Magnesium-zinc-zirconium-yttrium-magnesium alloy

A magnesium alloy, magnesium-zinc technology, applied in the field of magnesium-zinc-zirconium-yttrium-magnesium alloy, to achieve the effects of improving plasticity, increasing extrusion rate, and reducing extrusion deformation resistance

Inactive Publication Date: 2010-08-25

CHONGQING UNIV

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In view of the fact that the existing magnesium-zinc-zirconium magnesium alloys are difficult to meet the demand for room-temperature plasticity of deformed magnesium alloy products in practical applications, the purpose of the present invention is to provide a medium-strength and excellent room-temperature tensile plasticity, which can meet the requirements of extruded products at room temperature. The subsequent forming of magnesium-zinc-zirconium-yttrium-magnesium alloy, through the design of appropriate zinc, zirconium, and yttrium content and the ratio of zinc to yttrium content, together with a reasonable pre-extrusion heat treatment process and extrusion deformation process, makes this Invented magnesium alloy has excellent room temperature tensile plasticity while meeting the moderate strength required by most applications

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Login to View More

Abstract

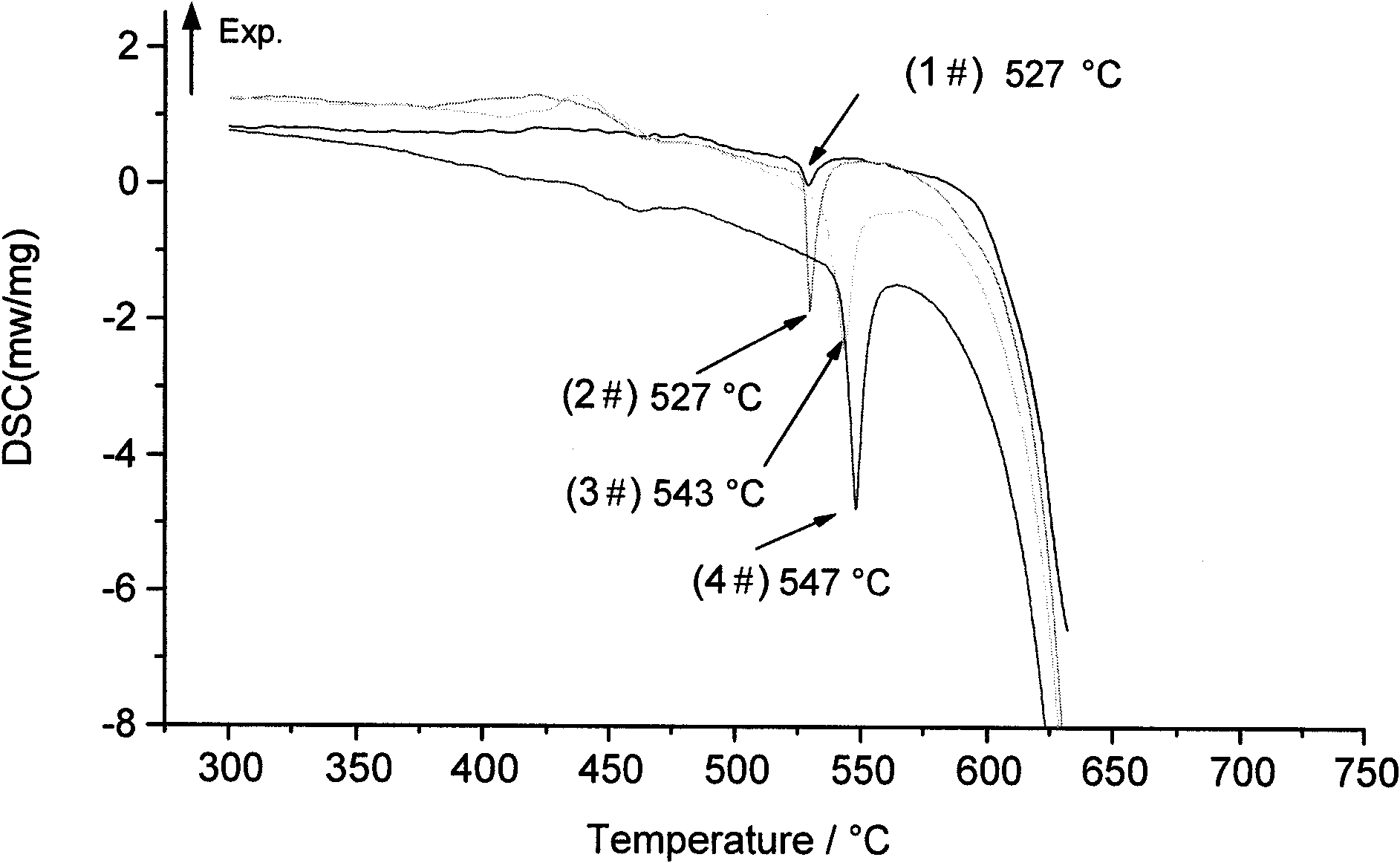

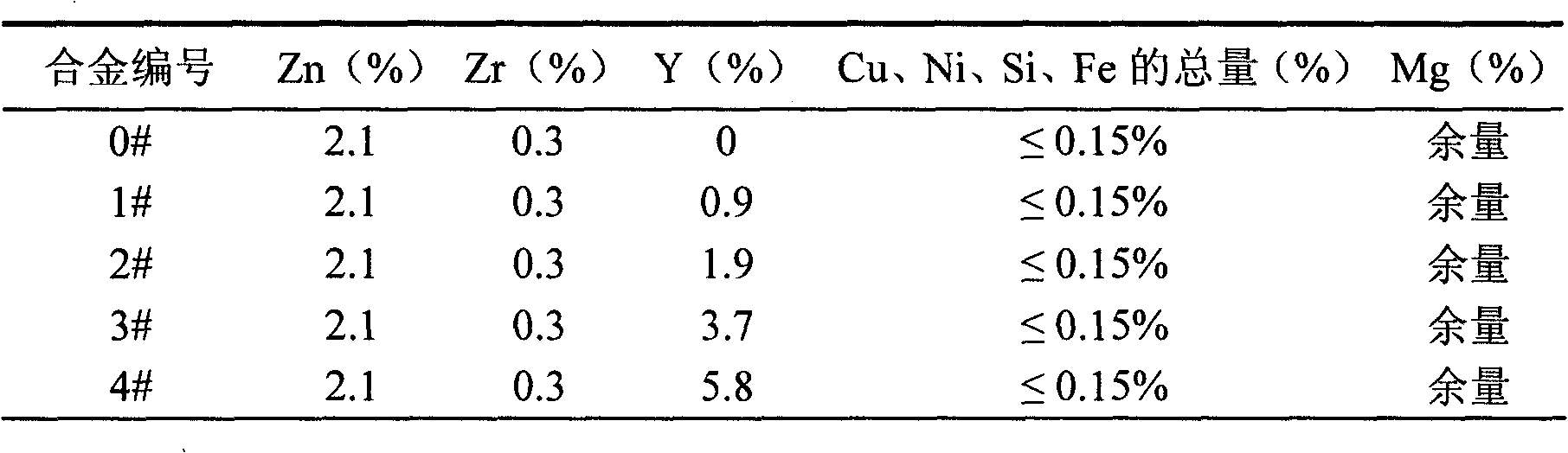

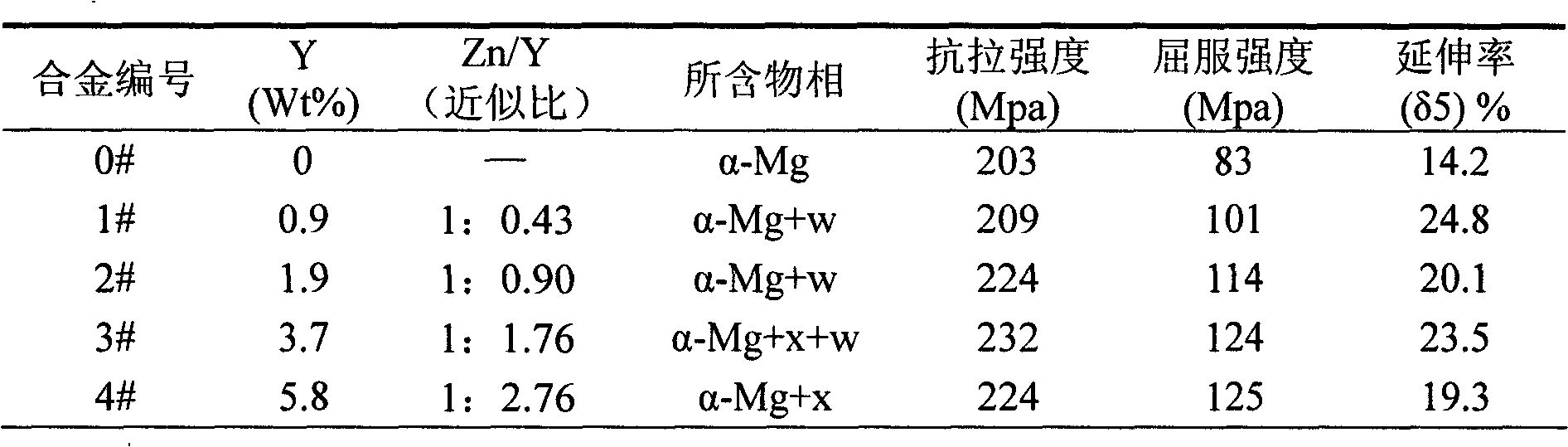

The invention provides a magnesium-zinc-zirconium-yttrium-magnesium alloy which comprises the following components in percentage by weight: 2.0-4.0% of zinc, 0.2-0.5% of zirconium and 0.9-5.8% of yttrium and the balance magnesium and impurity. The invention improves optional heat deflection temperature range of the alloy by controlling zinc content in the magnesium-zinc-zirconium series magnesium alloy and adding yttrium element with a proper proportion; higher deflection temperature is favorable for improving the heat deflection plasticity of magnesium alloy and improving extrusion rate; and meanwhile, alloy crystalline grain is refined by the action that high melting point second phase containing yttrium prevents crystalline grains from growing in the heat extrusion deformation recrystallization process so as to obtain magnesium alloy with moderate strength and favorable plasticity. The magnesium-zinc-zirconium-yttrium-magnesium alloy with the optimal proportion has the room-temperature tensile strength of 279 MPa, yield strength of 184 MPa and elongation percentage of 28%.

Description

technical field The invention relates to a magnesium alloy material, in particular to a magnesium-zinc-zirconium-yttrium-magnesium alloy with medium strength and excellent plasticity. Background technique The crystal structure of magnesium alloy is a close-packed hexagonal lattice, and its plastic deformation ability is not as good as that of aluminum and steel, which increases the difficulty of plastic processing of magnesium alloy and the cost of production and preparation. The design of alloy phases in magnesium alloys and the adoption of new deformation processes, etc., pay more attention to improving the plastic processing ability of magnesium alloys while ensuring a certain strength. Magnesium-zinc-zirconium magnesium alloys are usually used as high-strength deformed magnesium alloys, and are widely used in aviation, aerospace, weapons and civilian cars. In order to improve the heat resistance and toughness of magnesium-zinc-zirconium magnesium alloy materials, scient...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C23/04

Inventor 彭建潘复生吕滨江王敬丰

Owner CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com