A high plasticity rare earth deformed magnesium alloy

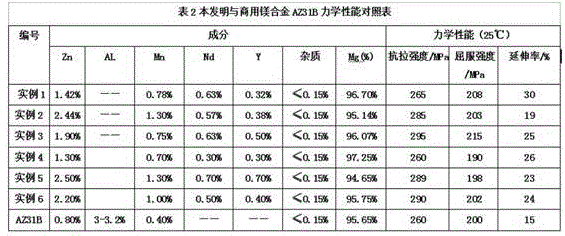

A technology for deforming magnesium alloys and high plasticity, applied in the field of magnesium alloy materials, can solve the problems of hot tendency, low degree of alloying, coarse grains, etc., and achieve the effects of increasing fluidity, improving mechanical properties, and improving hot deformation plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

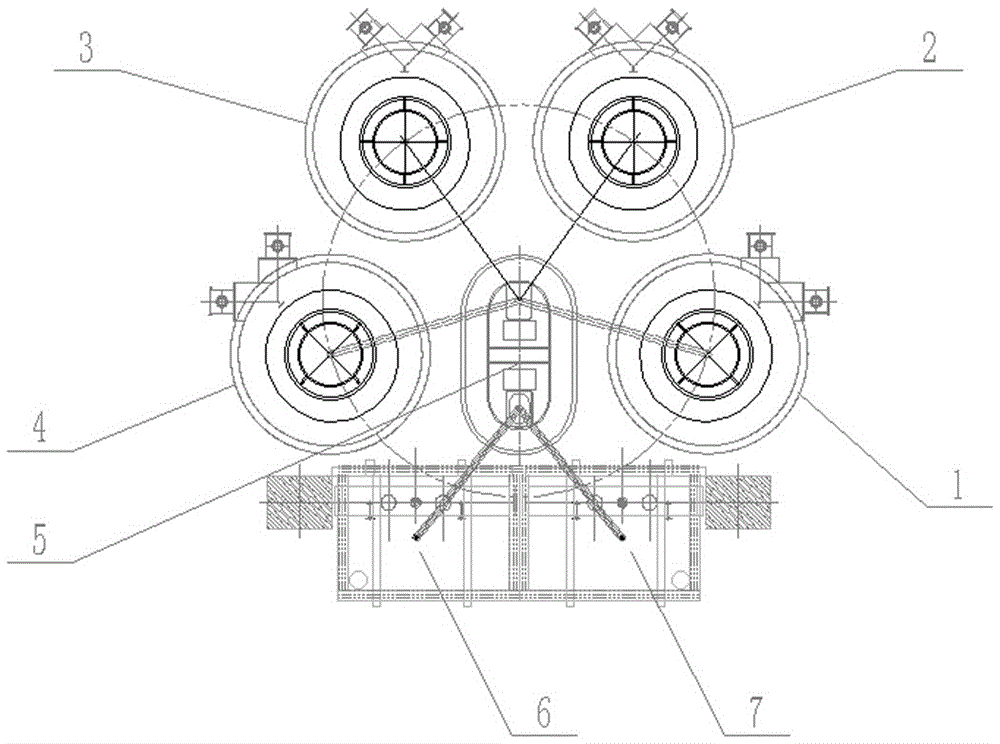

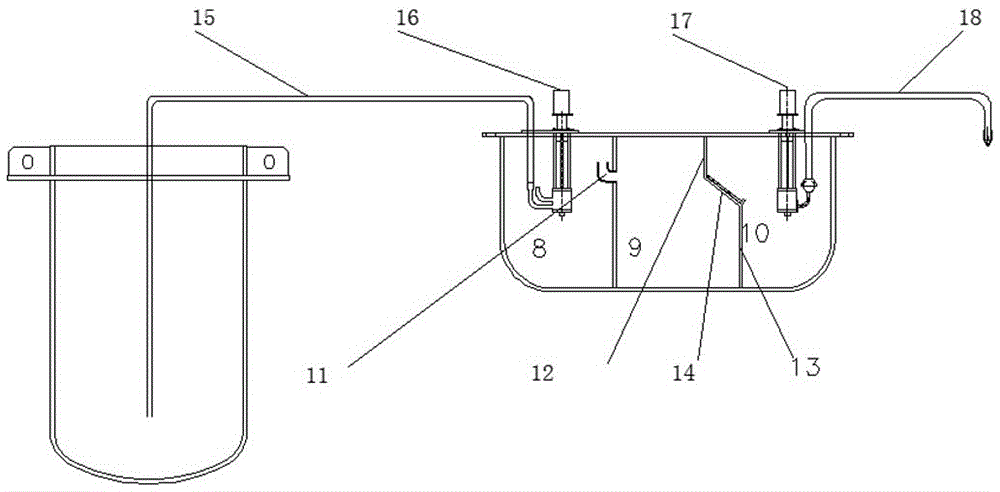

[0025] Put the preheated 748.3kg magnesium ingot into figure 1 The round crucible of the melting furnace is melted with flux. The amount of flux accounts for 4-7% of the total charge. During the melting process, a covering agent is sprinkled to prevent burning. The entire melting process is controlled within 3-6 hours, and the final temperature of the magnesium liquid is controlled at 670- 690°C. After melting, use a stirring device to add 11.6kg of zinc ingots and 6.7kg of manganese powder during the process of heating and stirring. At 720-750°C, use a feeding device to evenly add refining agent. The amount of refining agent accounts for 2-3% of the total furnace charge. Refining 40 -60min, after refining, use the slag extractor to clean the slag, then raise the temperature to 760-770°C, add 22.4kgMg-30%Nd, 12.50kgMg-30%Y with a colander, and blow and refine for 5-10min. The magnesium liquid is left to cool down to allow the flux and inclusions to settle. The whole process t...

Embodiment 2

[0027] Put the preheated 741kg magnesium ingot into figure 1 The round crucible of the melting furnace is melted with flux. The amount of flux accounts for 4-7% of the total charge. During the melting process, a covering agent is sprinkled to prevent burning. The entire melting process is controlled within 3-6 hours, and the final temperature of the magnesium liquid is controlled at 670- 690°C. After melting, use a stirring device to add 19.8kg zinc ingots and 11kg manganese powder during the process of heating and stirring. When the temperature is 720-750°C, use a feeding device to evenly add refining agent. The amount of refining agent accounts for 2-3% of the total furnace charge. After 60 minutes of refining, clean the slag with a slag extractor, then raise the temperature to 760-770°C, add 20.0kgMg-30%Nd, 14.50kgMg-30%Y with a colander, and refine by air blowing for 5-10min. The magnesium liquid is left to cool down to allow the flux and inclusions to settle. The whole p...

Embodiment 3

[0029]Put the preheated 734kg magnesium ingot into the round crucible of the melting furnace shown in Figure 1 and add flux to melt. The amount of flux accounts for 4-7% of the total charge, and the covering agent is sprinkled during the melting process to prevent burning. The entire melting process is controlled at 3- 6 hours, and the final temperature of the magnesium solution is controlled at 670-690°C. After melting, use a stirring device to add 15.2kg of zinc ingots and 6.5kg of manganese powder during the process of heating and stirring, and add refining agent evenly with a feeding device at 720-750°C. The amount of refining agent accounts for 2-3% of the total furnace charge. Refining 40 -60min, after refining, use the slag extractor to clean the slag, then raise the temperature to 760-770°C, add 22.0kgMg-30%Nd, 17.50kgMg-30%Y with a colander, and blow and refine for 5-10min. The magnesium liquid is left to cool down to allow the flux and inclusions to settle. The whole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com