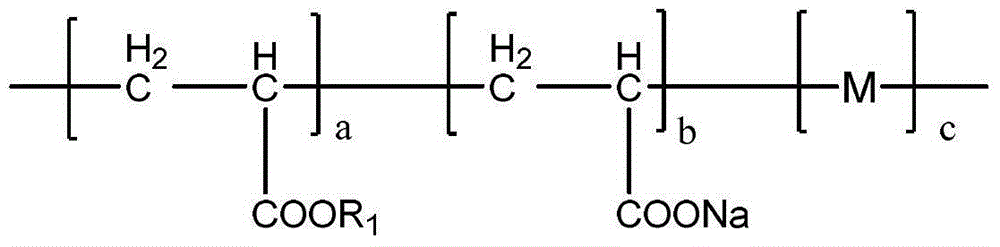

Polycarboxylate water reducer containing modified water-soluble acrylate and preparation method thereof

An acrylate and water-soluble technology, which is applied in the field of building materials and water reducing agents, can solve the problems of sensitive dosage, poor mud tolerance, etc., and achieve the effects of enhanced fluidity, high water reducing rate, and prolonged setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

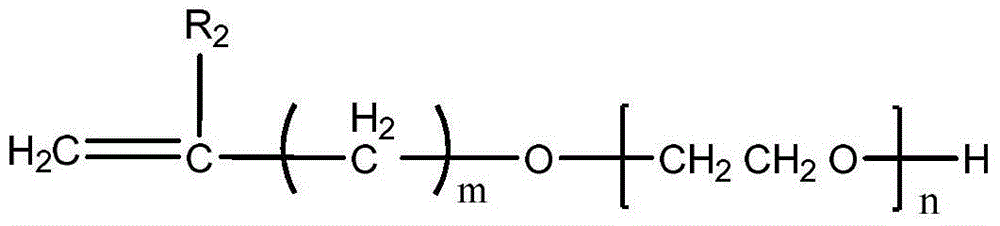

Method used

Image

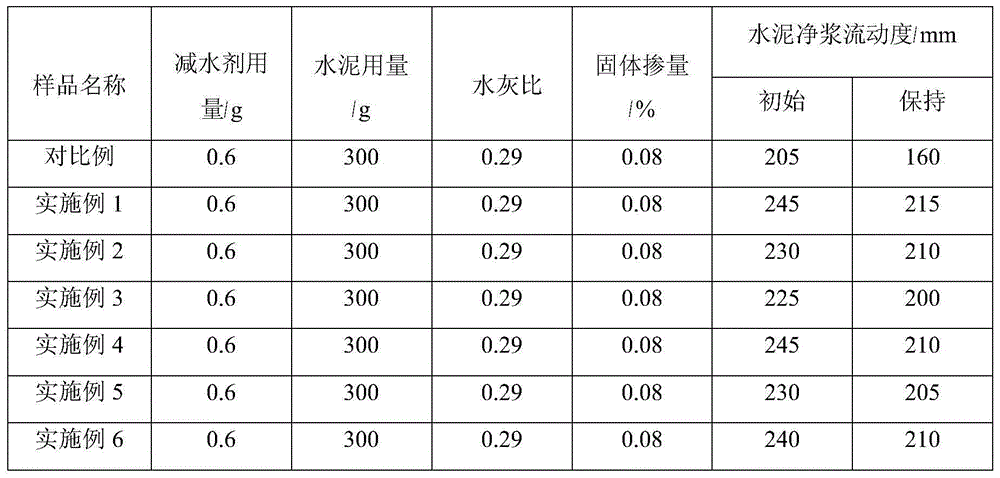

Examples

Embodiment 1

[0037] In a 500ml reaction flask equipped with a stirrer and a condenser, add 205g of acrylic acid, 144g of glucose, 4.4g of hydroquinone, and 6.88g of p-toluenesulfonic acid, and stir at room temperature for 10 minutes, but the raw materials are not completely dissolved. Heat slowly, and when the temperature rises to 80-90°C, the solution becomes clear and all the raw materials are dissolved. Continue to heat up, starting at 90°C, the color of the reaction solution turns yellow, and gradually turns dark brown, within 1 hour the temperature is raised to 95-100°C and maintained, and the stirring is continued for 4-5 hours to obtain a small water-soluble glucose acrylate monomer.

[0038] Add 180g of methallyl polyoxyethylene ether (4-carbon macromonomer) with an average molecular weight of 2500 into 99g of deionized water, heat properly and fully dissolve to make a reaction bottom liquid; Add 54.4g of glucose ester, 10.8g of acrylic acid, and 1.48g of thioglycolic acid into 62....

Embodiment 2

[0040] In a 500ml reaction flask equipped with a stirrer and a condenser, add 205g of acrylic acid, 144g of glucose, 4.4g of hydroquinone, and 6.88g of p-toluenesulfonic acid, and stir at room temperature for 10 minutes, but the raw materials are not completely dissolved. Heat slowly, and when the temperature rises to 80-90°C, the solution becomes clear and all the raw materials are dissolved. Continue to heat up, starting at 90°C, the color of the reaction solution turns yellow, and gradually turns dark brown, within 1 hour the temperature is raised to 95-100°C and maintained, and the stirring is continued for 4-5 hours to obtain a small water-soluble glucose acrylate monomer.

[0041] Add 180g of isoprenyl polyoxyethylene ether (5-carbon macromonomer) with an average molecular weight of 5000 into 99g of deionized water, heat properly and fully dissolve to make a reaction bottom liquid; Add 35.2g of glucose ester and 1.48g of thioglycolic acid into 62.5g of deionized water in...

Embodiment 3

[0043]Add 233.6g of acrylic acid, 145.6g of sorbitol, 5g of p-methoxyphenol, and 7.12g of p-toluenesulfonic acid into a 500ml reaction flask equipped with a stirrer and a condenser, and stir at room temperature for 10 minutes, but the raw materials are not completely dissolved. Heat slowly, and when the temperature rises to 80-90°C, the solution becomes clear and all the raw materials are dissolved. Continue to heat up, starting at 90°C, the color of the reaction solution turns yellow, and gradually turns dark brown, within 1 hour the temperature is raised to 105-110°C and maintained, and the stirring is continued for 4-5 hours to obtain a small water-soluble sorbitol acrylate monomer .

[0044] 180g of allyl polyoxyethylene ether (3-carbon macromonomer) with an average molecular weight of 2500 was added to 99g of deionized water, heated and fully dissolved to make a reaction bottom liquid; Add 61.2g of ester and 1.48g of thioglycolic acid into 62.5g of deionized water in tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com