Modified phosphogypsum and preparation method thereof

A phosphogypsum and modification technology, which is applied in the field of modified phosphogypsum and its preparation, can solve the problems of low active aluminum content and ideal setting time of phosphogypsum-based cement concrete, and achieve low cost, shortened setting time, and mixed less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of modified phosphogypsum (modified phosphogypsum slurry): Measure the free water content of phosphogypsum (taken from Hubei Huangmailing Phosphorus Chemical Co., Ltd.), and then mix it with slag Portland cement according to the ratio in Table 1 , plus 60% of water (free water in phosphogypsum, the amount of water added is 60% of the total mass of phosphogypsum and slag portland cement), wet ground into phosphogypsum slurry, stirred evenly and according to Table 1 Aging time After aging, a modified phosphogypsum is obtained.

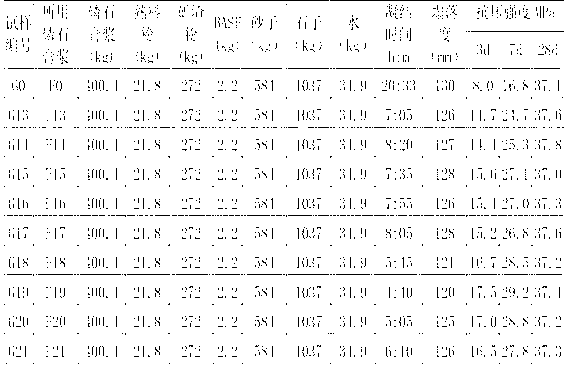

[0022]Prepare phosphogypsum-based cement concrete according to the mix ratio in Table 2. Then measure the setting time of the phosphogypsum-based cement concrete mixture according to GB / T 50080-2002 "Standards for Test Methods of Properties of Ordinary Concrete Mixtures"; The strength of gypsum-based cement concrete is shown in Table 2.

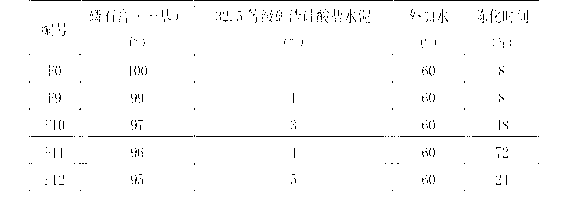

[0023] Table 1 Proportion of phosphogypsum slurry

[0024]

[0025] The BASF described in Ta...

Embodiment 2

[0030] Preparation of modified phosphogypsum (modified phosphogypsum slurry): measure the free water content of phosphogypsum (taken from Huangmailing Phosphorus Chemical Co., Ltd. After mixing according to the ratio in Table 4, add 60% water (free water in phosphogypsum, the amount of water added is 60% of the total mass of phosphogypsum and general-purpose Portland cement), and wet grind to make phosphogypsum slurry , stirred evenly and aged according to the aging time in Table 4, the modified phosphogypsum was obtained.

[0031] Clinker powder, slag powder, limestone powder, fly ash, and natural gypsum are made into various general-purpose Portland cements according to the ratio in Table 3, and then made into phosphogypsum slurry according to the ratio in Table 4, and stirred evenly. After a certain period of time, modified phosphogypsum (modified phosphogypsum slurry) is obtained. Prepare phosphogypsum-based cement concrete according to the mix ratio in Table 5. Then mea...

Embodiment 3

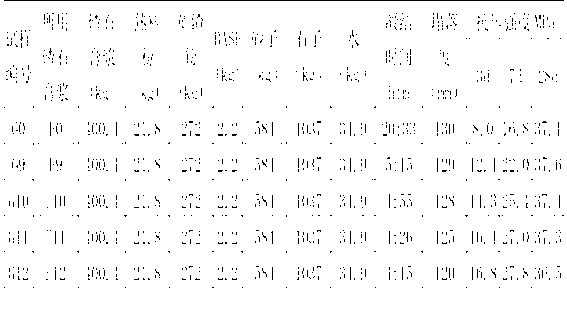

[0041] Preparation of modified phosphogypsum (modified phosphogypsum slurry): measure the free water content of phosphogypsum (taken from Hubei Huangmailing Phosphorus Chemical Co., Ltd.), and then mix it with slag portland cement according to the ratio in Table 6 , add different water (free water in phosphogypsum), wet grind into phosphogypsum slurry, stir evenly and age according to the aging time in Table 6 to obtain modified phosphogypsum slurry.

[0042] Prepare phosphogypsum-based cement concrete according to the mix ratio in Table 7. Then measure the setting time of the phosphogypsum-based cement concrete mixture according to GB / T 50080-2002 "Standards for Test Methods of Properties of Ordinary Concrete Mixtures"; The strength of gypsum-based cement concrete is shown in Table 7.

[0043] Table 6 Proportion of phosphogypsum slurry

[0044]

[0045] The BASF described in Table 7 is a commercially available concrete admixture with polycarboxylic acid as the main compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com