Electrode active material for lead-acid storage battery

A technology for electrode active materials and lead-acid batteries, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve problems such as active material utilization, charging efficiency, large current discharge capacity is not ideal, quality products are rare, and preparation conditions are harsh.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

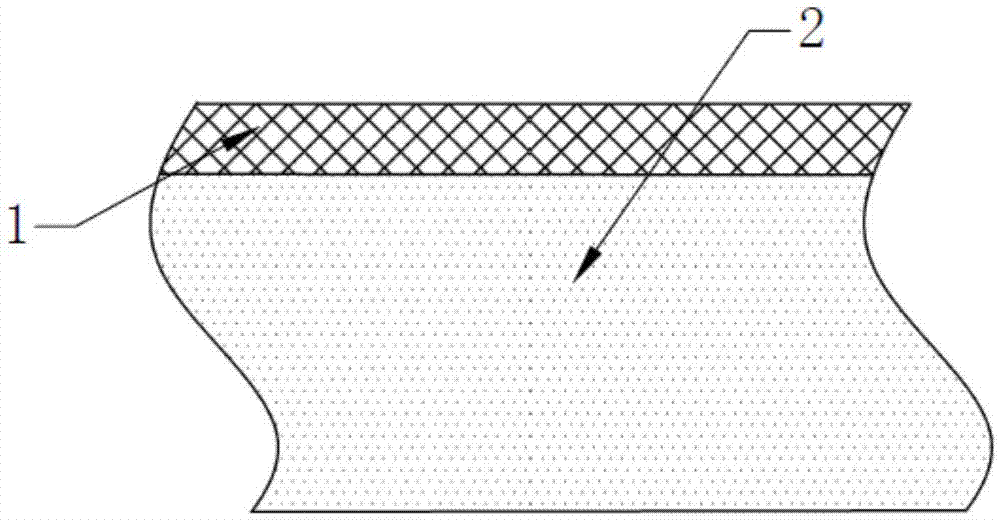

[0045] The active material of the lead-acid battery electrode of this embodiment is made of PbO powder, TiO 2 / Al (coating layer / core) coated composite material particles are mixed and prepared. The specific formula is shown in Table 1:

[0046] Table 1 The formulation of the active material of the lead-acid battery electrode of Example 1

[0047] Component Relative mass ratio The average particle size PbO powder1 500nm TiO 2 / Al particles

2% 500nm

[0048] TiO in formula 2 Including but not limited to martensitic type.

[0049] Preparation method: Weigh 1 part by mass of PbO lead powder and 2% by mass of TiO 2 / Al-coated composite material particles are poured into a stirring container, stirred for 10 minutes, and mixed evenly to obtain a dry powder state of the lead-acid battery electrode active material.

[0050] Applying the active material to the positive electrode of a lead-acid battery can increase the active material utilization rate of the positive electrode of the lead-...

Embodiment 2

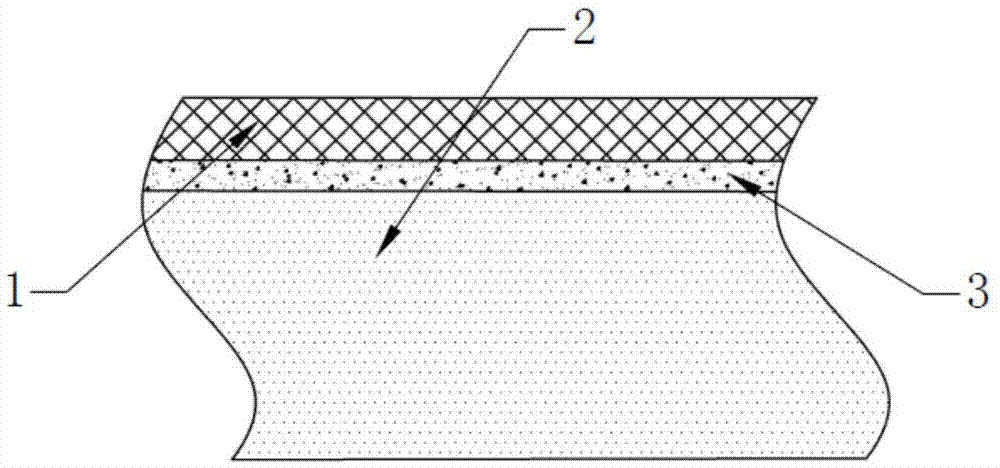

[0052] The active material of the lead-acid battery electrode in this embodiment is made of ball-milled lead powder, TiB 2 / Ti (coating layer / core) coated composite material particles are mixed and prepared. The specific formula is shown in Table 2:

[0053] Table 2 The formulation of the active material of the lead-acid battery electrode of Example 2

[0054] Component Relative mass ratio The average particle size Ball milled lead powder1 5μm TiB 2 / Ti particles

12% 5μm

[0055] Preparation method: weigh 1 part by mass of ball-milled lead powder and 12% by mass of TiB 2 / Ti-coated composite material particles are poured into a stirring container, and the dry powder is stirred for 15 minutes. After mixing uniformly, a dry powder state of the lead-acid battery active material is obtained.

[0056] Applying this active material to the positive electrode of a lead-acid battery can increase the active material utilization rate of the positive electrode of the lead-acid battery by 23...

Embodiment 3

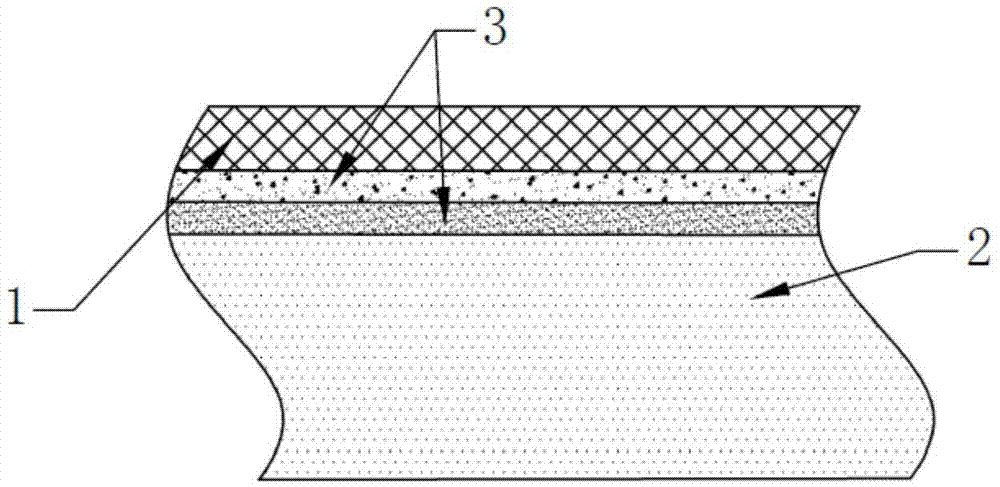

[0058] The active material of the lead-acid battery electrode of this embodiment is made of Batun lead powder, Ti 3 N 4 / Ti / Al (coating layer / single-layer intermediate layer / core) coated composite material powder is mixed and prepared, wherein the thickness of the coating layer is 10μm and the thickness of the intermediate layer is 100nm. The specific formula is shown in Table 3:

[0059] Table 3 The formulation of the active material of the lead-acid battery electrode of Example 3

[0060]

[0061]

[0062] Preparation method: Weigh 1 part by mass of Batun lead powder and 5% by mass of Ti 3 N 4 The / Ti / Al coated composite material powder is poured into a mixing container, and the dry powder is stirred for 15 minutes. After mixing uniformly, a dry powder state of the lead-acid battery active material is obtained.

[0063] Applying this active material to the negative electrode of a lead-acid battery can increase the active material utilization rate of the negative electrode of the lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com