Heat treatment method of high-strength and high-flexibility 7055 aluminum alloy

A heat treatment method and flexibility technology, applied in the field of heat treatment of high-strength and high-flexibility 7055 aluminum alloy, can solve the problems of difficult deformation, cracking of components, deformation of aluminum alloy components with high residual stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

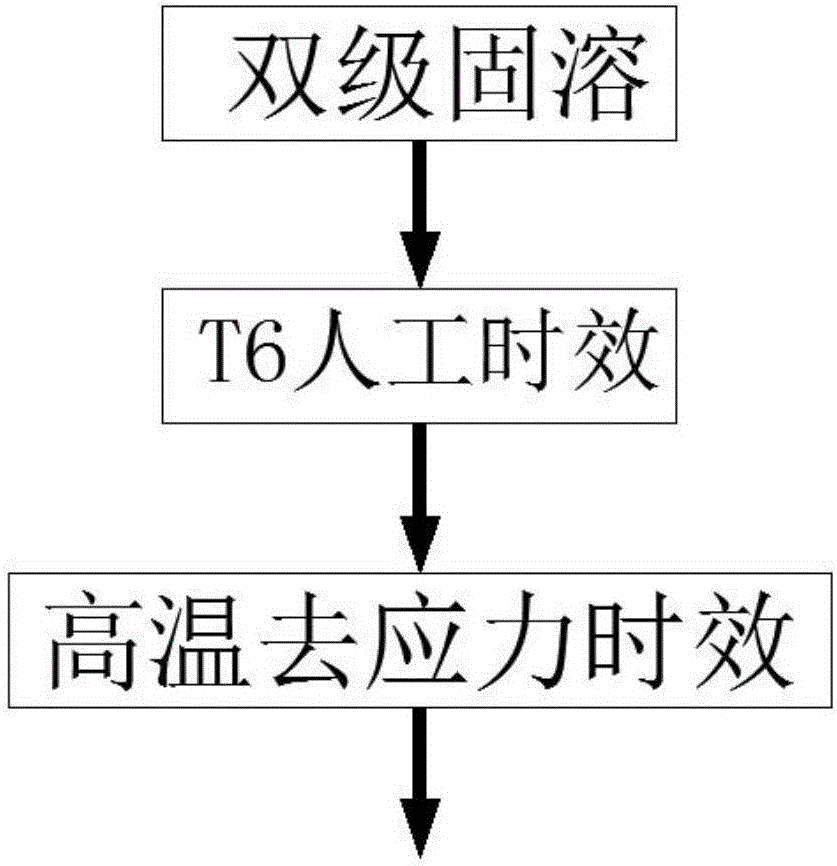

[0029] The 7055 aluminum alloy spray-formed ingot is extruded (extrusion ratio 14.8) into a Φ130mm bar after being wagoned, and the bar is roughly processed into a product blank, and the blank is subjected to heat treatment. The heat treatment steps are as follows:

[0030] a) Two-stage solid solution treatment, room temperature rises to 450°C for 2 hours, heats at 450°C for 3 hours, rises to 477°C in 0.5 hours, holds at 477°C for 3 hours, and quenches at 50°C.

[0031] b) T6 artificial aging treatment, the room temperature was raised to 120°C for 1 hour, and kept at 120°C for 24 hours.

[0032] c) High temperature stress relief aging, heat preservation at 140°C for 10 hours.

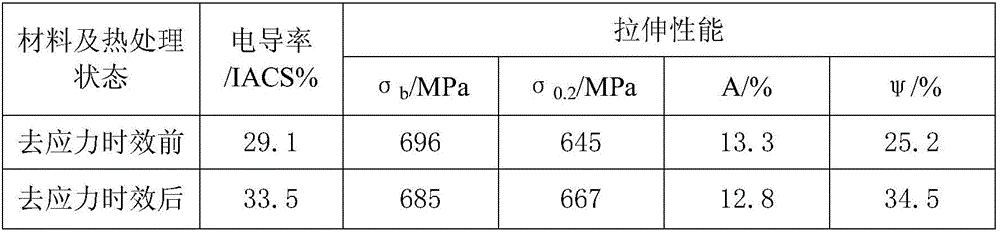

[0033] In the above examples, compared with the product blanks without high-temperature stress-relief aging, after high-temperature stress-relief aging, the deformation in the subsequent machining process is reduced, and the measured strength performance is basically maintained at the same level, while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com