Patents

Literature

163results about How to "Increase the nucleation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

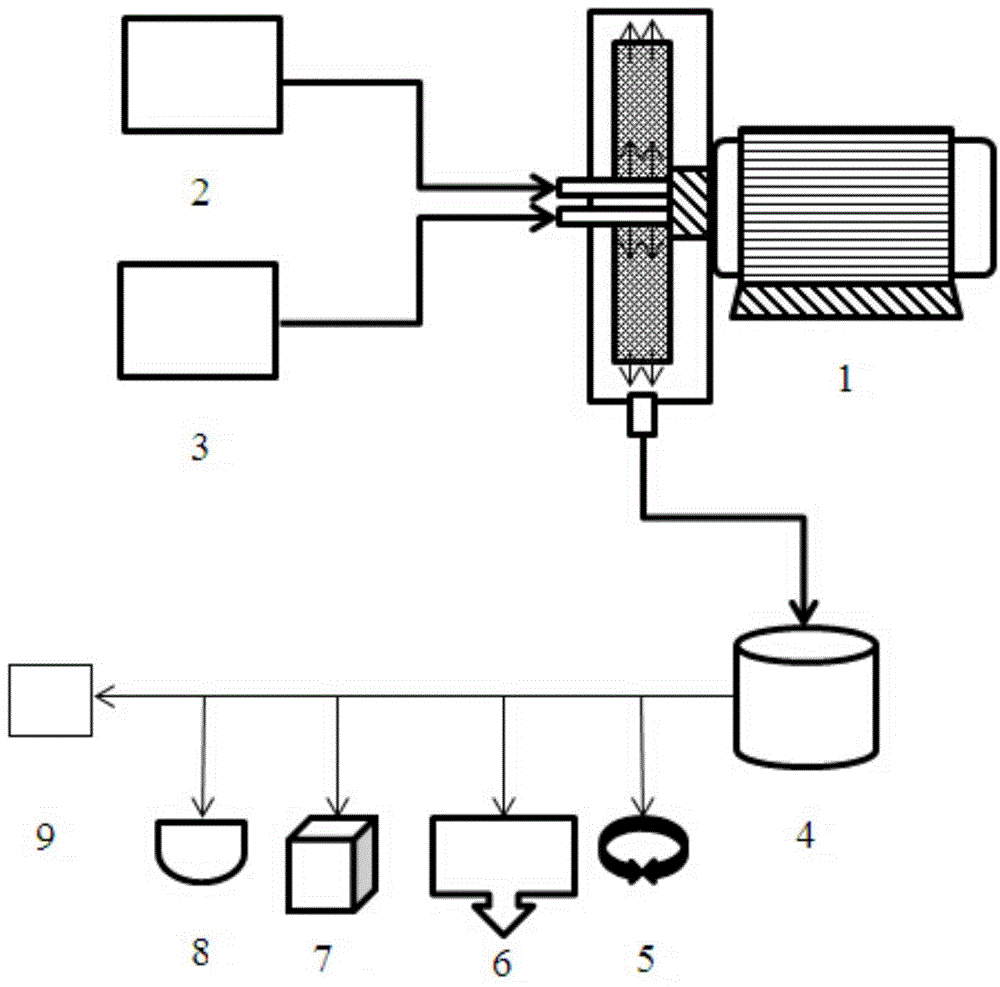

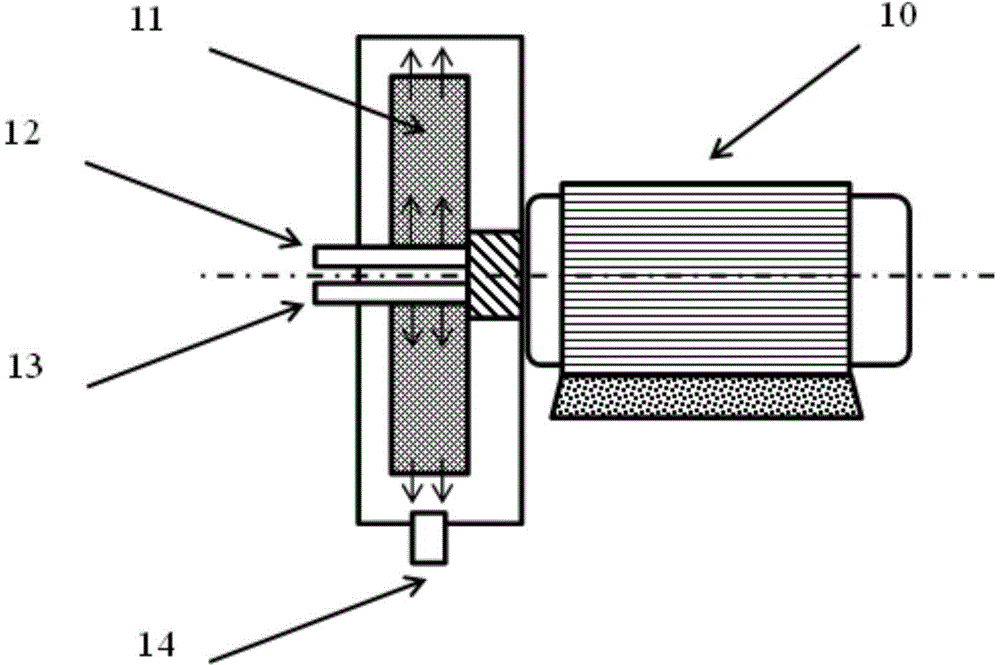

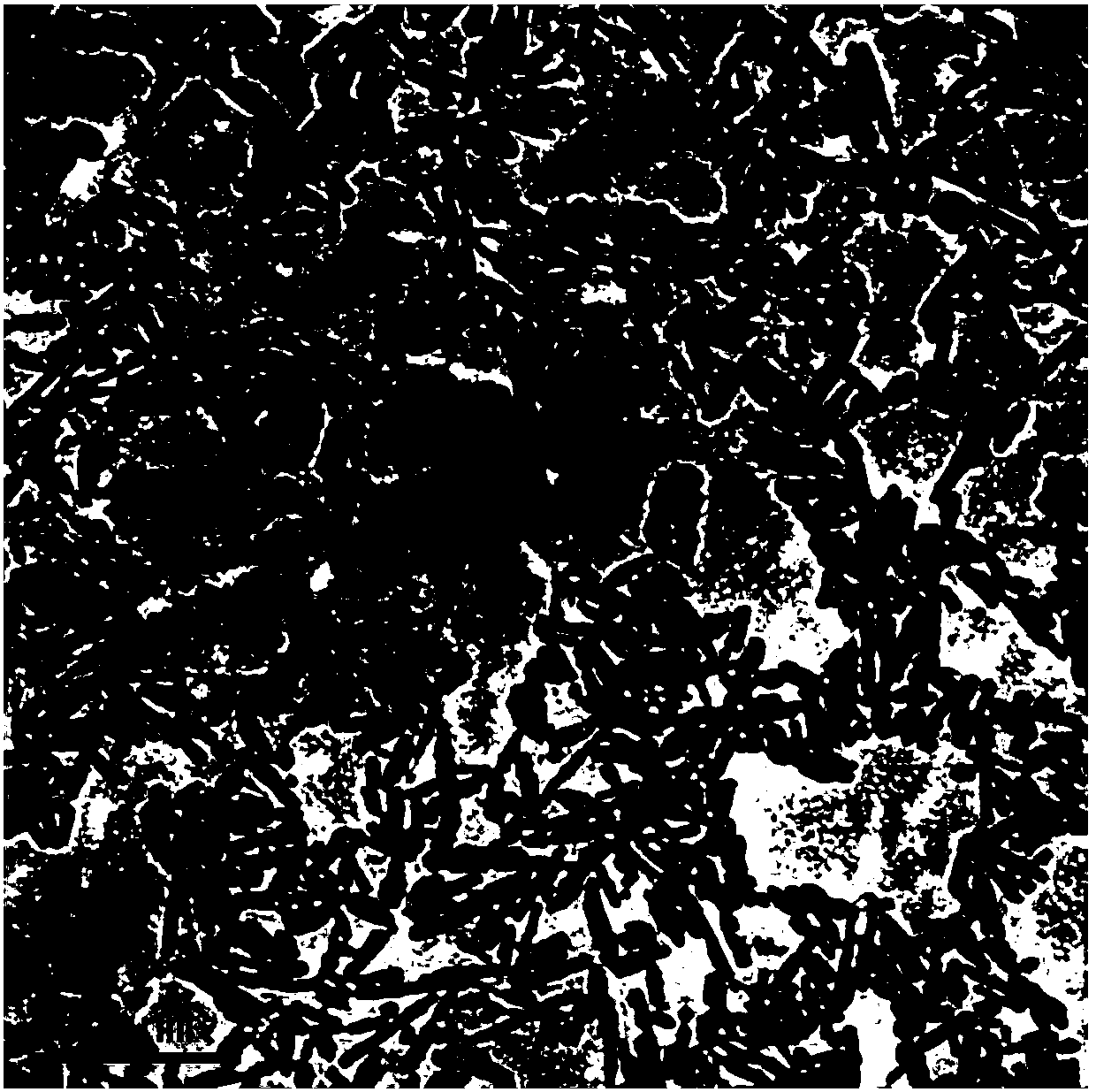

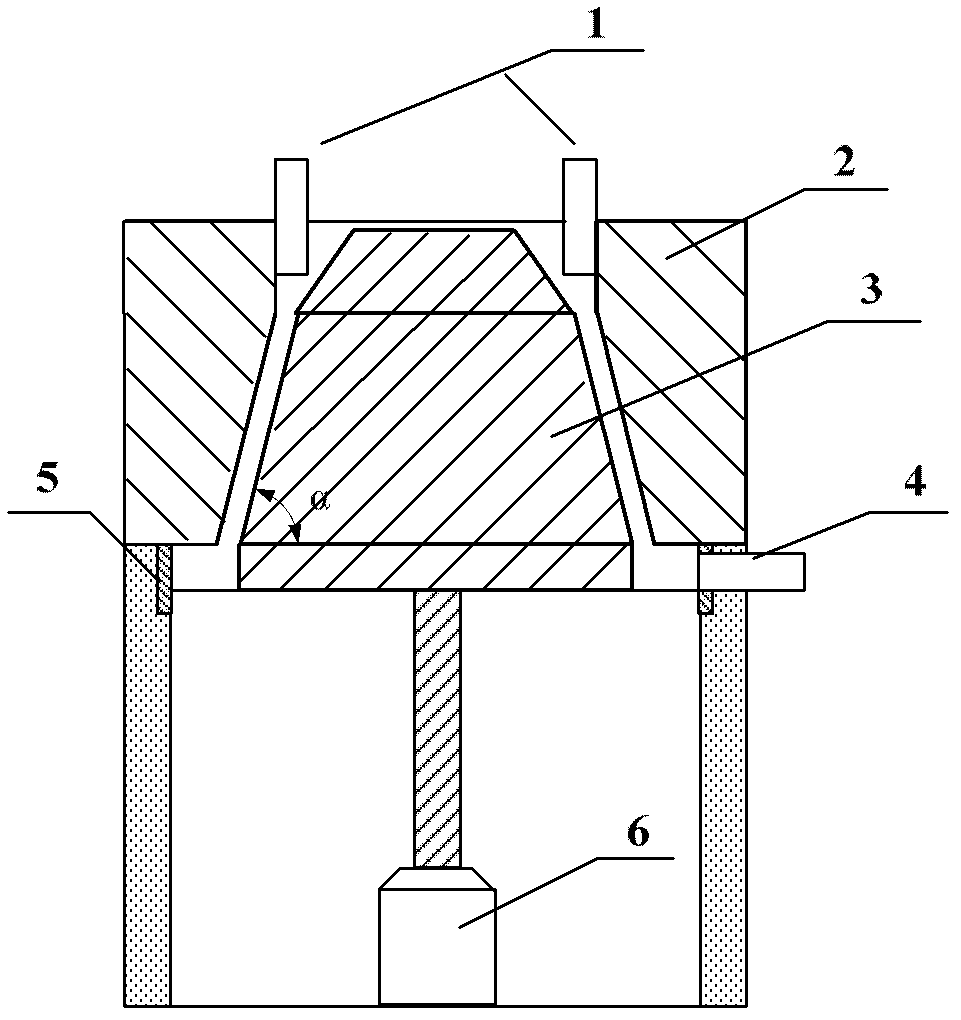

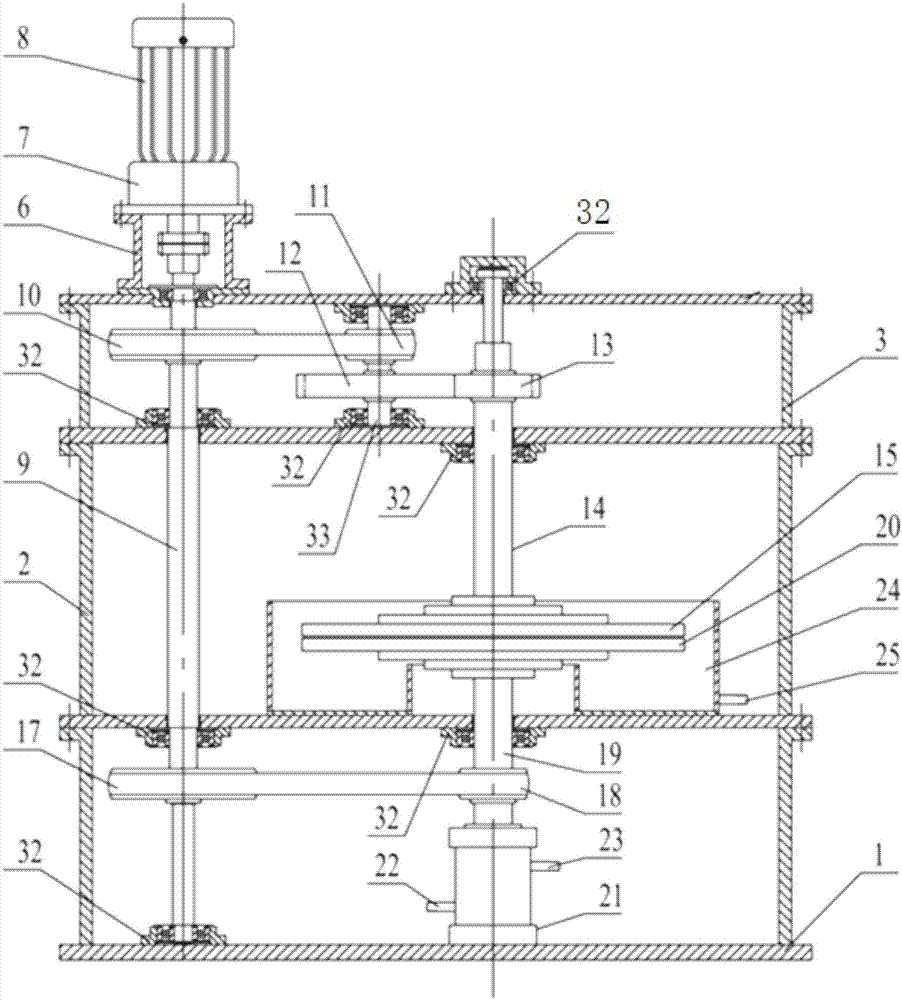

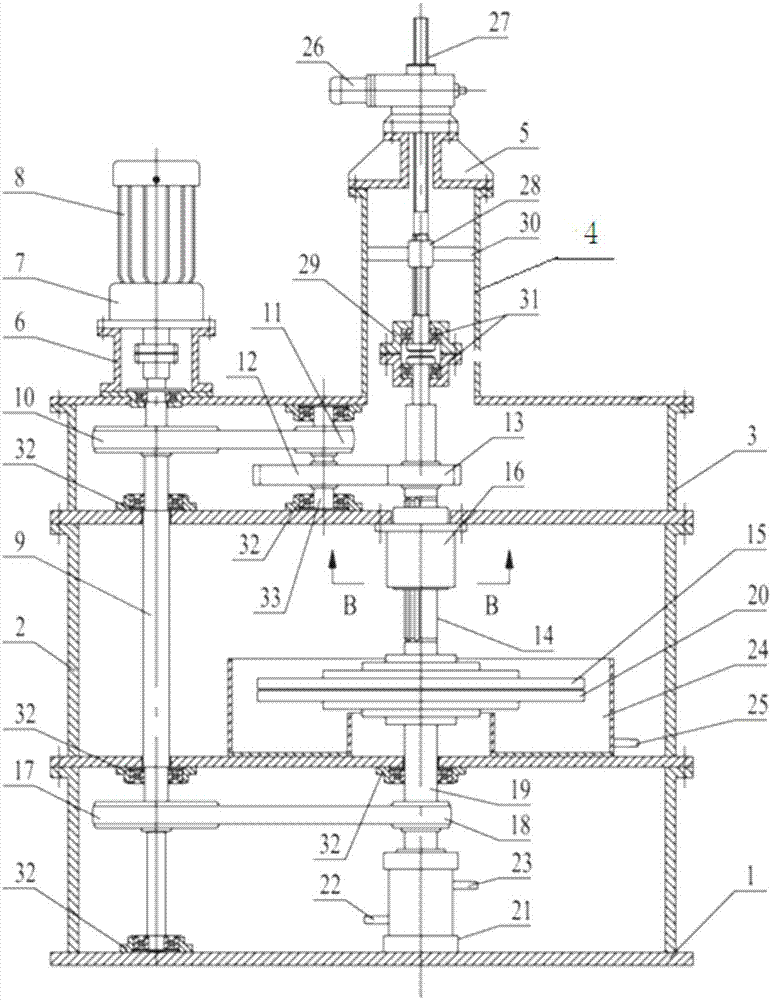

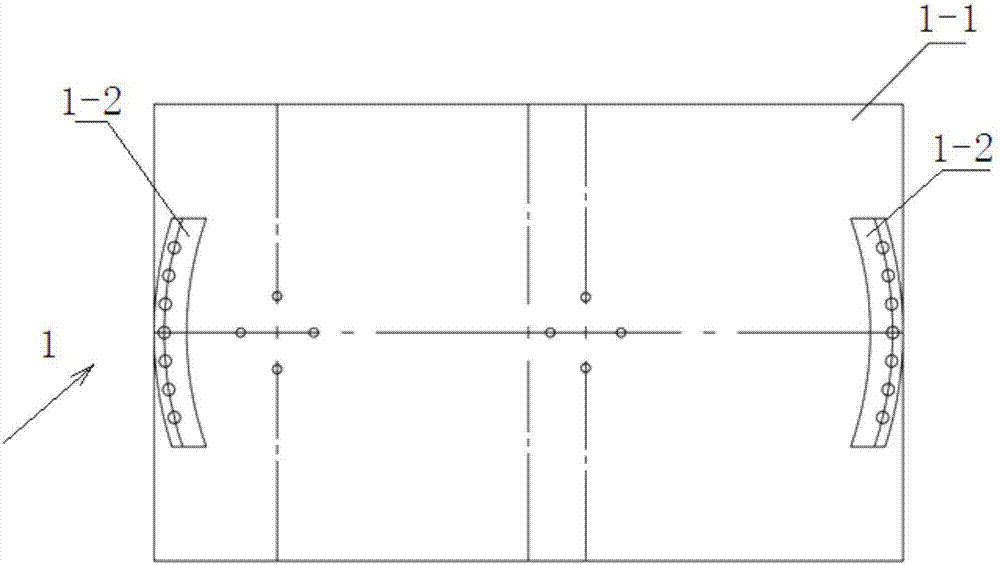

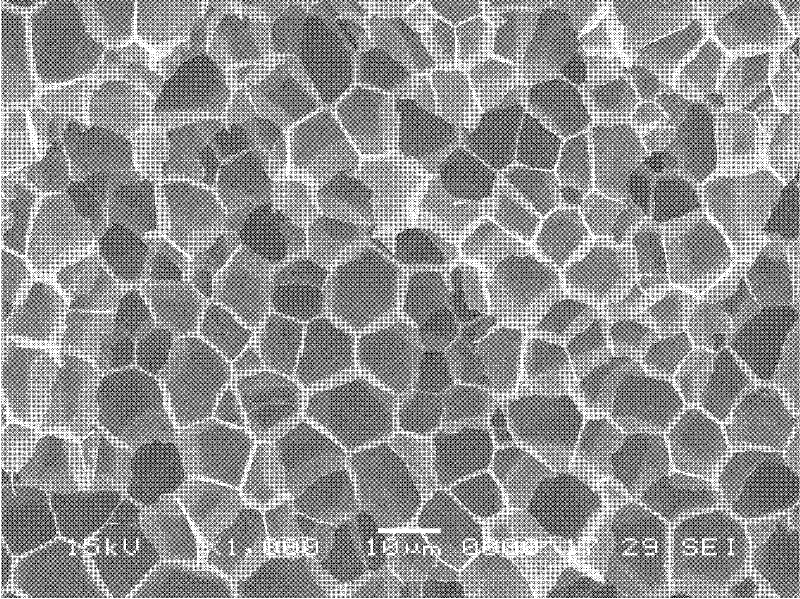

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:常州福源科技新材料有限公司

Gypsum material for 3D printing and preparation method thereof

ActiveCN104744000AHigh mechanical strengthGood dispersionAdditive manufacturing apparatusFilling materials3d printer

The invention discloses a gypsum material for 3D printing. The gypsum material is that a gypsum product is printed and formed through 1 part by mass of powder and 0.25 to 1 part by mass of liquid-phase material by a 3D printer, wherein the powder is prepared from the following raw materials in parts by mass: 90 to 98 parts of hemihydrate gypsum, 1 to 10 parts of filling material, and 0 to 2 parts of fibers; the liquid-phase material is prepared from the following raw materials in parts by mass: 80 to 90 parts of water, 5 to 15 parts of flexible adhering material, and 1 to 5 parts of coagulating material. The invention further discloses a preparation method of the gypsum material for 3D printing; the gypsum material is prepared by mixing and uniformly agitating all raw materials. The gypsum material for 3D printing and the preparation method have the advantage that the problems of small strength, poor fluidity, large fineness and poor flexibility in the prior art can be solved.

Owner:NANJING UNIV OF TECH

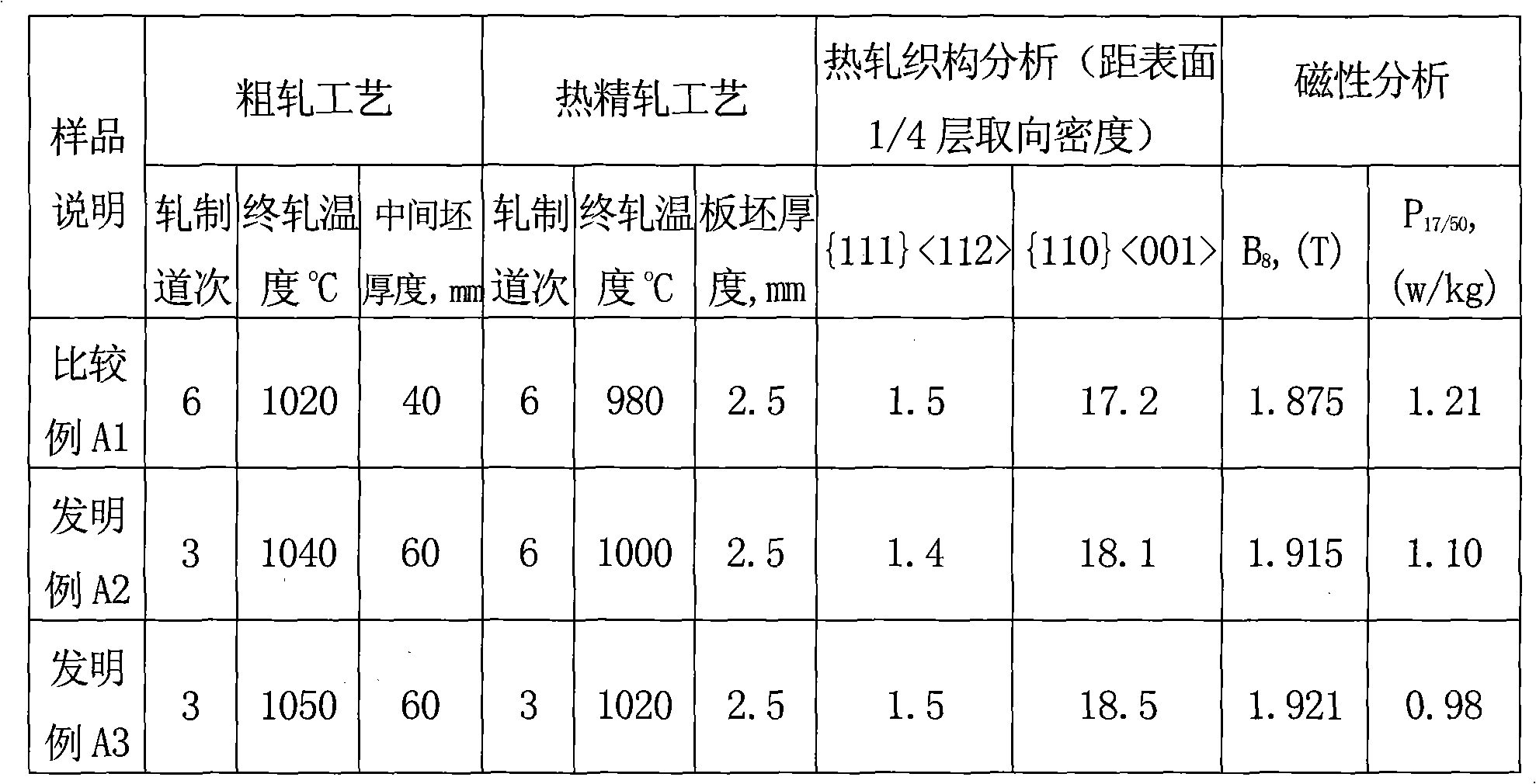

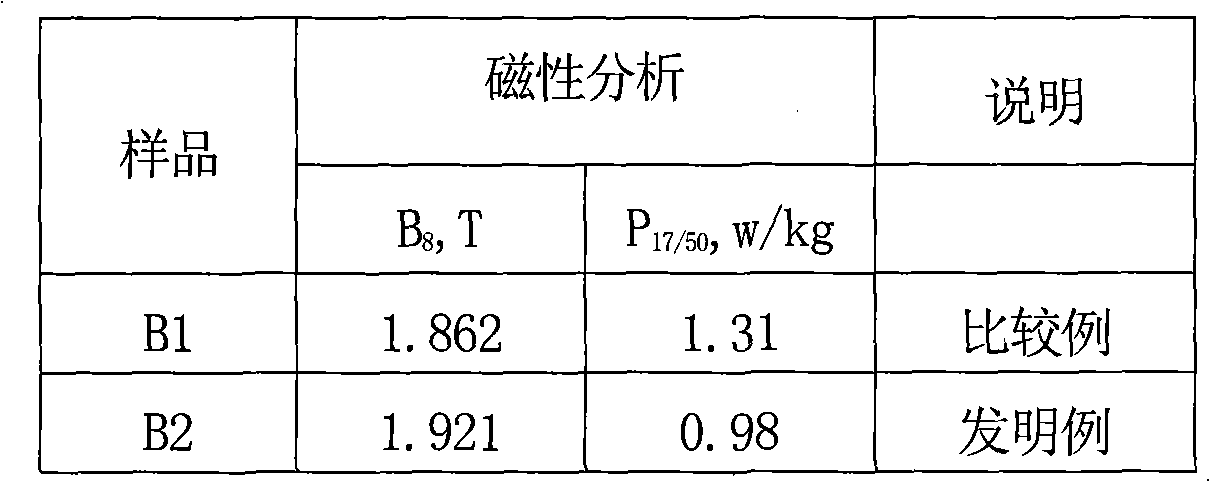

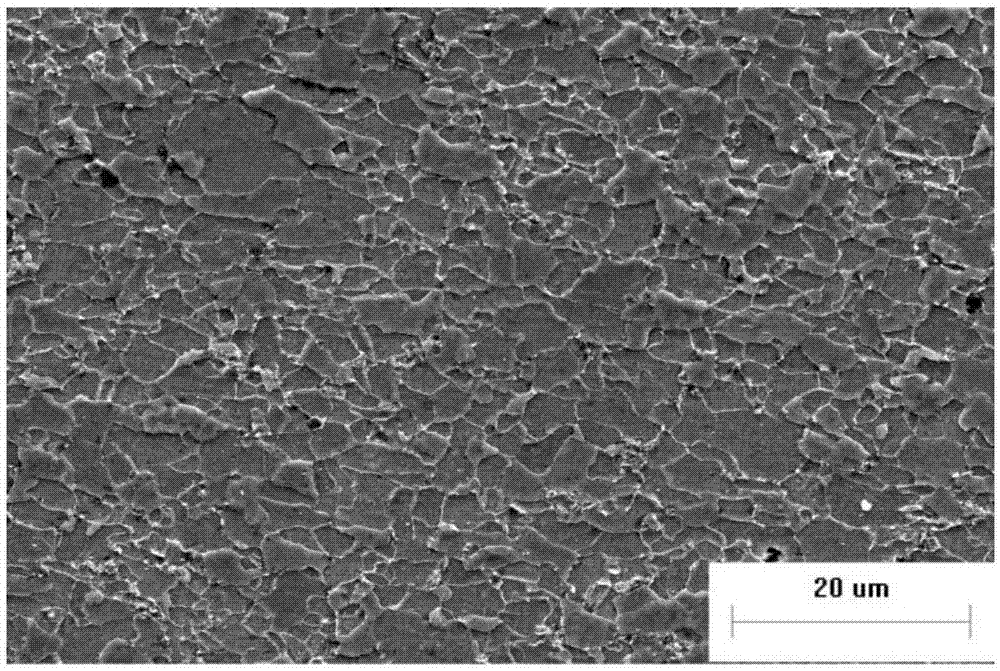

High magnetic induction grain-oriented silicon steel and production method thereof

ActiveCN101353760AReduce contentInhibition formationRoll mill control devicesMetal rolling arrangementsChemical compositionSilicon

The invention discloses a high magnetic induction oriented silicon steel and a production method thereof. The silicon steel comprises the following chemical composition: 0.055wt percent to 0.080wt percent of C, 2.9wt percent to 3.5wt percent of Si, 0.01wt percent to 0.02wt percent of Mn, 0.005wt percent to 0.010wt percent of Als, 0.0050wt percent to 0.0090wt percent of N, 0.25wt percent to 0.55wt percent of Sn, 0.010wt percent to 0.030wt percent of P, 0.10wt percent to 0.20wt percent of Cu, and the rest are Fe and unavoidable impurities. The production method comprises the following steps of: smelting, continuous casting, hot rolling, reeling, cold rolling, decarburizing annealing and high-temperature annealing. The production method effectively overcomes the shortcoming of poor producibility of the prior art and improves the production efficiency as well as the magnetism of the silicon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for preparing nanometer barium sulfate by using molecule mixing strengthening reactor

ActiveCN105329930ASmall particle sizeIncrease the nucleation rateMaterial nanotechnologyCalcium/strontium/barium sulfatesSulfateBarium salt

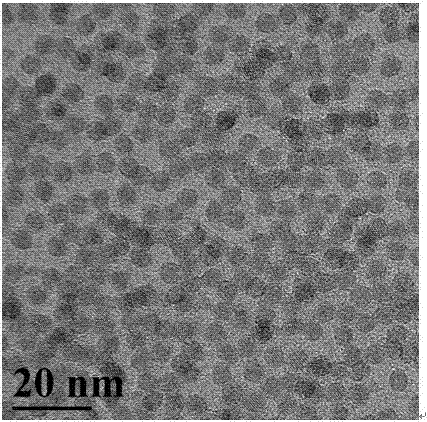

The invention discloses a method for preparing nanometer barium sulfate by using a molecule mixing strengthening reactor. A barium salt solution and dilute sulphuric acid or a sulphate solution are added into the molecule mixing strengthening reactor for reaction, after reaction, a barium sulfate suspending liquid is obtained; the molecule mixing strengthening reactor is a hypergravity rotating packed bed reactor or a tube-in-tube microchannel reactor; aftertreatment for the obtained barium sulfate suspending liquid is carried out, and nanometer barium sulfate powder is obtained. The hypergravity rotating packed bed reactor or the tube-in-tube microchannel reactor has the advantages of simultaneous control of reaction temperature, concentration of reaction solution, injection rate and injection speed ratio, and requirements of reaction product nanometer barium sulfate obtained finally, such as particle sizes (all smaller than 30nm) are smallest and distribution is narrowest, are met.

Owner:BEIJING UNIV OF CHEM TECH

3D printing gypsum ink and preparation method thereof

The present invention belongs to the technical field of 3D printing materials, and relates to a 3D printing gypsum ink, and the 3D printing gypsum ink is prepared from the following components by weight: 60% to 93% of gypsum powder, 2% to 20% of filler, 4% to 18% of a modifying solvent and 0.5% to 5% of a coagulant. The present invention also discloses a preparation method of the 3D printing gypsum ink, and all the raw materials are mixed and stirred evenly to obtain the 3D printing gypsum ink. The problems of low strength, poor mobility, coarse particles, poor toughness and high cost in the prior art can be solved, and an economical 3D printing forming material with industrial potential, high speed, good precision and low use cost is developed.

Owner:QINGHAI MINGYANG ENVIRONMENTAL TECH GRP CO LTD

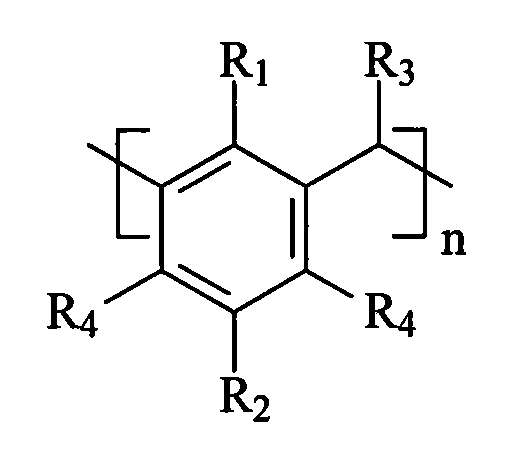

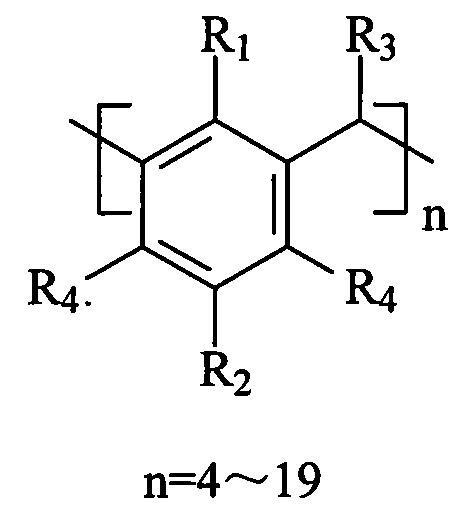

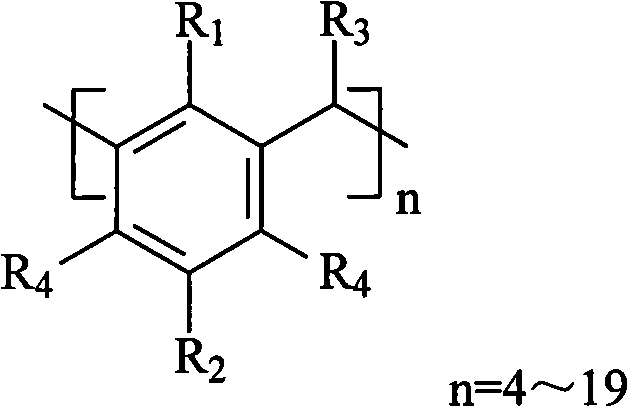

Self-assembled calixarene nucleating agent and application thereof in polylactic resin composition

InactiveCN102020784AIncrease the nucleation rateThere is no problem of degradationAlkaneStructural formula

The invention relates to a self-assembled calixarene nucleating agent and an application thereof in a polylactic resin composition. The self-assembled calixarene nucleating agent is a supermolecular nucleating agent self-assembled by the below A and B, wherein A is calixarene and derivatives thereof expressed by structural formula A while B consists of one or more organic micromolecular compounds as follows: C1-C30 alkane, C1-C30 halogenated alkane, C1-C30 alcohol, C1-C30 nitrile, a 5-6 membered heterocyclic compound, substituted 5-6 membered heterocyclic compound (substituent can be hydroxyl, aldehyde group and alkyl), benzene, naphthalene, substituted benzene and substituted naphthalene. The invention has the advantages of simple production process, relative low cost and great nucleating speed, thereby overcoming the low crystallization rate of polylactic resin and reducing the processing and forming period.

Owner:EAST CHINA UNIV OF SCI & TECH

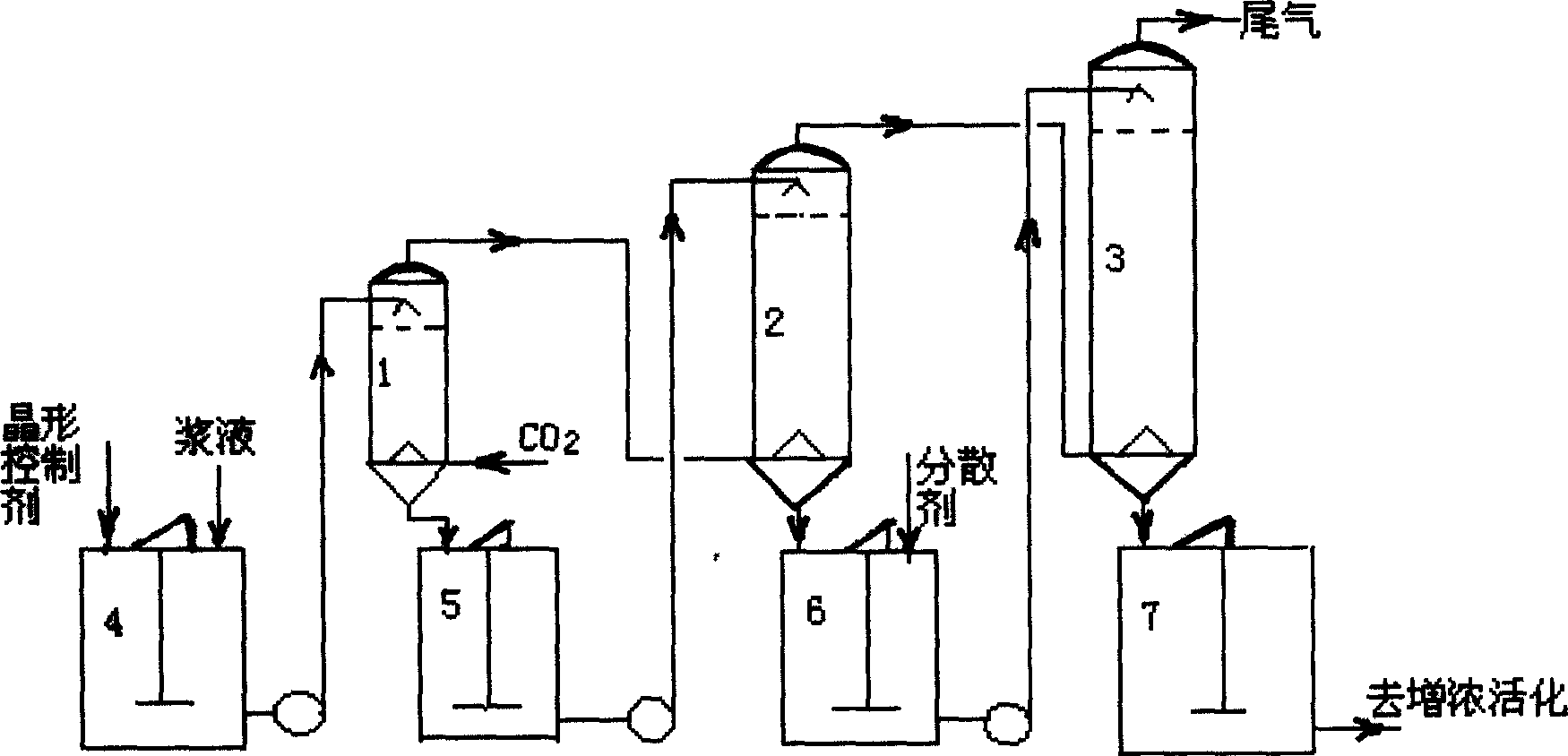

Continuous bubbling carbonizing new process for producing super fine active calcium carbonate

InactiveCN1749168AIncrease the nucleation rateIncrease production intensityCalcium/strontium/barium carbonatesHigh concentrationCO2 content

The present invention discloses continuous bubbling carbonizing process for producing superfine active calcium carbonate in the installation with pre-carbonizing tower with high concentration carbonizing gas with CO2 content of 50-99 %, No. 1 carbonizing tower and No. 2 carbonizing tower connected serially. Calcium other slurry passes successively through fine slurry trough, pre-carbonizing tower, No. 1 slurry trough, No. 1 carbonizing tower, No. 2 slurry trough, No. 2 carbonizing tower and chamotte trough; while carbonizing gas passes successively through pre-carbonizing tower, No. 1 carbonizing tower and No. 2 carbonizing tower before being exhausted to air. There are crystal form controlling agent added into the fine slurry trough and dispersant added into the No. 2 slurry trough, and the calcium carbonate slurry in the chamotte trough is prepared into the superfine active calcium carbonate through thickening, activating, dewatering, drying and crushing.

Owner:颜鑫

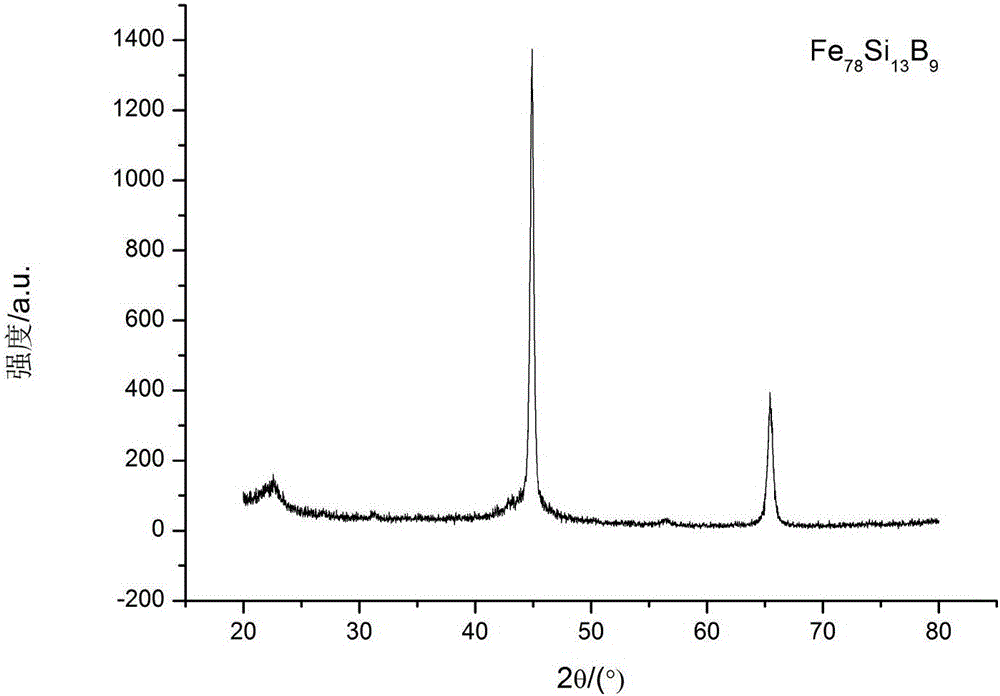

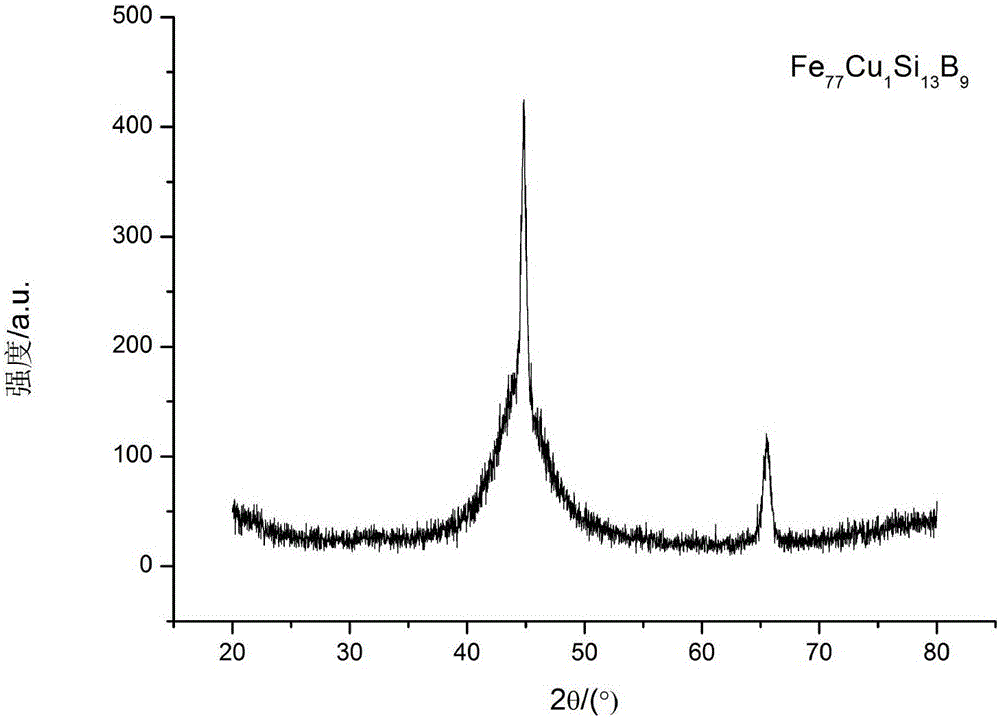

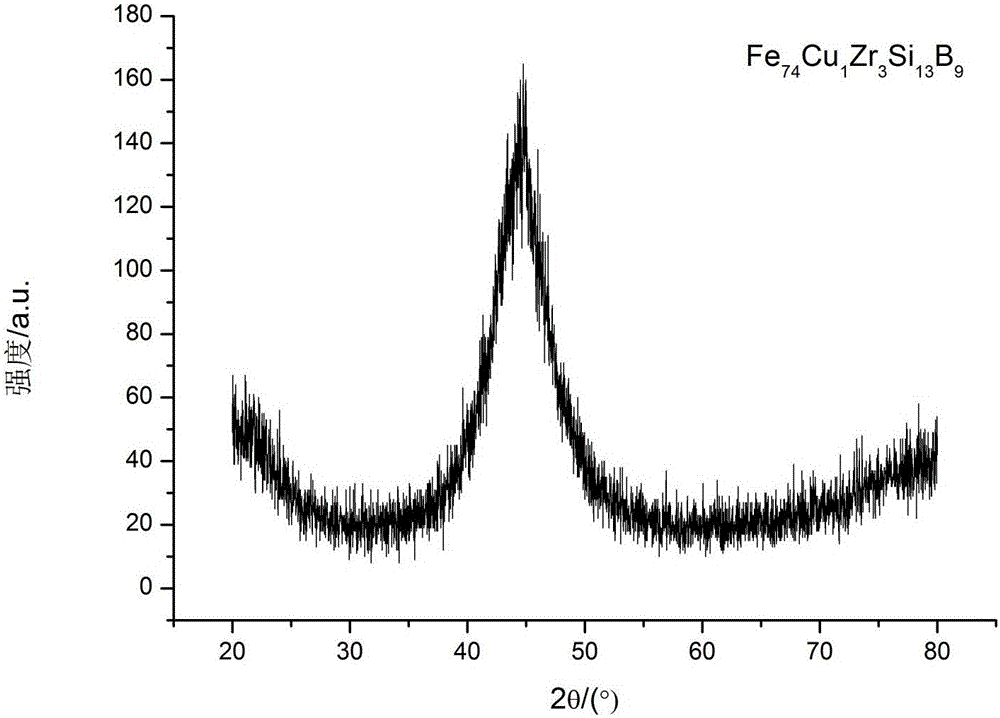

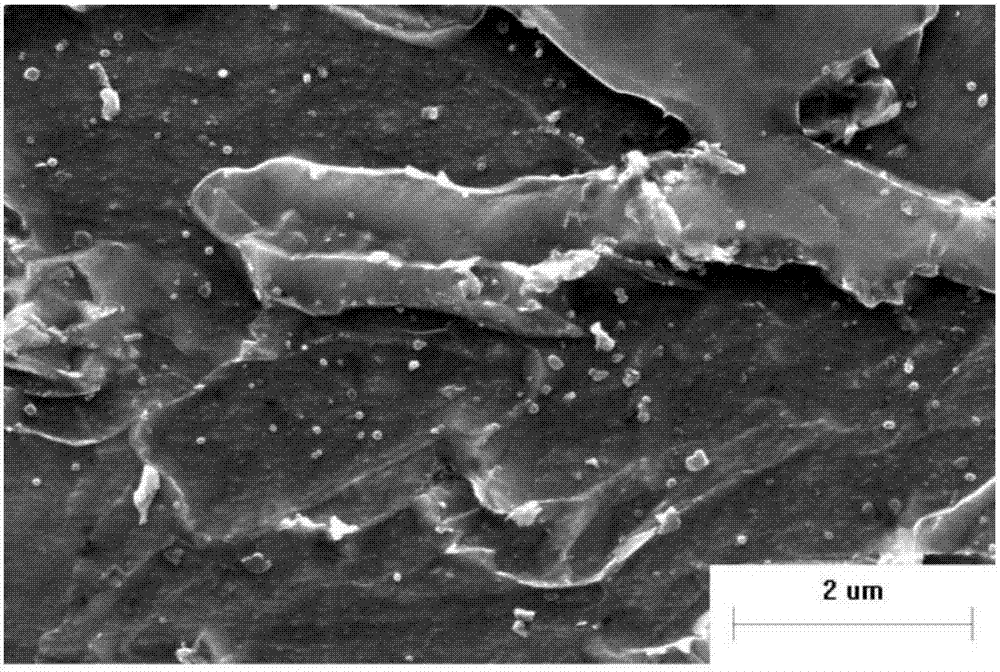

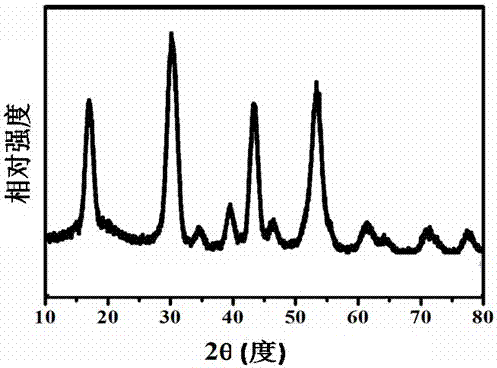

Fe-based amorphous/nanocrystalline soft magnetic alloy thin belt and preparation method thereof

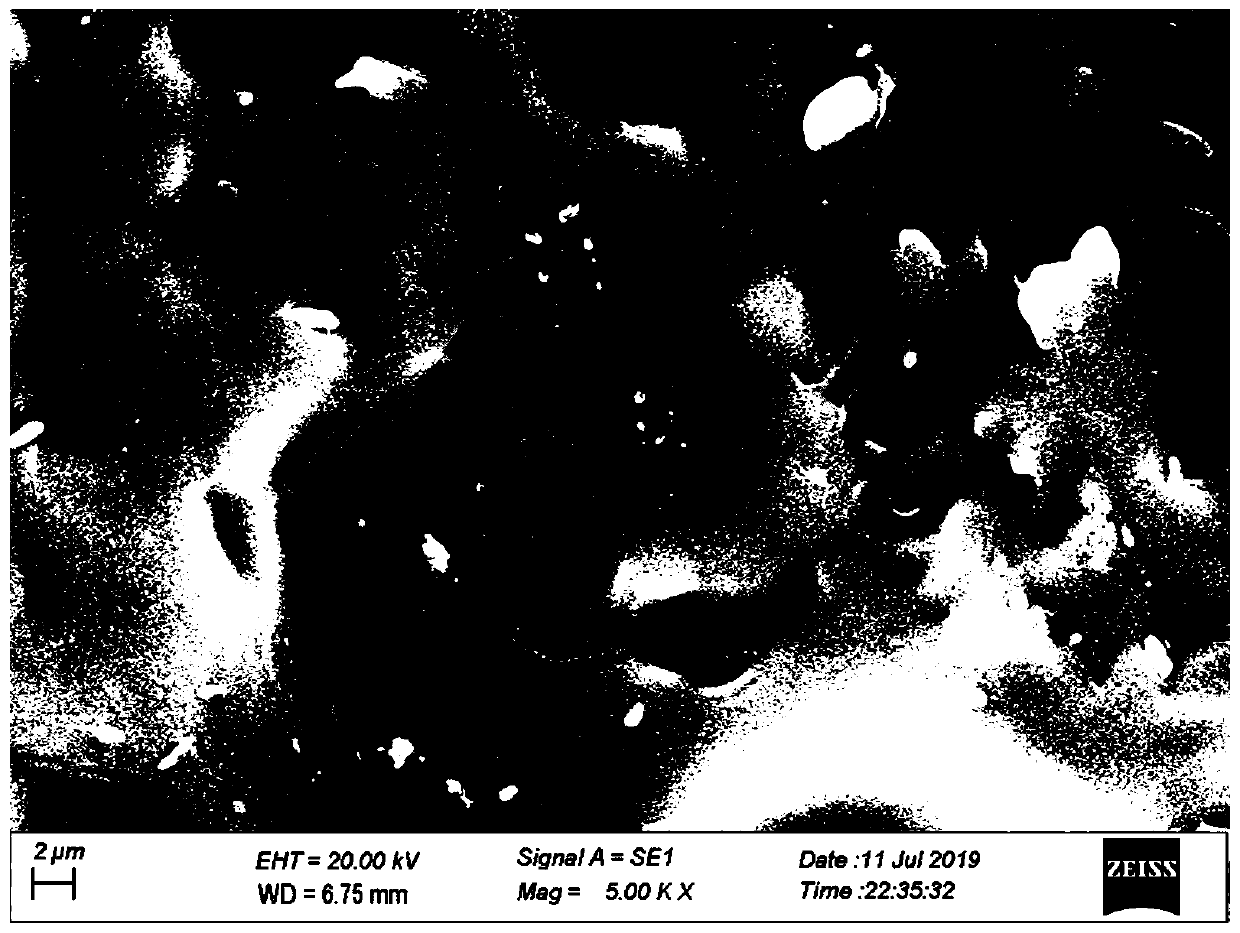

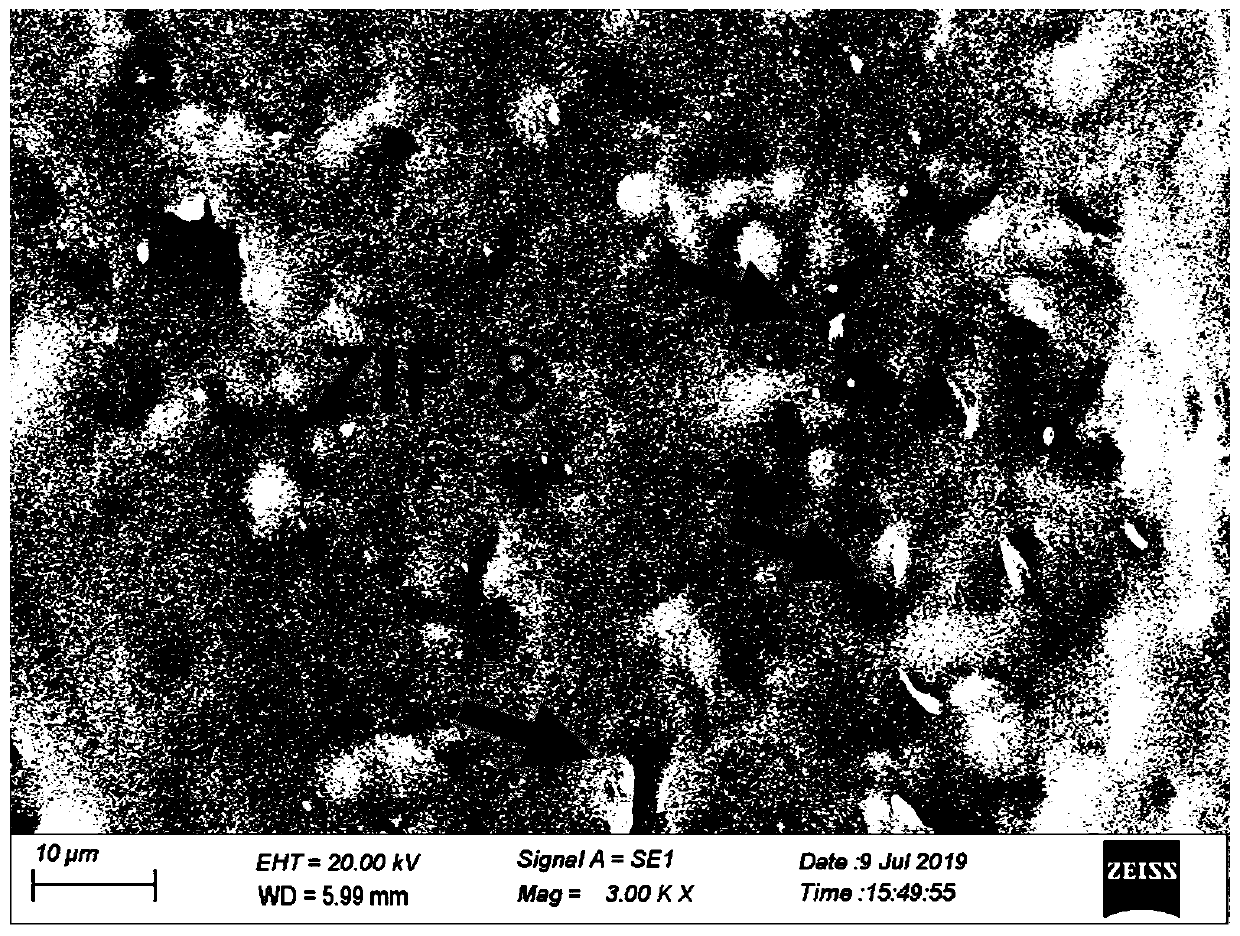

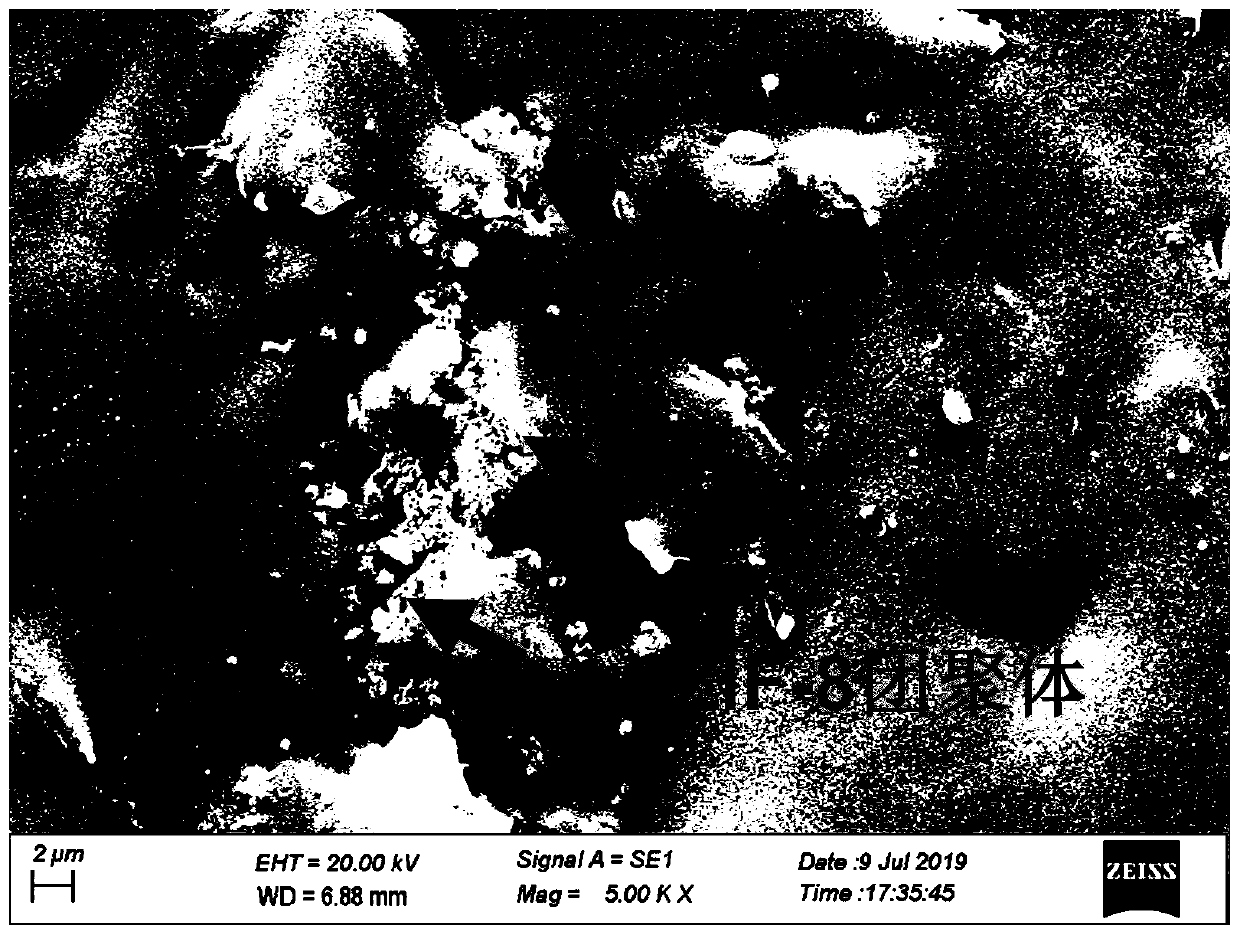

The invention relates to a Fe-based amorphous / nanocrystalline soft magnetic alloy thin belt. A chemical expression formed by elements of the alloy thin belt is FeaSibBaCudMee, wherein the atomic percent of the elements is shown as follows: a is equal to 80-85, b is equal to 2-13, c is equal to 5-13, d is equal to 0.5-2, e is equal to 0.5-5, a+b+c+d+e is equal to 100; Me is Zr, Nb or Mo. The alloy thin belt has a thickness of 15-40 [mu]m and a width of 1-5 mm. Through adding the Me element in the method, the nucleation rate of super-cooled liquid is effectively improved, and the precipitation of a BCC nanocrystalline iron phase is promoted, Fe-based nano alloy is prepared, and the magnetostriction coefficients of a material are reduced, so that the initial magnetic conductivity is improved, and the saturated magnetic induction intensity is obviously improved.

Owner:HEBEI UNIV OF TECH

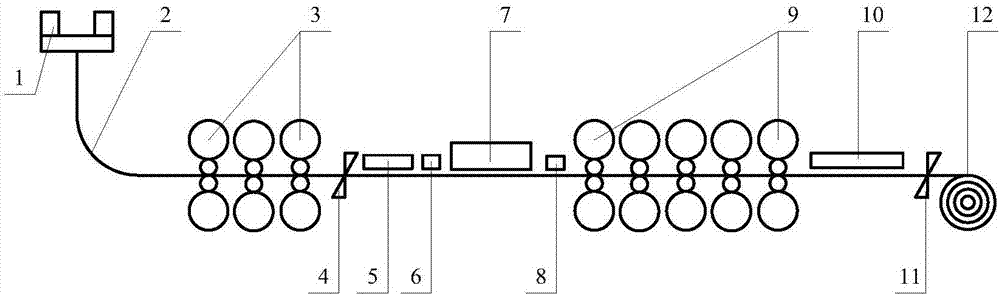

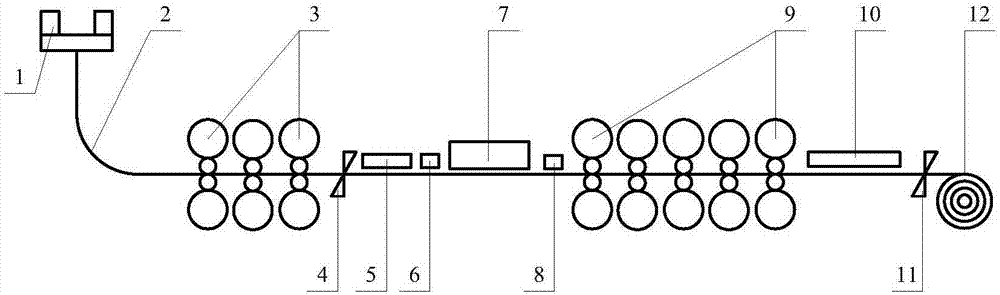

Preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel

InactiveCN107460413AImprove mechanical propertiesGood atmospheric corrosion resistanceWeather resistanceAustenite grain

The invention relates to a preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel and belongs to the technical field of metallurgy. The preparation method comprises the steps that continuous casting blanks directly enter an M rack rough rolling unit under the high pulling speed and are subjected to M-pass continuous heavy reduction (50-60%) rough rolling, and austenite grains are greatly refined; after rough rolling, middle blanks are rapidly heated through an induction heating furnace to the temperature needed for a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then sequentially through a finish rolling set, laminar flow cooling and a reeling machine, finally the organization characteristics that the surface and the core part are coarse, and the portion of the 1 / 4 thickness position is fine are formed. In the production process, finish rolling and rough rolling are both full-headless rolling. An ultra-fine grain high-strength weather-resistant hot-rolling steel belt with the weather resistance being equivalent to corten-A is obtained, and the effects that the thin effect replaces the thick effect and the hot effect replaces the cold effect are achieved; while the weight of a car body is small, the service life of a car plate is prolonged, the production efficiency is improved, and the production cost is reduced; and meanwhile energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

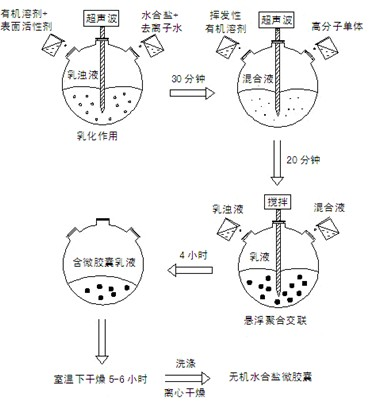

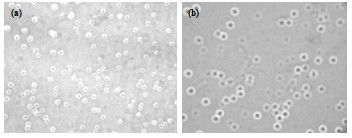

Inorganic hydrous salt phase change energy storage microcapsule and preparation method thereof

InactiveCN102676124AReduce subcoolingOvercoming phase separationEnergy storageHeat-exchange elementsActive agentSurface-active agents

The invention discloses an inorganic hydrous salt phase change energy storage microcapsule and a preparation method thereof. According to the microcapsule, an inorganic hydrous salt phase change material serves as a core material, and a high polymer serves as a capsule wall material. By means of a selection of an appropriate organic solvent, a surface active agent serves as a supplement, polymer monomer materials of the core material and the capsule wall material form an evenly dispersed mixed solution under the ultrasonication action, by means of an addition of functional additives of an initiating agent, a lubricating agent, a stabilizing agent, and a retarder and the like, under the reaction condition, the polymer monomers are subjected to suspension polymerization and solidification in the mixed solution, and then the core material is coated by the polymer monomers to form a phase change energy storage microcapsule. The preparation method is simple in operation and low in equipment requirements, the preparation method range of an inorganic core microcapsule is effectively widened, and by means of the sealing form of the microcapsule, the problems of the supercool and the phase separation of the hydrous salt phase change material are solved.

Owner:GUANGDONG UNIV OF TECH

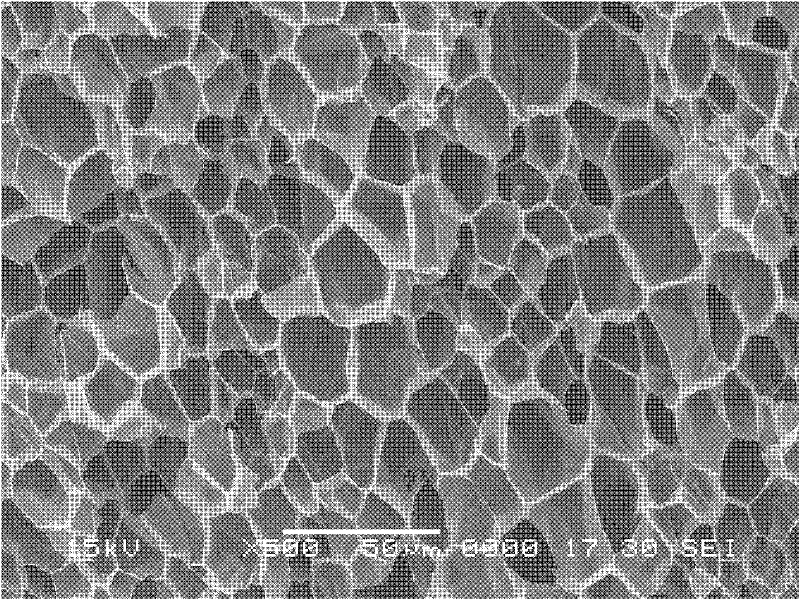

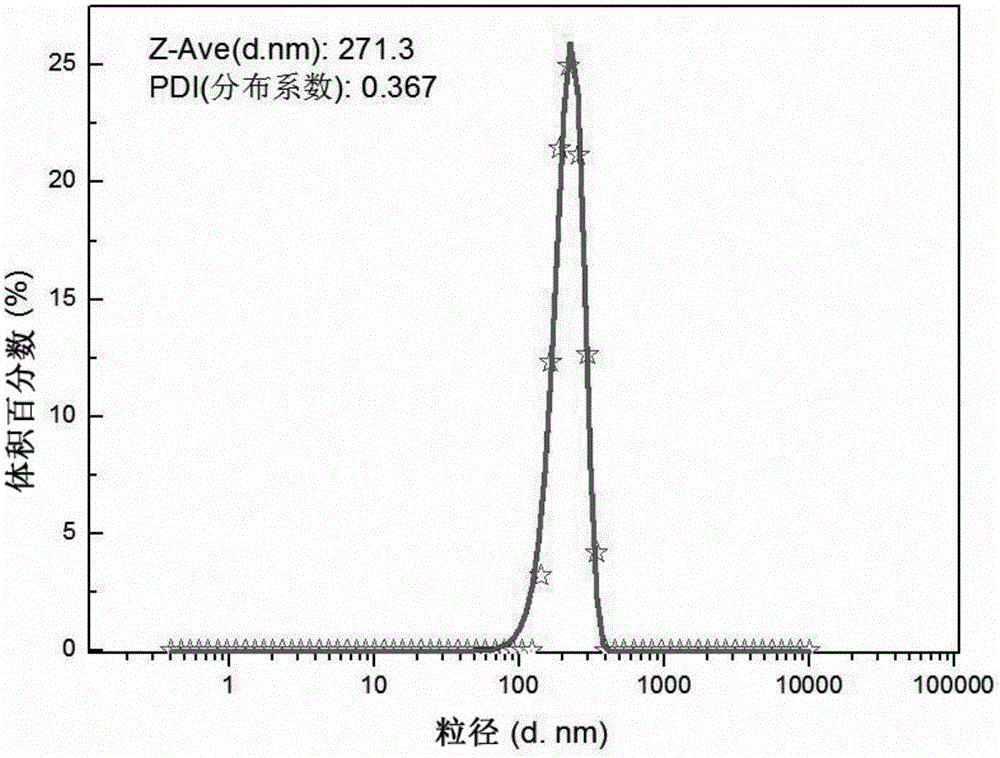

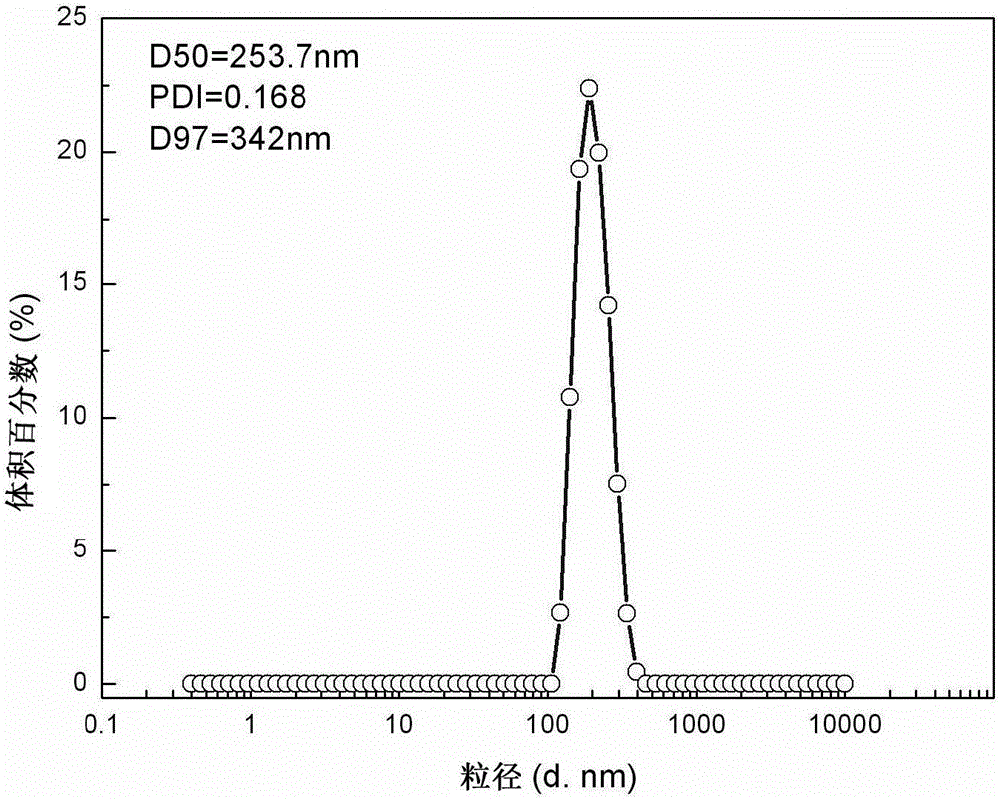

Nanometer hydroxyapatite dispersion body and preparation process thereof

ActiveCN107555406AImprove particle uniformityReduce reunionPhosphorus compoundsOrganic solventNano hydroxyapatite

The present invention discloses a nanometer hydroxyapatite dispersion body and a preparation process thereof. According to the nanometer hydroxyapatite dispersion body, nanometer hydroxyapatite particles are uniformly dispersed in a liquid phase medium, the solid content of the nanometer hydroxyapatite dispersion body is 1-5 wt%, the size of the nanometer hydroxyapatite particles is 40-60 nm, theaspect ratio of the nanometer hydroxyapatite particles is 1-5, and the liquid phase medium is water, an organic solvent, the mixture of a water-miscible organic solvent and water, or the mixture of different organic solvents. According to the present invention, by combining the hydrothermal method and the super gravity technology, the microcosmic mixing effect is strengthened, and the method has advantages of low production cost, simple operation and good repeatability; the prepared nanometer hydroxyapatite dispersion body has advantages of controlled particle size, good dispersion effect andgood stability; and with the technical scheme, the problems of easy agglomeration, poor dispersibility and the like of the nanometer hydroxyapatite particles can be solved, and the product can be endowed with the high application performance and the broad application range.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method for synthesizing platy flame-retardant magnesium hydroxide by using light burned magnesia powder

InactiveCN102060314AIncrease the nucleation rateHigh industrial application valueMagnesium hydroxideFire retardantAmmonia

The invention relates to a preparation method for synthesizing platy flame-retardant magnesium hydroxide by using light burned magnesia powder. The method comprises the following steps of: preparing MgSO4 solution from light burned magnesia serving as a magnesium ion providing source by using sulfuric acid, filtering to remove impurities, controlling the ratio of [NH3.H2O] to [Mg<2+>] to be 1.5-1 and the ratio of [OH<->] to the [Mg<2+>] to be 2-1.5 by using ammonia water and NaOH solution as precipitating agents, and synthesizing the platy flame-retardant magnesium hydroxide by a two-step method, wherein the temperature of the ammonia water precipitating stage is between 50 and 60 DEG C, the temperature of the NaOH solution precipitating stage is between 120 and 160 DEG C, and the hydrothermal reaction time is 2 to 10 hours. The obtained platy magnesium hydroxide has the primary particle size of 0.5 to 1mu m and the magnesium hydroxide content of over 97 percent. The method is low in cost and high in added value; the prepared magnesium hydroxide has high purity, a stable structure and narrow particle size distribution; and a good way is provided for highly utilizing magnesium hydroxide and even magnesite resources. The magnesium hydroxide product prepared by the method can be used as a flame retardant in the industries of rubber, plastic, electric wires and cables, building materials and the like.

Owner:辽宁法库陶瓷工程技术研究中心

Electrode active material for lead-acid storage battery

InactiveCN106876667AHigh porosityInhibition of agglomeration and cloggingLead-acid accumulatorsCell electrodesSpecific energyMixed type

The invention discloses an electrode active material for a lead-acid storage battery. The electrode active material comprises lead powder and composite material granules; the lead powder comprises one or more kinds of metal lead powder, ball-milling lead powder, Barton lead powder, Pb<2>O powder, PbO powder, Pb<2>O<3> powder, Pb<3>O<4> powder and PbO<2> powder; and the composite material granules comprise one or more kinds of coating type composite material granules and mixed type composite material granules. By virtue of the electrode active material for the lead-acid storage battery with an improved formula, the specific power, specific energy, active material utilization rate, charging-discharging efficiency, cycle life, low-temperature performance and the like of the applied lead-acid storage battery can be obviously improved.

Owner:杨春晓

High-performance copper alloy prepared by casting method

The invention relates to a high-performance copper alloy prepared by a casting method, and belongs to the field of copper alloys. The copper alloy comprises Cu, Cr, Zr and M, wherein the mass percentof the Cr is 0.1-5.0%, and the mass percent of the Zr is 0.1-5.0%; the M is composed of RE and at least two of Mg, Ag, B, Ga, Si, Li, Ti, Fe and Mn; the RE is selected from at least three of Ce, La, Yb, Pr, Nd and Sm; and the mass ratio of the M in the high-performance copper alloy is 0.05-0.5%. The high-performance copper alloy is subjected to casting to obtain an as-cast alloy ingot, and the as-cast alloy ingot is subjected to heat treatment and deformation treatment to obtain a finished product with excellent mechanical properties and electrical conductivity.

Owner:CENT SOUTH UNIV

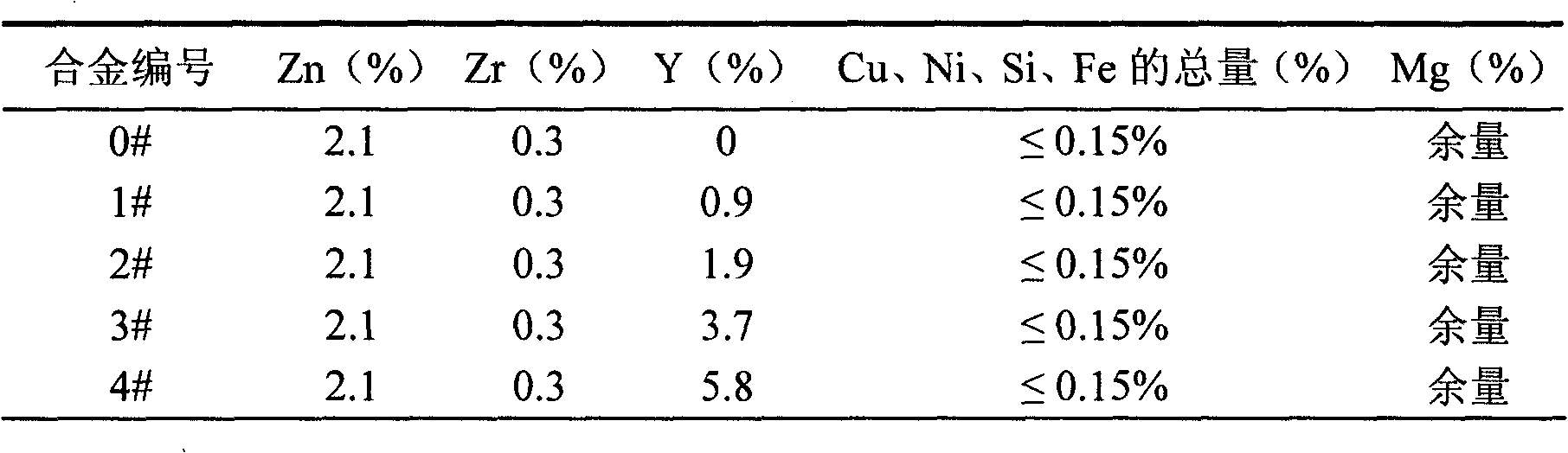

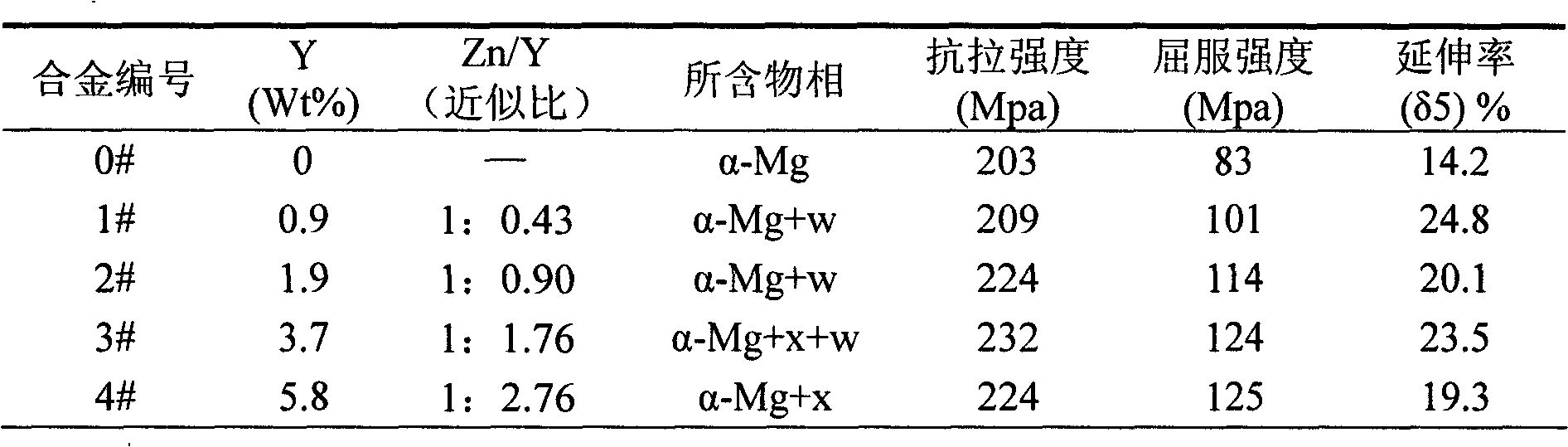

Magnesium-zinc-zirconium-yttrium-magnesium alloy

InactiveCN101812620AImprove heat deformation plasticityReduce extrusion deformation resistanceHeat deflection temperatureYttrium

The invention provides a magnesium-zinc-zirconium-yttrium-magnesium alloy which comprises the following components in percentage by weight: 2.0-4.0% of zinc, 0.2-0.5% of zirconium and 0.9-5.8% of yttrium and the balance magnesium and impurity. The invention improves optional heat deflection temperature range of the alloy by controlling zinc content in the magnesium-zinc-zirconium series magnesium alloy and adding yttrium element with a proper proportion; higher deflection temperature is favorable for improving the heat deflection plasticity of magnesium alloy and improving extrusion rate; and meanwhile, alloy crystalline grain is refined by the action that high melting point second phase containing yttrium prevents crystalline grains from growing in the heat extrusion deformation recrystallization process so as to obtain magnesium alloy with moderate strength and favorable plasticity. The magnesium-zinc-zirconium-yttrium-magnesium alloy with the optimal proportion has the room-temperature tensile strength of 279 MPa, yield strength of 184 MPa and elongation percentage of 28%.

Owner:CHONGQING UNIV

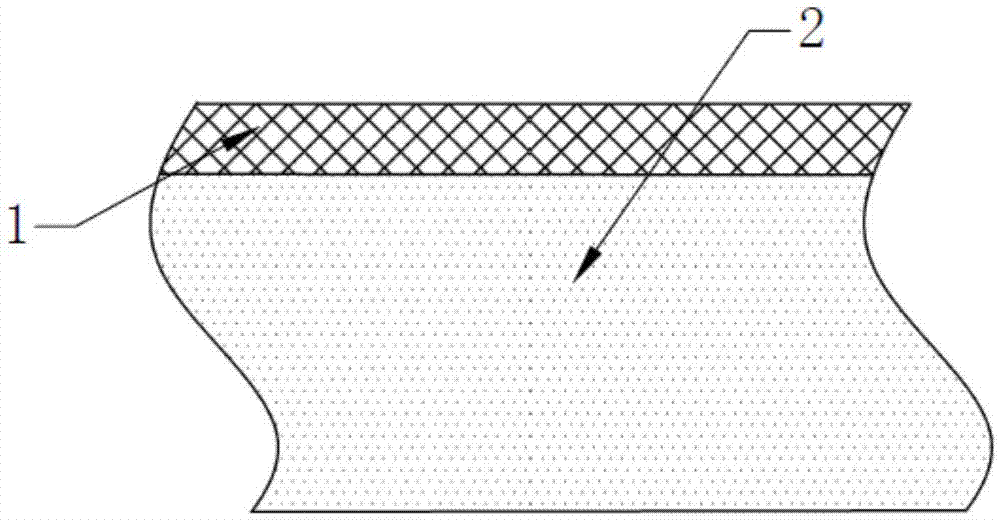

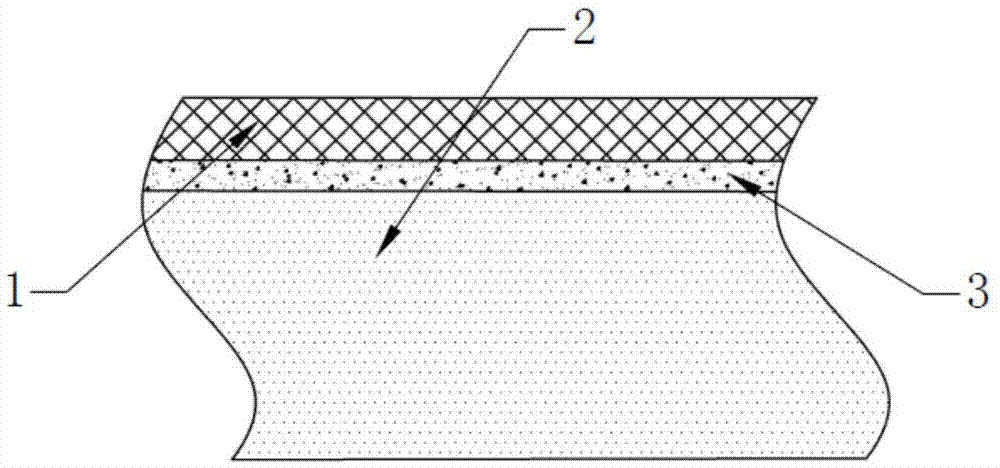

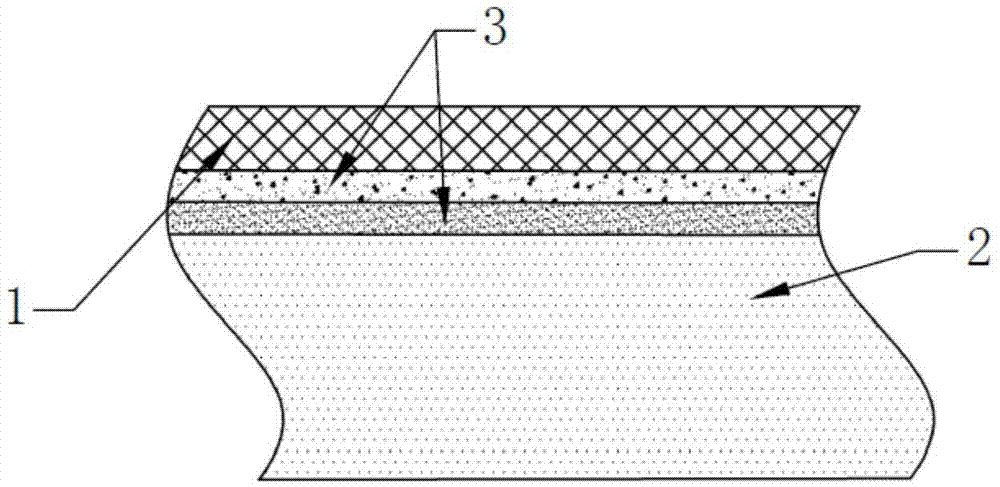

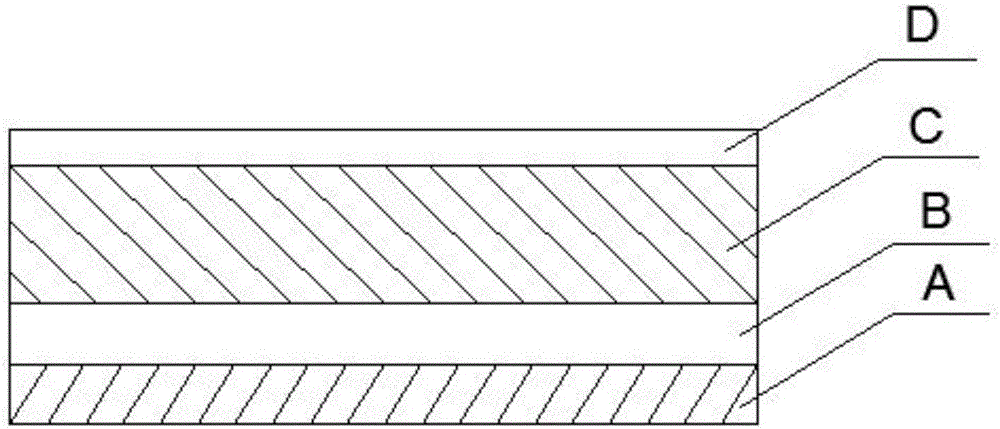

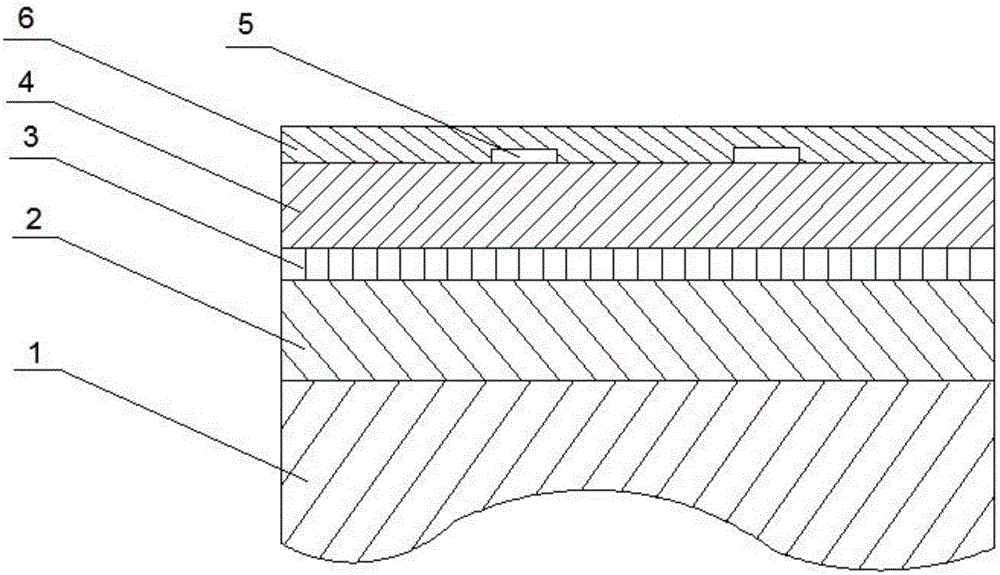

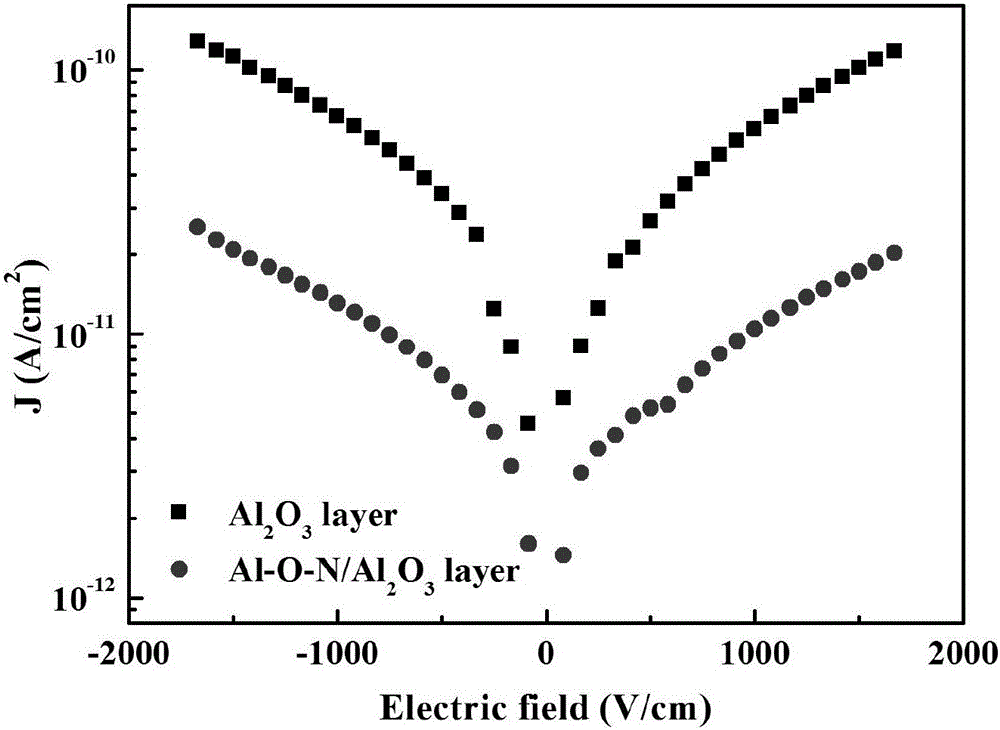

Composite insulating layer for thin film sensor and preparation method of composite insulating layer

InactiveCN105970168AFast film formationImprove compactnessMeasurement devicesVacuum evaporation coatingThin film sensorEvaporation

The invention belongs to the technical field of thin film sensors, and relates to a composite insulating layer for a thin film sensor. The composite insulating layer comprises four layers of structures which comprise the amorphous Al-O-N diffusion impervious layer, the Al-O-N-to-Al2O3 transition layer, the electron beam evaporation Al2O3 thin film layer and the microcrystal Al2O3 oxygen diffusion barrier layer in sequence from bottom to top. An amorphous Al-O-N thin film in the composite insulating layer is good in compactness and is in an amorphous state, and a good diffusion barrier effect is achieved for metal atoms. The adhesive force between the amorphous Al-O-N layer and the Al2O3 layer can be effectively improved through the transition layer. The microcrystal layer on the Al2O3 thin film layer can effectively prevent outside oxygen atoms from diffusing into the Al-O-N layer at a high temperature, the amorphous state of the Al-O-N thin film in the high-temperature oxygen-enriched environment is kept, and therefore the composite insulating layer still has good insulation performance in the high-temperature oxygen-enriched work environment, and the stability and the service life of the thin film sensor in the high-temperature environment are effectively guaranteed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

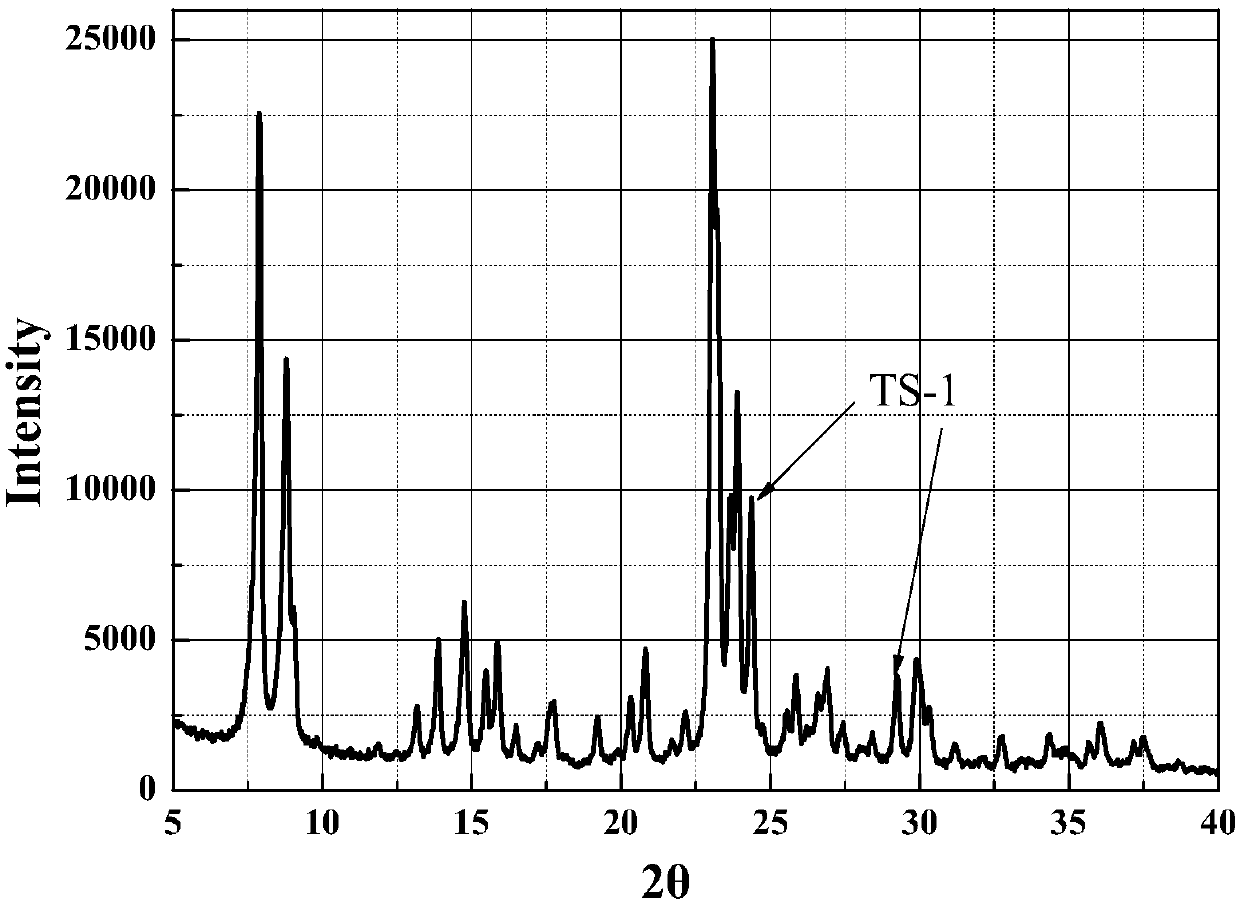

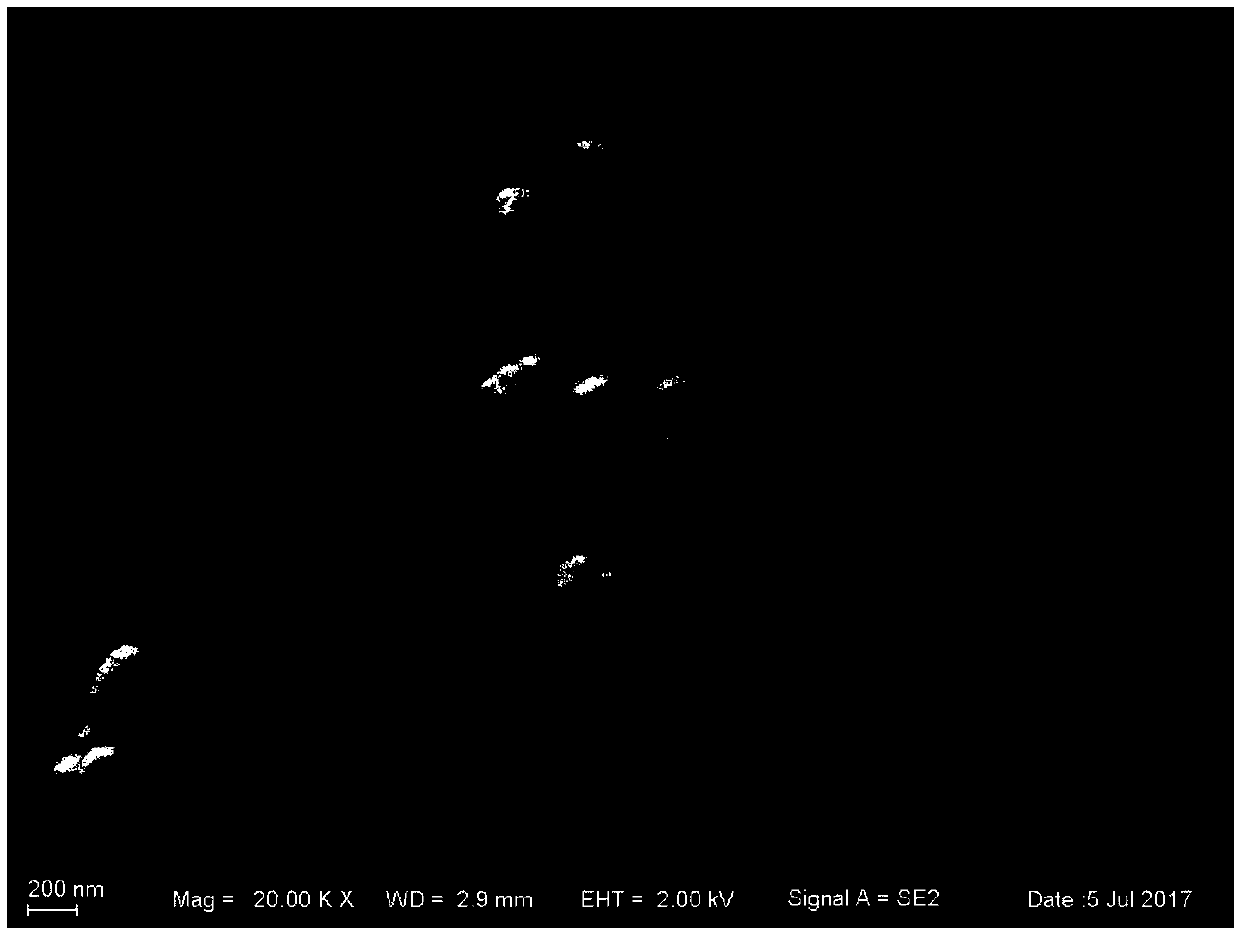

Method for synthesizing titanium silicalite molecular sieve TS-1 for catalytic hydrogen peroxide oxidation

ActiveCN107792863AReduce side effectsImprove conversion rateMolecular sieve catalystsOximes preparationMolecular sievePhysical chemistry

The invention relates to a method for synthesizing a titanium silicalite molecular sieve TS-1 for catalytic hydrogen peroxide oxidation. The method comprises the following steps of (1) uniformly mixing a titanium source with a silicon source through stirring, so as to obtain clear liquid; (2) mixing an organic template agent with the first clear liquid, hydrolyzing through drastic stirring till clear liquid is formed again, warming to remove glycol so as to obtain second clear liquid, wherein the pH is 11-14; (3) slowly dripping an ammonia solution of ammonium fluoride into the second clear liquid, and stirring while dripping, and finally obtaining clear mother liquid with the same pH as the second clear liquid; (4) crystallizing the clear mother liquid for 12-36 hours at 130-190 DEG C under autogenous pressure, then separating, drying and burning so as to obtain solid powder TS-1 molecular sieve. Compared with the prior art, the method has specific process steps, reduces the particlesize of the crystal due to introduction of fluoride, and improves the catalysis performance.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel

InactiveCN107365940AIncrease surface temperatureReduce the temperatureAustenite grainResource saving

The invention relates to a preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel. The preparation method includes the steps that a continuous casting blank directly enters an M rack rough rolling unit at a high pulling speed and is subject to M-gate continuous high reduction (50%-60%) rough rolling, austenite grains are greatly refined, after rough rolling is carried out, an intermediate billet is quickly heated by an induction heating furnace to the temperature needed by a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then the blank sequentially passes through a finish rolling unit, a laminar cooling part and a reeling machine, and the microstructure characteristics that the surfaces and core parts are thick and 1 / 4 thickness parts are thin are finally formed. In the production process, finish rolling and rough rolling are both full-endless rolling. By means of the preparation method, an ultra-fine grain high-strength weathering steel strip with the weather fastness equal to that of corten-A can be obtained, the effects of replacing thick parts with thin parts and replacing cold with heat are achieved, and the automotive body weight is small; and meanwhile, the service life of an automotive sheet is prolonged, the production efficiency is improved, the production cost is reduced, energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved. The preparation method and application belong to the technical field of metallurgy.

Owner:UNIV OF SCI & TECH BEIJING +1

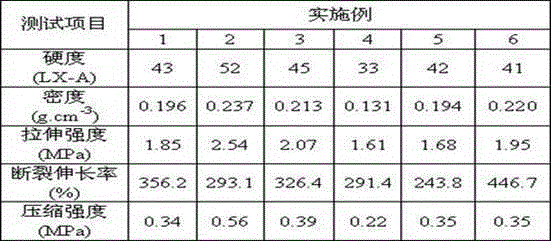

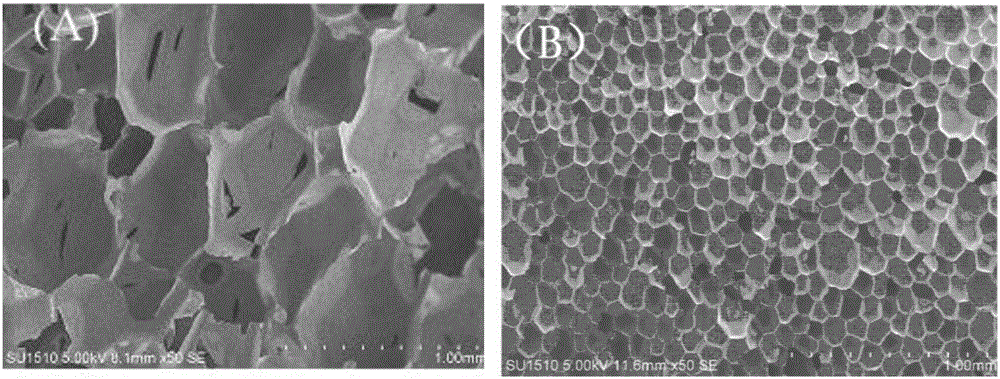

EVA foam material taking four components as base material and preparation method of EVA foam material

The invention provides an EVA foam material taking four components as base materials and a preparation method of the EVA foam material. The foam material comprises the following substances in parts by mass: 70-90 parts of ethylene-vinyl acetate copolymer, 10-30 parts of rubber, 1-9 parts of starch, 1-9 parts of calcium carbonate, and 4.6-7.3 parts of an additive, wherein the additive comprises a foaming agent, a cross-linking agent and a combined foaming aid. The foam material has the characteristics of being excellent in mechanical property, uniform in foam hole distribution, capable of realizing natural degradation, and the like, can be widely applied to shoe materials, jigsaw puzzle for kids, foamed floors, precise electronic instruments, electrical equipment, packing materials of medical instruments, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing stratiform hydrotalcite PVC (Poly Vinyl Chloride) heat stabilizer by using rotary liquid membrane reactor

ActiveCN102633294ASmall sizeAvoid mixed reactionsAluminium compoundsZinc compoundsGeneration rateChemical physics

The invention provides a rotary liquid membrane reactor, belonging to the technical field of an inorganic functional material and used for preparing the stratiform hydrotalcite PVC heat stabilizer. Starting from a basic technique of a coprecipitation method and based on a crystal chemical principle, the invention designs the rotary liquid membrane reactor through calculation and analysis of fluid mechanics, so that two fluids flow in a turbulence manner within a confinement space. Therefore, the supersaturation degree is uniform, the nucleation rate of a system is improved, and the crystallization generation rate is reduced; alamellar hydrotalcite PVC heat stabilizer with smaller grain size and narrower grain size distribution is obtained. The grain size of the product can be controlled within a range of 10-150 nm, and the size distribution range can be reduced to 20-50 nm.

Owner:青海西部镁业新材料有限公司

Fe-based nanocrystalline soft magnetic alloy and preparation method

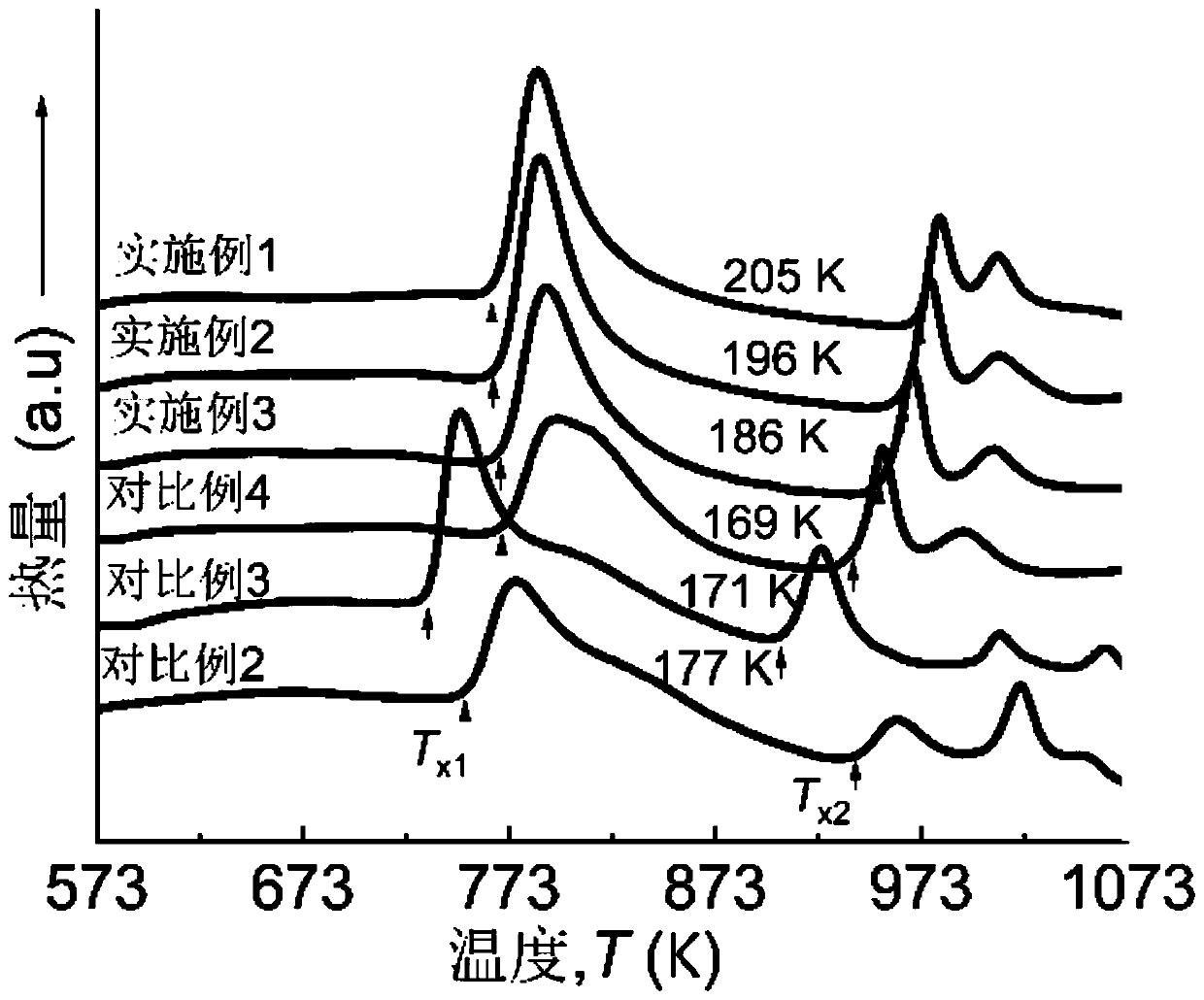

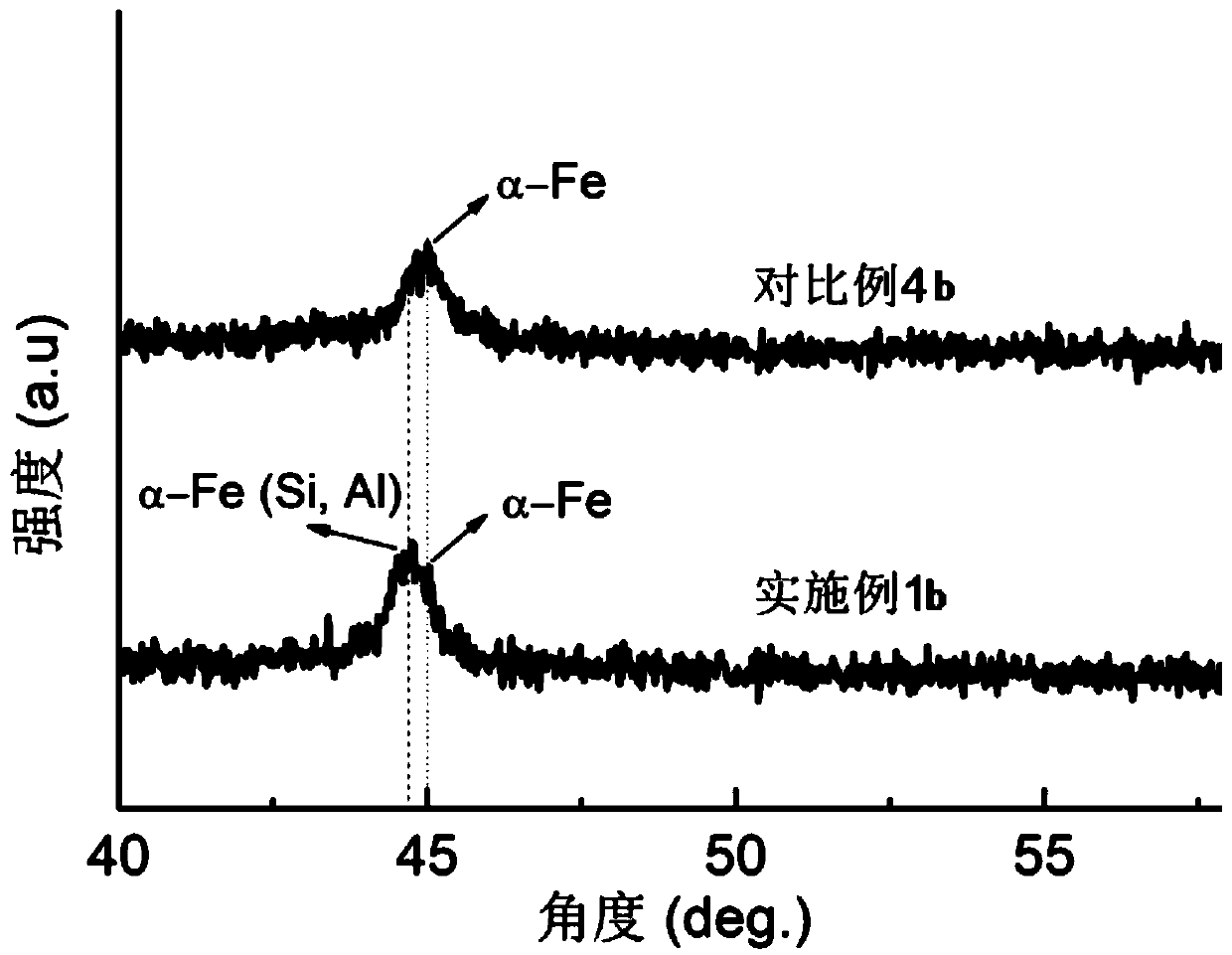

ActiveCN111020410AReduce the content of precious metal elementsImprove thermal stabilityMagnetic materialsAmorphous matrixHeat treated

The invention discloses an Fe-based nanocrystalline soft magnetic alloy. The molecular formula of the alloy is FeaSibBcMdCuePfAlg, M refers to the metallic element Nb, Mo, V, Mn or Cr, a, b, c, d, e,f and g are mole percentage content of corresponding atoms, b is larger than or equal to 6 but smaller than or equal to 15, c is larger than or equal to 5 but smaller than or equal to 12, d is largerthan or equal to 0.5 but smaller than or equal to 3, e is larger than or equal to 0.5 but smaller than or equal to 1.5, f is larger than or equal to 0.5 but smaller than or equal to 3, g is larger than or equal to 0.5 but smaller than or equal to 10, and the balance is Fe and inevitable trace impure elements; the structure of the Fe-based nanocrystalline soft magnetic alloy is the two-phase alloywith the Fe adopting the body-centered cubic structure and Fe(Si, Al) mixed nanocrystalline grains embedded in an amorphous matrix, and the average size ranges from 10 nm to 13 nm. The invention further provides a preparation method of the Fe-based nanocrystalline soft magnetic alloy. The method includes two-step heating and two-step cooling heat treatment. The Fe-based nanocrystalline soft magnetic alloy has the advantages of low cost, excellent soft magnetic property, high corrosion resistance as well as good manufacturability and heat treatment processability, and has the broad applicationprospects in the fields of noise suppression, filtration, wireless charging and the like in complex and harsh environments.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

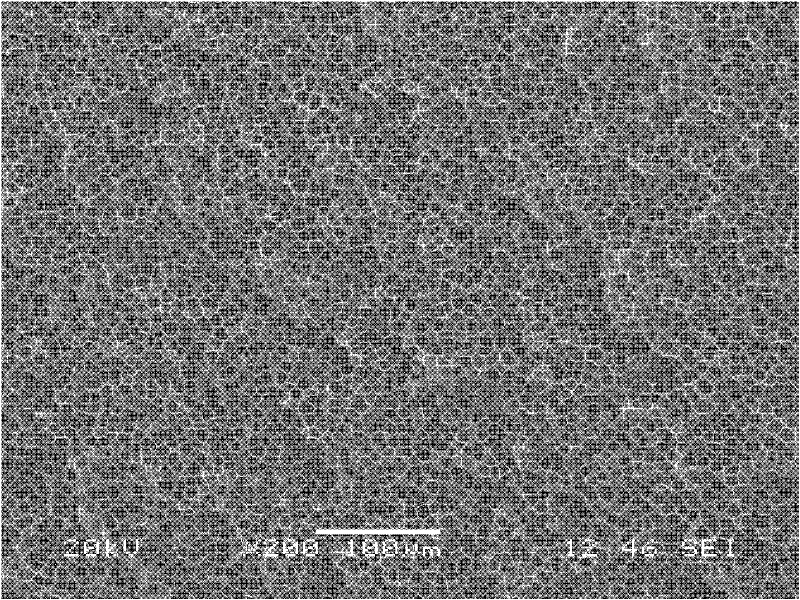

Method for synthesis of nanometer ZSM-5 molecular sieve from mother liquor flocculate

InactiveCN106044793AShort synthesis timeReduced nucleation activation energyMaterial nanotechnologyPentasil aluminosilicate zeoliteFlocculationAdditive ingredient

The invention relates to a method for synthesis of a nanometer ZSM-5 molecular sieve from mother liquor flocculate and belongs to the field of chemical engineering. The method comprises carrying out flocculation on a ZSM-5 molecular sieve crystallization mother liquor, separating the flocculate, drying the flocculate and recycling the flocculate as a ZSM-5 molecular sieve synthesis raw material. The method flocculates unreacted effective ingredients in the ZSM-5 molecular sieve crystallization mother liquor, recycles the flocculate, prevents synthesis waste liquid discharge, reduces environment pollution, recovers and recycles the mother liquor, saves raw materials and reduces a molecular sieve synthesis cost. Microcrystallines are formed in the mother liquor flocculate after the reaction so that a nucleation rate and quantity of crystal nucleuses in an induction period of crystallization are greatly improved, molecular sieve nucleation activation energy is reduced, crystallization time is shortened, the molecular sieve crystal grain size is reduced and a molecular sieve crystallization degree is improved.

Owner:JIANGSU TIANNUO NEW MATERIAL TECH

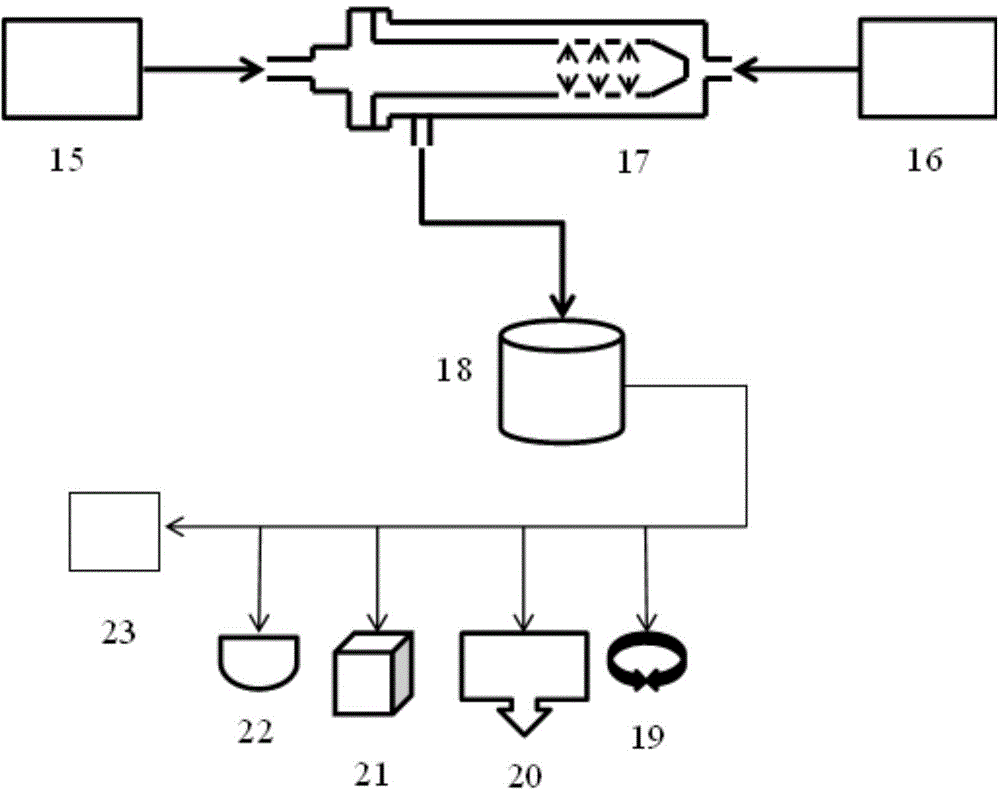

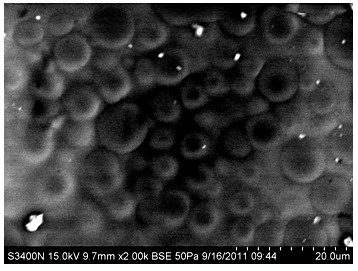

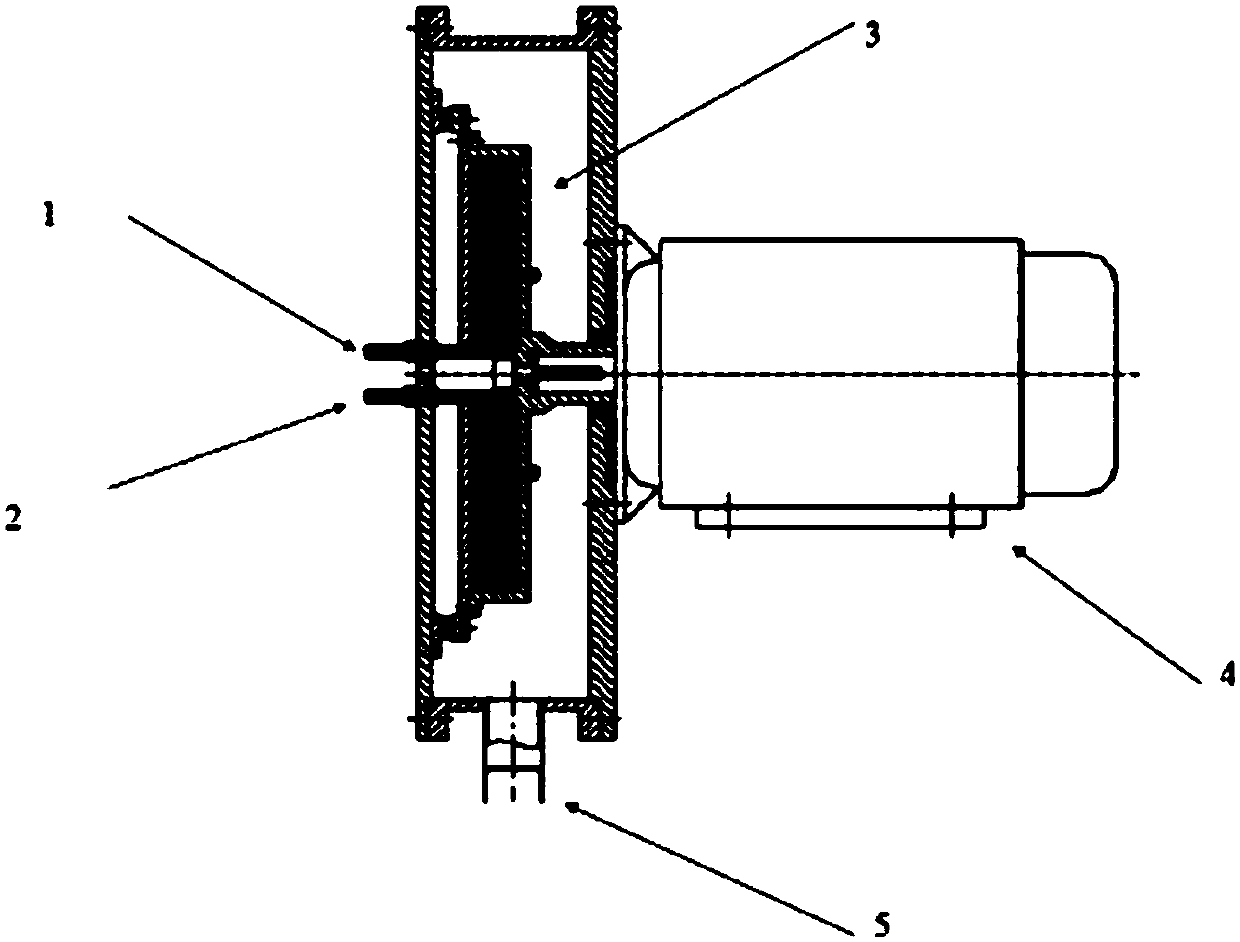

Supergravity field micro-reactor, and method for preparing nanometer material through liquid phase precipitation method

ActiveCN107224949AIncrease flow rateShort reaction residence timeMaterial nanotechnologyStrontium carbonatesMicroreactorSupporting system

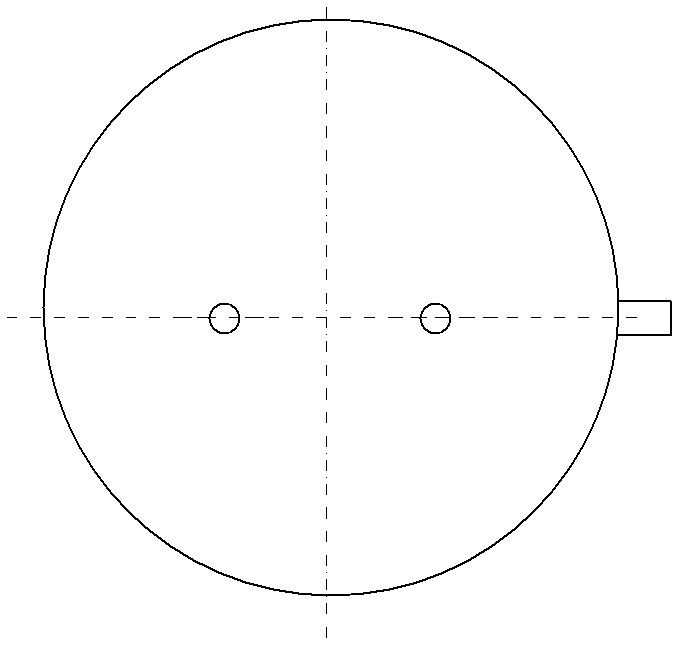

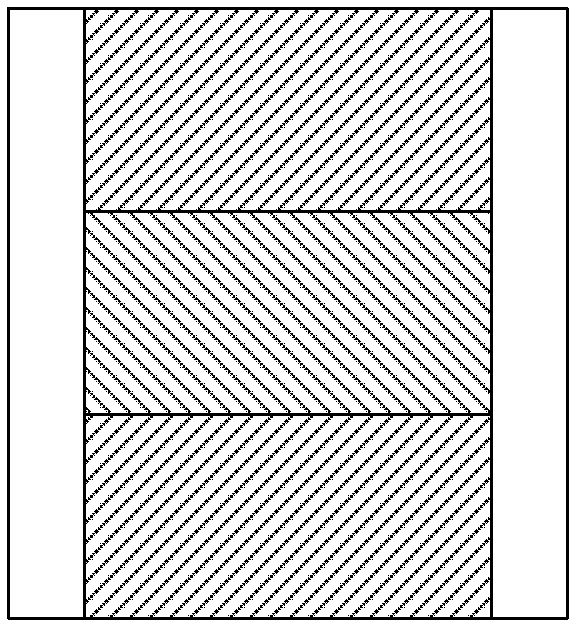

The invention relates to a supergravity field micro-reactor for preparing a nanometer material. The supergravity field micro-reactor comprises a micro-reaction assembly, a material receiving groove provided with a material outlet, a first motor, a transmission system, a material inlet system and a support system, wherein the micro-reaction assembly comprises an upper disc and a lower disc, micro-grooves are respectively distributed on the bottom surface of the upper disc and the top surface of the lower disc, the center position of the lower disc is provided with a material inlet micro-pore channel, a 0.03-0.1 mm gap is arranged between the bottom surface of the upper disc and the top surface of the lower disc after the combination, the first motor drives the transmission system to operate so as to make the upper disc and the lower disc in the micro-reaction assembly rotate in opposite rotation directions, and an upper disc lifting system can be additionally arranged so as to conveniently adjust the gap between the bottom surface of the upper disc and the top surface of the lower disc in the micro-reaction assembly and wash the upper disc and the lower disc. With the supergravity field micro-reactor of the present invention, the nanometer material is prepared by using the liquid phase precipitation method, such that the high dispersion property and the uniform particle distribution of the nanometer material can be maintained while the treatment capacity can be increased and the clogging of the micro-reaction assembly can be avoided.

Owner:SICHUAN UNIV

Method for preparing polymer microporous foaming material by supercritical mould foaming

The invention provides a method for preparing a polymer microporous foaming material by supercritical mould foaming. The method comprises the following steps of: heating a foaming mould on a mould press to the foaming temperature; placing a polymer into the mould; closing the mould by using the mould press; sealing the mould; introducing supercritical fluid, which swells and diffuses to the polymer, into the mould; and opening the mould by using the mould press to release pressure and foam to obtain the polymer microporous foaming material. Compared with the prior art, the method has the advantages that: the high-temperature and high-pressure supercritical fluid is used for swelling the polymer, so the moulding cycle is greatly shortened; the limit that only microporous foaming sheet material with lesser thickness can be manufactured in the prior art is broken through, so a polymer microporous foaming plate with greater thickness can be manufactured; when the mould is opened, the pressure-releasing speed is high and the foaming pore core-forming speed is high, so the formed microporous foaming material has smaller foaming pores, higher pore density and more excellent performance; and multiple layers of moulds can be placed on one mould press, so the method is suitable for industrialized scale production.

Owner:SHINCELL NEW MATERIAL CO LTD

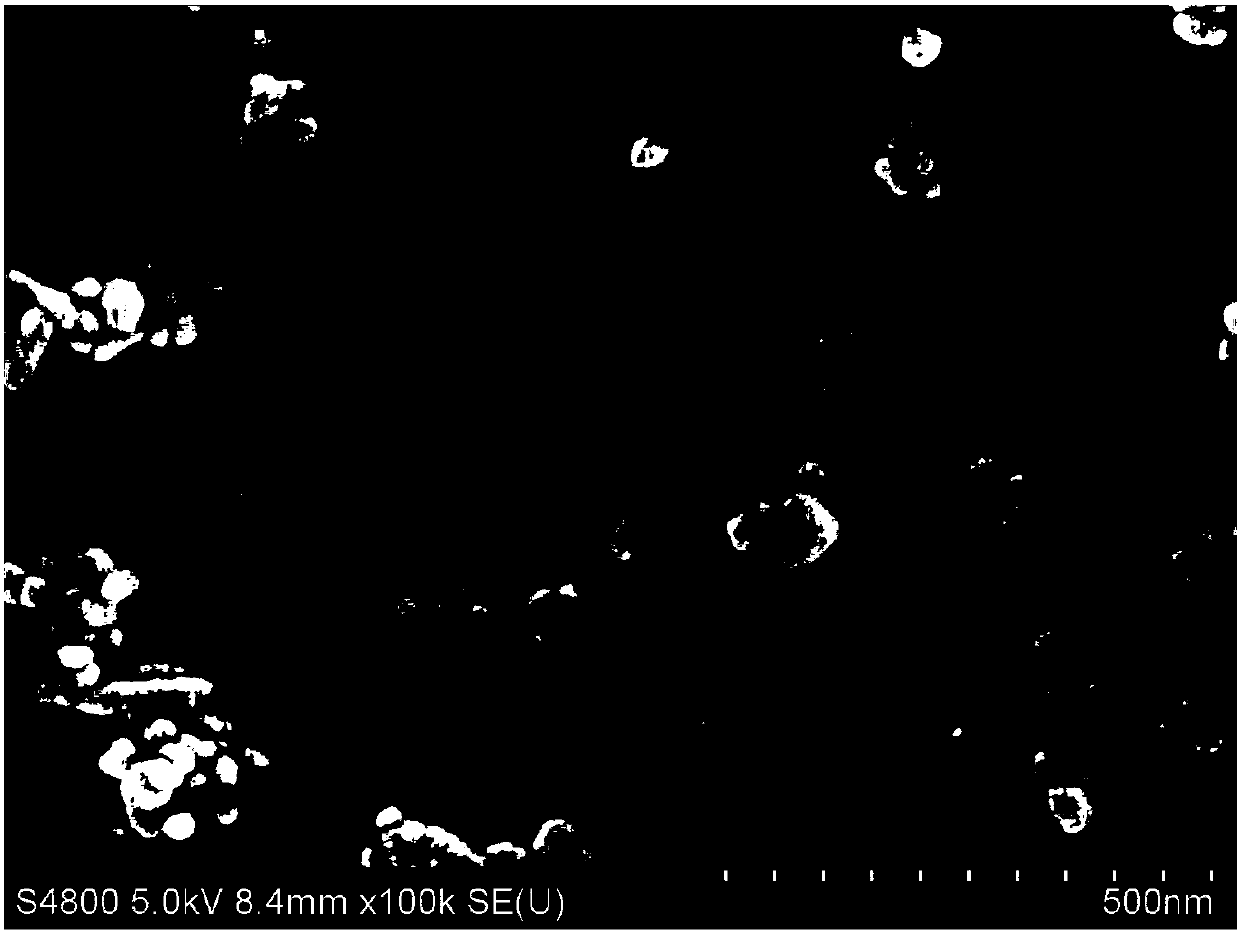

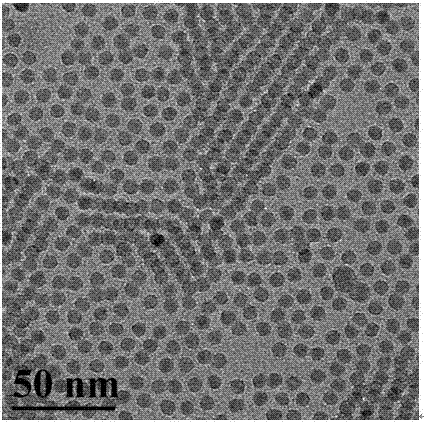

Method for preparing rare earth doped beta-NaYF4 upconversion nanocrystal with size of less than 8nm

ActiveCN106957654APromote changeHigh repeatabilityNanoopticsLuminescent compositionsSodium oleateComputational chemistry

The invention discloses a method for preparing a beta-NaYF4:Yb3+,RE3+(RE=Tm,Er,Ho) upconversion nanocrystal with the size of less than 8nm. Nucleation rate of a beta phase is accelerated and conversion from alpha-NaYF4 to beta-NaYF4 is efficiently promoted by introducing a sodium oleate ligand in a preparation process, so that reaction time for obtaining a pure phase beta-NaYF4: Yb3+,RE3+(RE=Tm,Er,Ho) upconversion nanocrystal can be shortened, and reaction temperature can be lowered. The prepared beta-NaYF4:Yb3+,RE3+(RE=Tm,Er,Ho) upconversion nanocrystal is small in size (4-8nm), good in dispersibility and free of an impure phase (alpha-NaYF4), the preparation method is simple, repeatability is high, and the beta-NaYF4:Yb3+,RE3+(RE=Tm,Er,Ho) upconversion nanocrystal has a wide application prospect.

Owner:TONGJI UNIV

Poly-L-lactic acid (PLLA)/ZIF-8 composite bone scaffold and preparation method thereof

ActiveCN110538350AGood dispersionEnhanced interface bindingTissue regenerationProsthesisSelective laser sinteringUltimate tensile strength

The invention provides a poly-L-lactic acid (PLLA) / ZIF-8 composite bone scaffold and a preparation method thereof. The composite bone scaffold is prepared from the following components in percentage by weight: 97-99.5% of PLLA, and 0.5-3% of ZIF-8. The preparation method of the composite bone scaffold includes the steps that the PLLA and ZIF-8 powder are subjected to liquid-phase mixing, and through stirring, ultrasound, separation and drying, composite powder is obtained; and then by utilizing a selective laser sintering process, after the composite powder is sintered layer by layer, the PLLA / ZIF-8 composite bone scaffold is finally obtained. By utilizing good combination between the ZIF-8 and a PLLA substrate, interface combination between the PLLA and the ZIF-8 is improved, and thus themechanical strength of the composite bone scaffold is improved; and in addition, by utilizing the characteristic of degradation of the ZIF-8 in the acidic environment, the degradation rate of the PLLA is increased, and cell proliferation is improved.

Owner:JIANGXI UNIV OF SCI & TECH +1

Preparation method of intensity-improvable glass ceramics

InactiveCN108675640ALow costImprove resource utilizationGlass shaping apparatusRare-earth elementTO-18

The invention discloses a preparation method of intensity-improvable glass ceramics. The method comprises the following step of 1, weighing the following raw materials in corresponding percentage by weight for later use: 32 to 38 percent of SiO2, 26 to 30 percent of Al2O3, 12 to 18 percent of MgO, 0.3 to 0.5 percent of Fe2O3, 14 to 18 percent of electrolytic manganese residue, 0.02 to 0.06 percentof tin phosphorus compounds, 0.01 to 0.05 percent of rare earth elements and 0.01 to 0.03 percent of intensity auxiliary agents. The preparation method of the intensity-improvable glass ceramics hasthe advantages that the intensity of the glass ceramics is greatly improved through being compared with that in the prior art; high use values and good application prospects are realized.

Owner:合肥钢骨玻璃制品有限公司

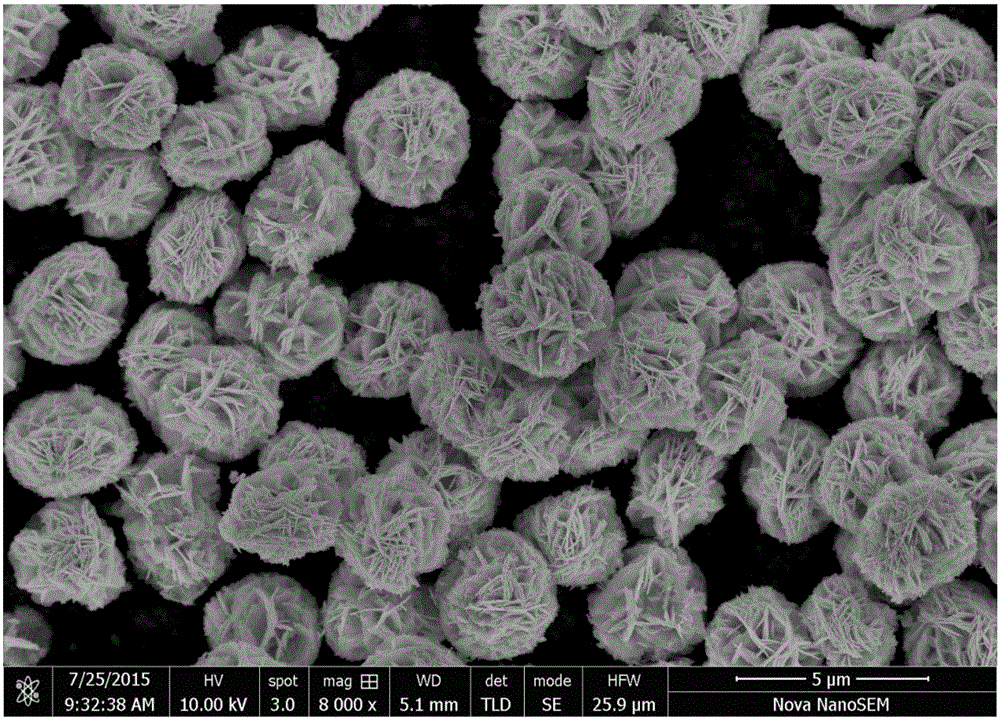

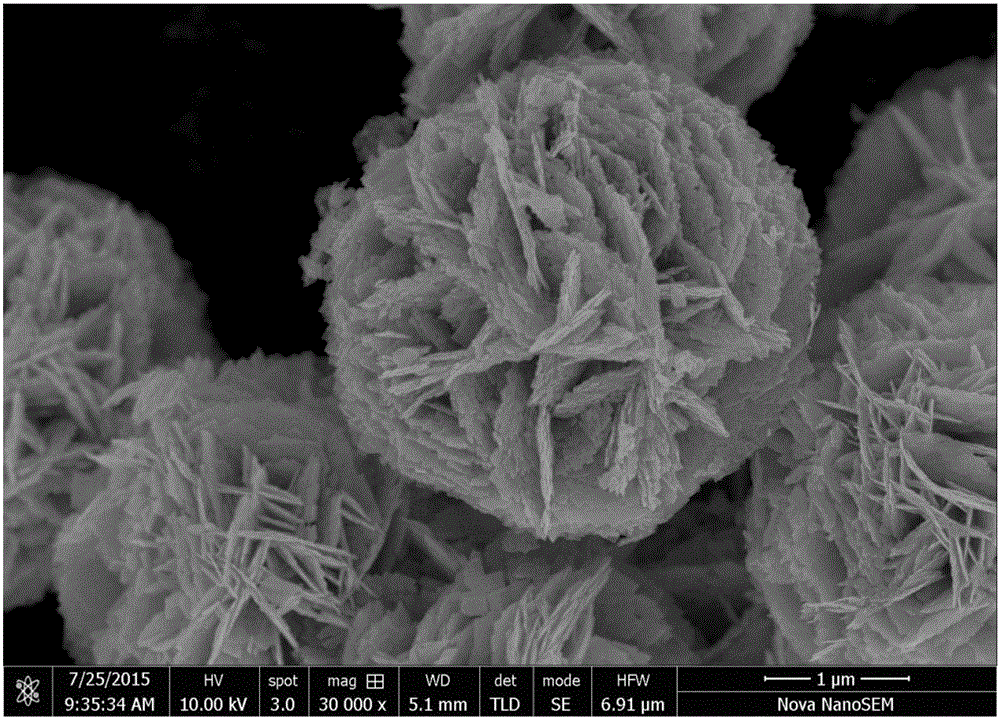

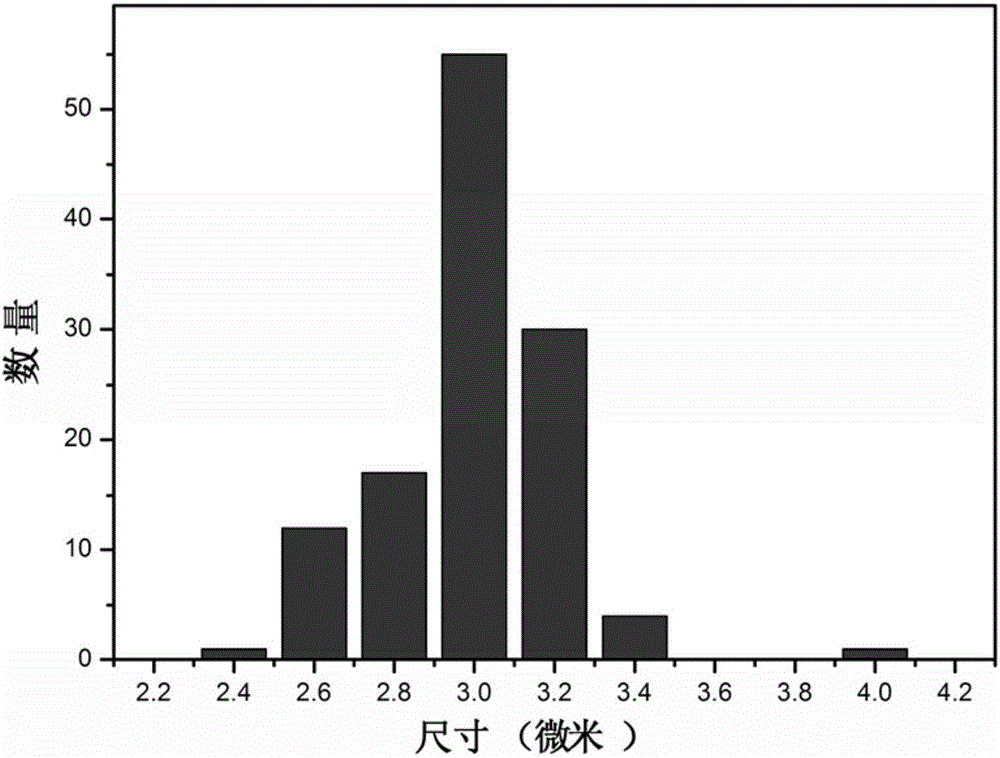

Microspheric three-dimensional grading micro-nano structure bismuth tungstate photocatalytic material and preparation method thereof

InactiveCN105753054AAvoid reunionEvenly distributedMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsRough surfaceMicro nano

The invention relates to a microspheric three-dimensional grading micro-nano structure bismuth tungstate photocatalytic material and a preparation method thereof. The microspheric three-dimensional grading micro-nano structure bismuth tungstate photocatalytic material is of a microspheric structure formed by assembling two-dimensional nanosheets with rough surfaces, is uniformly distributed, and has the microsphere diameter being 2.5 to 3.5mum. The preparation method comprises the following steps of a reacting sodium tungstate solution and a bismuth nitrate solution in a reaction kettle for 8 to 24 hours under the condition that pH is equal to 1 and the temperature is 150 to 200 DEG C, separating to obtain a solid product, washing and drying. The obtained product is good in stability, large in specific surface area, and beneficial to diffusing and transmitting pollutant molecules, and greatly increasing the photocatalytic activity, and in addition, the preparation method is simple, controllable in reaction condition, and low in temperature.

Owner:SHAANXI NORMAL UNIV

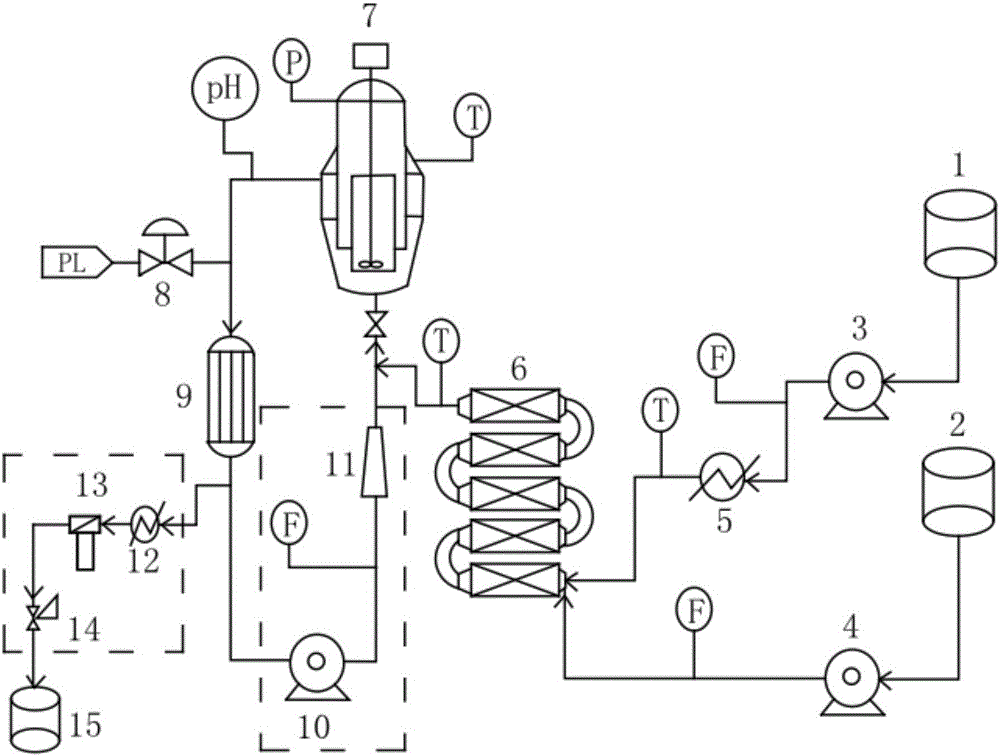

Device system and preparation technology for preparing submicron material through continuous hydrothermal method

ActiveCN104986796AAchieve growthHigh crystallinitySolution crystallizationTitanium dioxideProcess engineeringSlurry

The invention provides a device system and preparation technology for preparing a submicron material through a continuous hydrothermal method. The device system comprises burdening kettles, a preheater, a first crystallizer and a second crystallizer. The first burdening kettle is communicated with the first crystallizer through a first feeding pump and the preheater, and the second burdening kettle is communicated with the first crystallizer through a second feeding pump. The first crystallizer is communicated with the second crystallizer, a discharging opening of the second crystallizer is communicated with an inlet of a heat exchanger, one outlet of the heat exchanger is communicated with an outer circulating unit and then communicated with an inlet of the second crystallizer, and the other outlet of the heat exchanger is communicated with an aftertreatment unit and a slurry collector. The first crystallizer is a tubular reaction crystallizer, and the second crystallizer is a continuous crystallizer. The device system is adopted in the preparation technology. According to the device system and preparation technology, the device cost is low, meanwhile, the submicron material with even particle size distribution and the high degree of crystallinity can be prepared continuously, and the device system and preparation technology are suitable for industrial production.

Owner:ZHANGJIAGANG HEZHI NANO TECH CO LTD

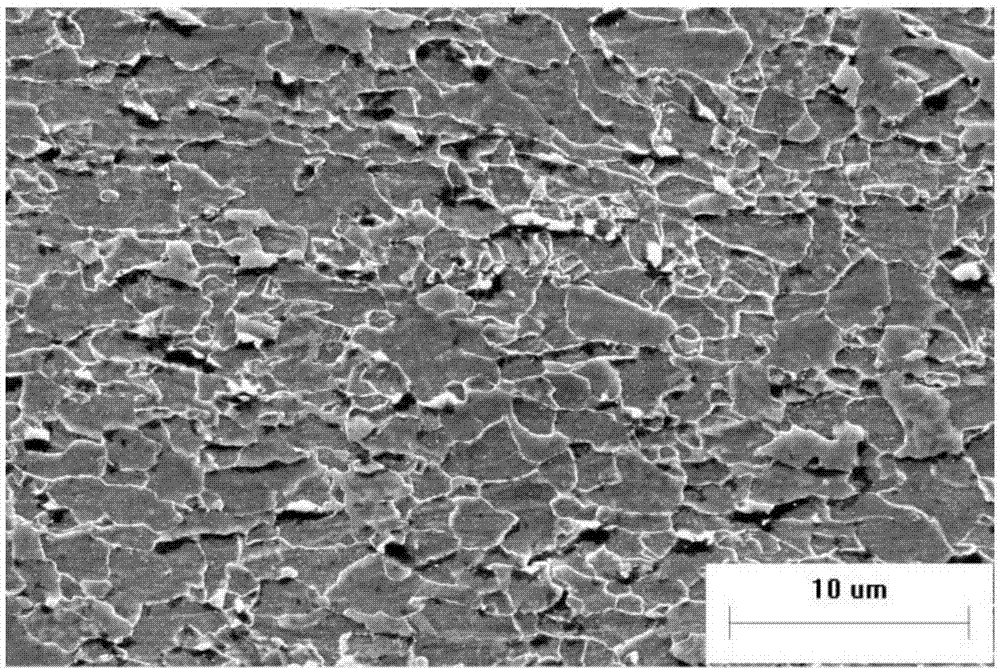

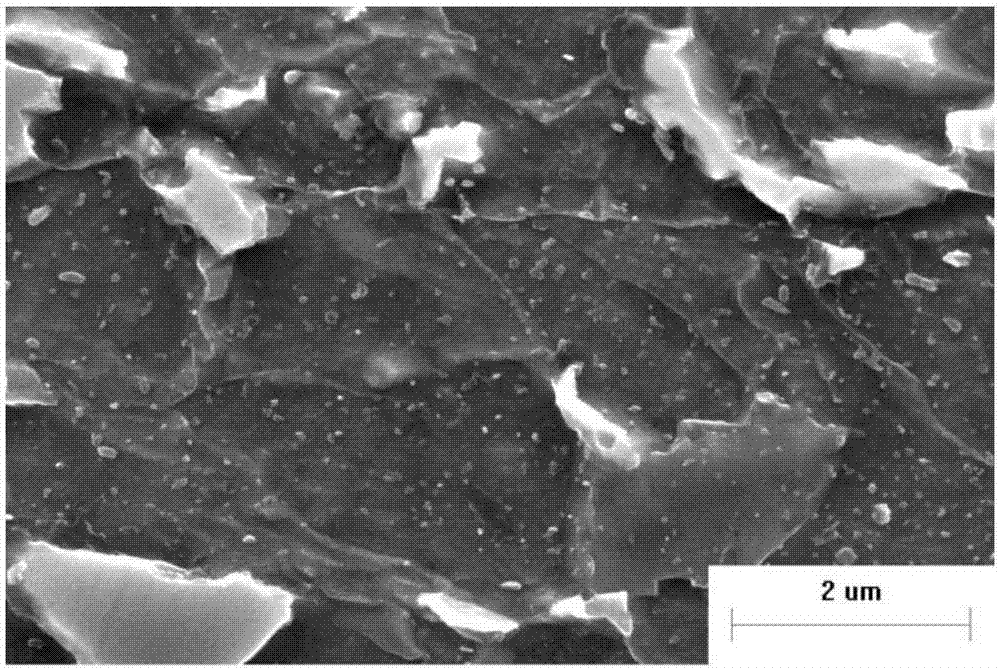

Heterogeneous nucleating agent toughening-modified phenolic resin foam and preparation method thereof

ActiveCN106009490ALower wetting angleImprove mechanical propertiesMechanical propertyOrganic chemistry

The invention discloses heterogeneous nucleating agent toughening-modified phenolic resin foam and a preparation method thereof. The preparation method of the foam comprises the following steps of preparing a heterogeneous nucleating agent and preparing the modified phenolic resin foam. According to the method, silane coupling agent modified graphene is added for regulating the foam pore structure; meanwhile, the synergistic effect of graphene nanoparticles is exerted, the defects that phenolic foam is poor in mechanical property, high in brittleness and prone to disengagement are effectively overcome, and wide application of the phenolic foam in the engineering field is promoted.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com