Gypsum-based composite binding material for extruded 3D printing and preparation method thereof

A composite gel material and 3D printing technology, which is applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., can solve the problems of poor printing accuracy, obstruction of extrusion printing, and inability to obtain early strength, etc., to achieve proper setting time , setting time control, and the effect of easy operation and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

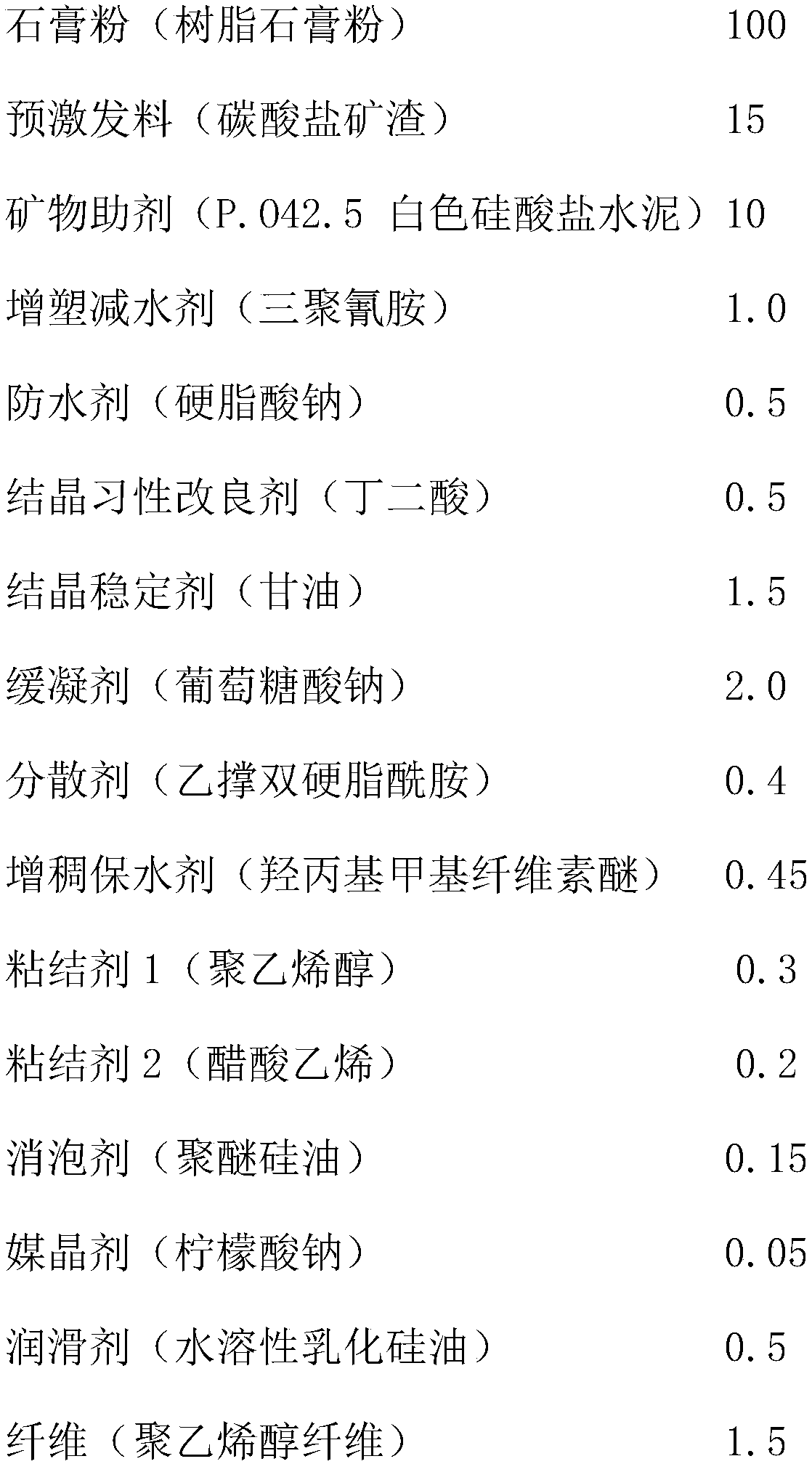

[0038] Prepare the following substances in parts by weight:

[0039]

[0040] Preparation method: Weigh the raw materials according to the formula, add gypsum powder (resin gypsum powder), pre-excitation material (carbonate slag), mineral additives (P.O42.5 white Portland cement), Plasticized water reducer (melamine), retarder (sodium gluconate) and fiber (polyvinyl alcohol fiber), fully stirred evenly, so as to obtain powdery gypsum-based composite gelling material;

[0041] Measure 25 parts of water, add waterproofing agent (sodium stearate), crystallization habit modifier (succinic acid), crystallization stabilizer (glycerin), dispersant (ethylene bisstearamide), Thickening water-retaining agent (hydroxypropyl methylcellulose ether), binder 1 (polyvinyl alcohol), binder 2 (vinyl acetate), defoamer (polyether silicone oil), crystallization agent (sodium citrate ) and lubricant (water-soluble emulsified silicone oil), stirred evenly to obtain a mixed solution.

[0042] A...

Embodiment 2

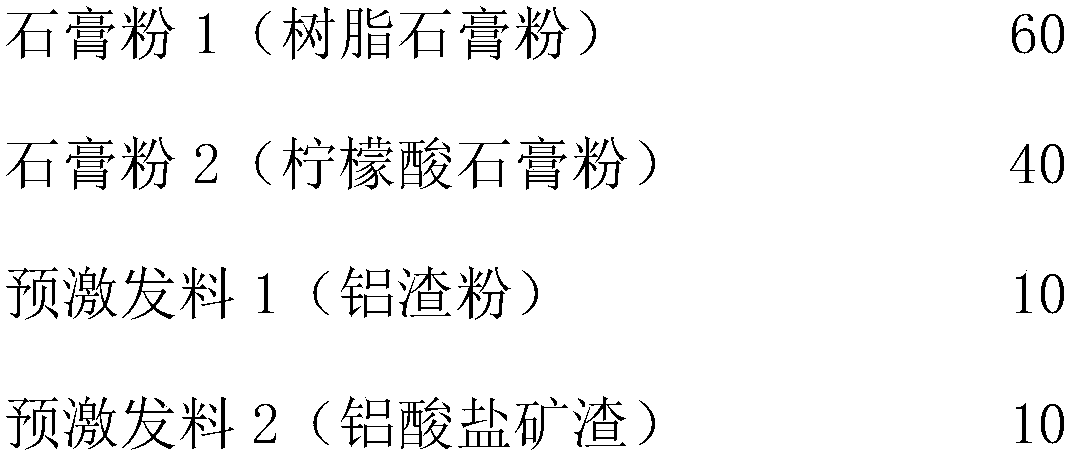

[0045] Prepare the following substances in parts by weight:

[0046]

[0047]

[0048] Preparation method: Weigh raw materials according to the formula, add gypsum powder 1 (resin gypsum powder), gypsum powder 2 (citric acid gypsum powder), pre-excitation material 1 (aluminum slag powder), pre-excitation material 2 ( aluminate slag), mineral additive 1 (silicon powder), mineral additive 2 (first-class fly ash), plasticizing water reducer (melamine sulfonated polycondensate), retarder (citric acid monohydrate ) and fibers (polyimide fibers), fully stirred evenly, so as to obtain powdery gypsum-based composite cementitious material;

[0049] Measure 30 parts of water, add waterproofing agent (magnesium stearate), crystallization habit modifier (sodium dodecylbenzenesulfonate), crystallization stabilizer (sodium isobutyrate), dispersant ( acrylic acid), thickener (carboxymethyl hydroxyethyl cellulose), binder (epoxy resin), defoamer (high carbonic acid), crystallization ag...

Embodiment 3

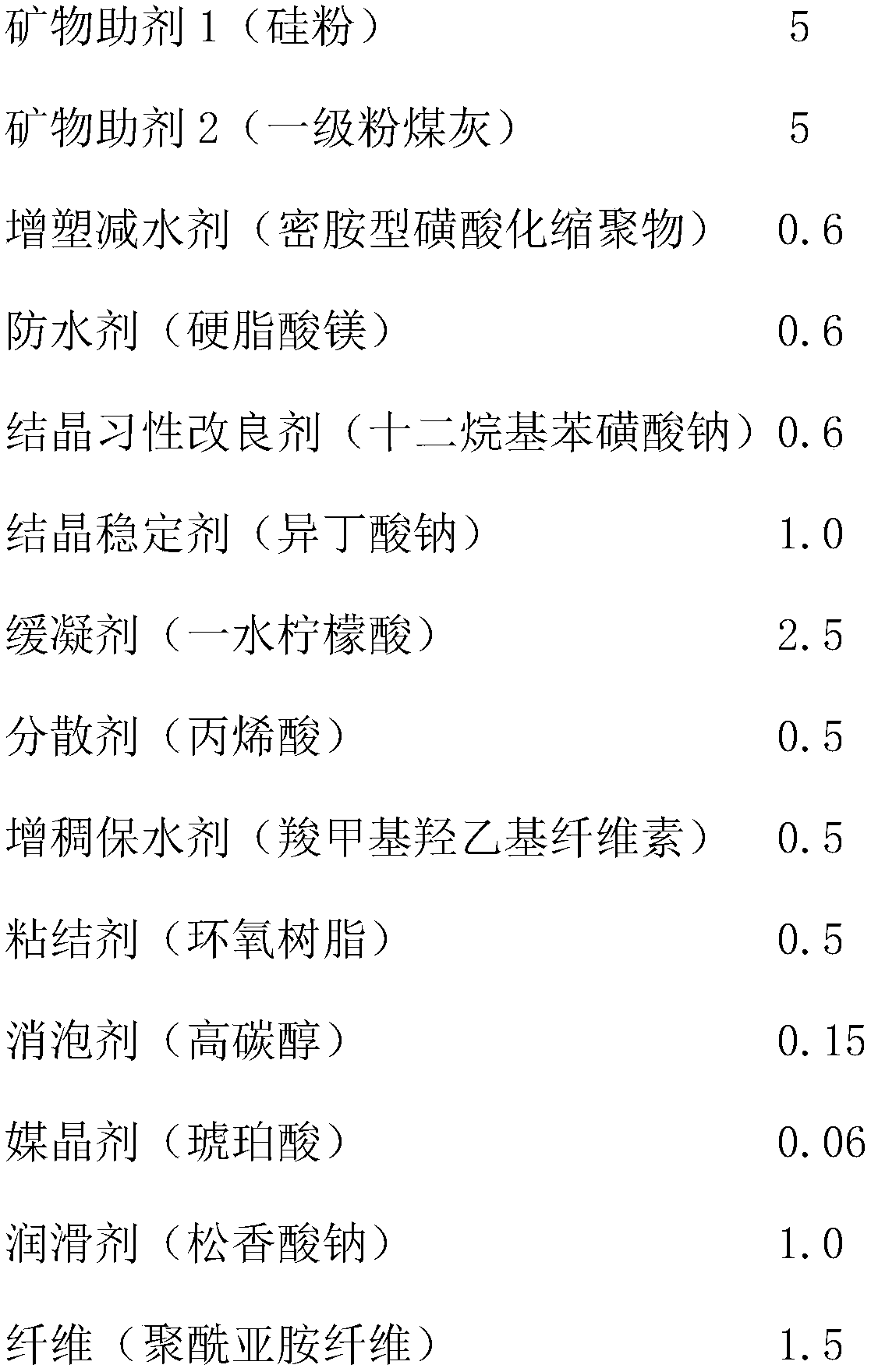

[0053] Prepare the following substances in parts by weight:

[0054]

[0055]

[0056] Preparation method: Weigh the raw materials according to the formula, add gypsum powder 1 (citric acid gypsum powder), gypsum powder 2 (desulfurized gypsum powder), pre-excitation material (aluminum slag powder), mineral additive 1 (a grade fly ash), plasticizing water reducer (sulfamic acid polycondensate), retarder (citric acid monohydrate) and fiber (polyvinyl alcohol fiber), fully stir evenly to obtain powdery gypsum-based composite adhesive Concrete material;

[0057] Measure 30 parts of water, add waterproofing agent 1 (sodium stearate), waterproofing agent 2 (potassium stearate), crystallization habit modifier 1 (sodium dodecylbenzenesulfonate), crystallization Habit modifier 2 (succinic acid), crystallization stabilizer (sodium citrate), dispersant (polyoxyethylene), thickener and water retaining agent (sodium propylene sulfonate), binder (vinyl acetate), defoaming agent agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com