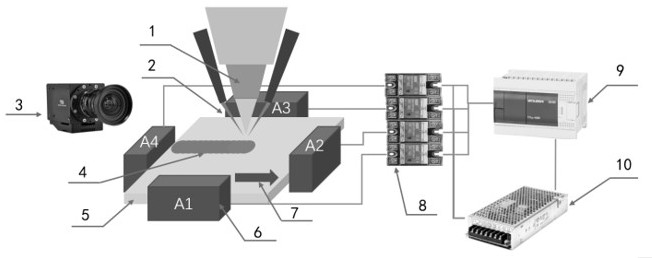

External field assisted high-entropy alloy laser additive manufacturing device and method thereof

A laser additive and high-entropy alloy technology, applied in additive manufacturing, additive processing, etc., can solve problems such as limited control performance, and achieve the effects of concise device structure, reduced pores, and reduced internal residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

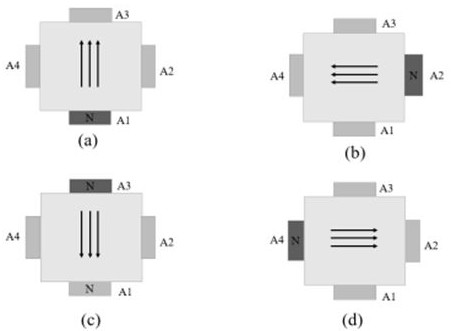

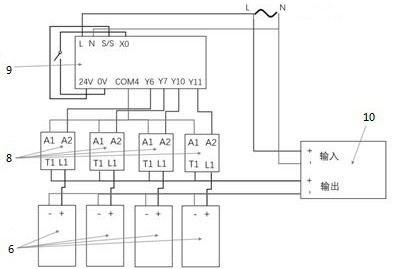

Method used

Image

Examples

Embodiment 1

[0054] Dry the WTaNbMo refractory high-entropy alloy powder in a vacuum oven at 100°C for 1 hour, and take it out for use. The In718 substrate is cut and polished, pickled to clean the oil on the surface of the In718 substrate, and placed in the magnetic field unit 6, and the direction and frequency of the magnetic field are adjusted by the PLC controller 9. After the laser beam is focused, the magnetic field unit is turned on, and the WTaNbMo bulk material is prepared by coaxial powder feeding, and the argon gas protection is turned on at the same time. In the laser processing process, the experimentally optimized laser preparation process parameters using a disk laser (TruLaser Cell3000) are shown in the table below.

[0055]

[0056] The macroscopic morphology of the cross-section of the single-layer WTaNbMo refractory high-entropy alloy obtained after laser additive manufacturing is as follows: Figure 5 shown, combined with Figure 6-7 The EDS surface scan and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com