Supergravity field micro-reactor, and method for preparing nanometer material through liquid phase precipitation method

A hypergravity field, microreactor technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical mobile reactors, etc. The problem of small processing capacity, etc., can achieve the effect of reducing the reaction residence time, increasing the body surface area, and reducing the mass transfer distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

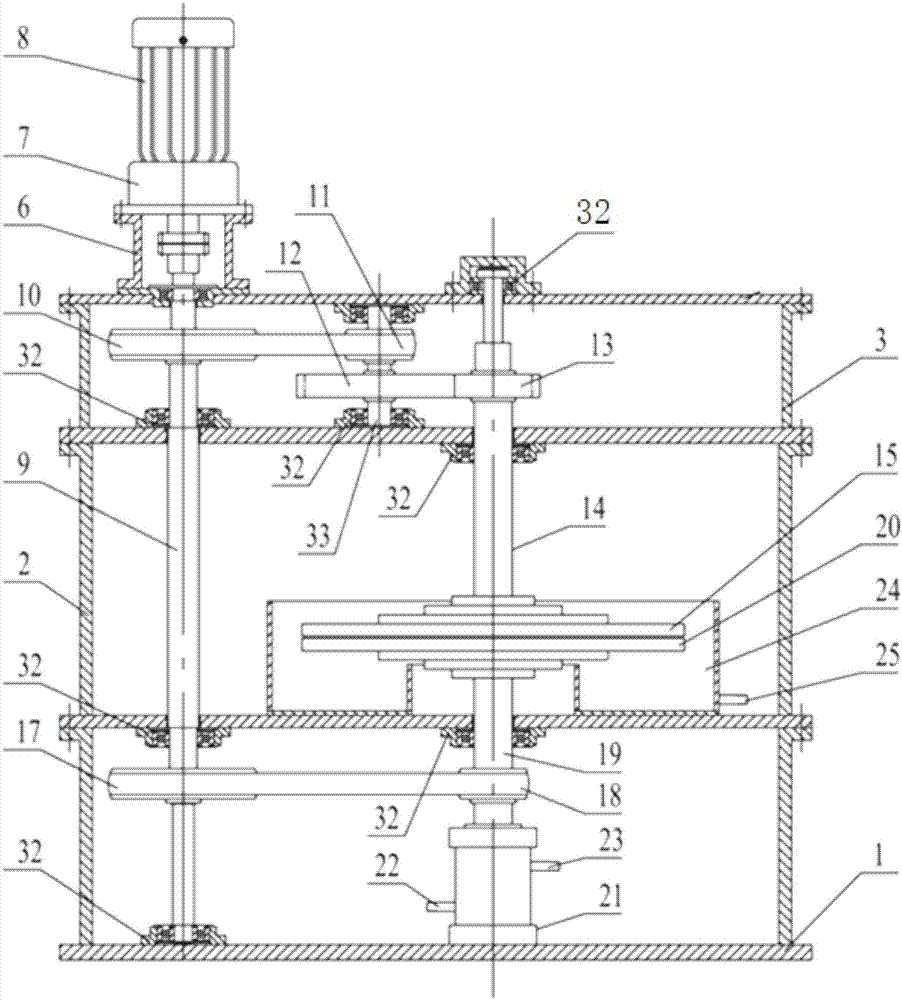

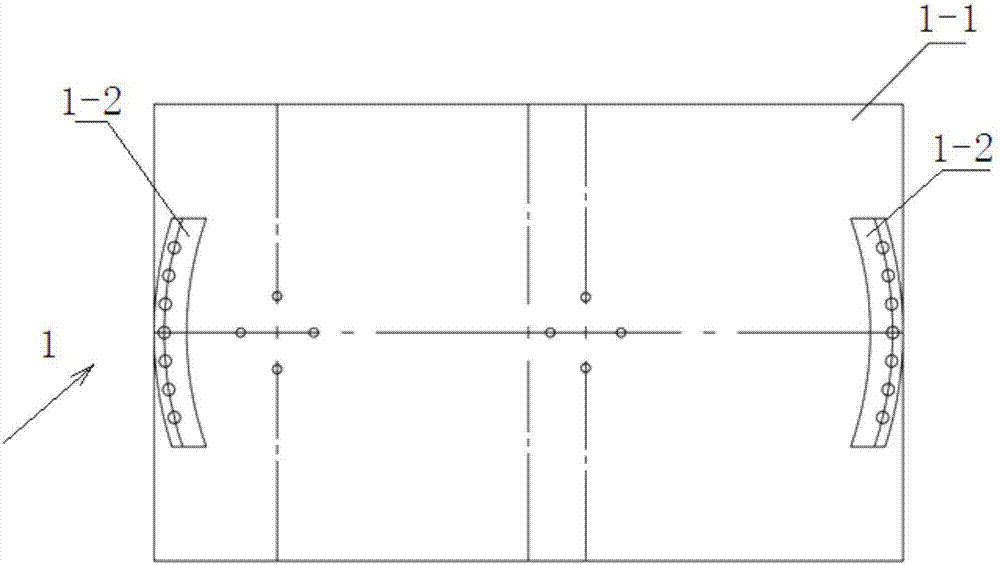

[0053] In this embodiment, the supergravity field microreactor for preparing nanomaterials is as figure 1 As shown, it consists of a micro-reaction assembly, a material receiving tank 24 provided with a material outlet 25, a first motor 8, a transmission system, a feeding system and a supporting system.

[0054] Described micro reaction component is made up of upper plate 15 and lower plate 20, and upper plate 15 is as Figure 19 , Figure 20 As shown in Fig. Figure 23 As shown in the spiral micro-shaped groove, the center of the bottom surface of the upper plate is provided with a buffer groove 15-1, and the lower plate 20 is as follows: Figure 21 , Figure 22 As shown, the shape is a stepped conical shape with a large top and a small bottom, and the top surface is distributed like Figure 23 In the spiral micro-groove shown, the center of the lower plate is provided with two feeding micro-channels, which are named as the first feeding micro-channel 20-1 and the second ...

Embodiment 2

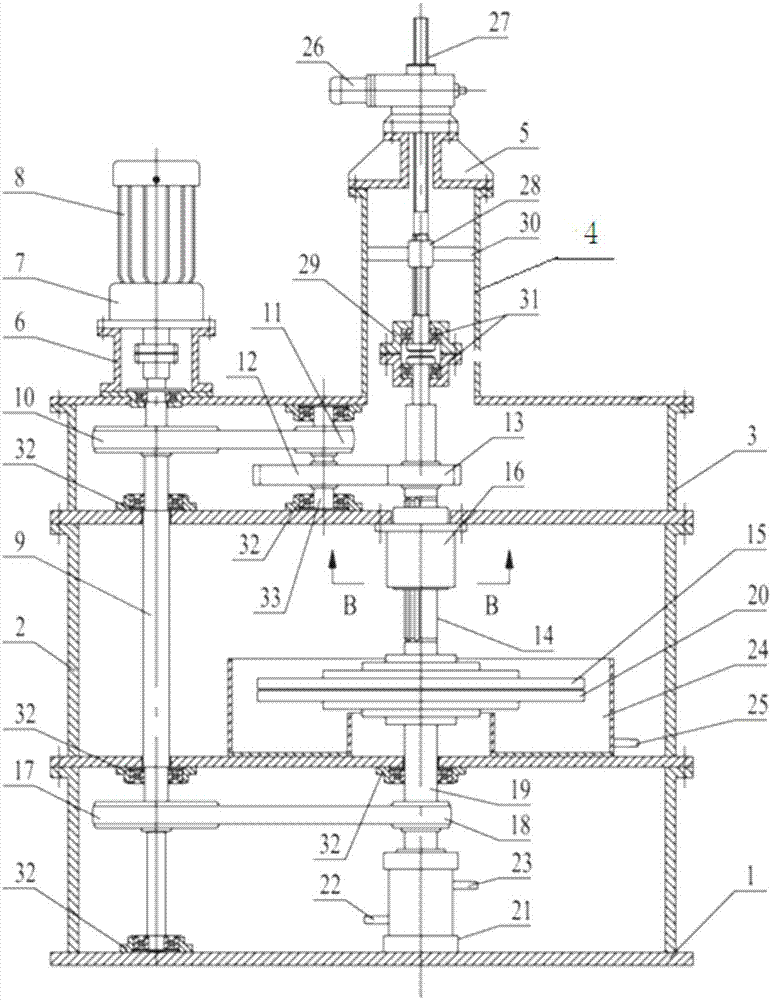

[0060] In this embodiment, the supergravity field microreactor for preparing nanomaterials is as figure 2 As shown, it is composed of a micro-reaction assembly, a material receiving trough 24 provided with a discharge port, a first motor 8, a transmission system, a feeding system, a support system and an upper plate lifting system. The difference from Embodiment 1 is that the upper plate lifting system is added; the lower part of the third transmission shaft 14 in the transmission system is provided with a spline segment 14-2 (see Figure 9 ), the spline section is combined with the female rotary ball spline 16 installed on the upper frame bottom plate 3-1 (see figure 2 ); the micro-grooves distributed on the bottom surface of the upper plate 15 and the micro-grooves distributed on the top surface of the lower plate 20 in the micro-reaction assembly are as follows Figure 24 In the fan-shaped micro-grooves shown, the fan-shaped micro-grooves on the bottom surface of the upp...

Embodiment 3

[0063] This embodiment uses the supergravity field microreactor described in Example 2 to prepare nano-strontium carbonate, and the operation is as follows:

[0064] (1) Weigh 321.56g of strontium chloride, prepare 2000mL of strontium chloride solution with distilled water, and mark it as liquid A; weigh 189.74g of ammonium bicarbonate, add distilled water to dissolve it, then add 664.2mL of ammonia water and 333.4mL of anhydrous ethanol, and distilled water was added to make the total liquid volume reach 2000mL, and then stirred evenly to prepare a 2000mL mixed solution, which was marked as liquid B;

[0065] (2) Start the first motor, drive the transmission system to run under the drive of the first motor, so that the upper plate and the lower plate in the micro-reaction assembly rotate at a speed of 1000 rad / min in the opposite direction of rotation (the separation factor is 219);

[0066] (3) Send the configured A liquid and B liquid into the feed channel provided in the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com