Patents

Literature

260results about How to "No hardening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

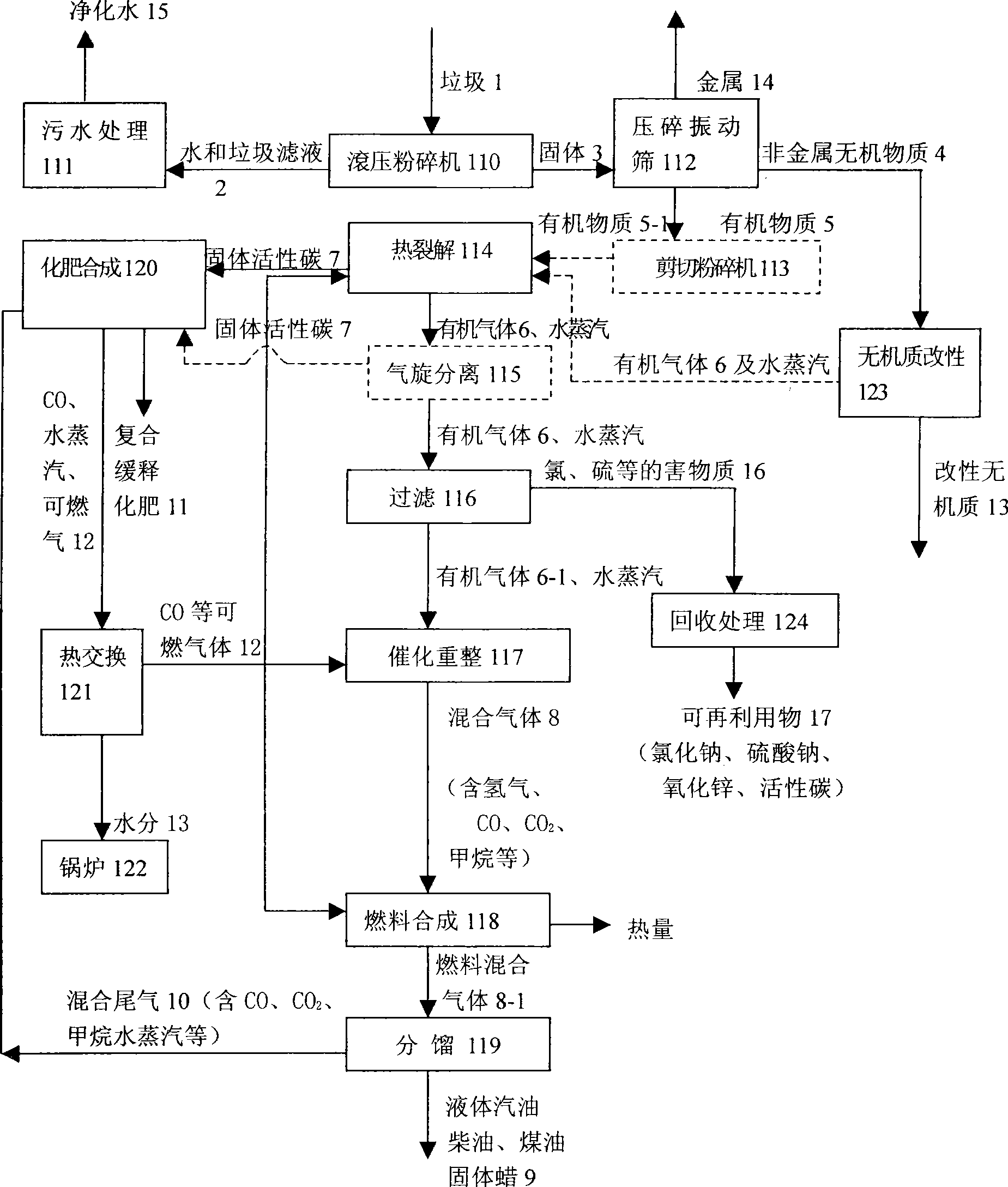

Energy sources regeneration of urban domestic garbage and non-waste comprehensive utilization processing technique

InactiveCN101433904AEffective generationAchieve conversionWaste processingSolid waste disposalFiltrationFuel oil

The invention relates to a manufacturing technique for energy regeneration and non-waste comprehensive utilization of municipal domestic waste, which is characterized by comprising the steps of waste classification, pretreatment and treatment of nonmetallic inorganic substances, schizolysis, filtration and reforming of organic substances, synthesis of fuel oil and treatment of organic substance byproducts. The manufacturing technique completely treats waste, has no secondary pollution during the whole treatment, and really realizes complete conversion and utilization of the waste. When the technology is used for treating organic substance waste and so on, including organic substance parts of the municipal domestic waste and various animal and plant waste, not only the environmental problem caused by the municipal domestic waste and the waste problem of the waste can be solved but also energy and slow release fertilizer which returns to earth can be efficiently generated, so that green circulation of renewable energy resources is realized. The applied proposal has reasonable energy consumption in the whole process, has no pollution, has controllable products, high output value and stable and reliable sources of raw materials, and realizes sustainable development.

Owner:深圳开普蓝生能源环保有限公司

Fermented organic fertilizer

InactiveCN104744087AReduce usageImprove filtration efficiencyBio-organic fraction processingOrganic fertiliser preparationMicrobial agentCorn meal

The invention discloses a fermented organic fertilizer. The fermented organic fertilizer comprises the following components in parts by mass: 1000-1500 parts of stalk, 1000-1300 parts of chicken manure, 1000-1500 parts of cattle manure, 800-1200 parts of pig manure, 1200-1800 parts of soybean meal, 35-50 parts of a microbial agent, 10-20 parts of peat humic acid, 50-80 parts of corn meal, 60-90 parts of composite enzyme preparation and 30-60 parts of complex bacteria. The invention also discloses a fermentation method of the fermented organic fertilizer. As the method adopts the microbial bacteria and the composite enzyme preparation, the fermentation efficiency is improved, the fermentation time is effectively reduced, the consumption amount of water, electricity and steam is reduced, the production cost is lowered, and the method is suitable for industrial large-scale production; the fermented organic fertilizer disclosed by the invention has no malodor when used in fields, is cost-saving due to the reduction in the consumption, does not result in soil impoverishment, hardening and salinization, and meets the trend of energy-saving, environment-friendly and sustainable development.

Owner:福建亚森农业综合开发股份公司

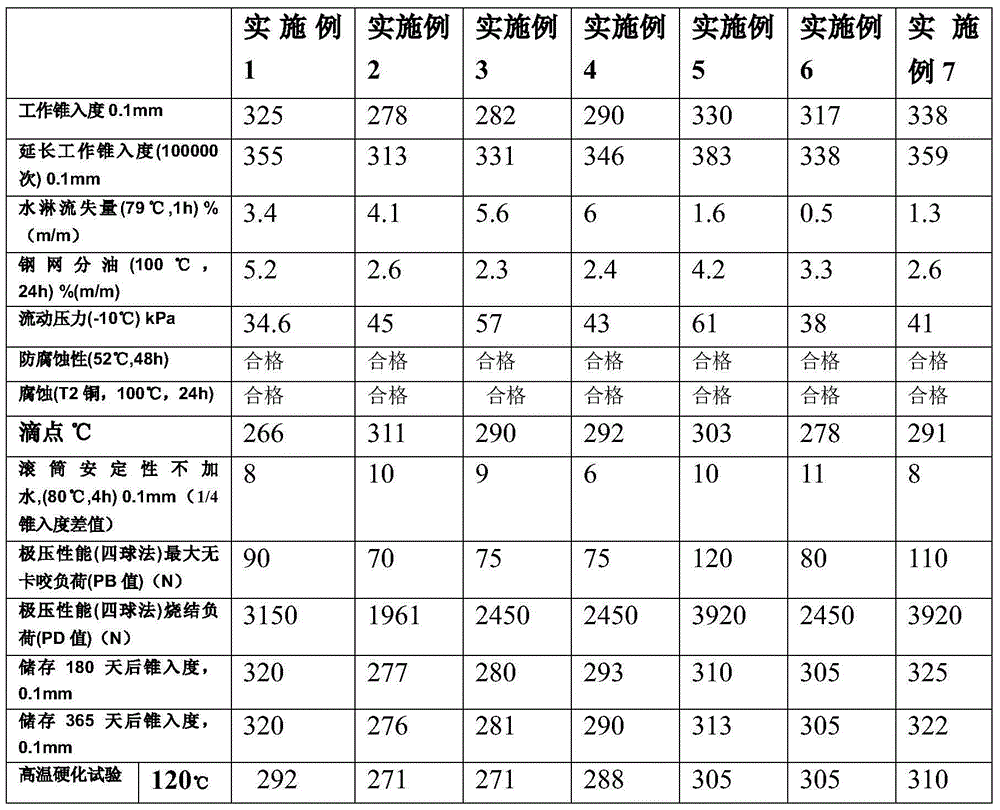

Lithium-calcium complex lubricating grease composition and preparation method

InactiveCN104449983AGood mechanical stabilityGood colloidal stabilityLubricant compositionLithium soapLong chain fatty acid

The invention relates to a lithium-calcium complex lubricating grease composition and a preparation method. The lubricating grease comprises the following components: (1) 60%-87% of base oil; (2) 10%-38% of a thickening agent; and (3) 1.5%-11% of an additive, wherein the thickening agent disclosed by the invention is a lithium-calcium complex thickening agent, comprises one or more long-chain fatty acid lithium soap and one or more micromolecular acid calcium soap, and is obtained from the reactants of acid and lithium hydroxide and calcium hydroxide. The lithium-calcium complex lubricating grease prepared by the method has good mechanical stability, colloid stability, water resistance and good extreme pressure antiwear property; and above all, the hardening phenomenon is not generated under room-temperature long-term storage and high-temperature (120 DEG C) conditions on the basis that excellent performances of the original lithium-calcium complex lubricating grease are reserved.

Owner:CHINA PETROLEUM & CHEM CORP

Long-acting slow release fertilizer for grapes

The invention relates to the technical field of agricultural fertilizer, and particularly relates to a long-acting slow release fertilizer for grapes. The long-acting slow release fertilizer comprises the following components in parts by mass: 32-40 parts of nitrogen, phosphorus and potassium, 25-30 parts of organic matter, 10-15 parts of calcium, magnesium and sulfur serving as secondary elements, 4-5 parts of trace element, 0.1-0.3 part of polyacrylamide, 0.01-0.03 part of a soil conditioner, 0.08-0.15 part of a fertilizer synergist, 0.01-0.03 part of a fertilizer controlled-release agent and 3-6 parts of bentonite. By adopting the long-acting slow release fertilizer for grapes provided by the invention, the effective time of the fertilizer is long, the yield and the quality of the grapes are greatly improved, the pulp is delicious, the nutrition is abundant, soil hardening is avoided, the grape plant grows vigorously, and the disease and insect resistance is strong.

Owner:丹阳市现代生态水产养殖场

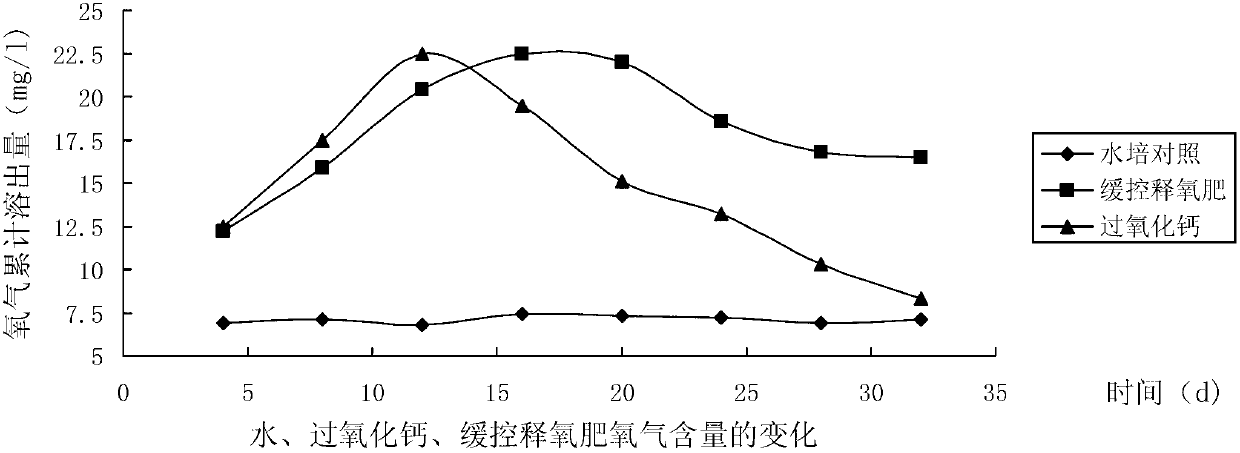

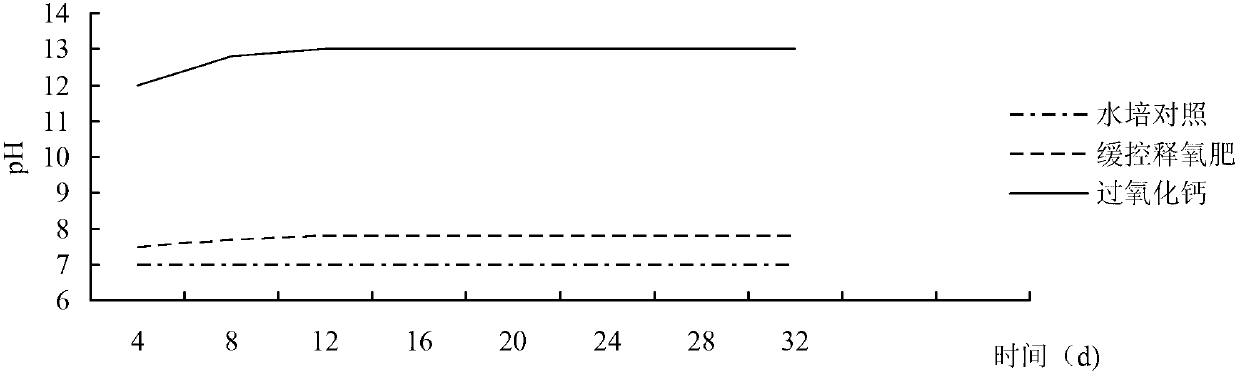

Sustained oxygen release fertilizer and preparation method thereof

InactiveCN102924176AMaintain physiological metabolismMaintain normal growth and developmentFertilizer mixturesPolyvinyl alcoholSuperoxide

The invention discloses a sustained oxygen release fertilizer which adopts a mixture comprising calcium superoxide, sodium bentonite and polyvinyl formal. The mass ratio of sodium bentonite to calcium superoxide is 12 to 5, and the mass of the polyvinyl formal is 15 percent of the gross mass of the sustained oxygen release. The sustained oxygen release fertilizer discusses the oxygen release feature and the pH value variation in the condition of aqueous medium. Experimental results show that compared with applying calcium superoxide powder only, the sustained oxygen release fertilizer has the characteristics that the fertilizer effect period is long, the applying method is simple, the production technology is simple, the source of material selected is wide, the material is environmentally friendly, and the sustained oxygen release fertilizer can be widely applied.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Agrocybe cylindracea waste residues and livestock and fowl manure fermented organic fertilizer

InactiveCN104892139AReduce dosageDoes not cause barrennessFertilizer mixturesMicroorganismOrganic fertilizer

The invention discloses an agrocybe cylindracea waste residues and livestock and fowl manure fermented organic fertilizer, a raw material formula of which comprises the following ingredients, by weight, 3000-3500 parts of agrocybe cylindracea waste residues, 400-600 parts of straw, 100-150 parts of plant ash, 120-300 parts of soil of humic acid, 150-200 parts of turf, 4000-5500 parts of chicken manure, 800-1200 parts of pig manure, 200-300 parts of wormcast, 160-200 parts of composite microbial inoculants and 80-120 parts of a complex enzyme preparation. According to the agrocybe cylindracea waste residues and livestock and fowl manure fermented organic fertilizer, organic wastes and agrocybe cylindracea waste residues are degraded. When the fermented organic fertilizer is used, there is no foul smell in the field, and consumption of the fertilizer can be reduced. Cost is saved, and depletion, hardening and salinization of soil will not be caused. The agrocybe cylindracea waste residues and livestock and fowl manure fermented organic fertilizer conforms to the trends of energy conservation, environmental protection and sustainable development.

Owner:RUIJIN XIANGRUI BIOTECH CO LTD

Turbine cylinder block sealing surface repairing process

The invention relates to the field of steam turbines, in particular to a turbine cylinder block sealing surface repairing process. According to the turbine cylinder block sealing surface repairing process, adopted cold metal transition (CMT) welding is an MIG / MAG additive manufacturing technique, and the process is used for repairing the turbine cylinder block sealing surface. According to turbinecylinder block materials including P265GH and medium high temperature and high pressure steam, Ni-based alloy welding wire Ni-Cr-Mo is selected as an additive manufacturing material. According to theturbine cylinder block sealing surface repairing process, cold metal transition (CMT) additive manufacturing is used for repairing the sealing surface, operation is easy, the efficiency is high, andthe bonding force is better.

Owner:浙江翰德圣智能再制造技术有限公司

Method for reducing the moisture percentage of wood materials to zero by using paraffin wax heat-treated process

ActiveCN101116984AHigh strengthGood dimensional stabilityWood treatment detailsParaffin waxCooling down

The invention relates to a heat treating method of paraffin wax to reduce the moisture content to the nearest zero, comprising the following steps: firstly, lumber is delivered to a heat treating furnace which comprises a lignum treating chamber, cut into lumber pieces; the pieces then are piled together, the lumber treating chamber is heated then to make the paraffin wax pre-positioned in the treating chamber melt into liquid paraffin wax to submerge the lumber pieces. Then the temperature in the furnace is heated to 140-160 DEG C, for 44 to 58 hours. Resin is added into the furnace to increase the temperature into 175-185 DEG C, for 67 to 77 hours. Heating stopping, the lumber pieces is cooled down to 58-110 DEG C and discharged out of the furnace. The resin takes up 10-50 parts by weight against the 100 parts by weight of the paraffin wax. The lumber after being processed by the method of the invention has a rate of moisture content more than 0 and less than 0.01 percent.

Owner:江阴市青阳世盛老红木家俱厂

Silico-calcium magnesium-potassium mineral multielement compound fertilizer and preparation method thereof

The invention discloses silico-calcium magnesium-potassium mineral multielement compound fertilizer and a preparation method thereof. The mineral multielement compound fertilizer is a water-insoluble dissolving resisting fertilizer prepared based on potassium-rich rock and comprises microelement potassium, secondary element silicon, calcium, magnesium and multiple trace elements, wherein the mass fraction of potassium oxide is larger than or equal to 8%; the total mass fraction of the silica, the calcium oxide and the magnesium oxide is larger than or equal to 5%; the mass fraction of water is less than or equal to 3%; and simultaneously the trace elements are considered. The silico-calcium magnesium-potassium mineral multielement compound fertilizer is the water-insoluble dissolving resisting fertilizer and is characterized by non-infiltration, non-infiltration and non-loss, can not cause the acidification, alkalization and hardening of the soil after being used, can be used as the base fertilizer or top application, and is of great benefit to improving the soil structure and increasing the efficient nutrition components.

Owner:NORTHWEST A & F UNIV +1

Ecological organic fermented fertilizer and preparation method thereof

InactiveCN105967956AHigh degree of harmlessnessGood efficiencyExcrement fertilisersBioloigcal waste fertilisersBacterial agentGermination

The invention discloses an ecological organic fermented fertilizer which comprises the following components in parts by mass: 1,200-1,800 parts of crop waste, 2,500-4,000 parts of composted excrement, 1,600-2,000 parts of river mud, 1,200-1,600 parts of cake meal, 800-1,200 parts of bentonite, 300-600 parts of waste oil residue, 80-200 parts of corn flour, 800-1,200 parts of waste fungus spores and 100-140 parts of microbial fermentation bacterial agent. In the organic fertilizer disclosed by the invention, the damage on the crops and seed germination caused by diseases and pests and the influence on the purity and quality of agricultural products after fertilization are avoided; when in use, foul smell in the field is avoided, the dosage of chemical fertilizer is reduced, the cost is saved, and the soil depletion, hardening and salinization are avoided; after use, the soil fertility is improved, the immunity of agricultural and forestry crops is enhanced, the grain yield increase is realized, and the trends of energy saving, environmental protection and sustainable development are met.

Owner:佛山杰致信息科技有限公司

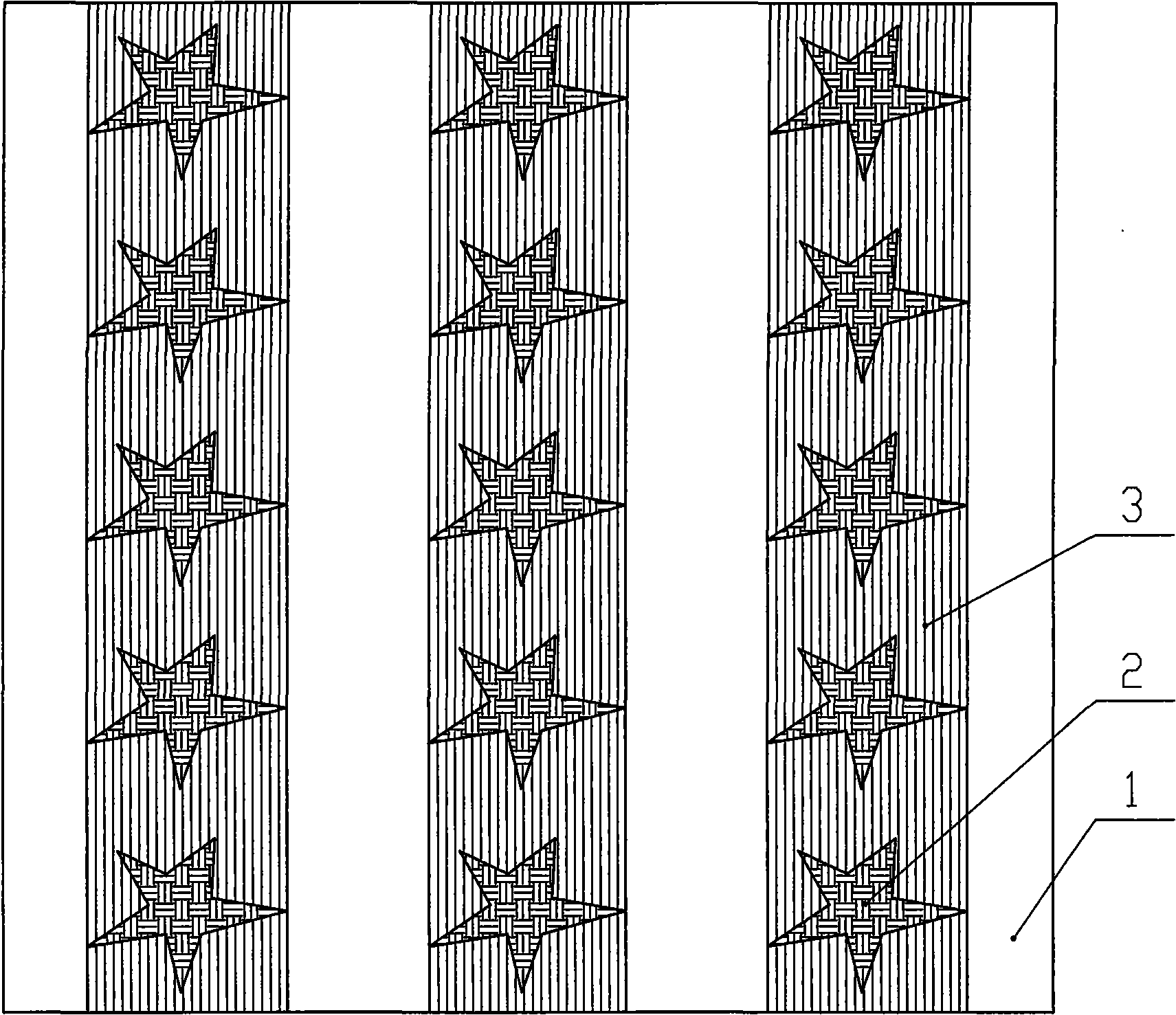

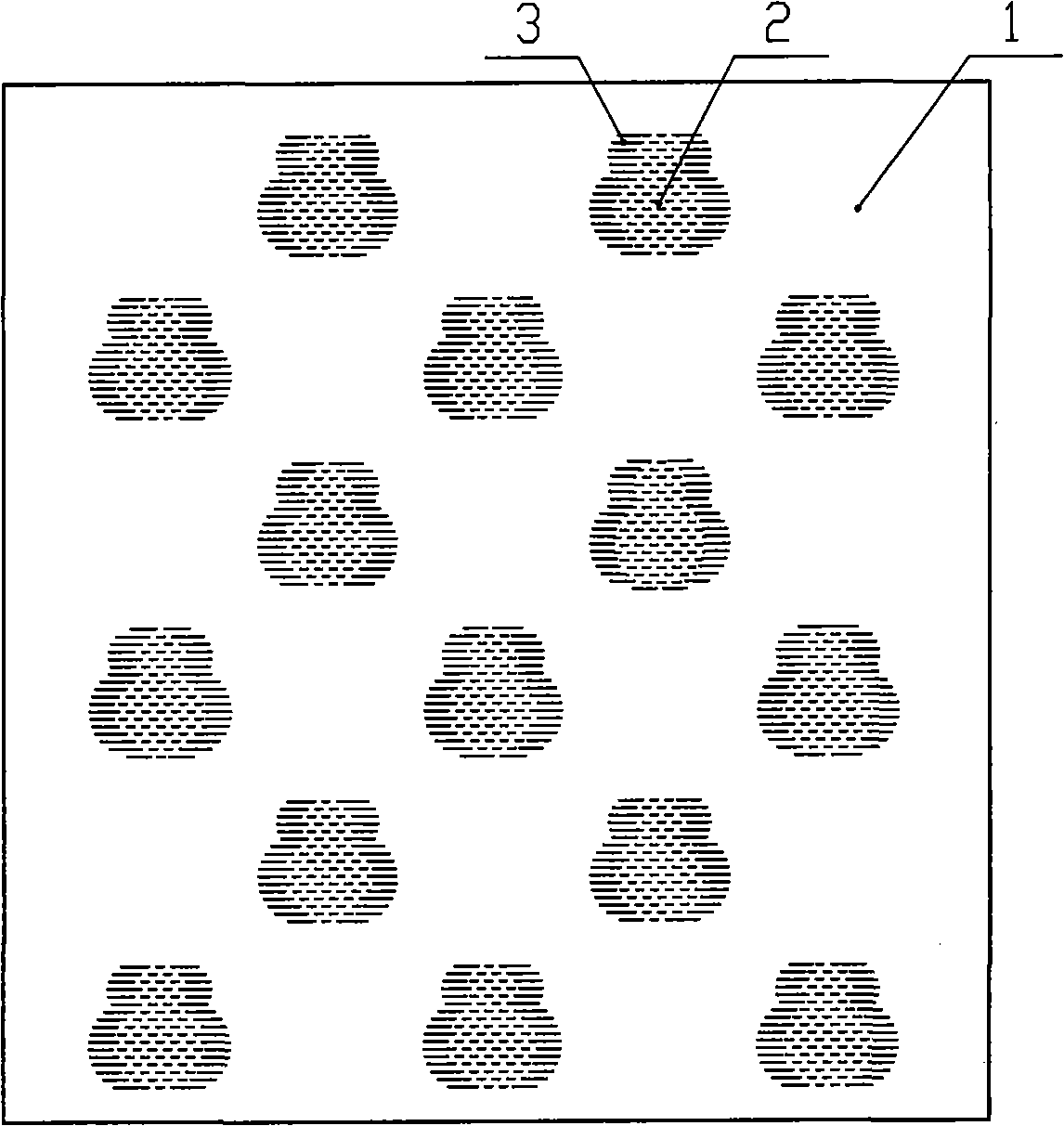

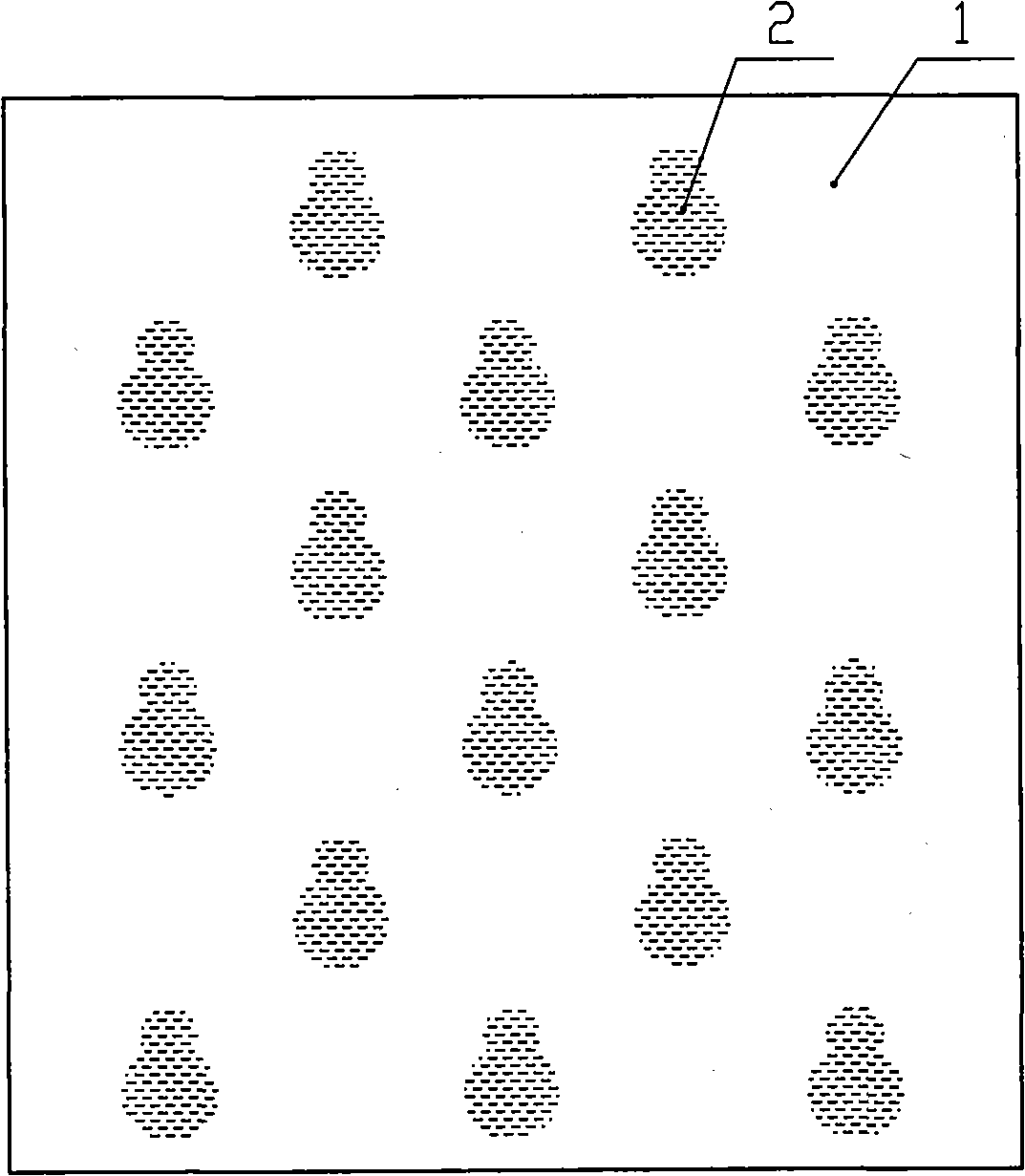

Cutting motif fabric and method of manufacture

The invention relates to a yarn-dyed fabric as well as the manufacturing method technology field thereof, in particular to a clipping and carving fabric which is applied in high-grade fashionable dresses, high-grade children dresses, high-grade bed clothes, etc., as well as the manufacturing method. The clipping and carving fabric is provided with a tabby bottom tissue and local additional tissues which are interwoven on the surface of the tabby bottom tissue. The clipping and carving fabric of the invention has the advantages of plump tissue effect like the feeling of attaching, rich meaning, perfect ornamental effect, embroidery visual effect, no bone on the fabric with patterns, soft feeling, and firm and permanent connection of the local additional tissues and the tabby bottom tissue.

Owner:倪爱东

Preparation method and application of phosphate inorganic casting binder suspension curing agent

InactiveCN101941045AHigh solid contentHigh solid content (>60%)Foundry mouldsFoundry coresOrganic acidPhosphate

The invention discloses a phosphate inorganic casting binder suspension curing agent and a preparation method thereof. The preparation method comprises the following steps of: adding organic resin to an alcoholic solvent; stirring to be fully dissolved and adding organic acid; stirring to be fully dissolved and then adding powder magnesia; and evenly stirring and dispersing to prepare the suspension curing agent. The invention also discloses the application of the curing agent to the foundry industry. The preparation method of the phosphate inorganic casting binder suspension curing agent is simple and adopts easily obtained raw materials with lower cost. The curing agent has the excellent performances of high efficiency, suspension rate and solid content, free toxicity, moderate reaction speed with the binder, and the like; a casting sand mould bonded by utilizing the curing of the curing agent and the organic binder has high sintering strength and stable sintering performance without a dust flying phenomenon in a sand-mixing process or generating dust pollution and is easy to popularize and apply in the foundry industry.

Owner:HUBEI UNIV OF TECH

Autoclaved desulfurized gypsum aerated building block without calcination

InactiveCN102674783AImprove water resistanceGood physical and chemical indicatorsPolymer scienceGypsum

The invention relates to an autoclaved desulfurized gypsum aerated building block without calcination. The autoclaved desulfurized gypsum aerated building block is formed by directly modifying solid wastes (such as desulfurized gypsum) produced by wet desulphurization in thermal power plants, without calcinations. The invention relates to the technical field of resourceful comprehensive utilization. The aerated building block is prepared from the components of, by weight, 60-75 % of original state dihydrate desulfurized gypsum, 10-30% of vulcanic ash active mineral materials, 10-25% of active materials, 0.5-2% of accelerating materials, 0.5-2.0% of early strength materials, 0.1- 0.5% of gas forming materials. The preparation method comprises the steps of preparing raw materials, slurrying, pouring, standing for maintenance, cutting, and autoclaving. By preparing the aerated building block, a lot of the solid wastes-dihydrate desulfurized gypsum can be consumed, and resources can be saved because the aerated building block is prepared by direct modification and utilization without processes of calcining and drying. The aerated building block is energy-saving, environment-friendly, low carbon and benefit for waste, and has good product performance, high strength, good water resistance, and low cost.

Owner:SHANGHAI JINMA BUILDING MATERIALS

Artificial active soil for greening rock side slope using organic fertilizer

InactiveCN1454461ANo hardeningRaw materials are easy to getExcavationsCultivating equipmentsGrowth plantFiber

The invention provides a man-made active soil comprising organic fertilizer to make rock slope green composed of organic fertilizer, organic fiber, fine-particle soil, water-retaining agent and compound fertilizer, in preparing ratios of (volume percentage): 20-40, 10-30, 30-60, 0.1-0.5, and 0.3-0.8, respectively. The soil can not only simulate the activity of the farming soil, also provide soil, water nutrient and microbe environments for plant growth, and has a certain cohesive force by itself, and can not make the soil harden, and depends on the anchor rod and the net to form a stable interger which close adheres to the rock slope.

Owner:张俊云 +1

Method for preparing high-efficiency magnetized liquid composite fertilizer for drip irrigation and liquid composite fertilizer prepared therefrom

InactiveCN101381253AImprove solubilityComprehensive nutritionOrganic fertilisersUrea compound fertilisersChemistryCrop

The invention discloses a method for preparing a highly-efficient magnetized liquid compound fertilizer for drip irrigation and a liquid compound fertilizer prepared by the method. The method comprises the following steps: sodium humate, potassium humate, water or landfill leachate, ammonium biphosphate, potassium chloride or potassium sulfate, urea and ammonia are stirred and chelated; simultaneously, under the condition that the strength of a central magnetic field is more than or equal to 20,000 gausses, the mixture is magnetized; and the PH value of the mixture is adjusted to between 4 and 5 through concentrated sulphuric acid or concentrated nitric acid. Compared with the prior art, the liquid drip irrigation fertilizer has good dissolution and full nutrition, is very favorable for absorption by crops, greatly improves the utilization rate of the fertilizer and simultaneously causes no soil hardening.

Owner:黄启田 +1

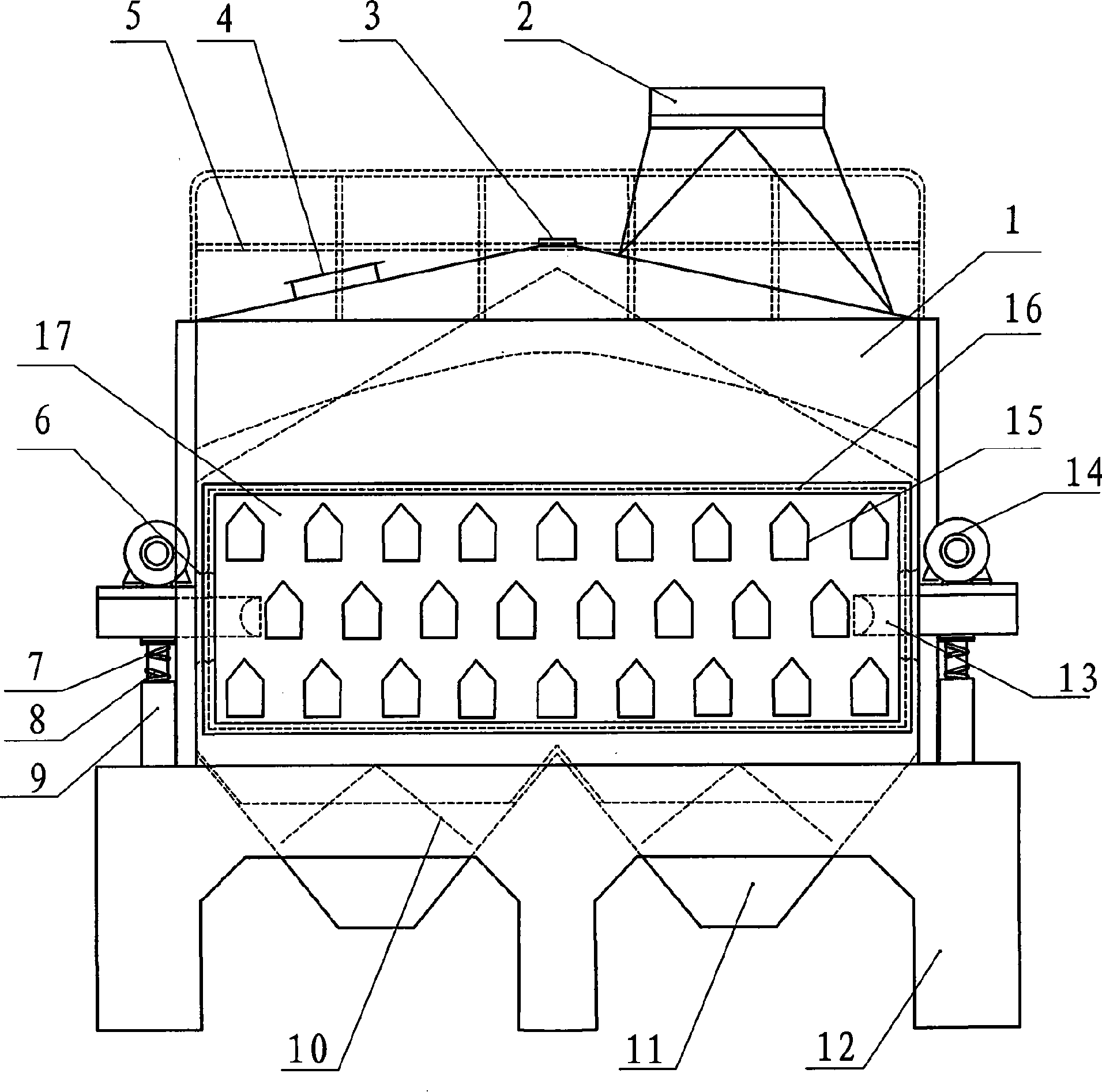

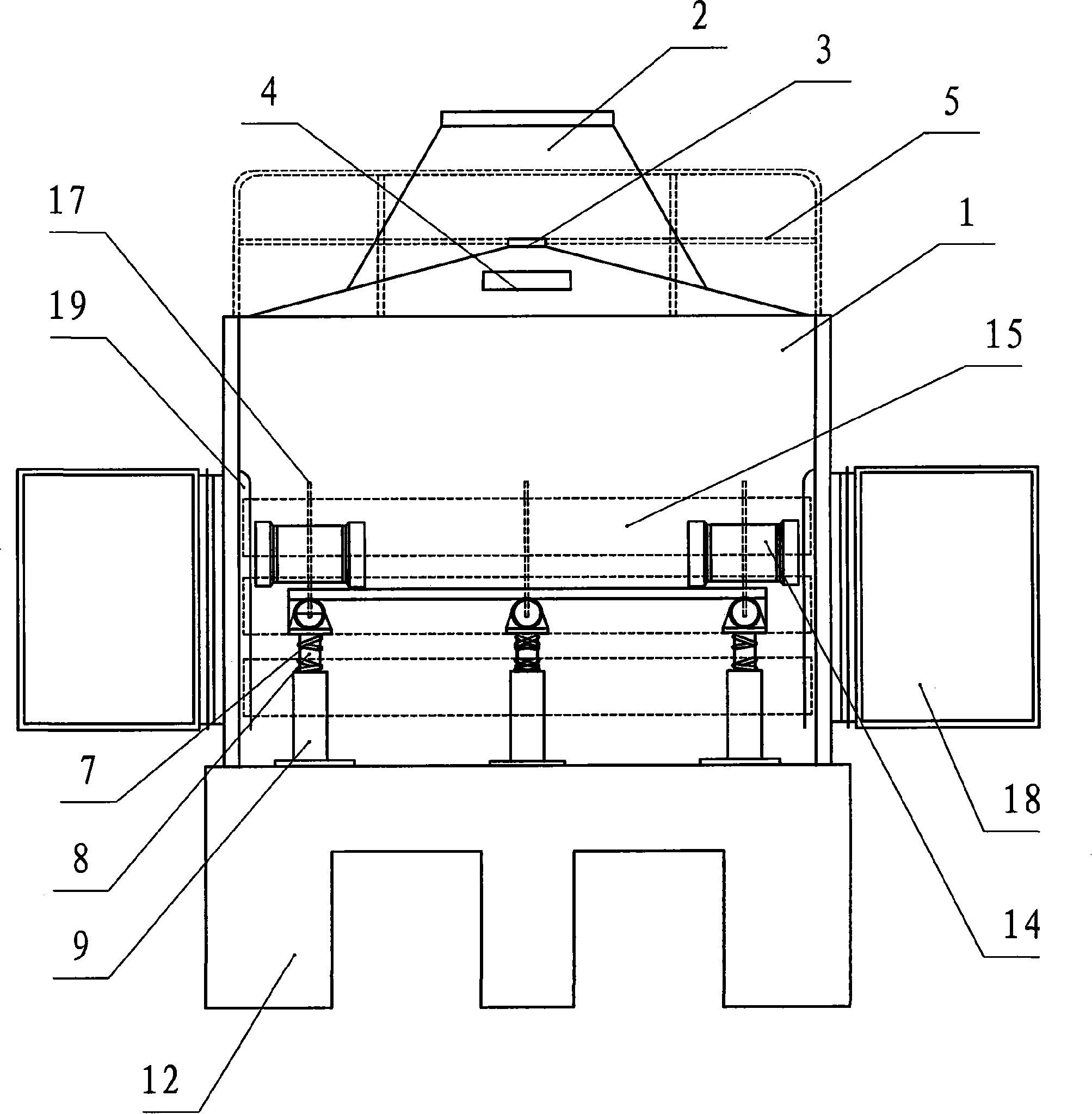

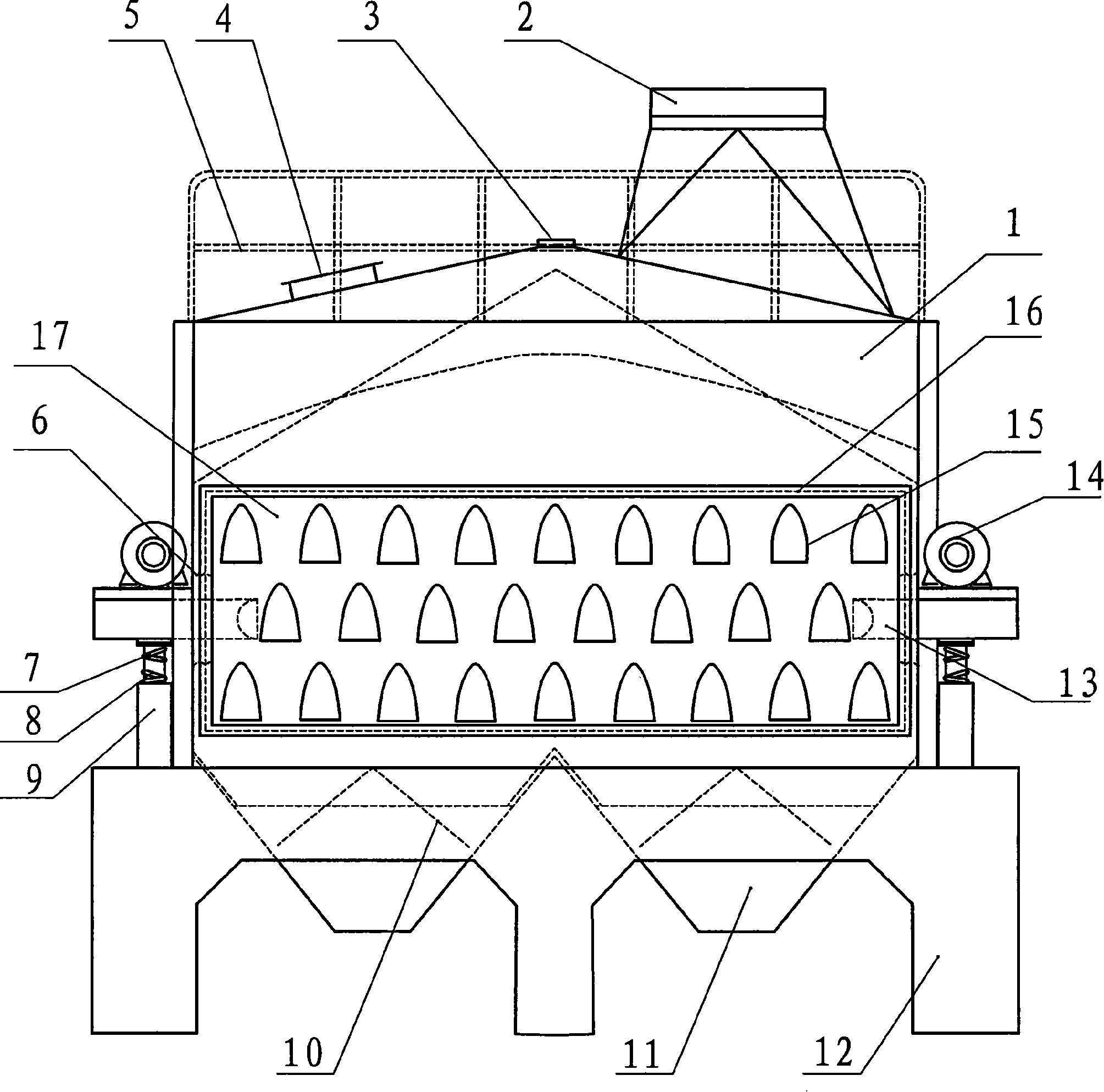

Granule material vibration cooling machine

InactiveCN101187533AEven temperature inside and outsideImprove cooling effectDirect contact heat exchangersCold airCooling chamber

A granular material vibrating cooler comprises a ventilating mechanism, wherein a material cooling chamber and a vibrating mechanism are fixedly mounted on the a base, a material inlet and an air outlet are arranged on the upper portion of the material cooling chamber, and a material outlet is arranged on the lower portion, air inlets are evenly arranged on two corresponding lateral wall of the material cooling chamber, the air inlet is connected with an air inlet pipe, the ventilating mechanism which is mounted in the material cooling chamber is provided with a plate-frame skeleton and a certain amount of air grooves. An opening of the air groove is arranged downwards, the air grooves which have at least two layers are alternately arrayed in parallel and penetrated through and fixed on the plate-frame skeleton, two ends of the air groove are positively faced to the air inlets and communicated with the air inlets. The plate-frame skeleton is connected with the ventilating mechanism by penetrating the two lateral wall of the material cooling chamber through a connecting piece. The granular material vibrating cooler adopts the mode that cold air blast is combined with vibration, which has a good cooling effect on high temperature material, in particular to composite fertilizer which is being cooled. The invention cools completely, which can not being hardened, and is benefit to popularization and application.

Owner:河南金谷干燥工程技术有限公司

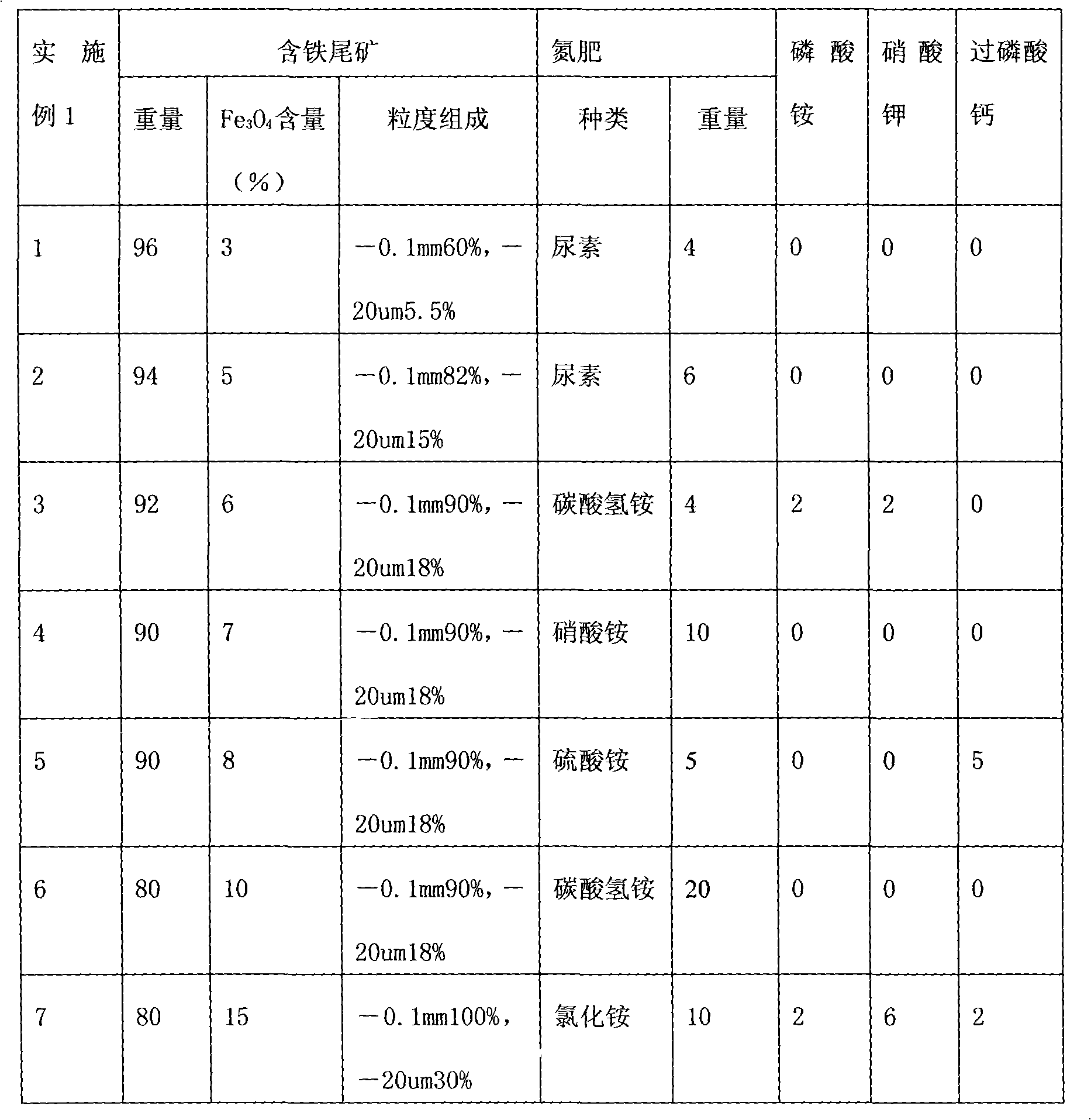

Magnetized tailings composite soil modifier

InactiveCN101265409ASimple componentsSimple preparation processOrganic fertilisersSoil conditioning compositionsGranularityPhosphor

The invention discloses a magnetized iron tailing compound soil amendment, which is prepared by iron-containing tailing, nitrogen fertilizer or nitrogen, phosphor and kalium compound fertilizer through the processes of mixing, magnetizing treatment, bagging and so on. The magnetized iron tailing compound soil amendment has the components according to the content ranges as follows: the iron-containing tailing 80%-96% (weight), the nitrogen fertilizer or the nitrogen, phosphor and kalium compound fertilizer 4%-20% (weight); and the ferriferrous oxide content in the iron-containing tailing 3%-15%(weight). The particle size of the iron-containing tailing is minus 0.1 mm, and the content occupies 60 to 100 percent (weight), wherein minus 20 um content is less than or equal to 30 percent. The magnetized iron tailing compound soil amendment has the advantages that the components are simple, the cost is low, the magnetized effect is good, the tailing used amount is large, and the soil hardening can not be caused during long use, and the agriculture crop wealth effect is obvious after application.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Crop rotation planting method for preventing successive cropping obstacles of solar greenhouse cucumbers

InactiveCN103843568AReduce manufacturing costOvercome obstacles to continuous croppingClimate change adaptationHorticultureMicroorganismSoil science

The invention discloses a crop rotation planting method for preventing successive cropping obstacles of solar greenhouse cucumbers. After twice crop rotation of solar greenhouse cucumbers and straw mushrooms, the crop rotation of solar greenhouse cucumbers and aquatic crops is performed at the third time. According to the method provided by the invention, the happening of the successive cropping obstacles of solar greenhouse cucumbers is effectively prevented; the dosage of pesticides is reduced; the production cost of the solar greenhouse cucumbers is lowered; the content of beneficial microorganisms in solar greenhouse soil is increased, the soil is improved, the growth of the cucumbers is boosted, the yield of the cucumbers is increased and the quality of the cucumbers is increased through salt-leaching and acid-regulating, so that the economic benefit of the solar greenhouse cucumbers is increased. Besides, the use ratio of the solar greenhouse is also increased, the economic income of peasants is increased and better environmental benefit and economic benefit are achieved.

Owner:JIANGSU XUHUAI DISTRICT HUAIYIN AGRI SCI RES INST

Biological organic fertilizer and preparation method and application thereof

InactiveCN106187510APackaged in mild conditionsLittle loss of organic matterCalcareous fertilisersMagnesium fertilisersHumic acidNitrogen fertilizer

The invention provides biological organic fertilizer. The biological organic fertilizer comprises 40-60% of amino acid fermentation waste liquid, 0-5% of nitrogen fertilizer, 15-25% of monoammonium sulfate, 5-15% of potassium sulfate, 0-5% of ammonium phosphate, 0.1-0.3% of compound microbial additive, 5-15% of humic acid, 10-20% of lime powder, 0.4-1.0% of hardening preventer. A preparation method of the biological organic fertilizer includes the steps of firstly, selecting the amino acid fermentation waste liquid, the nitrogen fertilizer, the potassium sulfate, the monoammonium sulfate, the lime powder, the ammonium phosphate and the humic acid, regulating pH to 5.5, and performing granulation; secondly placing prepared organic fertilizer granules into a coating barrel, cooling to 30-60 DEG C, spraying hardening-preventing oil on the surfaces of the granules, and spraying hardening-preventing powder and the compound microbial additive onto the surfaces of the fertilizer granules to obtain the biological organic fertilizer. The biological organic fertilizer has the advantages that the fertilizer uses the amino acid fermentation waste liquid as the raw material and is low in organic matter loss, high in strain survival rate and capable of avoiding hardening after being applied. The invention further provides application of the biological organic fertilizer to crops.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

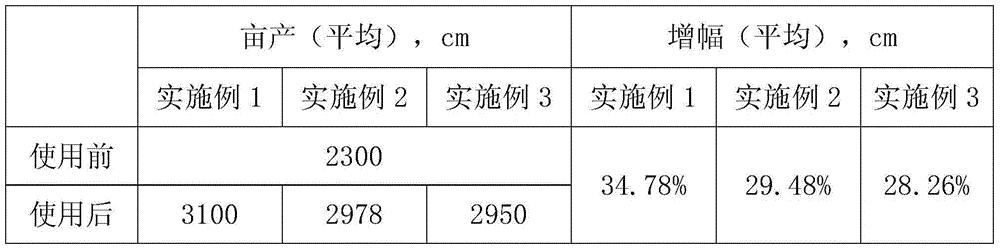

High-yield planting method for pollution-free tea

InactiveCN105191631AIncrease productionQuality improvementSuperphosphatesExcrement fertilisersDiseasePlant disease

The invention discloses a high-yield planting method for pollution-free tea. The method includes the steps of tea land selection, land preparation, biogas liquid watering and base fertilizer application, tea tree and bead tree interplanting, topdressing, tea garden management, disease and pest prevention and control and leaf fertilizer spraying. The planting method meets the requirements for planting the pollution-free tea in the whole process from tea land selection and construction, fertilizer application management to disease and pest prevention and control. In the planting process, kinds of fertilizer can be used according to nutrition requirements of the tea at different growth stages and are applied reasonably, in this way, nutrition requirements of pekoe tea can be met, the fertilizer loss will not be generated, in the whole process of fertilizer application, with organic fertilizer being the main fertilizer, in combination with a small amount of N, P and K fertilizer, growth of tea trees can be accelerated, and the yield of the tea can be increased. The yield of the tea is increased by about 30%, the tea color and tea taste of the tea are greatly improved, and the tea is popular among consumers in the market.

Owner:GUANGXI BAIRUNYUAN AGRI

Method for improving sandy soil

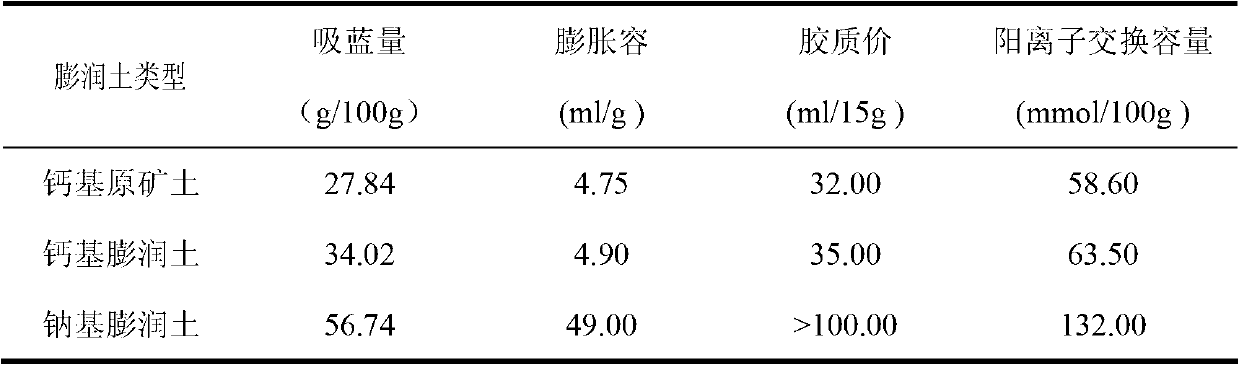

InactiveCN102127455ANo hardeningNo secondary pollutionOrganic fertilisersSoil conditioning compositionsSodium BentoniteGranularity

The invention discloses a method for improving sandy soil. A straw modified material is added into soil and is fully mixed with surfaced soil; when a ratio of sand with granularity of more than 0.02mm in the soil is over 85 percent, the adding amount of the straw modified material is 1,400 to 1,750kg / mu; when a ratio of sand with granularity of more than 0.02mm in the soil is between 55 and 85 percent, the adding amount of the straw modified material is 750 to 1,000kg / mu; when a ratio of sand with granularity of more than 0.02mm in the soil is below 55 percent, the adding amount of the straw modified material is 300 to 500kg / mu; and the straw modified material is prepared by uniformly mixing rotted and decomposed crop straw, calcium bentonite and anion polyacrylamide. The method has the advantages of no secondary pollution, low cost and no soil hardening; the straw modified material has the characteristics of a soil modifier and an organic fertilizer; and sand soil or tilled land is not needed to be reconstructed, and final-period management is avoided.

Owner:SOUTHWEST UNIVERSITY

Saline and alkaline soil improvement agent including soil loosening agent, and preparation method of soil improvement agent

InactiveCN106396883AImprove soil structureIncrease soil aerationAlkali orthophosphate fertiliserExcrement fertilisersIonIon exchange

The invention discloses a saline and alkaline soil improvement agent including a soil loosening agent. The saline and alkaline soil improvement agent comprises 120-180 parts of the soil loosening agent, 250-400 parts of a soil improving organic fertilizer, 160-200 parts of rhamnolipid, 120-160 parts of a blue alga decomposition accelerator, 80-120 parts of hydroxyethyl cellulose, 30-60 parts of potassium dihydrogen phosphate, 8-20 parts of potassium dihydrogen phosphate, 800-1200 parts of water and 10-14 parts of a microbial fermentation agent. The saline and alkaline soil improvement agent including the soil loosening agent improves the soil structure, increases the air permeability of soil and supplements organic matters; and the saline and alkaline soil improvement agent can be combined with common chemical improvements in the prior art to realize ion change of sodium ions in oil in order to reduce alkalis and remove salts, so the saline and alkaline soil is thoroughly improved without replacing soil, and the saline and alkaline soil improvement agent can be used in agricultural production.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Magnesium nitrate-calcium nitrate complex salt type compound fertilizer and preparation method thereof

ActiveCN103833444AImprove fluidityGood anti-caking performanceFertilizer mixturesAgricultural engineeringCaking

The invention relates to the production technology of granular fertilizers, and specifically relates to a magnesium nitrate-calcium nitrate complex salt type compound fertilizer and a preparation method thereof. The magnesium nitrate-calcium nitrate complex salt type compound fertilizer is characterized in that the total mass percent of magnesium nitrate and calcium nitrate in the compound fertilizer ranges from 50% to 90%, the mass percent of crystal water in the compound fertilizer ranges from 10% to 50%, and the mass ratio of magnesium nitrate to calcium nitrate is (3.5-0.1):1. Compared with the prior art, the magnesium nitrate-calcium nitrate complex salt type compound fertilizer and the preparation method thereof have the beneficial effects that (1) the magnesium nitrate-calcium nitrate complex salt type compound fertilizer is far better than compound fertilizers obtained by doping and pelletizing by a mechanical pressing method in free-running property and anti-caking property, the caking time of the product is above 30 days and therefore, the product can be used very conveniently; (2) the preparation method is lower in cost than a process of batch crystallization as well as mechanical mixing and pelletizing, and also applicable to continuous large-batch production, and therefore, a convenient condition is provided for automatic process control.

Owner:山西东锦肥业有限公司

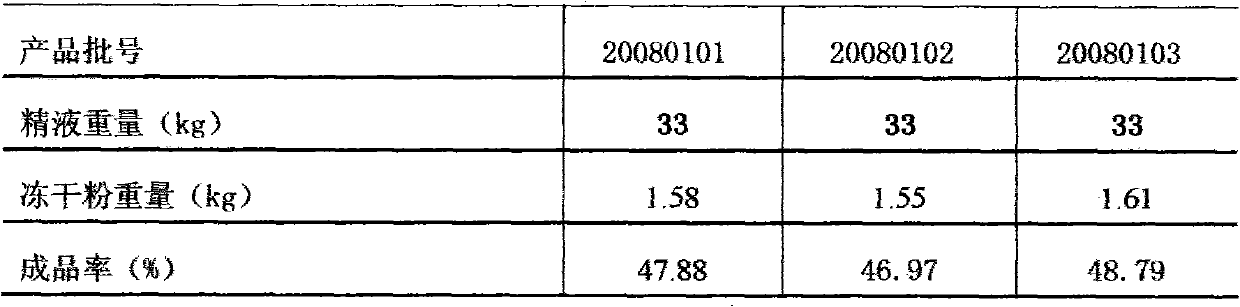

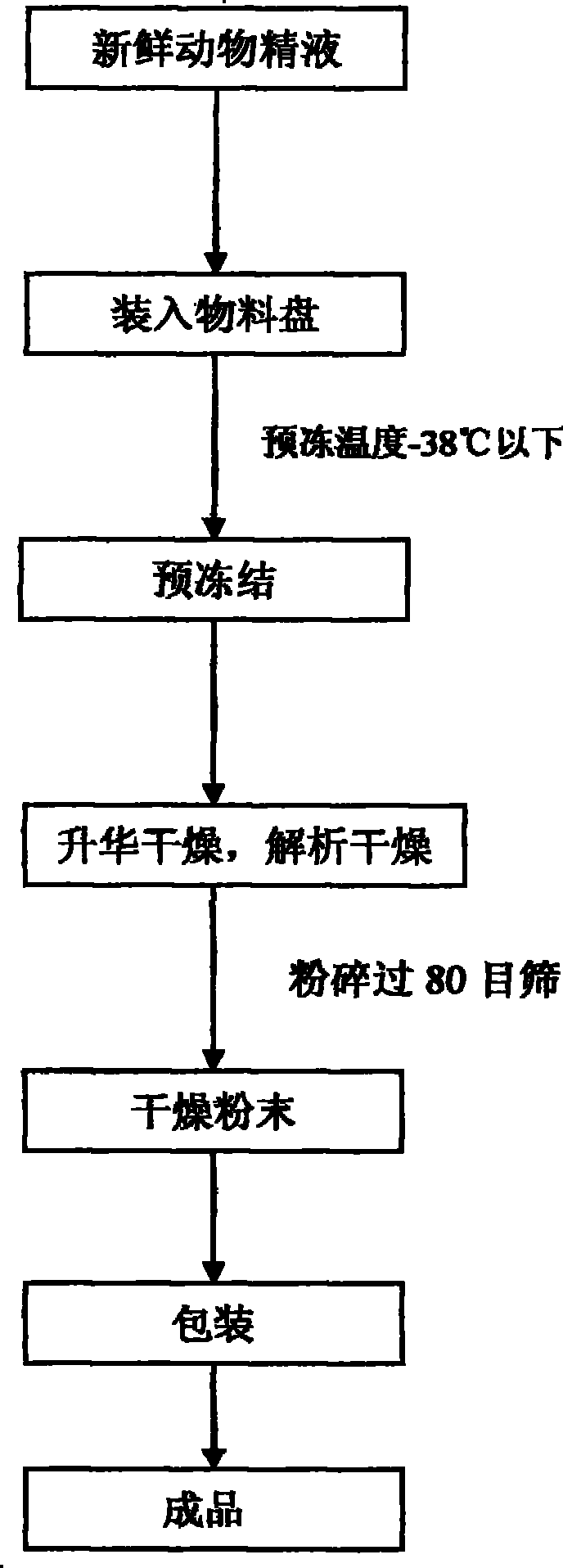

Method for preparing animal semen freeze-dried powder

ActiveCN101904869AHigh medicinal valueReduce lossesPowder deliveryMetabolism disorderMicroorganismFreeze-drying

The invention relates to a method for preparing animal semen freeze-dried powder, which is used for preparing by adopting freeze-dried fresh semen and comprises the steps of prefreezing, sublimation drying and analysis drying. The invention has the following advantages that: (1) protein, microorganisms and the like can not denature or lose biological activity; (2) the loss of certain volatile components in the matter is small; (3) the growth of microorganisms and the action of enzymes are prohibited, so that the original nature of the freeze-dried powder can be maintained; (4) the volume is almost unchanged, the original structure is maintained, and the phenomena of concentration and hardening do not occur; (5) the dried matter is loose, porous and spongy, the dissolution is quick and complete after water addition, and the original nature can be recovered immediately; (6) certain easily oxidized substances in vacuum are protected; and (7) more than 95-99% of water can be removed by drying, and the dried product can stored for a long time without deterioration.

Owner:程辉

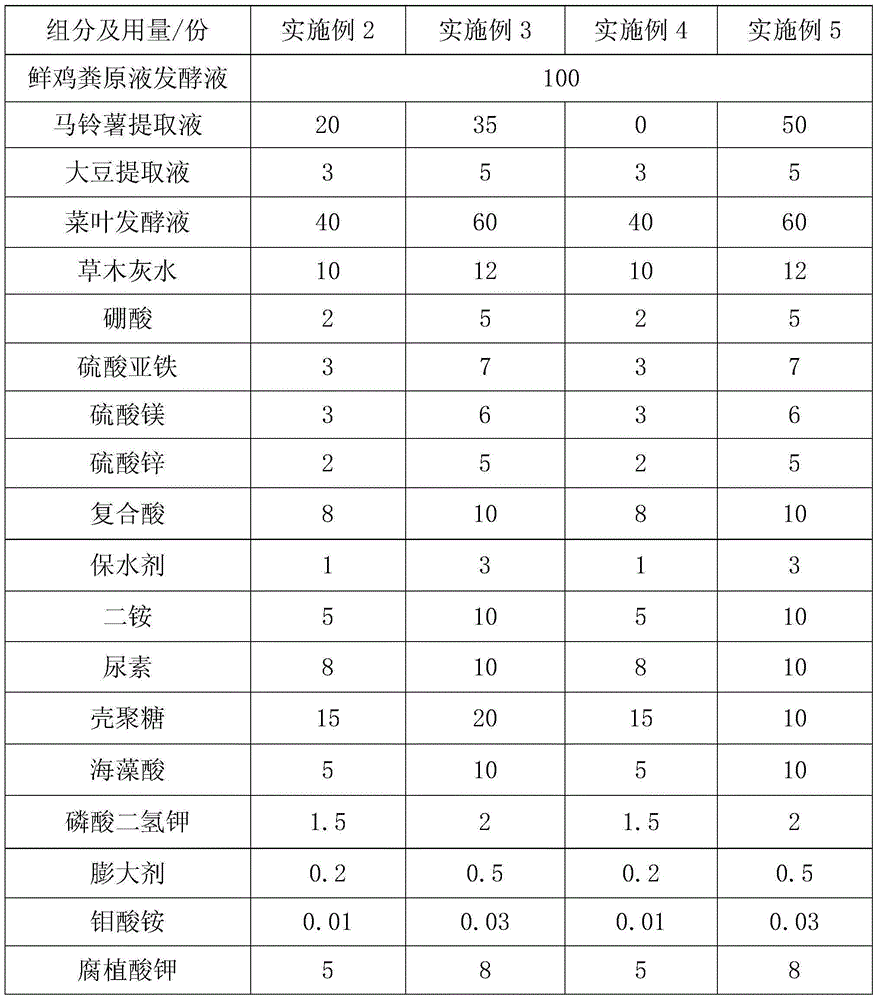

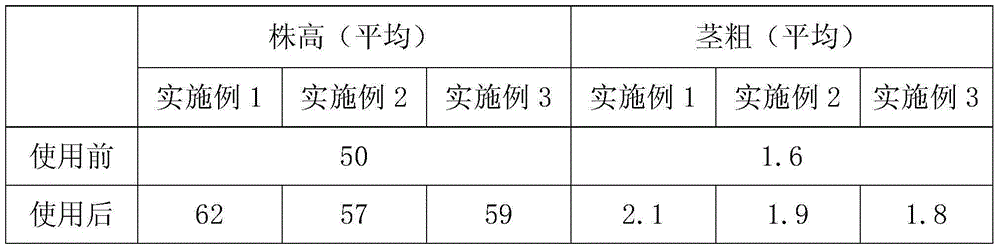

Special liquid water flush fertilizer for potatoes and preparation method for special liquid water flush fertilizer for potatoes

ActiveCN105036851ANot afraid of the tideNo problem of decreased solubilityFertilizer mixturesLiquid waterMonopotassium phosphate

The invention discloses a special liquid water flush fertilizer for potatoes. The special liquid water flush fertilizer for potatoes is characterized by being prepared from the following raw materials in parts by weight: 100 parts of fresh chicken manure raw liquid fermentation liquor, 8-10 parts of urea, 1.5-2 parts of monopotassium phosphate, 5-8 parts of potassium humate, 0.01-0.03 part of ammonium molybdate, 2-5 parts of boric acid, 3-7 parts of ferrous sulfate, 3-6 parts of magnesium sulfate, 2-5 parts of zinc sulfate, 8-10 parts of a compound acid, 1-3 parts of a water-retaining agent, 5-10 parts of diammonium, 20-35 parts of a potato extraction solution, 15-20 parts of chitosan, 5-10 parts of alginic acid, 3-5 parts of a soybean extraction solution, 0.2-0.5 part of a swelling agent, 10-12 parts of plant ash water and 40-60 parts of vegetable fermentation liquor. By taking chicken manure and vegetable fermentation liquor as main organic matters, the fertilizer is comprehensive and abundant in nutrient and the two organic matters are waste which is low in price. The two organic matters are applied to the fertilizer, so that the waste is turned into wealth, an effect of protecting the environment is exerted, and the special liquid water flush fertilizer for potatoes has good social and economical benefits.

Owner:甘肃省昕农福农业科技有限责任公司

Corn compound fertilizer with slow-release and insect-resistant effects

InactiveCN105418217AIncrease productionImprove qualityFertilizer mixturesPhosphoric acidMonopotassium phosphate

The invention relates to a corn compound fertilizer with slow-release and insect-resistant effects. The corn compound fertilizer is prepared from, by weight, 35-40 parts of urea, 10-15 parts of monopotassium phosphate, 12-15 parts of bentonite, 6-10 parts of charcoal, 0.5-1 part of boric acid, 1-1.5 parts of BSFA, 1.2-1.5 parts of manganese sulfate, 1-1.5 parts of ammonium molybdate, 12-15 parts of superphosphate, 5-7 parts of modified starch and 1.5-2 parts of extracts of traditional Chinese medicine. The corn compound fertilizer with the slow-release and insect-resistant effects can provide good nutrient elements for corn for meeting the requirement of corn for nutrient elements; meanwhile, plant raw materials are used based on the scientific proportion for preventing pests and diseases at the root, and the corn yield and quality are improved.

Owner:颍上县永祥旱粮研究所

Special organic compound modifier used in carbonate-type paddy fields and preparation method thereof

InactiveCN101659869AAvoid toxic effectsAchieve reuseAgriculture tools and machinesOther chemical processesAlkalinityBrown coal

A special organic compound modifier used in carbonate-type paddy fields and a preparation method thereof relate to a special organic compound modifier used in paddy fields and a preparation method thereof. The modifier and the preparation method thereof solve the problems of soil hardening easily caused by modifiers used in the carbonate-type paddy fields, worsening of physicochemical properties,poor effect on reducing soil alkalinity and high preparation cost. The modifier is made from the following materials by mass percentages: 50-60% of furfural residue, 5-12% of furnace ash, 30-35% of animal manure and 3-7% of brown coal. The preparation method comprises the following steps: blending the furfural residue and the furnace ash to obtain a mixture; mixing the animal manure and the browncoal for fermentation, and obtaining an organic fertilizer; mixing the mixture and the organic fertilizer for fermentation, and then sequentially granulating, ball blasting, sieving and packaging, thus obtaining the modifier. The modifier contains 60-70% of organic matter with pH of 3-4, and has advantages of convenient use, easy mechanical application at large area, simple preparation process andlow cost of raw materials.

Owner:RES INST OF ENVIRONMENTAL RESOURCE & RURAL ENERGY RESOURCE OF HEILONGJIANG ACAD OF AGRI SCI

Coconut rice and production method thereof

The invention discloses coconut rice and a production method thereof. The method comprises the following steps of: 1) cutting a circular opening with the diameter of between 6 and 8 centimeters at the fruit base of a coconut fruit to form a spherical coconut bowl and a coconut shell cover, and pouring coconut water; 2) juicing coconut flesh with the fruit age of between 11 and 12 months, and adding a complex additive and mixing uniformly to obtain pre-prepared coconut juice, wherein the complex additive consists of a flavoring agent and an antiaging agent; 3) soaking glutinous rice in water for 0.5 to 2 hours, and presteaming at the temperature of 100 DEG C under normal pressure for 10 to 30 minutes to obtain presteamed glutinous rice; and 4) adding the presteamed glutinous rice and the pre-prepared coconut juice in the spherical coconut bowl, stirring uniformly, covering by using the coconut shell cover, and steaming to obtain the coconut rice. The coconut rice has the mouthfeel of tender coconuts and concentrated fragrance of matured coconuts; and the rice cooked in a coconut shell is aged and uniform, soft and elastic and stable in quality by a reasonable process, and the coconut shell is formed into a container which is used for containing the rice and is provided with the bottom and the cover skillfully, so the rice is not needed to be contained or heated by additional containers when eaten, and is convenient and practical.

Owner:HAINAN UNIVERSITY

Processing method for a chicken wing

The invention provides a processing method for a chicken wing. The processing method comprises the following steps of: mixing the chicken wing with a batching solution for salting; streaming and roasting the staled chicken wing in a steaming and roasting oven, wherein the relative humidity in the steaming and roasting oven is 50%-90%; and quickly freezing the steamed and roasted chicken wing. According to the processing method, the chicken wing is salted, steamed and roasted under the condition with relative humidity of 50%-90% to prepare the chicken wing product which is fresh and tender in texture, fully flavored, delicious in taste and soft in mouthfeel.

Owner:SHANDONG FENGXIANG

Grease-like sewage treatment method and chemical agent

ActiveCN104003495AQuick condensationDestabilizationFatty/oily/floating substances removal devicesLiquid separationChemical industryOil and grease

The invention relates to a grease-like sewage treatment method and a chemical agent and belongs to the technical field of grease-like chemical-industry type sewage treatment. According to the technical scheme, the chemical agent includes 0.2-0.5% of sodium alkyl benzene sulfonate, 0.5-0.7% of zeolite, 10-15.5% of sodium carbonate, 5-7.3% of calcium hydroxide, 4-9.5% of triacylglycerol acylhydrolase, 1-2.5% of cellulose, 1-3% of sodium percarbonate, 23-36.7% of polyaluminum chloride and 18-24.3% of ferrous sulfate. The grease-like sewage treatment method and the chemical agent have the advantages that the existence forms of water-in-oil and oil-in-water are thoroughly broken, a large quantity of SS, chromaticity colors, grease and COD can be quickly removed, efficiency is high, performance is reliable, the requirement for temperature changes is low, hardening and corroding are avoided, and sewage cannot cause secondary pollution in the later period.

Owner:TANGSHAN HENGTONG SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com