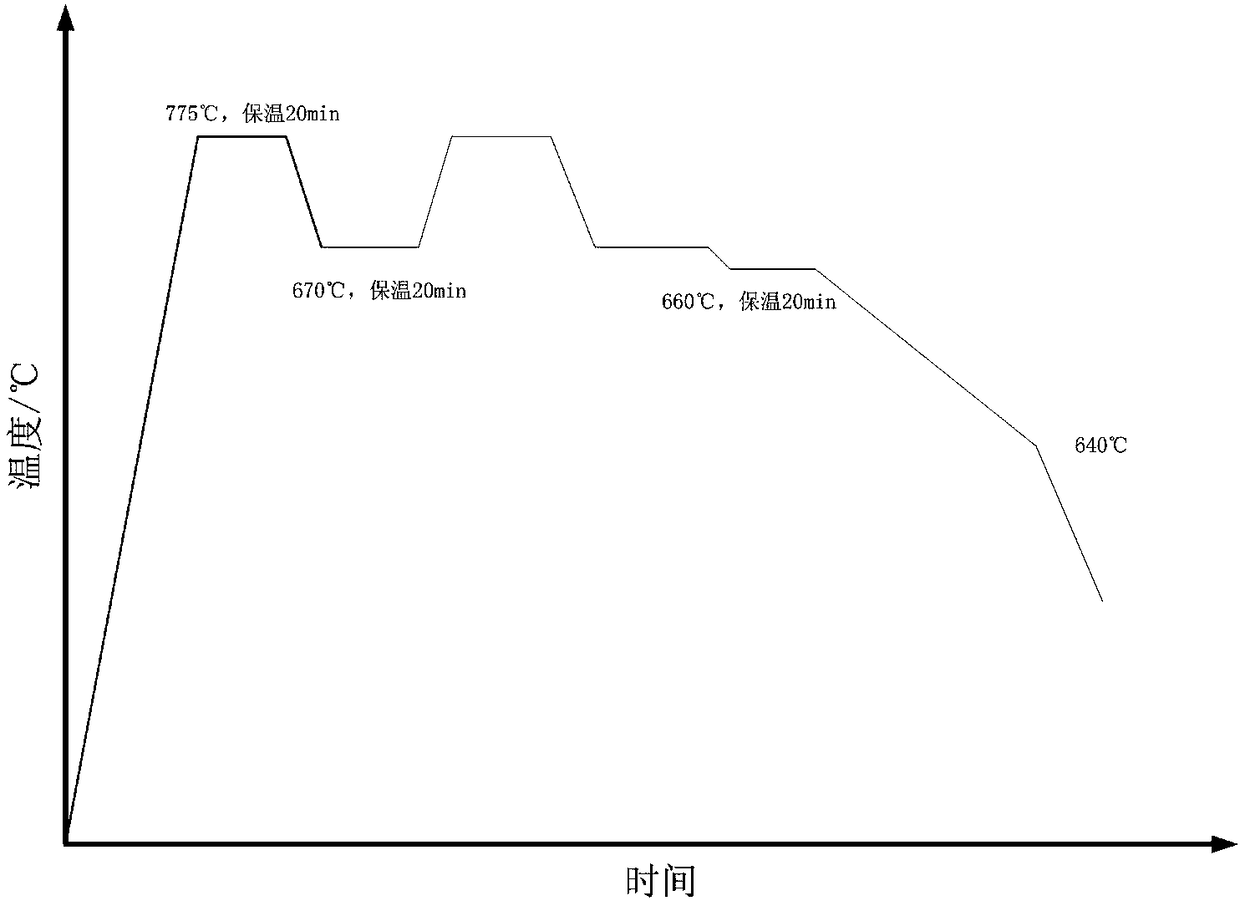

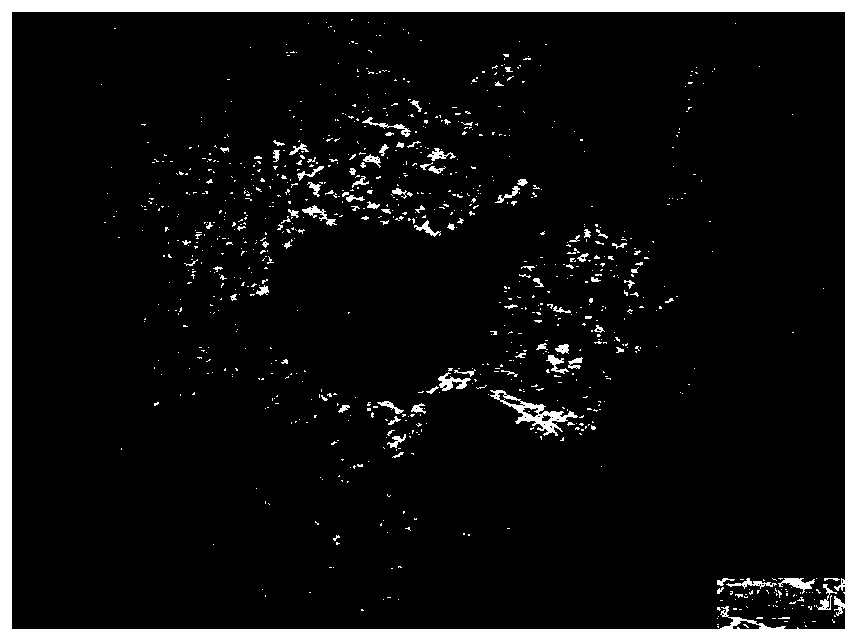

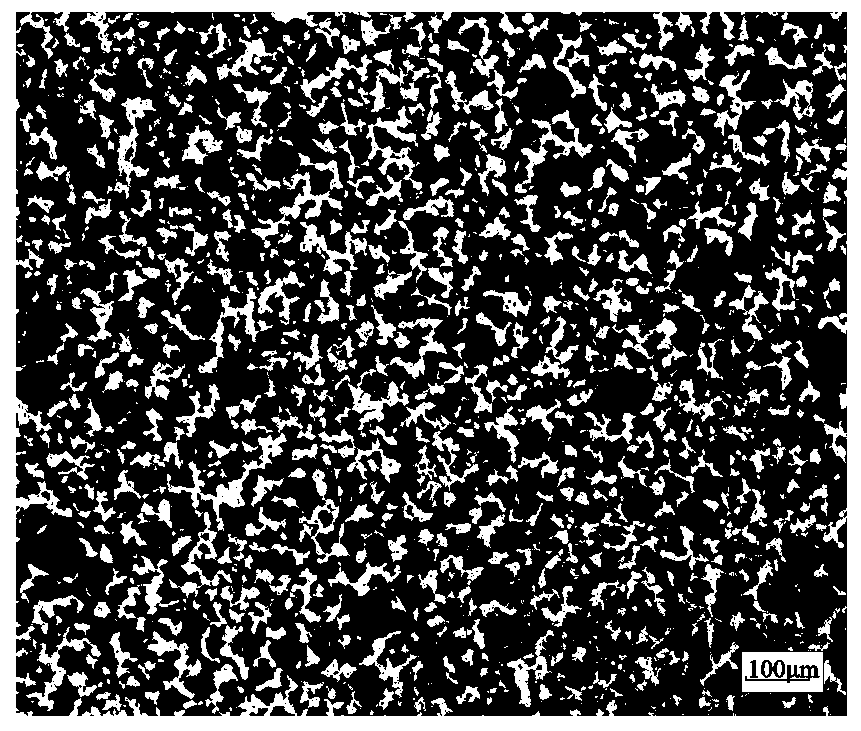

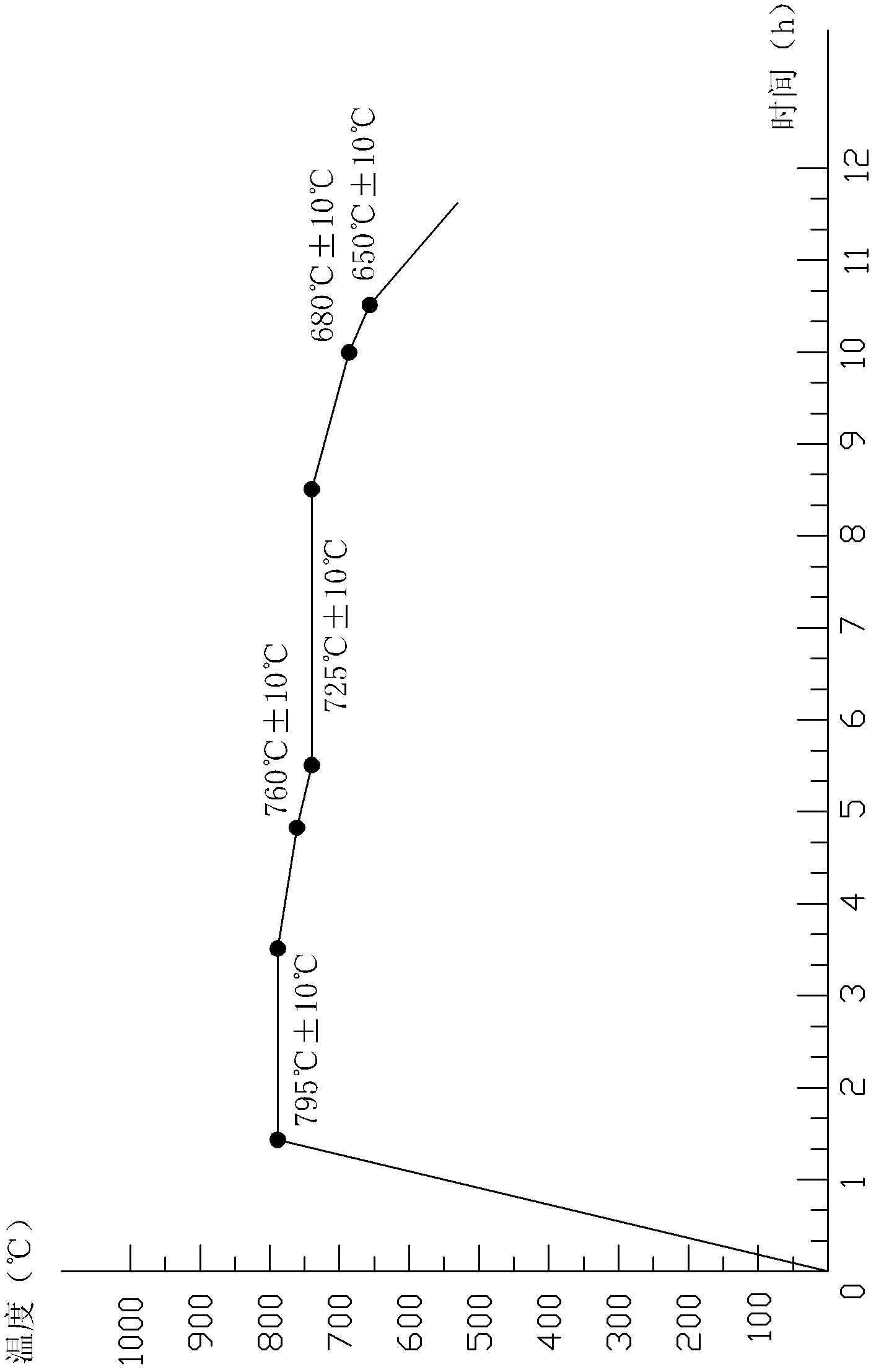

Quick spheroidizing annealing technology for GCr15 bearing steel pipe

ActiveCN102382962BShort stayPrevent precipitationFurnace typesHeat treatment furnacesRetention timeCarbide

The invention discloses a quick spheroidizing annealing technology for a GCr15 bearing steel pipe. The technology comprises the following steps of: performing water passing quick cooling on the hot-rolled perforated GCr15 bearing steel pipe with the final rolling temperature of between 950 and 1,000 DEG C through a controlled cooling device to the temperature of between 550 and 650 DEG C, and performing first air cooling to room temperature; spheroidizing and heating the GCr15 bearing steel pipe to the temperature of 795+ / -10 DEG C after the first air cooling is finished, and performing firstheat preservation; performing first slow cooling to the temperature of 760+ / -10 DEG C; performing second quick cooling to the temperature of 725+ / -10 DEG C; performing second heat preservation; performing second slow cooling to the temperature of 680+ / -10 DEG C; performing furnace cooling to the temperature of 650+ / -10 DEG C; and finally, discharging and performing second air cooling. The technology has the advantages of effectively shortening the retention time of the netlike carbide precipitation interval, inhibiting the precipitation of netlike carbides, obtaining good spheroidized structure in short time and greatly shortening the spheroidizing time.

Owner:ZHEJIANG JIANLI CO LTD

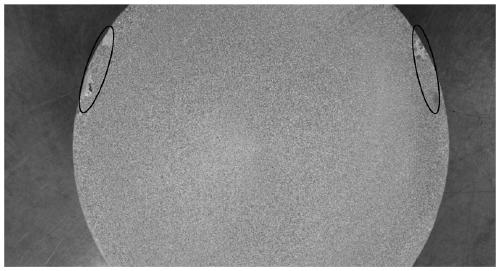

A Method for Effectively Eliminating Center Defects of Solidified Billet and Refining Solidified Structure

The invention discloses a method for effectively eliminating the central defect of a solidification blank and refining a solidification structure. The method relates to preparation of various castings with dead heads, round continuous casting blanks with the diameter of between phi 100 and phi 2,000 millimeters, square continuous casting blanks with the thickness of between 100 and 1,500 millimeters, 5-700-ton mould casting steel ingots, casting blanks and hollow blanks, is applied to preparation of carbon steel, alloy steel and non-ferrous metal under conditions of vacuum and non vacuum, andhas an inhibitory action on cavity shrinkage and loosen of various casting which are provided with the dead heads and made of black alloy material, the steel ingots and casting blanks. For the steel ingot and the casting, a vibration device is arranged in a steel ingot dead head after completion of pouring, and for the continuous casting blank, the vibration device is arranged in a crystallizer during pouring; the vibration device is connected with a refractory material; the refractory material is immersed in metal liquid and used for vibrating the metal liquid to increase the number of primary crystallization of the metal liquid; and a crystal nucleus is triggered to fall under the action of vibration to increase nucleation particles inside the steel ingot, eliminate cavity shrinkage andloosen inside the steel ingot, the casting and the casting blanks and refine the solidification structure.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

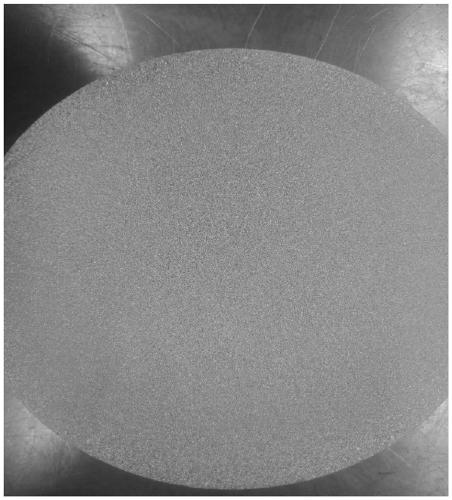

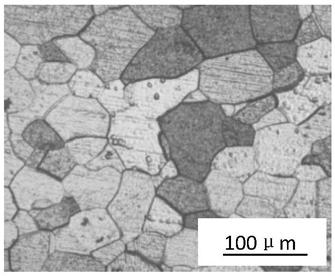

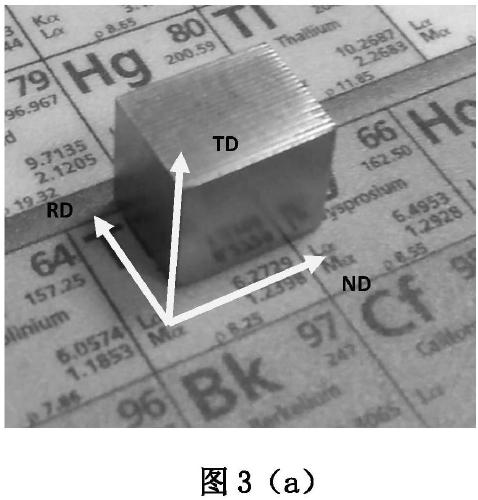

Ultra-pure tantalum with controllable tissues and textures and preparation method and application thereof

ActiveCN109338316AEliminate defects such as shrinkage and porosityPrevent oxidationVacuum evaporation coatingSputtering coatingHardnessUltimate tensile strength

The invention relates to an ultra-pure tantalum with controllable tissues and textures and a preparation method and application thereof. The purity of ultra-pure tantalum is greater than or equal to 99.995%, the grain size degree is 45-80 [mu]m, the{100} texture content is not greater than 15% in the thickness direction of a panel, the {111}texture content is greater than or equal to 33%, the ultimate strength is 372-410 MPa, the yield strength is 260-287 MPa, the ductility is 41-46%, and the hardness is 87-89 HV. The preparation method comprises the steps of high vacuum degree (10<-4>Pa) electron beam smelting furnace, argon chamber stainless steel sleeve packaging, three-dimension heat forging cogging of cooperative control of gate forging deformation amount and total deformation amount,multiple variable angle control rolling and heat treatment, turning, packaging and the like. According to the process, the distribution of grain sizes and the grain size degree of finished products can be effectively controlled, and the finished products and texture distribution of the finished products in the thickness direction are effectively regulated and controlled. Necessary conditions areprovided for the finished products to be used as high-quality target materials.

Owner:CENT SOUTH UNIV +1

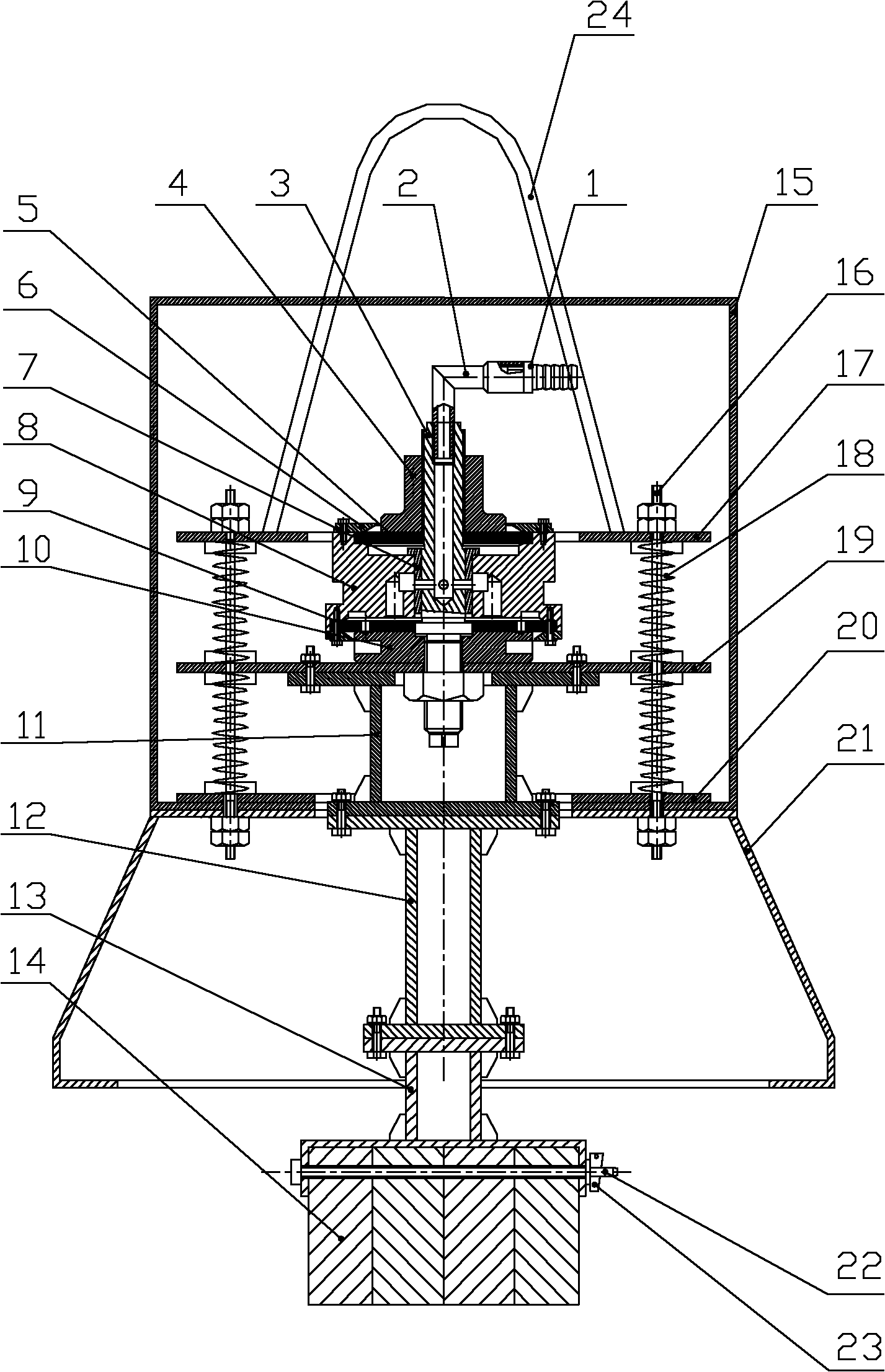

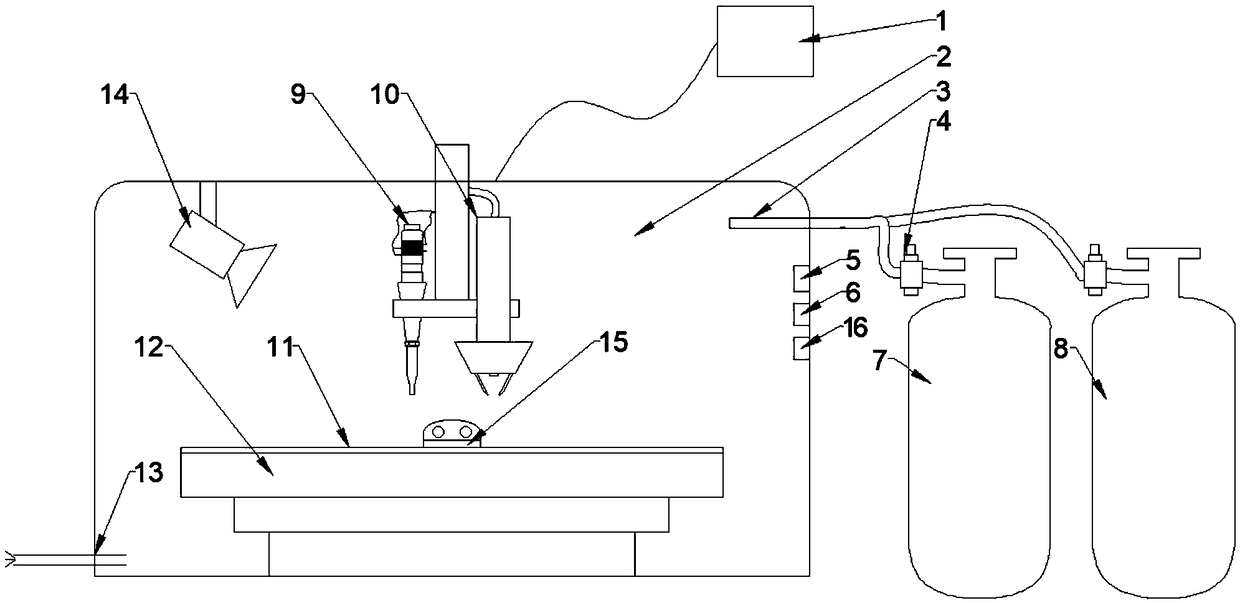

Device for refining additive manufactured titanium alloy grains

PendingCN109128171ARefine tissue performanceBroaden your mindAdditive manufacturing apparatusIncreasing energy efficiencyTitanium alloyVolume deformation

The invention relates to a device for refining additive manufactured titanium alloy grains, belonging to the technical field of additive manufacturing. The device comprises an atmosphere protection box, an additive manufacturing system, an external force volume deformation system, a gas supply system and a control system. The atmosphere protection box is a sealed box body, one side of the box bodyis provided with a mixed gas inlet, the opposite side of the box body is provided with an air outlet, and a gas supply system is connected at the mixed gas inlet for supplying gas to the atmosphere protection box. The box body of the atmosphere protection box is provided with a working part of the additive manufacturing system and a working part of the external force volume deformation system. The device also comprises a hydrogen concentration monitoring device, a hydrogen concentration alarm device, a pressure sensor, a temperature regulating plate, a moving platform and an infrared camera.The above-mentioned equipment is arranged in the atmosphere protection box. With the device for refining additive manufactured titanium alloy grains, the advantages of grain refinement, high efficiency and convenient realization are realized.

Owner:SHENYANG AEROSPACE UNIVERSITY

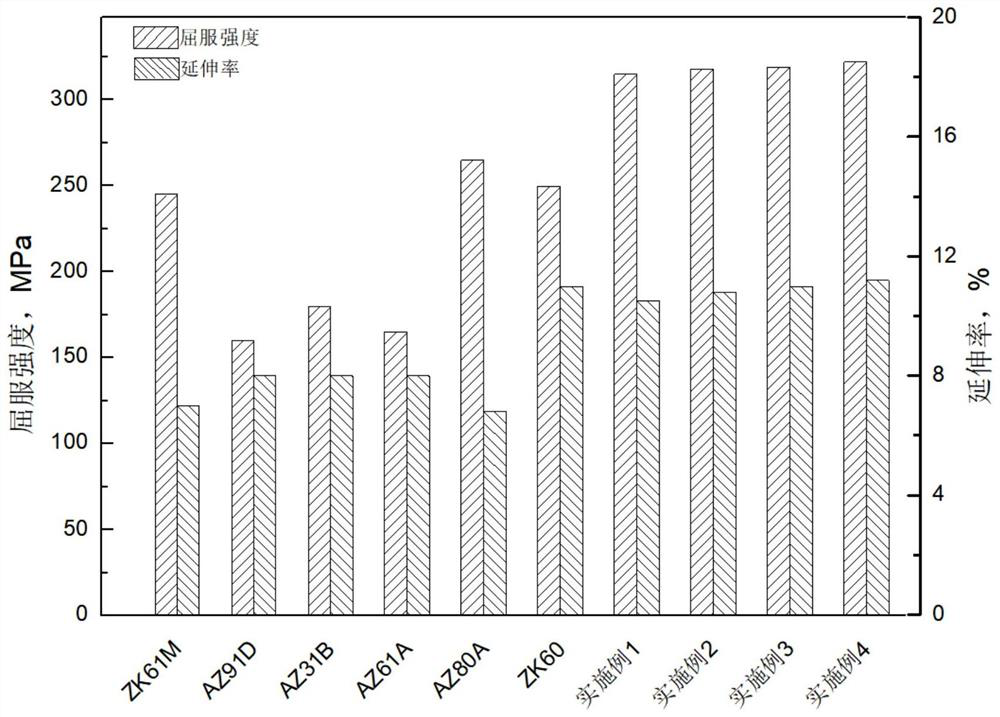

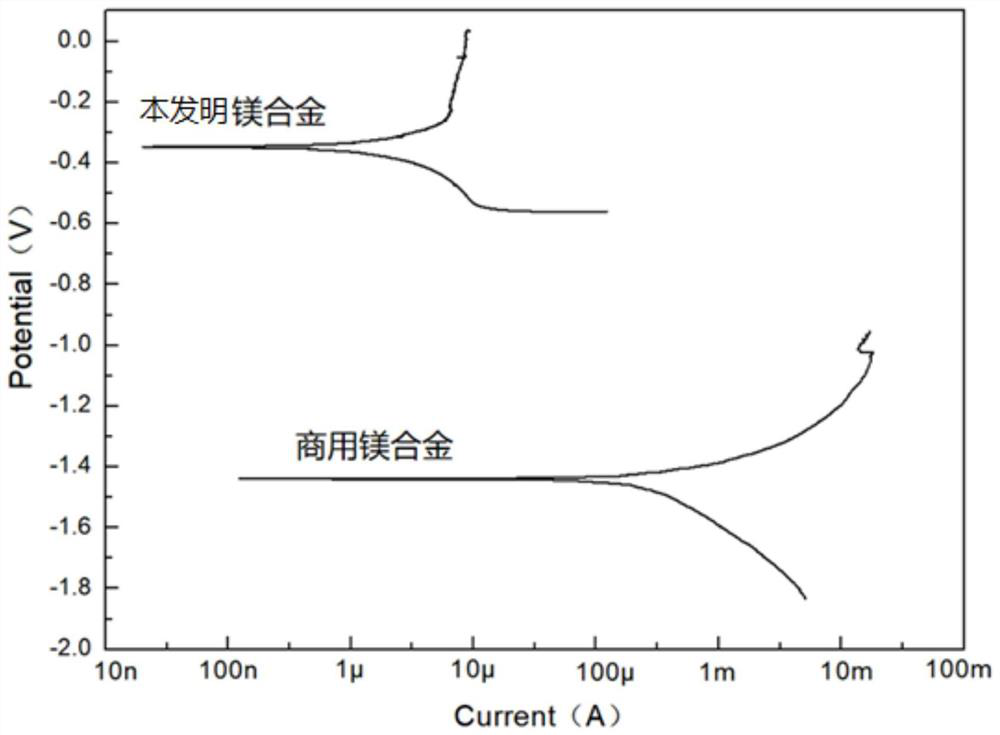

High-strength and high-corrosion-resistance rare earth magnesium alloy and preparation method thereof

ActiveCN113355573AImprove strength and plasticityIncrease driving abilityRare-earth elementCorrosion

The invention discloses a high-strength and high-corrosion-resistance rare earth magnesium alloy plate and a preparation method thereof. The high-strength and high-corrosion-resistance rare earth magnesium alloy plate comprises the following components in percentage by mass: 6-8% of aluminum, 0.4-0.6% of heavy rare earth elements, 0.2-0.5% of manganese, 0.2-0.6% of light rare earth elements, and the balance of magnesium. The preparation method comprises the following steps that: the raw materials are mixed and heated to 750-780 DEG C for insulation by 15-20min, and are cooled to 720-730 DEG C for standing by 5-10min; a magnesium alloy cast ingot is obtained by a semi-continuous casting method; the cast ingot is peeled to obtain a heat treatment cast rod after solution treatment by 8-12h at 380-410 DEG C; the heat treatment cast rod is pre-extruded; the extruded plate is hot-rolled by 9-11 times; the single rolling reduction is 8-10% of rolling deformation; and the rolled plate is annealed to obtain the high-strength and high-corrosion-resistance rare earth magnesium alloy plate. The rare earth magnesium alloy plate has the advantages of high strength, high corrosion resistance and low cost; and the preparation method is simple in flow, high in efficiency and high in yield.

Owner:XI AN JIAOTONG UNIV

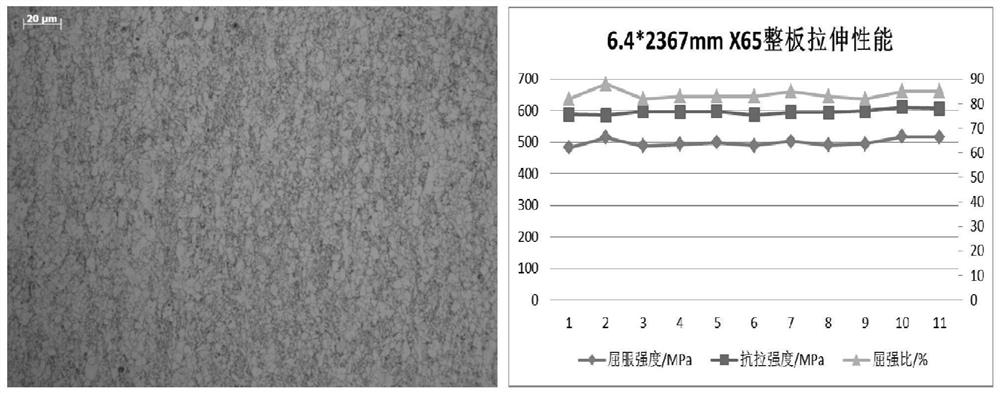

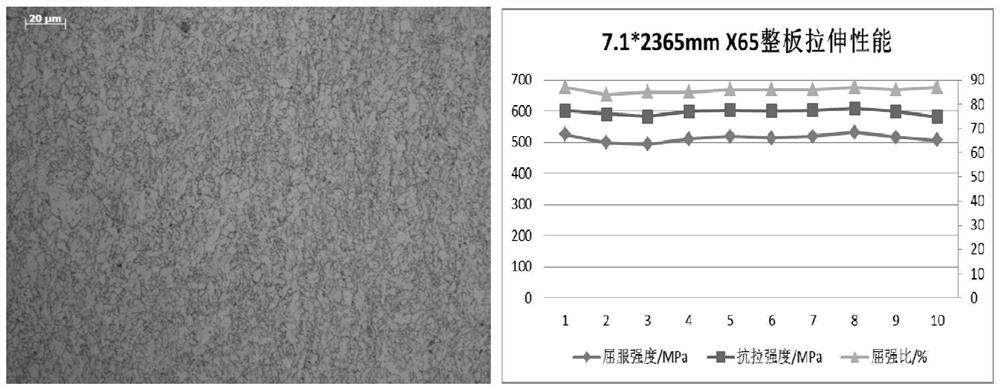

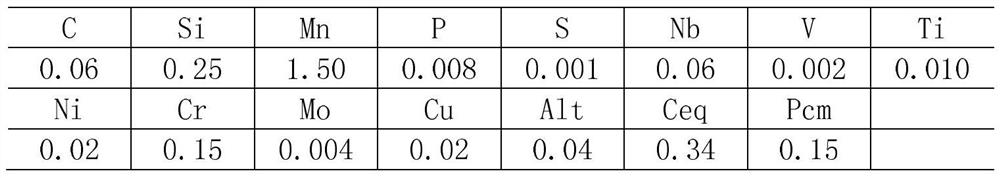

Thin-specification X65 steel-grade pipeline steel of single-stand steckel mill and rolling method

InactiveCN111790754AImprove temperature uniformityImprove the uniformity of mechanical propertiesTemperature control deviceTension/compression control deviceLine tubingRolling mill

The invention discloses thin-specification X65 steel-grade pipeline steel of a single-rack steckel mill and a rolling method. The steel is composed of the following components in percentage by weight:0.03 to 0.07 percent of C; 0.10 to 0.30 percent of Si, 1.30 to 1.70 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.0050 percent of S, 0.040 to 0.060 percent of Nb, less than or equal to 0.10 percent of V, 0.006 to 0.020 percent of Ti, 0.10 to 0.25 percent of Cr, less than or equal to 0.30 percent of Ni, less than or equal to 0.10 percent of Mo, less than or equalto 0.10 percent of Cu, 0.015 to 0.050 percent of Al and the balance of Fe and impurities. According to the rolling method, a blank with the thickness of 150 mm is used for producing the thin-specification pipeline steel plate with the finished product specification of (6-8) mm X65 grade. By controlling the tapping temperature, the coiling furnace temperature, the second-stage initial rolling temperature, the rough rolling final pass reduction rate, the final rolling speed, ACC cooling and the like, the thin-specification X65 steel-grade pipeline steel plate with the performance and the plateshape meeting the requirements is obtained, the productivity and the yield of a rolling mill are improved, and the performance percent of pass is high.

Owner:NANJING IRON & STEEL CO LTD

Low-volatility monocrystalline silicon slice texturing solution and preparation method thereof

InactiveCN105133023AEffective control of surface tensionImprove surface propertiesAfter-treatment detailsGluconic acidCocamidopropyl betaine

The invention discloses a low-volatility monocrystalline silicon slice texturing solution which is characterized by being prepared from the following raw materials in parts by weight: 0.5-1 part of sodium hydroxide, 3-5 parts of an auxiliary agent, 0.2-0.4 part of sodium gluconate, 0.5-1 part of raffinose, 0.3-0.5 part of sodium citrate, 0.3-0.5 part of polyvinylpyrrolidone, 0.5-1 part of cocamidopropyl betaine, 0.3-0.5 part of propylene glycol alginate, 0.1-0.2 part of dimethyl silicone, and 80-100 parts of water. The texturing solution effectively improves the consistency and repeatability of a texturing technology, increases the textured surface density, thereby increasing the efficiency of solar cells and improving the quality of the product; and the texturing solution does not contain IPA and other volatile components, is beneficial to environmental protection and human health, is safe and environmentally friendly, can be reused more frequently, is strong in durability, and saves costs.

Owner:CHINALAND SOLAR ENERGY

Production process of 5052 aluminum alloy plate with low earing rate

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a production process of a 5052 aluminum alloy plate with a low earing rate. The aluminum alloy plate is prepared from the raw materials: 2.2-2.6% of Mg, 0.05-0.35% of Fe, less than or equal to 0.16% of Si, less than or equal to 0.10% of Mn, 0.20-0.25% of Cr, less than or equal to 0.03% of Cu, less than orequal to 0.04% of Zn, less than or equal to 0.025% of Ti, less than or equal to 0.05% of a single impurity, less than or equal to 0.15% of total amount of impurities, and the balance of Al. An aim ofimproving orientation distribution of a matrix structure is achieved from angles of adjusting composition of ingotting and homogenizating process, and thus the earing rate of a material is lowered andyield of the 5052 aluminum alloy plate is improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

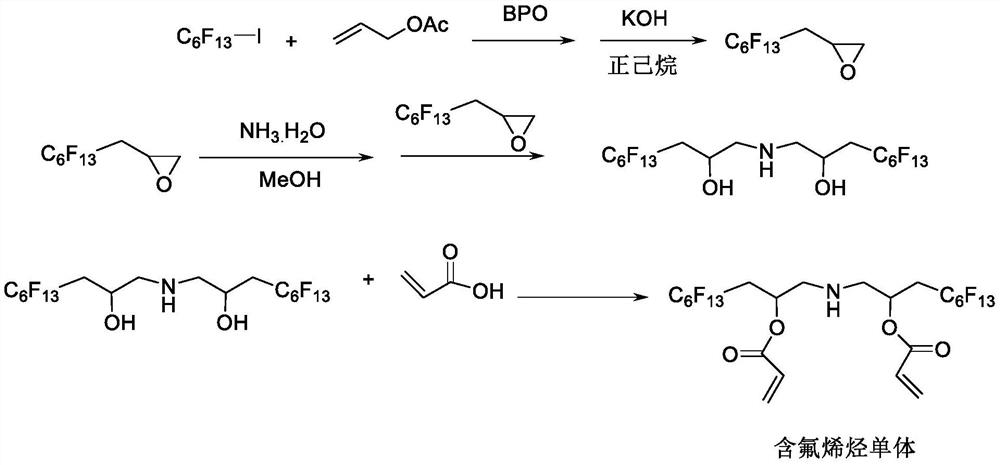

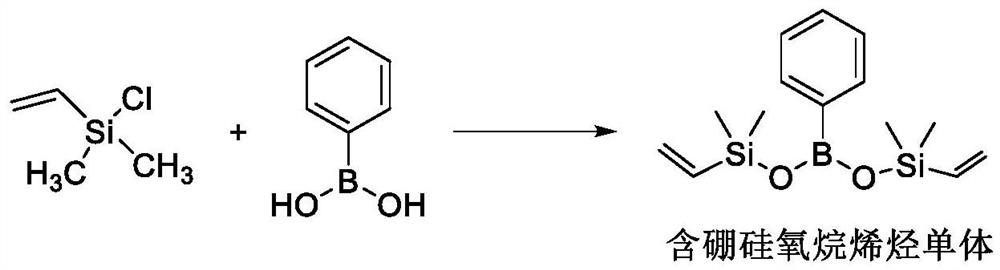

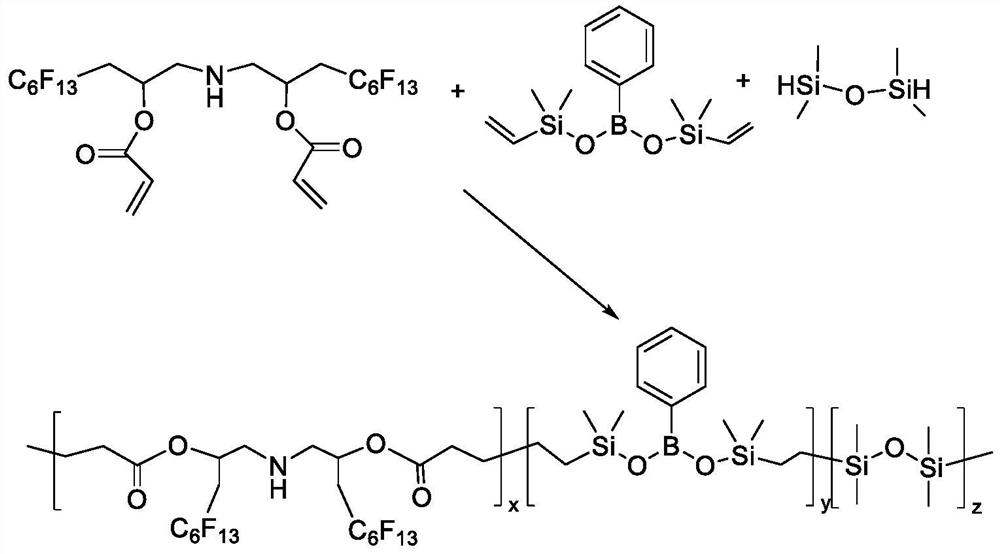

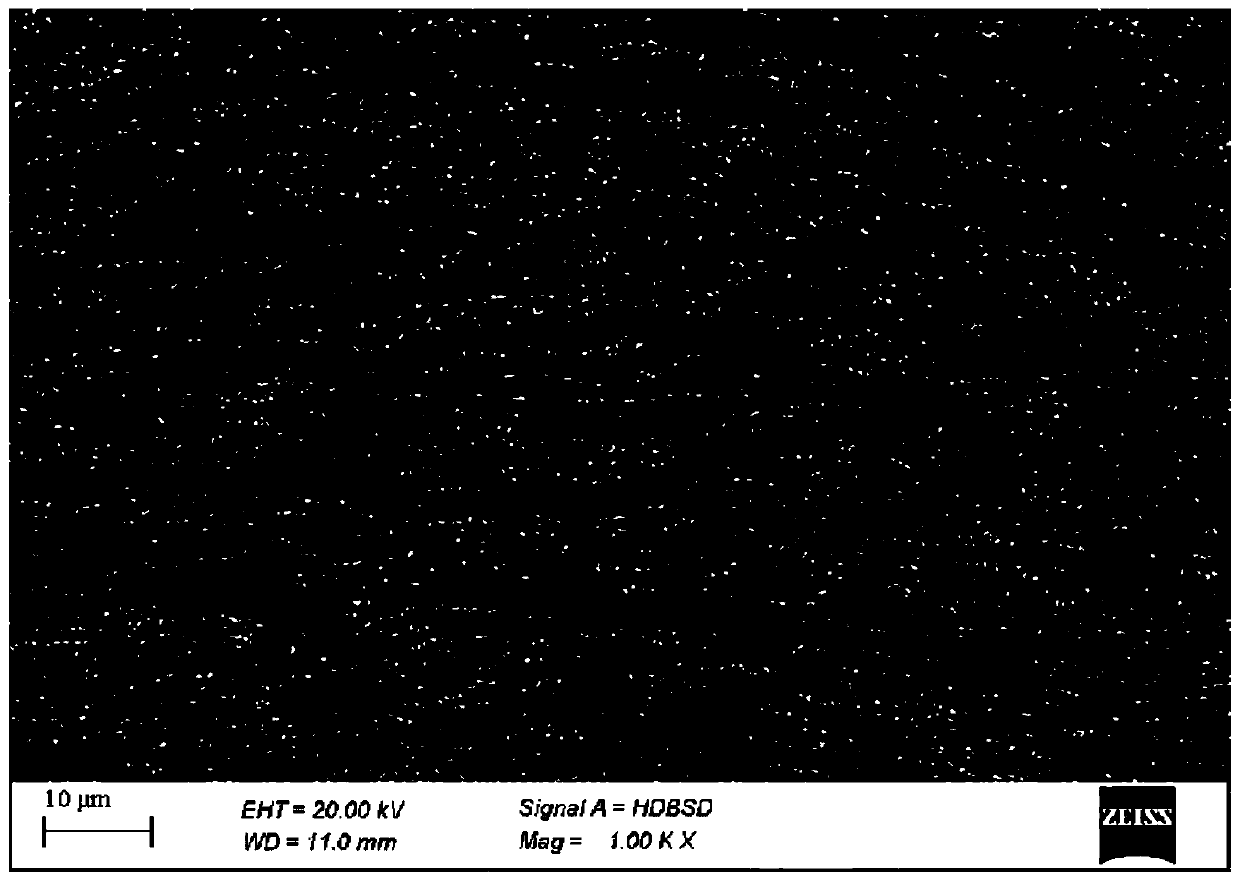

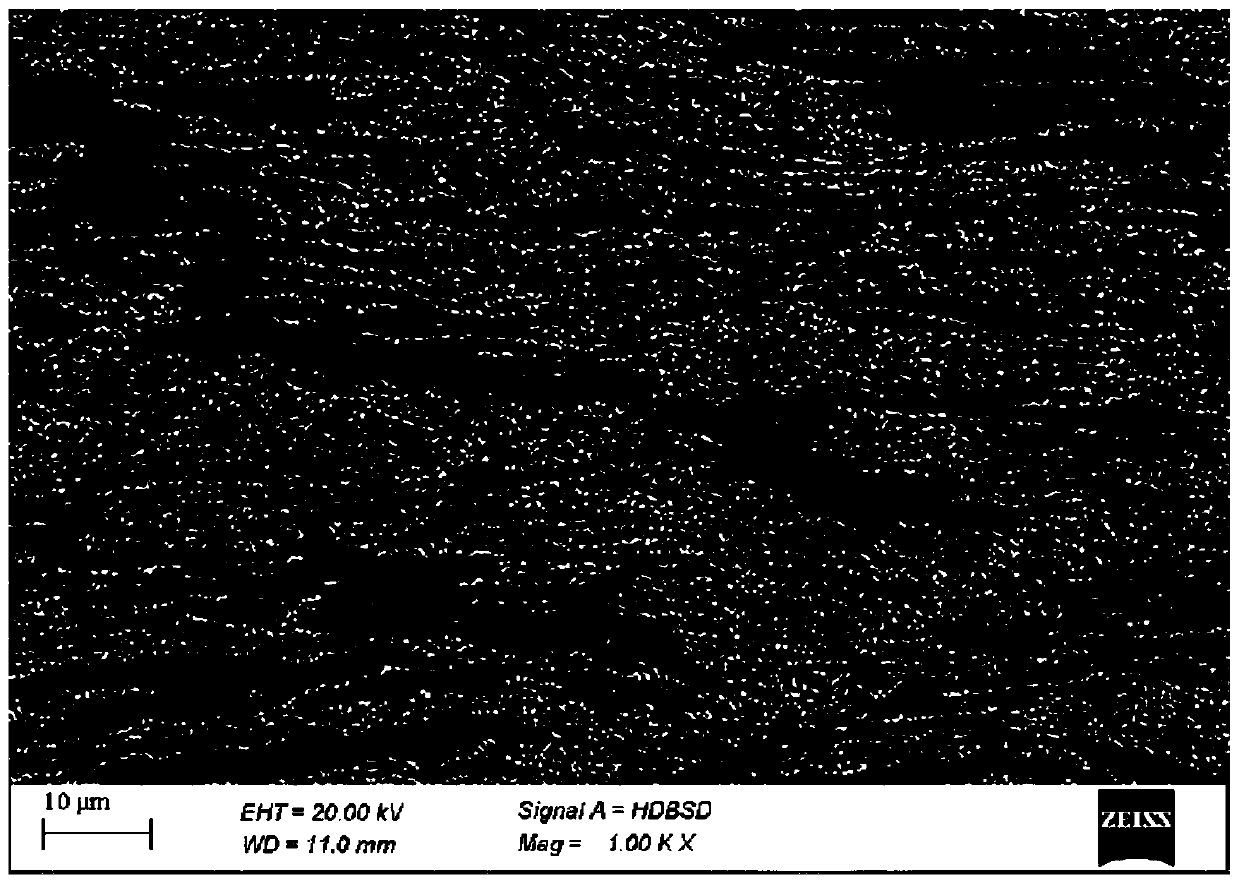

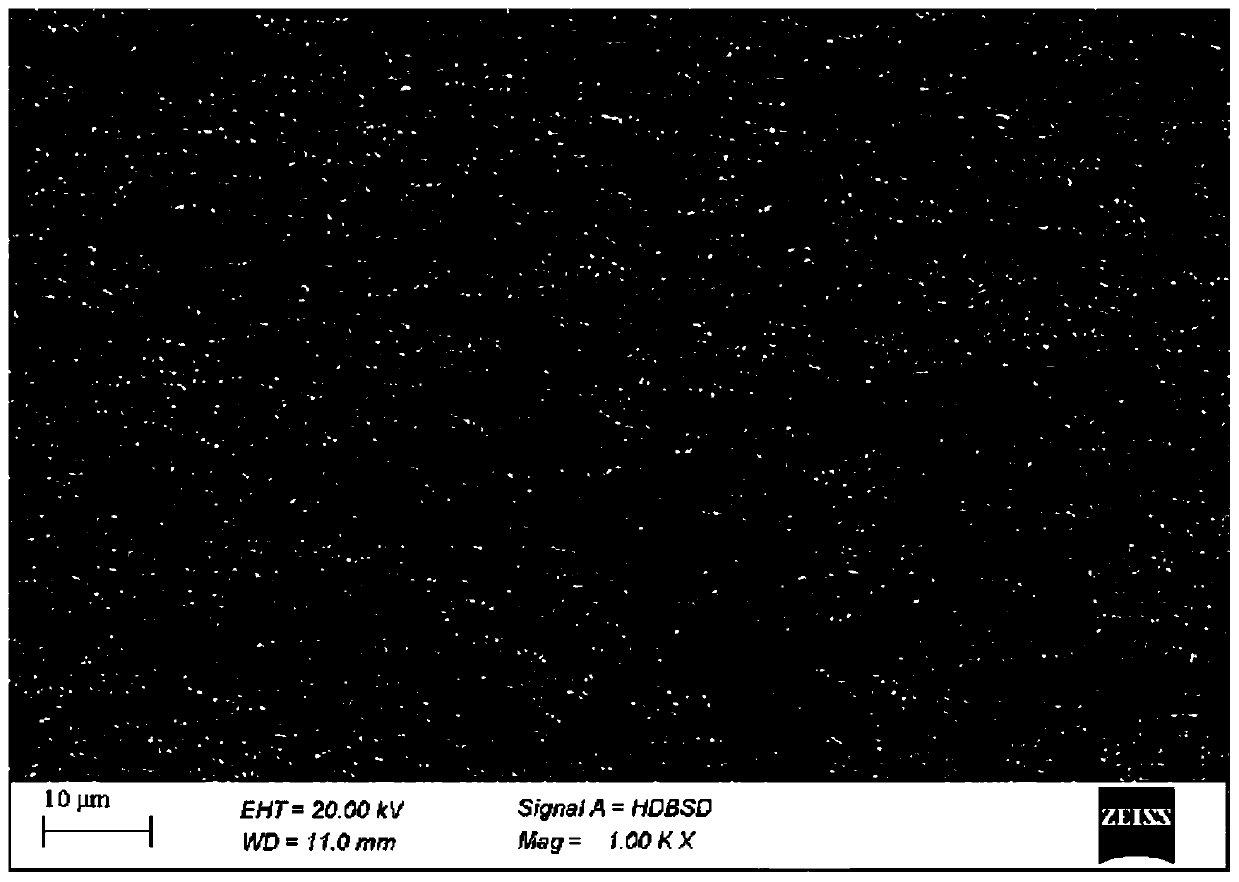

Modified foaming polyurethane and preparation method thereof

InactiveCN113583431AEvenly dispersedDispersion Homogenization and UniformityPolymer scienceFoam polyurethanes

The invention discloses modified foaming polyurethane and a preparation method thereof, and belongs to the technical field of polyurethane. The modified foaming polyurethane is prepared from the following raw materials in parts by weight: 90 to 110 parts of a component A, 40 to 55 parts of a component B and 0.1 to 2 parts of modified polyborosiloxane. Organic fluorine modified polyborosiloxane is introduced into a foamed polyurethane system, so that the impact resistance of the foamed polyurethane is improved, and the impact resistance of the foamed polyurethane in a water environment is maintained. According to the organic fluorine modified polyborosiloxane, a fluorine-containing olefin monomer is used as one of monomers of polyborosiloxane, fluorine-containing chains are contained in fluorine-containing olefin monomer molecules, so that fluorine-containing chain branched chains are introduced into polyborosiloxane molecular chains, the fluorine-containing chains are prone to migration and aggregation to form a fluorine-containing chain layer, then contact between water and Si-O-B is prevented, the stability of the polyborosiloxane in the water environment is further improved, and the impact resistance of the foamed polyurethane in the water environment is maintained.

Owner:CHUZHOU YULIN POLYURETHANE

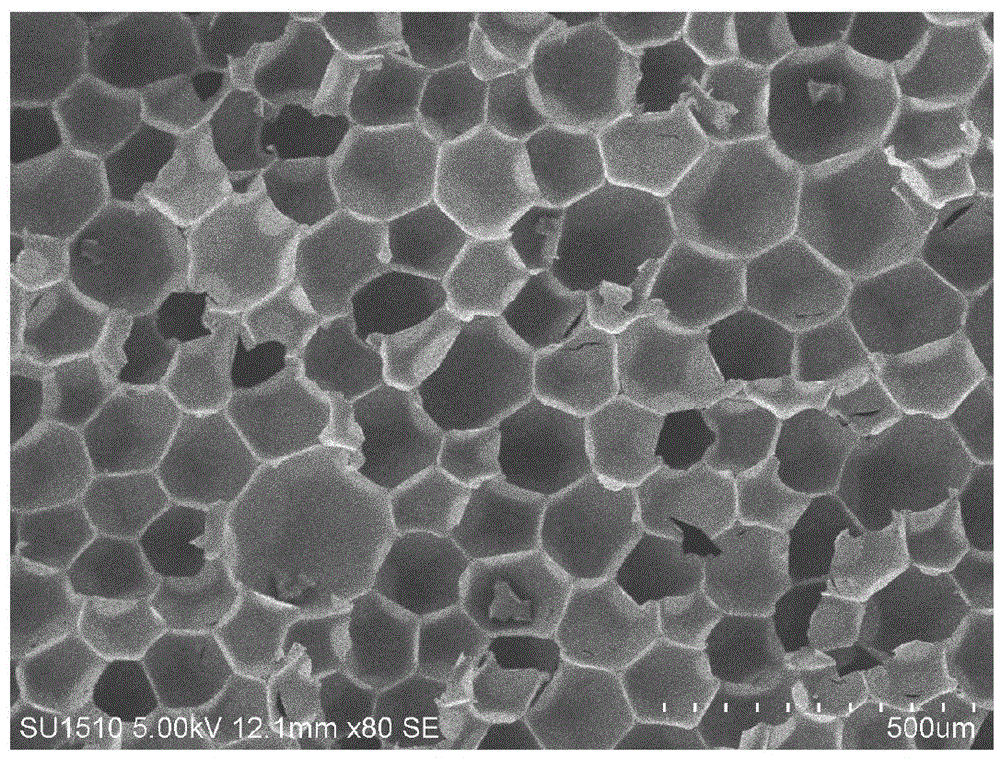

Preparing method and application of cobalt tantalum zirconium alloy target material

ActiveCN110735068AHigh purityImprove performanceMetal-working apparatusVacuum evaporation coatingThin membraneManufactured material

The invention discloses a preparing method and application of a cobalt tantalum zirconium alloy target material, and belongs to the technical field of preparation of special materials. The preparing method comprises the steps of component design, high-vacuum vertical sintering and high-vacuum electron beam melting, three-dimensional isothermal hot forging cogging, angle-varying controlled rollingand the like. In this way, the organization structure of the alloy and the performance of the target material are controlled, and the high-quality cobalt tantalum zirconium alloy target material is prepared. The oxygen content of the cobalt tantalum zirconium alloy target material is smaller than or equal to 15 ppm, the average grain size of the cobalt tantalum zirconium alloy target material is 5-20 micrometers, the phase distribution of the target material is uniform, the magnetic permeability is larger than 40%, and the heterogeneity of magnetic permeability is smaller than 2%. By means ofthe designed process, the oxygen content, organization structure heterogeneity and magnetic performance of the finished product target material can be effectively controlled, and a raw material guarantee is provided for sputtering high-quality thin films by means of the preparing method.

Owner:CENT SOUTH UNIV

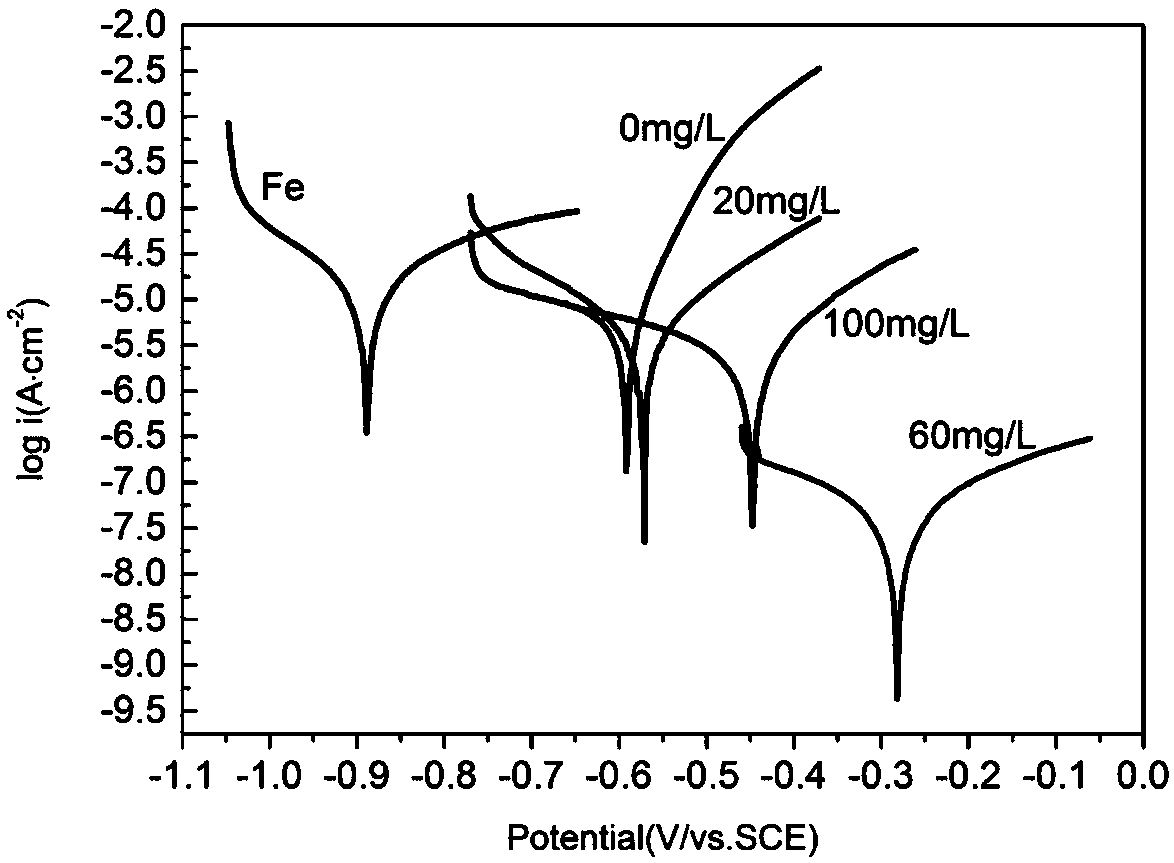

Method for preparing copper-graphene compound plating layer, chemical plating solution and plating solution preparation method

InactiveCN109252147AImprove corrosion resistanceAccelerated corrosionLiquid/solution decomposition chemical coatingChemical platingPhase function

The invention provides a method for preparing a copper-graphene compound plating layer, a chemical plating solution and a plating solution preparation method. Hydrophilic graphene oxide and a proper amount of complexing agent, stabilizer, reductant and the like are added into chemical plating solution, and a Cu-Gr compound chemical plating layer is formed on the surface of a workpiece. The invention can be used for solving the technical problem of poor workpiece surface corrosion resistance in the prior art. The method disclosed by the invention has the simpleness in operation and high repeatability, the form and the excellent performance of Gr can be kept, a wild phase function is realized in the compound plating layer so as to greatly improve plating layer performance, and the method hasa wide application prospect in fields including corrosion resistance, electronics, automobiles, chemical engineering, oceaneering, military projects and the like.

Owner:SHENZHEN RES INST OF WUHAN UNIVERISTY

Low-reflectivity monocrystalline silicon piece texture surface making liquid and preparation method thereof

InactiveCN105113015AEffective control of surface tensionImprove surface propertiesAfter-treatment detailsEthylenediamineHuman health

The invention discloses low-reflectivity monocrystalline silicon piece texture surface making liquid. The low-reflectivity monocrystalline silicon piece texture surface making liquid is characterized by being prepared from, by weight, 0.5-1 part of sodium hydroxide, 3-5 parts of auxiliaries, 2-4 parts of ethoxy urea, 0.1-0.2 part of xanthan gum, 0.5-1 part of sodium lauroyl sarcosine, 0.1-0.2 part of decyl glucoside, 0.1-0.2 part of isopropyl myristate, 0.01-0.02 part of N-beta-hydroxyethyl ethylenediamine triacetate and 80-100 parts of water. According to the texture surface making liquid, the consistency and repeatability of a texture surface making process are effectively improved, the density of a fabric surface is increased, the dense fabric surface is formed, the surface reflectivity of silicon pieces is reduced, the photoelectric conversion efficiency is improved, and therefore the efficiency of a solar cell is improved, and product quality is improved. No IPA is included, environmental protection and human health are facilitated, and safety and environment friendliness are achieved.

Owner:CHINALAND SOLAR ENERGY

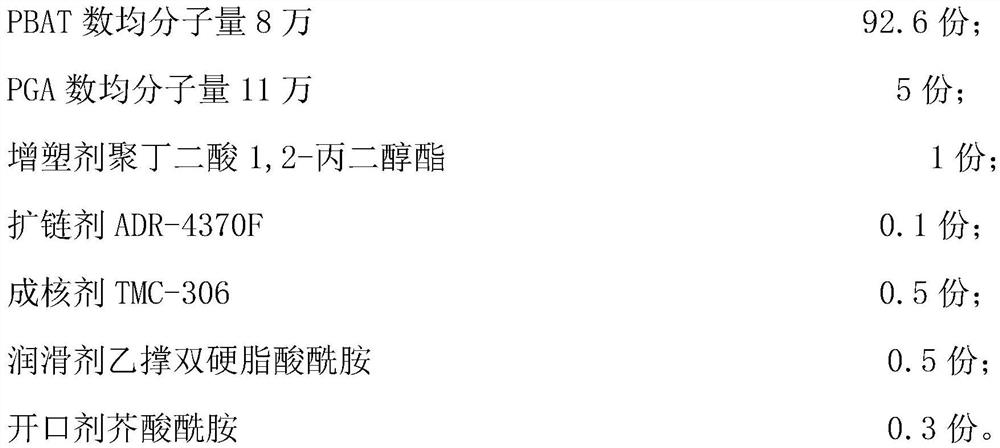

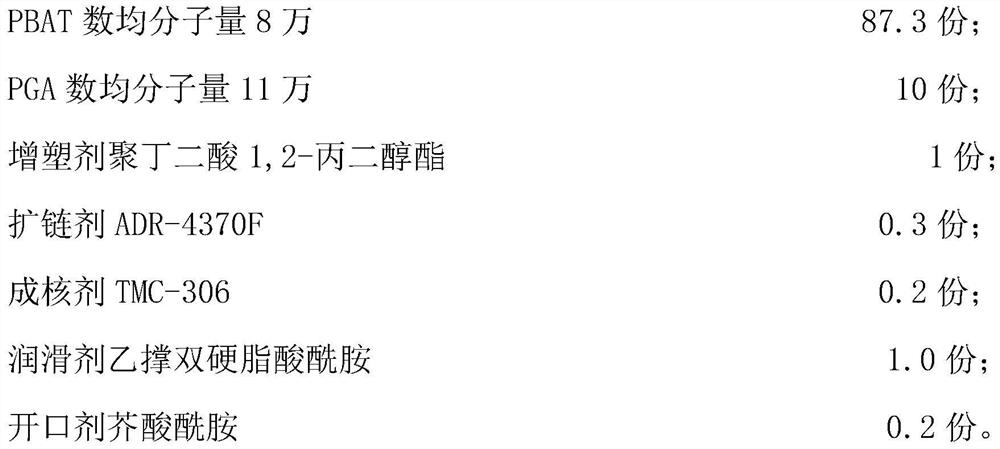

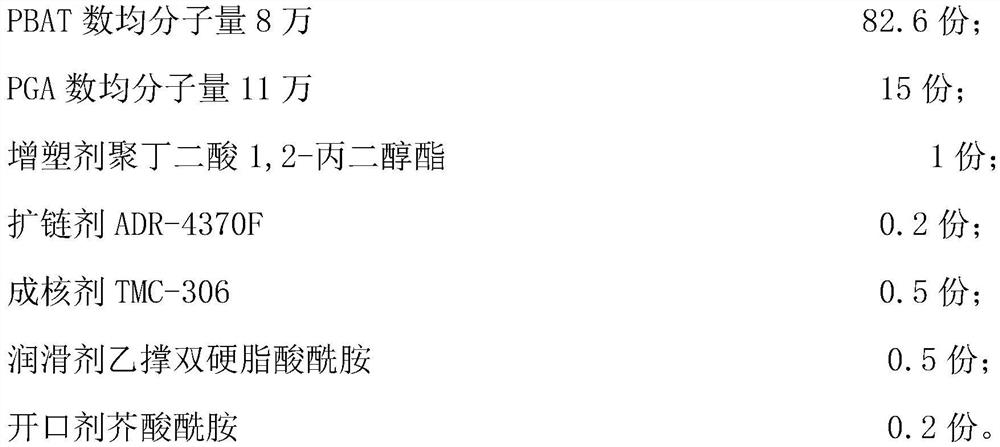

Completely biodegradable film and preparation method thereof

PendingCN113956630AImprove biodegradabilityIncreased tensile elongation at break and tear strengthPlasticizerStearic acid

The invention discloses a completely biodegradable film and a preparation method thereof. The completely biodegradable film is prepared from poly(butylene adipate-co-terephthalate), polyglycolic acid, a chain extender styrene-acrylic acid-glycidyl methacrylate copolymer, a plasticizer poly(succinic acid-1, 2, 4-trimethyl-1, 3-pentanedionate), a plasticizer poly (butylene adipate-co-butylene terephthalate), a plasticizer polysuccinic acid-1, 2-propylene glycol ester, a nucleating agent, a lubricant ethylene bisstearamide and an anti-blocking agent erucyl amide. The preparation method comprises the following steps: weighing the components according to the formula, mechanically mixing to form a premix, metering and adding the plasticizer polysuccinic acid-1, 2-propylene glycol ester from a liquid feeding port of a twin-screw extruder, carrying out melt extrusion, water cooling, pelletizing and drying to obtain special resin for film blowing, and carrying out blow molding film forming through a film blowing machine to obtain the completely biodegradable film. The chain extender, the nucleating agent and the plasticizer can effectively improve the tensile elongation at break and tear strength of the film and obviously improve the rheological behavior of the material, and the film has good mechanical properties and excellent biodegradability and can replace PE, PP, PVC and the like to prepare films and sheets.

Owner:江苏碧升生物新材料有限公司 +1

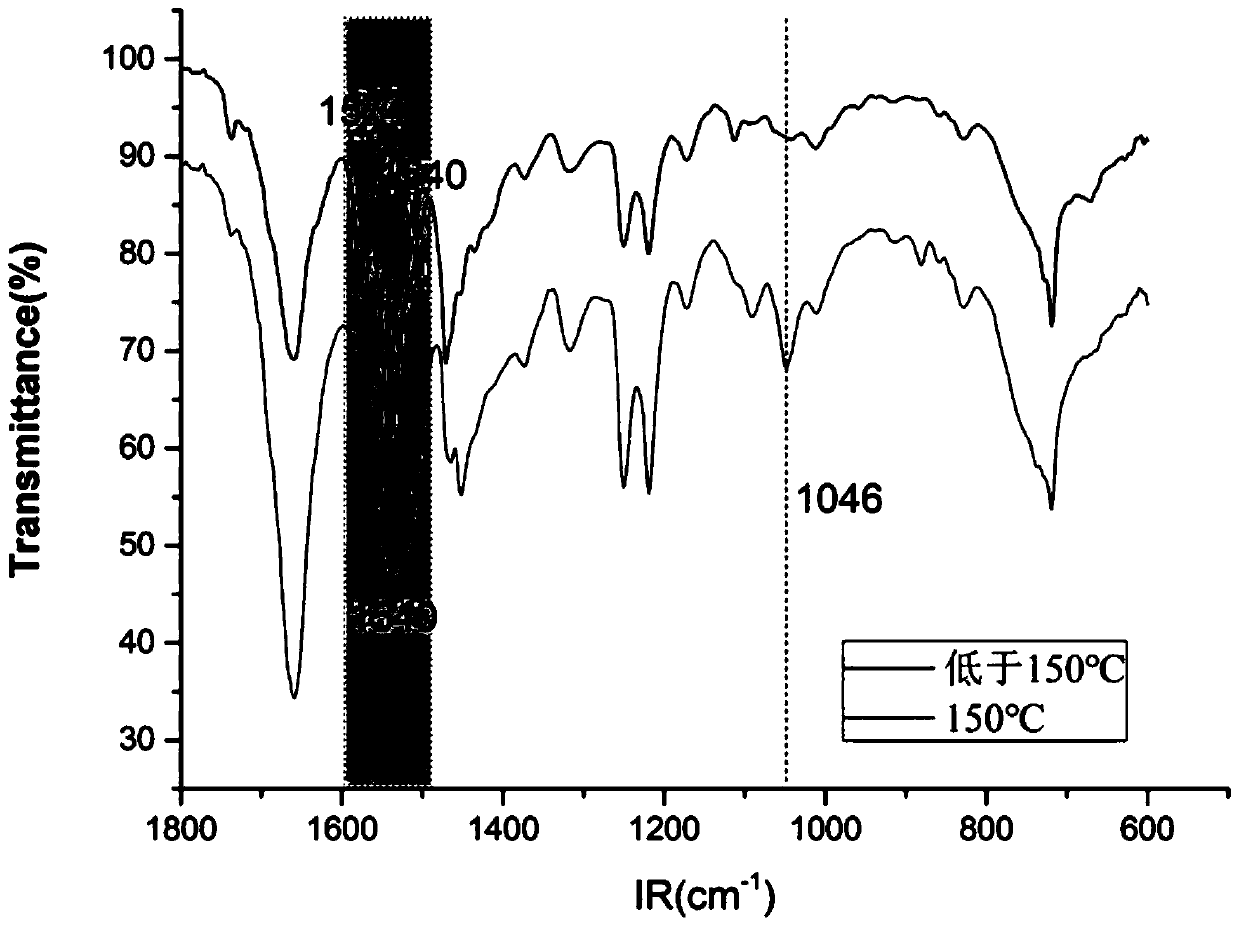

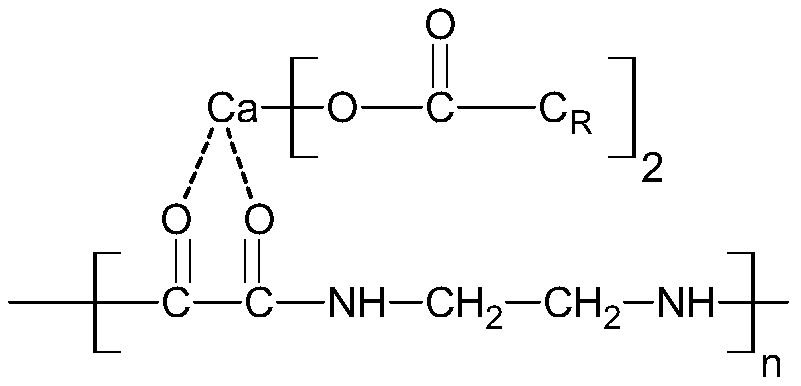

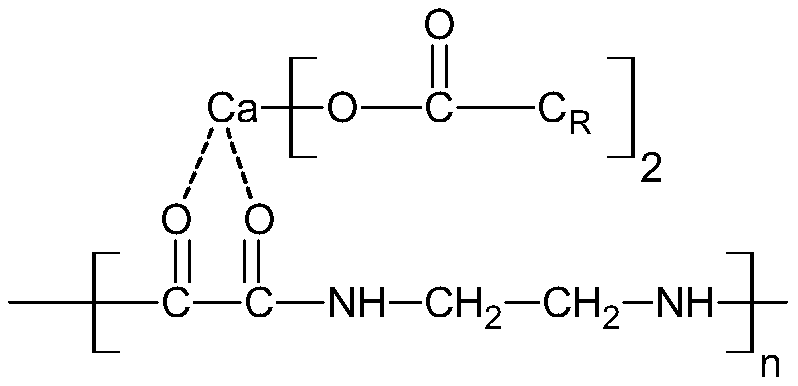

Complexing type nylon nucleating agent and compound containing nylon nucleating agent, and preparation methods thereof

The invention discloses a complexing type nylon nucleating agent and a preparation method thereof, and also provides a nylon compound containing the nylon nucleating agent, and a preparation method thereof. Carbonyl groups in polyamide 22 react with calcium ions in long-carbon-chain fatty acid calcium salt at a high temperature to generate a complex, so the hydrogen bond acting force between molecules of the nucleating agent is reduced, the nucleating agent does not agglomerate in a nylon resin system, and the dispersity is better, thereby the nucleating points are increased, the nucleating efficiency is increased, the crystallization temperature is increased, the crystallinity is increased, and the rigidity, toughness, heat resistance and transparency of a nylon product are improved. Theproblems that the single variety of nylon 22 (P22), calcium monophosphate (CaV102), inorganic filler and the like which are commercially available in the prior art is poor in dispersity and cannot beobtained in crystallization, lubrication and demolding at the same time are solved.

Owner:SHANXI CHEM RES INST

Method for improving inner quality of continuous casting billet with thick and large section

The invention relates to the filed of the manufacture of continuous casting billets, in particular to a method for improving inner quality of a continuous casting billet with a thick and large section, which can solve the problems of the centerline shrinkage, porosity and segregation of the continuous casting billet with the thick and large section in the prior art. In the invention, through controlling degree of purity of molten steel and degree of superheat of pouring, and cooperatively adopting the micro-region oscillation technology and the solidification self-feeding technology, the inner quality of the continuous casting billet can be improved. The micro-region oscillation technology can effectively eliminate the defects of segregation in the continuous casting billet, can also effectively reduce solidification tissues, and decreases the centerline shrinkageand porosity; and the solidification self-feeding technology can realize simultaneous solidification and plastic movement of solid metal in the subsequent solidification shrinkage process, so that the purpose of radial self-feeding of high-temperature deformable metal can be achieved, further, the centerline shrinkage in the continuous casting billet can be eliminated, and the porosity in the continuous casting billet can be remarkably improved and is even eliminated. The invention is suitable for carbon steel, alloy steel and nonferrous metal casting billets with the thick and large sections, particularly for continuous casting sheet billets with the thickness being over 300mm, square billets, and round casting billets with the section phi being over 500mm.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

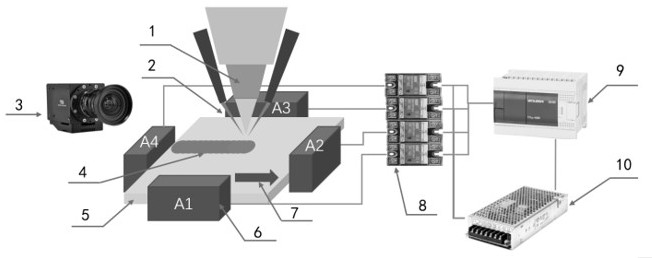

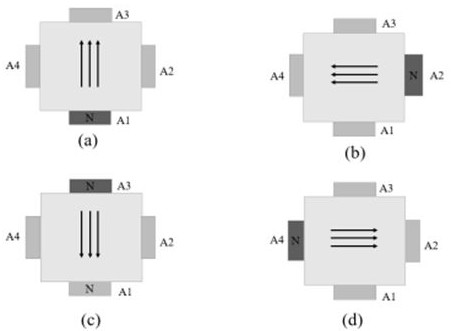

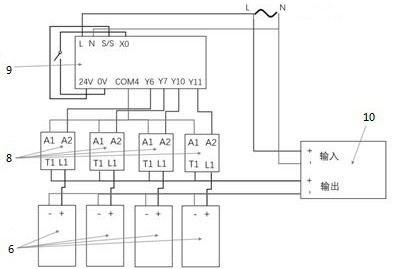

External field assisted high-entropy alloy laser additive manufacturing device and method thereof

PendingCN114669759AImprove liquidityEasy to overflowAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysControl cell

The invention belongs to the field of laser additive manufacturing, and particularly relates to an external-field-assisted high-entropy alloy laser additive manufacturing device and method.The external-field-assisted high-entropy alloy laser additive manufacturing device comprises a metal substrate, a magnetic field unit located around the metal substrate, a magnetic field control unit, a laser and a laser additive manufacturing coaxial powder feeder; the magnetic field unit comprises electromagnets A1, A3, A2 and A4 which are respectively arranged in the front direction, the rear direction, the left direction and the right direction of the metal substrate; the magnetic field control unit comprises a PLC (Programmable Logic Controller), an electromagnetic relay and a working power supply, the electromagnetic relay is respectively connected with the electromagnets A1, A2, A3 and A4, the PLC controls the electromagnetic relay to realize the on-off among the electromagnets A1, A2, A3 and A4, a dynamic reciprocating electromagnetic field is formed around the metal substrate, and the working power supply is connected with the electromagnetic relay. And electromagnetic force is generated through regular changes of the dynamic magnetic field to regulate and control fluid movement in the molten pool, the turbulence effect in the molten pool is improved, the fluidity of the WTaNbMo refractory high-entropy alloy molten pool is improved, the defects of looseness and air holes can be reduced, and important application value is achieved.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com