Patents

Literature

44results about How to "Increase extrusion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium-zincium-manganese based magnesium alloy containing cerium

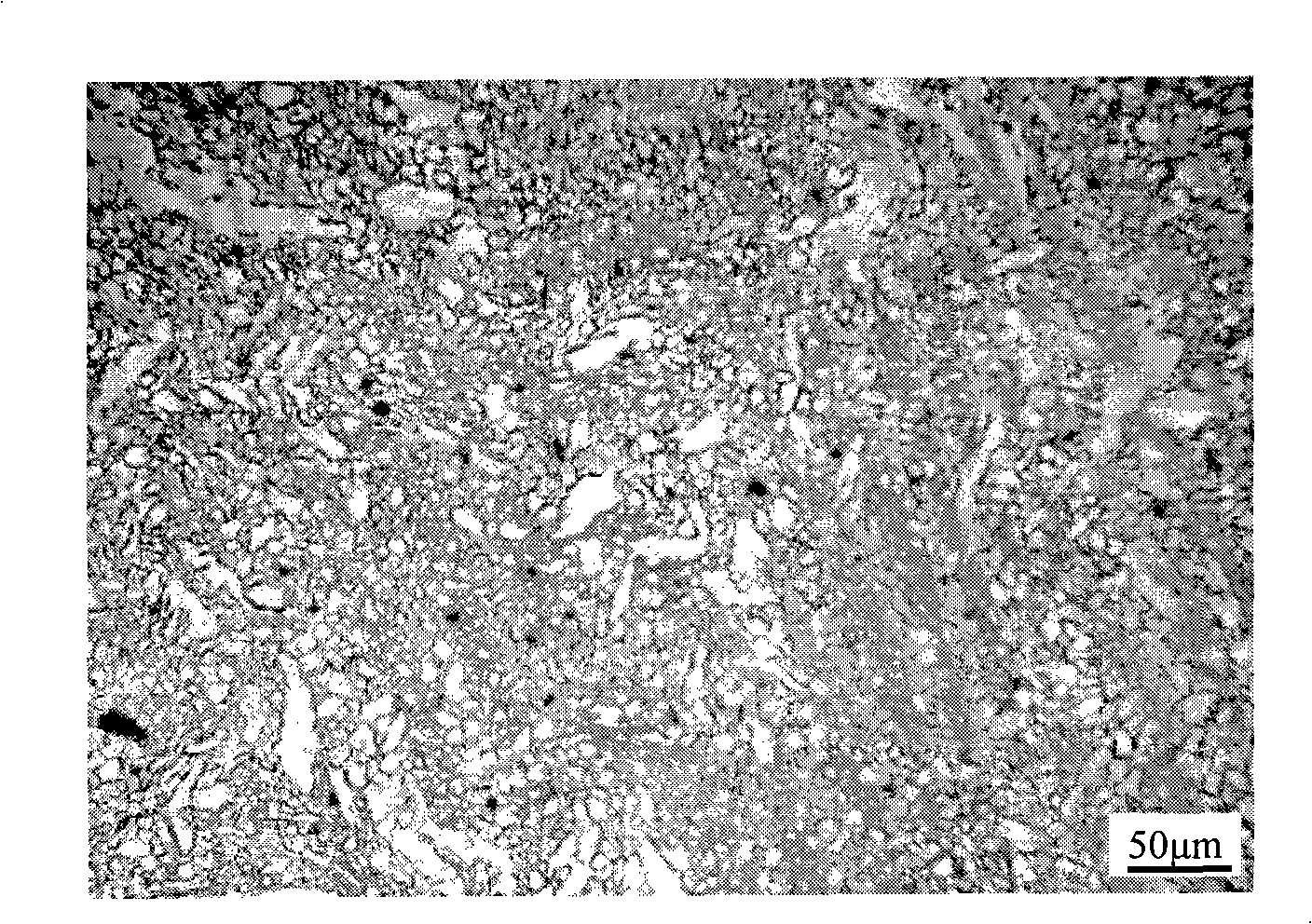

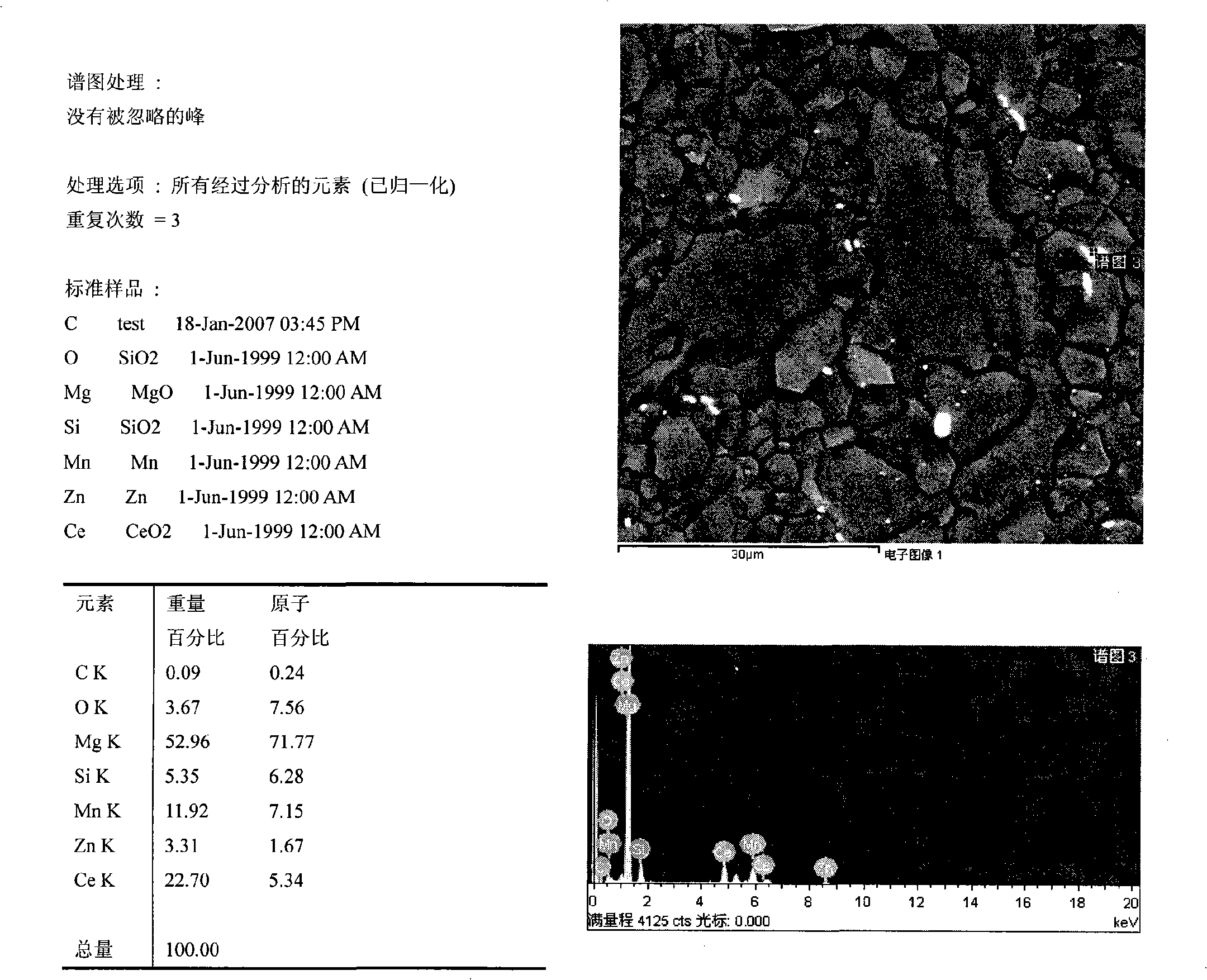

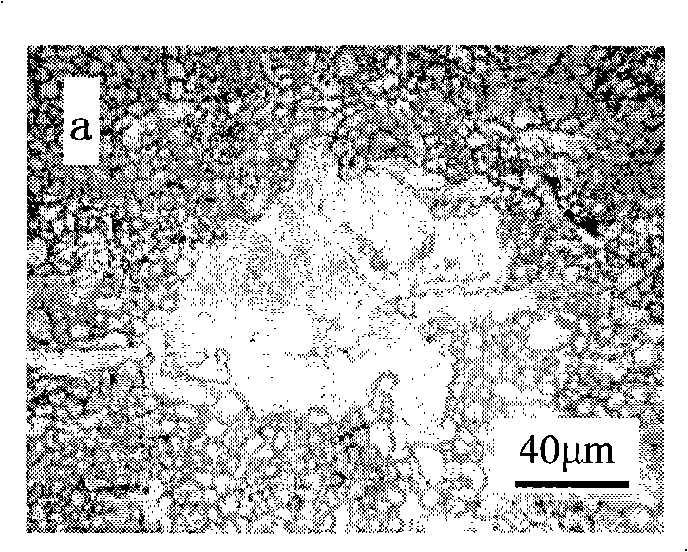

The invention relates to a Magnesium-Zinc-Manganese alloy containing Cerium. The components of Magnesium alloy have the following mass percentage: 1.8 to 4.0 percent of Zinc, 0.5 to 1.5 percent of Manganese, 0.15 to 0.80 percent of Cerium and less than or equal to 0.15 percent of inevitable impurities and the remaining part is Magnesium. The Magnesium alloy of the invention has the advantages of the good hot-workability, the rapid extrusion deformation, obtaining fine crystal grain after many times of thermoplastic deformation, greatly promoting plasticity and keeping strength, achieving the tensile strength in room temperature to 285 Megapascal and the elongation to 20 percent.

Owner:福建镁孚科技有限公司 +1

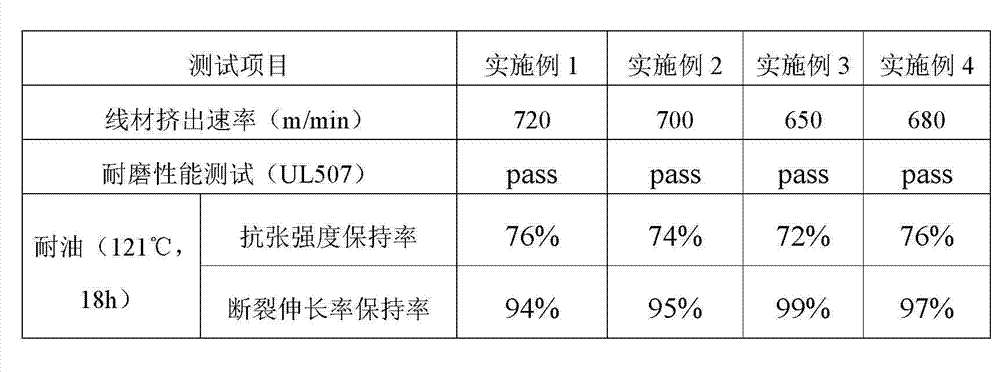

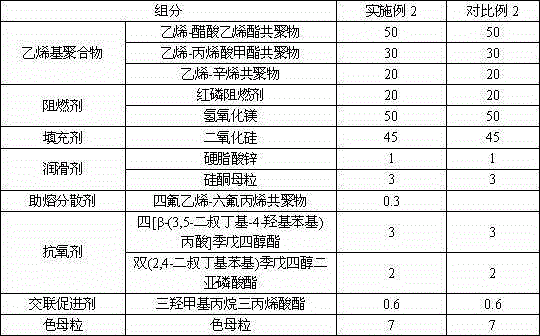

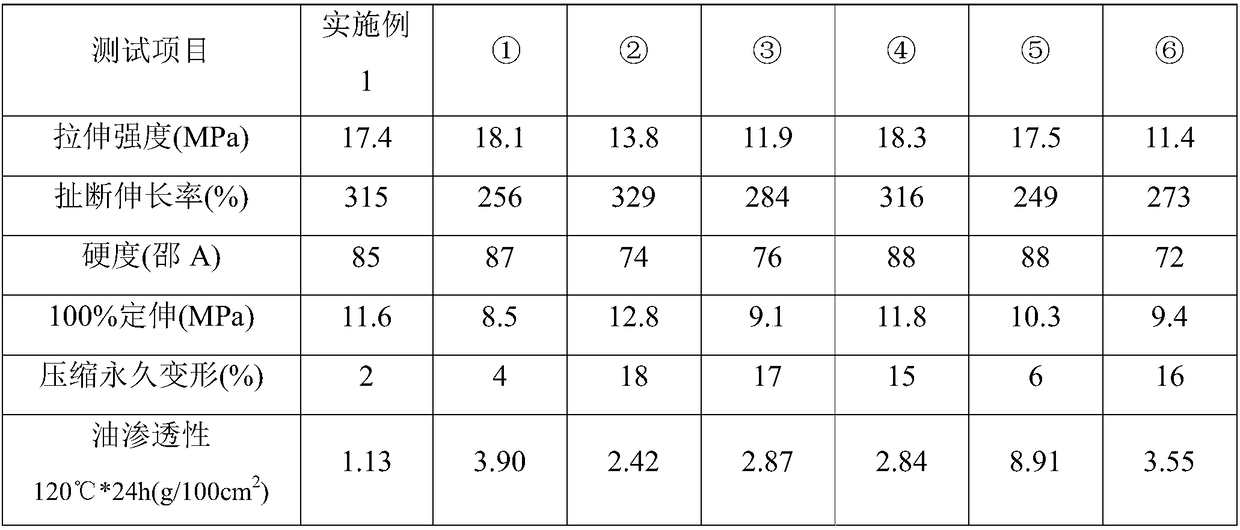

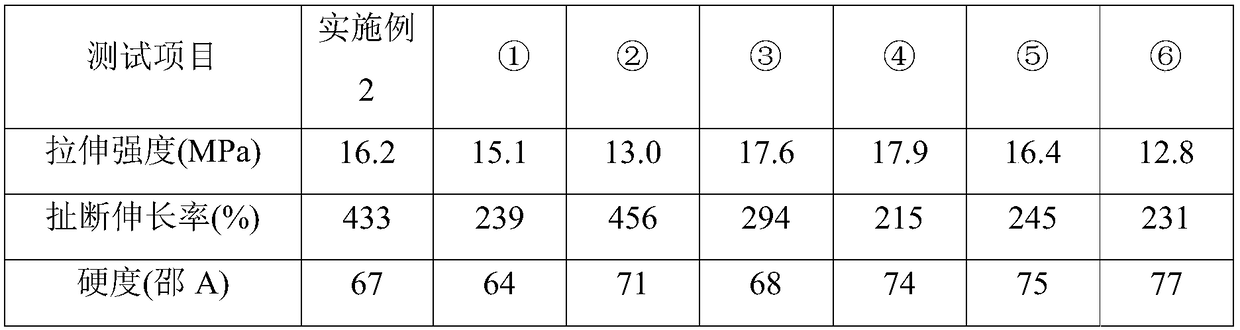

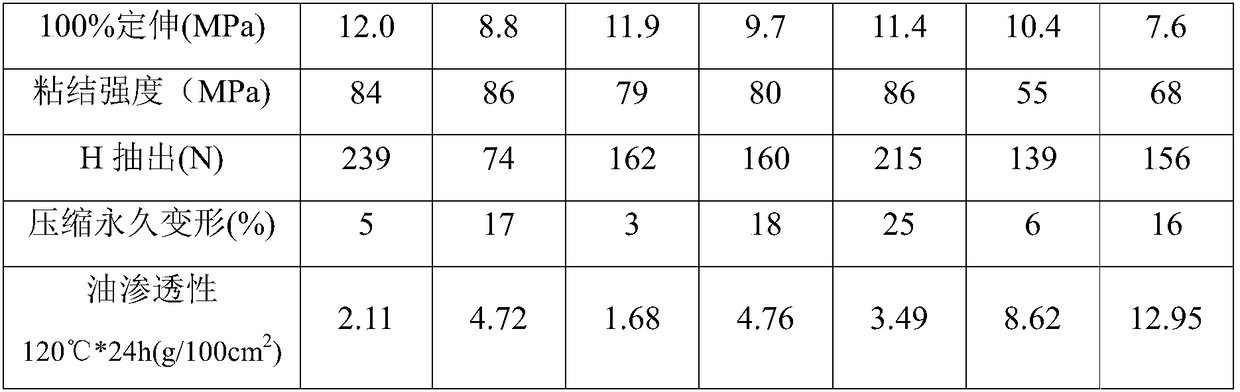

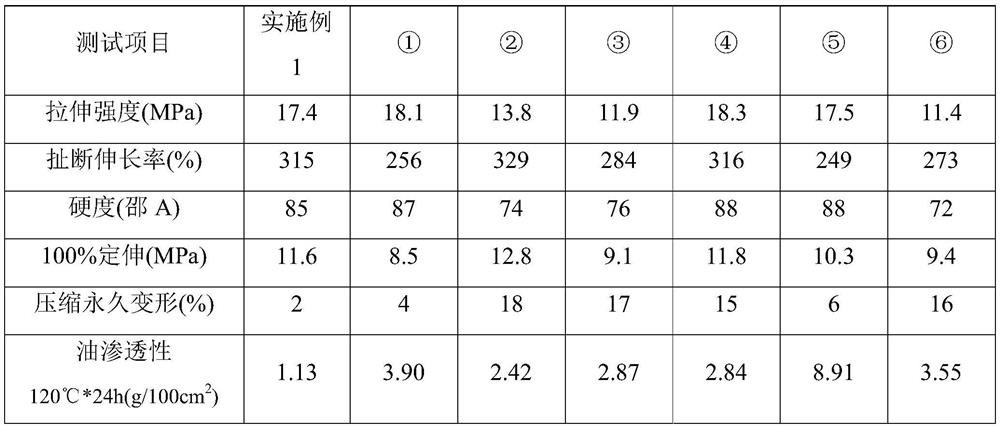

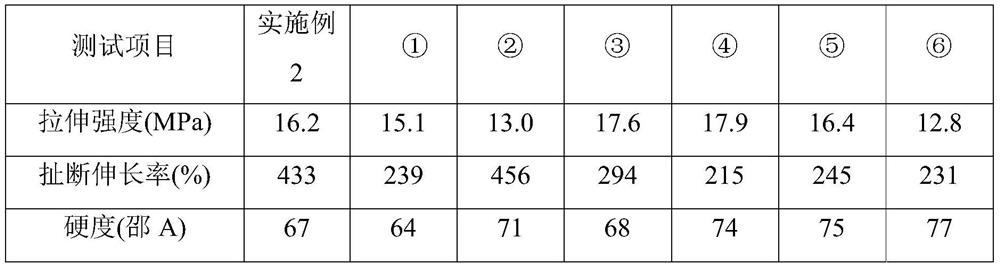

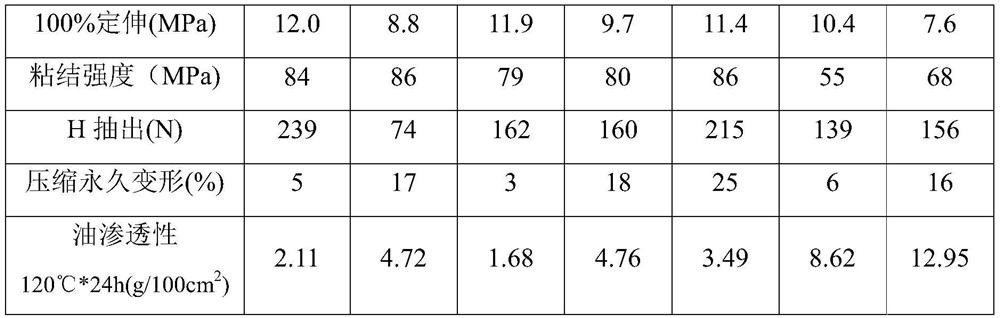

High-speed-extruding oil-proof wear-resisting irradiation crosslinking rubber material and preparation method thereof

ActiveCN102731919AIncrease extrusion rateIncrease productivityPlastic/resin/waxes insulatorsInsulated cablesRubber materialPolymer science

The invention discloses a high-speed-extruding oil-proof wear-resisting irradiation crosslinking rubber material and a preparation method thereof. The high-speed-extruding oil-proof wear-resisting irradiation crosslinking rubber material comprises the following components in parts by weight: 30 to 70 parts of chlorinated polyethylene, 4 to 20 parts of polyethylene, 10 to 30 parts of magnesium hydrate, 5 to 20 parts of calcium carbonate, 1 to 5 part(s) of stabilizer, 1 to 5 part(s) of compatilizer, 1 to 5 part(s) of silicone powder, 1 to 5 part(s) of silica, 1 to 10 part(s) of plasticizer, and 2 to 5 parts of carbon black. The rubber material disclosed by the invention can achieve the extruding at a high speed over 600m / min, has extremely high production efficiency and high cost performance on oil resistance, can meet the requirements of HPN-R lines of a UL507 standard in the aspect of wear-resisting performance, and also has high flame retardation.

Owner:JIANGSU DASHENG POLYMER

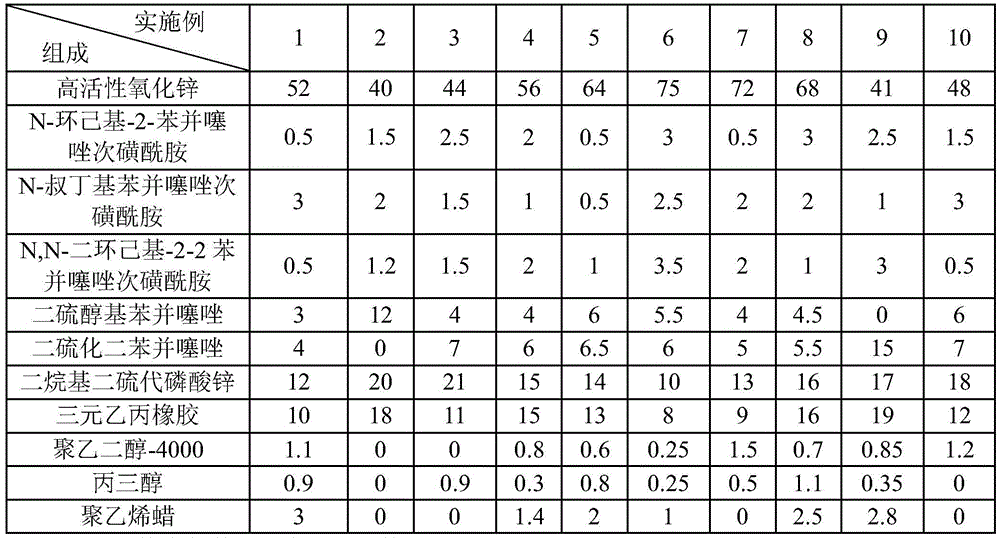

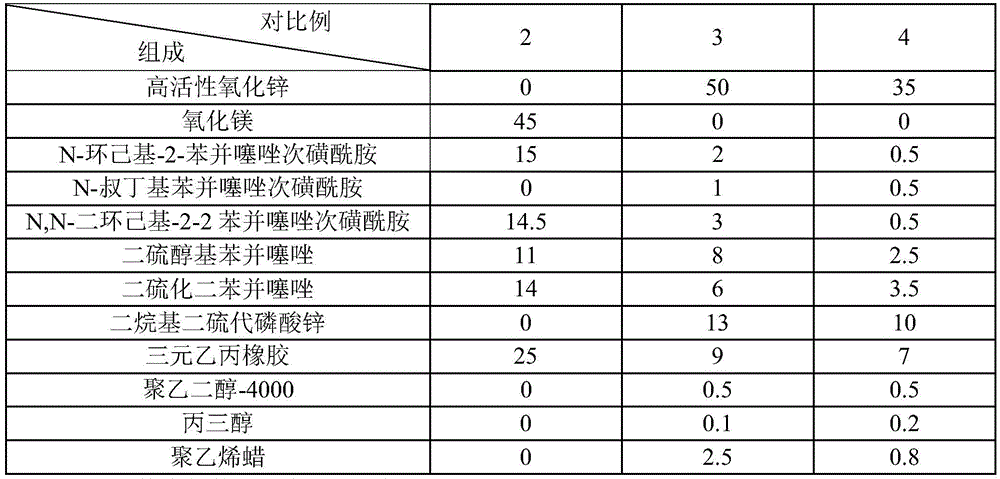

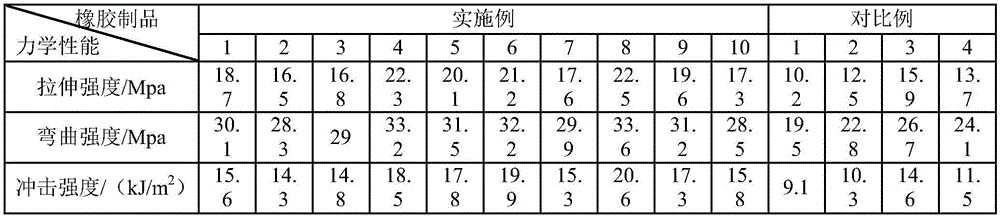

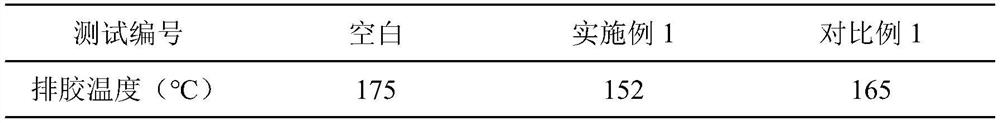

Rubber comprehensive accelerator and method for preparing same

The invention discloses a rubber comprehensive accelerator and a method for preparing the same.The rubber comprehensive accelerator mainly comprises, by weight, 40-75 parts of high-activity zinc oxide, 2-9 parts of after-effectiveness sulfenamide accelerators, 7-15 parts of thiazole accelerators, 10-21 parts of ultrahigh-speed accelerators and 8-19 parts of macromolecular carriers.The rubber comprehensive accelerator and the method have the advantages that different types of additives can be sufficiently mixed with one another by the aid of a step-by-step adding process, accordingly, the rubber comprehensive accelerator is excellent in aging resistance and yellowing resistance, and mechanical properties of rubber products further can be improved.

Owner:YONGJIA WEICHENG RUBBER IND & TRADE CO LTD

Special glass fiber reinforcement PA66 composition for heat-insulation strips and method for preparing special glass fiber reinforcement PA66 composition

The invention provides a special glass fiber reinforcement PA66 composition for heat-insulation strips and a method for preparing the special glass fiber reinforcement PA66 composition. The composition comprises, by weight, 55-75 parts of nylon 66, 0-10 parts of toughening agents, 0-15 parts of polyethylene, 20-30 parts of chopped glass fibers, 0.01-1 part of silane coupling agents, 0.01-1 part of antioxidants and 0.1-3 parts of lubricants. The special glass fiber reinforcement PA66 composition for the heat-insulation strips and the method have the advantages that the special glass fiber reinforcement PA66 composition is high in performance and extrusion rate and excellent in appearance, requirements of the heat-insulation strip industry on the performance and the appearance of materials can be met, and the special glass fiber reinforcement PA66 composition and the method have important application and popularization value.

Owner:TIANJIN KINGFA NEW MATERIAL

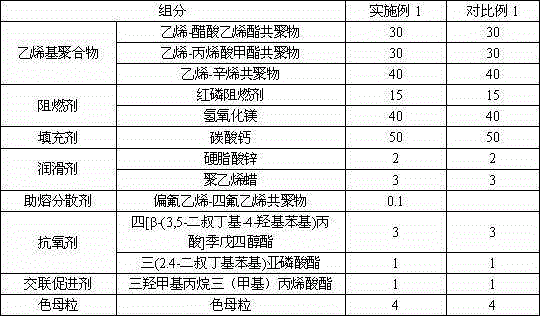

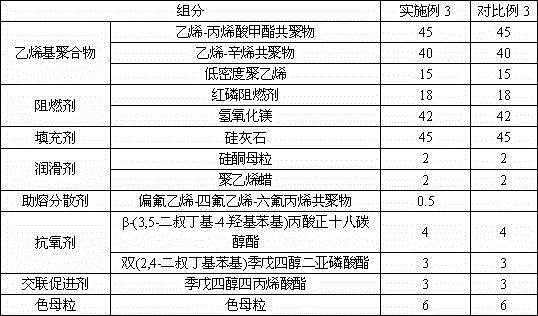

High-extrusion-rate heat-shrinkable tube and production method thereof

The invention discloses a high-extrusion-rate heat-shrinkable tube. The preparation materials of the high-extrusion-rate heat-shrinkable tube comprise, by weight, 100 parts of vinyl polymers, 0-70 parts of a fire retardant, 0-60 parts of filler, 0.1-5 parts of a lubricant, 0.1-3 parts of a flux dispersing agent, 0.1-10 parts of an antioxidant, 0-3 parts of a crosslinking accelerator and 0-10 parts of color master batch. The high-extrusion-rate heat-shrinkable tube has the advantages that not only is the extrusion rate high, but also the extrusion is stable in high speed, and good machining and use performances are also achieved.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

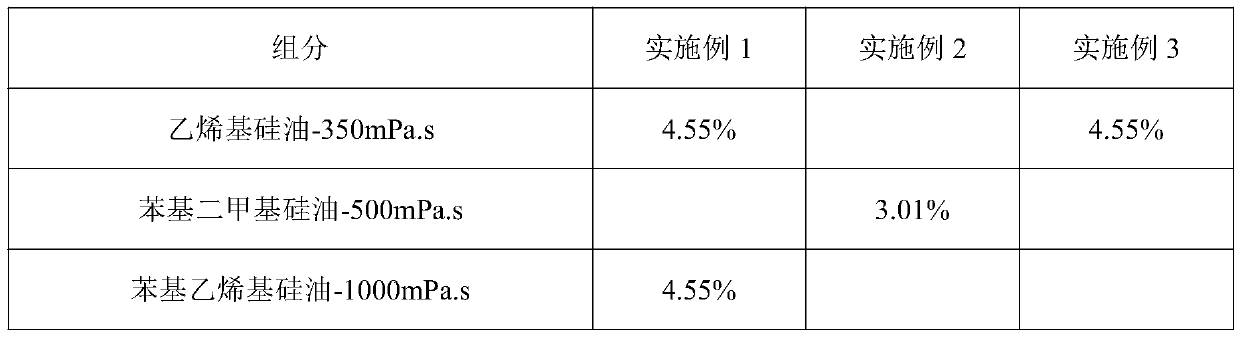

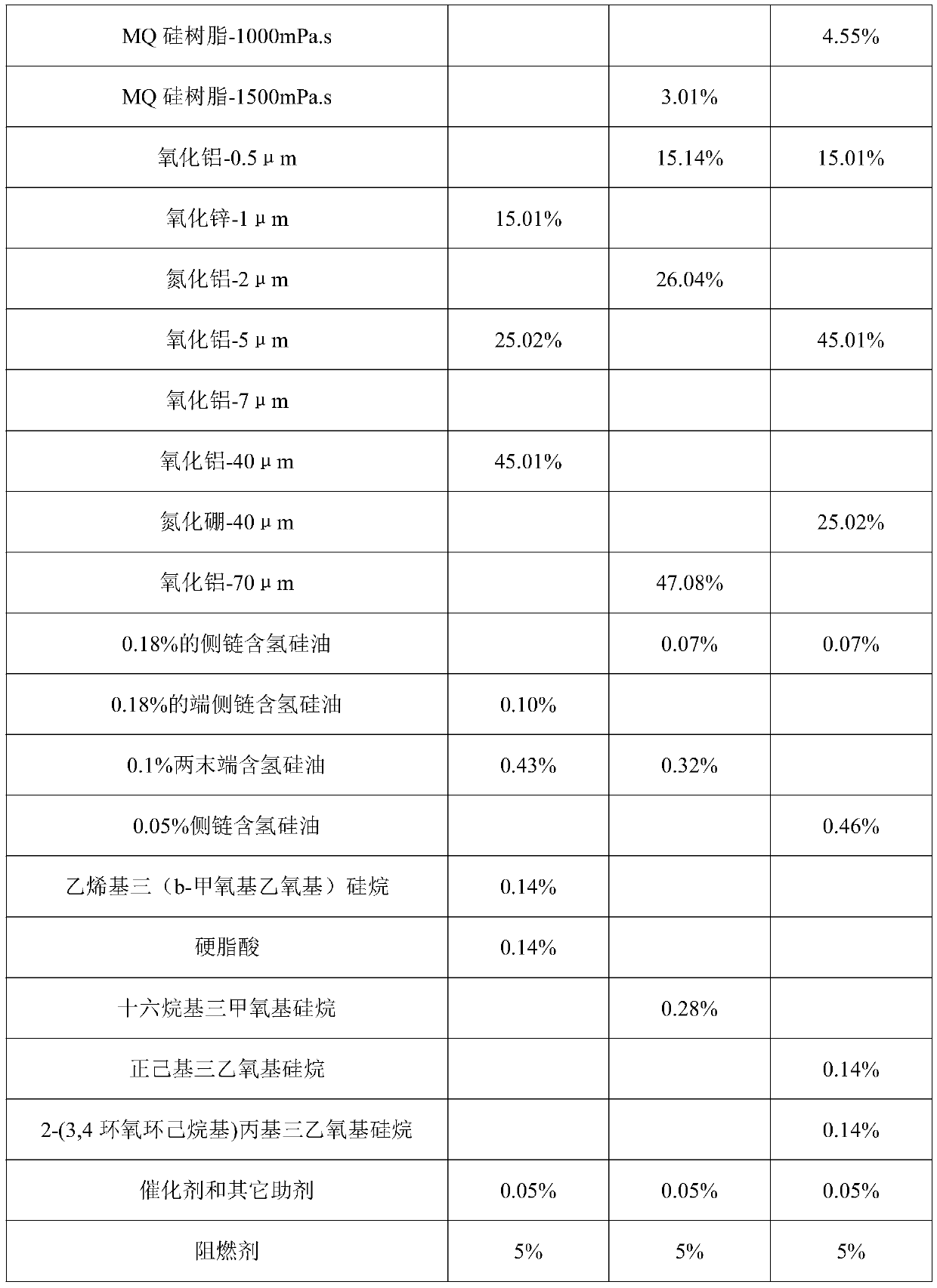

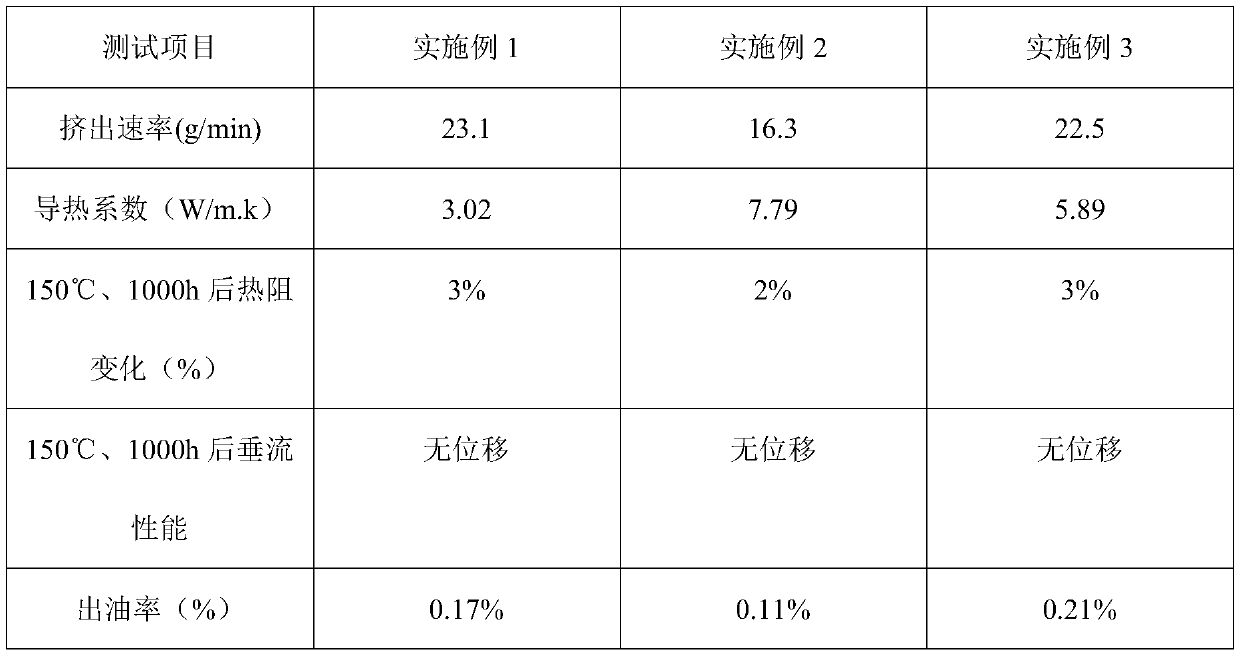

Mud-like high-temperature-resistant heat-conducting composite material and preparation method thereof

The invention discloses a mud-like heat-conducting composite material. The mud-like heat-conducting composite material comprises the following compositions according to a weight proportion: 3%-50% ofsilicone oil, 0.1%-5% of a cross-linking agent, 0.1%-5% of a surface modifier, 0-20% of a fire retardant, 50%-97% of heat-conducting filler, 0.05%-0.015% of a catalyst, and other auxiliaries. In addition, the invention further discloses a preparation method for the above mud-like high-temperature-resistant heat-conducting composite material. The mud-like heat-conducting composite material has theadvantages of excellent high temperature resistance, a high heat conductivity coefficient, good heat stability, a low oil yield, convenient extrusion, good storage stability and strong operability andthe like, and is capable of greatly improving efficiency, and very suitable for solving a heating problem of electronic components.

Owner:东莞市盛元新材料科技有限公司

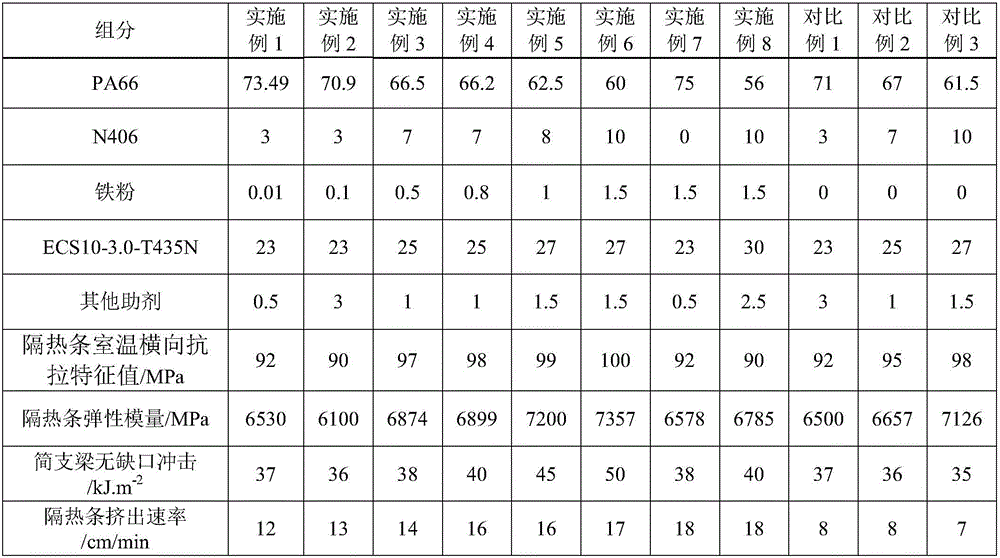

Glass fiber reinforced nylon 66 composition with high performance and high extrusion rate

The invention provides a glass fiber reinforced nylon 66 composition with high performance and a high extrusion rate. The preparation method of the glass fiber reinforced nylon 66 composition with the high performance and the high extrusion rate comprises the following steps: (1) drying the nylon 66 at 100-140 DEG C for 3-6h, and then putting a toughening agent, iron powder, other additives and the dried nylon 66 in a high-speed mixer to evenly mix the same to form a premix; and (2) adding the premix from a main feed opening of a twin-screw extruder, feeding short glass fibers from a side feed opening, and carrying out granulation after fusion extrusion to obtain aggregates of the glass fiber reinforced nylon 66 composition with the high performance and the high extrusion rate. According to the glass fiber reinforced nylon 66 composition with the high performance and the high extrusion rate, provided by the invention, the melt strength of the material in a fusion state is adjusted by POE-g-MAH components, so that more stable extrusion is realized.

Owner:TIANJIN KINGFA NEW MATERIAL

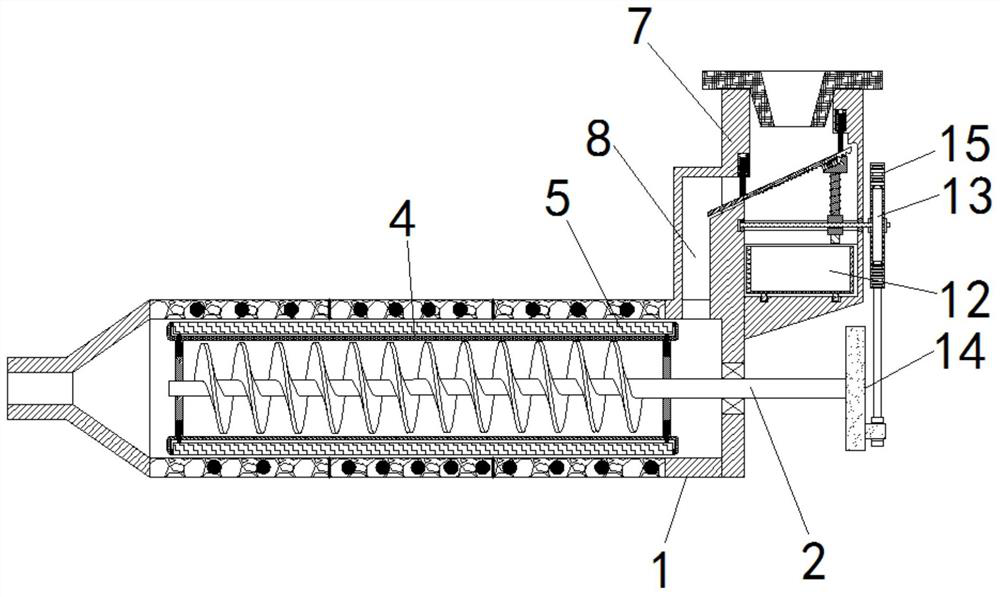

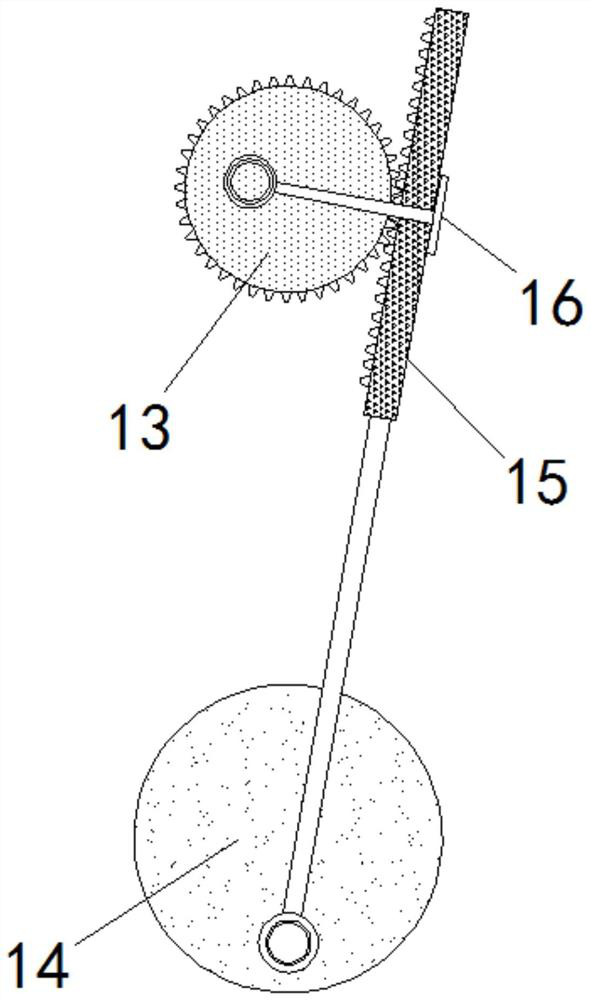

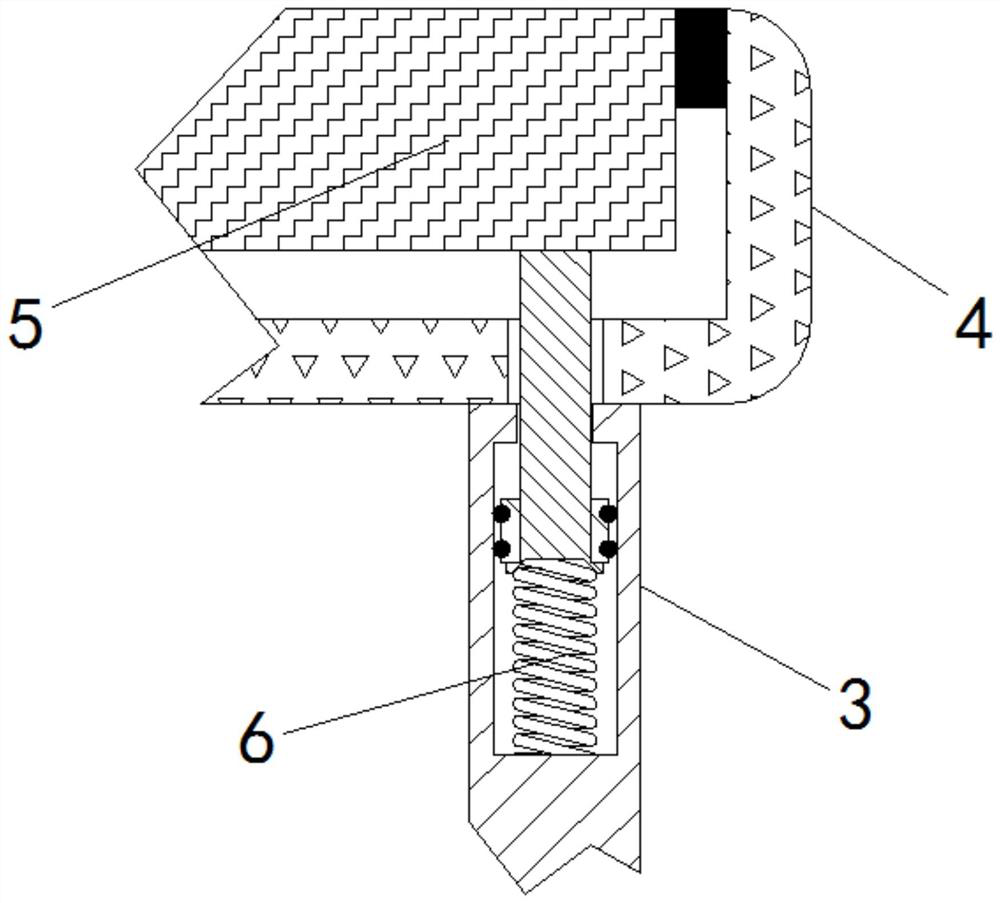

Polyester chip melting device for enhancing material screening effect

The invention relates to the technical field of artificial filament manufacturing, and discloses a polyester chip melting device for enhancing a material screening effect. The polyester chip melting device comprises an extrusion cylinder, an inner cavity of the extrusion cylinder is rotatably connected with an extrusion screw rod, the upper end and the lower end of the extrusion screw rod are bothfixedly connected with symmetrical sliding cylinders, storage strips is fixedly connected to the ends, away from the extrusion screw rod, of the sliding cylinders, scraping strips extending to the storage strips are slidably connected to inner cavities of the sliding cylinders, and first springs are fixedly connected between the scraping strips and the inner walls of the sliding cylinders. According to the polyester chip melting device capable of enhancing the material screening effect, the extrusion screw rods drive a transmission disc to rotate, racks drive a threaded toothed rod to rotatein a reciprocating mode, a screening block is matched with a pulley to intermittently extrude a screening plate to vibrate and remove impurities, the first springs enabling the scraping strips to haveelastic allowance are matched, and the first springs are arranged in the sliding cylinders in a sealed mode; and therefore, the service life and the use reliability of a scraping mechanism are improved, and the purity of raw materials is ensured.

Owner:郑勤峰

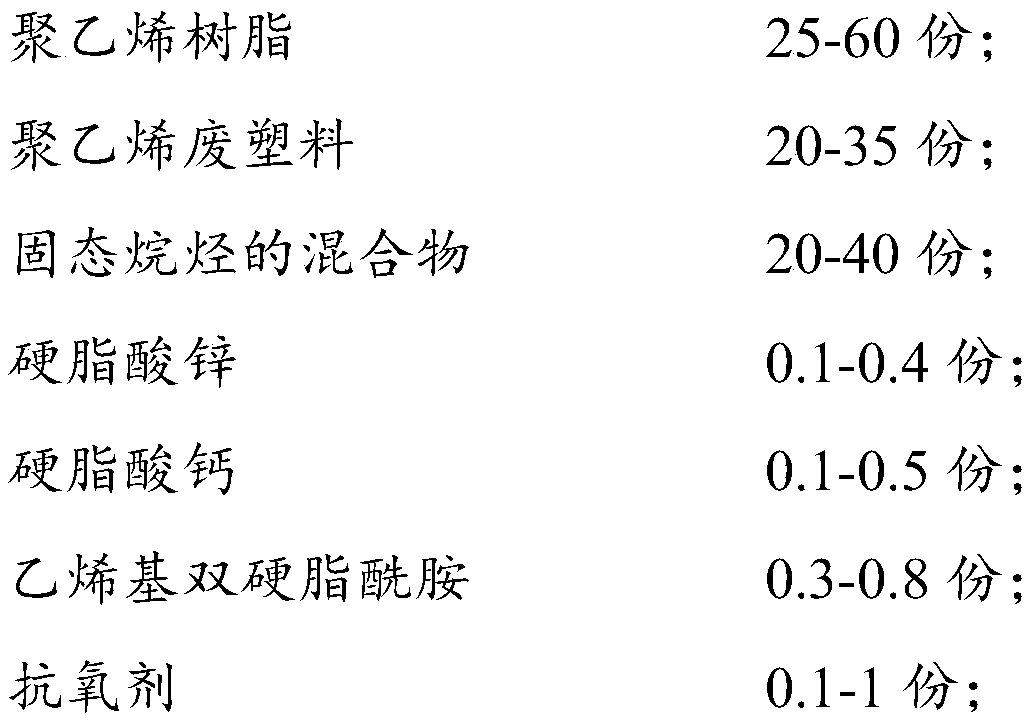

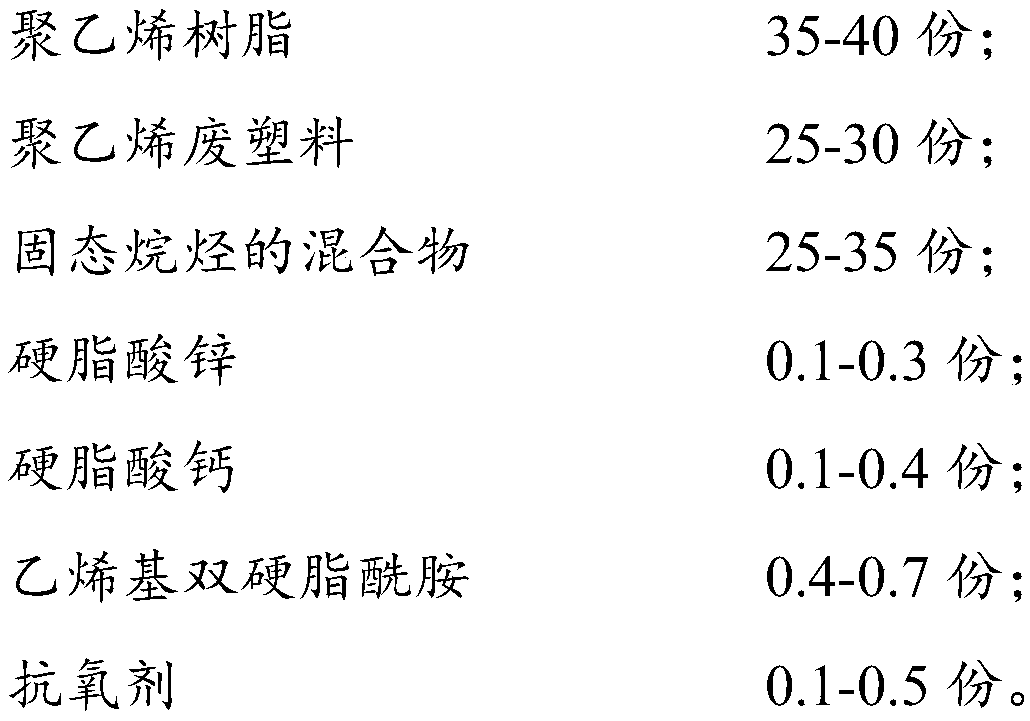

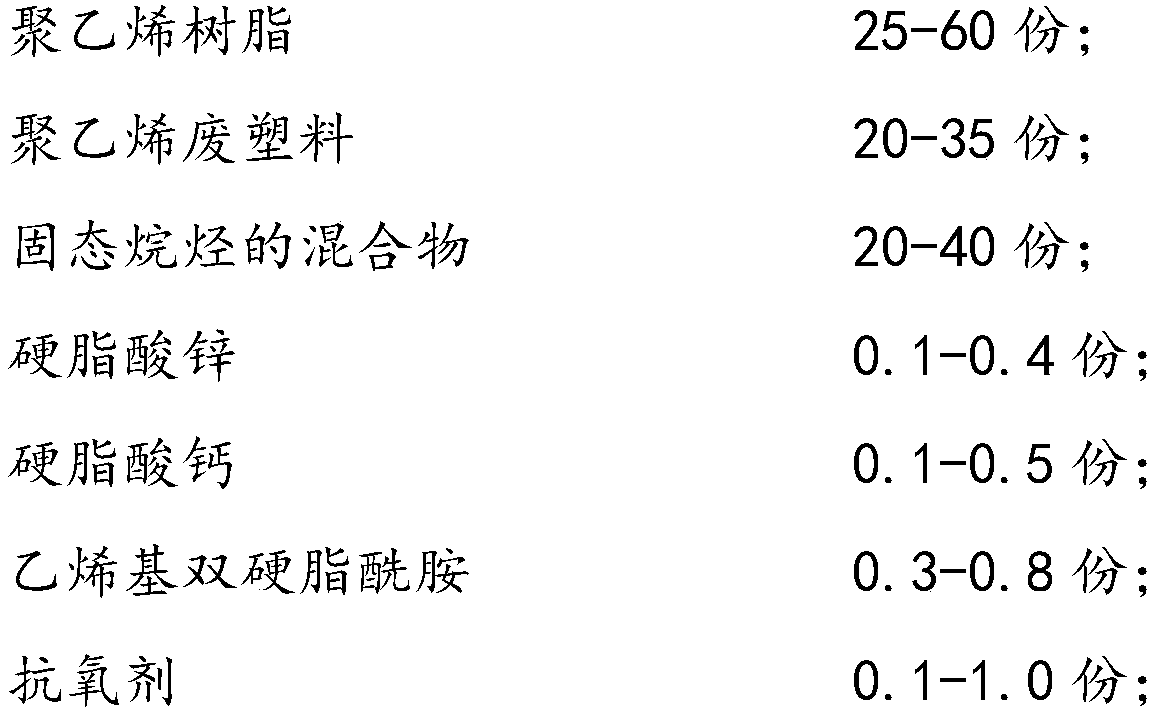

Polyethylene modified material and preparation method thereof

InactiveCN110684258AImprove toughnessImprove surface smoothnessPlastic recyclingPolymer chemistryAlkane

The invention belongs to the technical field of novel materials and in particular relates to a polyethylene modified material and a preparation method thereof. The polyethylene modified material comprises polyethylene resin, a waste polyethylene plastic, a mixture of solid alkane, zinc stearate, calcium stearate, vinyl bistearic amide and an antioxidant. The polyethylene resin and the waste polyethylene plastic are adopted as base materials, various aids are added, and the polyethylene modified material is prepared by using a preparation process researched in the invention. The modified material has excellent advantages of cold resistance, thermal resistance, chemical resistance, wearing resistance, lubrication performance, and the like, and so that has very good lubrication and compatibility functions in processing molding of a plastic or a color master batch. When the polyethylene modified material is used in processing molding of the plastic or the color master batch, the flowability of a material can be improved, the gloss, the lubrication performance and the processing performance of a product can be improved, the yield can be increased, and in addition, a higher filler concentration can be allowed.

Owner:成都盛腾科技发展有限公司

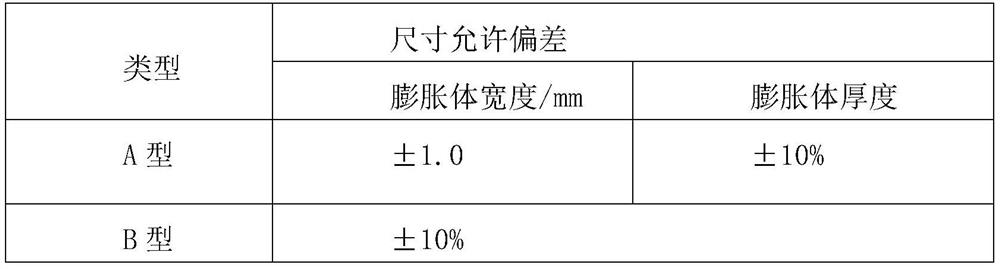

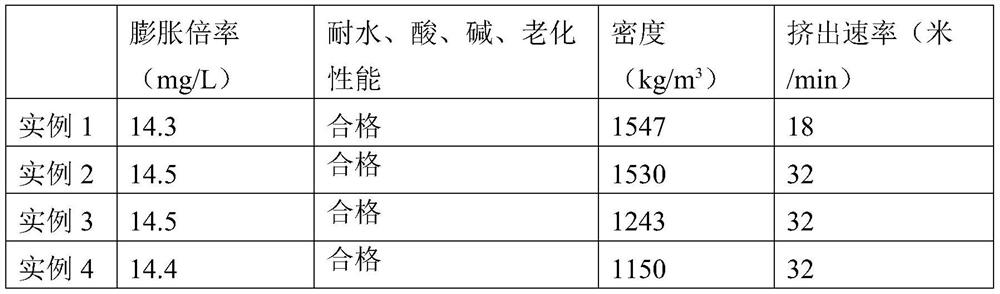

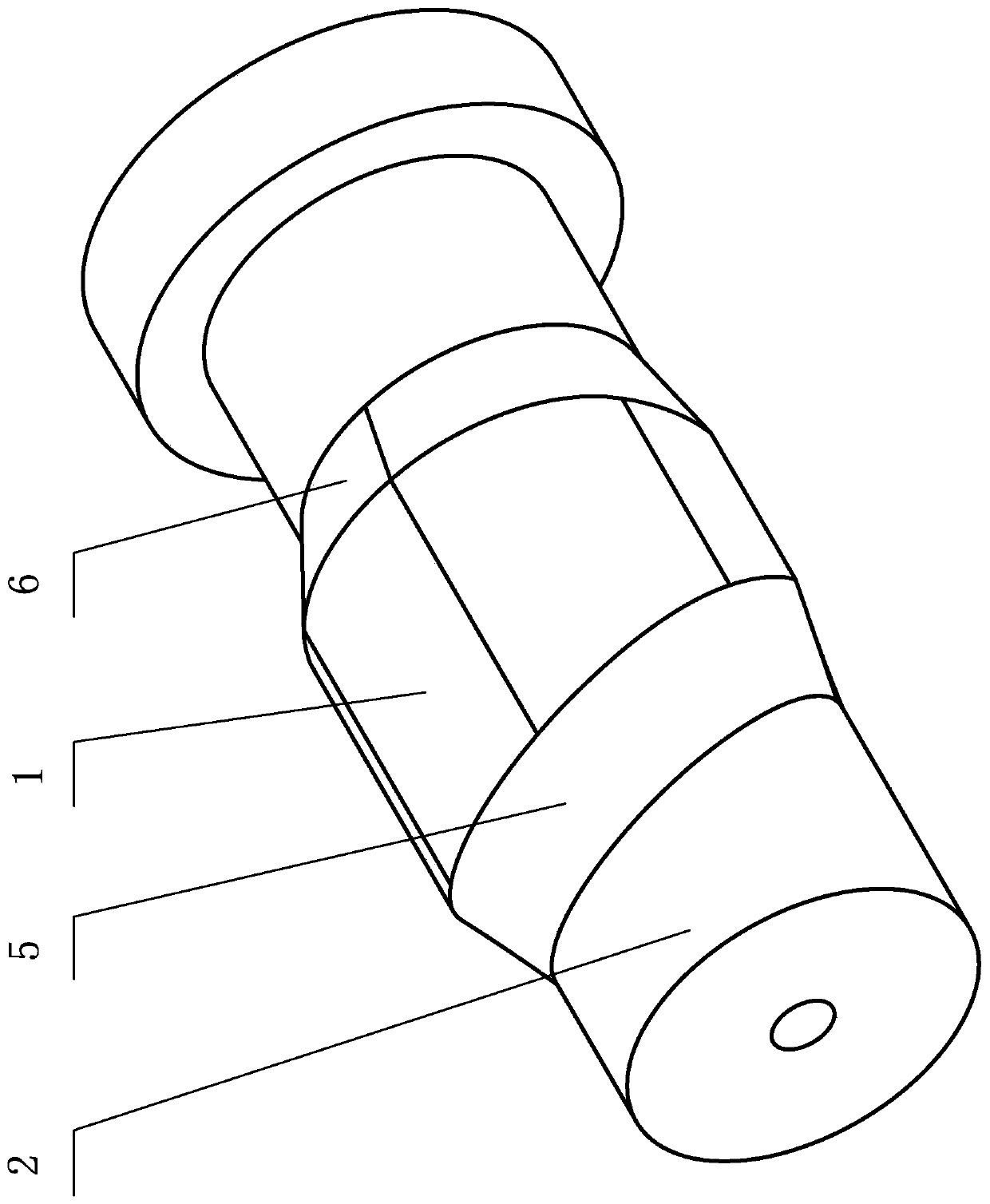

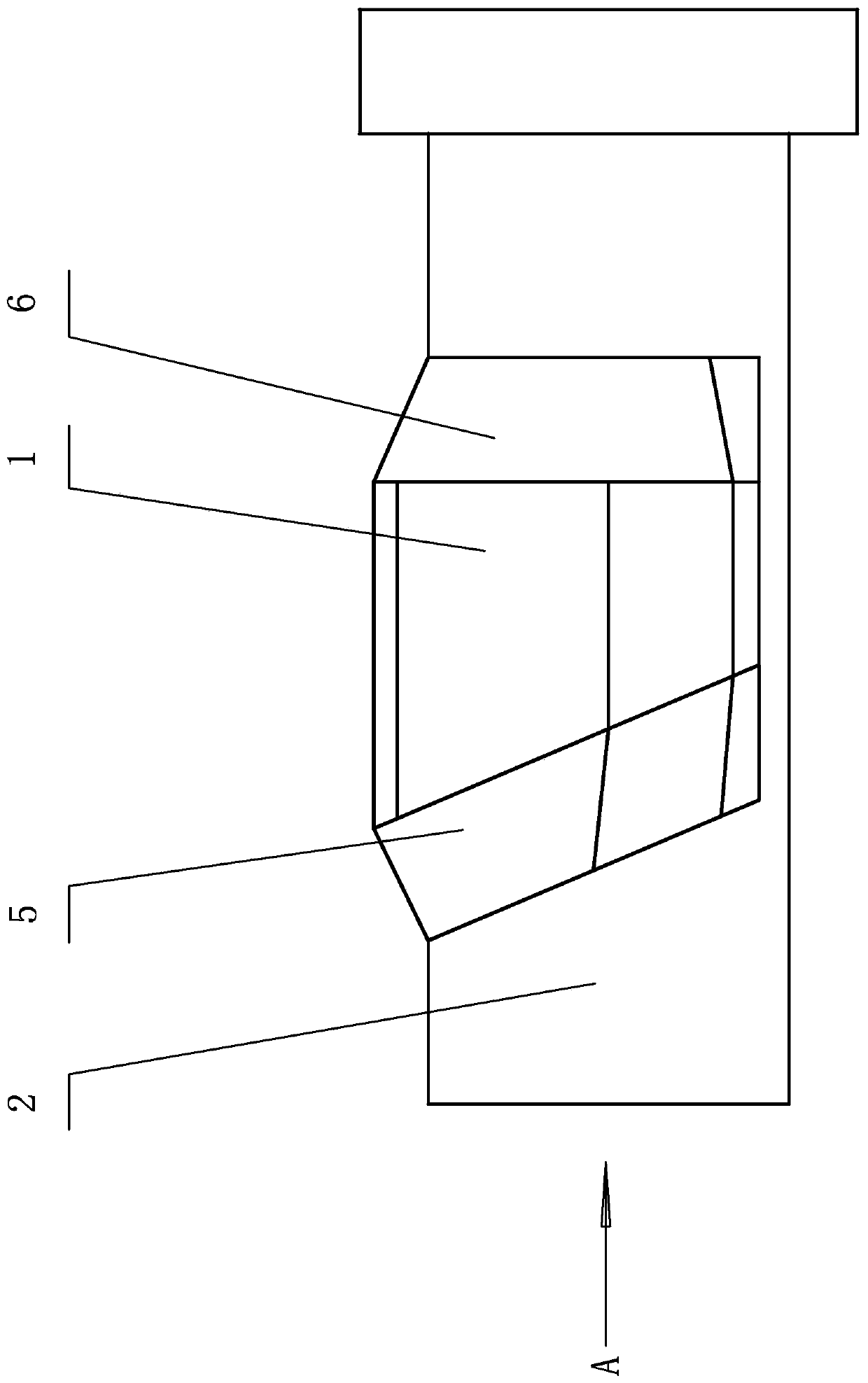

Low-density and high-extrusion-rate PVC fireproof sealing strip and preparation method thereof

The invention discloses a low-density and high-extrusion-rate PVC fireproof sealing strip, which comprises the following components in percentage by mass: 10-40% of polyvinyl chloride resin powder, 10-40% of expanded graphite, 5-30% of filler, 2-10% of light filler, 0.5-5% of a foaming agent, 0.5-5% of a cell regulator, 10-40% of a plasticizer, 0.5-5% of a heat stabilizer, 2-6% of a flame retardant and 0.5-5% of a processing aid. According to the invention, the lightweight fireproof raw material is utilized to replace part of the filler, and the foaming agent and the cell regulator are added, so that the density of the PVC sealing strip is reduced on the premise of not increasing the cost and not losing the performance, the sealing strip is prevented from falling off due to too high self weight in the use process, and the use condition of the PVC sealing strip is reduced.

Owner:湖北合扬科技有限公司

Insulating-layer semiconductive shielding material for ethylene propylene rubber cable

InactiveCN105218894AEvenly dispersedGood dispersionNon-conductive material with dispersed conductive materialStearic acidEthylene propylene rubber

The invention discloses an insulating-layer semiconductive shielding material for an ethylene propylene rubber cable. The material is characterized by being prepared from, by weight, 60-70 parts of nitrile butadiene rubber, 30-40 parts of chlorinated polyethylene, 30-50 parts of cable powder, 50-70 parts of conductive carbon black A, 10-30 parts of conductive carbon black B, 5-10 parts of magnesium oxide, 2-4 parts of paraffin, 2-8 parts of anti-aging agents, 20-30 parts of dioctyl phthalate, 0.5-1 part of dispersants, 2-5 parts of stearic acid and 1-8 parts of vulcanizing agents. The insulating-layer semiconductive shielding material for the ethylene propylene rubber cable has the advantages of good heat oxygen aging resistance, ozone aging resistance, acid-base resistance and chemical resistance performance, excellent oil resistance performance, good removability and glue liquidity, low cost and the like.

Owner:山东太平洋橡缆股份有限公司

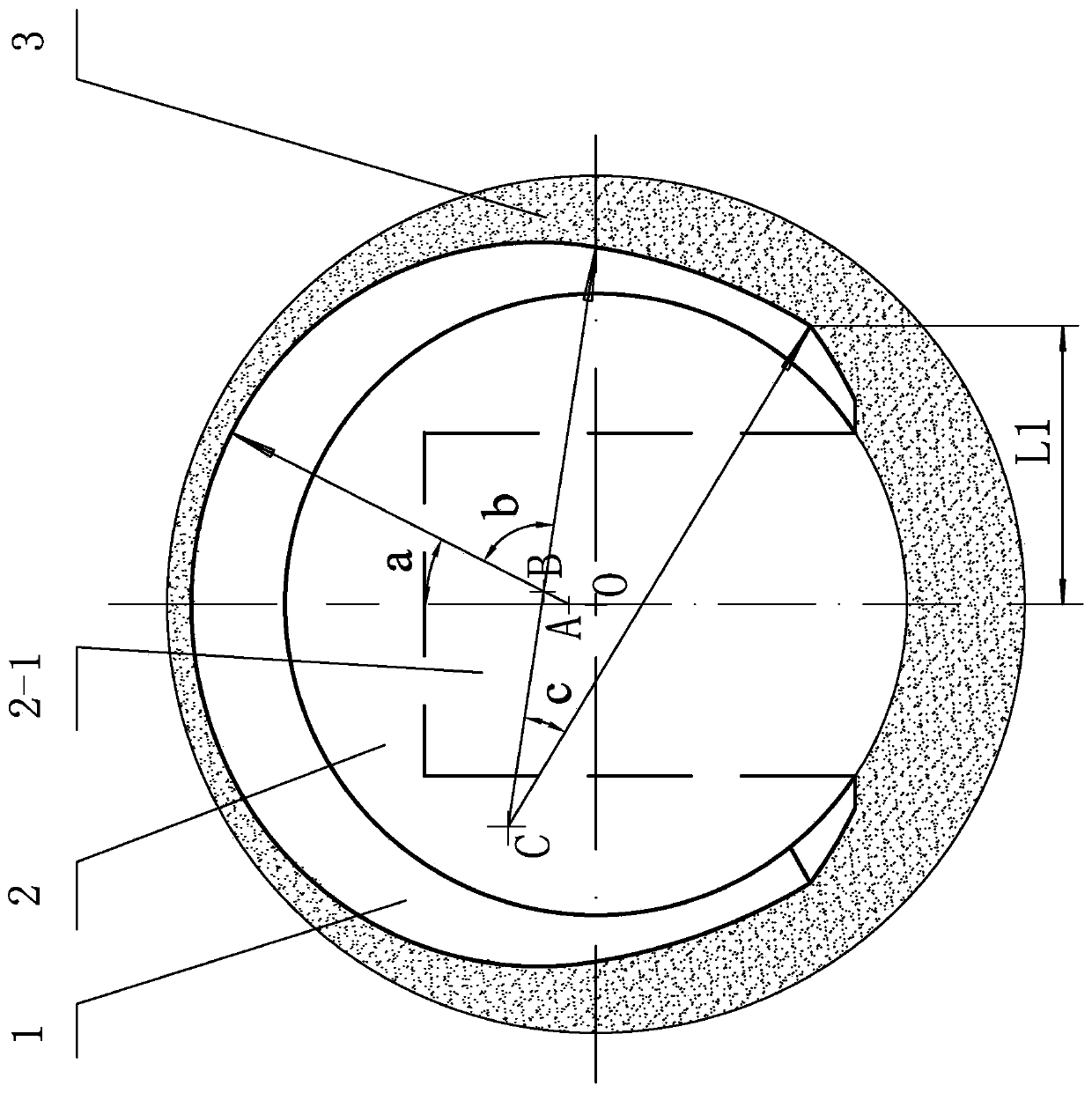

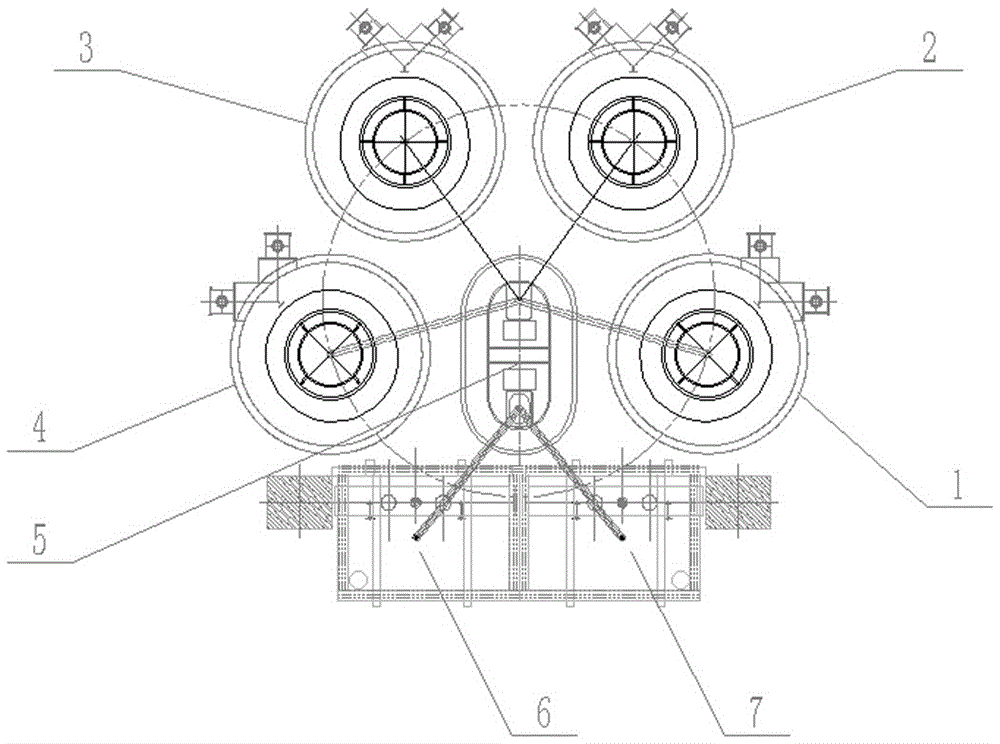

Detachable gradual type right-angle rubber pipe extrusion die pre-forming segment design method

ActiveCN110014602AIncrease extrusion rateMeet the industry requirements of green and sustainable developmentEngineeringDesign methods

The invention discloses a detachable gradual type right-angle rubber pipe extrusion die pre-forming segment design method. A flow dividing and resisting structure is designed to a flow dividing and resisting annular block clamped on a die core, the flow resisting annular face of the flow dividing and resisting annular block is designed to be symmetric on the left and right side, the width of the annular face is gradually reduced from top to bottom, the front end face of the flow dividing and resisting annular block is designed to the perpendicularity, the rear end face is designed to be inclined towards the lower front portion, the width of a plastic melt circulation channel formed between the flow dividing and resisting annular block and an extrusion die pre-forming die cavity is gradually increased to the lower portion of the die core from top to bottom, in the forward extrusion direction, the length of the plastic melt circulation channel is gradually reduced from top to bottom, a front guide conical face and a rear guide conical face which are connected with the front portion and the rear portion of the die core are arranged on the front end and the rear end of the flow dividing and resisting annular block. The traditional sudden change type flow dividing structure is designed to the gradual flow dividing structure, the extrusion rate of the plastic melt along the circulation channel is evenly distributed, the extrusion rate is improved, and the extrusion energy consumption is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Single-component high-temperature-soaking-resistant silicone adhesive and preparation method and application thereof

ActiveCN112280525AExcellent resistance to high temperature and water immersionLong storage shelf lifeNon-macromolecular adhesive additivesClimate change adaptationPolymer sciencePtru catalyst

The invention relates to a single-component high-temperature-soaking-resistant silicone adhesive and a preparation method and application thereof. The silicone adhesive is prepared from the followingcomponents in parts by weight: 90-150 parts of dihydroxy polydimethylsiloxane, 0-60 parts of dimethyl polydimethylsiloxane, 1-15 parts of an acyloxy silane cross-linking agent, 5-50 parts of filler, 0.002-0.5 part of a catalyst and 1-20 parts of a coupling agent. The silicone adhesive has excellent high-temperature soaking resistance and relatively long storage shelf life, and the silicone adhesive is maintained not liable to yellow without adding an anti-yellowing agent. The extrusion rate, the strength, the elongation and other mechanical properties of the silicone adhesive are well improved. The product is simple in production process and convenient to operate.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Melt processable thermoplastic polymer composition

The present invention relates to a melt processable polymer composition and a method of improving the melt processability of the host polymer. Said melt processable polymer composition comprises a thermoplastic non-aliphatic host polymer and a minor but effective amount of a fluoropolymer processing aid.

Owner:德弘公司

Pressurized molding process for plastic particles

InactiveCN110871559AIncrease extrusion rateEfficient pelletizingPlastic recyclingMetal working apparatusTap waterCeramic materials

The invention provides a pressurized molding process for plastic particles. The process comprises the following steps that firstly, a plastic granule cutting machine body carries out hot melting on waste plastic and extrudes the waste plastic into a butt joint pipe, so that molten plastic flows into a pressurizing cylinder, at the moment, a piston is driven to slide along the pressurizing cylinderin a reciprocating mode, when the piston slides into the pressurizing cylinder, the molten plastic in the pressurizing cylinder is extruded towards an extrusion part B, the pressure of the molten plastic is increased and the molten plastic is extruded from a butt joint hole; meanwhile, the pressurizing cylinder is driven to swing back and forth to move relative to cutting knives, and the cuttingknives cut the extruded strip-shaped plastic, so that the extruded strip-shaped plastic is cut into plastic particles and then falls down; then, the plastic particles fall into a water-cooling conveying device, and the water-cooling conveying device carries out water-cooling temperature reduction on the plastic particles and conveys the plastic particles to an air-drying and discharging device after tap water is filtered; and finally, the air-drying and discharging device carries out air-drying on the wet plastic particles and discharges the plastic particles outwards for collection.

Owner:六安丰恺尼机电科技有限公司

Preparation method of novel rubber additive

The invention discloses a preparation method of a novel rubber additive. The novel rubber additive is prepared from the following components in parts by weight: 20-30 parts of vinyl resin, 18-25 parts of unsaturated polyester resin, 12-16 parts of unsaturated fatty acid, 1.5-2 parts of zinc oxide and 6-9 parts of trifluoropropyl methyl dichlorosilane. The preparation method comprises the steps of adding unsaturated fatty acid into a container, heating to the temperature of 80-90 DEG C for melting, stirring, then adding zinc oxide, raising the temperature to 120-130 DEG C, and reacting for 2-3 hours to obtain viscous liquid; and adding the viscous liquid obtained in the step S1 into vinyl resin, unsaturated polyester resin and trifluoropropyl methyl dichlorosilane, raising the temperature to 110-115 DEG C, and carrying out melt blending for 3-5 hours to obtain the additive.

Owner:赣州晶鑫新材料有限公司

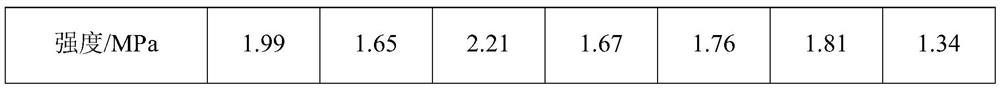

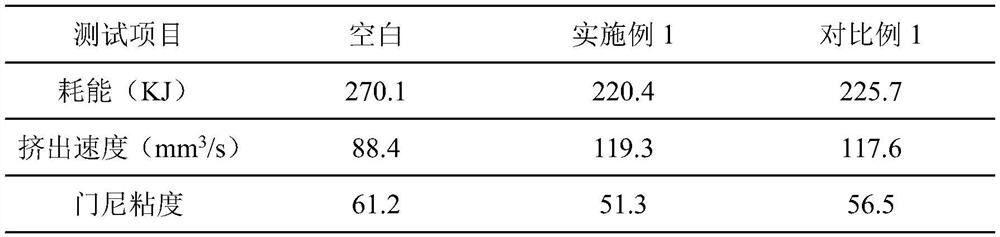

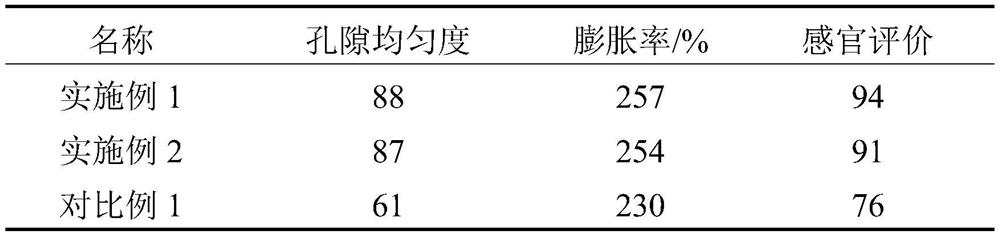

Preparation method of seasoned gluten

InactiveCN112674276AWell mixedIncrease extrusion rateVegetable proteins working-upProcess engineeringGluten

The invention provides a preparation method of seasoned gluten, and belongs to the technical field of foods. In the process of preparing the extruded seasoned gluten, ultrasonic assistance is applied together during flour mixing, so that various materials and flour can be effectively and uniformly mixed, and the obtained flour floccule is softer, fluffy and not prone to caking, thus the flour feeding uniformity and the green body extrusion rate can be effectively improved, the pore uniformity and the expansion rate of the extruded seasoned gluten are increased, and the production stability of the extruded seasoned gluten is improved. The seasoned gluten comprises the following components: wheat flour, edible salt, fructose powder, chili powder, monoacylglyceride, edible oil, sesame oil and water. According to the invention, a flour-mixing device of the ultrasonic-assisted extrusion seasoned gluten is adopted, the product stability and the pore uniformity can be effectively improved, and the preparation method has great application value in the extruded seasoned gluten industry.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Novel plastic steel door-window sectional material

The invention relates to a novel plastic steel door-window sectional material comprising the following raw materials by weight: 70-80kg of resin, 20-26kg of rock powder, 3-4kg of titanium pigment, 3-4kg of precipitant, 8-9kg of chlorinated polyethylene, 0.4-0.8kg of modified resin, 10-14g of ultramarine, 10-14g of whitening agent, 40-60g of polyethylene wax, 70-90g of stearic acid and 10-12g of ammonium polyphosphate. According to the novel plastic steel door-window sectional material, the resin is used as the main raw material, the rock powder for reducing the product cost as well as the titanium pigment, whitening agent and ultramarine achieving a whitening effect are added to ensure that the product can not turn yellow when used for a long time, and chlorinated polyethylene with impact resistance as well as PE wax and stearic acid for lubrication are added at the same time. The plastic steel door-window sectional material disclosed by the invention has relatively strong corrosion resistance, ultraviolet resistance, fire resistance, insulating property and the like, and is high in safety factor, low in cost and suitable for the level of mass consumption.

Owner:江苏荣光塑料科技发展有限公司

Outer layer rubber for high-temperature resistance flexible rubber hose

ActiveCN109337349AImprove corrosion resistanceReduce wear loss and compression fatigue temperature riseFlexible pipesMicaCarbon black

The invention discloses outer layer rubber for a high-temperature resistance flexible rubber hose. The outer layer rubber is prepared from the following components in parts by weight: 35 parts of rubber material Ethylene-Propylene-Diene Monomer (EPDM), 65 parts of polyurethane elastomer rubber TPU, 9 parts of mica powder, 55 parts of carbon black, 2.1 parts of stearic acid, 4.5 parts of a plasticizer, 1.3 parts of a promoter DM, 0.8 part of a vulcanizing agent DCP, 0.76 part of sulphur, 5.0 parts of an ant-ageing agent AW, and 0.7 part of a composite flame retardant FR201. The invention further discloses a high-temperature resistance flexible rubber hose. The outer layer rubber material prepared by the invention is very good in fluidity, so that the hose can be softened to be to coil, hasvery good affinity with a middle rubber layer, and is difficult to fracture and good in wear resistance, and scratch resistance of the hose is greatly improved.

Owner:LUOHE BONWELL RUBBER

Method for recycling polyvinylidene fluoride plastic

InactiveCN110540723AOvercoming severe agingHigh impact strengthSimple Organic CompoundsPolyvinylidene difluoride

The invention relates to the technical field of novel functional materials, and discloses a method for recycling polyvinylidene fluoride plastic. The method comprises the steps of mixing a prepared composite additive with crushed polyvinylidene fluoride waste plastic particles, adding a coupling agent, and performing extruding and granulating by virtue of a double-screw extruder, wherein the prepared composite additive is subjected to melt blending with polyvinylidene fluoride waste plastic, so that high compatibility is achieved, and the compactness and uniformity of the structure are improved; the composite additive is of a multi-metal organic compound structure, so that the crystallization area is reduced when the composite additive is in combination with polyvinylidene fluoride, the occurrence of a photooxidation reaction can be inhibited, and the tensile strength and the high temperature resistance are improved; meanwhile, the light resistance, the low temperature resistance and the thermal stability of the polyvinylidene fluoride molecules are improved, the problem that the waste polyvinylidene fluoride plastic is seriously aged, and the performance of the prepared plastic product is reduced is solved; and the quality problems such as surface defects caused by adding of a filler and the like are eliminated, and the low temperature resistance and the flexibility of the material are improved.

Owner:界首市宏茂塑业有限公司

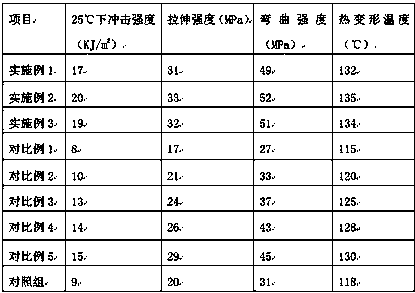

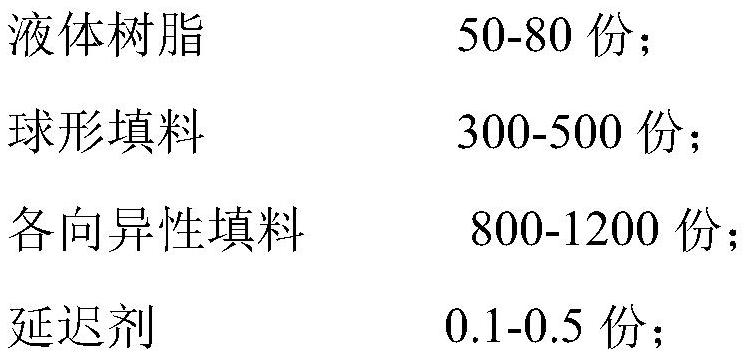

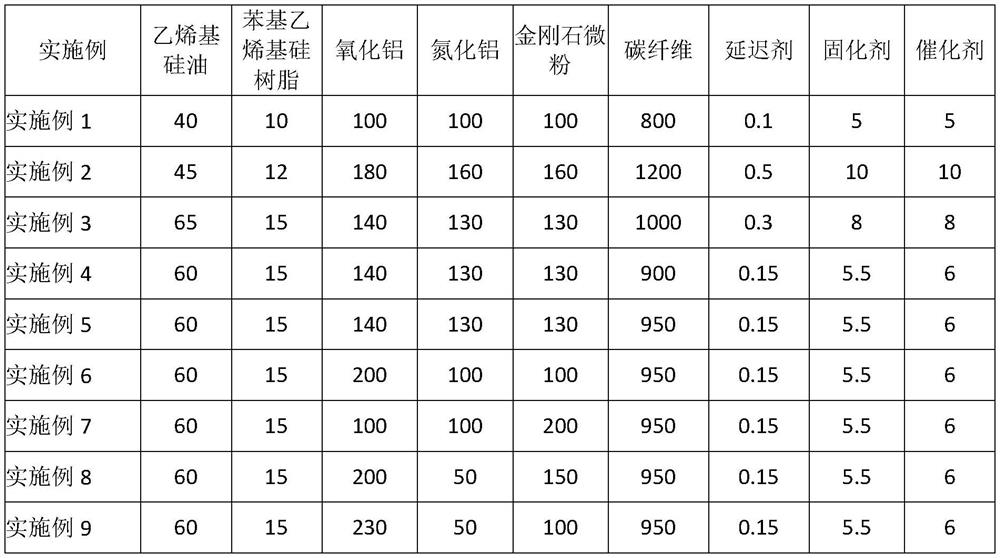

Oriented heat-conducting gel as well as preparation method and application thereof

PendingCN114106564AIncrease extrusion rateImprove thermal conductivityHeat-exchange elementsModifications by conduction heat transferPolymer chemistryLiquid resin

The invention relates to the field of thermal interface materials, and particularly discloses oriented heat-conducting gel as well as a preparation method and application thereof. The oriented heat-conducting gel group comprises the following raw materials: liquid resin, a spherical filler, an anisotropic filler, a retarder, a curing agent and a catalyst; the preparation method comprises the following steps: coating the oriented heat-conducting gel on a heat dissipation interface of a heating device of an electronic product in a dispensing manner, wherein the oriented heat-conducting gel exists on the heat dissipation interface of the electronic product in a glue point form; then the heat dissipation device is attached to the heating device through the viscidity of the orientation type heat conduction gel; and finally, curing and forming the oriented heat-conducting gel in a thermocuring or normal-temperature curing manner. The oriented heat-conducting gel can be used in the field of heat dissipation of electronic products. According to the oriented heat-conducting gel disclosed by the invention, the spherical filler and the anisotropic heat-conducting filler are reasonably proportioned and dispersed in the liquid resin, so that the prepared oriented heat-conducting gel has excellent heat-conducting property and also keeps relatively good extrusion property.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

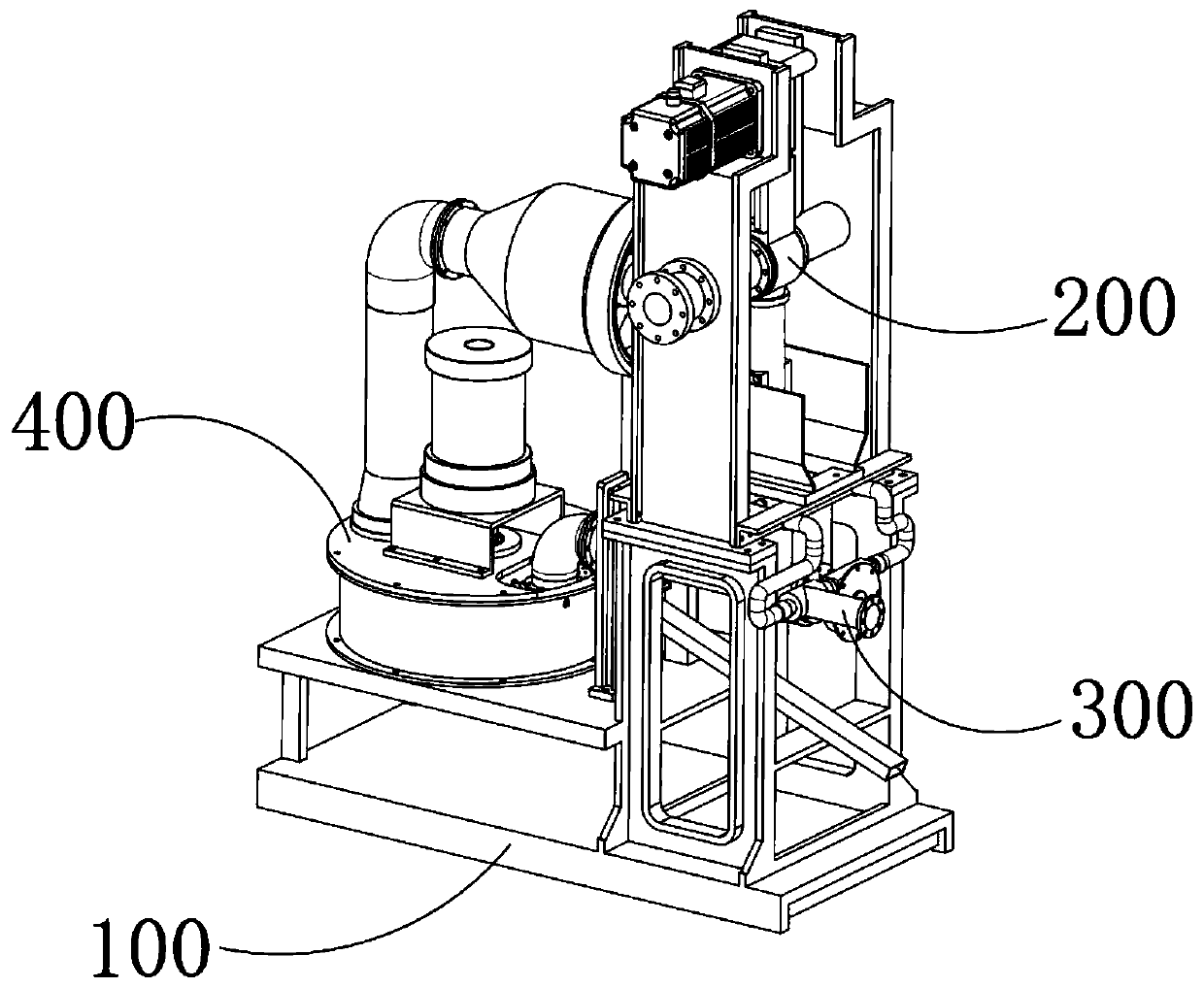

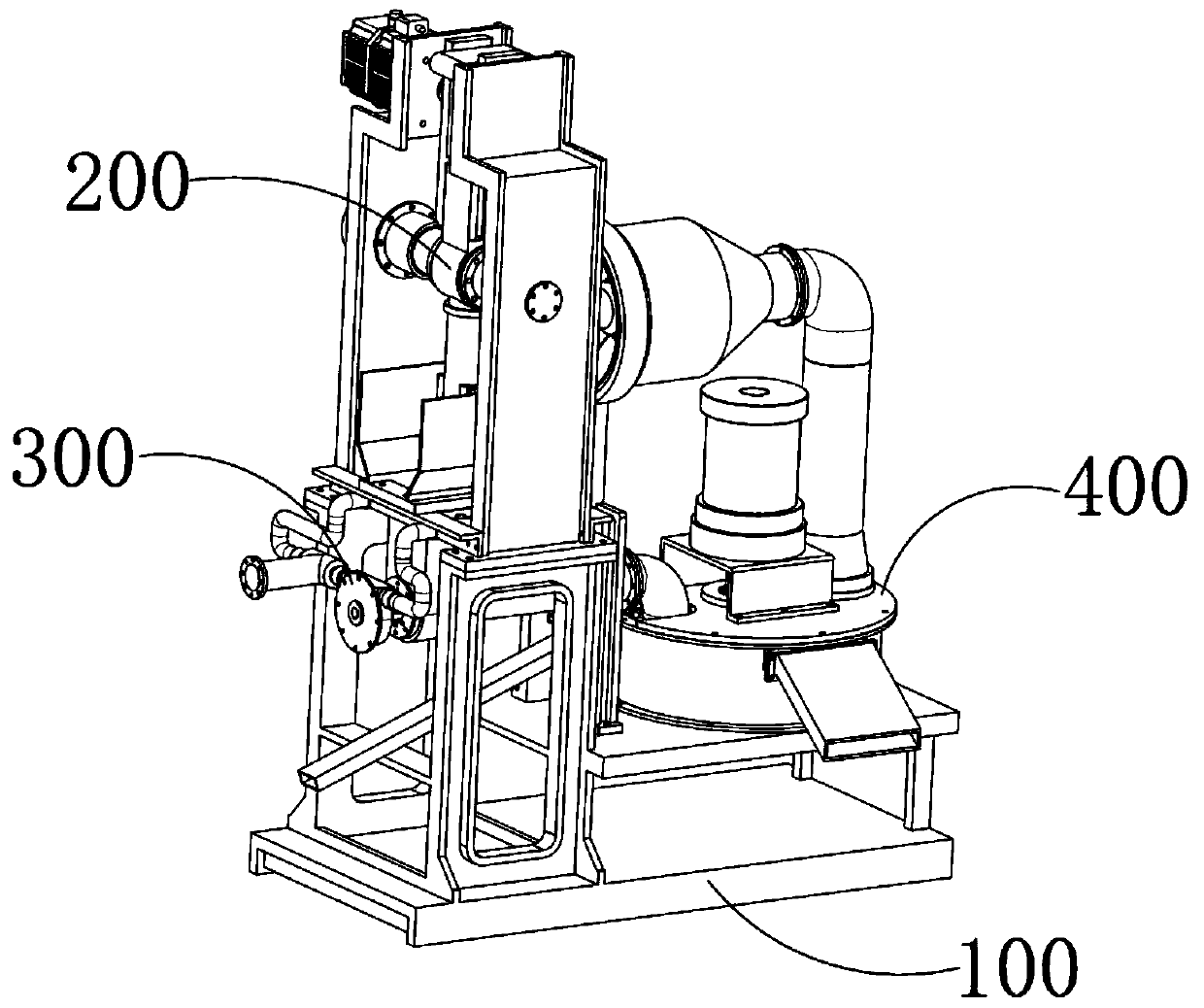

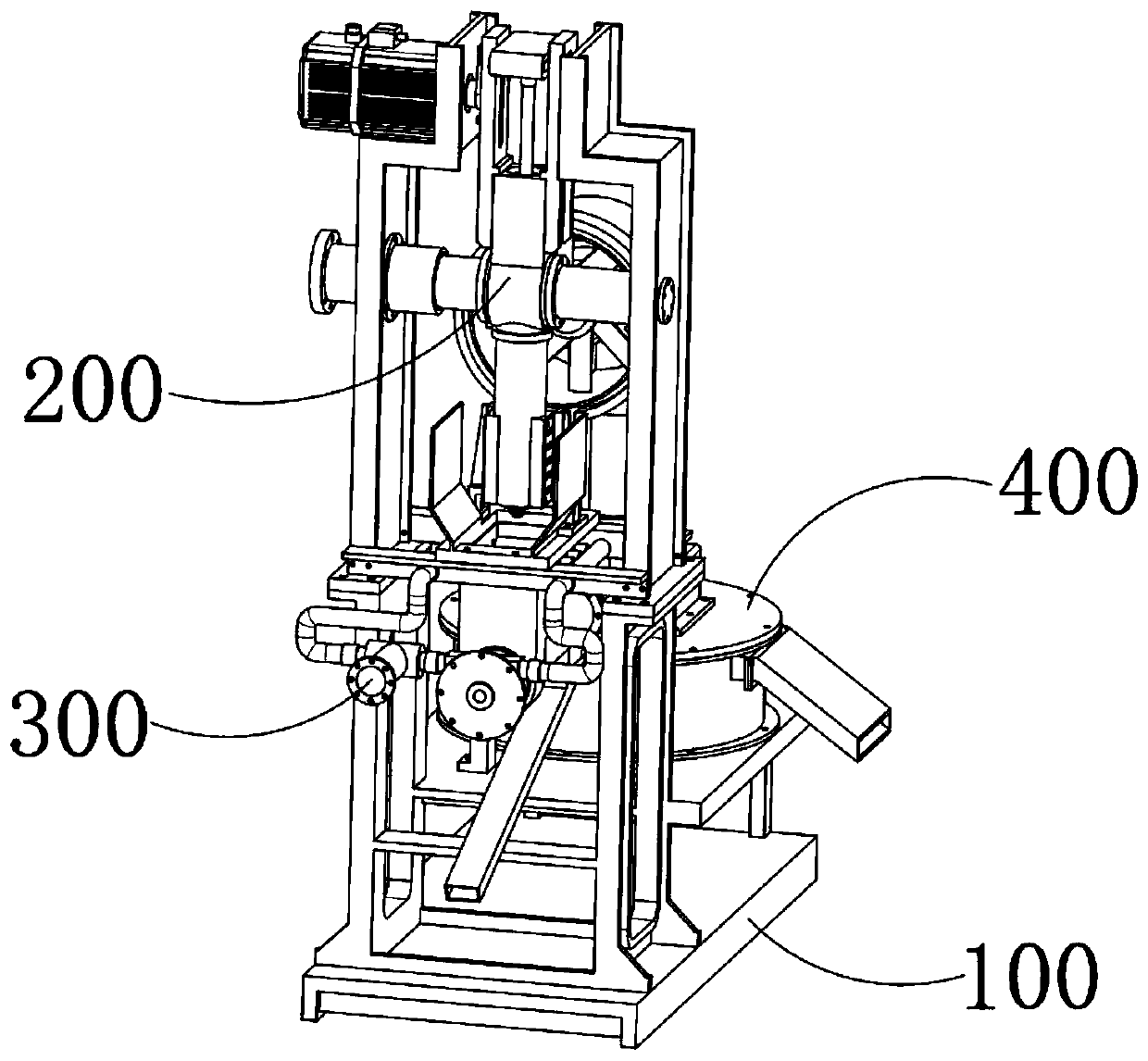

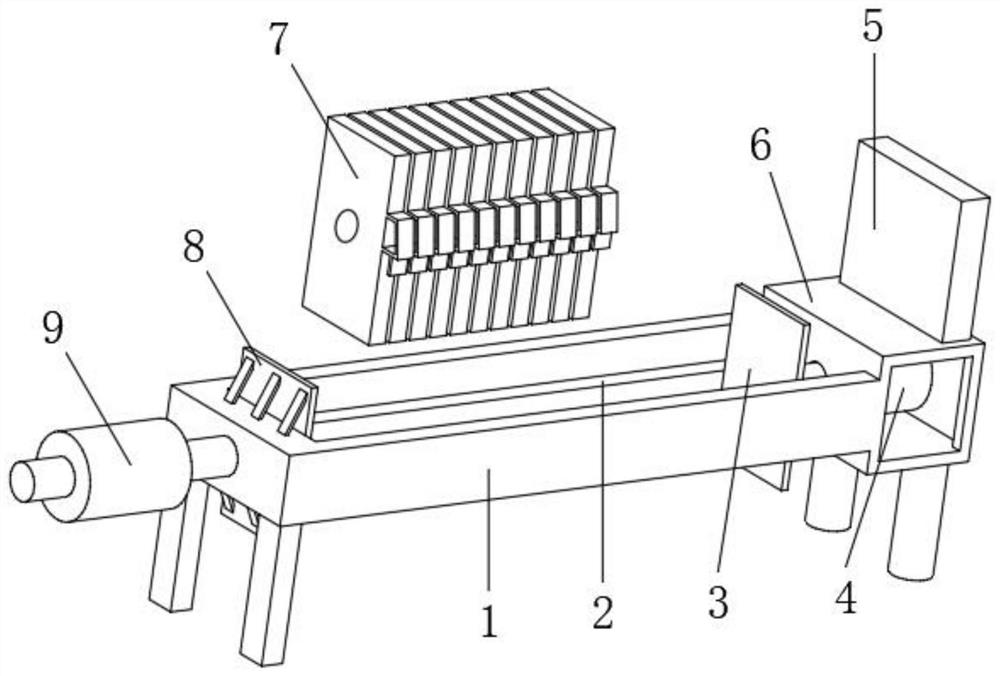

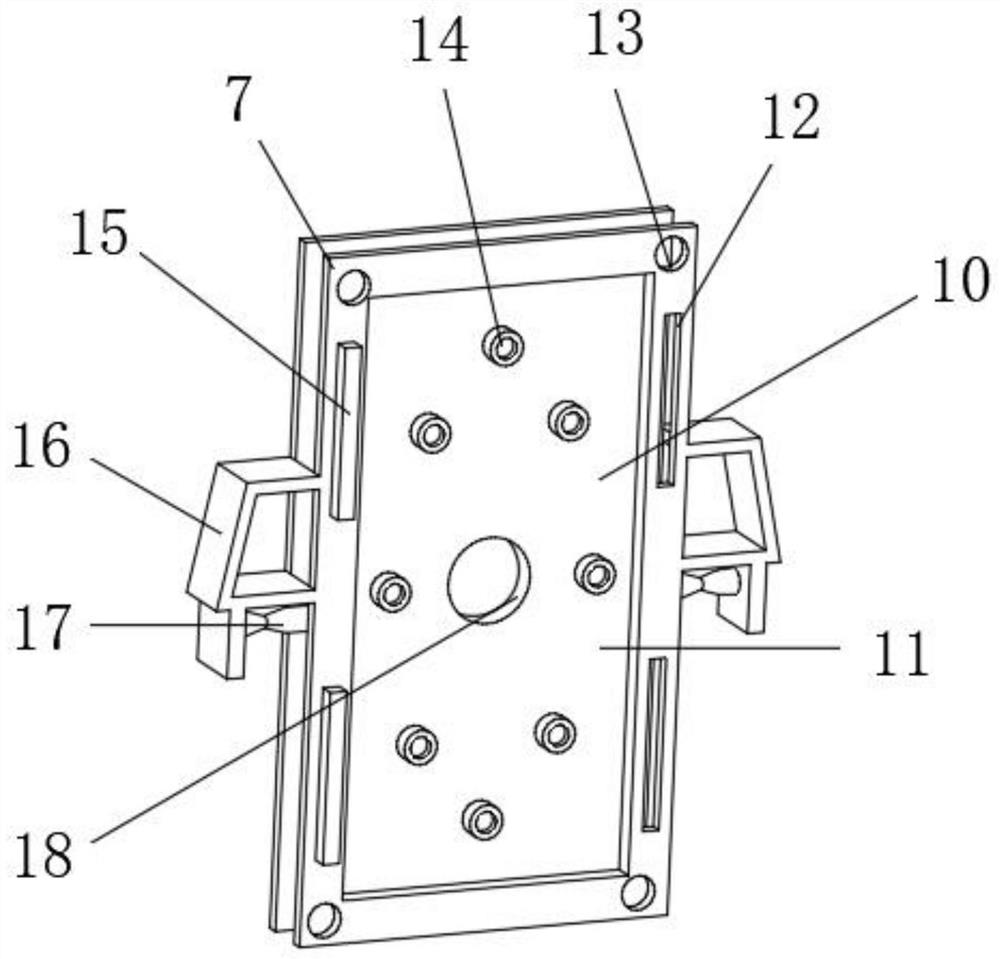

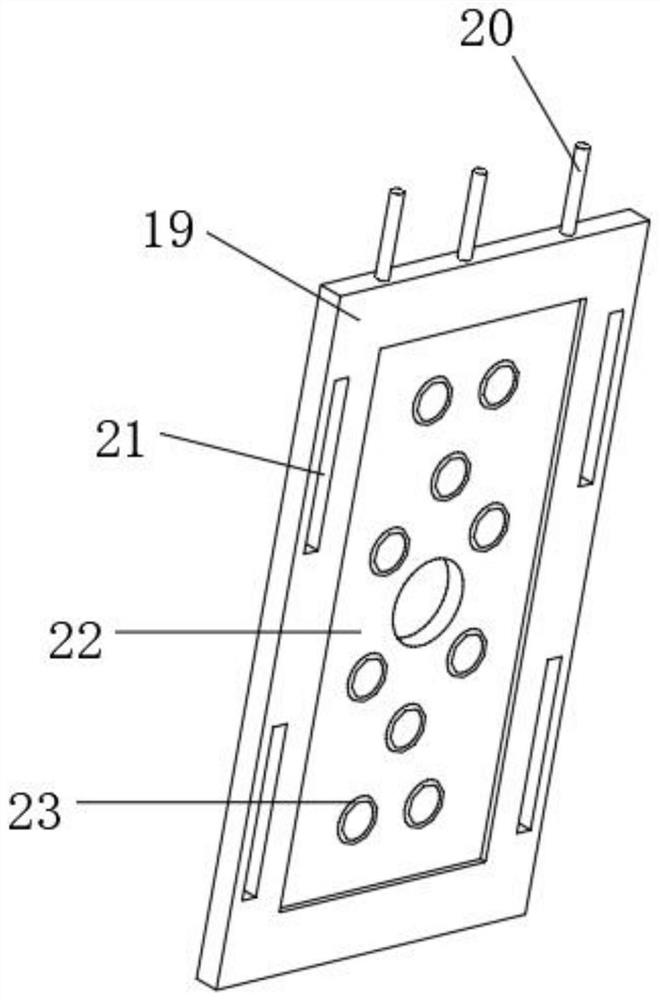

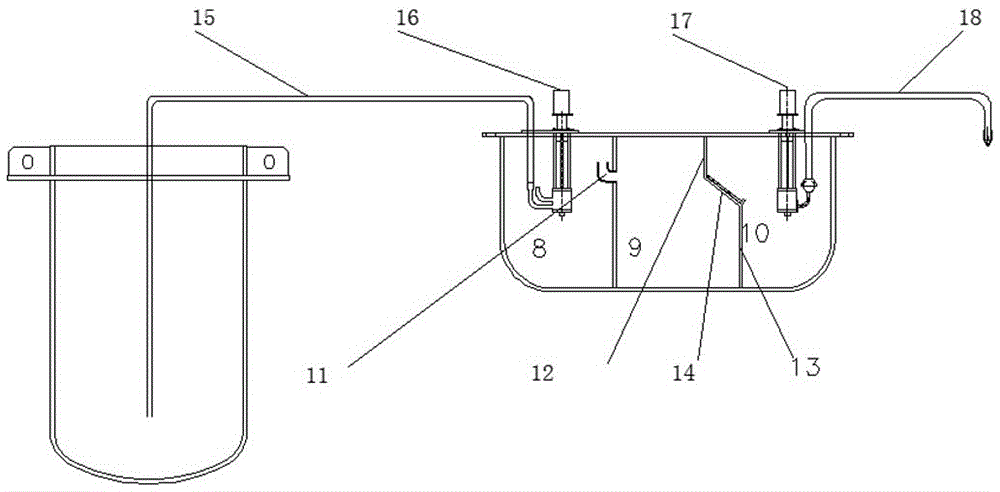

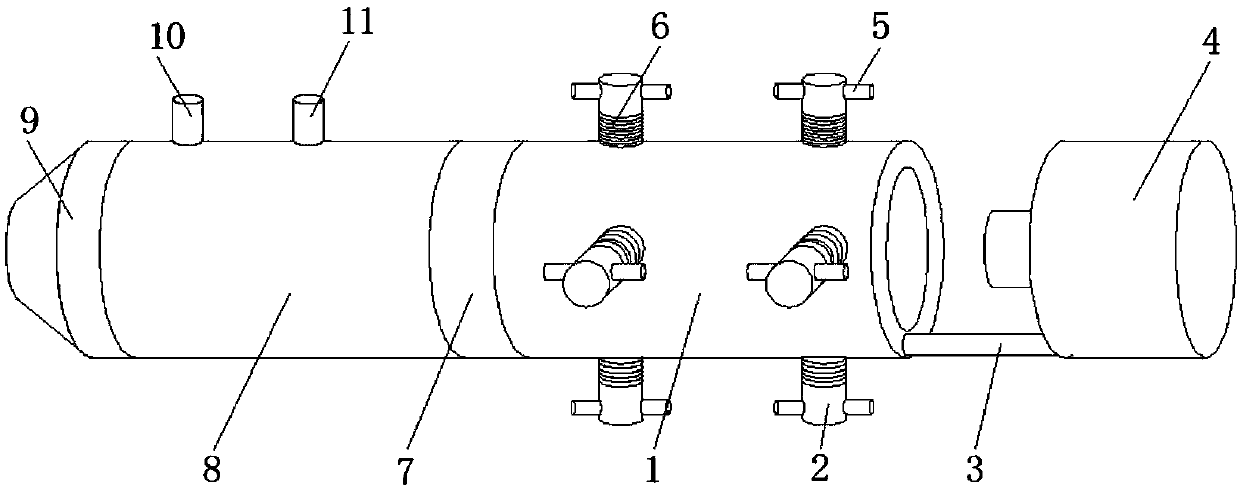

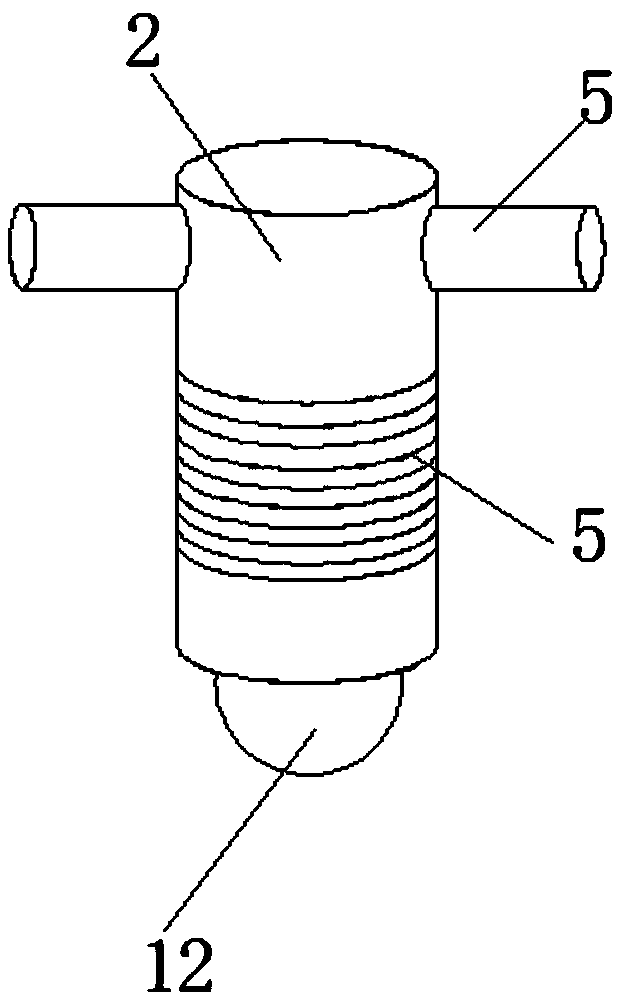

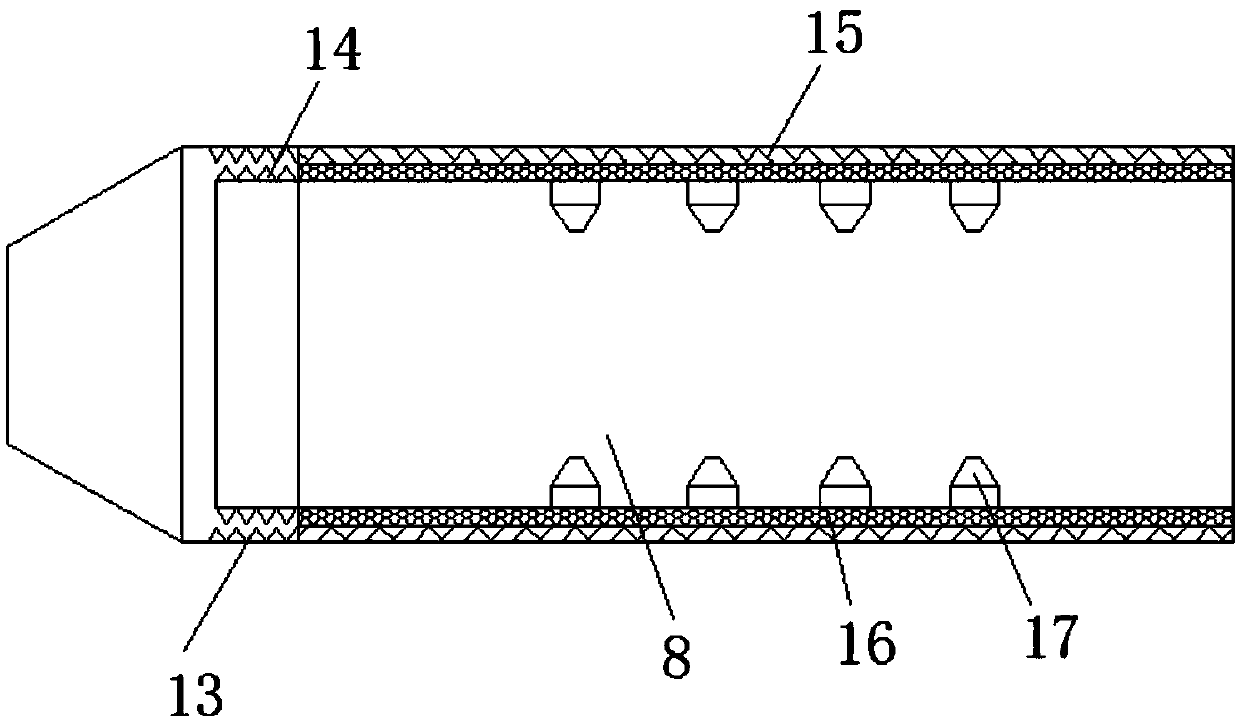

Full-automatic diaphragm filter press

ActiveCN113828022AEven by forceIncrease extrusion rateFiltration circuitsStructural engineeringFilter press

The invention belongs to the technical field of diaphragm filter presses, particularly relates to a full-automatic diaphragm filter press, and aims to solve the problems that a filter cake is insufficient in dehydration and a diaphragm hole is easy to block due to the fact that a filter cake is in a shape with a thin middle part and a thick periphery due to the mounting position of an existing diaphragm. The full-automatic diaphragm filter press comprises a main beam, and one end of the main beam is fixedly provided with a hollow frame; supporting legs are fixedly mounted at the bottom ends of the main beam and the hollow frame, guide rods are fixedly mounted on the two sides of the interior of the main beam, and a plurality of filter plates are placed at the top ends of the two guide rods. According to the invention, airflow is simultaneously conveyed to each corner in the diaphragm through the hose in the diaphragm and the plurality of S-shaped branch pipes, so that each part of a filter cake is uniformly stressed when the diaphragm is bulged and compressed, and the plurality of magnetic rings at the two ends of the diaphragm and the suction blocks of the two filter plates attract each other; the diameter of the magnetic ring is smaller than that of the sleeve, so that the two ends of the diaphragm are attracted by magnetic force to uniformly expand and extrude the filter cake during air blowing, and the extrusion rate of the filter cake is increased.

Owner:江苏沙英喜实业有限公司

Wood plastic composite material and its preparation method and application

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of outer layer rubber of high temperature resistant flexible rubber hose

Owner:LUOHE BONWELL RUBBER

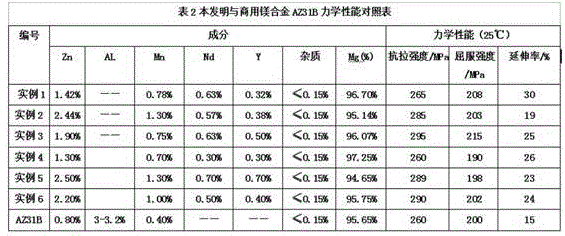

A high plasticity rare earth deformed magnesium alloy

The invention discloses a high-ductility rare earth wrought magnesium alloy Mg-Zn-Mn-Nd-Y. The magnesium alloy is prepared from the following components in percentage: 1.3-2.5% of Zn, 0.7-1.3% of Mn, 0.3-0.7% of Nd, 0.3-0.7% of Y, and the balance of magnesium and unavoidable impurities. In the high-ductility rare earth wrought magnesium alloy disclosed by the invention, Mn, Nd and Y are added based on the low alloyed Mg-Zn system to refine grains, so as to improve the strength at room temperature, heat stability and plastic forming performance; the hot extrusion performance of the alloy is better than that of an AZ31 alloy, the alloy is good in hot working plasticity, and capable of being quickly subjected to compressional deformation; at the room temperature, the tensile strength is 260-295 MPa, the yield strength is 190-208 MPa, and the ductility is 19-30%. When used for industrial production, the high-ductility rare earth wrought magnesium alloy can be extruded and machined to obtain a plate, a bar, a pipe, a profile and a forge piece product with diversified sizes.

Owner:SHANXI BADA MAGNESIUM

Thermal shrinkable flexible conductive tube and production process thereof

ActiveCN102254590AImprove insulation performanceHigh elongationNon-insulated conductorsCable/conductor manufacturePolyethylene terephthalate glycolConductive polymer

The invention discloses a thermal shrinkable flexible conductive tube and a production process thereof, belongs to the technical field of cables and in particular relates to a tube bus matched product. According to a formula, the thermal shrinkable conductive tube is characterized by comprising the following raw materials in part by mass: 50 to 60 parts of high polymer, 30 to 40 parts of conductive filler, 5 to 10 parts of white oil, 5 to 10 parts of polyurethane (PE) wax, 5 to 10 parts of phosphate, 1 to 5 parts of sodium benzoate and 1 to 2 parts of antioxidant. The high polymer obtained bypreheating, melting and mixing an ethylene vinyl acetate (EVA) hot melt adhesive and polyethylene terephthalate (PET) has a smooth and glossy surface, excellent electric insulativity and a higher electrical property at a high temperature and high frequency. Special conductive carbon black serves as the conductive filler, so the conductive filler has higher conductive performance due to a meshed structure; and when the conductive filler is mixed with the other raw materials, the conductive performance of the thermal shrinkable flexible conductive tube is improved.

Owner:山东七星电气科技发展有限公司

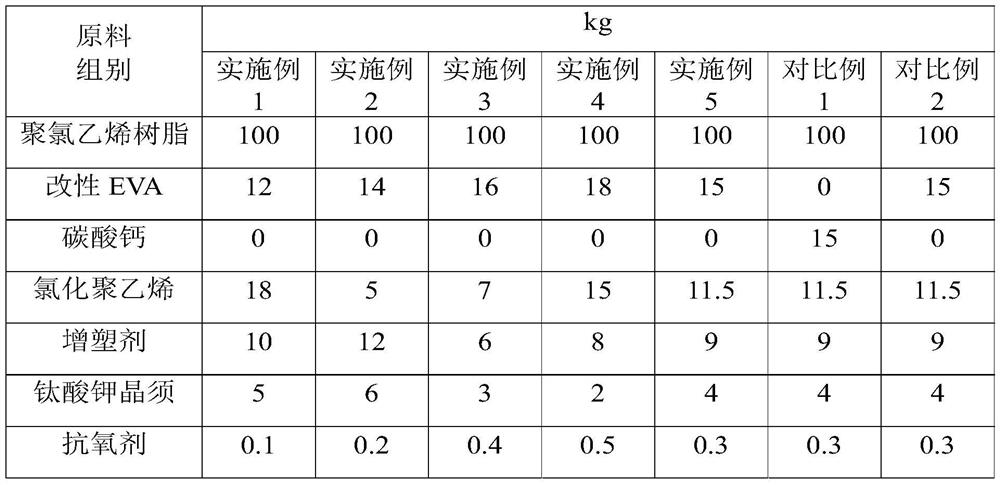

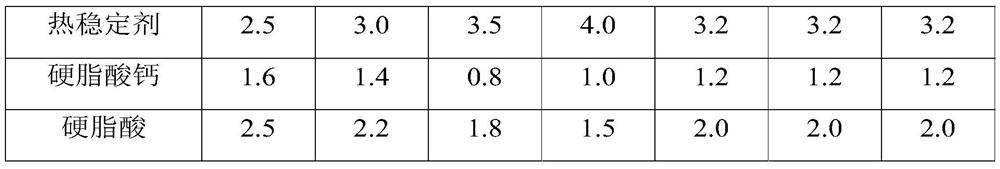

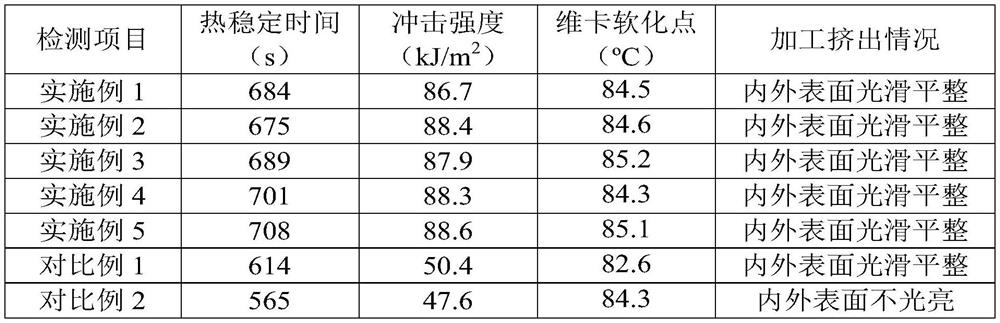

A kind of rapidly prototyping PVC-U pipe material and preparation method thereof

The invention discloses a rapidly prototyping PVC-U pipe and a preparation method thereof. The raw materials for preparing the rapidly prototyping PVC-U pipe include: 100 parts of polyvinyl chloride resin, 12-18 parts of modified EVA, chlorine 5-18 parts of polyethylene, 6-12 parts of plasticizer, 2-6 parts of potassium titanate whiskers, 0.1-0.5 parts of antioxidant, 2.5-4.0 parts of heat stabilizer, stearic acid 0.8-1.6 parts of calcium, 1.5-2.5 parts of stearic acid. The rapidly formed PVC-U pipe material prepared by the present invention has excellent thermal stability and impact resistance, has little adhesion with equipment during processing, is easy to process and form rapidly, and has a simple preparation method, easy operation of the preparation process, and economic benefits. good.

Owner:泉州兴源新材料科技有限公司

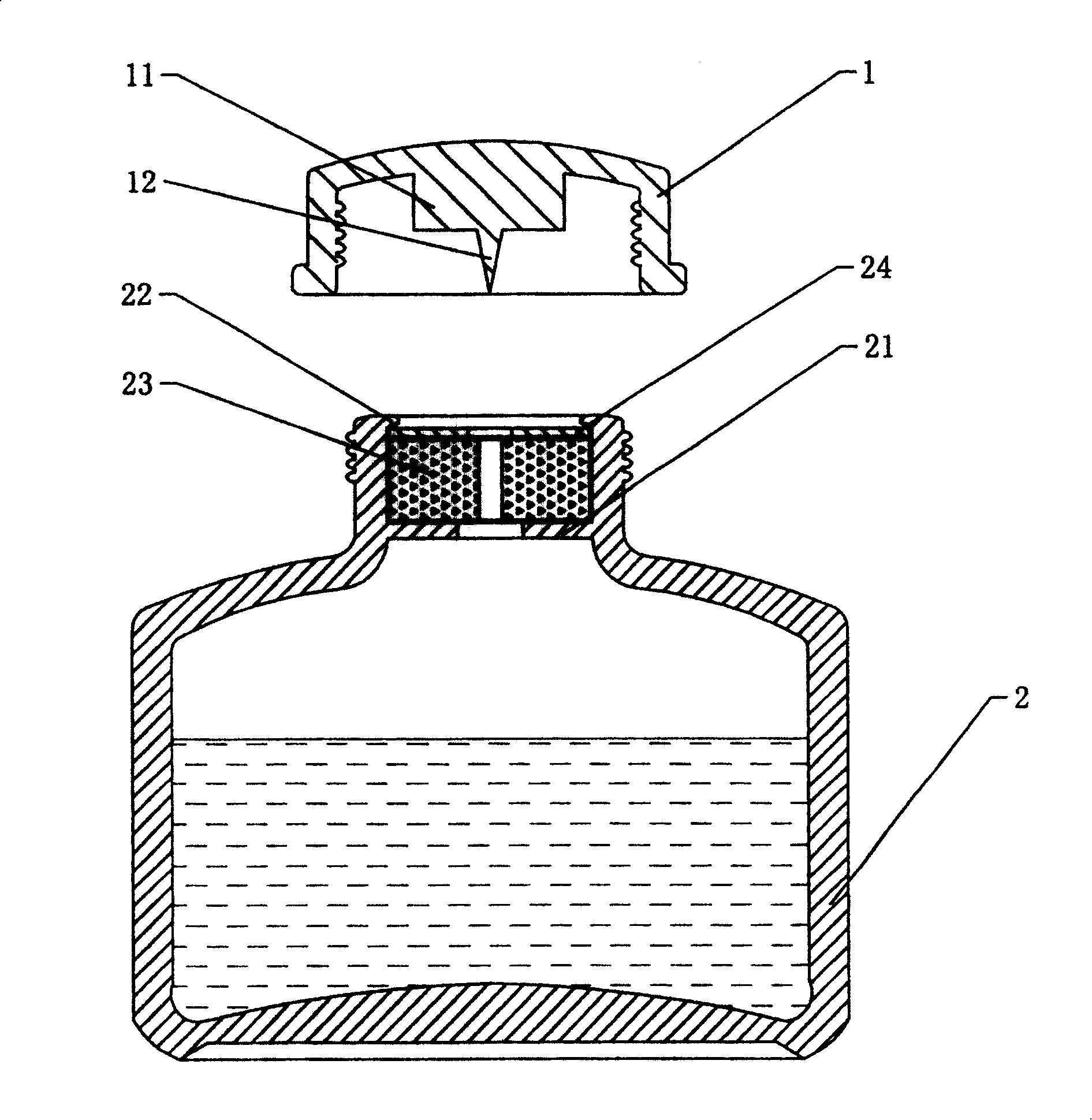

Clean ink bottle

The clean ink bottle includes one bottle body and one bottle cap to seal the bottle mouth. The bottle mouth has two ring flanges extending to the center separately in the bottom and the top, and one ink absorbing block of elastic ink absorbing material, with central hole and held with the ring flanges. The present invention can solve the problem of ink attachment onto the sucked pen shaft, avoid waste of ink and facilitate the ink sucking operation.

Owner:张洪梅

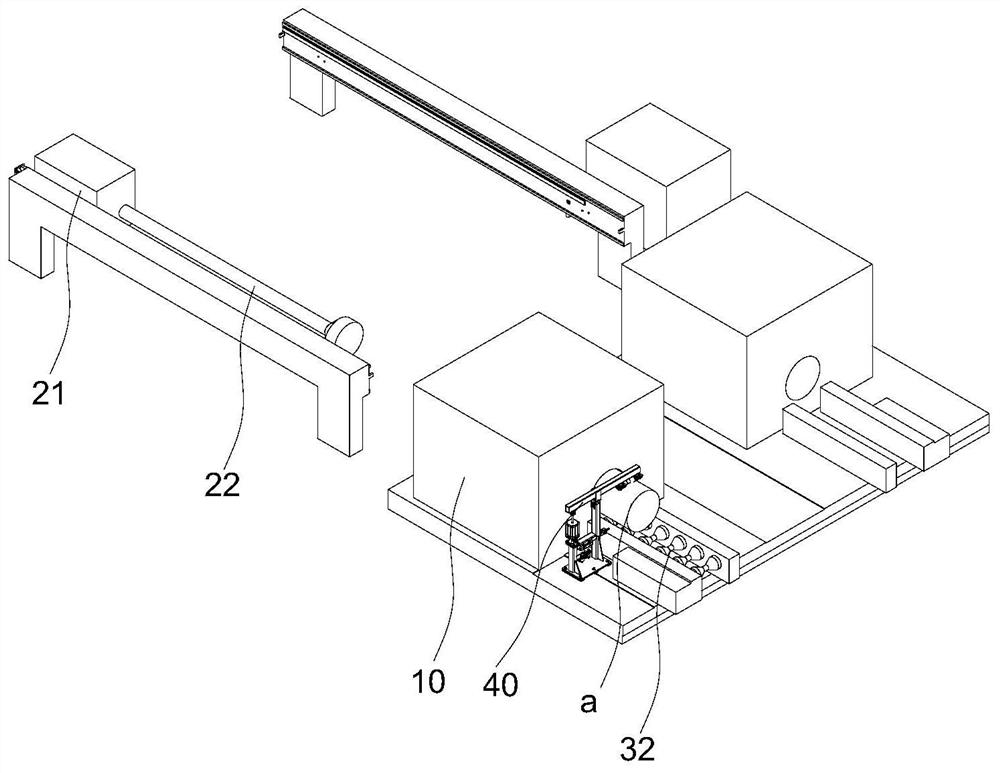

Extrusion device and technology for noble metal processing

The invention discloses an extrusion device and technology for noble metal processing. The extrusion device comprises a feeding pipe; the bottom end of one side of the feeding pipe is provided with arotary cylinder through a connection rod; the two sides of the feeding pipe are provided with regulation studs respectively; one side of the feeding pipe is provided with a connection pipe; one side of the connection pipe is provided with a heating pipe; one side of the top of the heating pipe is provided with a first gas inlet pipe; and the other side of the top of the heating pipe is provided with a second gas inlet pipe. For the extrusion device and technology, through matching of arranged first outside threads and first inside threads, the regulation studs are rotated, and a distance between rolling balls can be regulated, so that the purpose of fixing circular pipes in different sizes is realized; coal gas is connected into the arranged first gas inlet pipe, and oxygen is connected into the arranged second gas inlet pipe, so that the combustion rate of the coal gas is increased, and the coal gas is sprayed out through a fire jetting head; and the arranged rotary cylinder drives anoble metal circular pipe to gradually perform rotation movement toward the interior, so that the noble metal circular pipe can be uniformly heated.

Owner:山东金艺珠宝有限公司

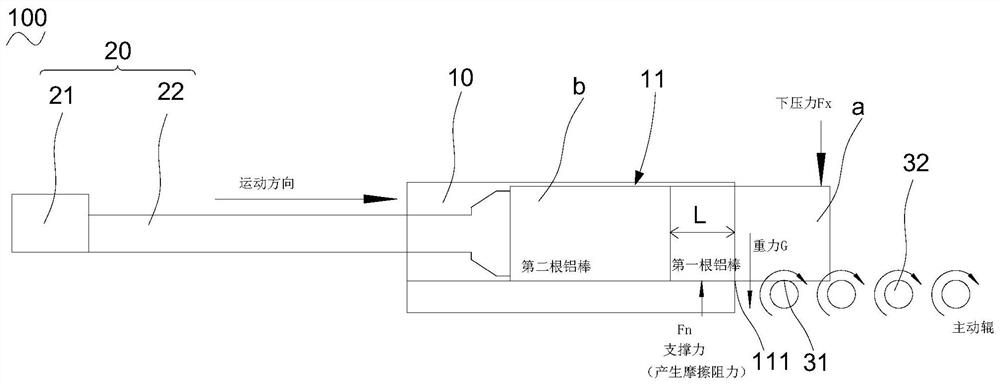

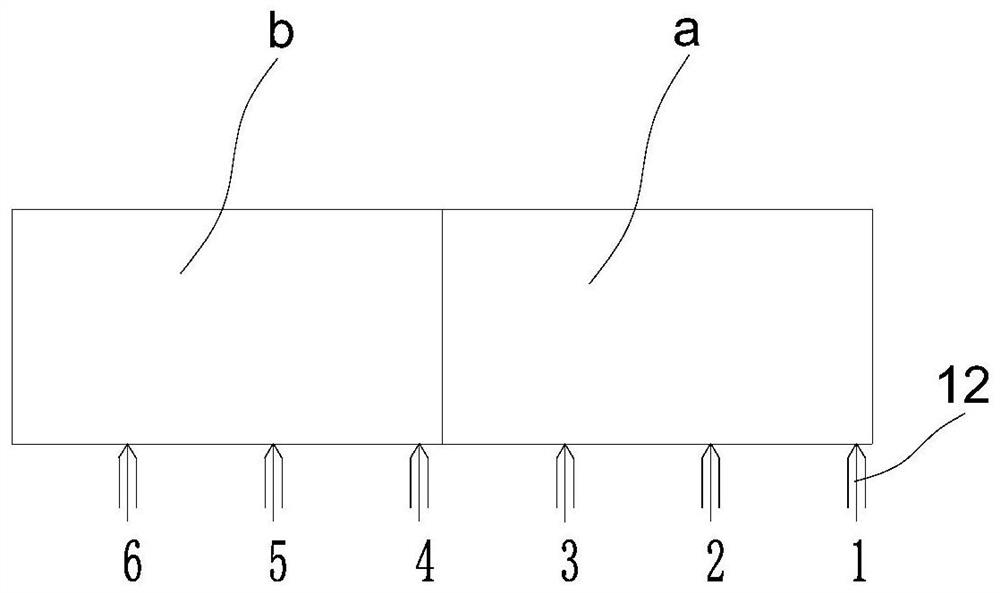

Extrusion production line and its control method

The invention relates to an extrusion production line and a control method thereof, comprising: a heating furnace provided with a heating chamber inside, the heating chamber can accommodate at least two raw materials along its extending direction; a pushing mechanism and a feeding mechanism, the pushing mechanism is used At least two raw materials accommodated in the heating chamber are pushed to move towards the direction close to the feeding mechanism, and the feeding mechanism is used to send the raw materials on it to the extruder; the pushing mechanism can push the first raw material relatively close to the feeding mechanism. The first part of the raw material moves to the feeding mechanism, and the second part of the first raw material stays in the heating chamber; the pressing mechanism, the pressing mechanism can apply a downward force towards the feeding mechanism on the first part, and in the feeding mechanism Under the action of power and downward pressure, the first raw material is completely moved out of the heating chamber; the feeding mechanism has a first bearing surface for bearing the first part, and the heating chamber has a second bearing surface for bearing the second part. The height of the surface is higher than the height of the second bearing surface.

Owner:SNTO TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com