Patents

Literature

35results about How to "Reduce internal residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gradient material steel rail frog prepared by laser cladding

ActiveCN110129674AImprove wear resistanceImprove carrying capacityMetallic material coating processesHeat-affected zoneGradient material

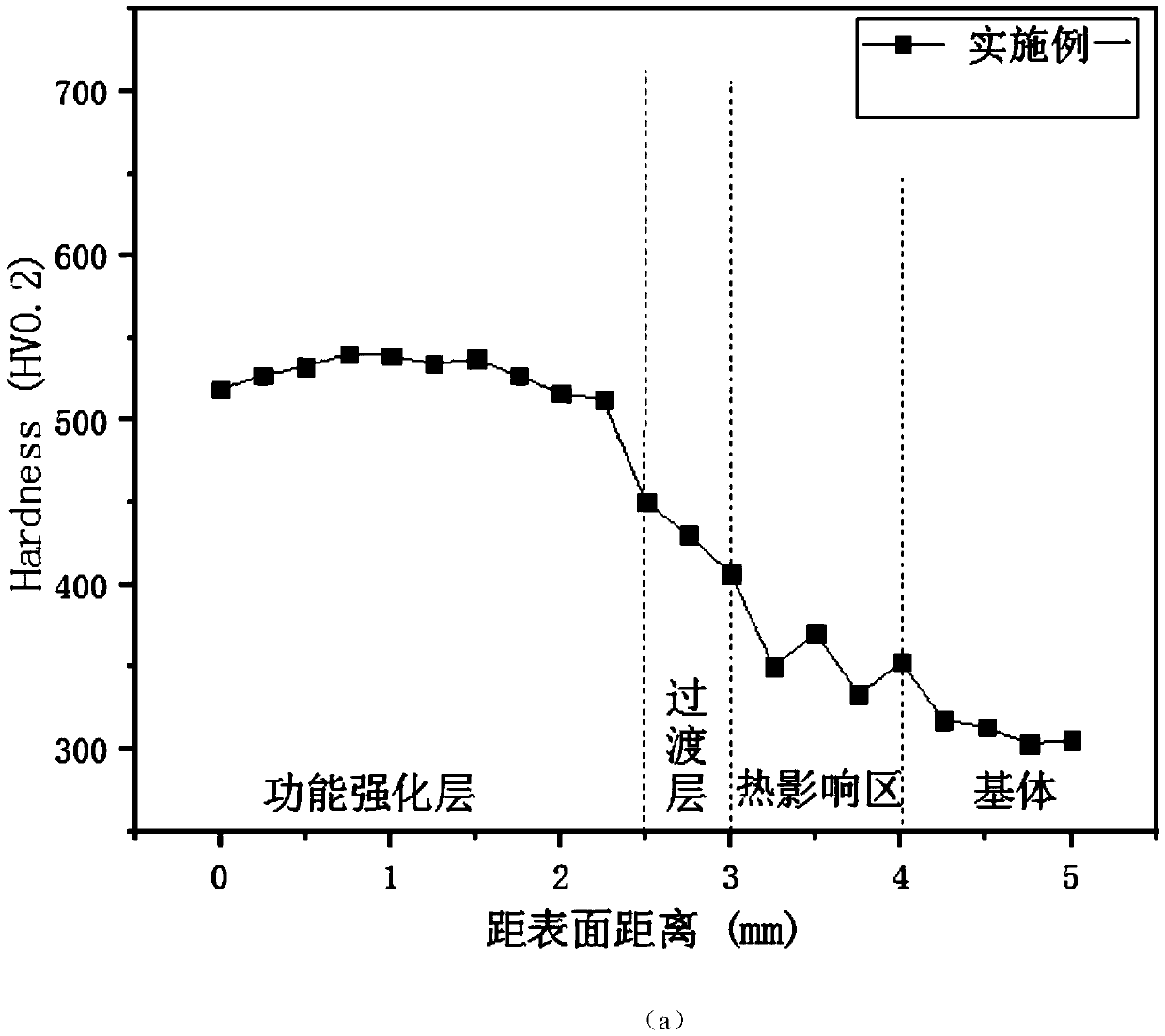

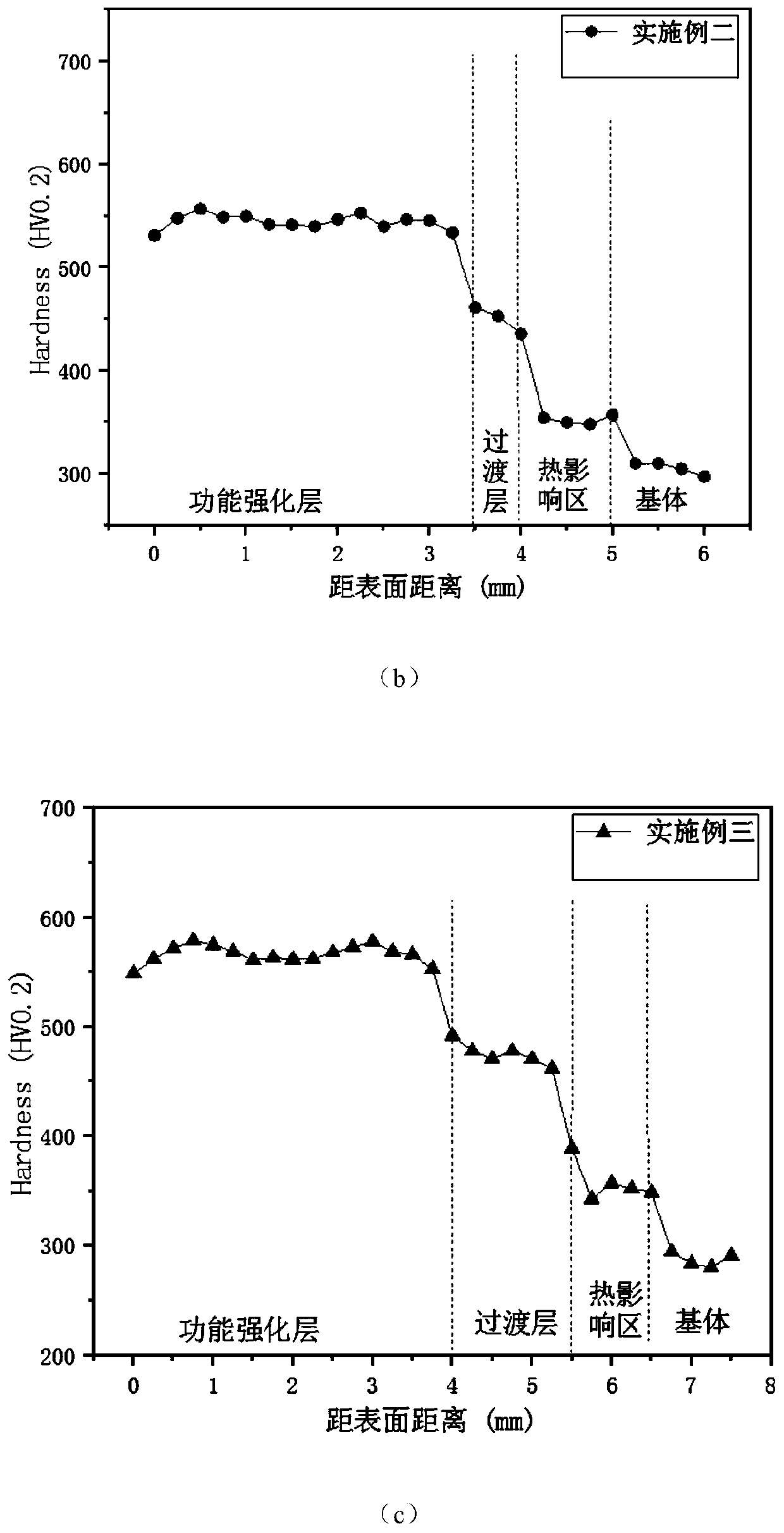

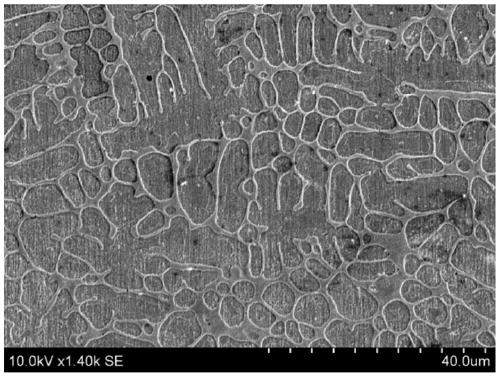

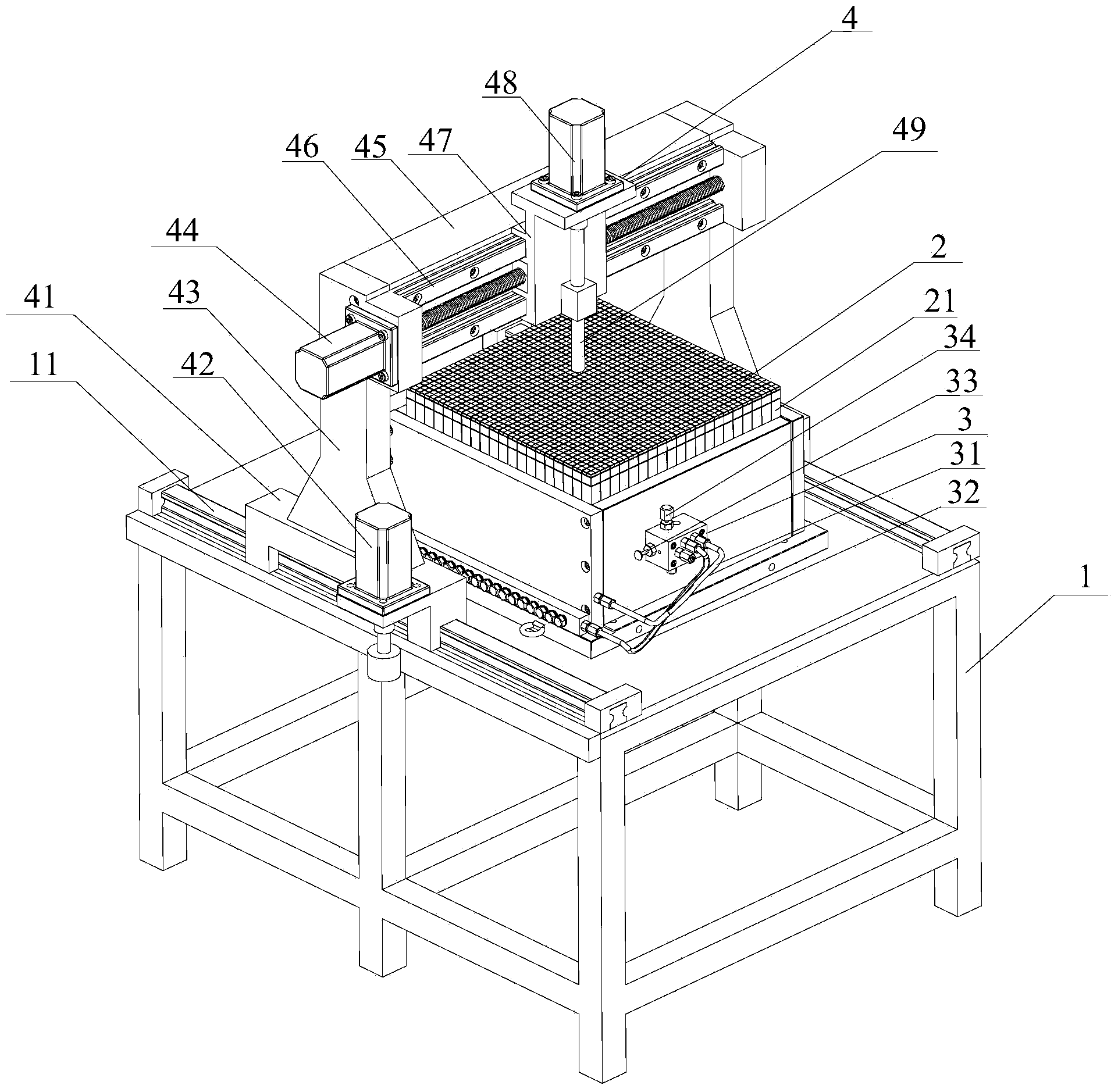

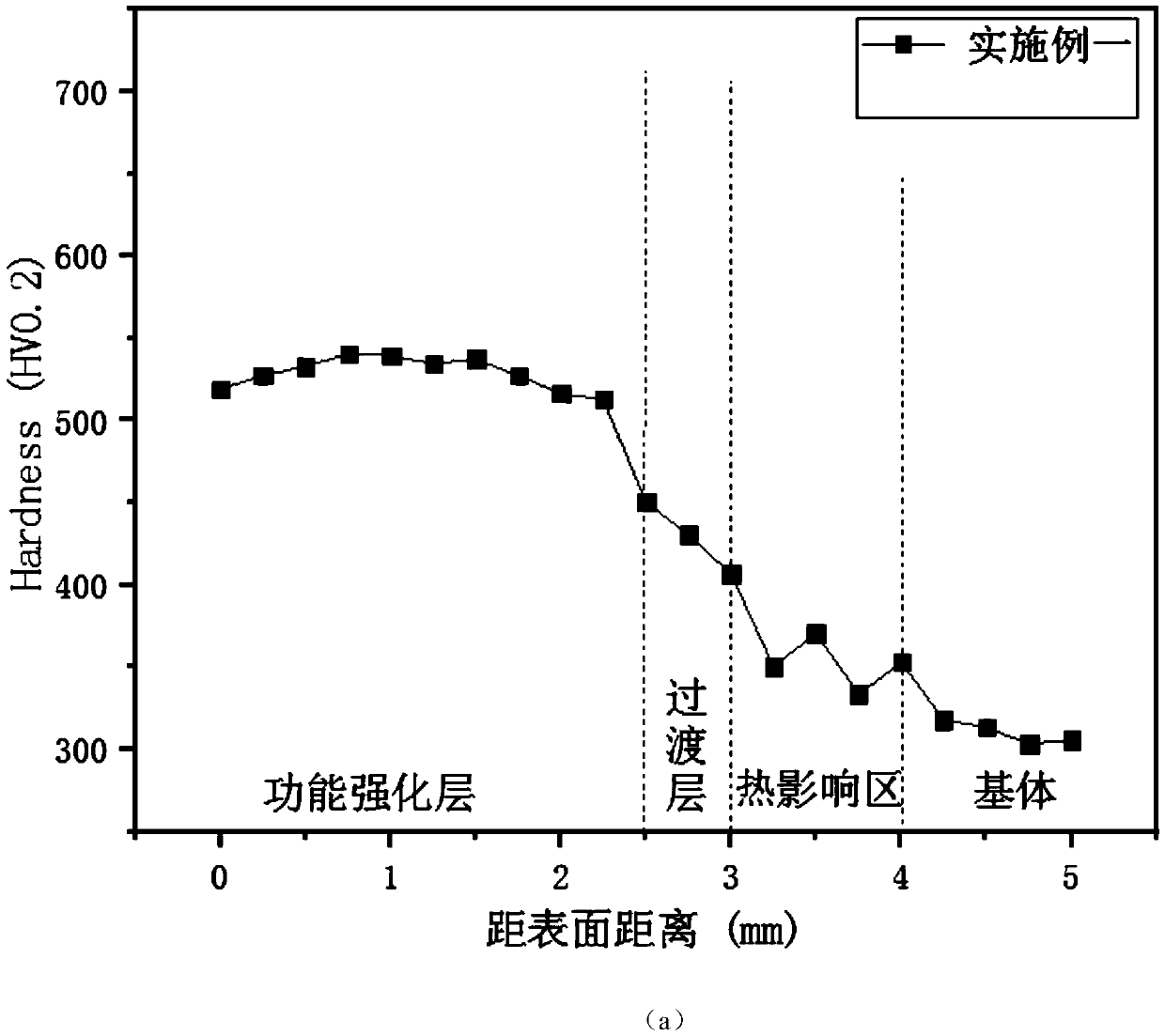

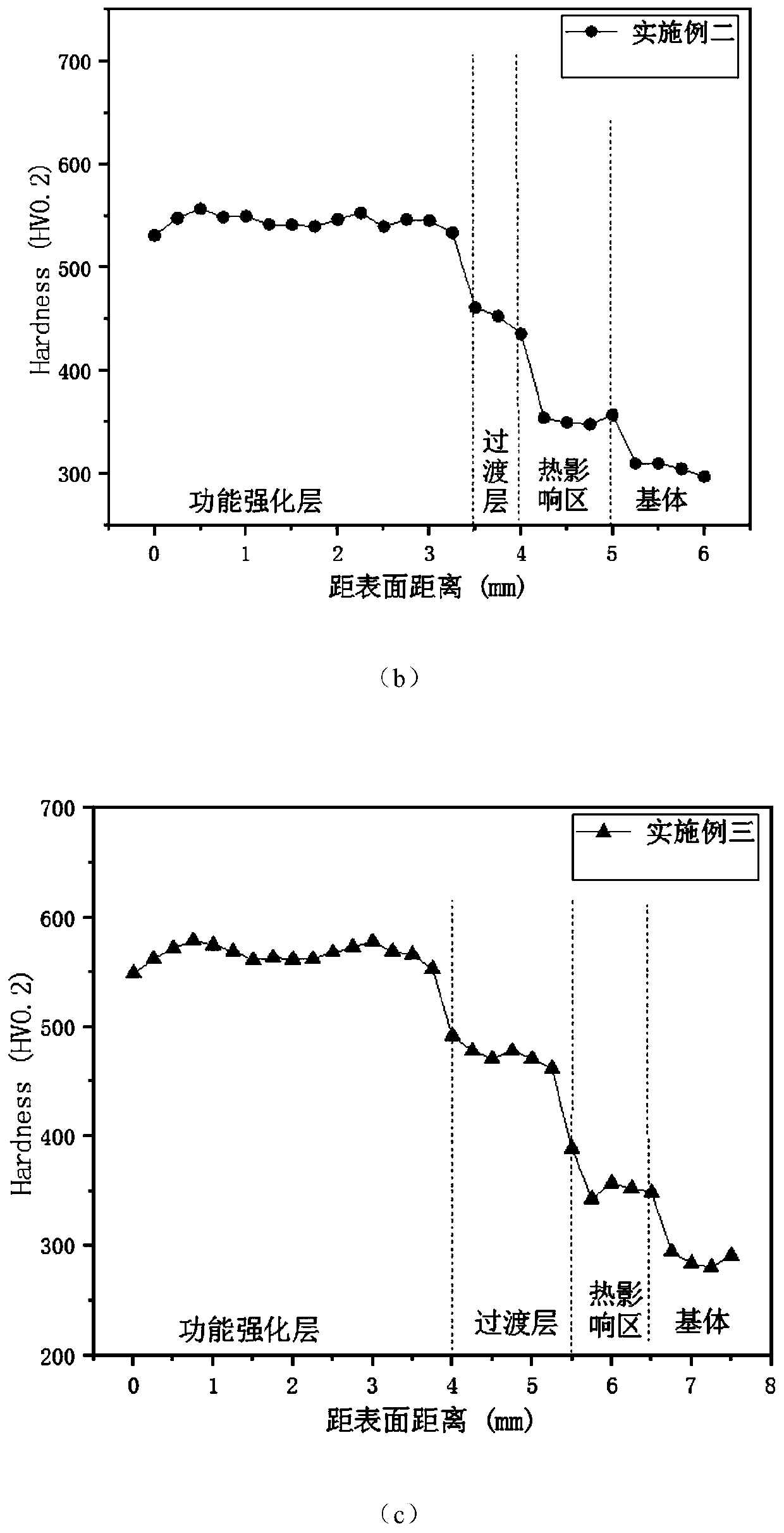

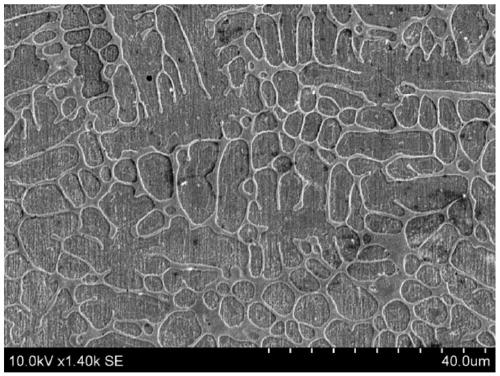

The invention provides a gradient composite material steel rail turnout coating prepared by laser cladding. The composite material is characterized in that a transition layer adopts a Fe-based alloy material, wherein the Fe-based alloy material comprises the following components of, in percentage by weight, 13wt%-17wt% of Cr, 3wt%-6wt% of Ni, 1wt%-1.5wt% of Si, 0.5wt%-1wt% of Mn, 0.3wt%-1.2wt% ofNb, 1wt%-1.5wt% of B, 0.05wt%-0.7wt% of C, 0.5wt%-1.2wt% of V, and the balance Fe; a strengthening layer is arranged above the transition layer, and the strengthening layer adopts a Fe-based metal nano-phase composite material. The preparation method comprises the following steps of preparing the Fe-based metal powder and the Fe-based metal nano-phase composite material coating; preheating a steelrail by using laser scanning heating so as to reduce the temperature gradient; preparing the gradient composite material coating on the surface of the steel rail by utilizing a laser cladding technology, and performing laser scanning heat treatment; and reducing the cooling rate after laser cladding, so that the martensite of the heat affected zone is prevented from being generated, and the cracking property of the coating is reduced. The prepared steel rail frog has the advantages that the hardness curve is smooth, the overall toughness and bearing performance are good, the strength and hardness is higher than a common heavy-load railway frog, the service life is longer, and manufacturing integration is relatively strong.

Owner:BEIJING UNIV OF TECH +2

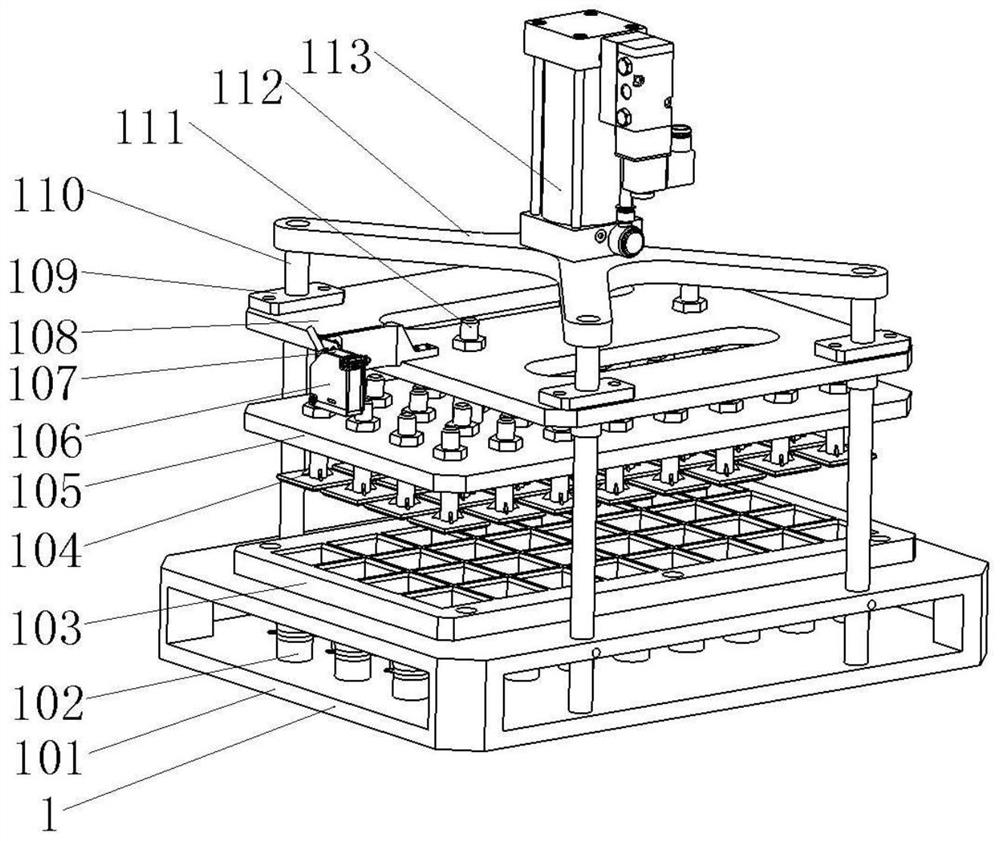

Reconfigurable die and forming device for same

The invention discloses a reconfigurable die. The reconfigurable die comprises a plurality of closely arranged hydraulic telescopic units and a hydraulic system connected with the hydraulic telescopic units, wherein each hydraulic telescopic unit comprises a pressure maintaining cylinder, a telescopic unit hydraulic valve, a hydraulic cylinder and a pressure head; the hydraulic system comprises an oil inlet line, a pressure maintaining oil line and a regulating valve used for switching between the oil inlet line and the pressure maintaining oil line. The invention also discloses a forming device for the reconfigurable die. A die point control mechanism is used for performing point control over the hydraulic telescopic units in the configurable die to form required curved surfaces. The reconfigurable die is low in cost and high in efficiency; through the closely arranged hydraulic telescopic units, unit contact points of the reconfigurable die and parts are increased, the smoothness of the curved surfaces formed by the reconfigurable die is improved, folds and indentation of punched parts can be reduced, internal residual stress of plates after punching is reduced, and the reconfigurable die is favorable for industrial popularization and application.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

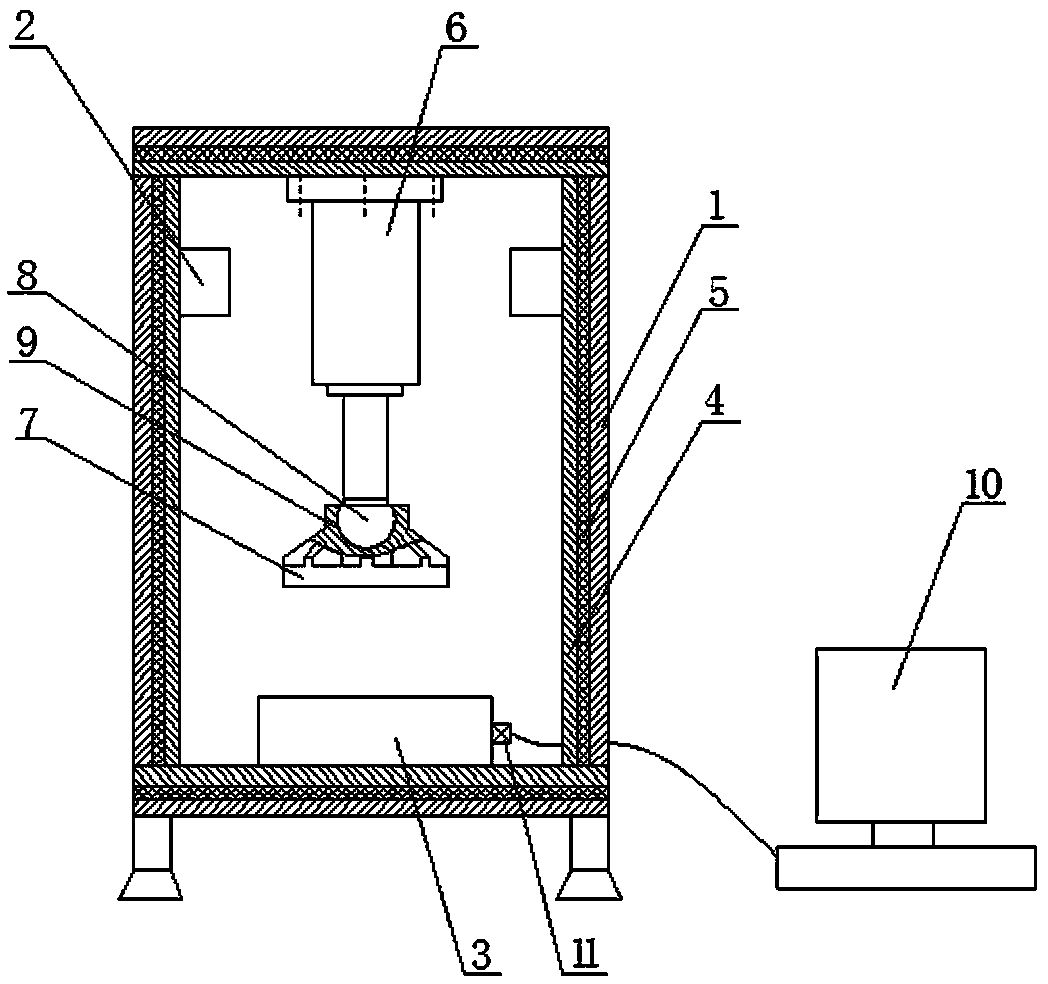

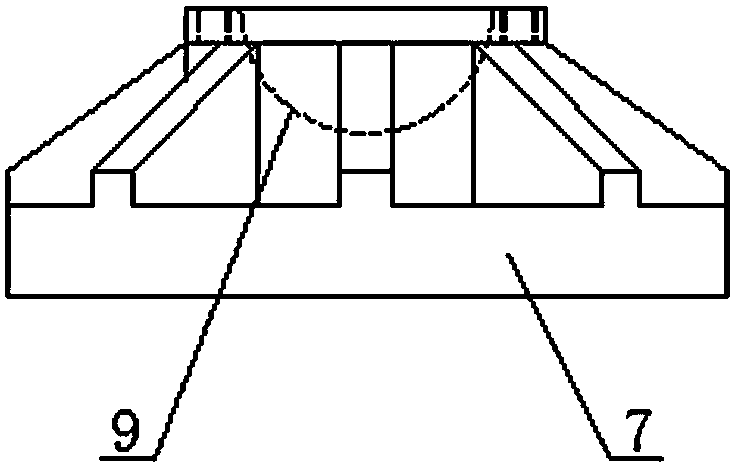

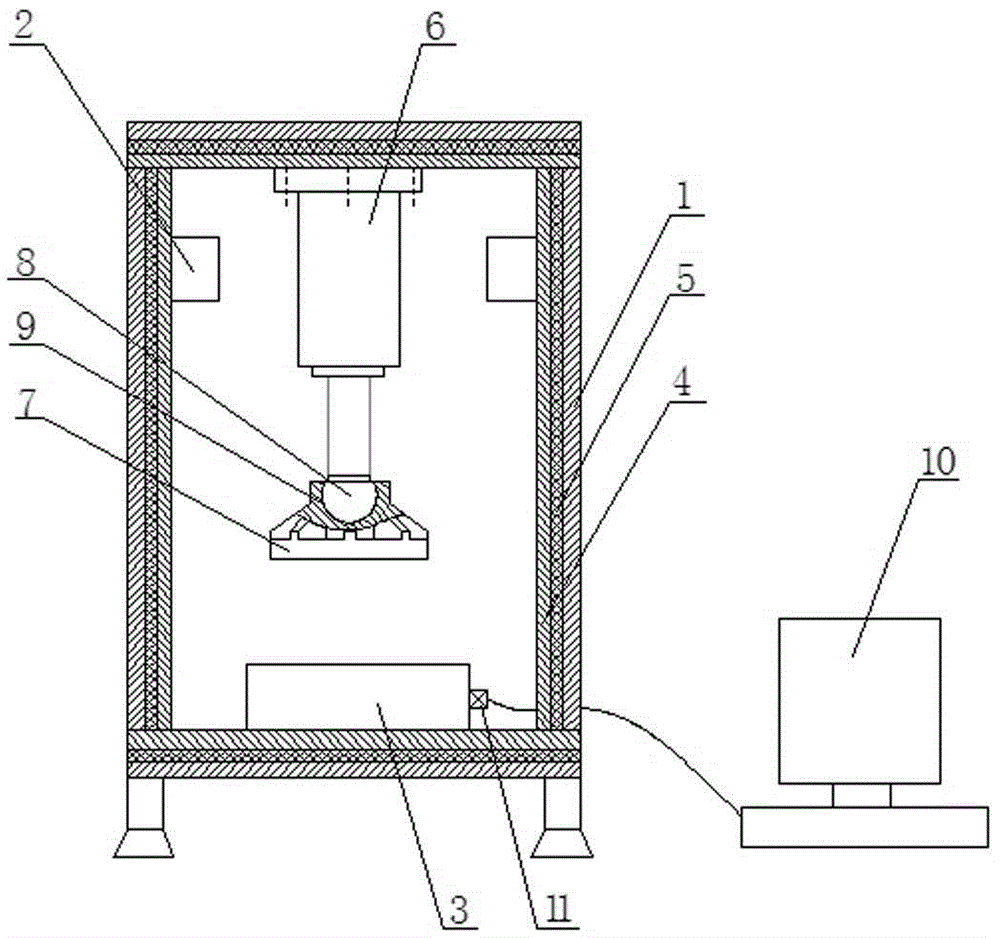

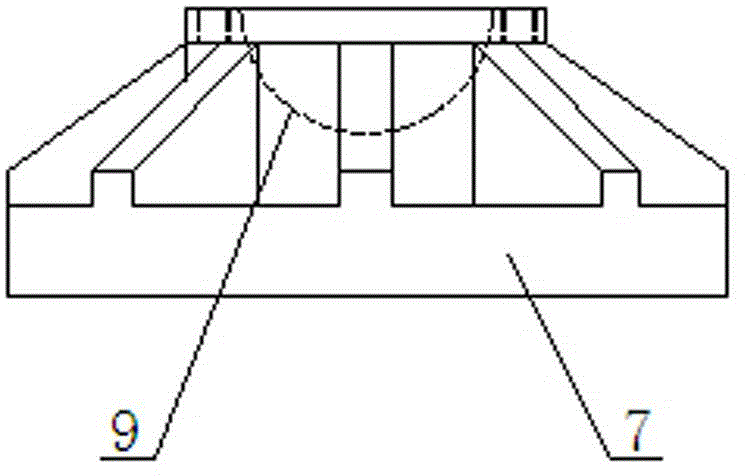

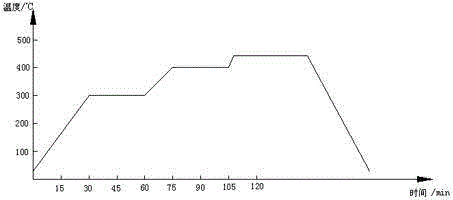

Dynamic pressurized tempering furnace for tempering saw blade matrix and tempering process

InactiveCN103981354AAvoid heat exchangeAvoid damageFurnace typesHeat treatment process controlFire protectionDisplay device

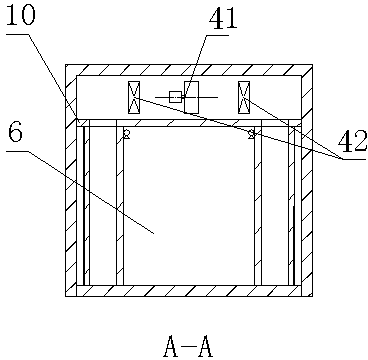

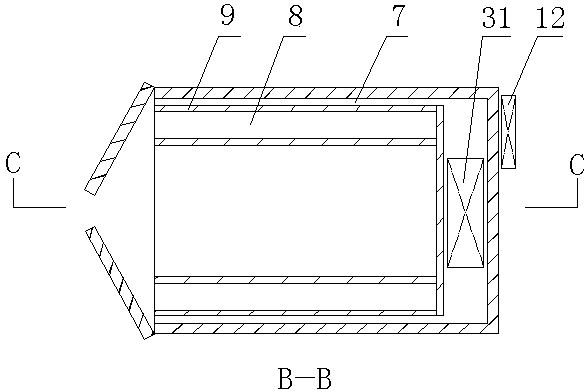

The invention discloses a dynamic pressurized tempering furnace for tempering a saw blade matrix. The dynamic pressurized tempering furnace comprises a furnace body (1), a heating device (2) and a bearing platform (3), wherein the heating device (2) and the bearing platform (3) are both arranged in the furnace body (1); the inner wall of the furnace body (1) is provided with a fire protection layer (4); an oil cylinder (6) is vertical to the top of the furnace body (1) and is arranged in the furnace body (1); the bottom of a piston rod of the oil cylinder (6) is provided with a spherical boss (8); a pressure head (7) is internally provided with a spherical groove (9). The dynamic pressurized tempering furnace also comprises a controller, a display (10) and a temperature sensor (11), wherein the controller is connected with the oil cylinder (6) and the heating device (2). The dynamic pressurized tempering furnace is compact in structure, capable of automatically regulating the angle of the pressure head according to the planeness of a saw blade and convenient for workers to operate. After being subjected to thermal treatment by the dynamic pressurized tempering furnace, the saw blade matrix is uniform in crystalline phase tissue, small in internal residual stress and low in saw blade planeness less than 0.03mm.

Owner:成都壹佰科技有限公司

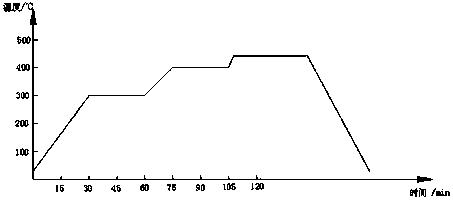

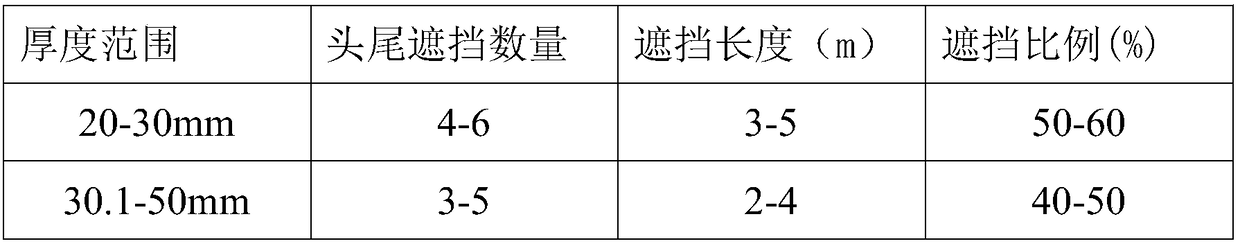

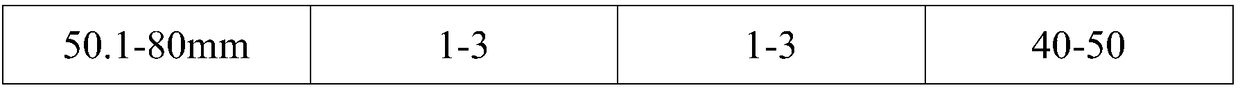

Plate shape control method of online-quenched high-strength steel plate

ActiveCN109266815AUniform deformationImprove cooling uniformityTemperature control deviceFurnace typesProduction lineSheet steel

The invention provides a plate shape control method of an online-quenched high-strength steel plate. The high-strength steel plate is formed by continuously casting blanks through the plate shape control method. The plate shape control method comprises the following steps of 1, heating, 2, descaling, 3, rolling, 4, online quenching, 5, retarded cooling and 6, tempering. The plate shape control method is applicable to a medium-thickness plate production line without arrangement of a pre-straightening machine, through a plate shape control technology, the plate shape quality of the online-quenched high-strength steel plate is improved, after tempering, the plate shape unevenness is controlled to be 7mm / 2m or below, hardening and tempering for remedy and size changing are avoided, the production cost is reduced, and the yield is increased.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

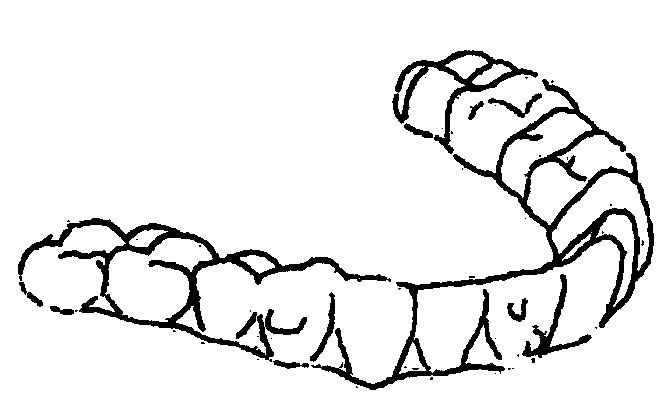

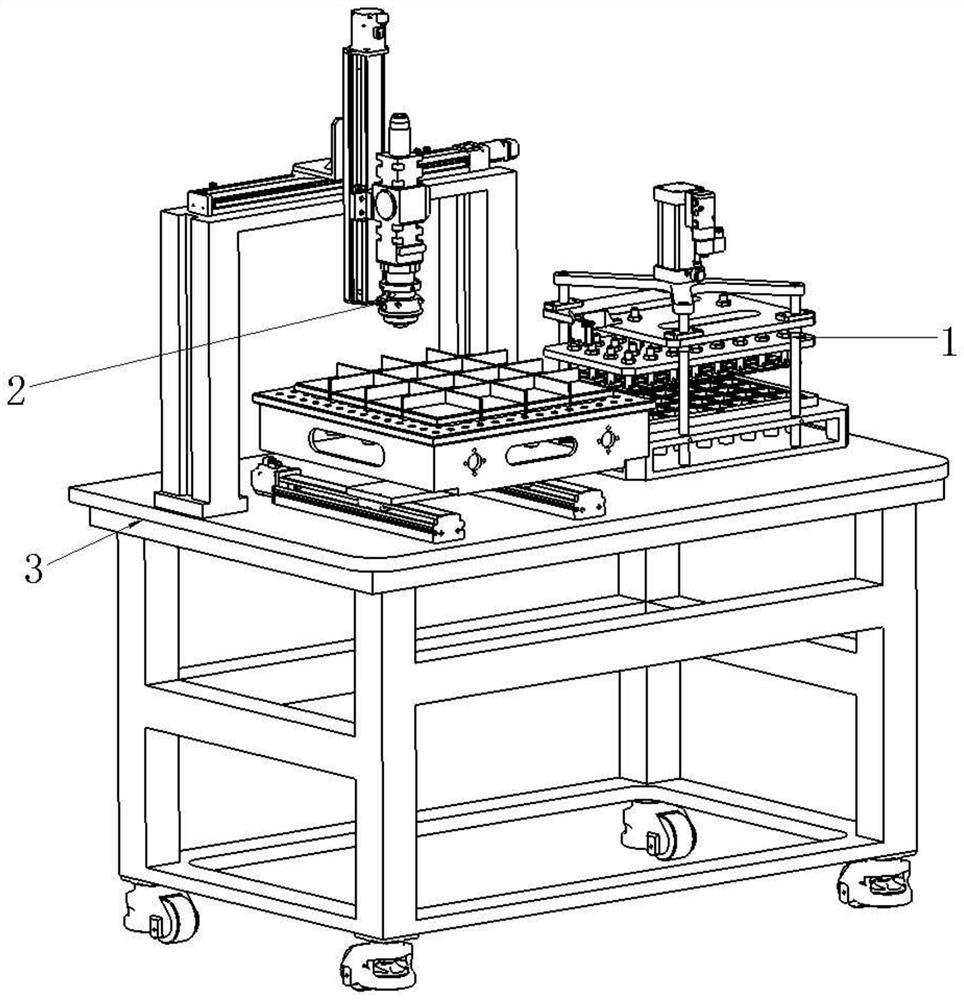

Equipment system and method for automatic cleaning and drying of braces

PendingCN109381271ARealize all-round cleaning without dead endsNo human intervention requiredTooth cleaningMegasonic cleaningEvaporation

The invention provides an equipment system and method for automatic cleaning and drying of braces. The equipment system comprises: an automatic loading platform for conveying a tool basket holding to-be-cleaned braces to a designated position; an automatic transferring module for grasping the tool basket and transferring the tool basket to each process position; a cleaning module comprising an ultrasonic cleaning module and a bubble cleaning module and used for cleaning the braces to remove residual materials on the surfaces of the braces; a compressed-air water cutting module for removing a large amount of liquid remaining on the surfaces of the braces after cleaning; a hot-air circulation drying module adopting circulating hot-air drying for evaporation of remaining moisture on the surfaces of the braces; a vacuum drying and sterilization module for sterilization of the braces in a vacuum ultraviolet sterilization manner and further evaporation of moisture; and a self-conveying unloading table for conveying the tool basket holding the cleaned and dried braces to a clean room for separation of the braces from the tool basket.

Owner:WUXI EA MEDICAL INSTR TECH

Thin wall low-pressure injection molding secondary forming mechanism

InactiveCN105034244AReduce injection pressureRelieve pressureFlat articlesHot runnerMaterials science

The invention belongs to the technical field of mold equipment and provides a thin wall low-pressure injection molding secondary forming mechanism. The thin wall low-pressure injection molding secondary forming mechanism comprises a front mold assembly and a lower mold assembly. The front mold assembly comprises an upper fixing plate, a female mold plate and a hot runner; a valve needle is arranged at the front end of the hot runner; the female mold plate is fixed to the upper fixing plate; the hot runner is arranged inside a female mold. The lower mold assembly comprises a lower fixing plate, a supporting block and a male mold plate, wherein the supporting block is fixed to the lower fixing plate. The lower mold assembly further comprises a secondary forming device located below a male mold core. The thin wall low-pressure injection molding secondary forming mechanism has the advantages that a core of a mold, namely an ejector block adopts the through hole and insert mode, the ejector block can vertically move in the oil cylinder driving mode, and the ejector block moves to drive the thickness of a cavity to change; an oil cylinder is controllable in stroke, so that the thickness of products changes with the controllable wall thickness, the injection molding pressure is low, pressure maintaining is even, internal residual stress of formed products is low, and products deform a little.

Owner:JIAXING XINYUAN PRECISION MOLD TECH

Vinyl ester resin heavy mortar floor

ActiveCN104652778AReduce curing heatSolve problems that cannot meet the requirements of heavy industrial production floor applicationsFlooringFiberIsolation layer

The invention provides a vinyl ester resin heavy mortar floor which consists of a priming coat, a vinyl ester resin mortar layer and a finish coat layer, wherein the vinyl ester resin mortar layer is directly paved on the priming coat, and an FRP (Fiber Reinforced Plastic) isolation layer is not needed to be manufactured; the once paving thickness of the vinyl ester resin mortar layer is 30-100mm, and the whole vinyl ester resin mortar layer is seamless; the vinyl ester resin mortar layer is prepared from the following raw materials in parts by weight: 1000-1200 parts of quartz sand aggregate, 100-120 parts of vinyl ester resin, 2-3 parts of methyl ethyl ketone peroxide, 1-1.5 parts of cumene hydroperoxide and 1-2 parts of cobalt iso-octoate. The vinyl ester resin heavy mortar floor has the characteristics of high mechanical strength, good load-carrying property, integrally seamless property, excellent anti-permeation property, excellent corrosion resistance property, high construction efficiency and the like, is especially applicable to regions with frequency rolling of heavy machinery, heavy high-altitude falling impact and corrosion caused by the continuous soaking of acid, alkali and saline solutions with relatively high concentrations.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

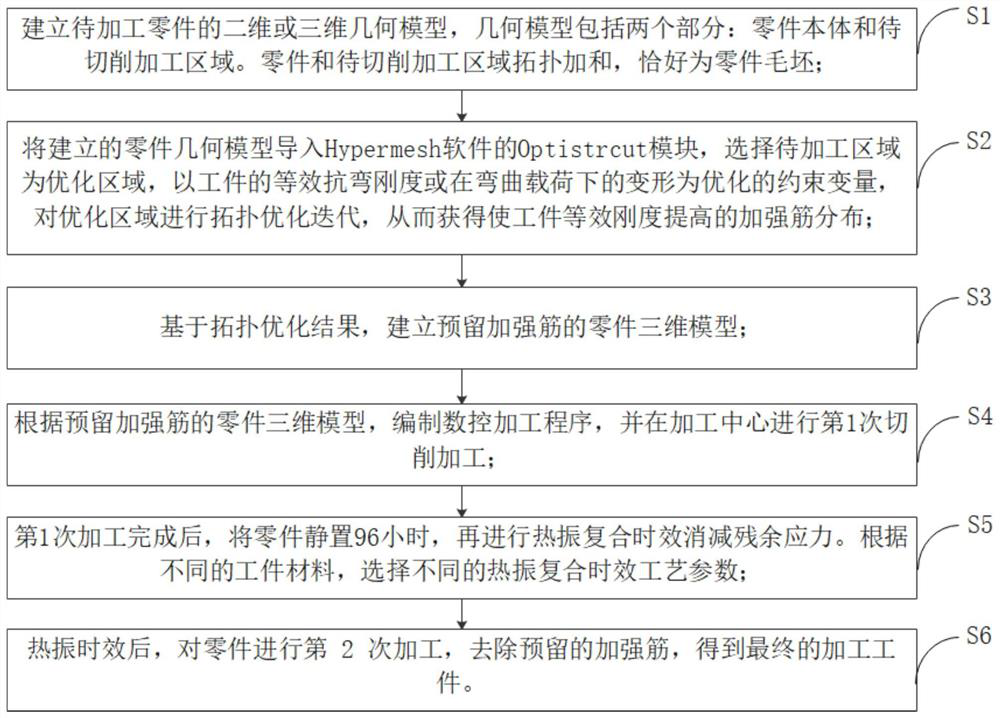

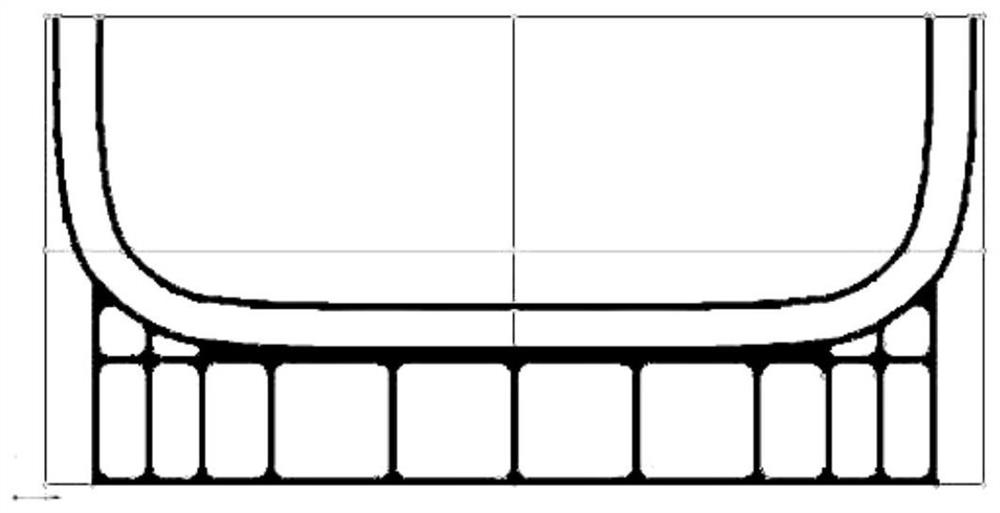

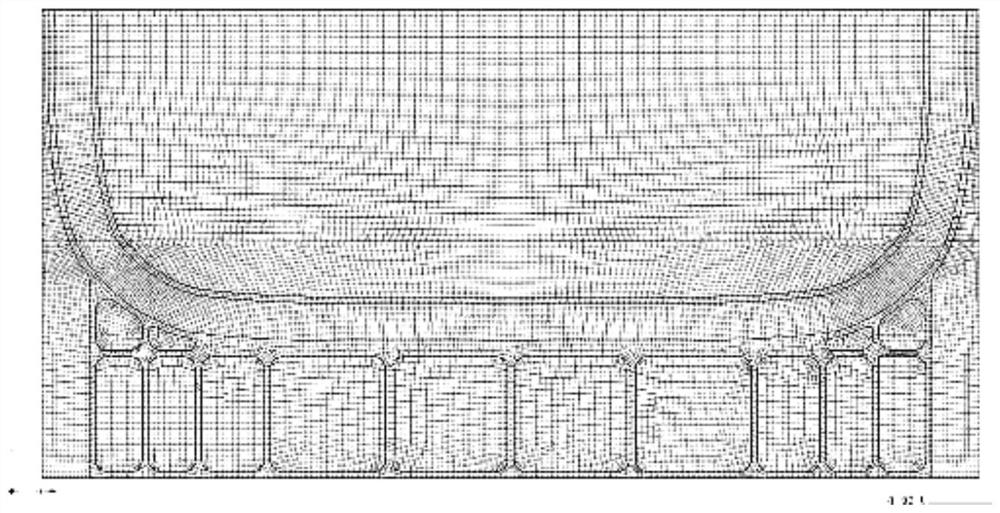

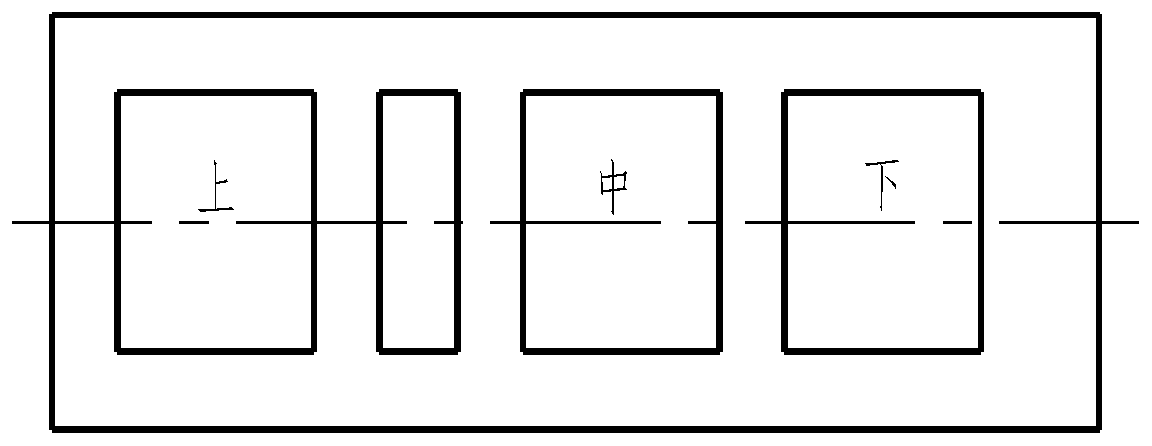

Workpiece machining deformation control method

ActiveCN112476053AIncreased bending stiffnessReduce processing deformationGeometric CADAutomatic control devicesMachining deformationLarge deformation

The invention discloses a workpiece machining deformation control method. Reinforcing ribs meeting certain conditions can be reserved through topological optimization in the primary machining stage, the bending rigidity of a workpiece is enhanced, and the machining deformation in the primary machining stage can be reduced to a great extent; the intermediate workpiece reserved with the reinforcingribs in the primary machining stage is placed for 96 hours or longer, after stress redistribution is sufficient and the size is relatively stable, the stable intermediate workpiece is obtained, then thermal vibration composite aging is conducted to reduce residual stress, workpiece deformation is further reduced, and finally the reinforcing ribs reserved in the intermediate workpiece are removed through secondary cutting machining; at the moment, due to the fact that stress is fully released and reduced, the number of the cut reinforcing ribs is smaller than that of removed materials of first-time machining, large stress redistribution caused by first-time machining cannot be generated, and after the reinforcing ribs are cut off, large deformation of a finally-obtained machined workpiece cannot be generated any more, so that the bending rigidity of the workpiece can be effectively improved, and internal residual stress can be reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

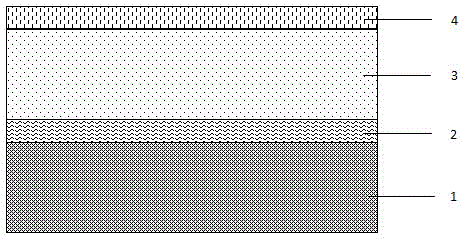

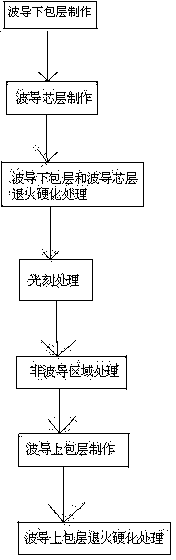

Silicon-dioxide optical waveguide production process for manufacturing optical divider

InactiveCN104360441AUniform refractive indexReduce internal residual stressOptical waveguide light guideGas phaseThermal stability

The invention discloses a silicon-dioxide optical waveguide production process for manufacturing an optical divider. The silicon-dioxide optical waveguide production process includes a lower waveguide wrapping layer manufacturing step, a waveguide core layer manufacturing step, a lower waveguide wrapping layer and waveguide core layer annealing and hardening step, a photoetching step, a non-waveguide area treatment step, an upper waveguide wrapping layer manufacturing step and an upper waveguide wrapping layer annealing and hardening processing step. The lower waveguide wrapping layer manufacturing step includes growing a SiO2 layer on a silicon wafer by the flame hydrolysis method or the chemical vapor deposition process, and doping phosphorous and boron ions as a lower waveguide wrapping layer. The waveguide core layer manufacturing step includes growing another SiO2 layer on the lower wrapping layer as a waveguide core layer by the flame hydrolysis method or the chemical vapor deposition process. The lower waveguide wrapping layer and waveguide core layer annealing and hardening step includes adopting annealing and hardening to let the two SiO2 layers be compact and uniform; the photoetching step includes protecting required waveguide graphs with photoresist. The non-waveguide area processing step includes etching a non-waveguide area by the reactive ion etching process. The upper waveguide wrapping layer manufacturing step includes removing the photoresist, covering another SiO2 layer on the waveguide core layer again by the flame hydrolysis method or the chemical vapor deposition process and doping the boron and phosphorous ions as an upper waveguide wrapping layer. The upper waveguide wrapping layer annealing and hardening step is used for fining and compacting the SiO2 layer of the upper waveguide wrapping layer. According to the above theory, the optical divider manufactured by the silicon dioxide optical waveguide is low internal residual stress, insignificant in birefrigent effect and is good in mechanical performance and thermal stability.

Owner:成都康特电子高新科技有限责任公司

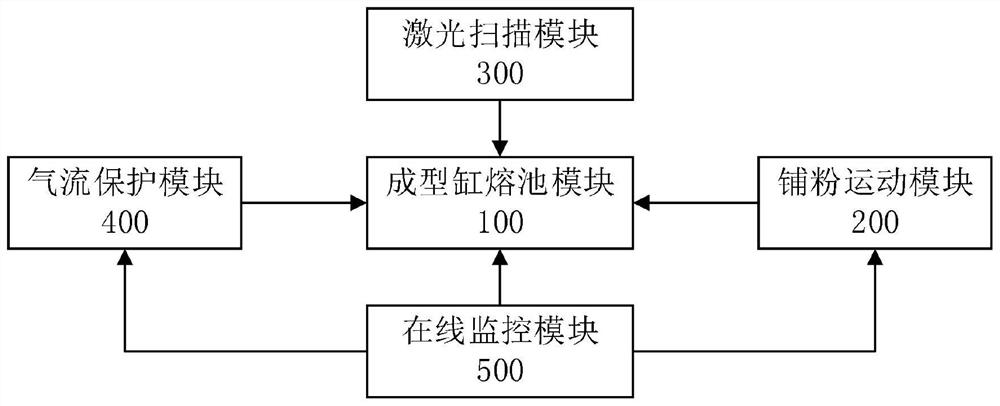

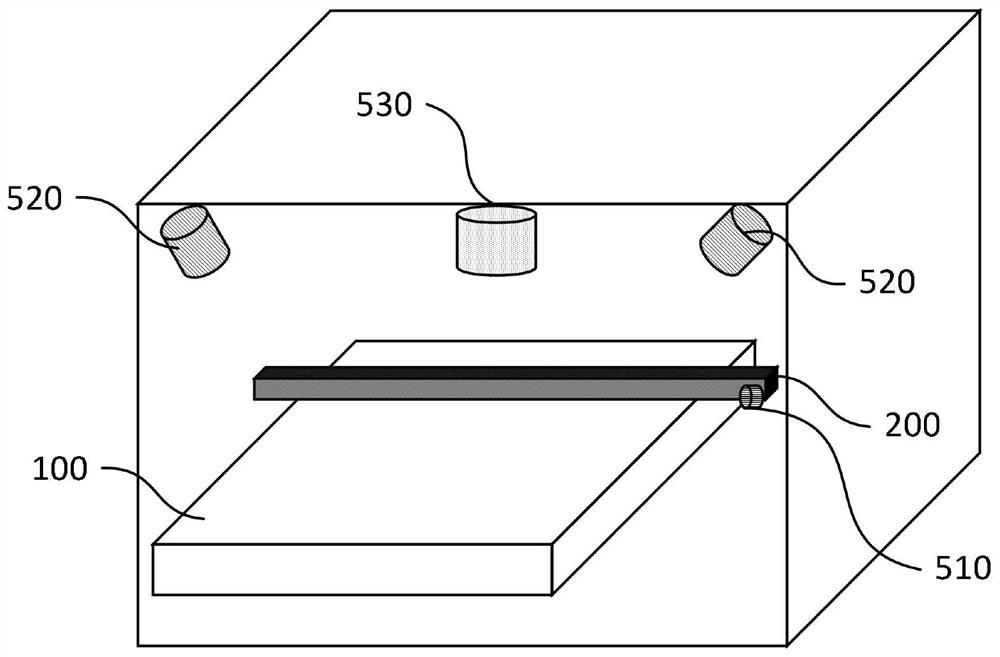

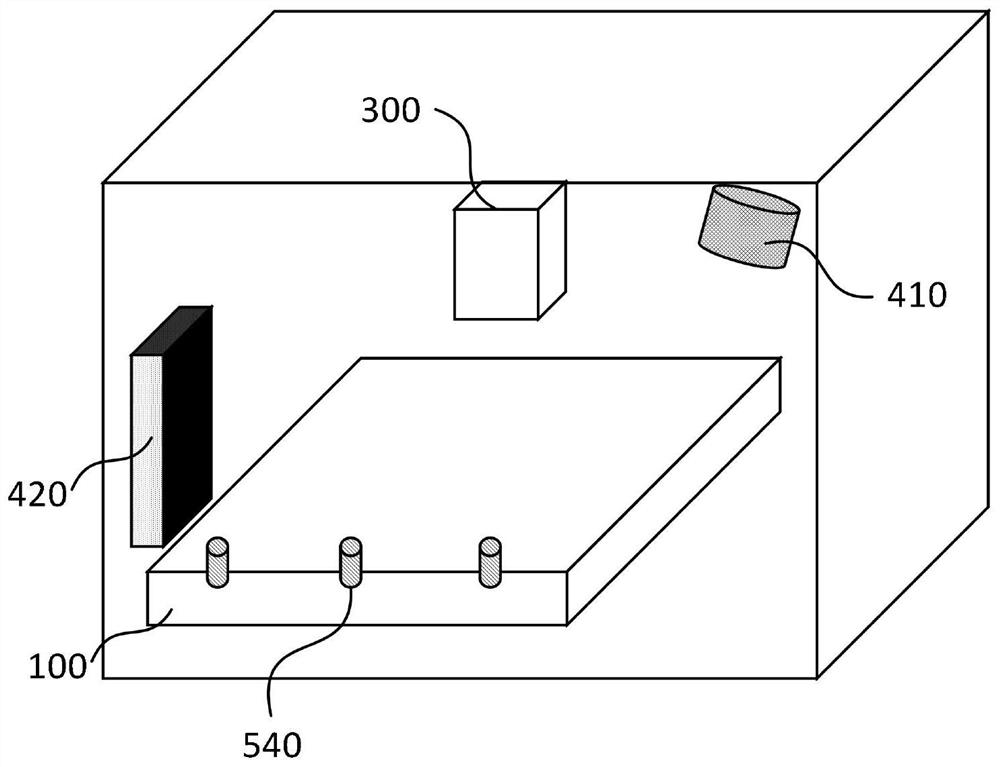

3D printing system and method based on selective laser melting

InactiveCN113172240AImprove performanceReduce internal residual stressAdditive manufacturing apparatusProcess engineeringLaser scanning

The invention provides a 3D printing system and method based on selective laser melting. A powder laying movement module conducts powder laying on a forming cylinder molten pool module; a laser scanning module is used for carrying out laser melting on the metal powder in the forming cylinder molten pool module; an airflow protection module provides inert protection gas during 3D printing; and an online monitoring module monitors product data and powder bed data in the forming cylinder molten pool module and data such as gas pressure and flow in the airflow protection module in real time, and controls work of the powder laying movement module, the laser scanning module and the airflow protection module according to the monitored data. The product and the powder bed are monitored in real time through the online monitoring module, and parameters of 3D printing of the next layer are adjusted according to the monitored result, so that abnormity can be found in time when the abnormity occurs in the 3D printing process of the product, the abnormity can be treated in time, and therefore, the SLM3D printing performance of the product is improved, and the problem of how to improve the SLM 3D printing quality is solved.

Owner:浙江机电职业技术学院

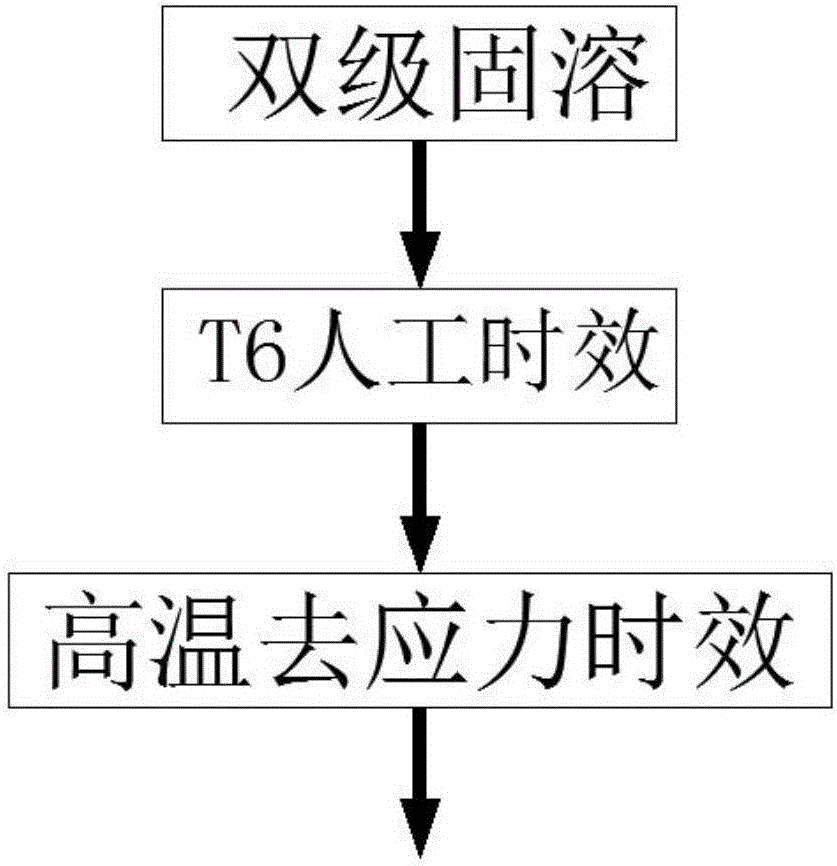

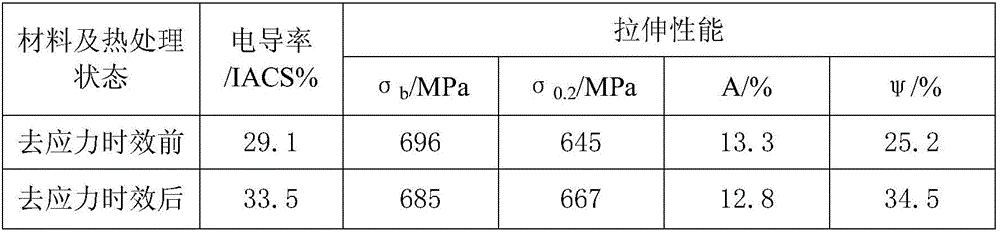

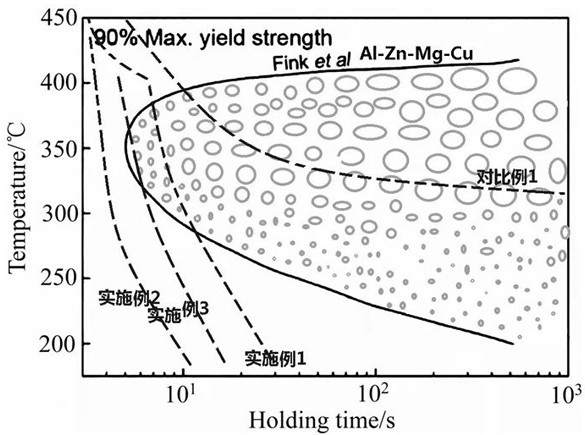

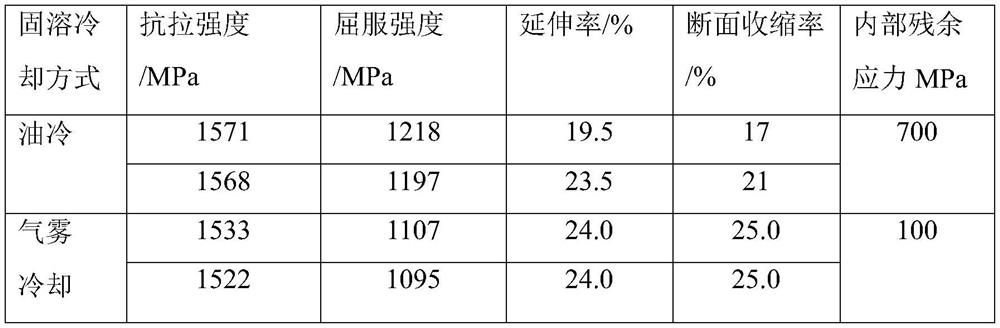

Heat treatment method of high-strength and high-flexibility 7055 aluminum alloy

The invention discloses a heat treatment method of a high-strength and high-flexibility 7055 aluminum alloy. The heat treatment method comprises the steps of double-stage solid solution and T6 manual aging in sequence; after the T6 manual aging step is finished, the high-temperature destressed aging is performed, that is, the insulation is performed by 8-10 hours at 140-150 DEG C; the double-stage solid solution step is to heat a product from the room temperature to 445-455 DEG C along with a furnace for insulation by 0.5-4 hours, to heat the product to 465-480 DEG C by 0.5 hour for insulation 0.5-4 hours and to quench the product at a water temperature of 40-50 DEG C; and the T6 manual aging step is to heat the product from the room temperature to 115-125 DEG C along with the furnace for insulation by 20-26 hours. The heat treatmeetn method maintains higher material strength level, can efficiently reduce residual stress of a sprayed 7055 aluminum alloy product, and meanwhile, improves comprehensive performances of the product. The heat treatment method solves the cracking problem of the product in subsequent machining process, reduces the machining deformation of the product, and improves the size precision.

Owner:JIANGSU HAORAN SPRAY FORMING ALLOY

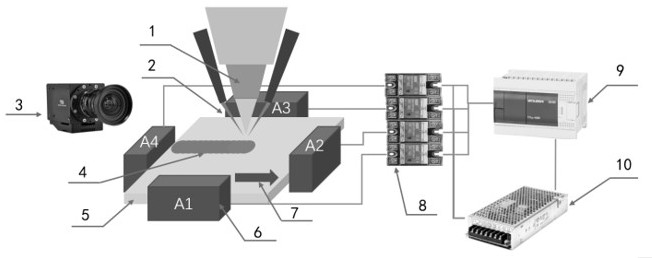

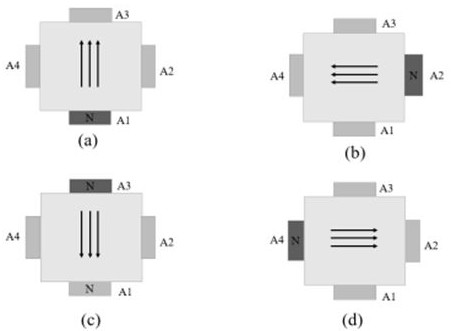

External field assisted high-entropy alloy laser additive manufacturing device and method thereof

PendingCN114669759AImprove liquidityEasy to overflowAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysControl cell

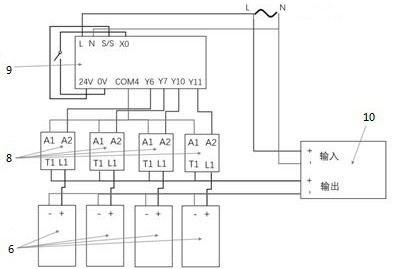

The invention belongs to the field of laser additive manufacturing, and particularly relates to an external-field-assisted high-entropy alloy laser additive manufacturing device and method.The external-field-assisted high-entropy alloy laser additive manufacturing device comprises a metal substrate, a magnetic field unit located around the metal substrate, a magnetic field control unit, a laser and a laser additive manufacturing coaxial powder feeder; the magnetic field unit comprises electromagnets A1, A3, A2 and A4 which are respectively arranged in the front direction, the rear direction, the left direction and the right direction of the metal substrate; the magnetic field control unit comprises a PLC (Programmable Logic Controller), an electromagnetic relay and a working power supply, the electromagnetic relay is respectively connected with the electromagnets A1, A2, A3 and A4, the PLC controls the electromagnetic relay to realize the on-off among the electromagnets A1, A2, A3 and A4, a dynamic reciprocating electromagnetic field is formed around the metal substrate, and the working power supply is connected with the electromagnetic relay. And electromagnetic force is generated through regular changes of the dynamic magnetic field to regulate and control fluid movement in the molten pool, the turbulence effect in the molten pool is improved, the fluidity of the WTaNbMo refractory high-entropy alloy molten pool is improved, the defects of looseness and air holes can be reduced, and important application value is achieved.

Owner:JIANGSU UNIV OF SCI & TECH

A Gradient Material Rail Frog Fabricated by Laser Cladding

ActiveCN110129674BImprove wear resistanceImprove carrying capacityMetallic material coating processesHeat-affected zoneLaser scanning

The invention provides a gradient composite material steel rail turnout coating prepared by laser cladding. The composite material is characterized in that a transition layer adopts a Fe-based alloy material, wherein the Fe-based alloy material comprises the following components of, in percentage by weight, 13wt%-17wt% of Cr, 3wt%-6wt% of Ni, 1wt%-1.5wt% of Si, 0.5wt%-1wt% of Mn, 0.3wt%-1.2wt% ofNb, 1wt%-1.5wt% of B, 0.05wt%-0.7wt% of C, 0.5wt%-1.2wt% of V, and the balance Fe; a strengthening layer is arranged above the transition layer, and the strengthening layer adopts a Fe-based metal nano-phase composite material. The preparation method comprises the following steps of preparing the Fe-based metal powder and the Fe-based metal nano-phase composite material coating; preheating a steelrail by using laser scanning heating so as to reduce the temperature gradient; preparing the gradient composite material coating on the surface of the steel rail by utilizing a laser cladding technology, and performing laser scanning heat treatment; and reducing the cooling rate after laser cladding, so that the martensite of the heat affected zone is prevented from being generated, and the cracking property of the coating is reduced. The prepared steel rail frog has the advantages that the hardness curve is smooth, the overall toughness and bearing performance are good, the strength and hardness is higher than a common heavy-load railway frog, the service life is longer, and manufacturing integration is relatively strong.

Owner:BEIJING UNIV OF TECH +2

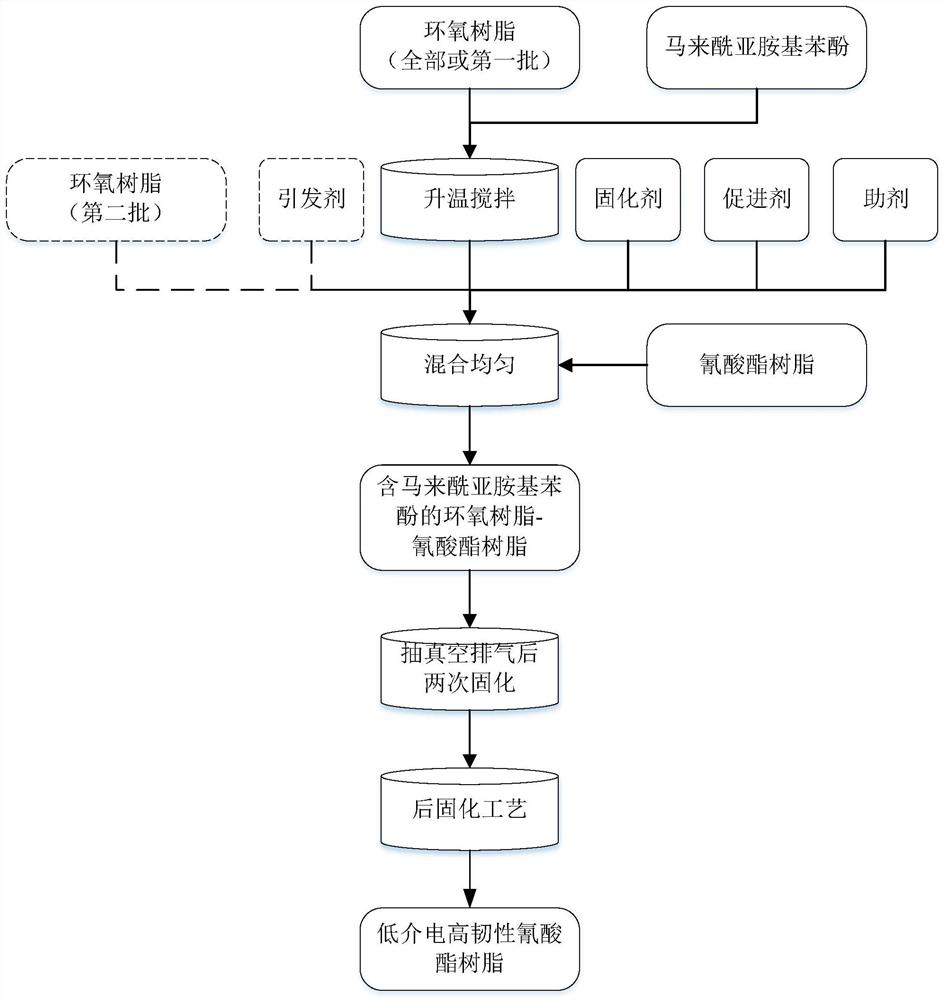

Low-temperature curing low-dielectric high-toughness cyanate ester resin and preparation method thereof

ActiveCN114149684ALow curing temperatureShorten the curing timeChemical industryImidePolymer science

The invention discloses low-temperature curing low-dielectric high-toughness cyanate ester resin and a preparation method thereof, and belongs to the field of organic polymer synthesis and thermosetting resin modification.On the basis that an existing mature cyanate ester resin system is not changed, maleimido phenol containing double bonds and phenolic hydroxyl groups is introduced, and the low-temperature curing low-dielectric high-toughness cyanate ester resin is obtained; according to the present invention, the cyanate ester resin can be cured under the medium-high temperature condition, and can be rapidly cured under the low temperature condition of less than 130 DEG C so as to prepare the cyanate ester resin with characteristics of low dielectric constant and high toughness, and the mechanical property and the dielectric property of the cyanate ester resin can be improved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

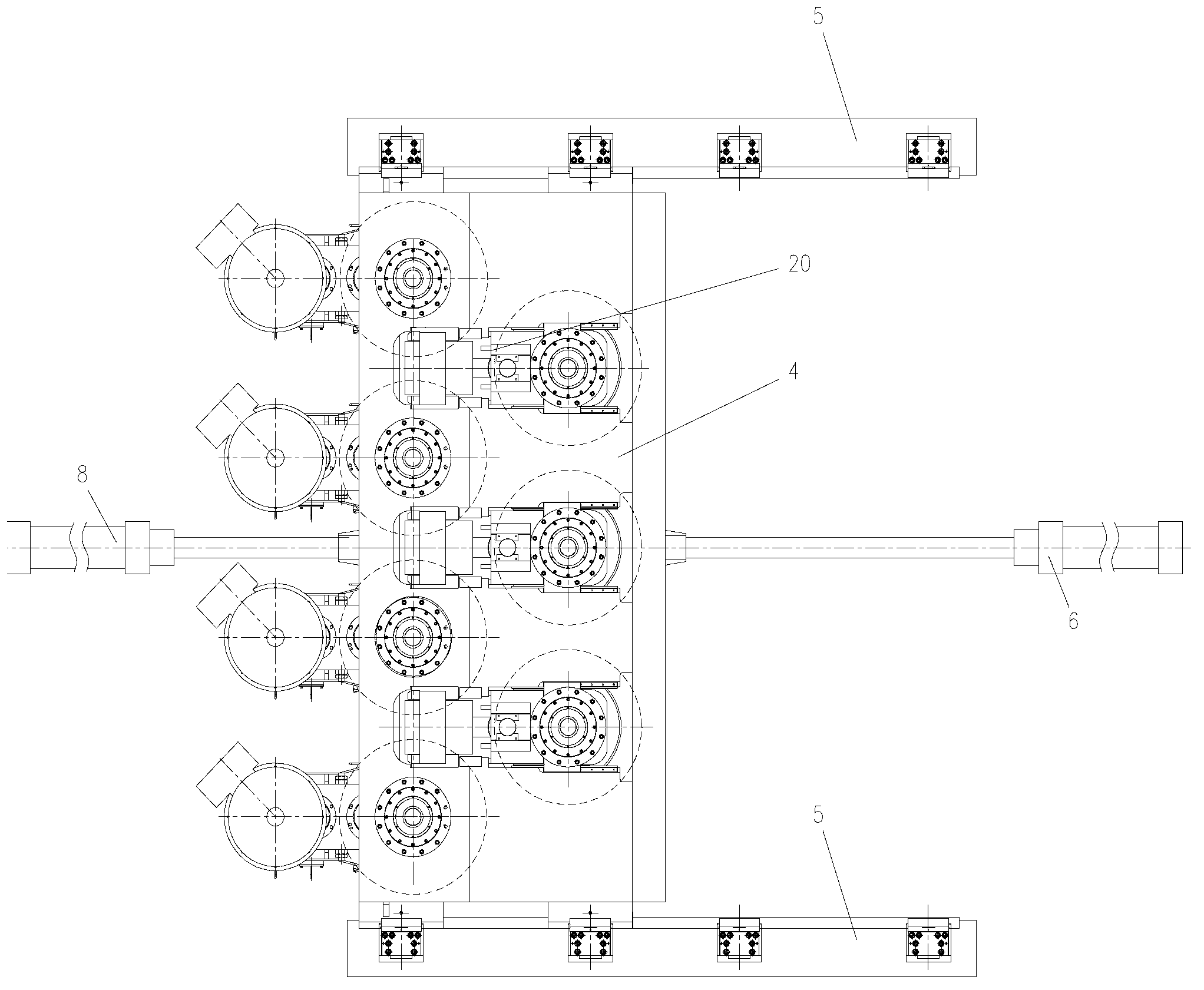

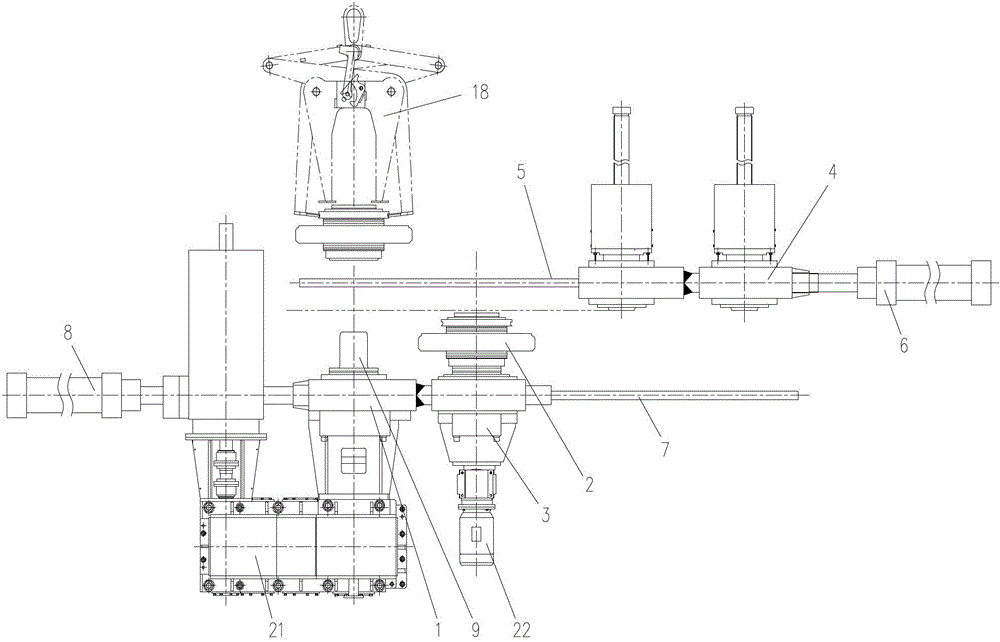

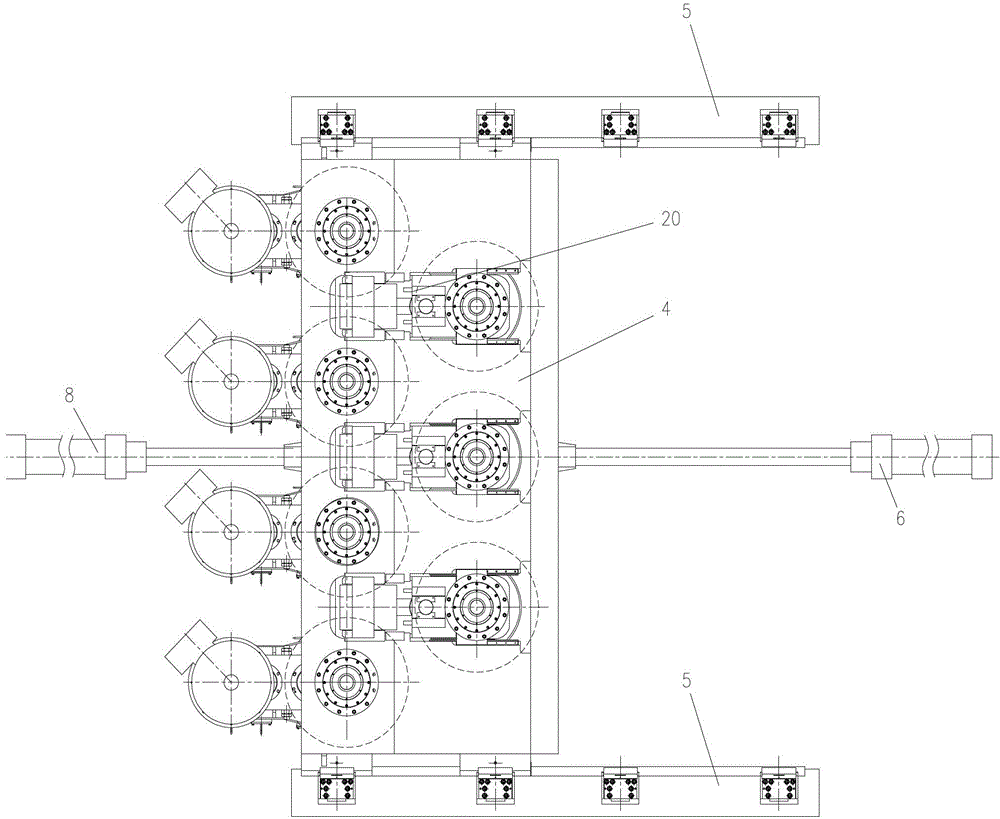

Double-bracing vertical type straightening machine

The invention discloses a double-bracing vertical type straightening machine. The double-bracing vertical type straightening machine comprises a drive side rack, a roll collar assembly, an axial adjusting device and a locking device. The double-bracing vertical type straightening machine further comprises an operation side rack and an operation side sliding seat, wherein the operation side sliding seat is fixedly arranged. The lower end of the roll collar assembly is arranged on the drive side rack, the upper end of the roll collar assembly is arranged on the operation side rack, and the operation side rack is arranged on the operation side sliding seat and is matched with the operation side sliding seat along a horizontal line in a sliding mode. The double-bracing vertical type straightening machine further comprises a roller-replacing hydraulic cylinder connected with the operation side rack. According to the double-bracing vertical type straightening machine, the upper end of the roll collar assembly and the lower end of the roll collar assembly are both supported by the racks, a simple-supporting structure is formed to enable the roll collar assembly and the rack to be better in rigidity, the roll collar assembly and the rack are not prone to deforming during a straightening process, the quality of a straightened product can be effectively improved, and internal residual stress of the product can be reduced. When rollers are replaced, the operation side rack can be moved away from the upper end of the roll collar assembly integrally through the roller-replacing hydraulic cylinder, the roller-replacing operation is simple, roller-replacing time is short, and production efficiency and equipment utilization rate can be improved.

Owner:CISDI ENG CO LTD

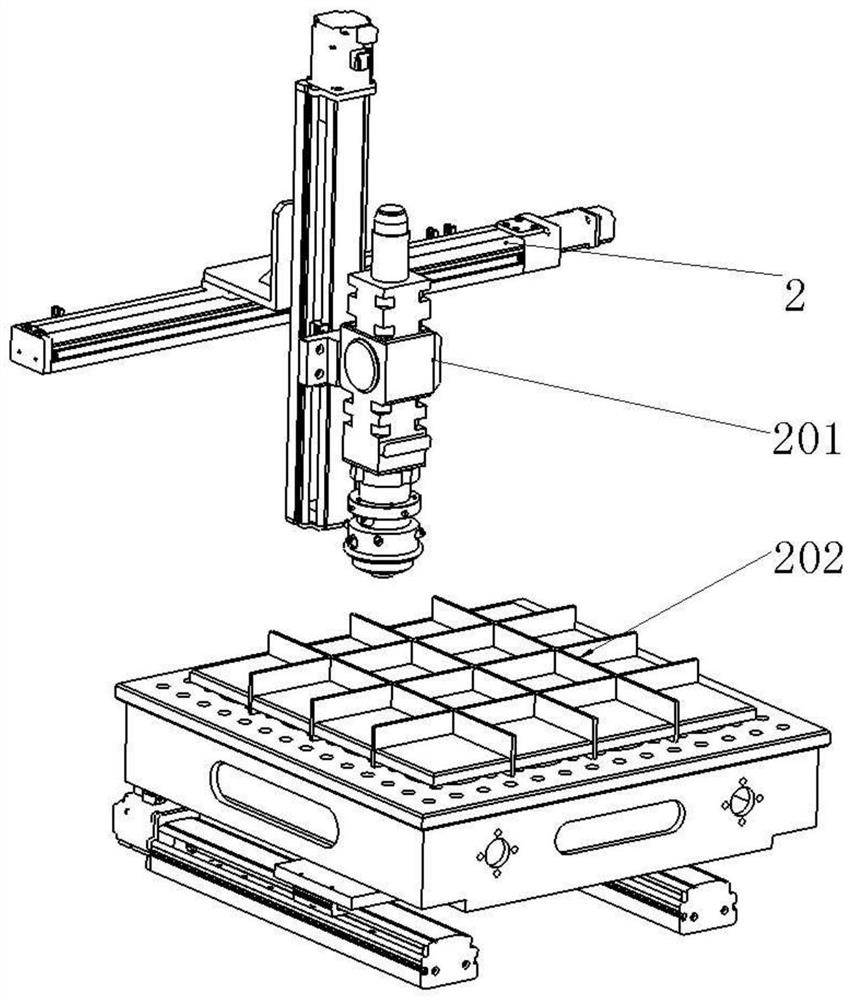

Ultrasonic-assisted laser micro-cladding method and device for gradient functional composite material

PendingCN114799182AImprove thermal conductivityFlat surfaceAdditive manufacturing apparatusMetallic material coating processesGradient materialGraphite

The invention provides an ultrasonic-assisted laser micro-cladding device for a gradient functional composite material. The ultrasonic-assisted laser micro-cladding device comprises a rack, a preset piece sample preparation assembly and an ultrasonic-assisted laser micro-cladding assembly, wherein the preset piece sample preparation assembly and the ultrasonic-assisted laser micro-cladding assembly are installed on the rack. The ultrasonic-assisted laser micro-cladding assembly comprises a laser micro-cladding head assembly and an ultrasonic-assisted workbench assembly. The invention also provides an ultrasonic-assisted laser micro-cladding method for the functional gradient composite material, which comprises the following steps: in the early stage of implementation, according to the gradient material theory, preparing a preset sheet sample through the procedures of controlling the component proportion of the copper-based composite material, performing a wet ball milling process, performing ultrasonic-assisted processing on the preset sheet, performing vacuum drying and demolding and the like; and then preparing the preset sheet sample into the graphene / copper-based gradient functional composite coating through a multi-channel and multi-layer processing mode under the action of a composite energy field based on an ultrasonic-assisted laser micro-cladding process. According to the method, the high-quality gradient functional composite coating can be formed in a metallurgical bonding mode through the laser micro-cladding technology.

Owner:WENZHOU POLYTECHNIC

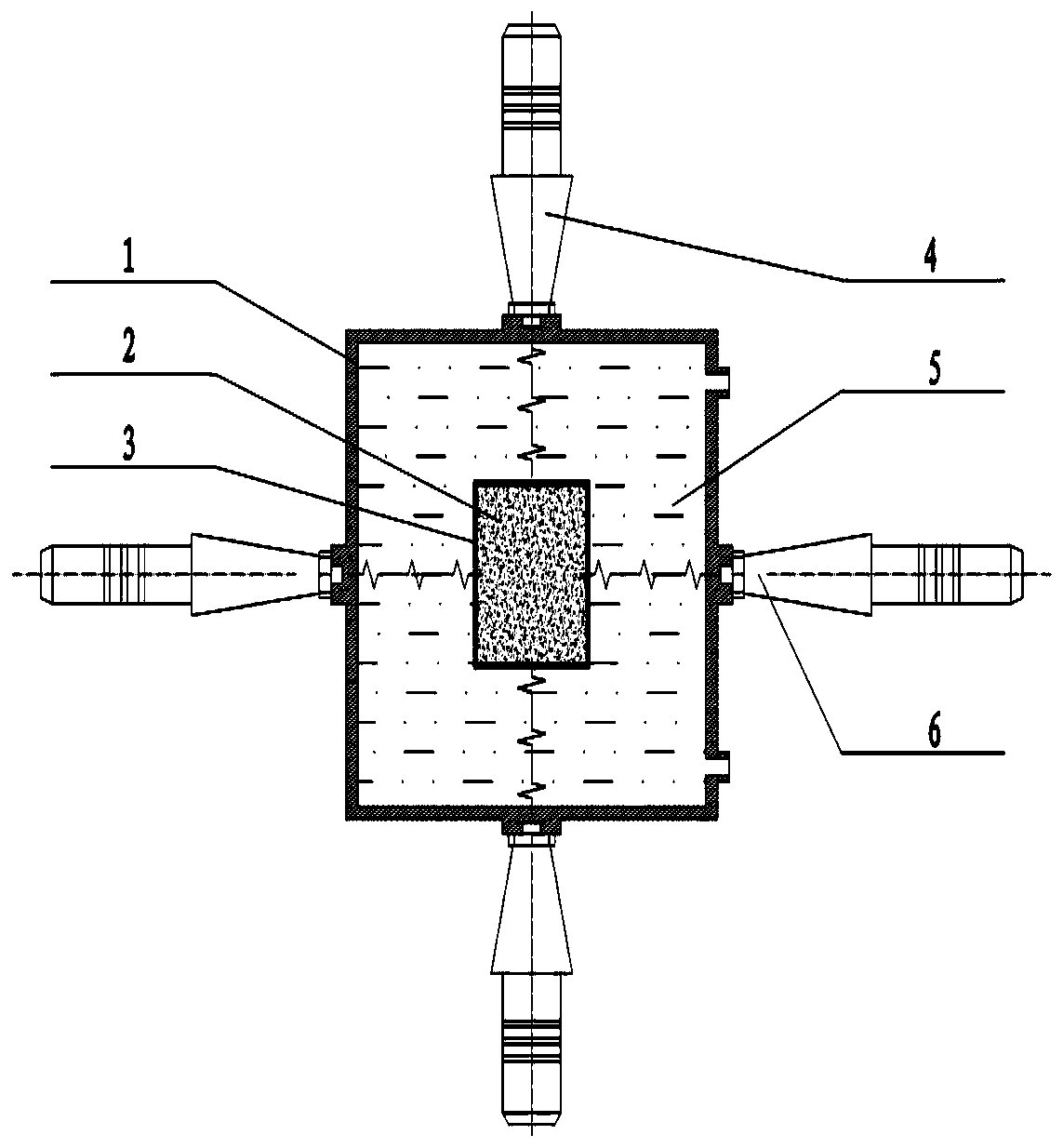

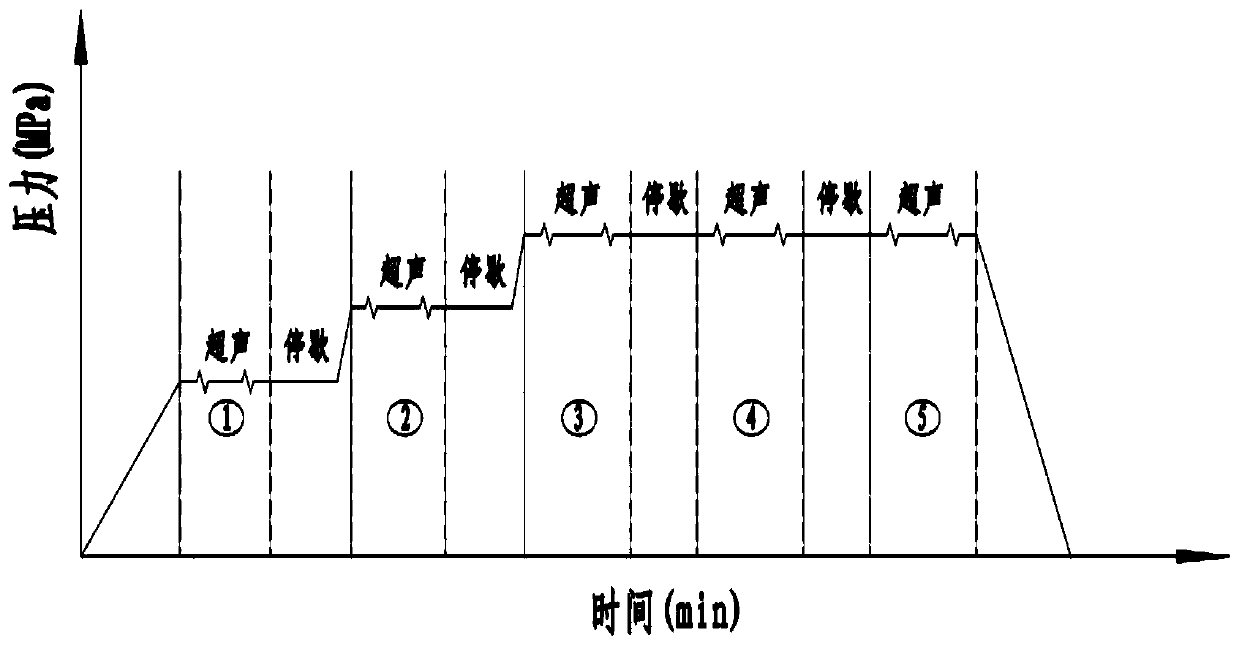

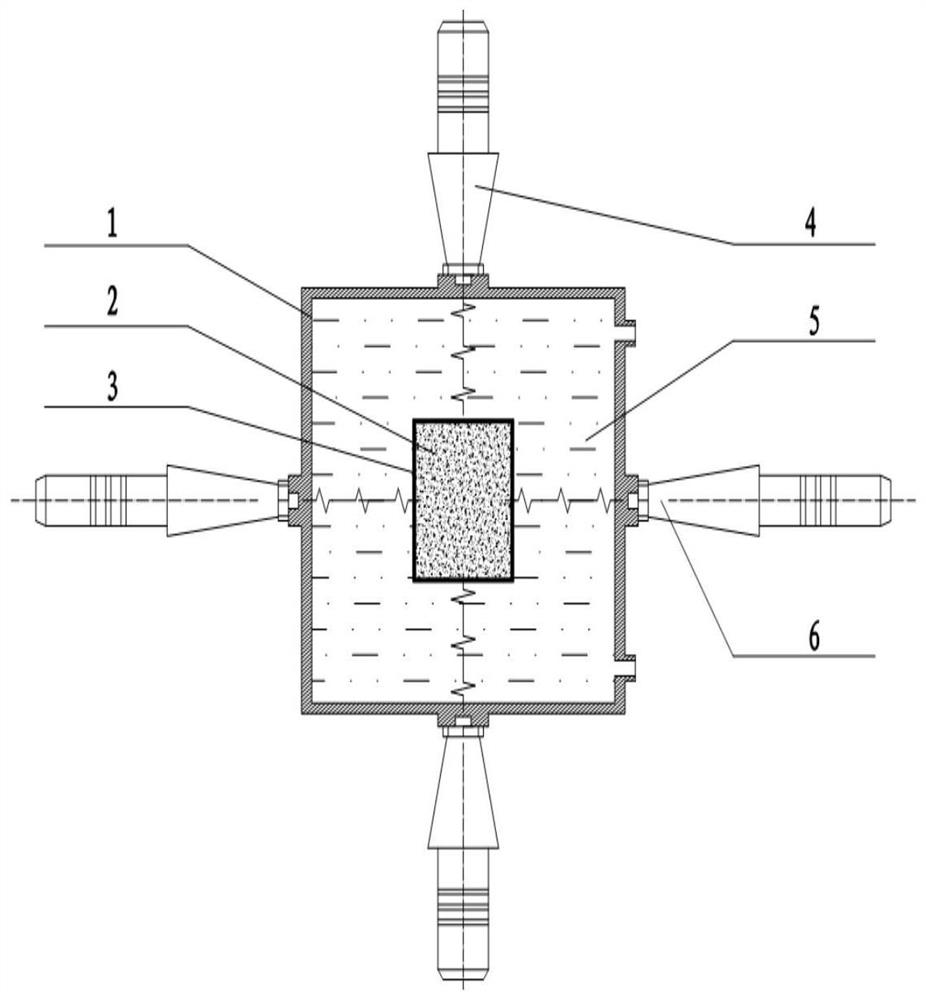

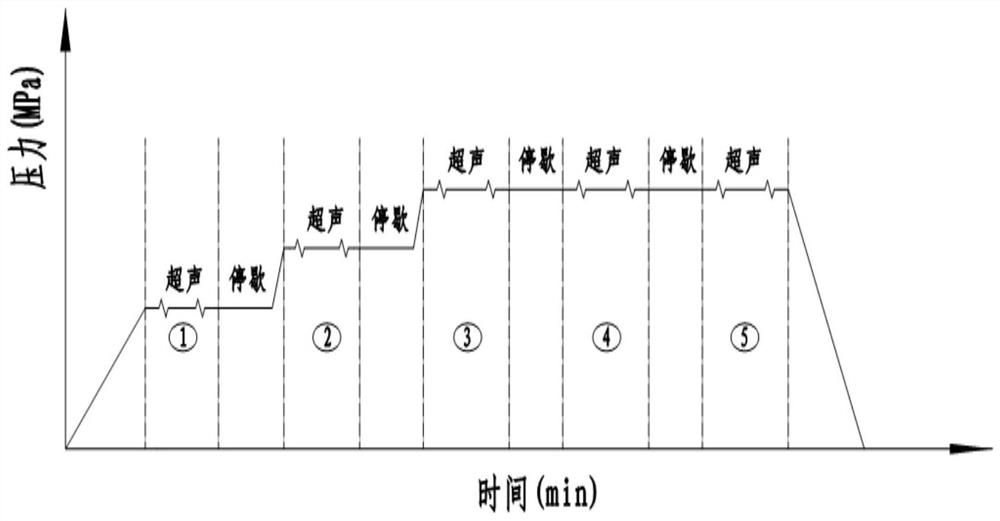

Ultrasonic auxiliary powder forming method in fluid environment

The invention discloses an ultrasonic auxiliary powder forming method in the fluid environment. Firstly, powder particles are formed under the action of hydrostatic pressure, the density of powder pressing blanks reaches about 80% of the theoretical density of the powder pressing blanks, application of the hydrostatic pressure is kept, power ultrasounds are introduced, and the powder pressing blanks are further densified and are uniform in stress under the ultrasonic vibration action. According to the ultrasonic auxiliary powder forming method in the fluid environment, the power ultrasounds are introduced in the powder particle hydrostatic pressure forming process, mobility and filling performance of the powder particles are improved, and the pressure needed for densification is reduced; and meanwhile, the density distribution uniformity of the formed pressing blanks can be improved, accordingly, residual stress of the powder pressing blanks is reduced, and the mechanical performance of the powder pressing blanks is improved. Meanwhile, the mechanical vibration action generated during spreading of ultrasonic waves in an oil medium, the ultrasonic cavitation effect, the heat actiongenerated due to sound wave absorption through the medium and the like are utilized, viscosity of the fluid medium can be obviously reduced, and the purpose of improving mobility of the fluid medium is achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

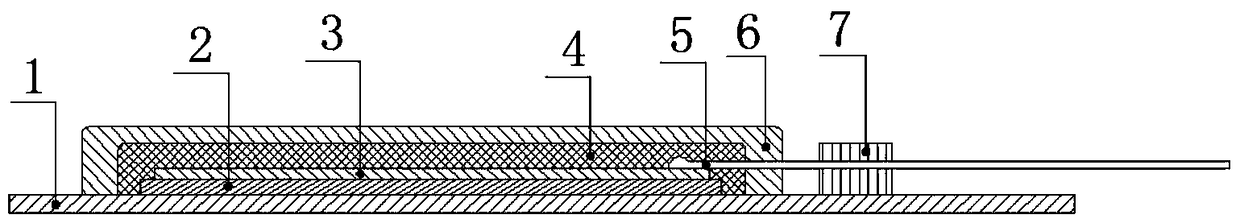

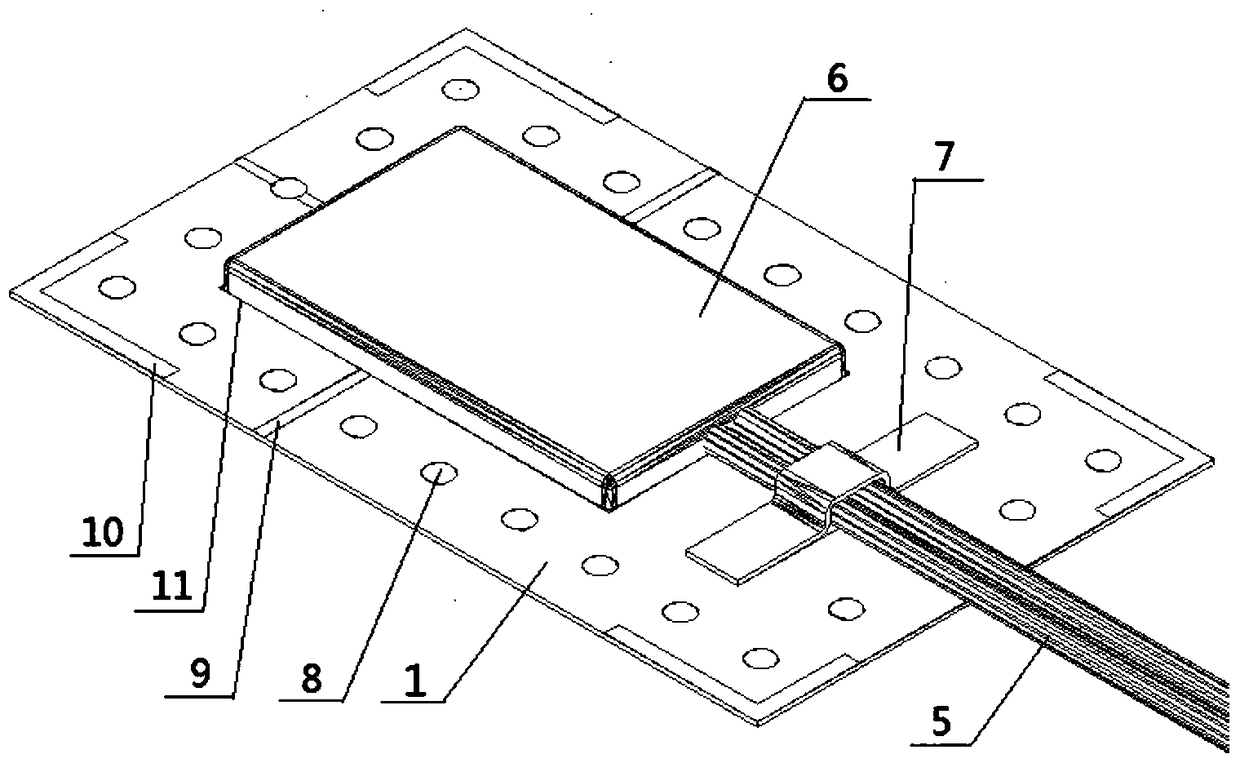

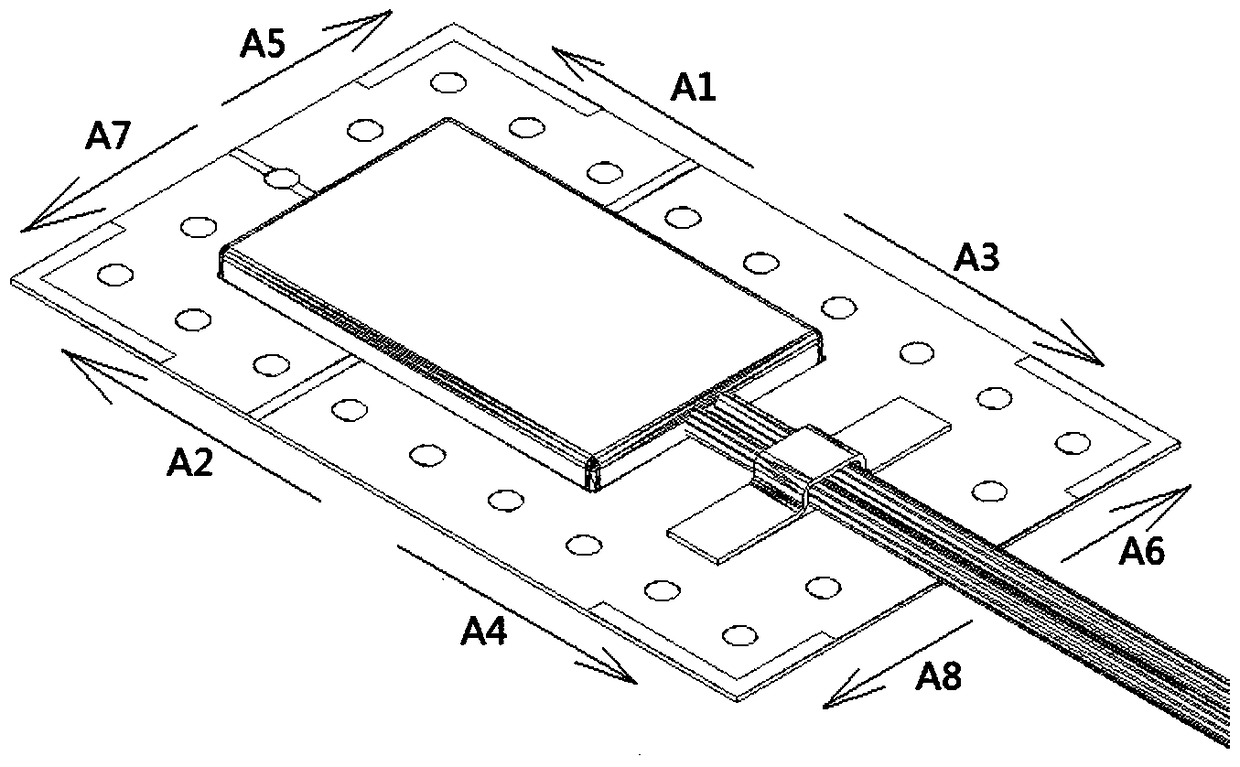

A kind of strain gauge and its manufacturing and installation method

ActiveCN104359393BExcellent heat and humidity resistanceFirmly connectedElectrical/magnetic solid deformation measurementAdhesiveEngineering

The invention provides a strain gauge which is quick to mount, high in test accuracy, high in resistance to heat and humidity, high in stability and suitable for stress strain test of medium-sized and large-sized metal components, and methods for manufacturing and mounting the strain gauge. The strain gauge comprises a metal base body, an adhesive layer, a resistance strain gauge, a moisture-proof layer, a signal lead and a protective layer, wherein the resistance strain gauge is fixedly mounted on the metal base body by virtue of the adhesive layer; the signal lead is electrically connected with a bonding pad of the resistance strain gauge and is led out; the moisture-proof layer coats the surface of the resistance strain gauge; the protective layer coats the surface of the moisture-proof layer. The manufacturing method comprises the following steps: (a) adhering the resistance strain gauge to the metal base body by virtue of an adhesive; (b) leading the signal lead out of the bonding pad of the resistance strain gauge; (c) forming the moisture-proof layer on the surface of the resistance strain gauge by virtue of a moisture-proof adhesive, wherein the coverage area of the moisture-proof layer is greater than that of the resistance strain gauge; (d) forming the protective layer on the surface of the moisture-proof layer by virtue of a protective adhesive, wherein the coverage area of the protective layer is greater than that of the moisture-proof layer. During mounting, the strain gauge is fused and welded on a measured metal component by virtue of spot welding equipment.

Owner:中航电测仪器(西安)有限公司

Plastic-wooden composite profile conditioning chamber

The invention relates to a plastic-wooden composite profile conditioning chamber which comprises a conditioning chamber, humidifying devices, a heating device and a ventilation device, wherein a compartment for containing a plastic-wooden composite profile is arranged at the front part of the conditioning chamber; an entrance is formed in the front side wall of the compartment; humidifying devices are arranged at the left and right sides of the compartment; the heating device comprises a microwave generator and a steam heater; the microwave generator is arranged at the rear part of the conditioning chamber; the steam heater and the ventilating device are arranged at the top of the conditioning chamber together. According to the plastic-wooden composite profile conditioning chamber, the plastic-wooden composite profile treated in the conditioning chamber is small in internal stress, high in size stability and wide in application scope; the plastic-wooden composite profile conditioning chamber is simple in structure and convenient to use; one conditioning chamber can contain plastic-wooden composite profiles produced by multiple plastic-wooden extrusion production lines; the existing extrusion production lines are completely reserved and the conditioning chamber has very good application prospect.

Owner:FUJIAN AGRI & FORESTRY UNIV

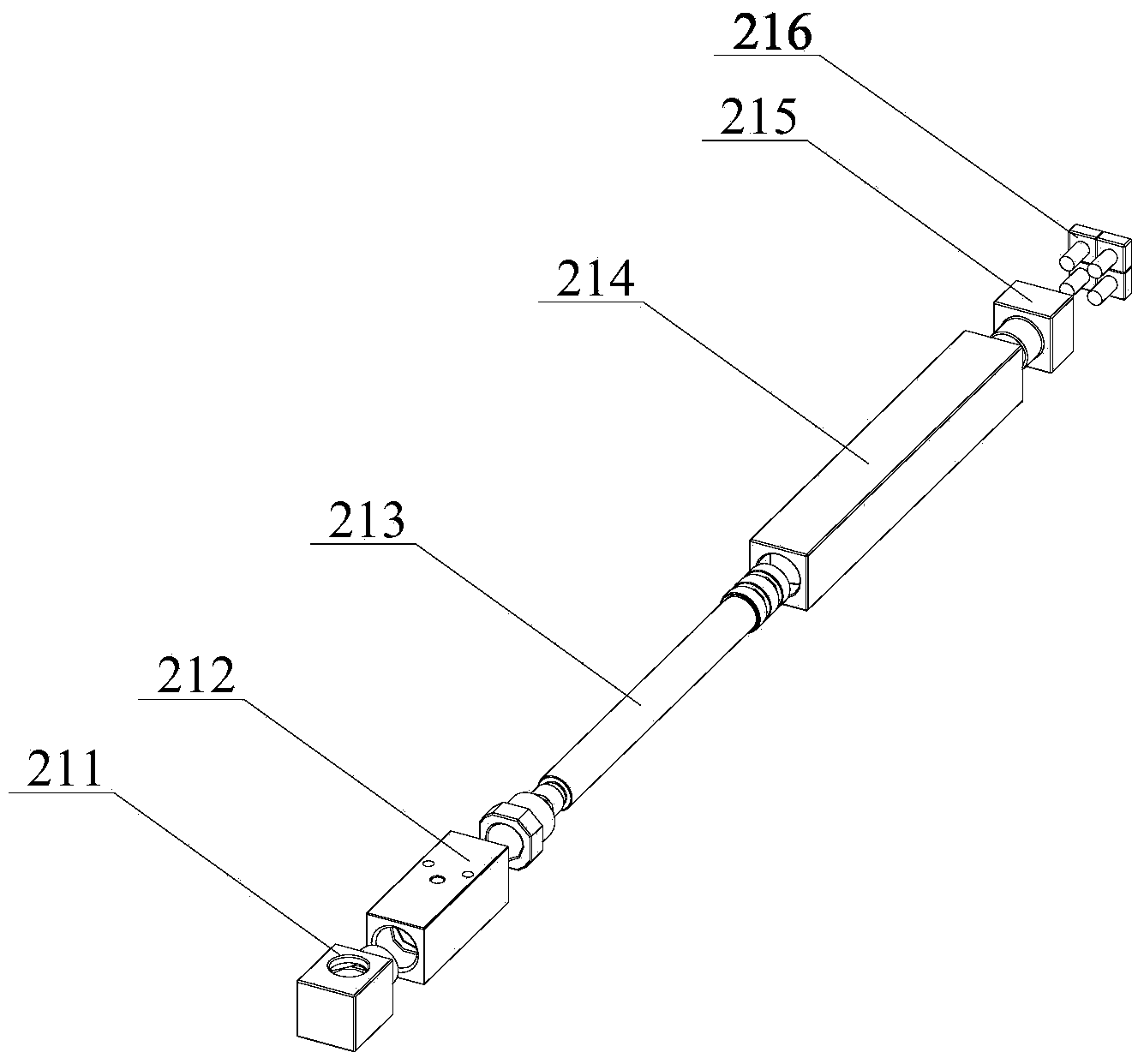

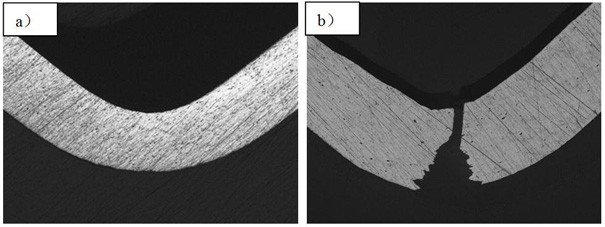

Production and processing method of pearlitic steel rail and lifting and moving steel lifting machine

ActiveCN109517957BExtended service lifeSimple structureFurnace typesHeat treatment furnacesFatigue damagePearlite

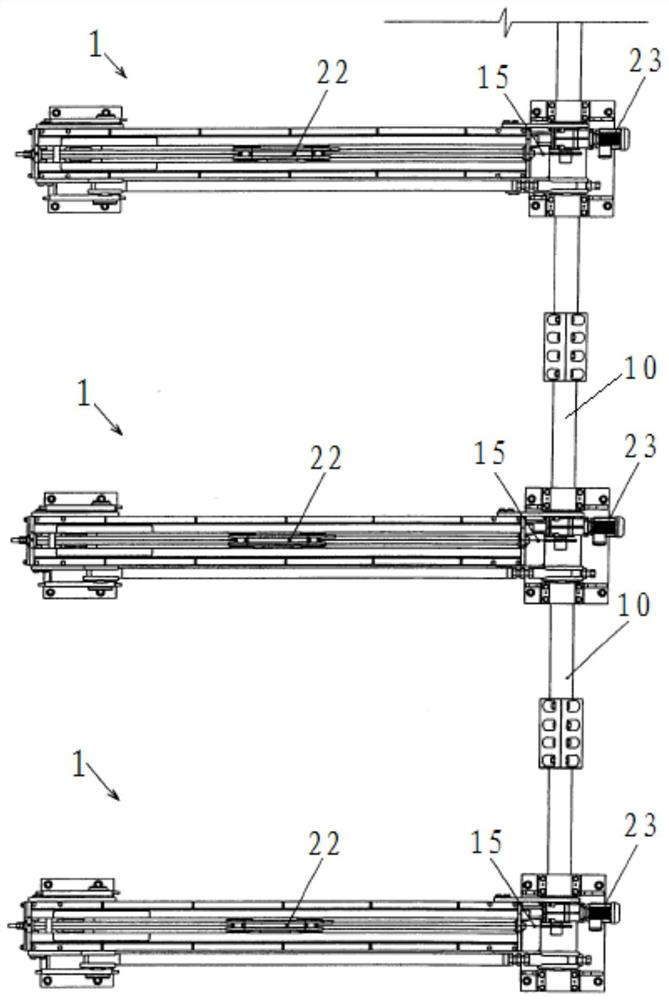

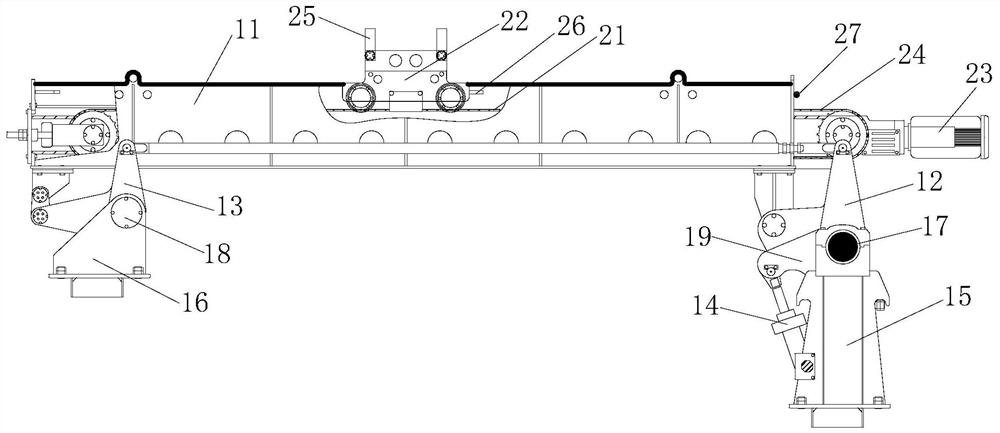

The invention discloses and relates to the technical field of metal heat treatment and particularly relates to a pearlite steel rail production treatment method and a lifting steel lifting and shifting machine thereof. The method comprises the followings steps that a, rolled pearlite steel rails are placed on a lifting steel lifting and shifting machine; b, during conveying of the pearlite steel rails, the lifting steel lifting and shifting machine applies acting force on the steel rails, so that S-shaped bending deformation or circular-arc bending deformation of the pearlite steel rails in the horizontal plane is achieved; c, the pearlite steel rails are conveyed to an inlet of a heat treatment unit; and d, the pearlite steel rails are fed into the heat treatment unit, and a cooling device is arranged in the heat treatment unit and used for cooling the pearlite steel rails in an accelerated mode. The strength and tenacity of the steel rails can be improved through bending deformation,an accelerated cooling medium is applied to the pearlite steel rails through the cooling device, the comprehensive performance of the steel rails is improved, the fatigue damage probability of the pearlite steel rails is lowered, and the overall service lives of the steel rails are prolonged.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

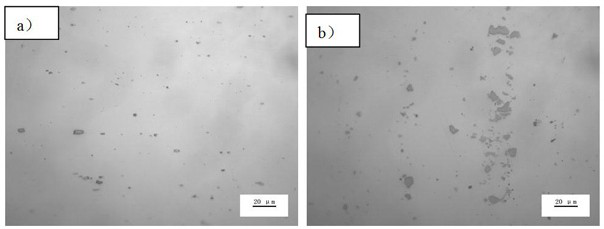

Preparation method of ultrahigh-strength 7-series aluminum sheet

ActiveCN114561577AReduce internal residual stressGuaranteed StrengthProcess efficiency improvementThin slabUltimate tensile strength

The invention discloses a preparation method of an ultrahigh-strength 7-series aluminum sheet. The ultrahigh-strength 7-series aluminum sheet comprises the following chemical components in percentage by mass: less than or equal to 0.20% of Si, less than or equal to 0.30% of Fe, 0.30-1.20% of Cu, 0.30-0.60% of Mn, 1.7-2.1% of Mg, 5.3-7.0% of Zn, 0.01-0.05% of Ti and the balance of aluminum and inevitable impurities, and the ultrahigh-strength 7-series aluminum sheet is prepared through semi-continuous casting, homogenizing heat treatment, surface milling, heating, hot rolling, cold rolling, solid solution quenching, artificial aging and the like. The thickness of the finished product ranges from 0.15 mm to 0.50 mm, the tensile strength is larger than or equal to 560 MPa, the yield strength is larger than or equal to 460 MPa, the ductility is larger than or equal to 10%, and the qualified product can be bent by 90 degrees (the radius R is smaller than or equal to 0.5 mm). The thin plate can be widely applied to backlight plates and structural parts of computers, mobile phones and display screens.

Owner:CHINALCO RUIMIN +1

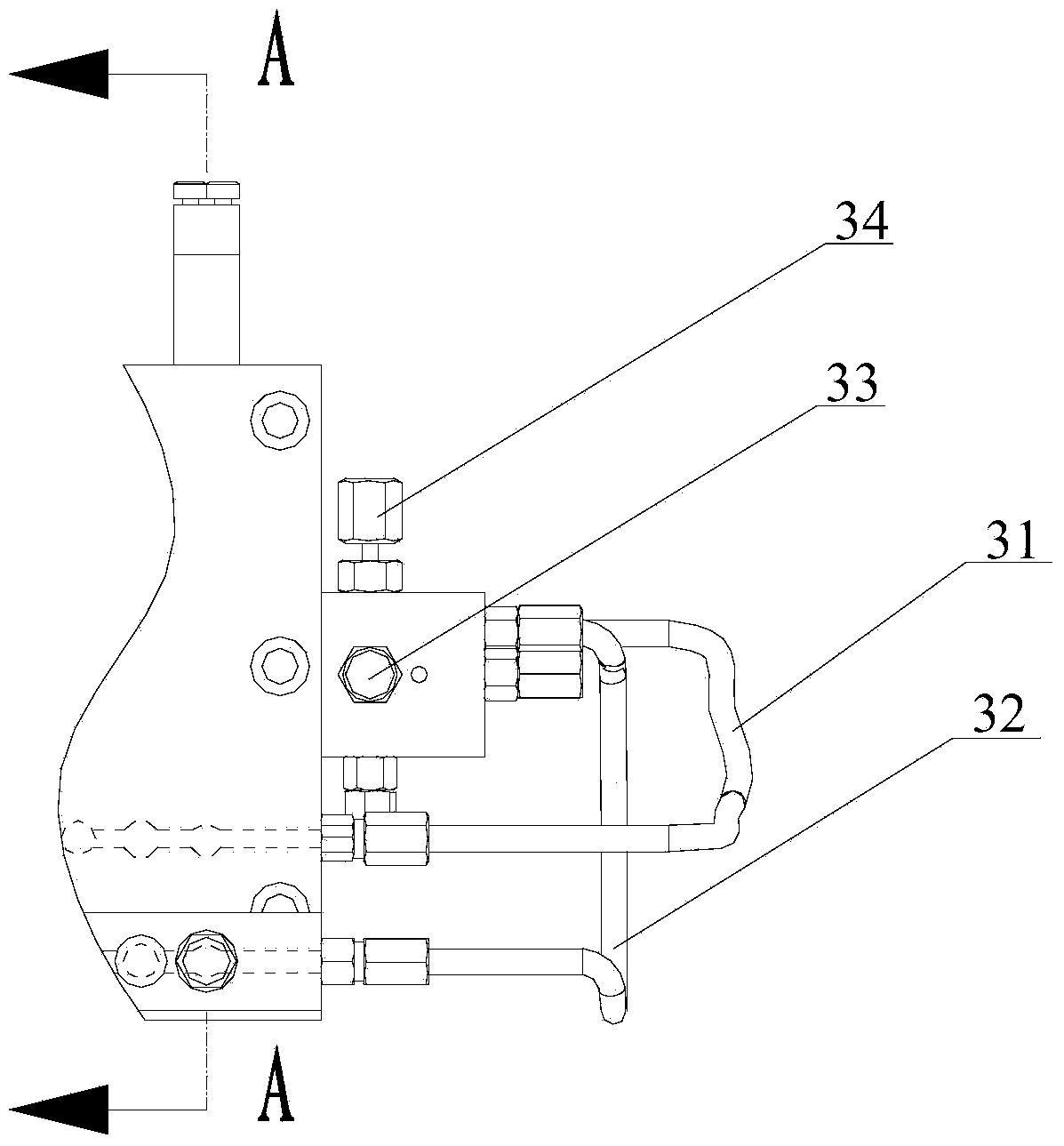

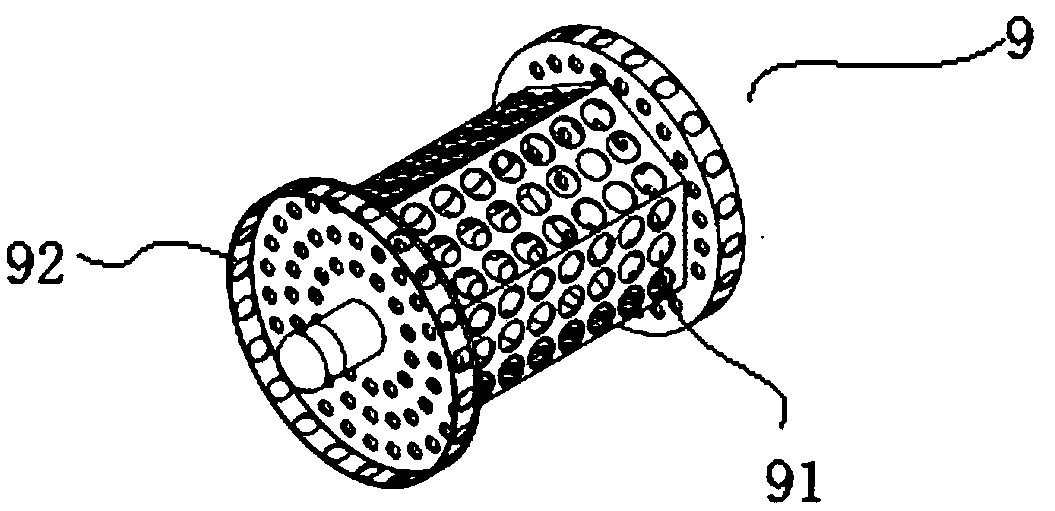

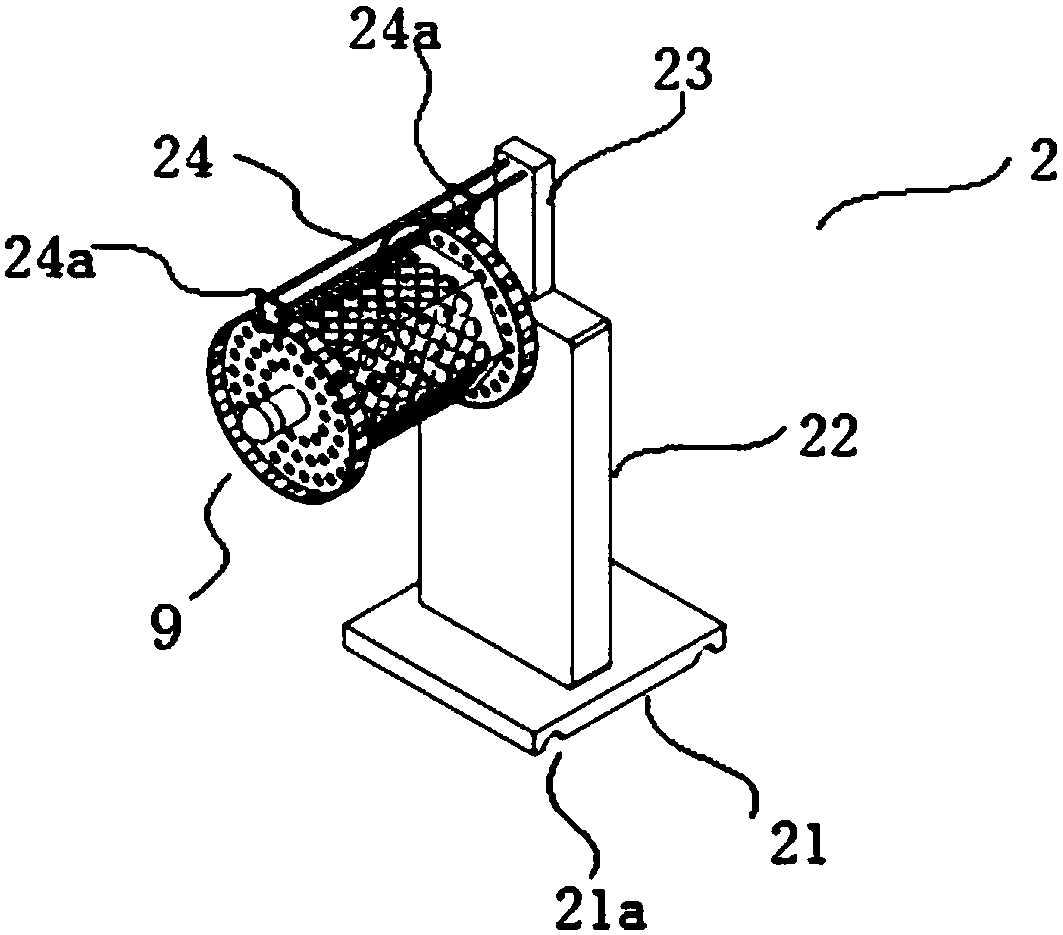

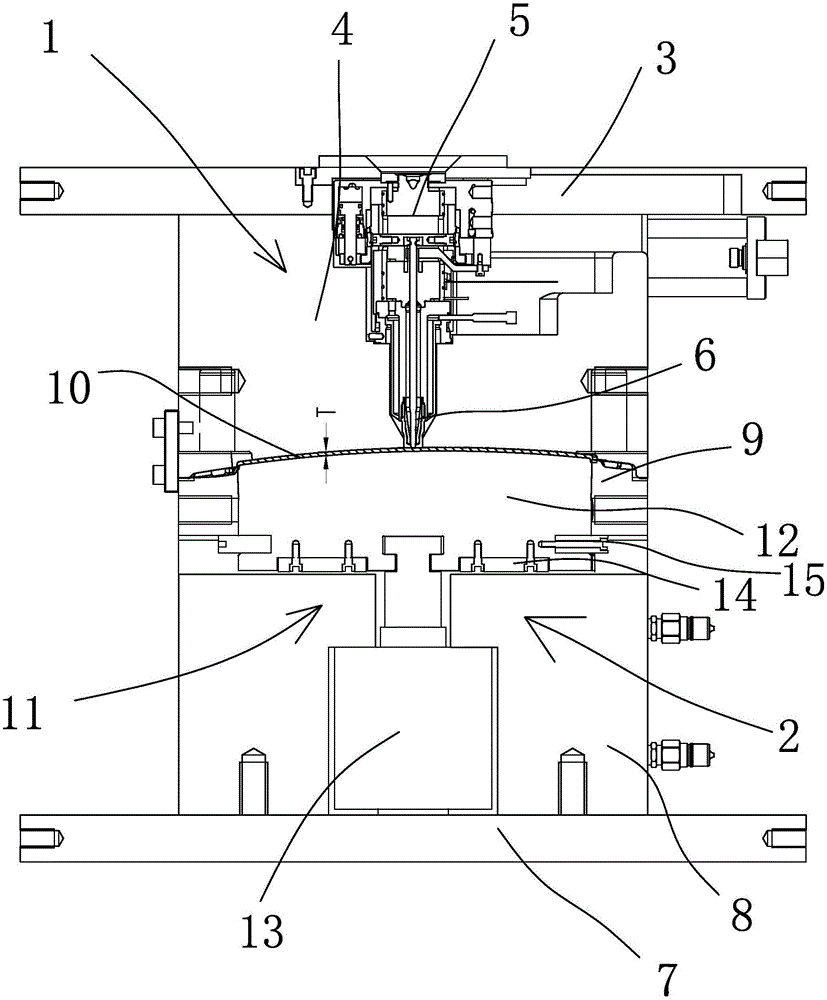

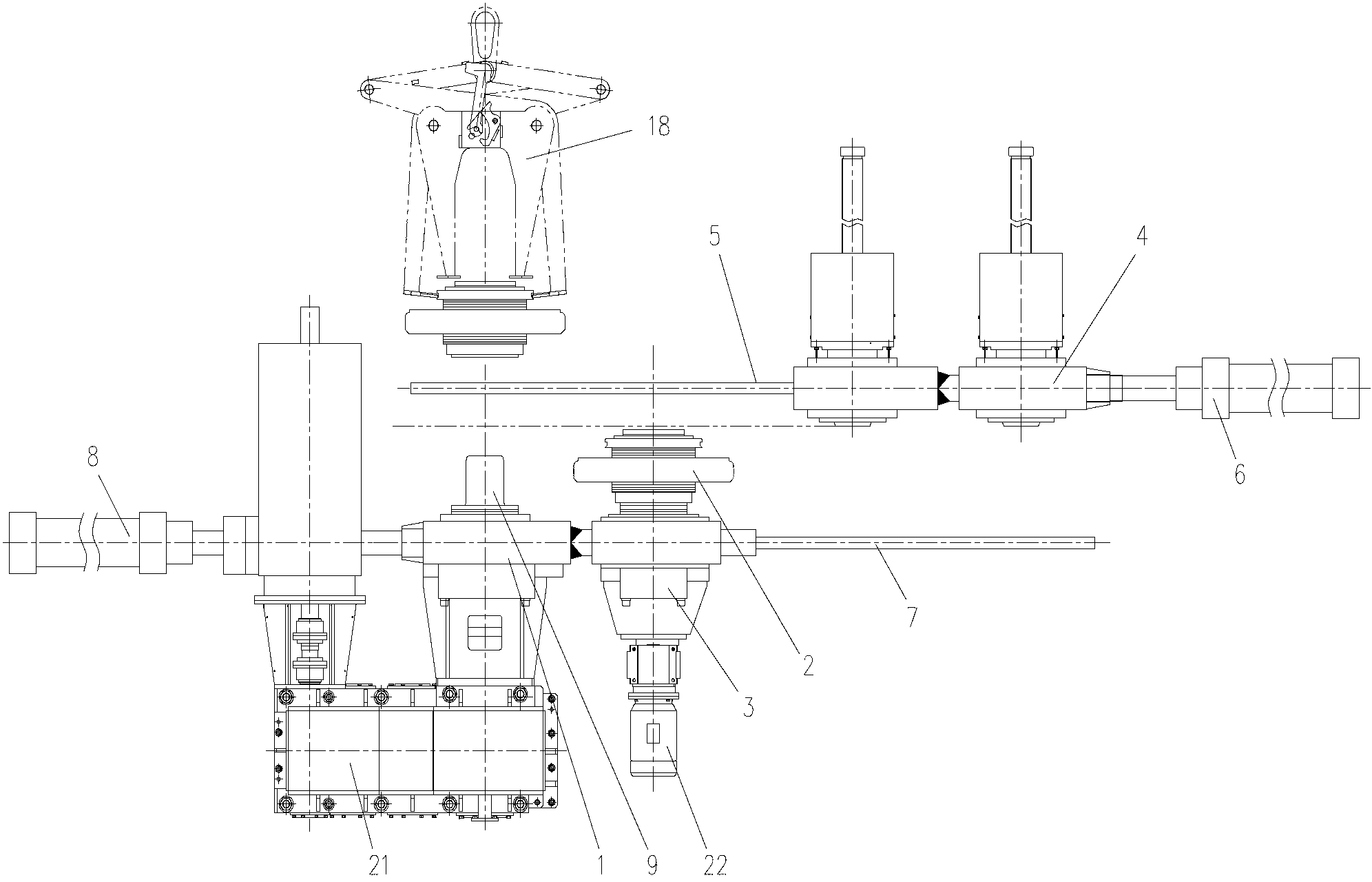

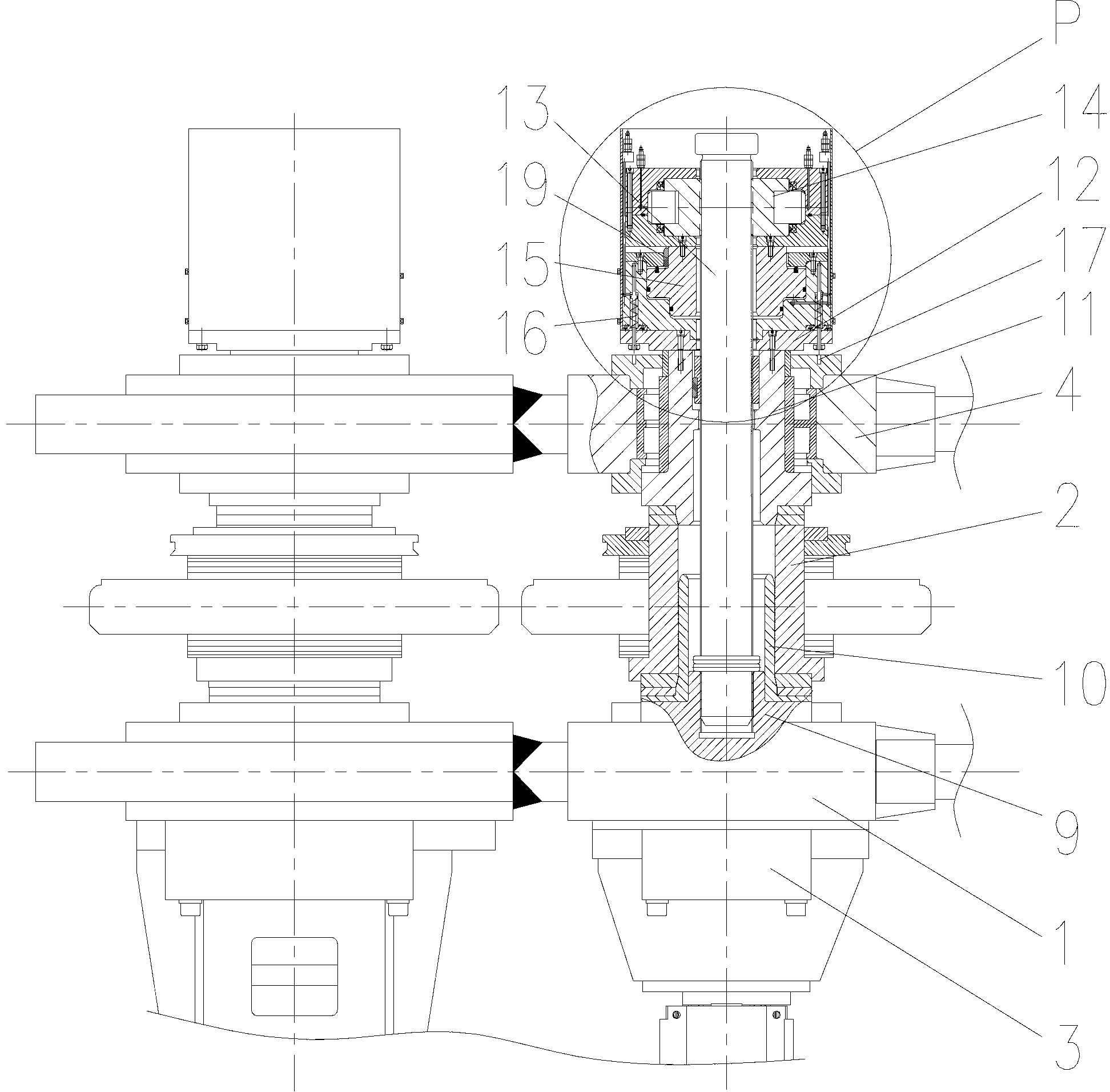

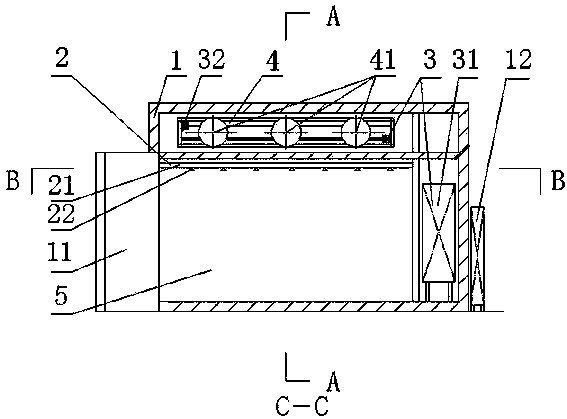

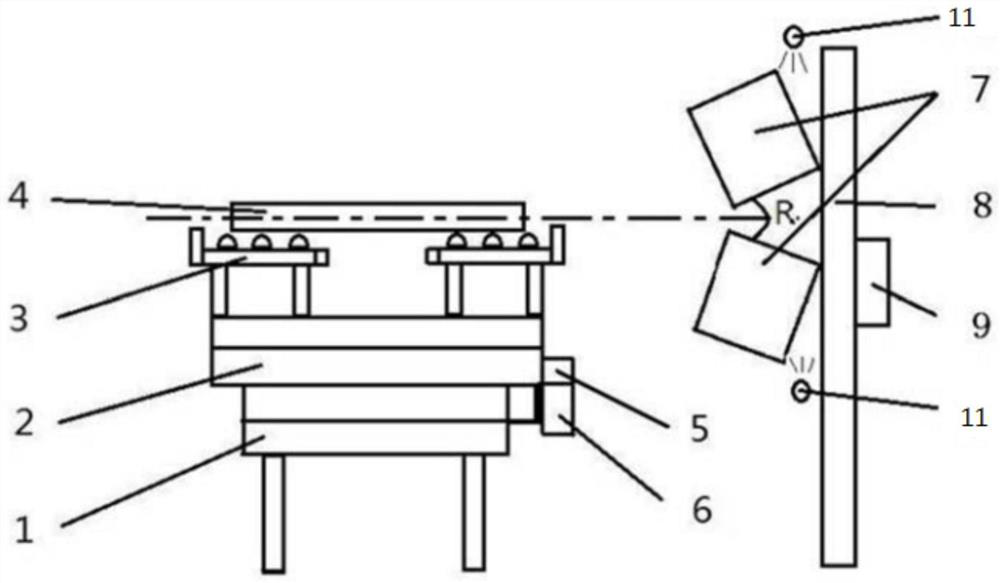

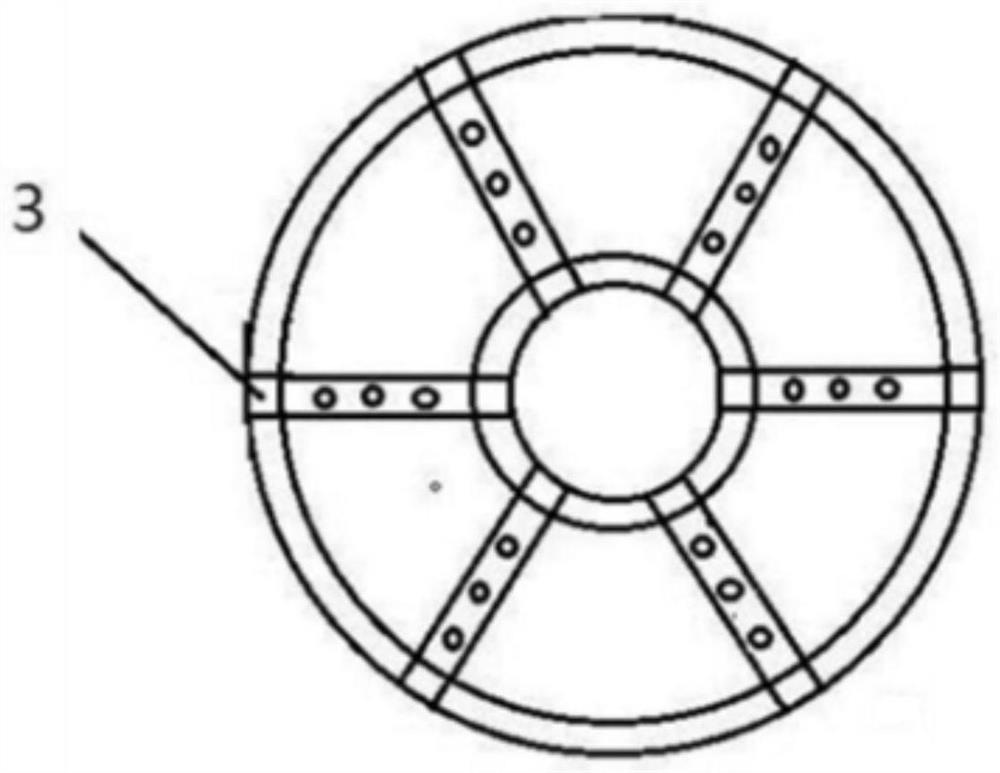

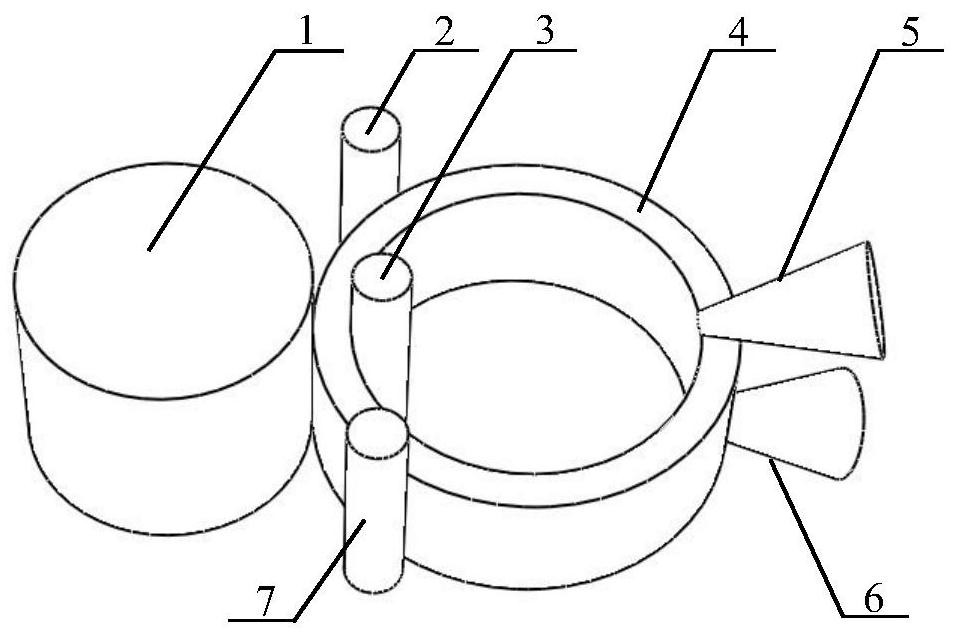

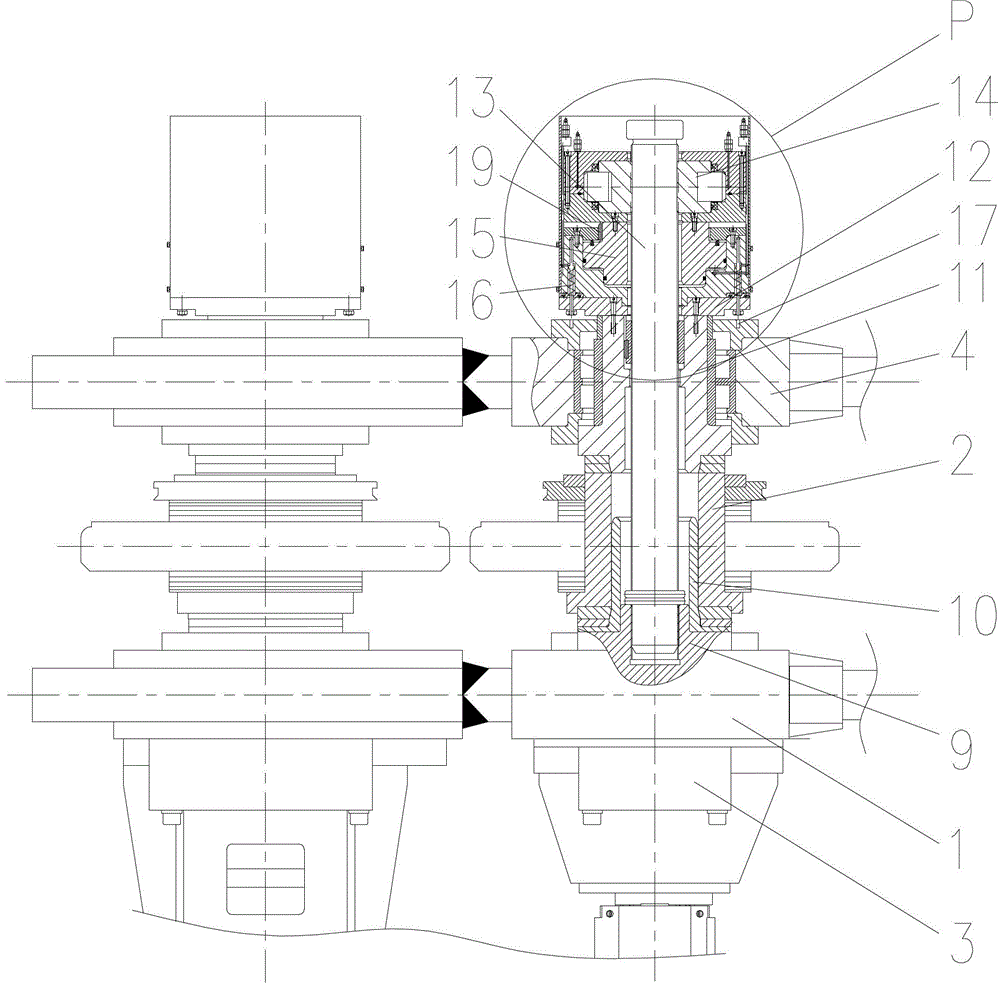

Heat treatment method and device for reducing internal residual stress of gh4096 alloy thin-wall disc ring

ActiveCN112226710BImprove cooling uniformityImprove performanceFurnace typesProcess efficiency improvementElectric machineReducer

The invention provides a heat treatment method and device for reducing internal residual stress of a GH4096 alloy disc ring forging, the device includes a platform base (1), a slewing support (2), a rotary table (3), a reducer (5), a motor (6 ), fan (7), fan support (8), control panel (9), spraying device (11). It can improve the uniformity of the workpiece cooling process, ensure the consistency of the process, and make the performance of the workpiece after heat treatment more stable and the residual stress lower.

Owner:AECC SICHUAN GAS TURBINE RES INST

Ultrasonic-assisted powder forming method in a fluid environment

The invention discloses an ultrasonic-assisted powder forming method in a fluid environment. Firstly, the powder particles are formed under the action of hydrostatic pressure, so that the density of the powder compact reaches about 80% of its theoretical density, and the hydrostatic pressure is kept applied and introduced Ultrasonic power makes the powder compact further compacted and stress homogenized under the action of ultrasonic vibration. The present invention improves the fluidity and filling performance of powder particles by introducing power ultrasound into the hydrostatic pressure forming process of powder particles, reduces the pressure required for compaction, and can improve the density distribution uniformity of the formed compact at the same time, thereby reducing the powder density. The residual stress of the body compact increases its mechanical properties. At the same time, the viscosity of the fluid medium can be significantly reduced and the fluidity of the fluid medium can be improved by using the mechanical vibration generated when the ultrasonic wave propagates in the oil medium, the ultrasonic cavitation effect, and the thermal effect generated by the medium absorbing the sound wave.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

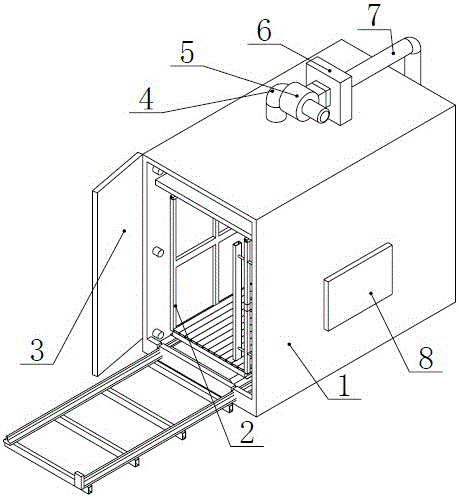

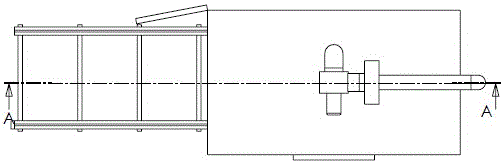

A dynamic pressure tempering furnace and tempering process for saw blade substrate tempering

InactiveCN103981354BAvoid heat exchangeAvoid damageFurnace typesHeat treatment process controlFire protectionDisplay device

The invention discloses a dynamic pressurized tempering furnace for tempering a saw blade matrix. The dynamic pressurized tempering furnace comprises a furnace body (1), a heating device (2) and a bearing platform (3), wherein the heating device (2) and the bearing platform (3) are both arranged in the furnace body (1); the inner wall of the furnace body (1) is provided with a fire protection layer (4); an oil cylinder (6) is vertical to the top of the furnace body (1) and is arranged in the furnace body (1); the bottom of a piston rod of the oil cylinder (6) is provided with a spherical boss (8); a pressure head (7) is internally provided with a spherical groove (9). The dynamic pressurized tempering furnace also comprises a controller, a display (10) and a temperature sensor (11), wherein the controller is connected with the oil cylinder (6) and the heating device (2). The dynamic pressurized tempering furnace is compact in structure, capable of automatically regulating the angle of the pressure head according to the planeness of a saw blade and convenient for workers to operate. After being subjected to thermal treatment by the dynamic pressurized tempering furnace, the saw blade matrix is uniform in crystalline phase tissue, small in internal residual stress and low in saw blade planeness less than 0.03mm.

Owner:成都壹佰科技有限公司

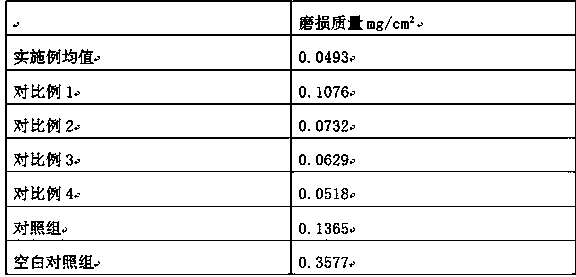

Additive for improving wear resistance of iron casting

The invention discloses an additive for improving wear resistance of iron casting, which relates to the technical field of iron casting. The additive is prepared from the following ingredients: humicacid modifying graphene, cryolite, sodium alginate and ferromolybdenum. By adding the additive for improving the wear resistance of the iron casting according to a given mass ratio, the wear resistance of the iron casting can be effectively improved.

Owner:含山县林头宝兴铸造厂

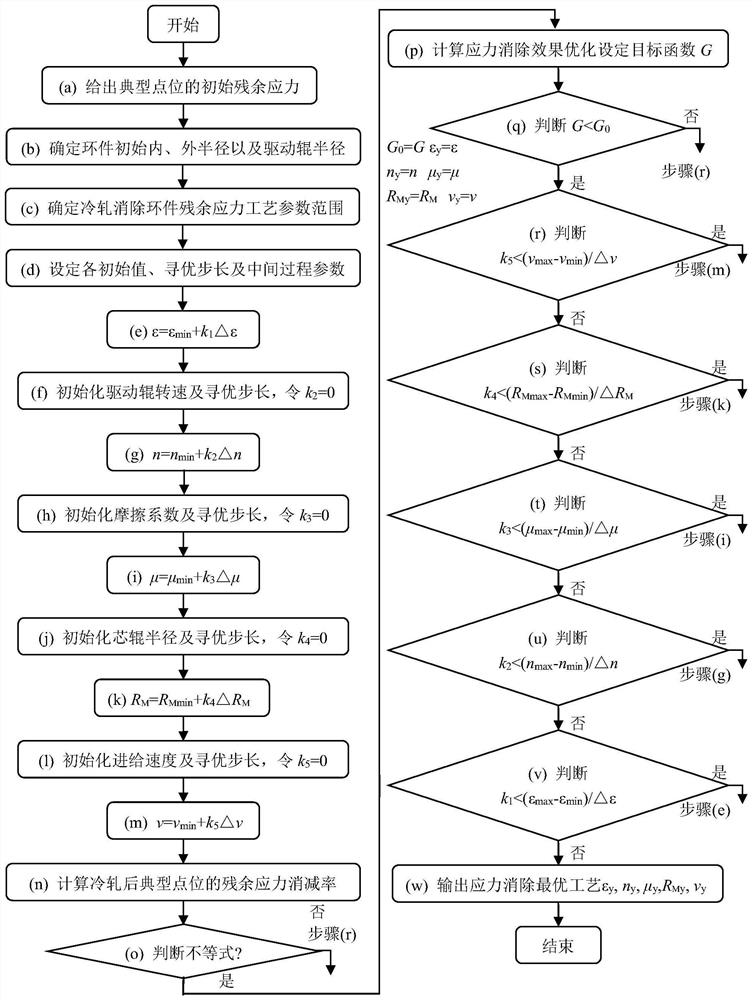

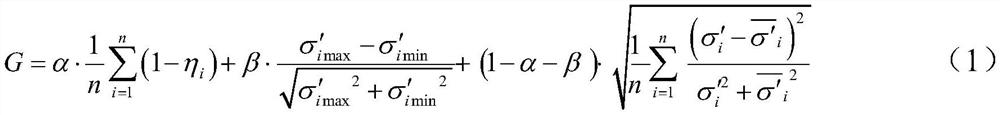

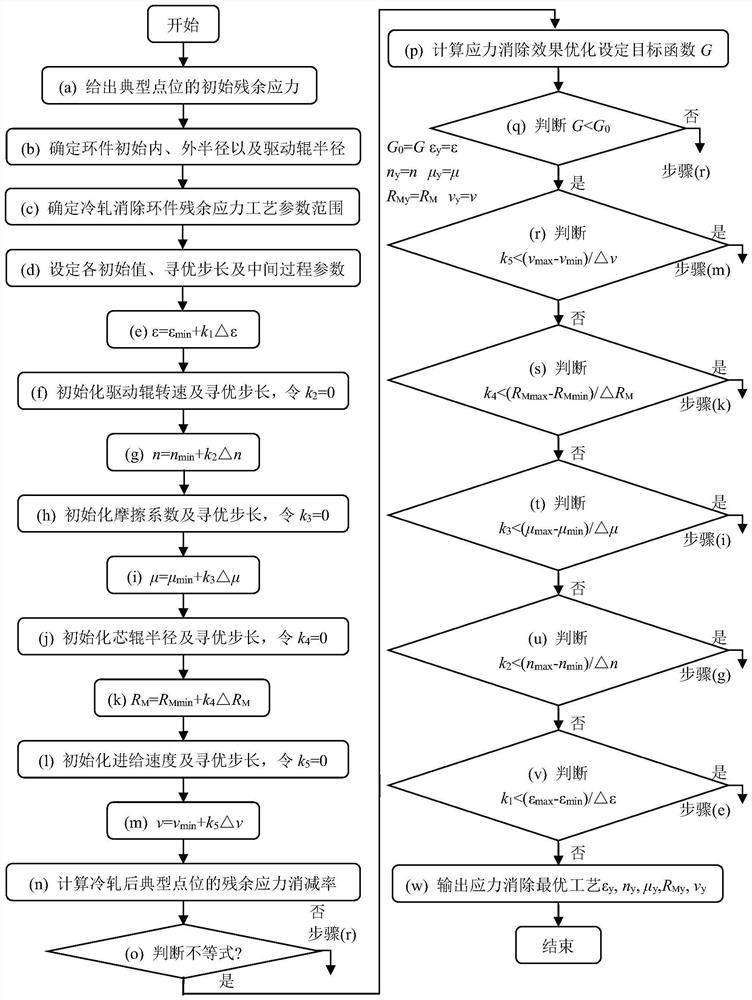

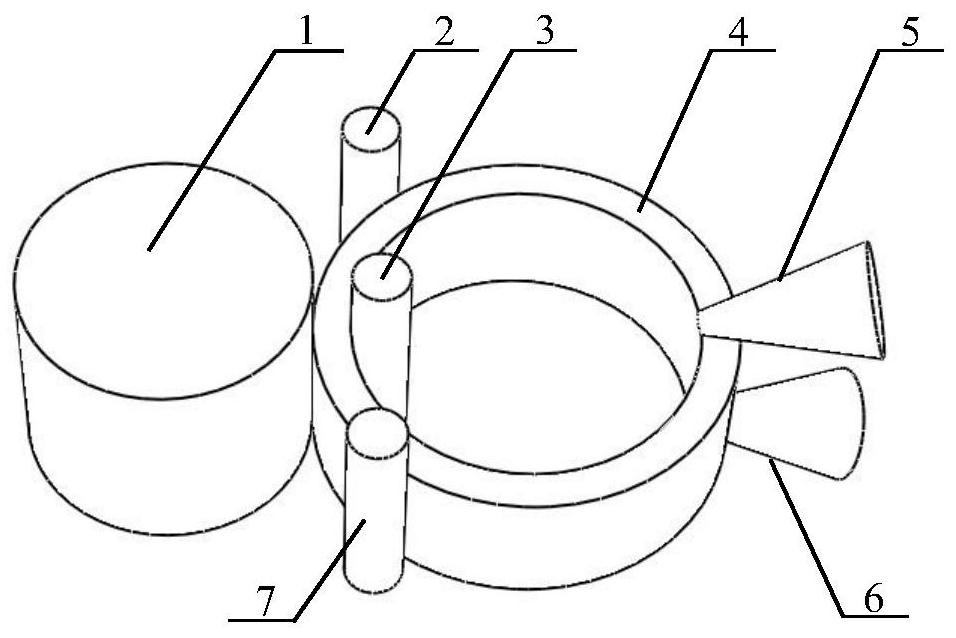

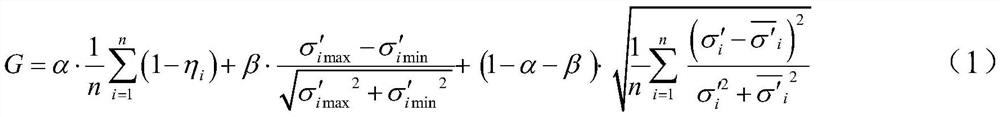

A process parameter optimization method for eliminating residual stress of rings by cold rolling

ActiveCN112222335BAvoid blindnessExtended service lifeRoll mill control devicesDesign optimisation/simulationProcess equipmentProcess engineering

The invention proposes a process parameter optimization method for eliminating the residual stress of a ring by a cold rolling method. According to the initial residual stress distribution state of the workpiece, based on the mechanical and kinematic conditions of ring rolling, combined with the final size and mechanical performance requirements of the ring, and considering the capability of the ring rolling process equipment, the residual stress reduction rate and distribution uniformity are taken as Controlling the optimization objective, taking the reduction rate, driving roll speed, friction coefficient, core roll radius and core roll feed speed as the constraints, a comprehensive optimization setting method for the process parameters of the cold rolling method to eliminate the residual stress of the ring is given , the present invention can systematically and comprehensively evaluate the effect of stress relief, formulate process parameters scientifically, efficiently and accurately, and carry out targeted cold rolling to eliminate residual stress on ring parts, greatly improving the effect of residual stress control, Give full play to the technical advantages of cold rolling method to eliminate residual stress of ring parts.

Owner:BEIHANG UNIV

Double-bracing vertical type straightening machine

The invention discloses a double-bracing vertical type straightening machine. The double-bracing vertical type straightening machine comprises a drive side rack, a roll collar assembly, an axial adjusting device and a locking device. The double-bracing vertical type straightening machine further comprises an operation side rack and an operation side sliding seat, wherein the operation side sliding seat is fixedly arranged. The lower end of the roll collar assembly is arranged on the drive side rack, the upper end of the roll collar assembly is arranged on the operation side rack, and the operation side rack is arranged on the operation side sliding seat and is matched with the operation side sliding seat along a horizontal line in a sliding mode. The double-bracing vertical type straightening machine further comprises a roller-replacing hydraulic cylinder connected with the operation side rack. According to the double-bracing vertical type straightening machine, the upper end of the roll collar assembly and the lower end of the roll collar assembly are both supported by the racks, a simple-supporting structure is formed to enable the roll collar assembly and the rack to be better in rigidity, the roll collar assembly and the rack are not prone to deforming during a straightening process, the quality of a straightened product can be effectively improved, and internal residual stress of the product can be reduced. When rollers are replaced, the operation side rack can be moved away from the upper end of the roll collar assembly integrally through the roller-replacing hydraulic cylinder, the roller-replacing operation is simple, roller-replacing time is short, and production efficiency and equipment utilization rate can be improved.

Owner:CISDI ENG CO LTD

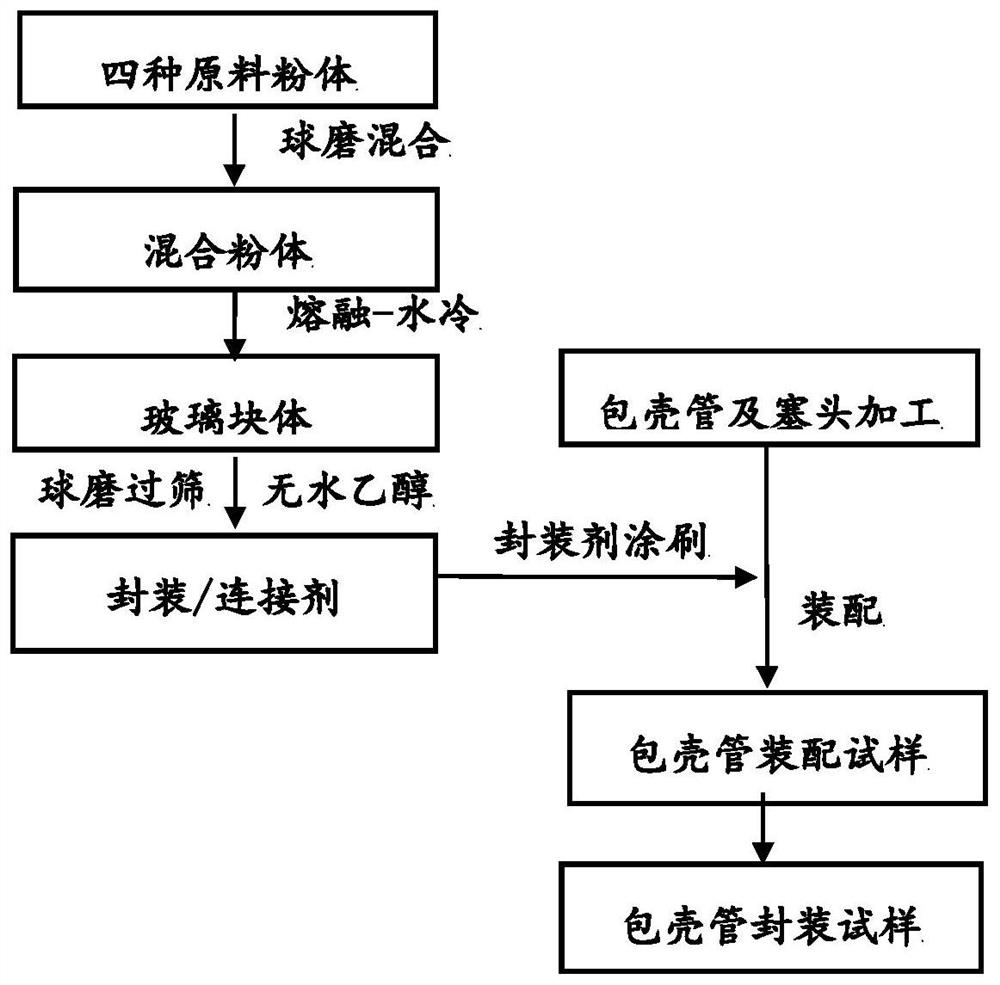

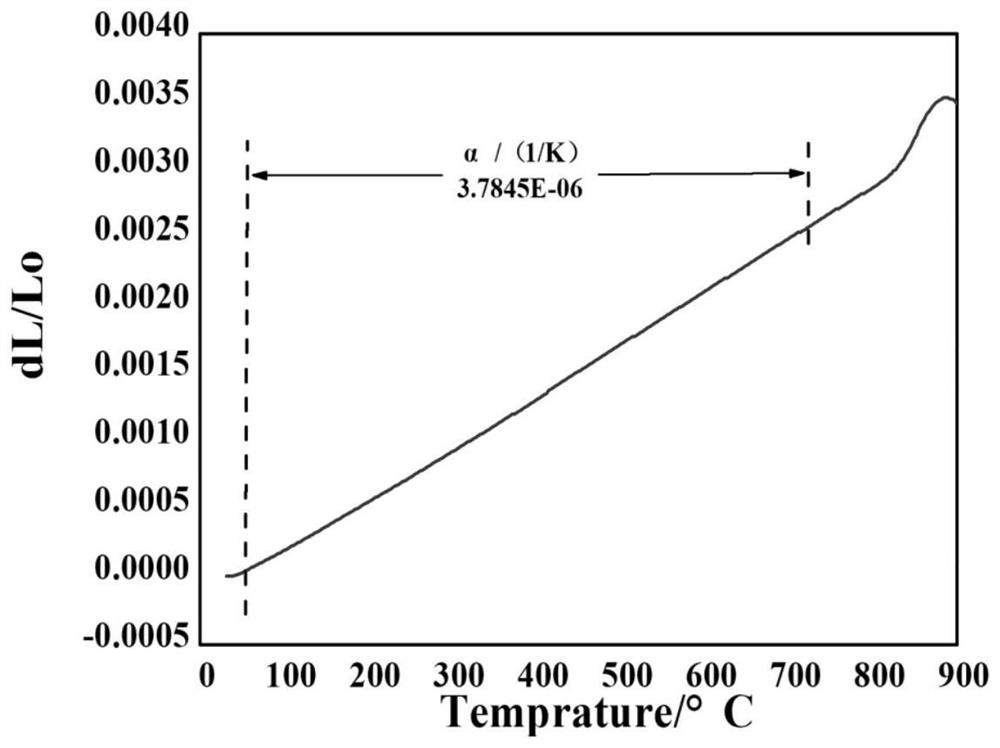

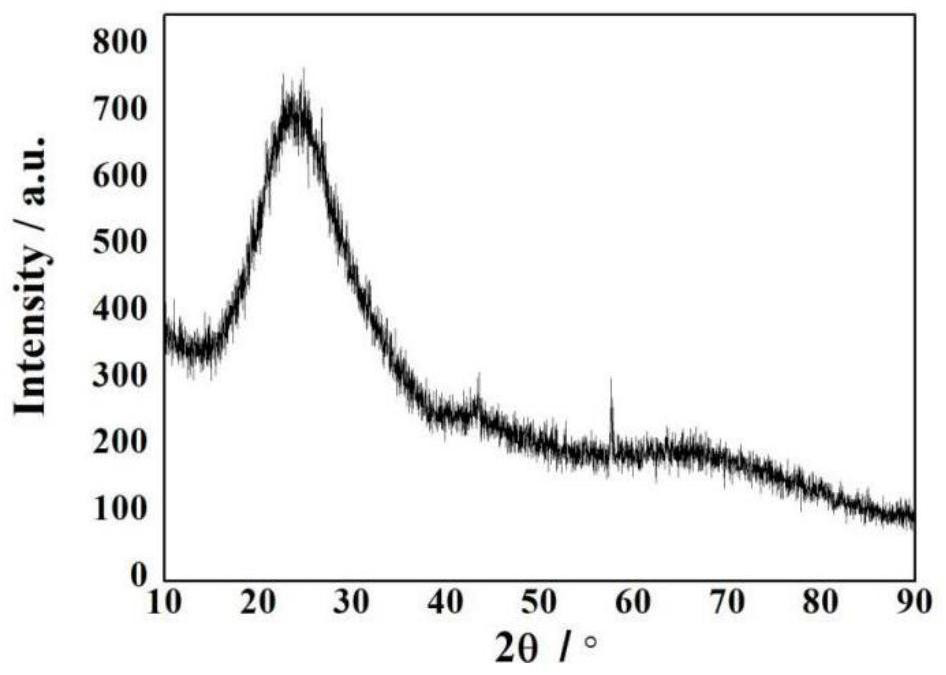

sic f /sic nuclear cladding tube port cao-mgo-al 2 o 3 -sio 2 Glass encapsulation method

ActiveCN109336634BReduce reactivityNuclear radiation decay rate is smallFuel elementsNuclear energy generationThermal dilatationNuclear radiation

Owner:NORTHWESTERN POLYTECHNICAL UNIV

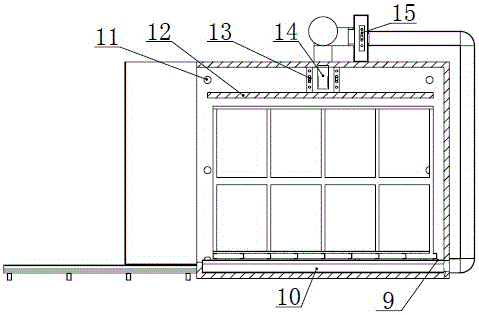

An ecological board oven and its operating method

InactiveCN104896880BReduce internal residual stressUniform moisture contentDrying solid materials with heatDrying gas arrangementsDisplay deviceEngineering

The invention discloses an ecologic plate oven and an operation method thereof. The ecologic plate oven comprises an oven body, wherein a door is arranged on one side surface; a bracket for placing an ecologic plate, a separation plate and a temperature measuring device arranged in the oven body; gaps for communicating with upper and lower layers of the oven body are arranged at the two ends of the separation plate; a heating device 1 is arranged on the upper layer; an air outlet is formed in the top of the heating device 1, and is connected with an air inlet of an exhaust fan; an air outlet of the exhaust fan is connected to the bottom in the oven body; and the temperature measuring device is connected with a digital display device. The ecologic plate is put in the oven for baking; the baking temperature can be known by the temperature measuring device; the temperature in the oven body reaches an uniform temperature state through the heating device for circularly flowing a hot air flow; the baked ecologic plate can reduce the internal residual stress; the water content is more uniform; the baking effect is good; the service life of the ecologic plate is prolonged; the oven is wholly manufactured by using a molded steel structure as a support, is light in weight, and is easy to be manufactured and carried; and the oven has the characteristics of simple structure, low cost and convenient and simple baking method.

Owner:六盘水康博木塑科技有限公司

Technological parameter optimization method for eliminating residual stress of ring part through cold rolling method

ActiveCN112222335AAvoid blindnessExtended service lifeRoll mill control devicesDesign optimisation/simulationEngineeringFrictional coefficient

The invention provides a technological parameter optimization method for eliminating residual stress of a ring part through a cold rolling method. According to the initial residual stress distributionstate of a workpiece, based on the rolling mechanical and kinematic conditions of the ring part, the requirements of the ring part for the final size and mechanical performance are combined, and meanwhile, the capacity of ring part rolling technological equipment is considered, the residual stress elimination rate and distribution uniformity serve as control optimization targets, the allowable ranges of the reduction rate, the driving roller rotating speed, the friction coefficient, the core roller radius and the core roller feeding speed serve as constraint conditions, and the comprehensiveoptimization setting method for technological parameters for eliminating the residual stress of the ring part through the cold rolling method is provided. According to the method, the stress elimination effect can be systematically and comprehensively evaluated, the technological parameters are scientifically, efficiently and accurately formulated, cold rolling residual stress elimination treatment is carried out on the ring part in a targeted mode, the residual stress regulation and control effect is greatly improved, and the technical advantages of eliminating the residual stress of the ringpart through the cold rolling method are fully exerted.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com