Patents

Literature

64results about How to "Ripe evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

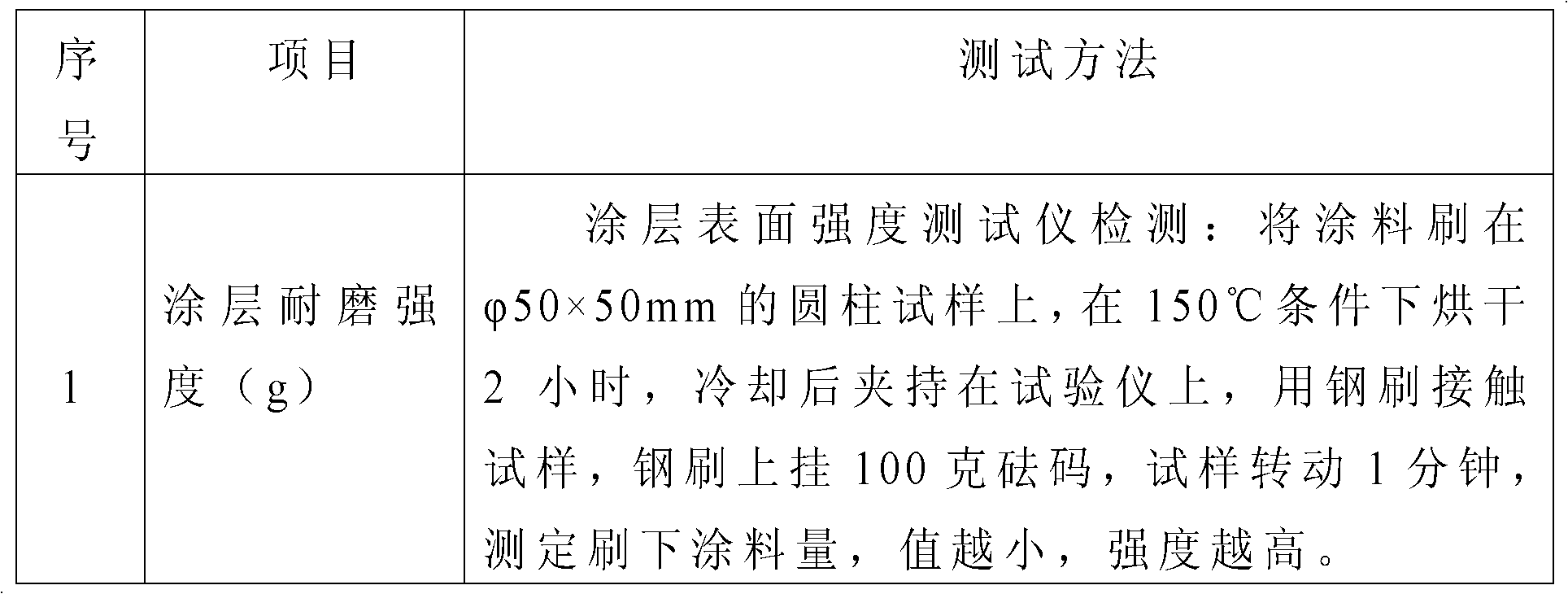

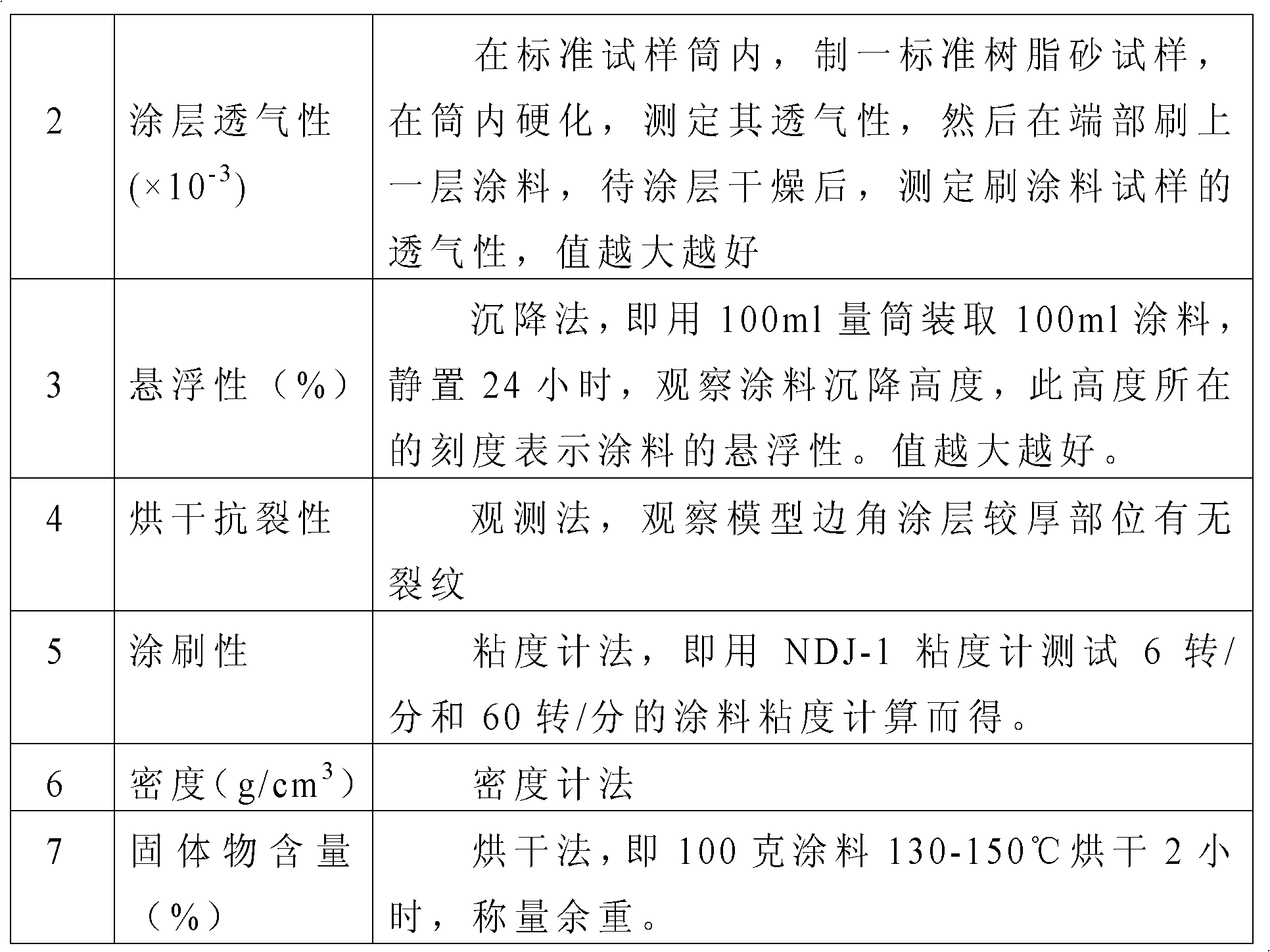

Solid pattern casting special paint and preparation method thereof

InactiveCN102049464AHigh strengthImprove integrityFoundry mouldsFoundry coresGraphiteSuspending Agents

The invention discloses a solid pattern casting special paint and a preparation method thereof. The mass percentages of various constituents in the paint are: 30-40% of bauxite chamotte, 20-30% of flaky graphite powder, 6.3-8.5% of bonder, 1-2% of iron oxide red powder, 4-6% of suspending agent, 0.8-1.5% of water reducing agent and 20-30% of water. The preparation method comprises the steps: mixing the various components of the solid pattern casting special paint according to the mass percentages and loading the constituents into a ball mill; adding 50-80 ceramic balls with a diameter of 30-50 mm into the ball mill; and mixing and stirring the materials evenly to obtain the paint. Practices show that the paint has strong abrasion performance, high adhesiveness, good air permeability and fast-dry performance both in low and high temperature environments; the paint can satisfy the production requirement of large casting production; the preparation method disclosed by the invention is simple; and the cost is low.

Owner:DONGFENG MOTOR CO LTD

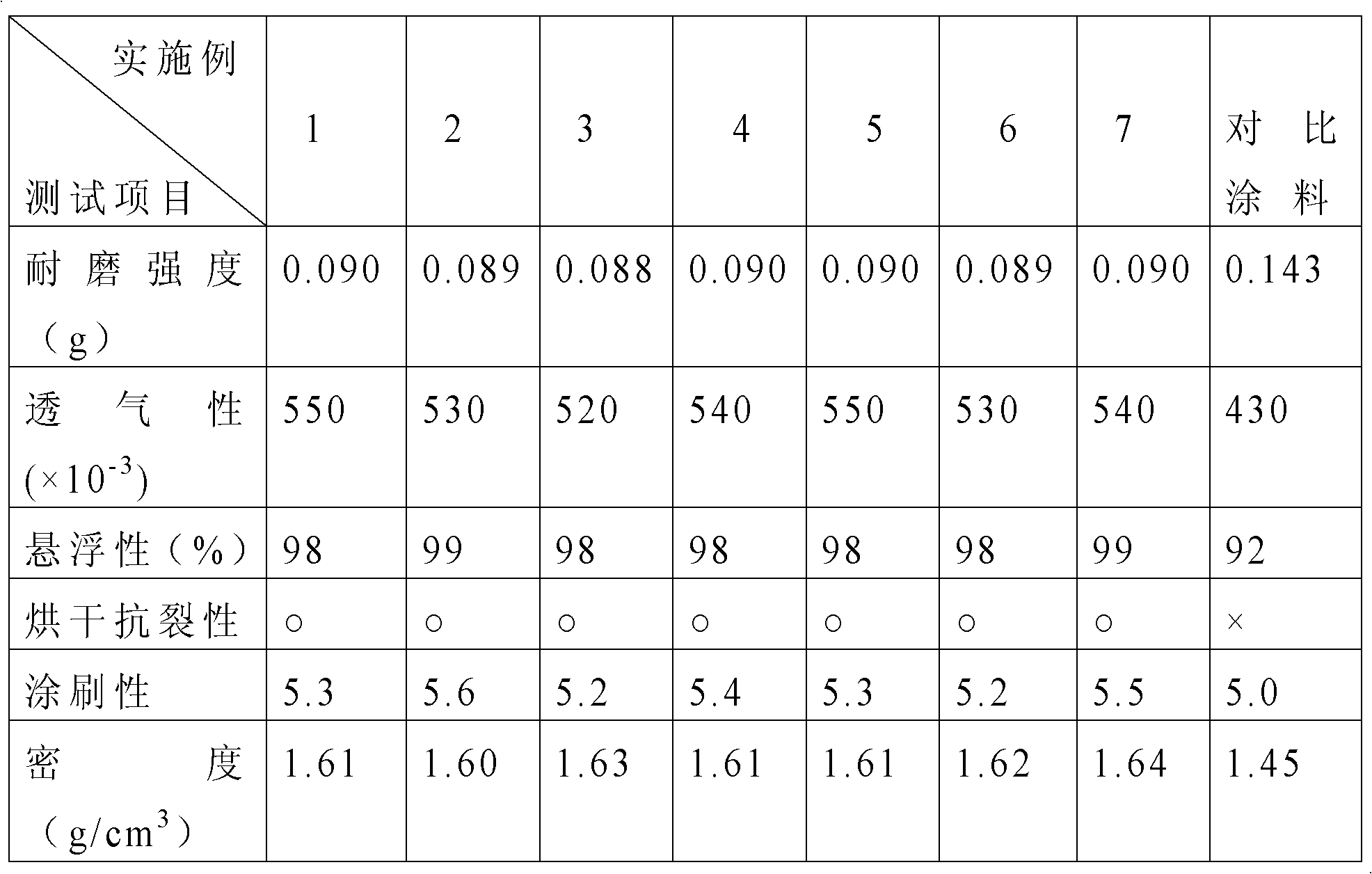

Production method of high-salt diluted and low-temperature fragrant soy sauce

The invention discloses a production method of a high-salt diluted and low-temperature fragrant soy sauce, which comprises the following steps of: (1) curing raw materials including wheat and defatted soybeans, and then uniformly mixing the wheat and the defatted soybeans; (2) inoculating aspergillus oryzae strains to the obtained raw material mixture so as to obtain a yeast; (3) cultivating the yeast for 44-48 hours at a temperature of 25-30 DEG C so as to obtain a mature yeast; (4) adding 2.0-2.5 weight times of saline water into the mature yeast so as to obtain a raw soy sauce mash; (5) moving the raw soy sauce mash to the inside of an airtight fermentation tank for fermenting: firstly fermenting for 23-27 days at a temperature of 13-17 DEG C, then continuing to ferment at a temperature of 28-32 DEG C, and on the 28-32nd days, adding mixed fermentation strains into the fermentation tank and continuing to ferment; in the process of fermentation, stirring by using a compressed air flow; and fermenting for more than six months so as to obtain a mature soy sauce mash; and (6) squeezing and filtering the mature soy sauce mash so as to obtain the low-temperature fragrant soy sauce. According to the invention, the conversion rate of proteins in raw materials is high, and the contents of ammonia nitrogen, total nitrogen, soybean peptides and soybean oligosaccharides in the prepared soy sauce are high.

Owner:好太太食品有限公司

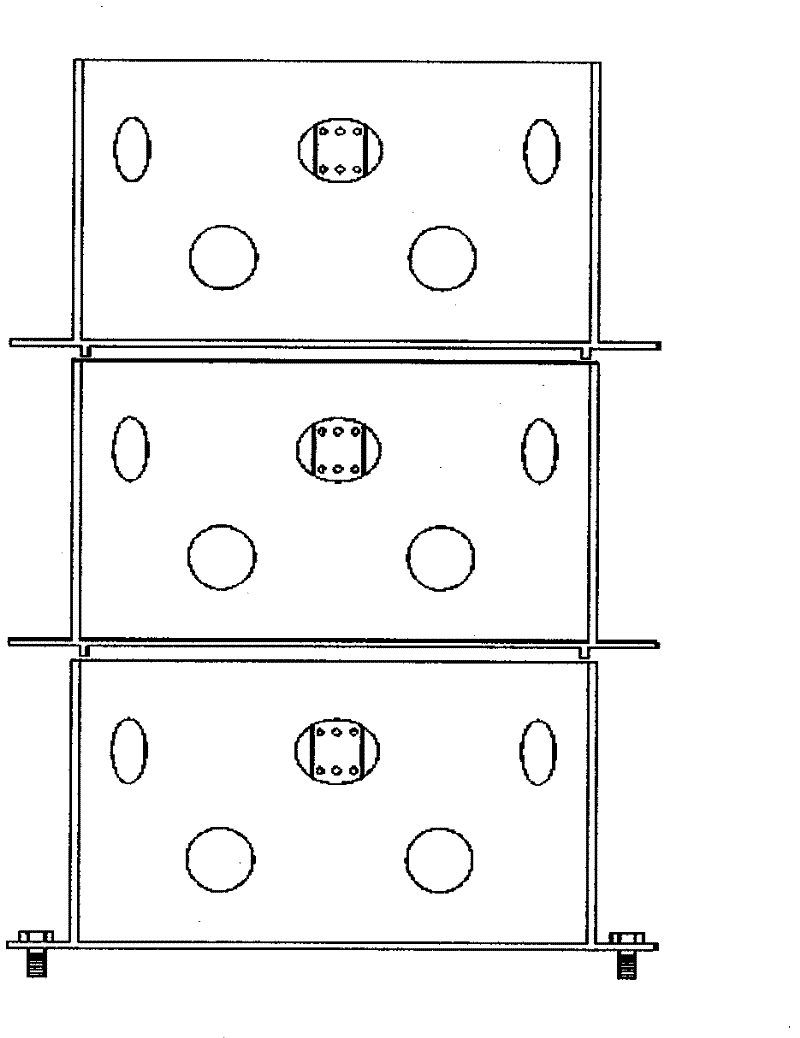

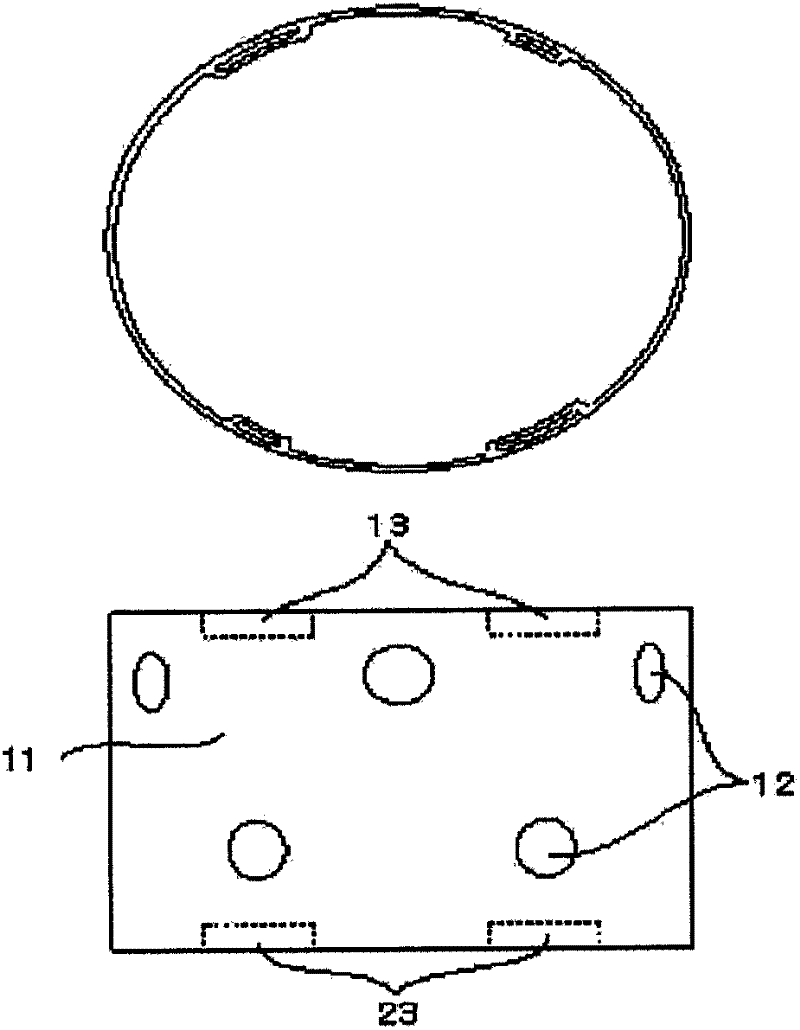

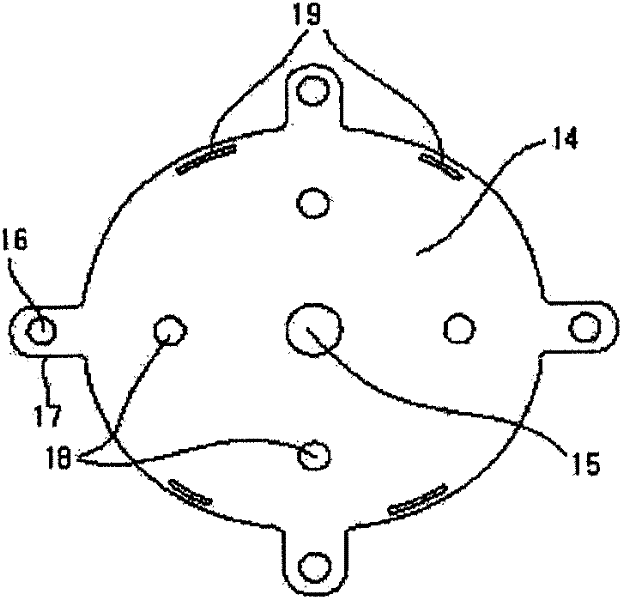

Cultivation device and method of strawberry and small leafy vegetables using multi-layer structure appliance

InactiveCN102300453AIncrease productionProtect the waistCultivating equipmentsReceptacle cultivationLeafy vegetablesPeat

The present invention relates to a device and method for cultivating large quantities of bulbous crops and ornamental plants including strawberries and small leafy vegetables in a narrow space, and more particularly relates to a cultivation device for strawberries and small leafy vegetables using multi-layer structure utensils and methods. The cultivation device for strawberries, small leafy vegetables, bulbous crops, and ornamental plants using a multi-layer structure device according to the present invention is characterized in that the multi-layer structure device is manufactured by assembling two or more layers of trays, a main body, and piping. The tray is formed with a plurality of holes, so that when water and / or nutrient solution is supplied, it flows downward by gravity; the main body is located on the upper part of the tray, and a plurality of holes for cultivating strawberries and small leafy vegetables are formed on the side. The hole is filled with peat soil, coarse sand, charcoal, coarse chaff mixture, carbonized chaff, pearlite, organic matter mixed loam and loess, so that water can be supplied to the planted crops and / or nutrient solution; the piping or hose is arranged in the center of the body, injecting or spraying water and / or nutrient solution and passing through the soil inside the body for supplying water and / or nutrient solution to the crops so that the crops Grow well.

Owner:姜赫

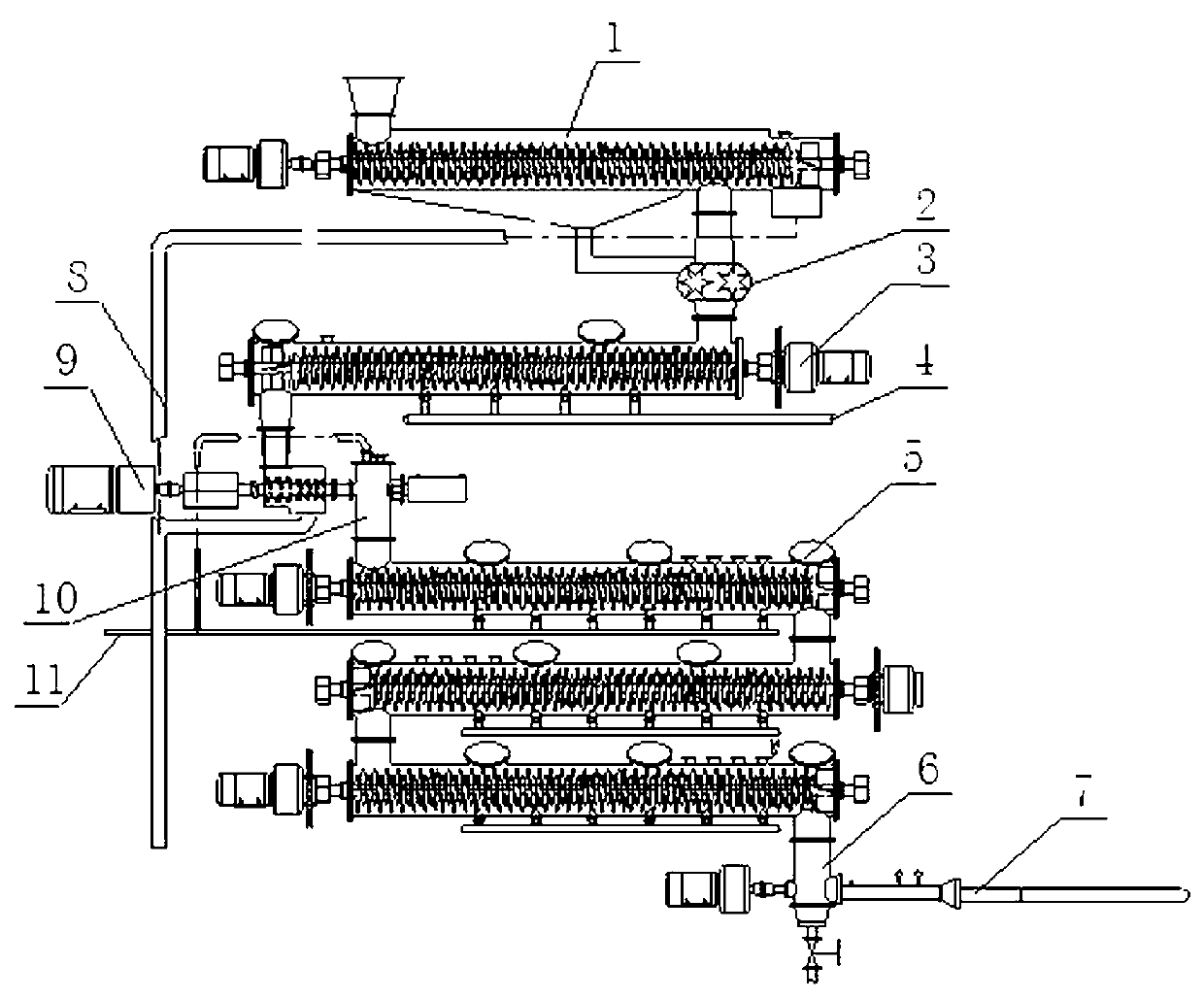

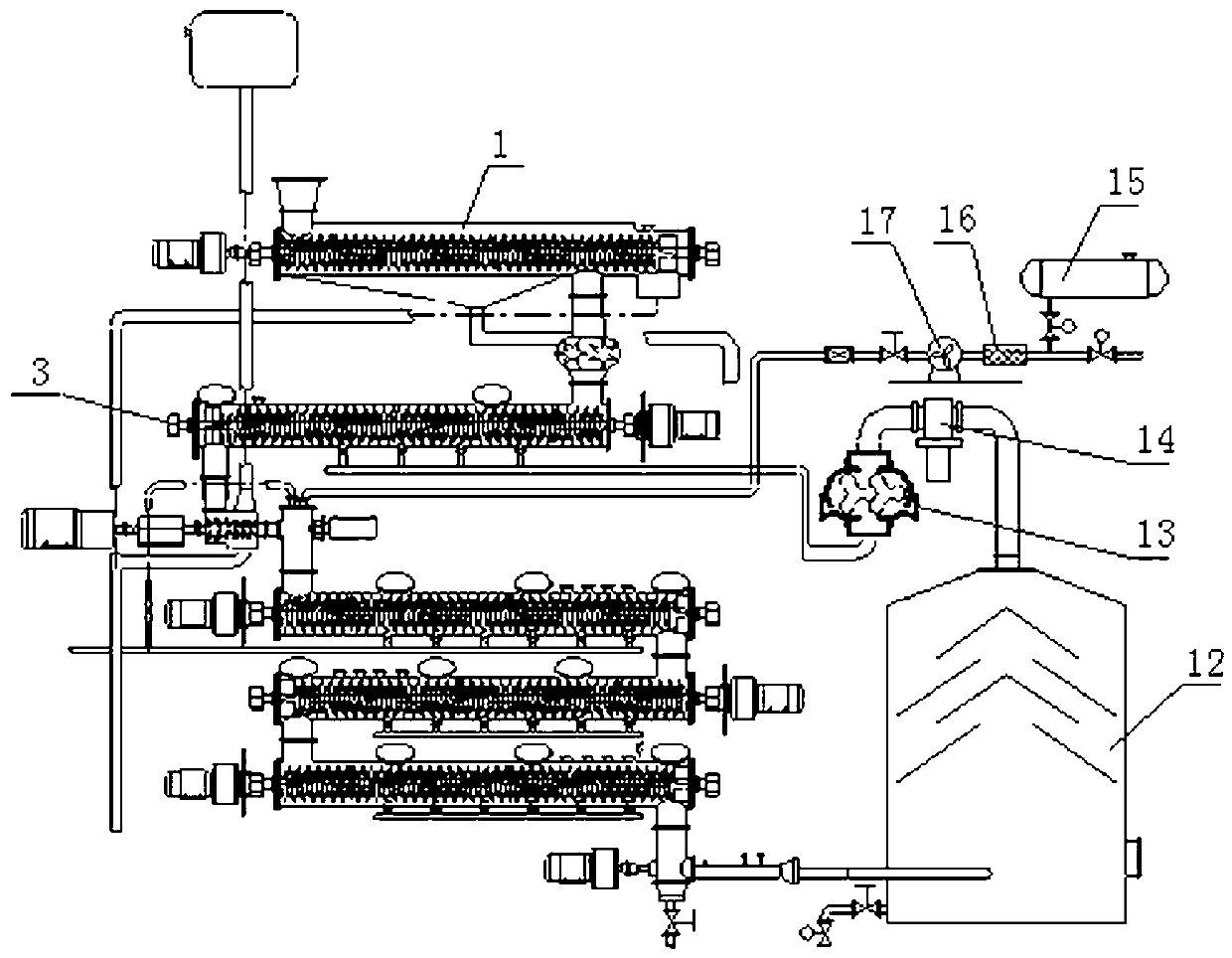

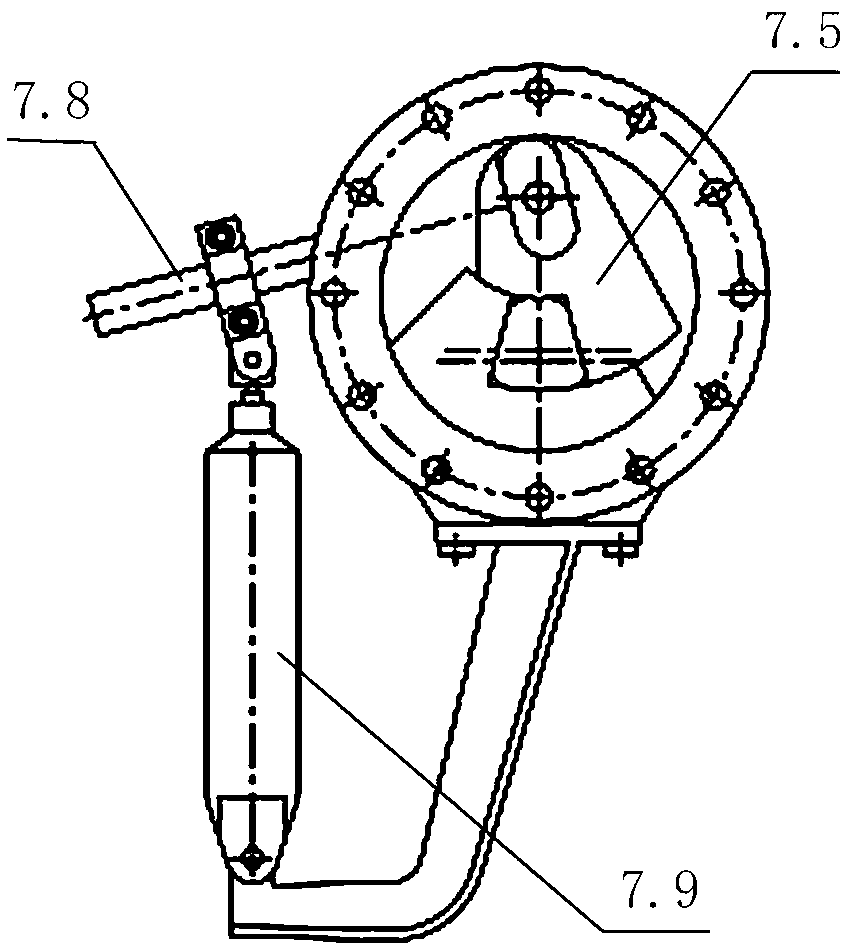

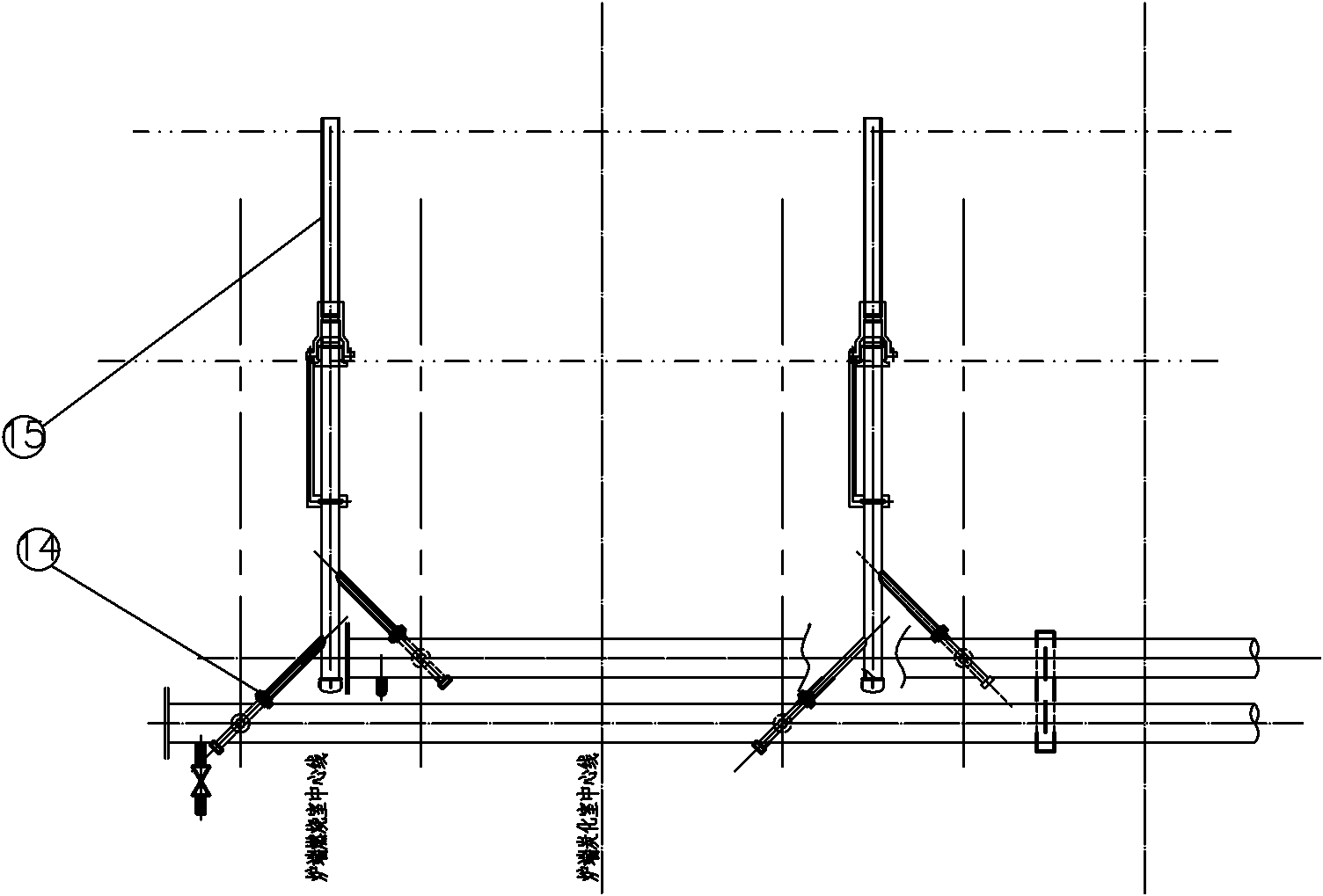

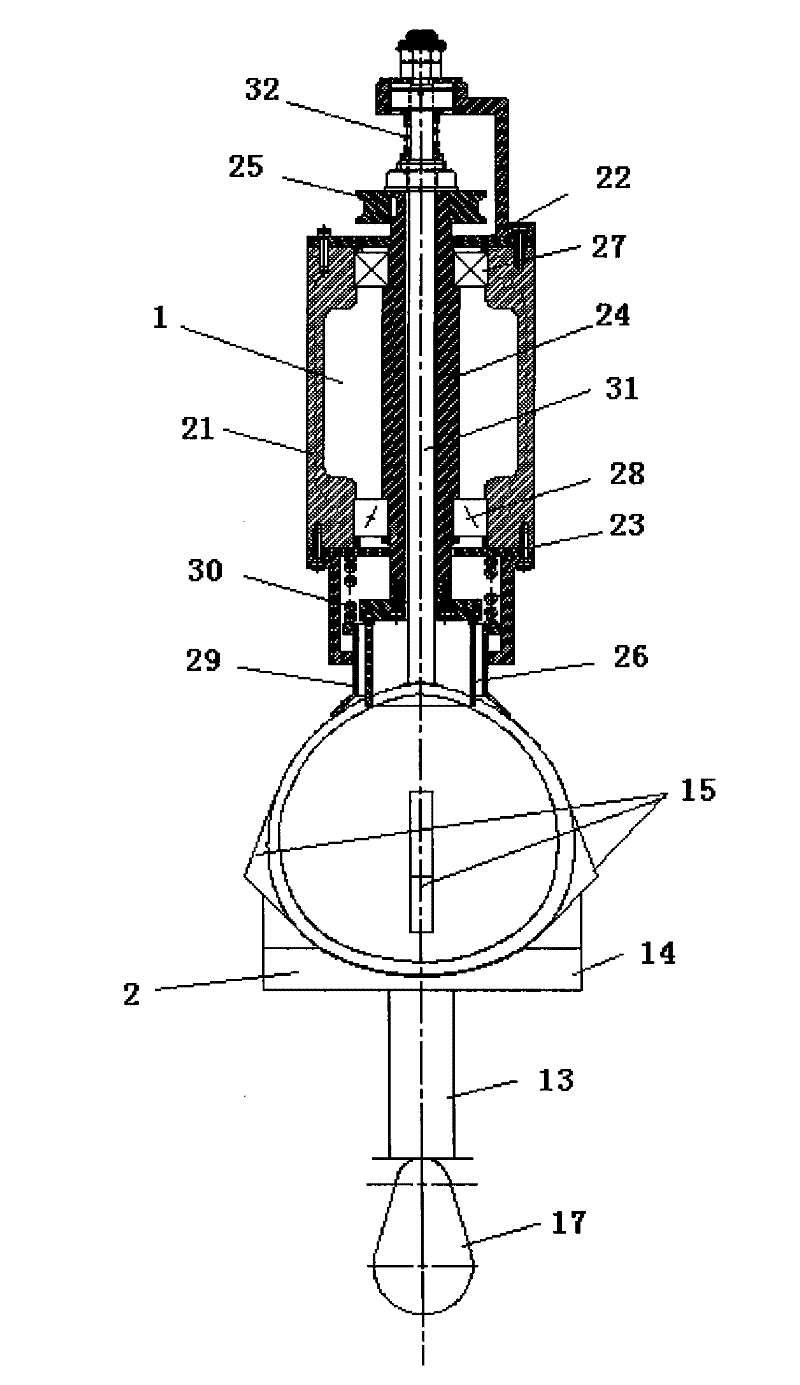

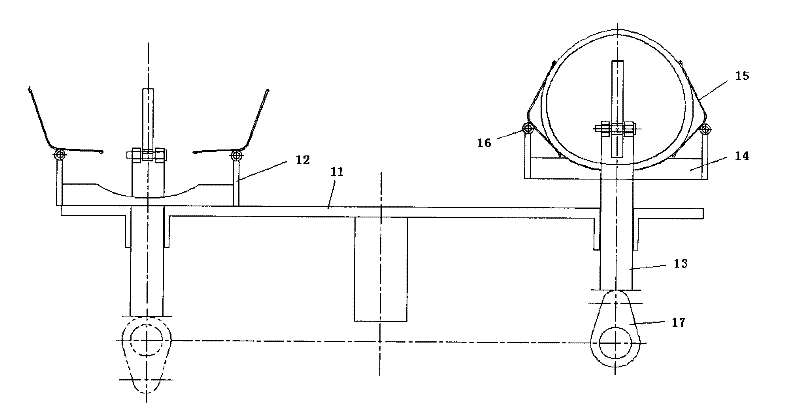

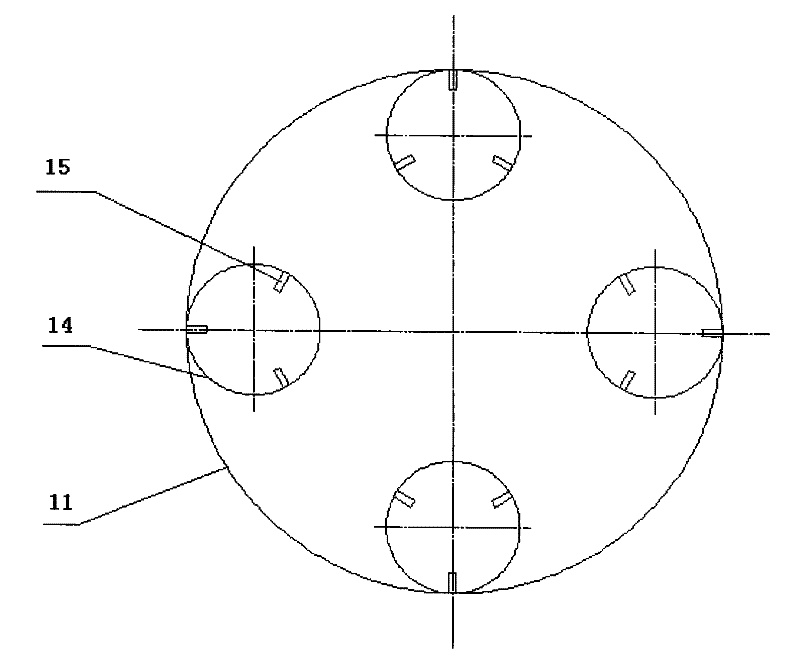

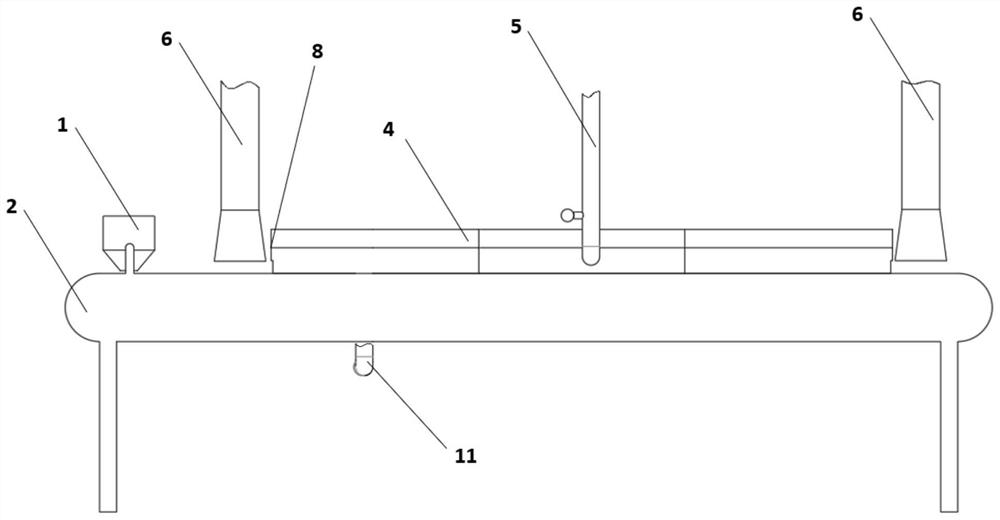

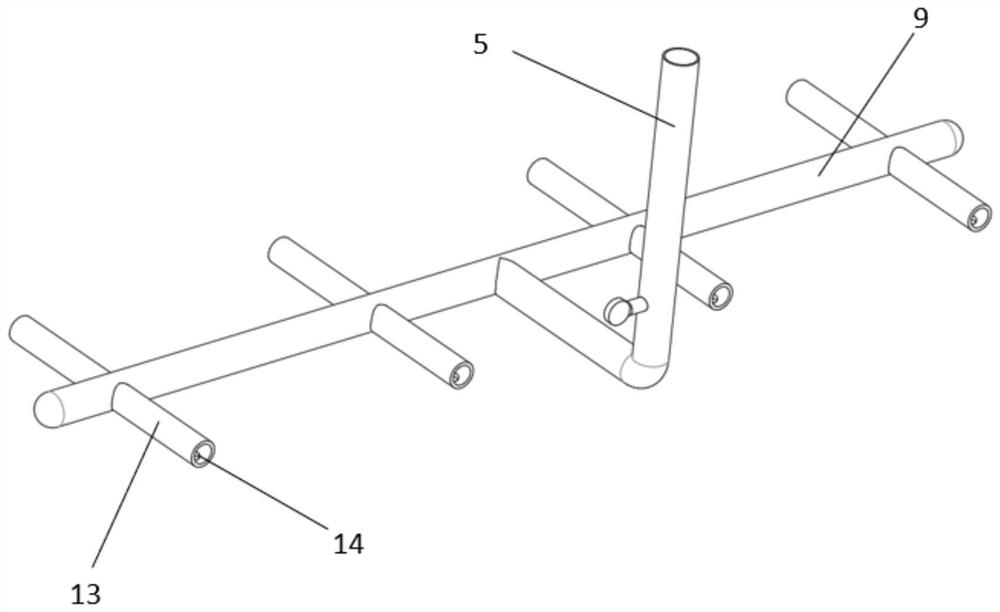

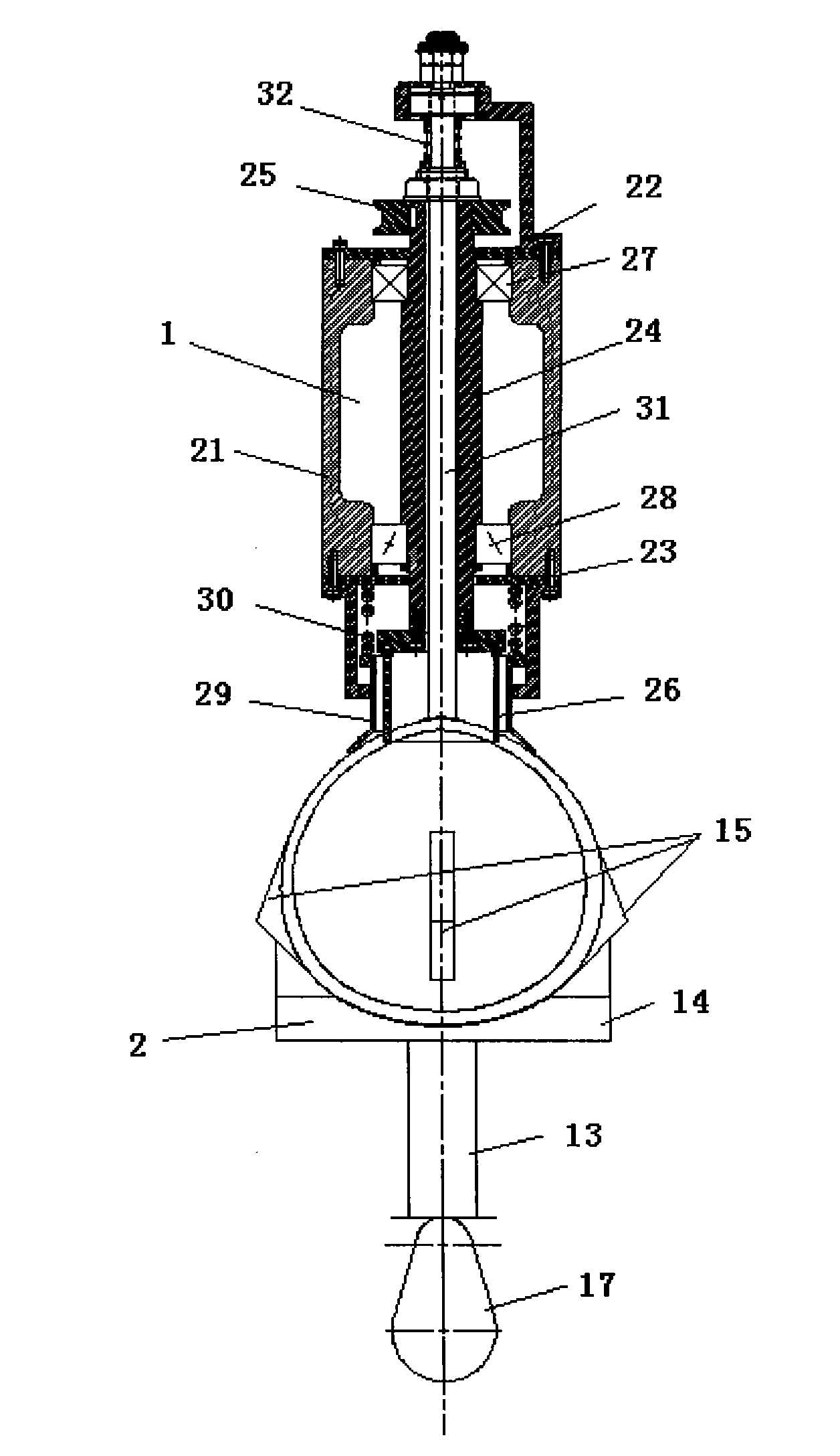

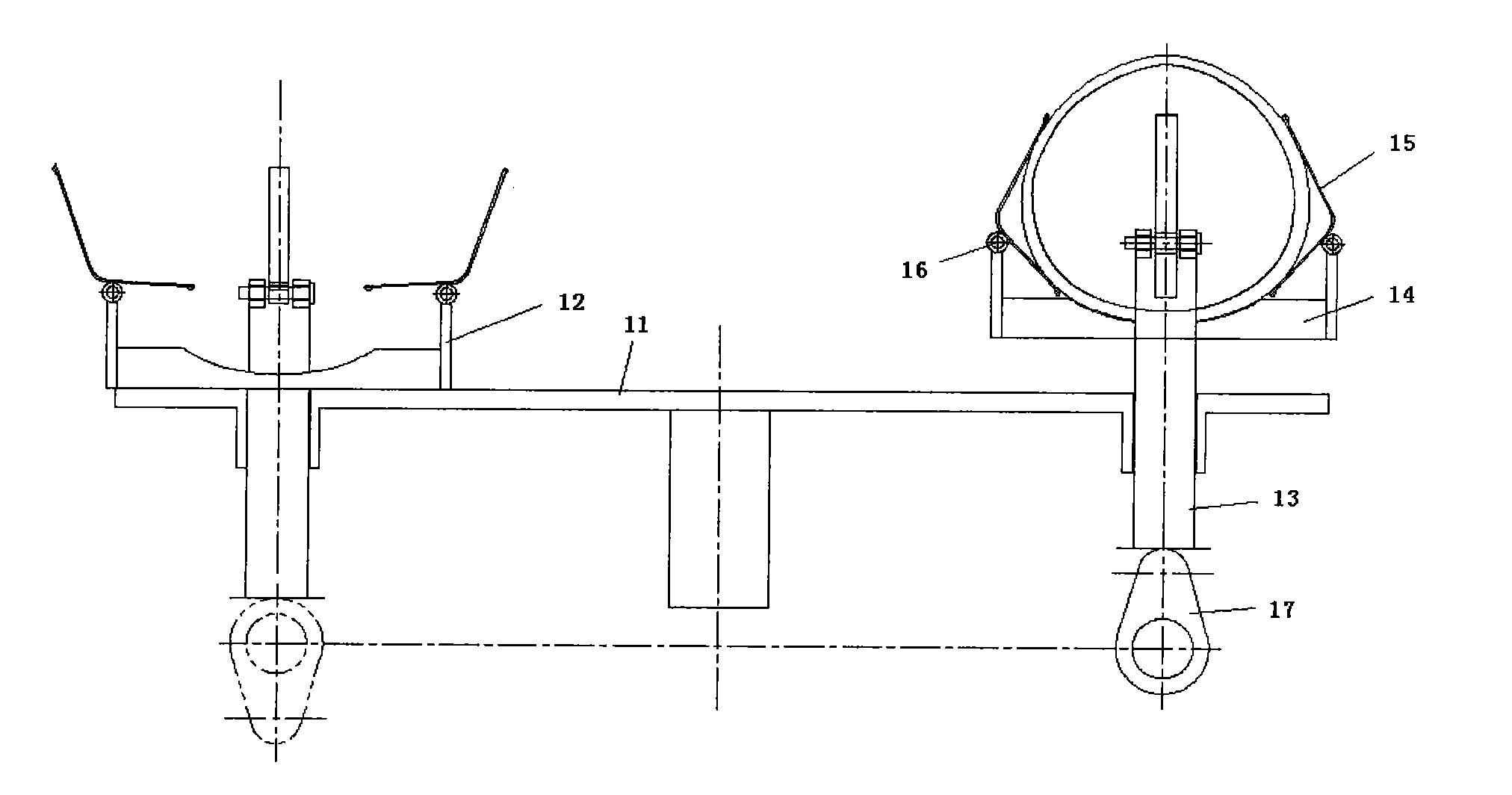

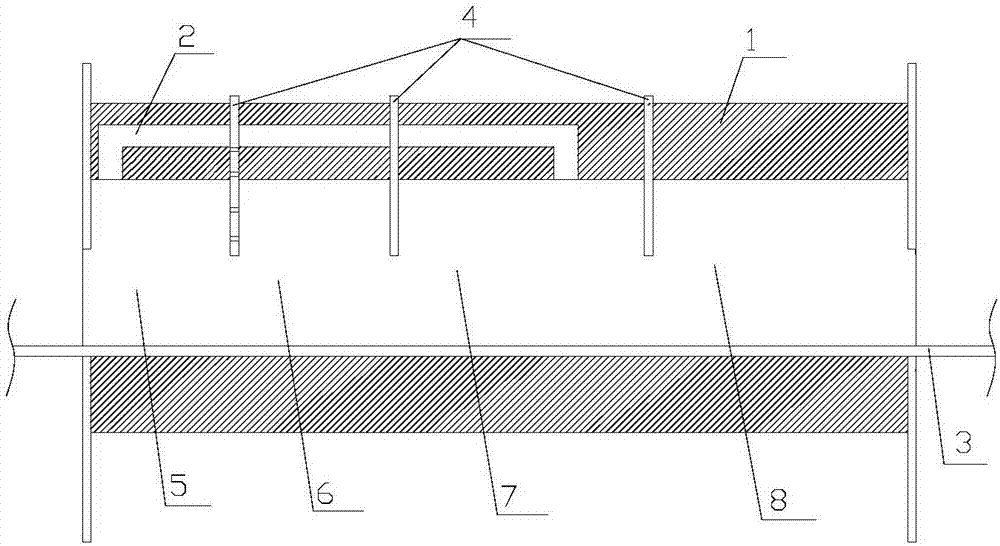

Transverse tube continuous cooking and steam explosion apparatus for biomass cellulosic ethanol

ActiveCN103132359AImprove dehydration efficiencyConsistent moistureDigestersPaper material treatmentFiberSpiral blade

The invention discloses a transverse tube continuous cooking and steam explosion apparatus for biomass cellulosic ethanol, which is provided with a preevaporation spiral tube and a transverse cooking tube, wherein the preevaporation spiral tube is connected with the transverse cooking tube through a spiral cork press and a T-shaped tube; the transverse cooking tube comprises an evaporation tube, a central shaft and a spiral blade; the evaporation tube is communicated with a steam input pipeline; the spiral blade comprises multiple spiral blade sections which have unequal thread pitches and unequal diameters; the edges of the spiral blade sections having small diameters are provided with shift teeth; every two neighboring ones among the shift teeth are respectively inclined towards the two sides; an outlet of the transverse cooking tube is connected with a horizontal blanking unit; a spiral blade of a feeding screw of the horizontal blanking unit is transversely arranged; and the horizontal blanking unit is connected with a pressurizing jet and explosion unit. The invention can realize large-scale production, ensures that raw materials are uniformed in cooked rate and straw fibers are pulverized and physically shaped into fine and soft pieces through steam explosion, and completely increases the late enzymolysis saccharification yield; and steam and a water source can be recycled, thereby saving the energy and reducing the consumption.

Owner:孟周强

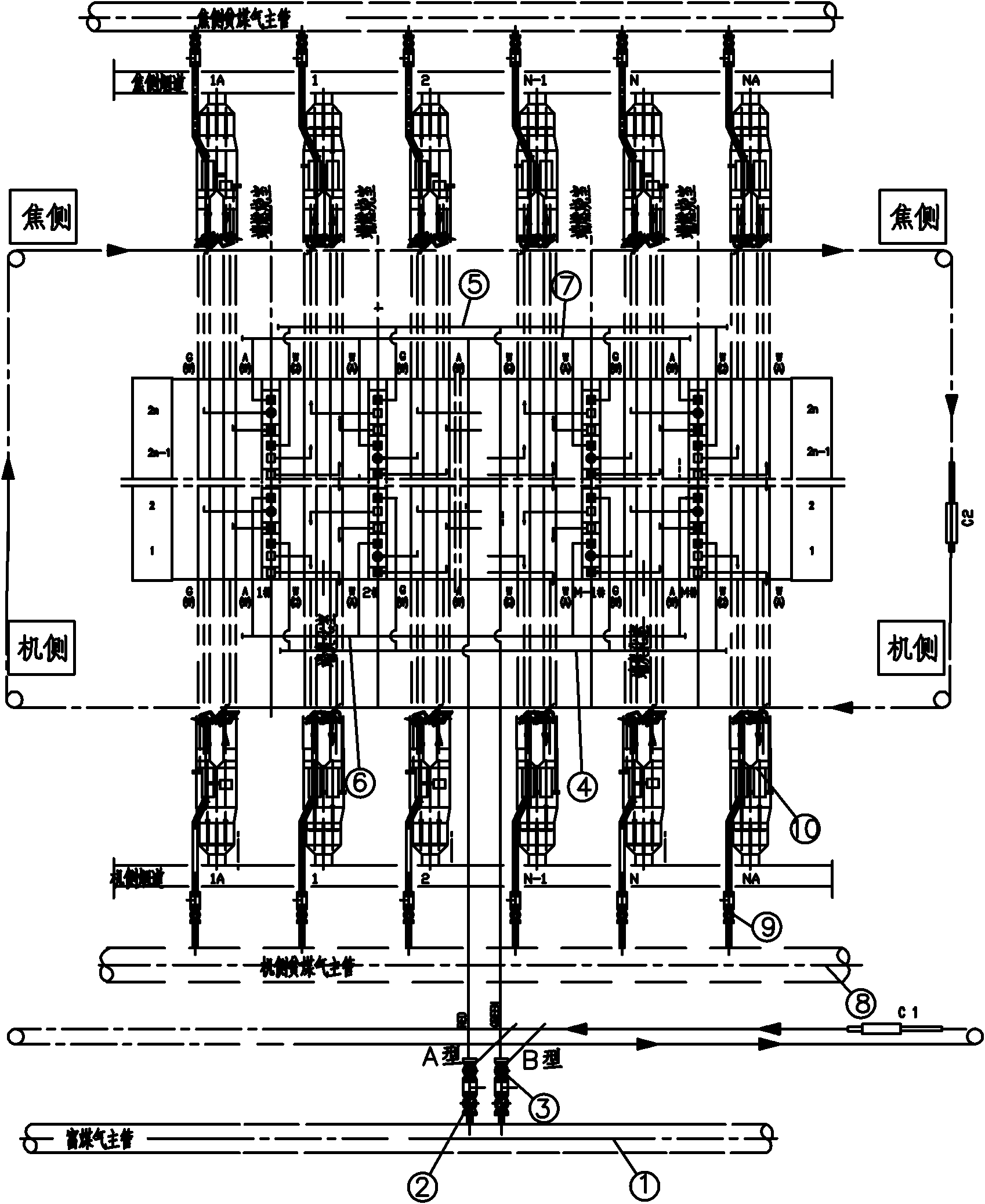

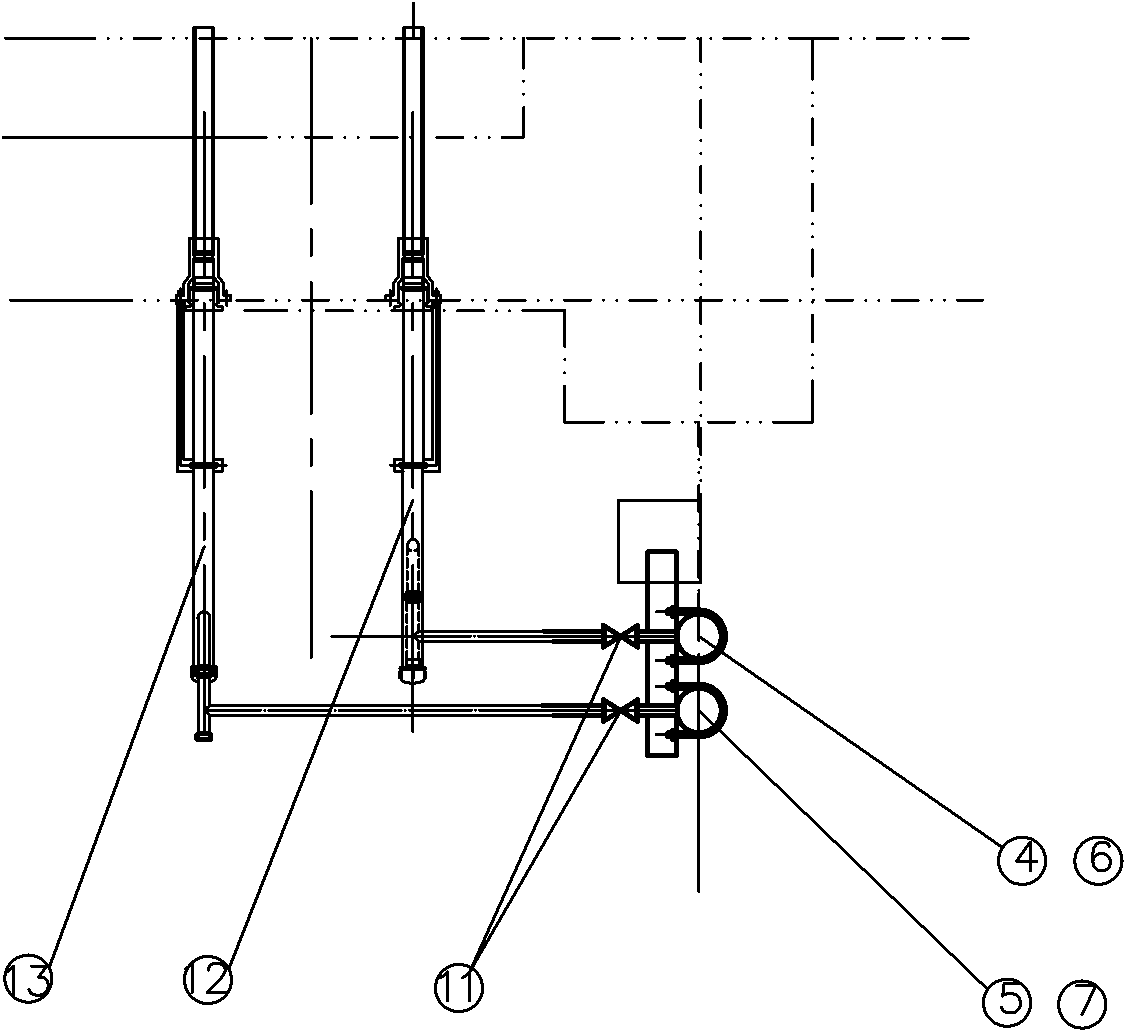

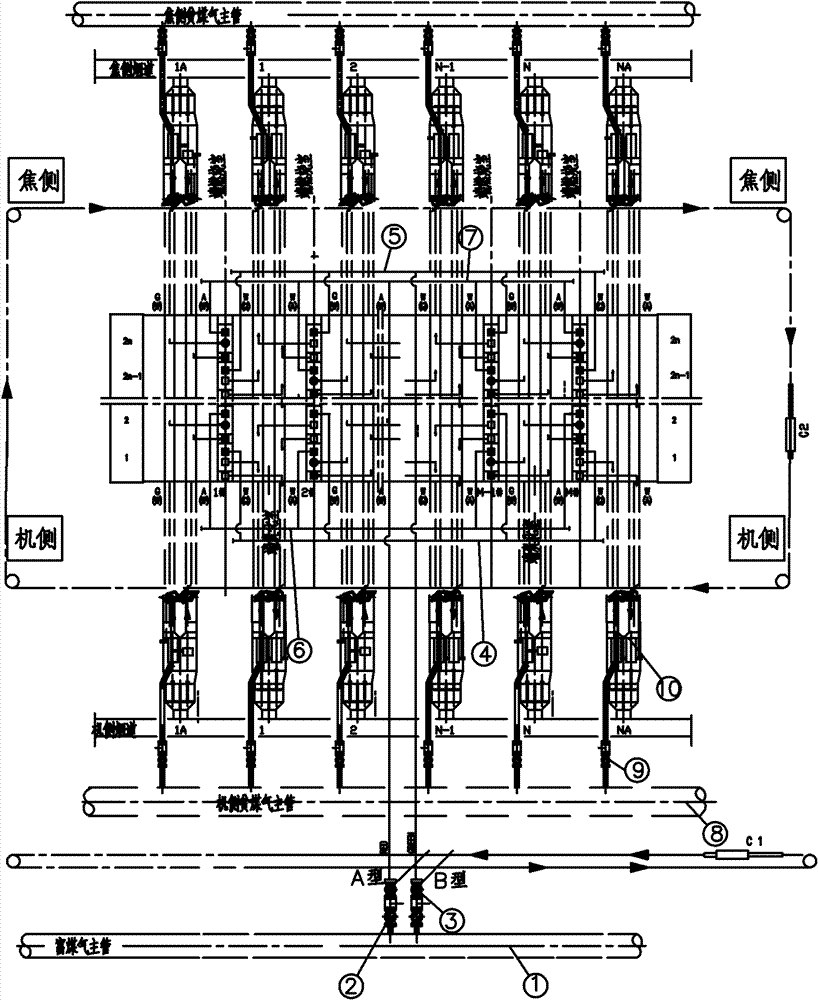

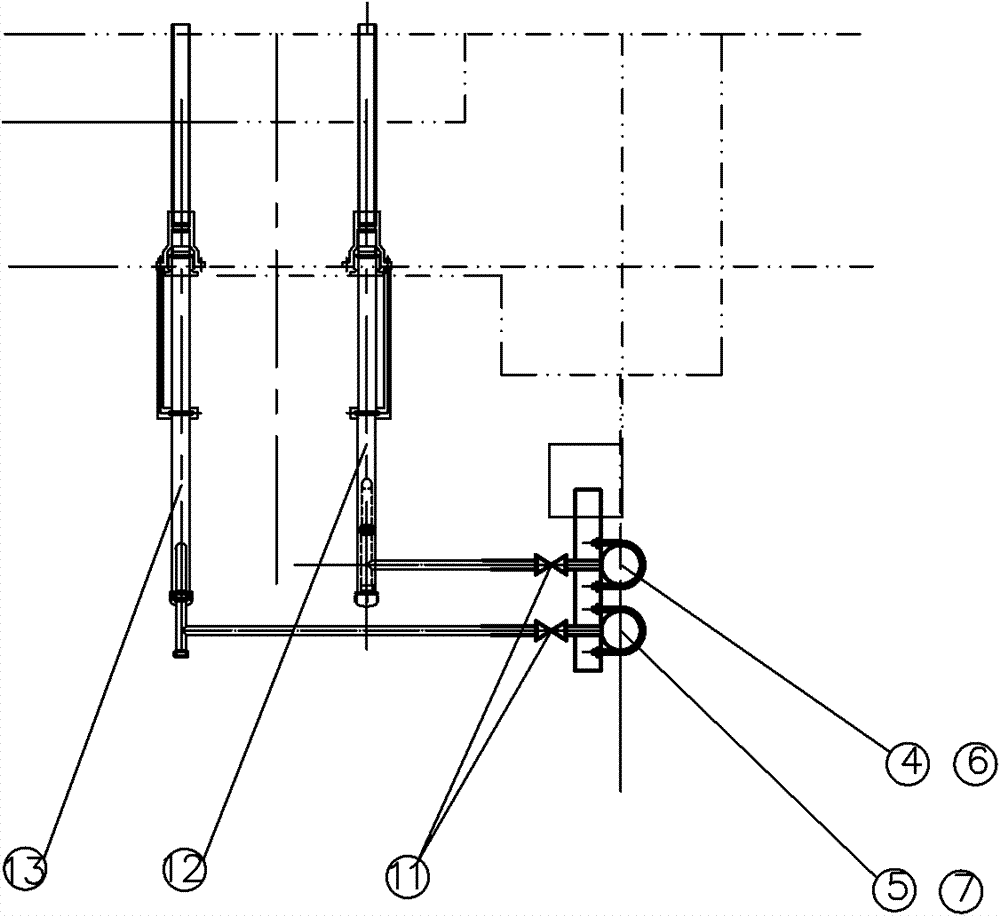

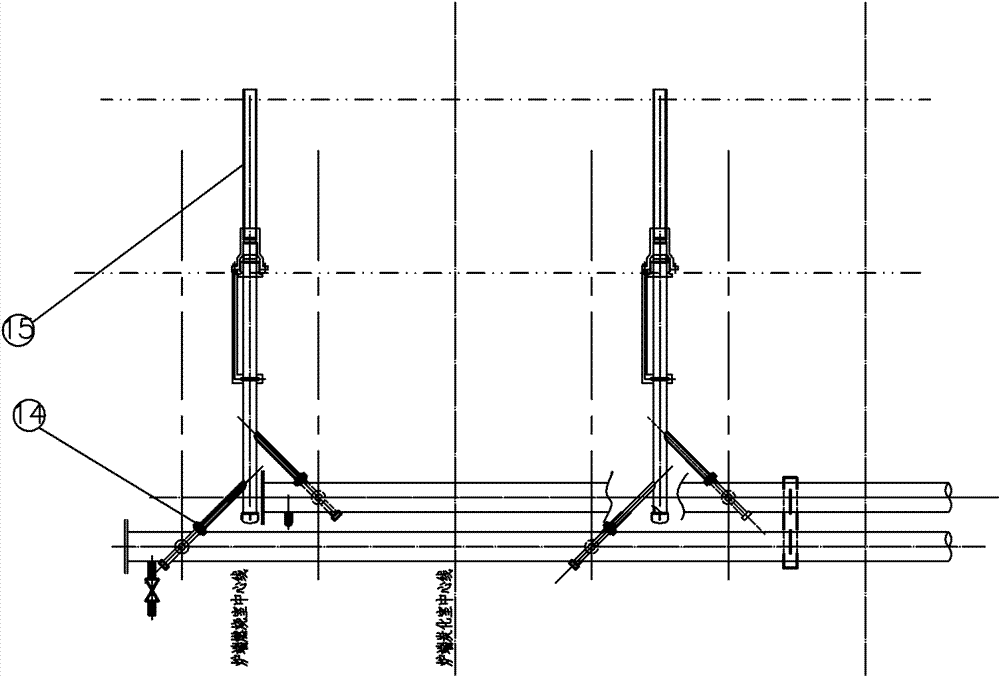

Coke oven burner double-flue supplemental heating method

ActiveCN101979464ASolving insufficient heating conditionsImprove the coefficient of uniformityCombustible gas coke oven heatingVena contracta diameterCombustion

The invention relates to a coke oven burner double-flue supplemental heating method, which belongs to the field of heating combustion of a recuperative heat coke oven and a lean-gas-burning single heat coke oven. In the method, auxiliary afterflaming is performed in two sets of vertical flues in the burner on the machine and coke side of a lean gas heating coke oven in a coke oven rich gas lower-jet mode; a rich gas main pipe is arranged as a coke oven rich gas pipeline for supplemental heating; two rich gas distribution pipes are led out from the rich gas main pipe on the oven machine and coke side respectively and connected with lower jet pipes of the vertical flues in the burner; a copper ball valve and a stainless steel orifice plate are arranged on each jet pipe for regulating gas volume entering the flues; and the gas exchange is realized by a coke oven exchange and transmission device. The method can effectively solve the problem of insufficient heat supply to the burner when the lean gas is burnt in the coke oven, and the burner temperature is improved so as to meet the requirements of the technology. Therefore, the uniformity coefficient of the burner temperature is improved, the uniformity of whole oven temperature is ensured, the uniformity and maturity of the burner coke and whole oven coke are guaranteed, and the service life of the coke oven is prolonged.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Coconut rice and production method thereof

The invention discloses coconut rice and a production method thereof. The method comprises the following steps of: 1) cutting a circular opening with the diameter of between 6 and 8 centimeters at the fruit base of a coconut fruit to form a spherical coconut bowl and a coconut shell cover, and pouring coconut water; 2) juicing coconut flesh with the fruit age of between 11 and 12 months, and adding a complex additive and mixing uniformly to obtain pre-prepared coconut juice, wherein the complex additive consists of a flavoring agent and an antiaging agent; 3) soaking glutinous rice in water for 0.5 to 2 hours, and presteaming at the temperature of 100 DEG C under normal pressure for 10 to 30 minutes to obtain presteamed glutinous rice; and 4) adding the presteamed glutinous rice and the pre-prepared coconut juice in the spherical coconut bowl, stirring uniformly, covering by using the coconut shell cover, and steaming to obtain the coconut rice. The coconut rice has the mouthfeel of tender coconuts and concentrated fragrance of matured coconuts; and the rice cooked in a coconut shell is aged and uniform, soft and elastic and stable in quality by a reasonable process, and the coconut shell is formed into a container which is used for containing the rice and is provided with the bottom and the cover skillfully, so the rice is not needed to be contained or heated by additional containers when eaten, and is convenient and practical.

Owner:HAINAN UNIVERSITY

Method for preparing bamboo charcoal with controllable aperture

InactiveCN104607145AUniform and dense microstructureRipe evenlyOther chemical processesAlkali metal oxides/hydroxidesNitrogenRoom temperature

The invention relates to a method for preparing bamboo charcoal with a controllable aperture. The method comprises the following steps: cutting bamboo, selecting a middle section of cut bamboo which is more than 1m above the ground for drying treatment, controlling the water content of the bamboo to be less than 20%, placing the bamboo in a high-temperature furnace, feeding high-purity nitrogen or argon into the high-temperature furnace at a flowing rate of more than 5L / min to carry out deoxidization, then, raising the temperature of the high-temperature furnace to 400-1,500 DEG C at a speed of 3-40 DEG C / min, charring at the constant temperature for 1 to 8h, naturally cooling the high-temperature furnace to the room temperature after the thermal decomposition and the charring are finished, taking the product out and grinding, controlling the fineness of the product to be more than 20 meshes, and modifying the pore structure to obtain the bamboo charcoal with the controllable aperture. Compared with the prior art, the method is simple in preparation process, can effectively reduce the production cost by pressure maintaining and charring and effectively improve the adsorption capability of the bamboo charcoal by adopting the pore structure modification; moreover, the prepared bamboo charcoal can be suitable for application scenarios of different adsorbates, and is wide in application range.

Owner:TONGJI UNIV

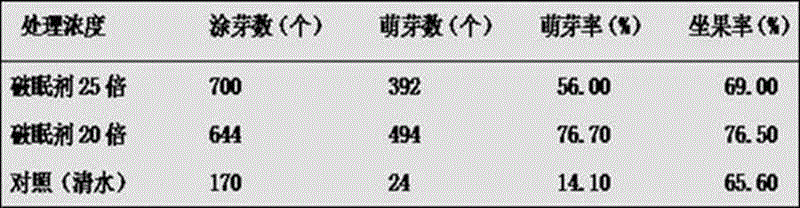

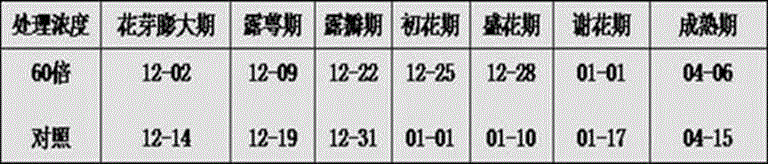

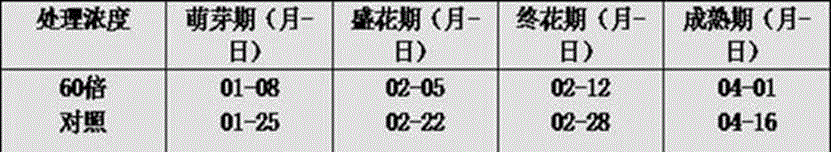

Dormancy breaking agent for fruit tree under protected cultivation and application method

InactiveCN104413063ASimple configurationLow priceBiocidePlant growth regulatorsFruit treeVitis vinifera

The invention provides a dormancy breaking agent for fruit trees under protected cultivation and an application method. The dormancy breaking agent is prepared from 50% by mass of cyanamide and 0.48% by mass of boron, and when in use, Bijia with a mass being 1500 times of the amount of the agent is added. The application method comprises the following steps: smearing or spraying grapes under protected cultivation with the dormancy breaking agent with an amount being 20-25 times of the amount of the fruiting branches 1 week before the temperature increases; spraying nectarines under protected cultivation with the dormancy breaking agent with an amount being 60-80 times of the amount of the branches at the day when the temperature increases or 1-2 days before and after the temperature increases; spraying sweet cherries under protected cultivation with the dormancy breaking agent with an amount being 60 times of the amount of the branches at the day when the temperature increases or 1-2 days before and after the temperature increases; spraying plums under protected cultivation with the dormancy breaking agent with an amount being 60-100 times of the amount of the branches at the day when the temperature increases or 1-2 days before and after the temperature increases. The dormancy breaking agent of the invention is easy to prepare, low in price, and safe in use, enables fruit trees to sprout and bloom earlier and orderly, can concentrate the flowering period, increases the flower amount, enables the fruit maturity period of the treated fruit trees to be earlier and uniform, and can improve fruit quality.

Owner:LIAONING AGRI COLLEGE

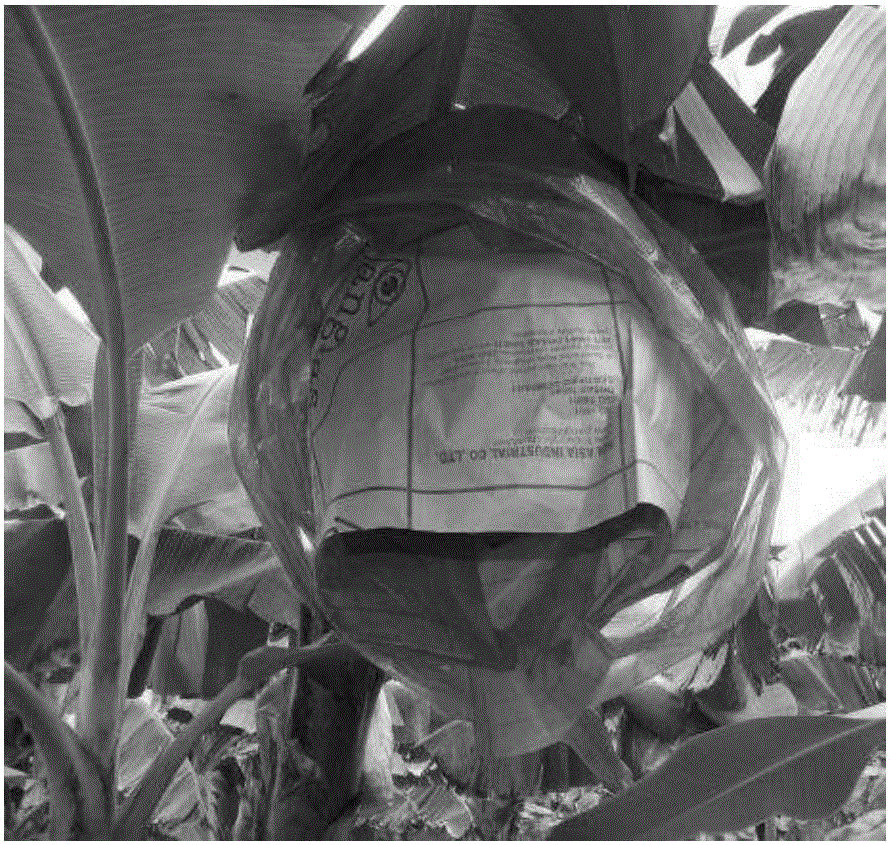

High-yield and high-quality cultivation method for anti-wilt banana variety

ActiveCN105993782AImprove efficiencyAvoid coldClimate change adaptationCultivating equipmentsBanana PlantCanned fruit

The invention discloses a high-yield and high-quality cultivation method for an anti-wilt banana variety. The method comprises the steps that the low-order planting anti-wilt banana variety is adopted for tissue culture seedlings; when the low order means soil preparation or planting, the ground of a planting hole is lower than a garden bed face, a step is formed, the paddy field banana garden level difference is 8-15 cm, and the mountain land banana garden is 14-22 cm; when banana plant corms begin to appear, earthing is performed to protect corms, and root growth is promoted. During early spring planting, the low planting density is adopted, plants can fruit earlier, and plants are prevented from fruiting or being frozen in winter; in summer and autumn, high planting density is adopted for planting, the yield per unit area can be increased, and meanwhile fruit quality is not affected; paper bags and nutritional agents are used for plant ears, so that the problem that fruits become green physiologically can be solved. According to the high-yield and high-quality cultivation method customized for the anti-wilt banana variety, the culture technology can achieve high yield, good quality and high benefits and achieves the great production significance.

Owner:POMOLOGY RES INST GUANGDONG ACADEMY OF AGRI SCI

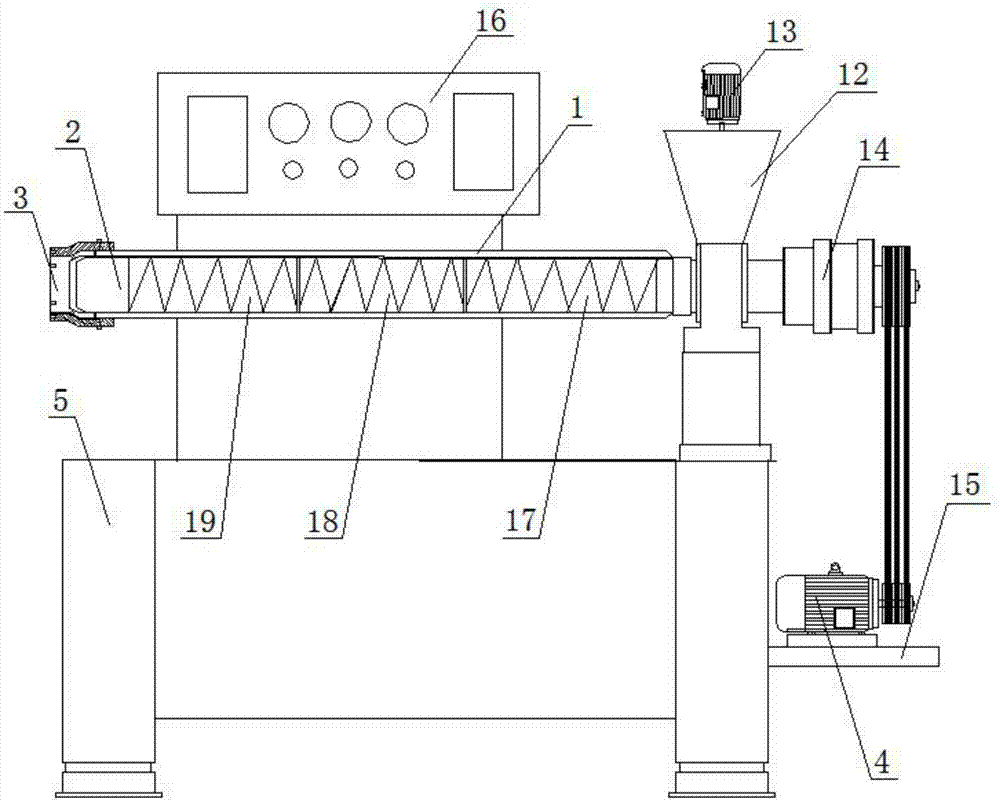

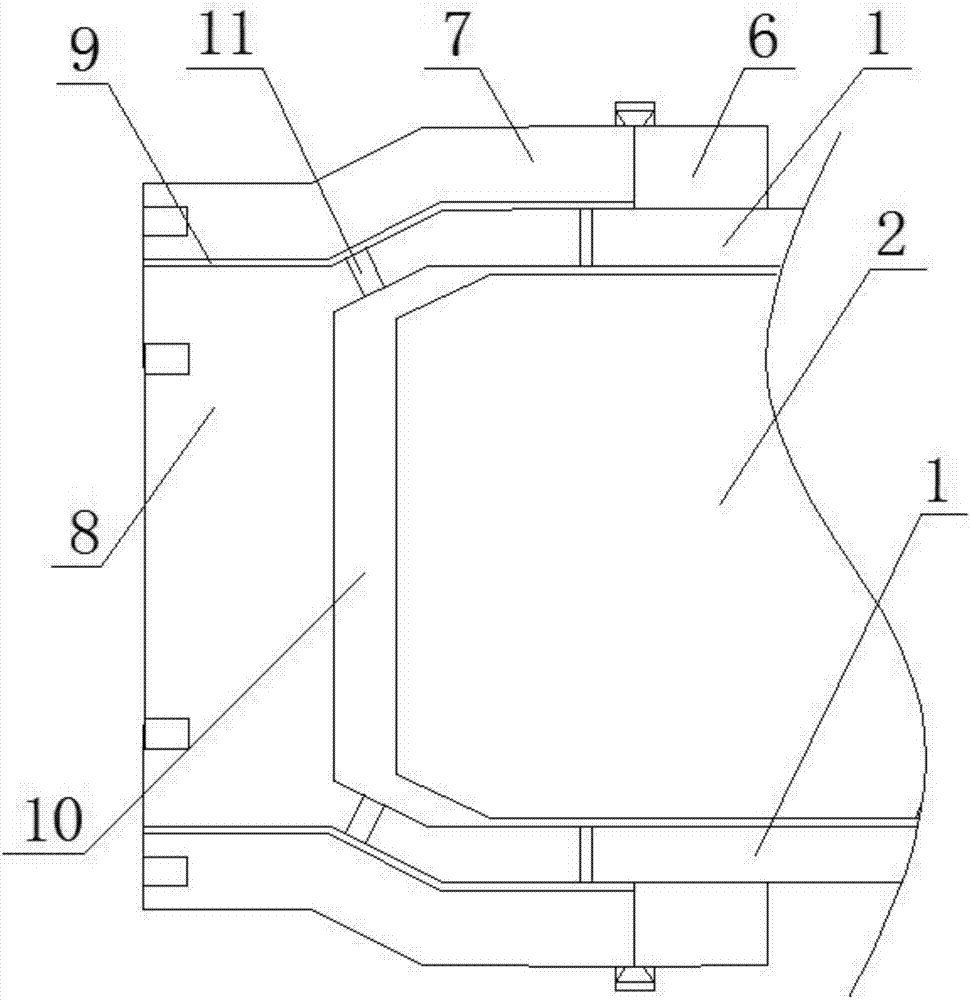

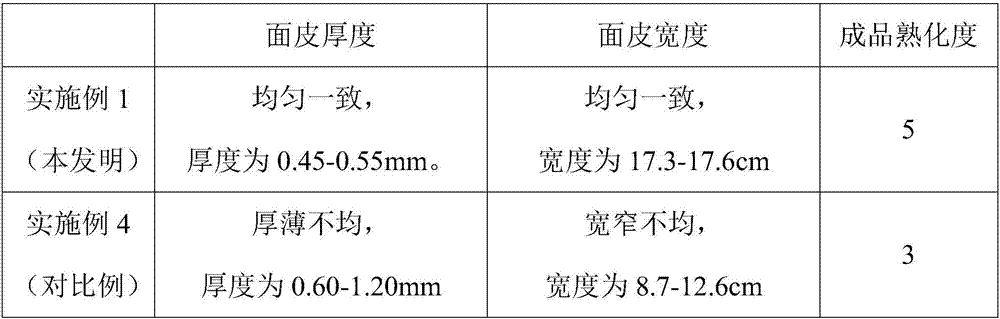

Preparation method of non deep-fried instant noodles and screw extrusion equipment

The invention discloses a preparation method of non deep-fried instant noodles and screw extrusion equipment, and solves the problems that in the prior art, a screw rod extrusion and curing production technology is used for non deep-fried instant noodles, cooking and curing need to be performed twice, else the curing degree is insufficient, and the production stability is poor. The preparation method comprises the following steps of uniformly mixing raw materials in proportion, adopting a three-stage heating and extruding manner for curing, then performing twisting, performing shaping twice so as to obtain uniform wrappers, cutting the wrappers into shreds, performing four-stage drying, and then performing packaging so as to obtain the non deep-fried instant noodles, wherein the curing, twisting and shaping twice are continuously performed. The method disclosed by the invention is simple, the operation is simple and convenient, the production technology stability of the non deep-fried instant noodles is improved, and the automatic and standardized production of the non deep-fried instant noodles is realized.

Owner:四川白家阿宽食品产业股份有限公司

Novel process for preparing soybean milk

InactiveCN102177972AShorten pulping timeImprove water retentionMilk substitutesFood sciencePetalSoybean meal

The invention relates to a novel process for preparing soybean milk. The process comprises a raw material supply stage at which a soybean raw material is provided, and a user side pulverization and pulping stage, wherein the raw material supply stage comprises the steps of crushing whole soybeans into a plurality of soybean petals and curing the soybean petals; and the user side pulverization and pulping stage comprises the steps of mixing the soybean petals and water, pulverizing and pulping. By the novel preparation process, the soybean petals are cured in the raw material supply stage, so that a step of boiling the soybean milk is not required in the user side pulverization and pulping stage, namely when people want to prepare the soybean milk, the cured soybean petals provided in the raw material supply stage are directly mixed with water for pulverization and pulping, so that the pulping time of a user side is greatly shortened.

Owner:JOYOUNG CO LTD

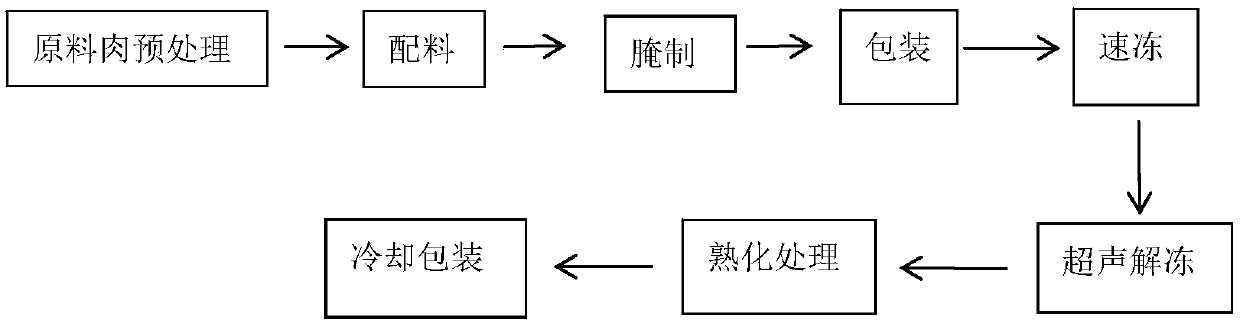

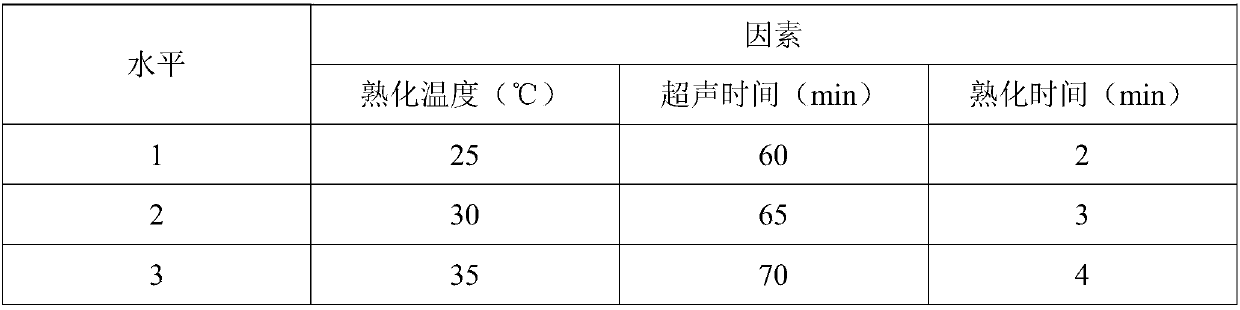

Preparation method of low-temperature cured prefabricated meat product

The invention discloses a preparation method of a low-temperature cured prefabricated meat product. The method comprises the following steps: slicing raw material meat, and pickling meat slices to obtain pickled meat; subjecting the pickled meat to vacuum packaging and freezing to obtain frozen meat; subjecting the frozen meat to ultrasonic treatment and curing to obtain cured meat; subjecting thecured meat to vacuum packaging to obtain a finished product. With the preparation method of the invention, curing time is short; the produced meat product is suitable in saltiness and moderate in acidity; remnant nitrite is less than 2 ppm; and pickling is complete, and is prepared for subsequent deep processing.

Owner:HUNAN AGRICULTURAL UNIV

Spicy bar and making method thereof

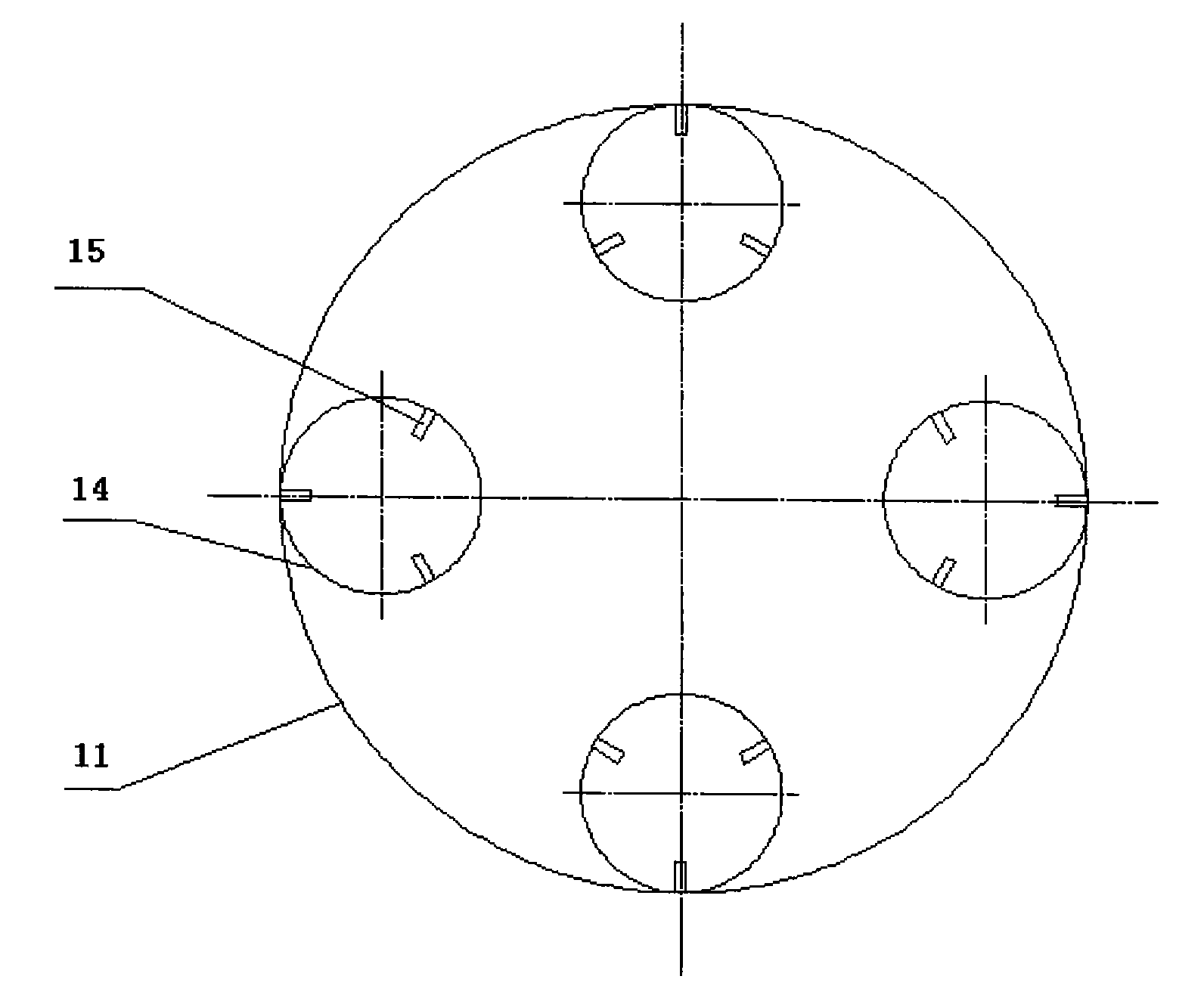

InactiveCN107788373AEvenly heatedRipe evenlyFood thermal treatmentFood preservationMicrowave ovenWork in process

The invention discloses a spicy bar. The spicy bar comprises the following components by weight: 40-60 jin of flour, 15-25 jin of water, 4-6 jin of salt, 20-40g of calcium propionate, 40-60g of monostearin and 50-70g of aspartame. The spicy bar is made through the following steps of firstly, weighing the raw materials by weight; putting the weighed raw materials in stirring equipment, and performing stirring and dough mixing, wherein the stirring time is 30s; performing comprehensive heating on periphery of the made dough with 8 Killiwatts of a circular copper heating lamp tube, and after heating, obtaining semi-finished products; and putting the semi-finished products in a microwave oven and performing sterilizing, so that finished products are obtained. The comprehensive heating is performed on periphery of the made dough with 8 Killiwatts of the circular copper heating lamp tube, the quality guarantee period of the obtained semi-finished products can be prolonged by about 2 months,the semi-finished products are put in the microwave oven, and sterilizing is performed, so that the quality guarantee period can also be prolonged by about 2 months. The quality guarantee period of the made spicy bar can achieve about 10 months, and healthy foods can be provided for consumers.

Owner:长沙神采奕奕食品有限公司

Cynomorium songaricum preparation method

The invention belongs to the technical field of medicine preparation, particularly relates to a cynomorium songaricum preparation method. The invention aims to solve the problems of long time consumption, high cost and low medical effect of the traditional cynomorium songaricum preparation method. The cynomorium songaricum preparation method provided by the technical scheme of the invention comprises the following steps: taking 100 parts by weight of cynomorium songaricum, cleaning the cynomorium songaricum, and cutting the cynomorium songaricum into small pieces the thicknesses of which are 1.5-2cm; putting the small pieces into a container, adding 20-30 parts by weight of yellow wine, and stirring uniformly; sealing the container, standing for 3-4 hours, and then, taking the small pieces out of the container; putting the small pieces which are taken out of the container into a stir-frying machine for frying until the colors of the small pieces change; and airing to obtain finished products. In the invention, by adopting the technical scheme, under the condition of ensuring that the cynomorium songaricum is well-done and uniform in the preparation process, the preparation time is shortened, the preparation cost is lowered, the contents of proline and ursolic acid which are used as main components in the cynomorium songaricum are increased, and the medical effect of the cynomorium songaricum is enhanced.

Owner:山西振东五和堂制药有限公司

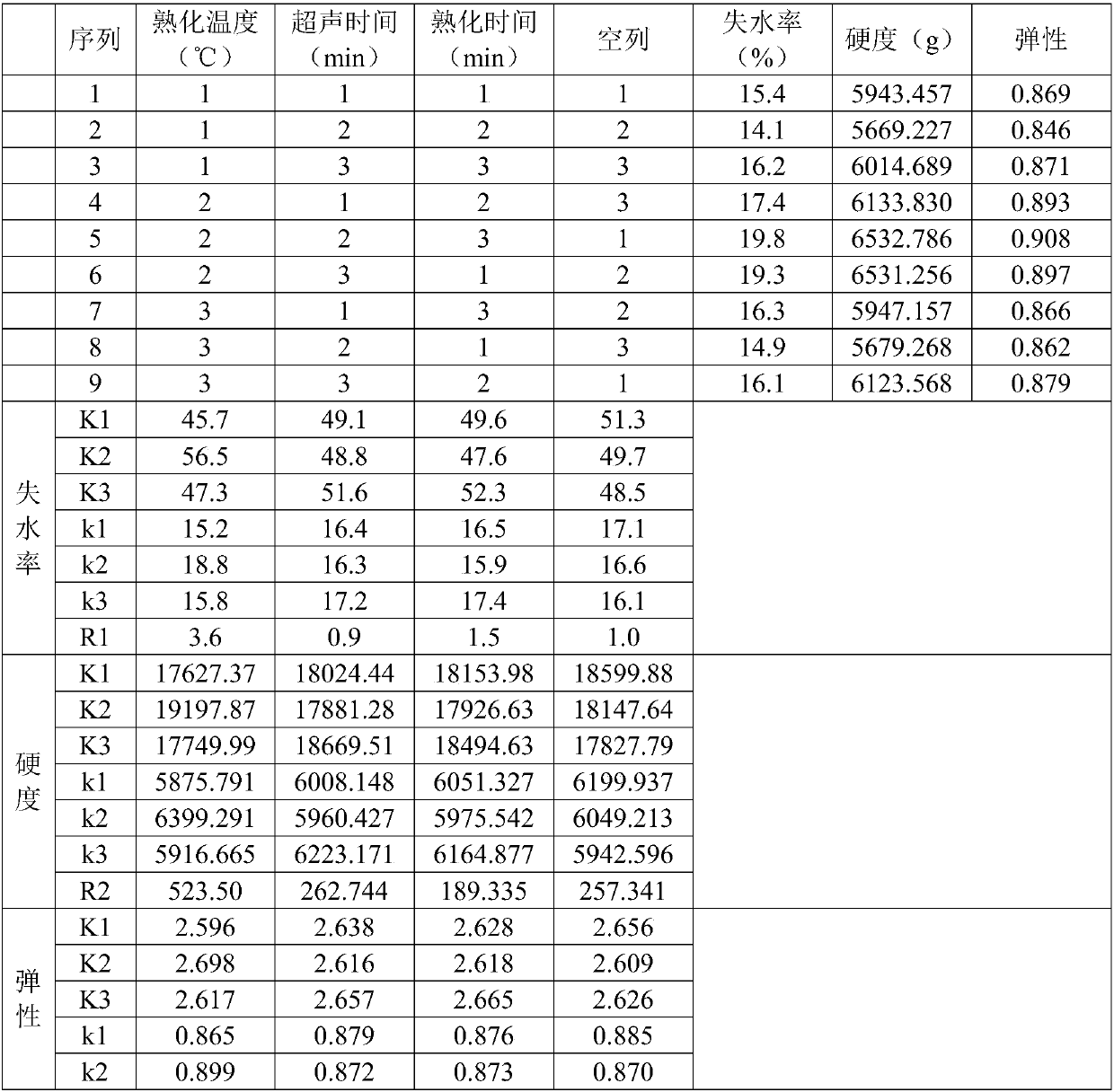

Large-leaf thick laver crisp chip and related production method

The present invention provides a large-leaf thick laver crisp chip and a related production method, the large-leaf thick laver crisp chip is prepared from a large-leaf thick laver sheet dry product, edible auxiliary materials and edible seasonings, the weight (gram) of large-leaf thick laver sheet dry product per unit area is 13.5mg / cm<2> to 20mg / cm<2>, the longest length of the leaf body is 2cm-5cm, the edible auxiliary materials are selected from sesame seeds, peanuts, pine nuts and walnuts, the edible seasonings include one or more of edible vegetable oil, sugar, malt dextrin, starch, edible salt, soy sauce and spices, the large-leaf thick laver crisp chip is prepared from the large-leaf thick laver sheet dry product by double-side baking, single and double-side flavoring, single and double-side material feeding and double-side baking, the baking temperature is 150 DEG C-180 DEG C, and the baking time is 25 seconds to 35 seconds. The large-leaf thick laver crisp chip is convenient to eat, nutritious, delicious, easy to bake, even to cook, good in baking effect, easy in attachment of accessories, accurate and easy to meter, and suitable for large-scale application.

Owner:JIANGSU RUIXUE OCEAN TECH CO LTD

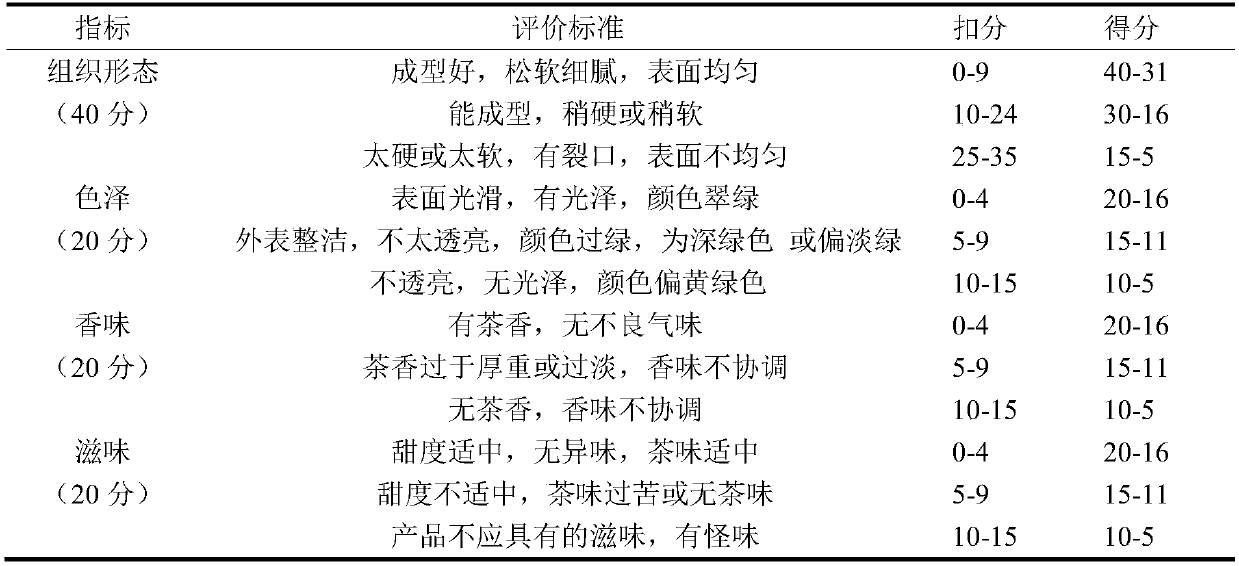

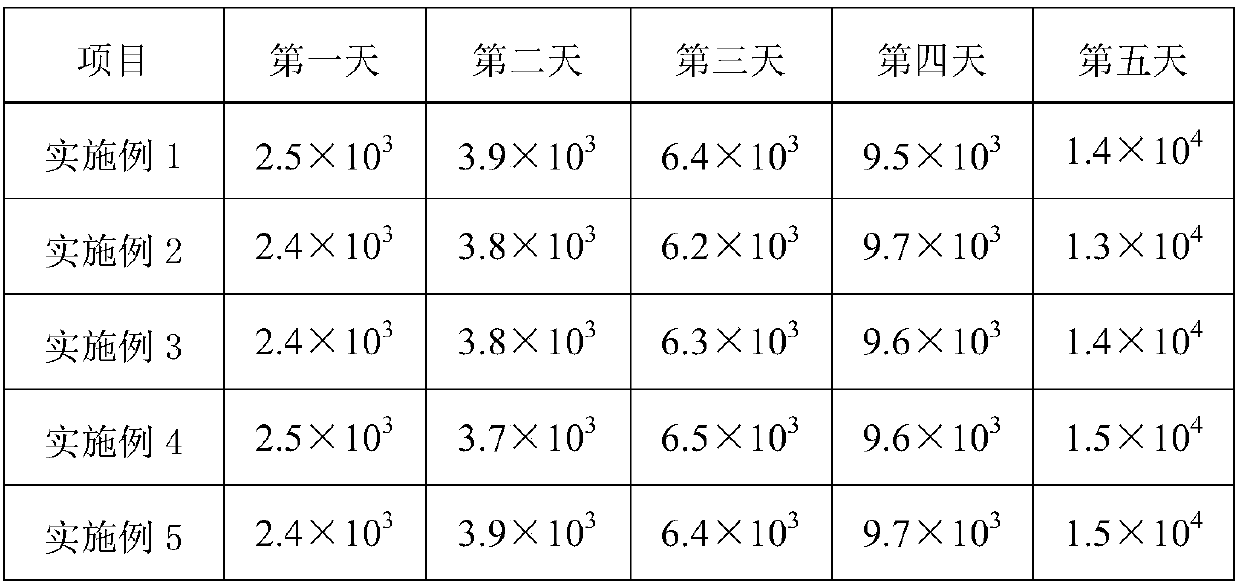

Sugarless matcha snowy mooncake and preparation method thereof

The invention discloses a sugarless matcha snowy mooncake and a preparation method thereof. The mooncake comprises tapioca starch, matcha powder, wheat starch, glutinous rice flour, milk, corn oil, maltitol and sticky rice flour. The preparation method includes preparing mooncake stuffing; stirring, mixing and sieving the tapioca starch, the matcha powder, the wheat starch, the glutinous rice flour and the sticky rice flour to obtain a mixture; mixing the maltitol, the milk and the corn oil, adding the mixture, and continuing to stir and mix until no particle dispersions exist in the paste mixture to obtain paste; repeatedly heating the paste though microwaves, curing the paste into a snowy wrapper, and covering the mooncake stuffing with the wrapper; performing molding and refrigerating to obtain the sugarless matcha snowy mooncake. The sugarless matcha snowy mooncake and the preparation method thereof have the advantages that matcha components are introduced, sucrose is replaced by the maltitol, the sugarless matcha snowy mooncake with a health care function is prepared, the overall quality of the snowy mooncake is improved, and the shelf life is prolonged.

Owner:武夷学院

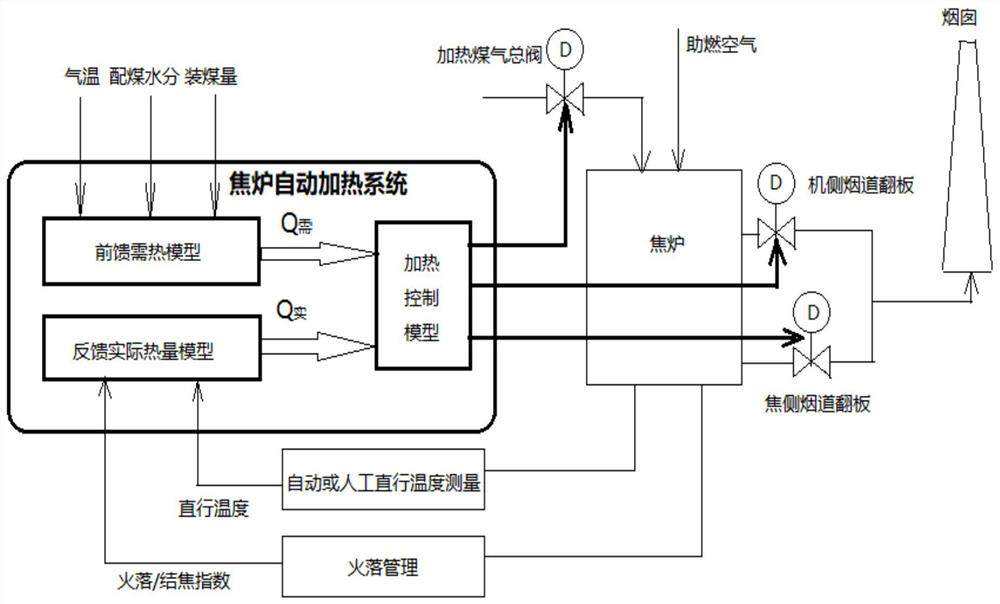

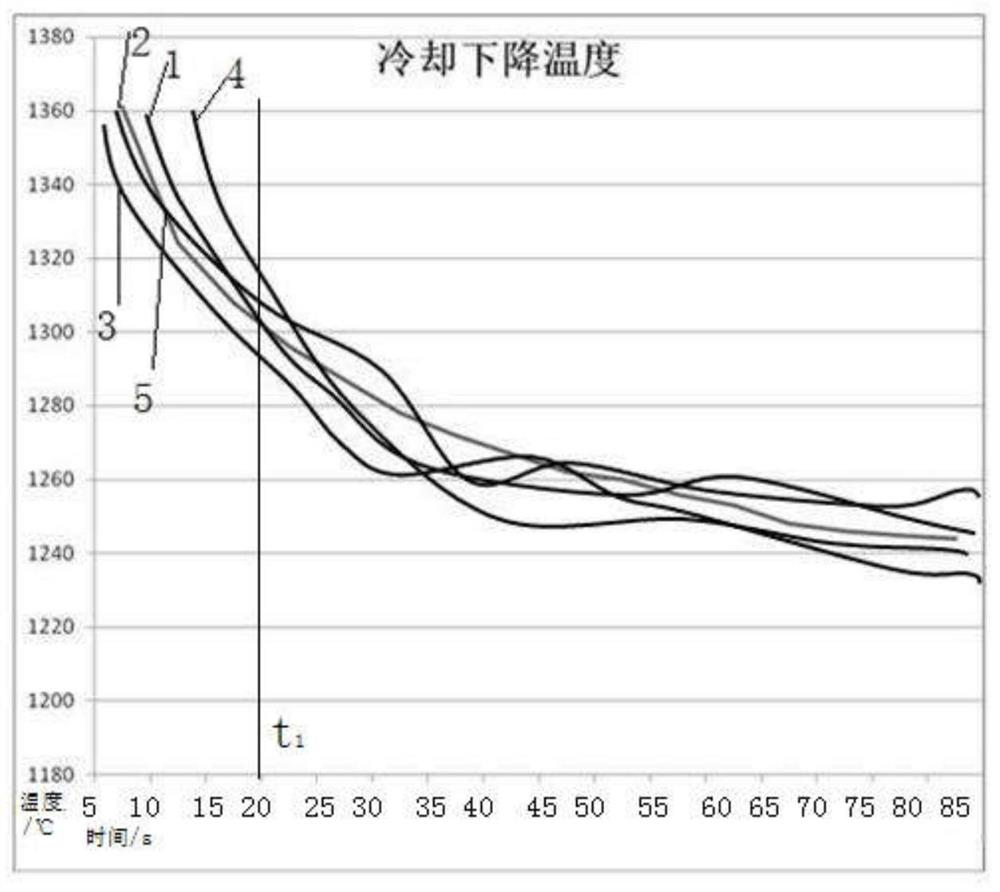

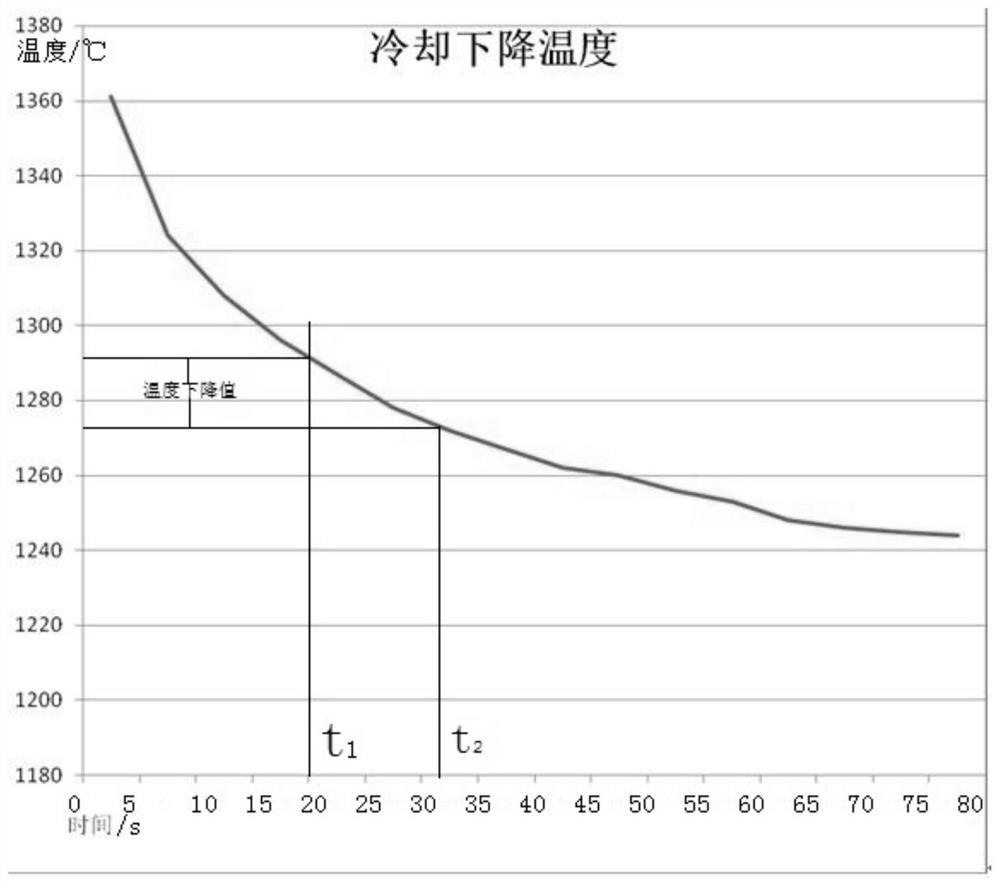

Method for automatically adjusting temperature of coke ovenAutomatic coke oven temperature adjusting method

PendingCN111651898ARipe evenlyAffect qualityCoke ovensDesign optimisation/simulationFurnace temperatureThermodynamics

The invention provides a method for automatically adjusting the temperature of a coke oven, which comprises the following steps of: constructing a feedforward heat requirement model to calculate the heat index Q required by coking, namely f (T, W, G...), and the like), where T is the air temperature, W is the coal blending moisture, and G is the coal charging amount; constructing a feedback actual heat model to calculate an actual heat index Q < real > = f (T < straight >, K < fire drop > and the like...) provided by the coke oven, wherein T < straight > is a straight temperature, and K < fire drop > is a fire drop management index; and calculating the difference between Q and Q, and sending a working signal of a heating gas main valve and / or a machine / coke flue flap control actuating mechanism through the difference. According to the method, cCoking heat consumption can be reduced to save energy; in addition, coke pushing difficulty caused by insufficient fire of coke can be avoided,damage to the furnace body is reduced, the service life of the coke oven is prolonged, the labor efficiency of temperature adjustment work of the coke oven is improved, the temperature adjustment work of the coke oven does not depend on staff work time, personal work experience level and staff responsibility any more, and intelligent work of coke oven production is promoted.

Owner:NANJING HUYOU METALLURGY MACHINERY MFG

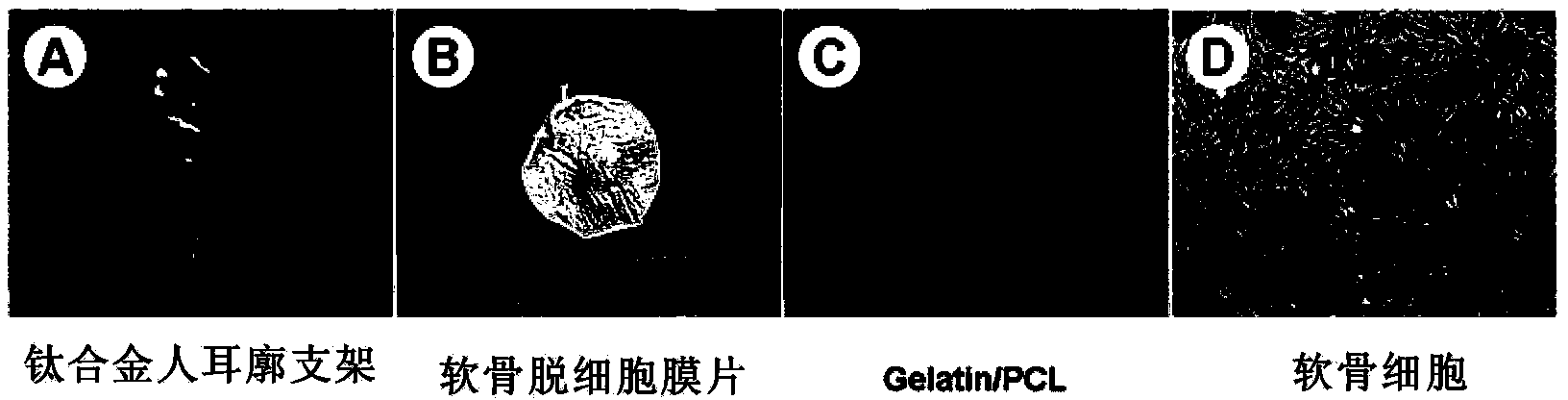

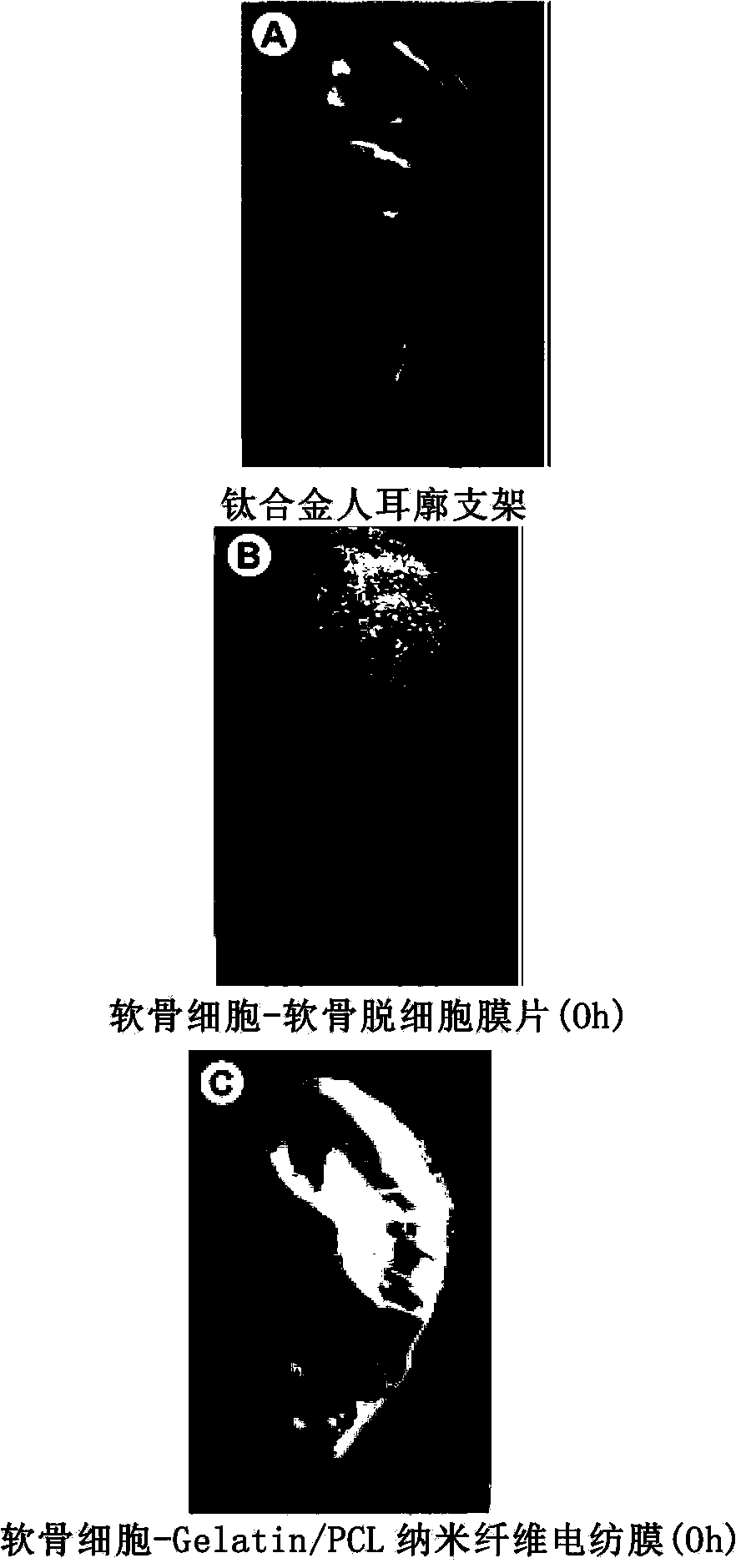

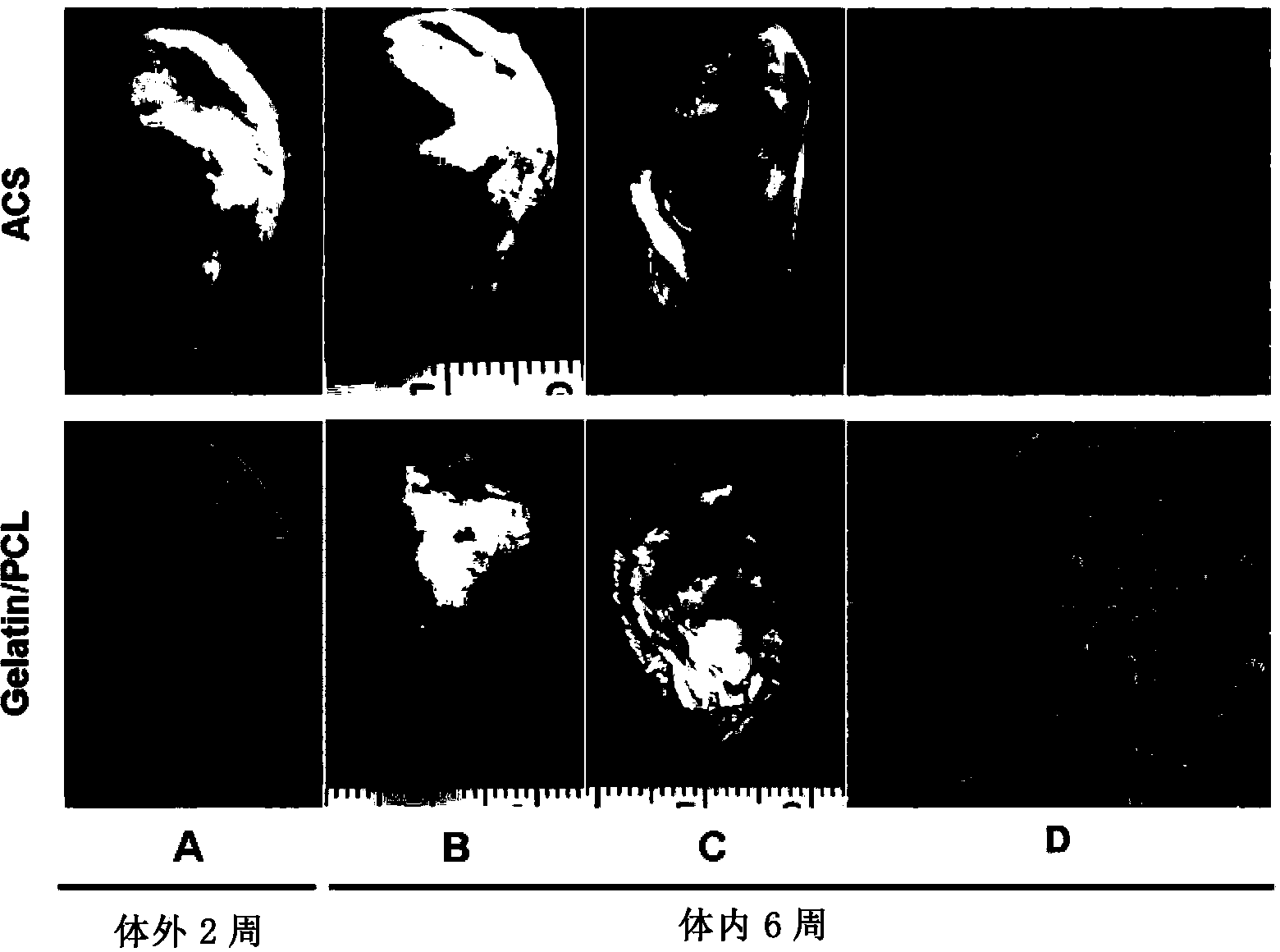

Method for constructing tissue engineering cartilage

The invention discloses a method for constructing tissue engineering cartilage. The method includes the steps of firstly, adding a membrane to an auricular-shaped support with a three-dimensional structure; secondly, adding cartilage cell suspension to the membrane; thirdly, adding a membrane to the cartilage cell suspension generated in the second step; fourthly, repeatedly executing the second step and the third step to obtain a composite; fifthly, culturing the composite in vitro to obtain the tissue engineering cartilage.

Owner:SHANGHAI TISSUE ENG LIFE SCI

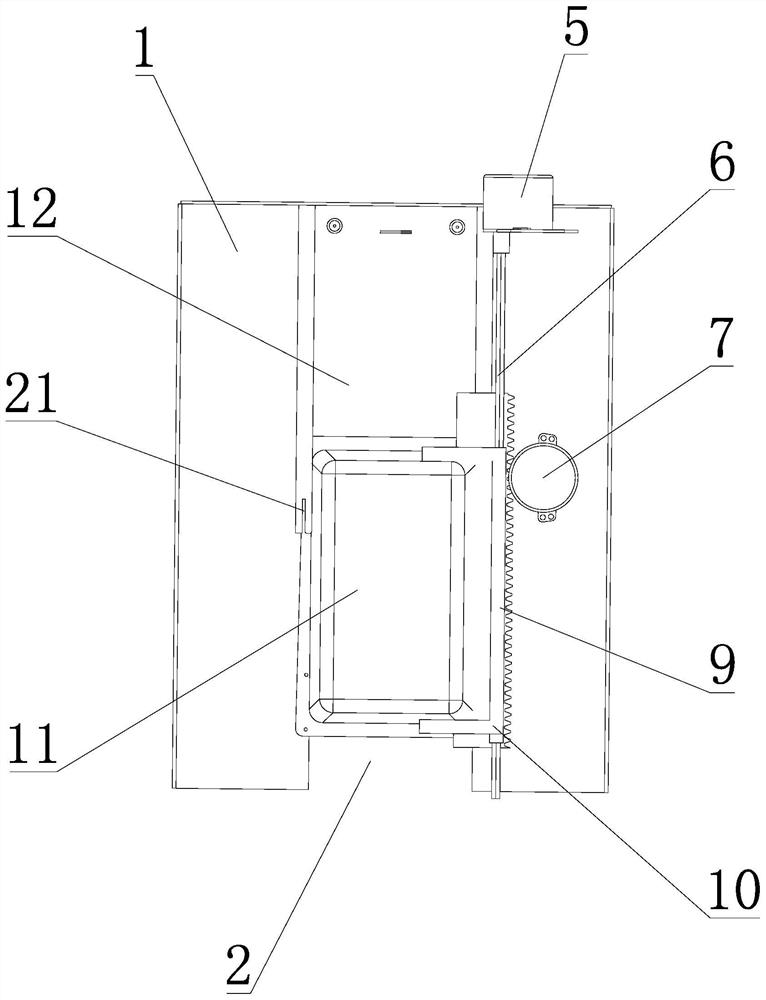

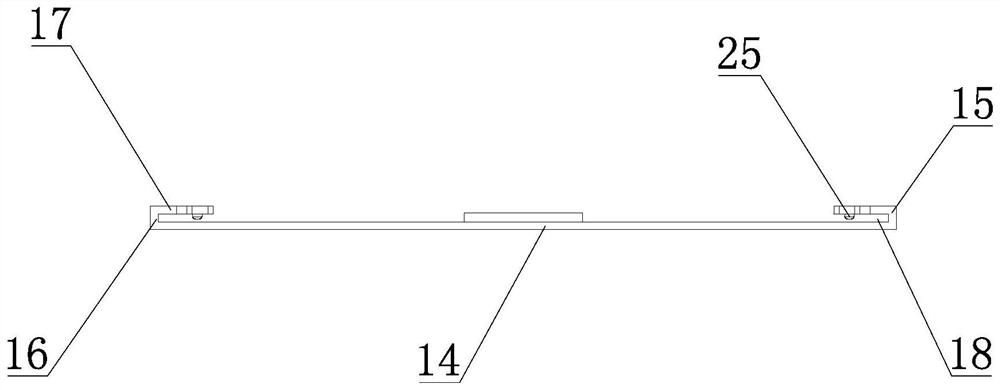

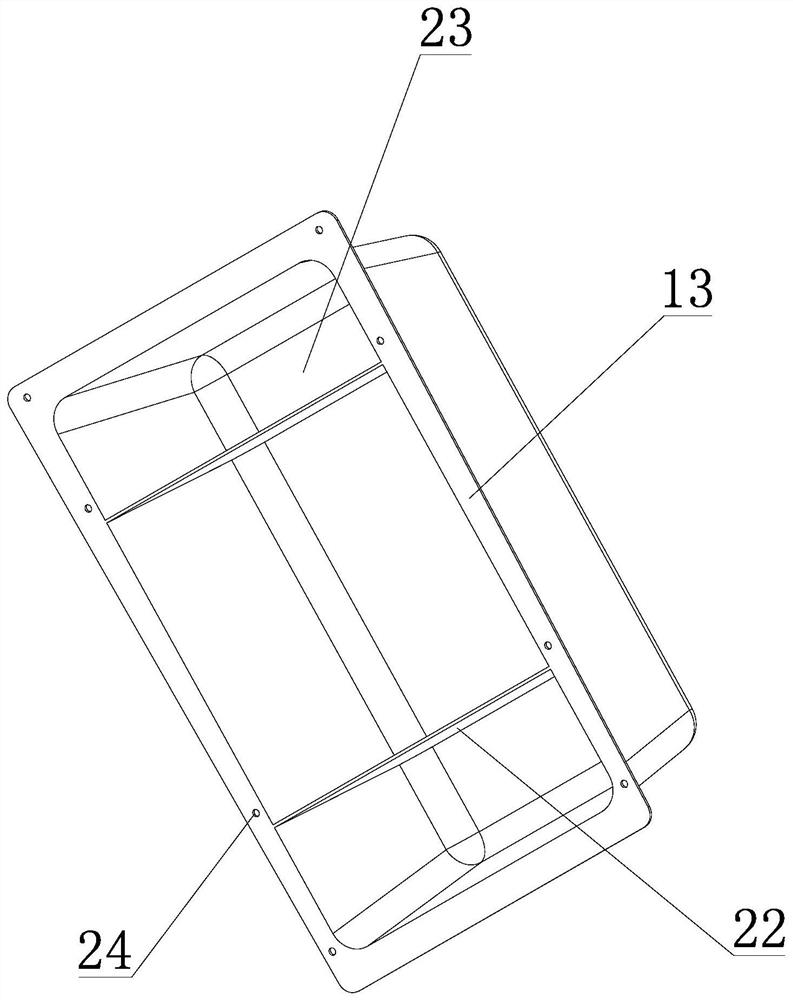

Vegetable distribution box

InactiveCN113180479AReduce complexityGuaranteed ripeningCooking vesselsMouthfeelManufacturing engineering

In order to overcome the defects that in the prior art, a side dish box cannot accurately control the sequence of auxiliary materials falling into a pot, the action of a previous auxiliary material falling into the pot and the action of a next auxiliary material falling into the pot cannot be accurately divided, and the auxiliary materials in the next discharging sequence possibly fall into the pot in advance in the stir-frying process; in order to solve technical problems in the prior art, the side dish box is provided, the side dish box comprises a box body, an opening of the box body faces downwards, a plurality of storage cavities are formed in the box body, a partition plate is arranged between every two adjacent storage cavities, and the box body is connected with a driving mechanism. According to the side dish box, the sequence of auxiliary materials falling into a pot can be accurately controlled, the auxiliary materials in the later discharging sequence cannot fall into the pot in advance, and it is guaranteed that the taste of dishes is kept at a high level; in the discharging operation, the side dish boxes do not need to be turned over, the side dish boxes only need to horizontally move, and complexity of the arranged feeding mechanical arm is greatly reduced.

Owner:ZHEJIANG AISHIDA ELECTRIC CO LTD +1

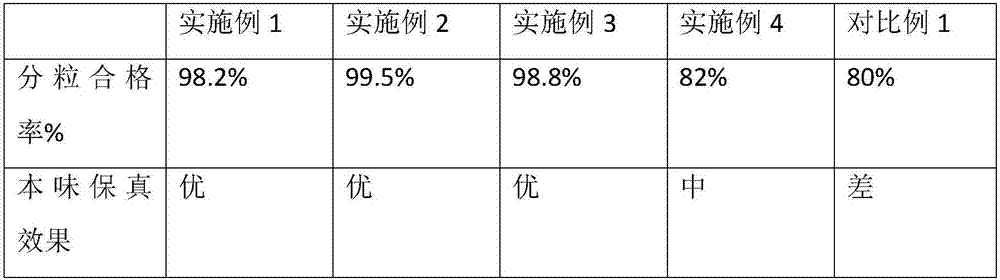

Original flavor retaining technology of shade-dried cooked glutinous rice

The present invention discloses an original flavor retaining technology of shade-dried cooked glutinous rice in the field of food production processes. The technology comprises the following steps of: material selecting, cleaning, washing, soaking, steaming, shade-drying and granule separating, screening and finished product packaging. In the soaking, a pollution-free water source is used. In the shade-drying and granule separating, a rapid ventilation and dehumidification device consisting of a stainless steel exhaust pipe and an exhaust fan directly conducts dehumidification and ventilation in a low-temperature baking device. The cooked glutinous rice is subjected to low temperature baking in the baking device in which the temperature is 40-60 DEG C, ventilation is controlled to be conducted for about half an hour, the granule separating is conducted, then the natural shade-drying is conducted, two-stage shade-drying is used, and the technology shortens the shaping cycle and at the same time retains the product flavor. By improving the technology of the steps of the material selecting, washing, soaking, shade-drying and granule separating, etc. and by using a pollution-free soaking technology, a rapid ventilation and dehumidification technology and a temperature-varying time-controlled shade-drying technology to process and shape the shade-dried cooked glutinous rice, the original flavor retaining technology can realize large-scale production of the shade-dried cooked glutinous rice, at the same time maximally preserves traditional shapes and original flavor of the shade-dried cooked glutinous rice, so that the original flavor of the shade-dried cooked glutinous rice is retained with high fidelity, and the shade-dried cooked glutinous rice is good in quality and flavor.

Owner:重庆源源龙脉食品有限公司

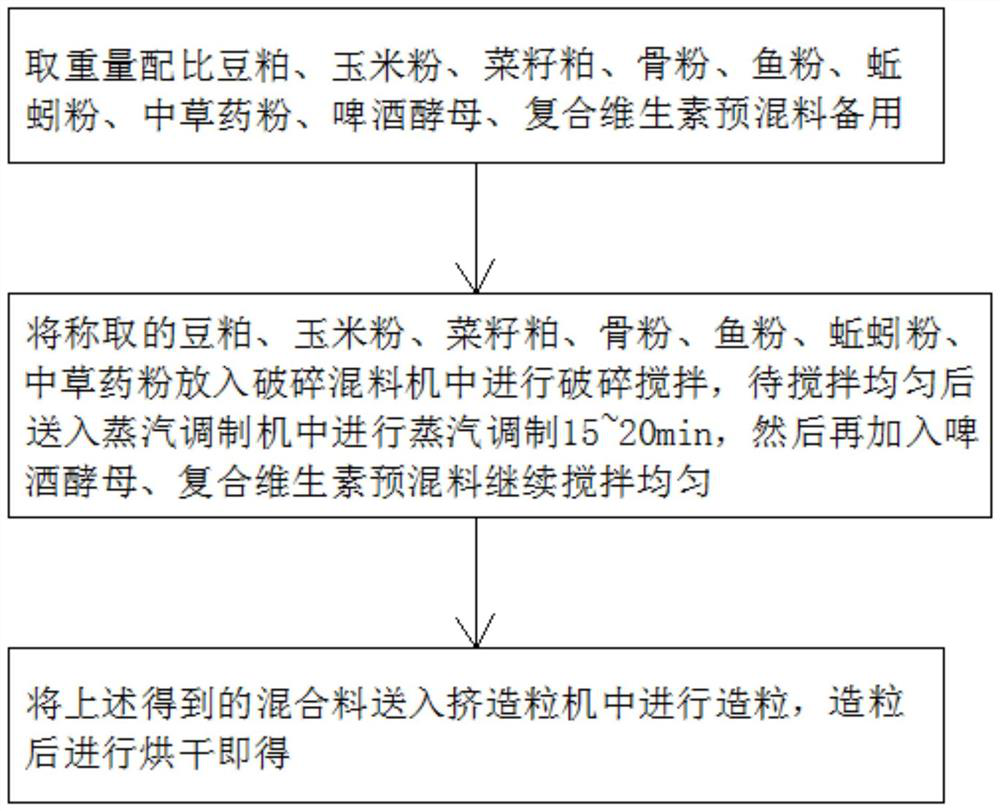

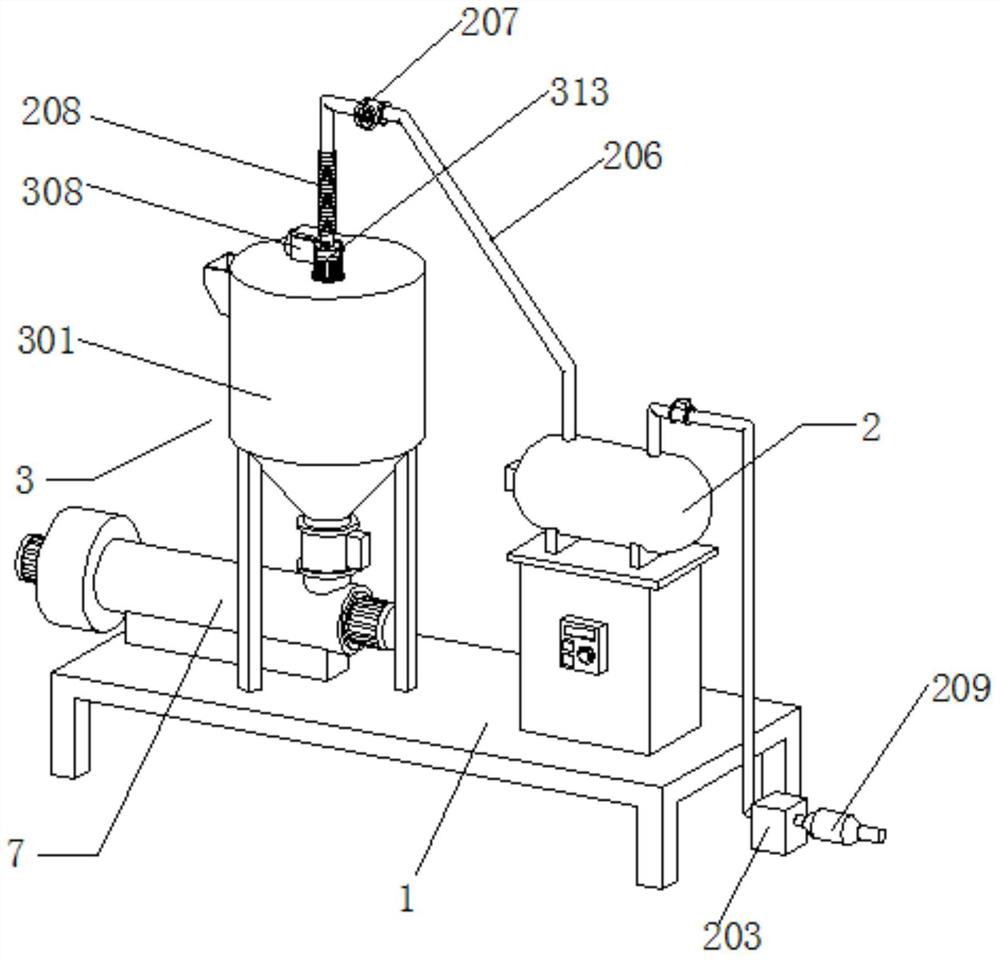

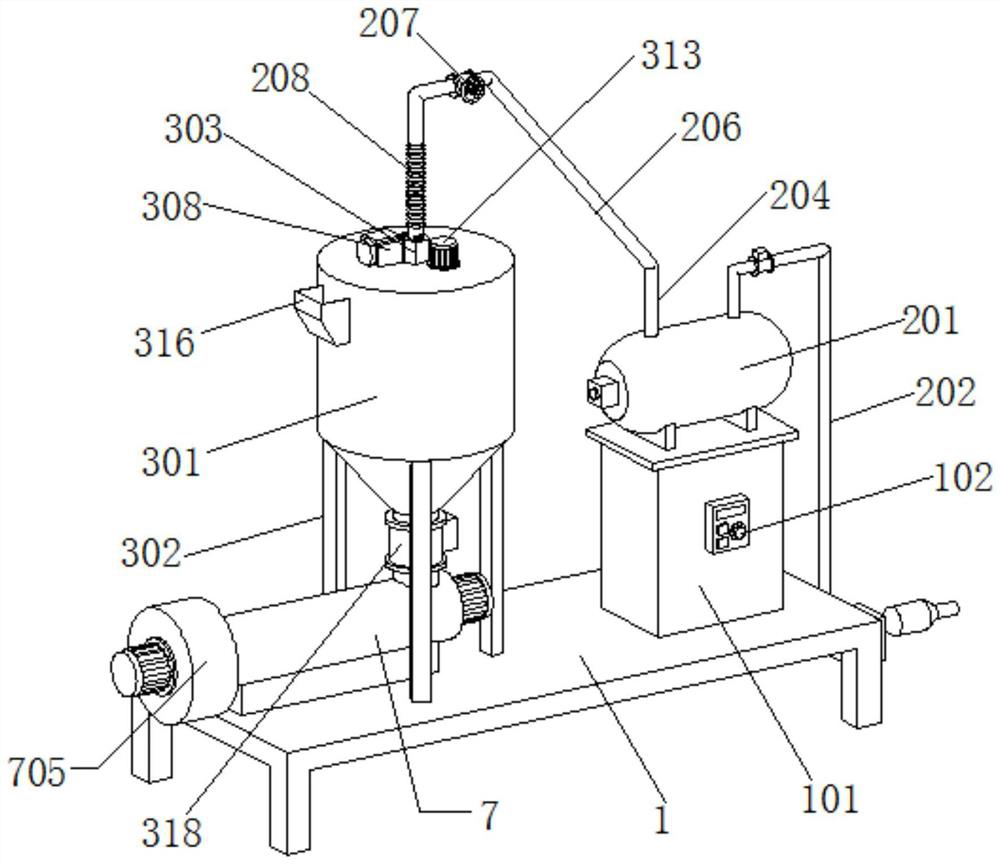

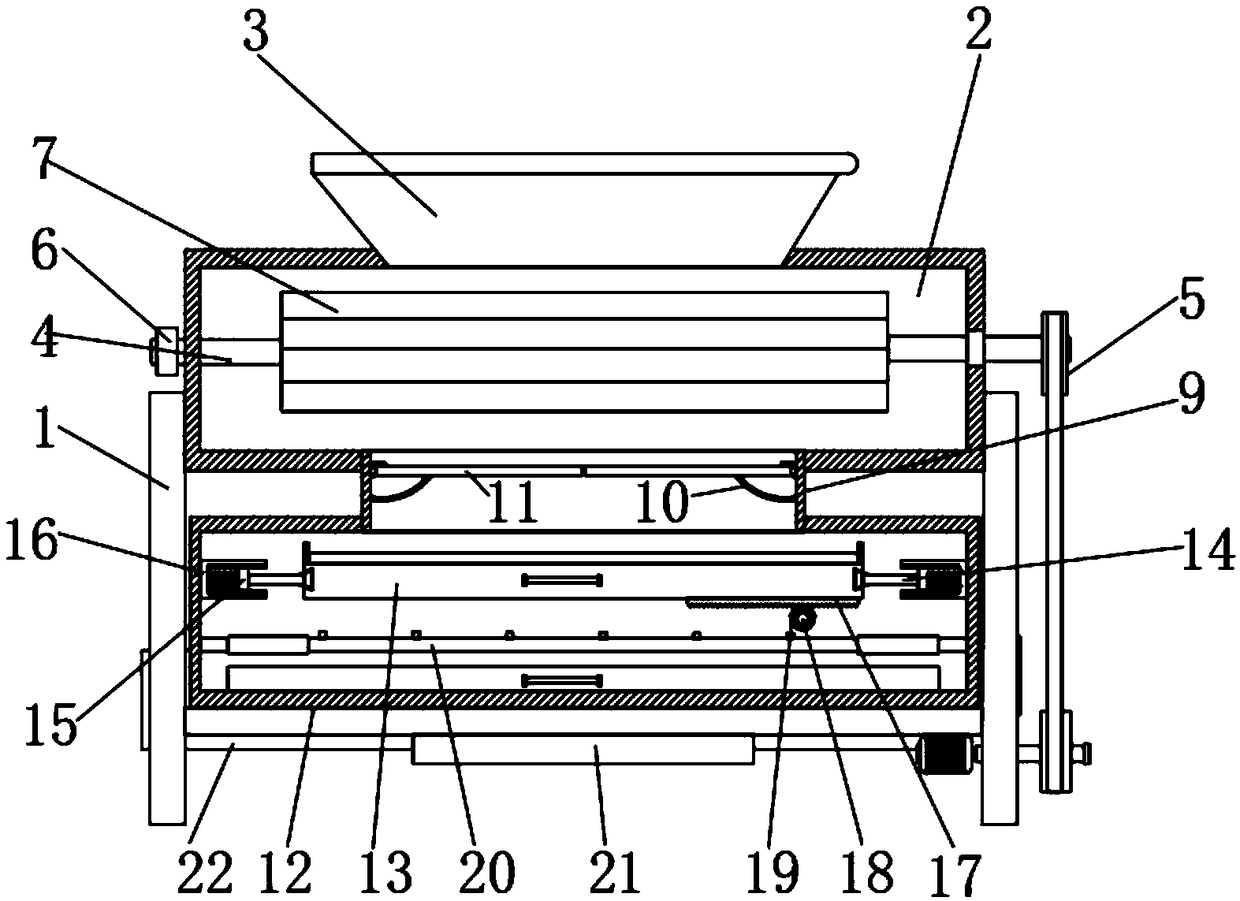

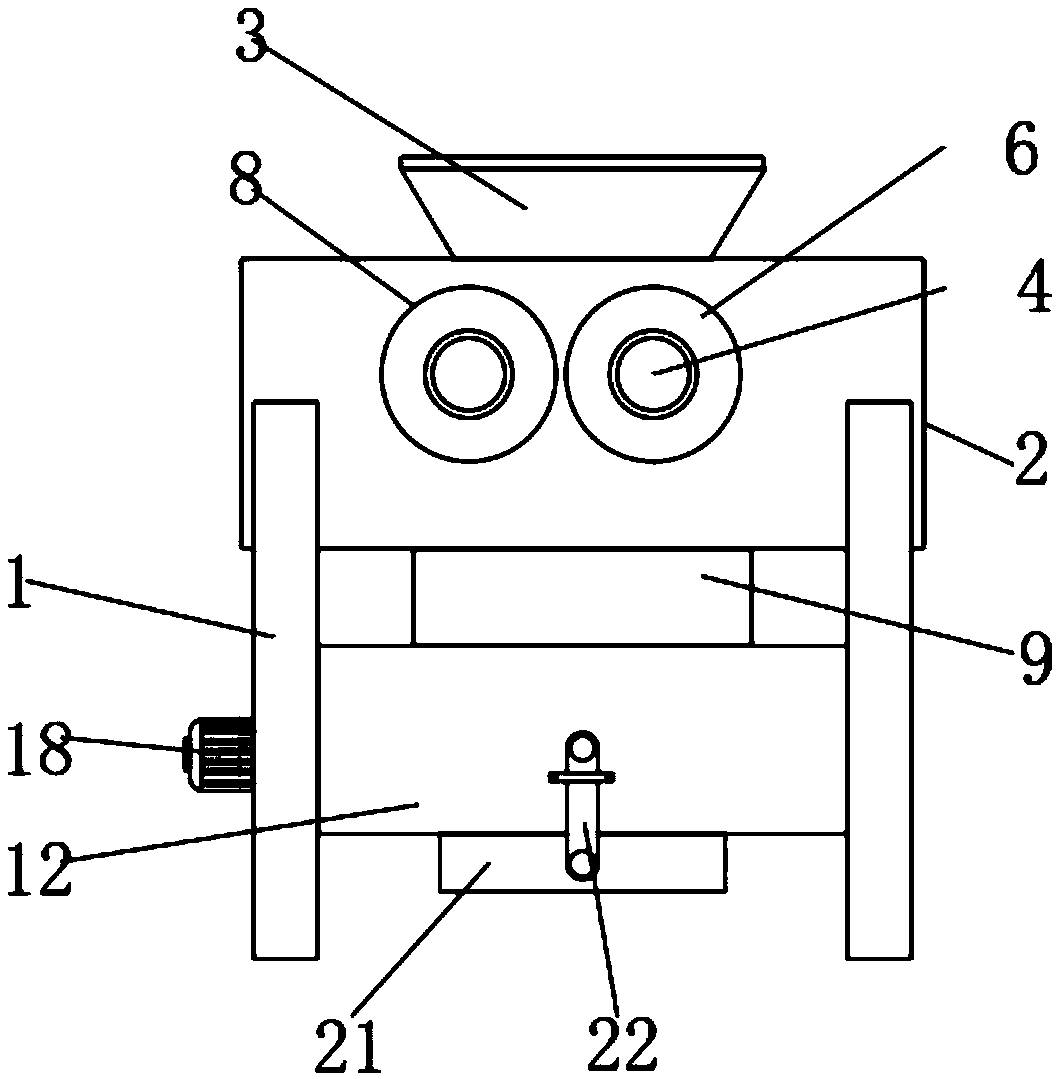

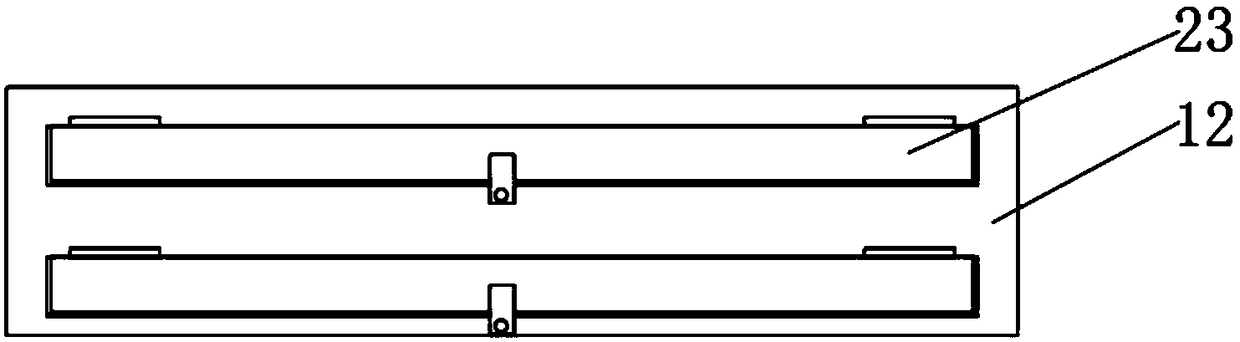

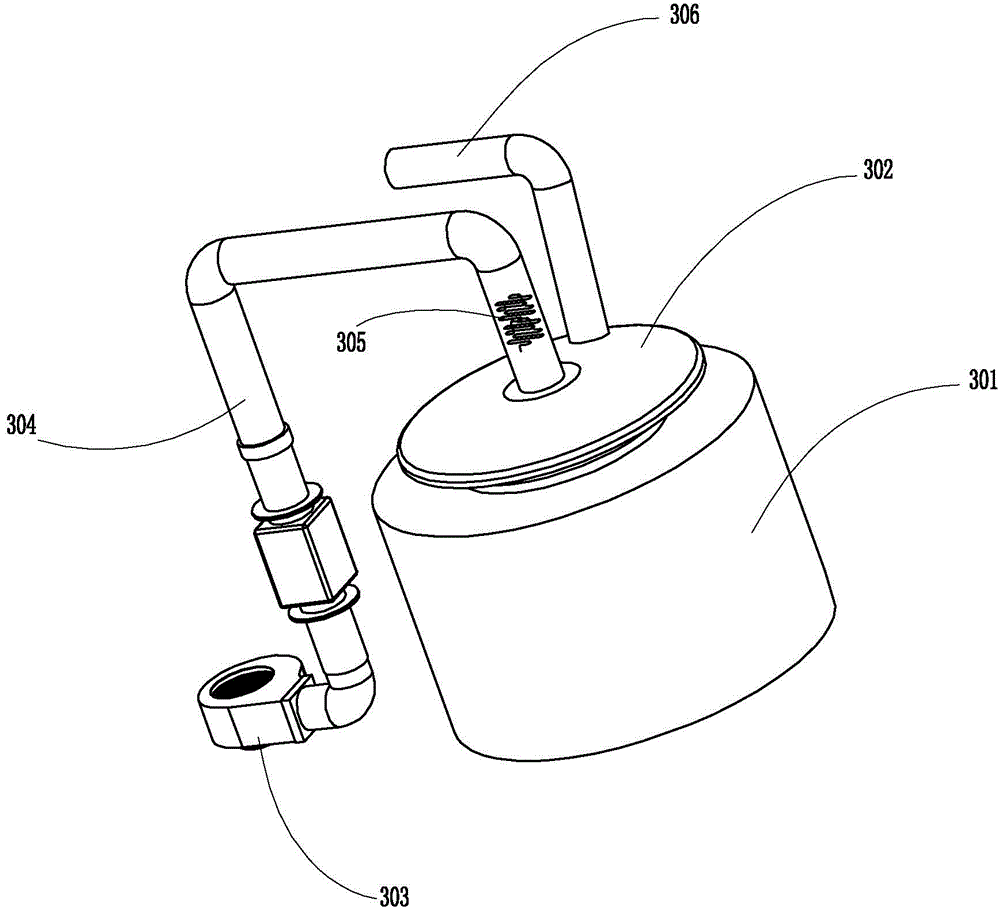

Feed formula capable of promoting growth of fishes and shrimps as well as production process and equipment

InactiveCN113951399AIncrease profitGuaranteed rapid growthFeeding-stuffFood processingChemistryNutrition

The invention relates to the technical field of fish and shrimp feed production, and particularly discloses a feed formula capable of promoting fish and shrimp growth and a production process and equipment. The feed formula comprises the following components in parts by weight: 150-165 parts of soybean meal, 26-30 parts of corn flour, 20-25 parts of rapeseed meal, 18-25 parts of bone meal, 12-18 parts of fish meal, 8-12 parts of earthworm powder, 4-6 parts of Chinese herbal medicine powder, 2-4 parts of beer yeast and 2-5 parts of a compound vitamin premix; the preparation equipment comprises a rack, a steam generation device, a steam conditioner and an extrusion granulator. According to the feed disclosed by the invention, various feed raw materials which are reasonable in proportion and balanced in nutrition are adopted, and then the feed raw materials are steamed by the steam conditioner before extrusion granulation, so that nutritional ingredients in the feed raw materials are cooked, the utilization rate of the feed by fishes and shrimps is greatly increased, and rapid growth of the fishes and shrimps is effectively ensured; the whole preparation equipment has novel structural design, excellent steam conditioning effect on the feed and high practicability.

Owner:福建大昌盛饲料有限公司

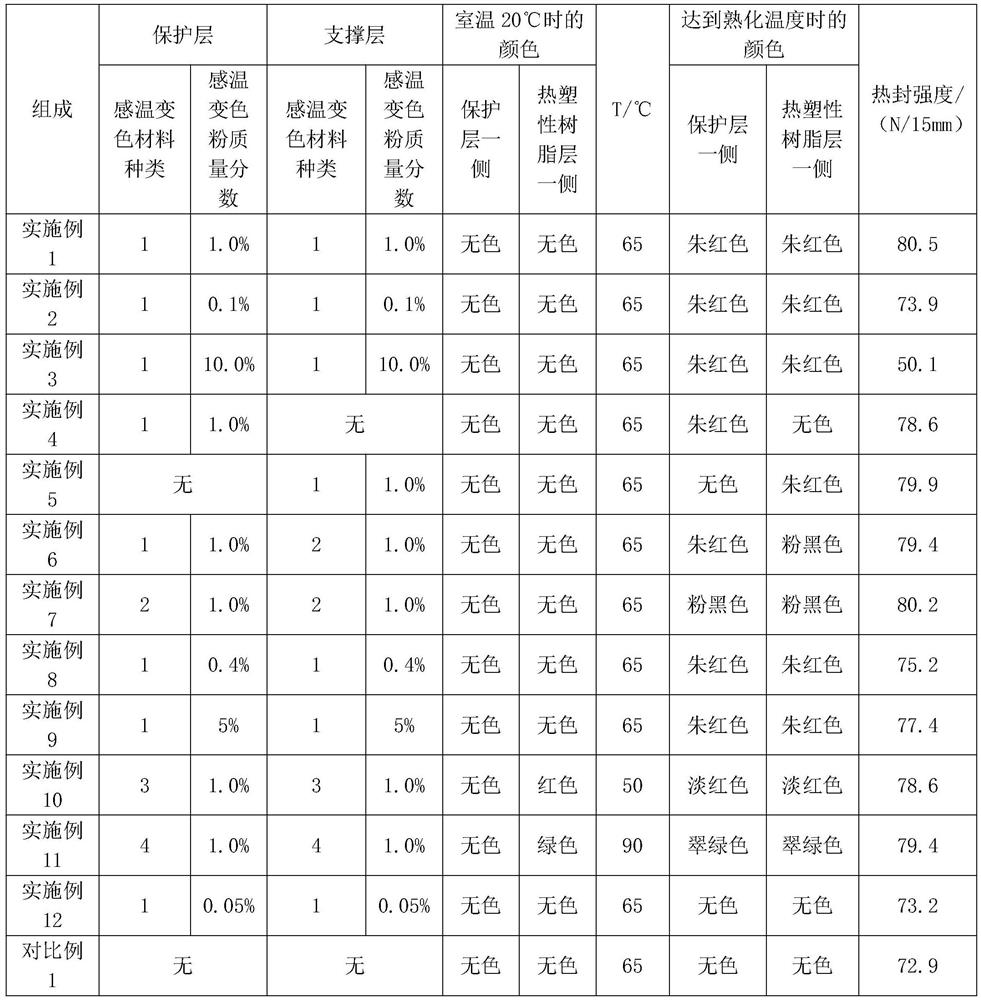

Soft package material for lithium battery

PendingCN114447404APenetrating influenceHumidity and heat resistanceLi-accumulatorsCell component detailsMetal foilPhysical chemistry

The invention discloses a soft package material for a lithium battery, the soft package material for the lithium battery comprises a metal foil layer, a protective layer located on one side of the metal foil layer and a thermoplastic resin layer located on the other side of the metal foil layer, and a bonding layer exists between the metal foil layer and the protective layer and / or between the metal foil layer and the thermoplastic resin layer; and the protective layer and / or the thermoplastic resin layer contain / contains a thermochromic material. According to the soft package material for the lithium battery, a temperature display function is realized by adding the thermochromic material, so that the temperature and curing uniformity of each part of the soft package material in a curing process can be indicated, the consistency of product performance is ensured, the product quality control and the use performance of subsequent products are facilitated, and the soft package material has a good application prospect.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Peanut kernel peeling machine with steam curing function

The present invention discloses a peanut kernel peeling machine with a steam curing function belonging to the technical field of peeling machines. The peanut kernel peeling machine comprises four support rods and a steam boiler; a peeling box is arranged between the outer walls of the top parts of the left and right support rods; the bottom part of the peeling box is provided with a material discharging passage; the bottom part of the material discharging passage is provided with a steam curing box; the top part of the inner cavity of the steam curing box is laterally provided with a placing plate; the left and right sides of the placing plate are movably connected with stop plates; the inner walls of the left and right sides of the steam curing box are both symmetrically provided with fixing blocks; and the two sets of the fixing blocks are both provided with grooves on the opposite sides. The peanut kernel peeling machine is practical and simple in use and reduces working costs. Steam in the steam boiler enters an air ejection connection pipe via two high-temperature steam connection pipes and then is ejected out to the bottom part of the placing plate; at the same time, a servomotor drives a driven wheel to rotate forward and backward; the driven wheel cooperates with a rack to drive the placing plate to move left and right, so that peanut kernels on the top part of the placing plate move left and right to enable the peanut kernels to be evenly cured by the steam.

Owner:苏州健乔食品科技有限公司

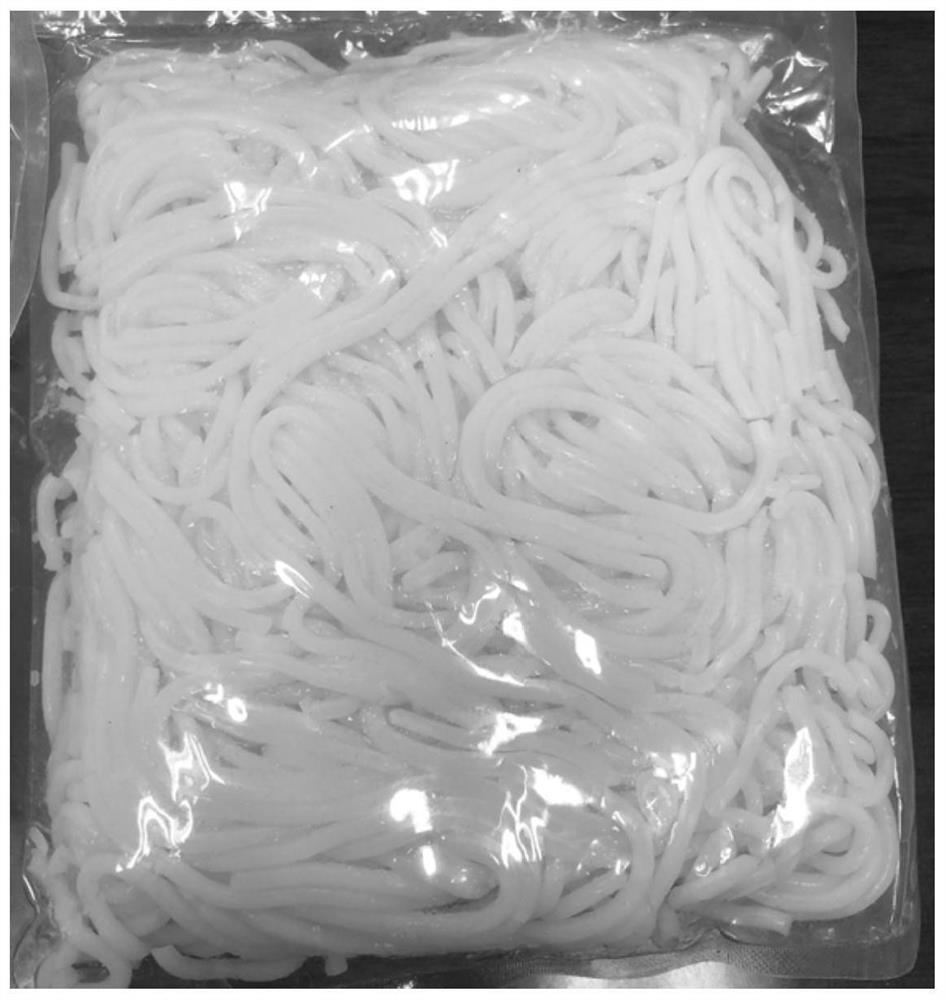

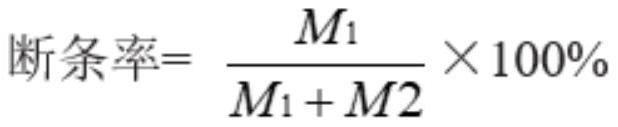

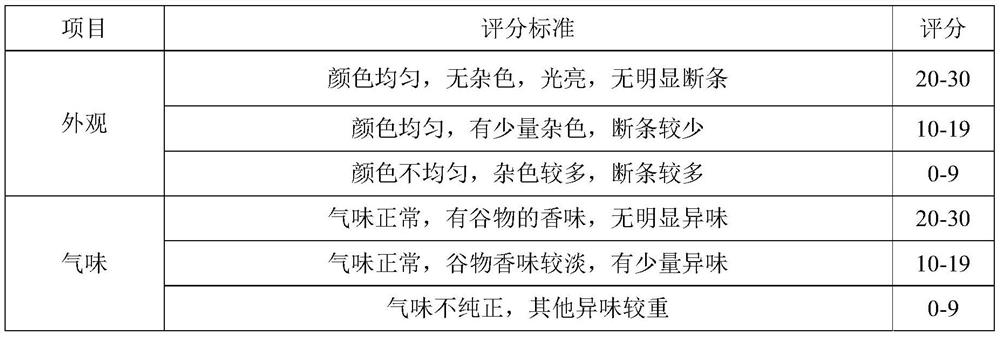

Processing method of fresh wet rice noodles

ActiveCN111838530AEnsure safetyEasy to eatClimate change adaptationFood ingredientsBiotechnologyFood additive

The invention discloses a processing method of fresh wet rice noodles, and belongs to the technical field of food processing. The preparation method comprises the following steps: cleaning early indica rice, removing impurities, soaking, grinding into thick liquid, uniformly mixing the thick liquid with corn starch in proportion, balancing moisture, and carrying out vacuum precuring, flash evaporation dehydration, extrusion molding, cold soaking, packaging, sterilization and the like to obtain the convenient instant fresh wet rice noodle product with smooth mouthfeel. Compared with the traditional dry rice noodles, the fresh wet rice noodles processed by the method disclosed by the invention do not need to be cooked, are ready to eat after being soaked in boiled water for 3-5 minutes, andare good in mouth feel. Compared with damp-heat treatment, vacuum pre-curing is easy to operate, short in consumed time, uniform in curing and high in curing degree, and the dehydration effect is achieved while the materials are further cured through the flash evaporation dehydration process. No food additive is added, starch is completely cured through vacuum precuring and flash dehydration, andthe quality of the fresh wet rice noodles is remarkably improved.

Owner:JIANGNAN UNIV +1

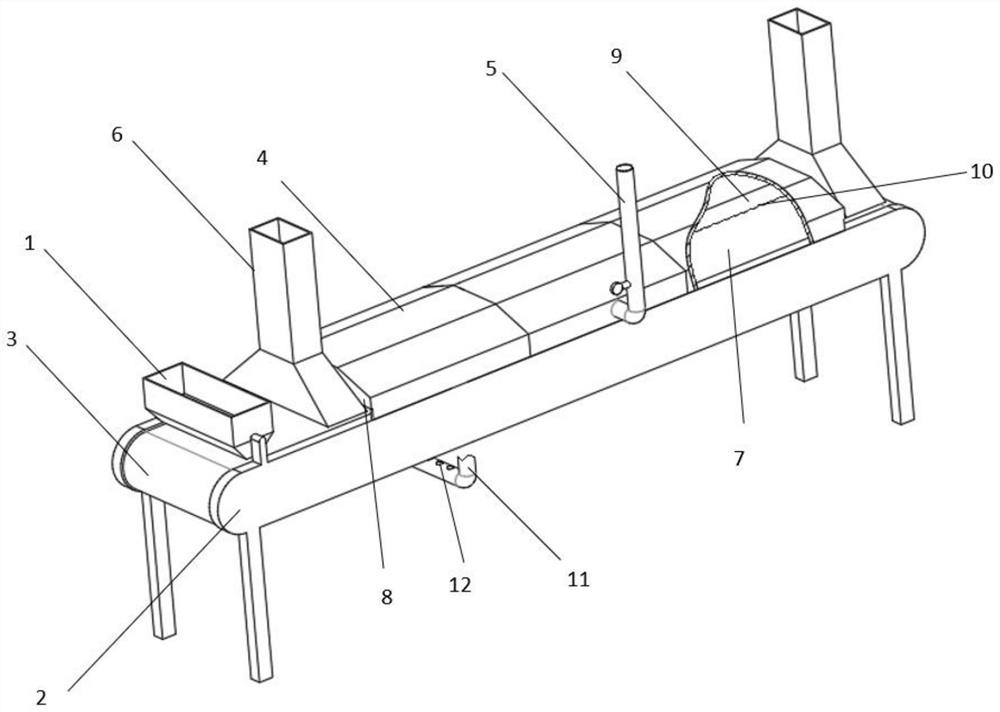

Rice noodle steaming equipment

PendingCN112155156AAvoid uneven ripeningFast production efficiencyFood scienceProcess engineeringMouthfeel

The invention discloses rice noodle steaming equipment, and relates to the technical field of rice noodle processing. The rice noodle steaming equipment comprises a feeding hopper, a conveying belt support frame, a conveying belt, a steam cover, a steam pipe and two steam overflow pipes, wherein fermented rice is made into rice milk, and then the rice milk is continuously sprayed onto the conveying belt through the feeding hopper to form a rice milk belt covering the upper surface of the conveying belt; and the rice milk belt is continuously conveyed into the steam cover along with the runningconveying belt, and steam sprayed out of the steam pipe is used for steaming the rice milk belt and then conveying the steamed rice milk belt to the next working procedure to be continuously made into rice noodles in various shapes. The problems that existing rice noodle curing equipment is uneven in curing, low in efficiency, not easy to clean, poor in mouth feel of the prepared rice noodles andthe like are solved, and the finished rice noodles made by the equipment are better in mouth feel and higher in processing and production efficiency.

Owner:湖南康洁食品科技发展有限公司

Coconut rice and production method thereof

The invention discloses coconut rice and a production method thereof. The method comprises the following steps of: 1) cutting a circular opening with the diameter of between 6 and 8 centimeters at the fruit base of a coconut fruit to form a spherical coconut bowl and a coconut shell cover, and pouring coconut water; 2) juicing coconut flesh with the fruit age of between 11 and 12 months, and adding a complex additive and mixing uniformly to obtain pre-prepared coconut juice, wherein the complex additive consists of a flavoring agent and an antiaging agent; 3) soaking glutinous rice in water for 0.5 to 2 hours, and presteaming at the temperature of 100 DEG C under normal pressure for 10 to 30 minutes to obtain presteamed glutinous rice; and 4) adding the presteamed glutinous rice and the pre-prepared coconut juice in the spherical coconut bowl, stirring uniformly, covering by using the coconut shell cover, and steaming to obtain the coconut rice. The coconut rice has the mouthfeel of tender coconuts and concentrated fragrance of matured coconuts; and the rice cooked in a coconut shell is aged and uniform, soft and elastic and stable in quality by a reasonable process, and the coconut shell is formed into a container which is used for containing the rice and is provided with the bottom and the cover skillfully, so the rice is not needed to be contained or heated by additional containers when eaten, and is convenient and practical.

Owner:HAINAN UNIV

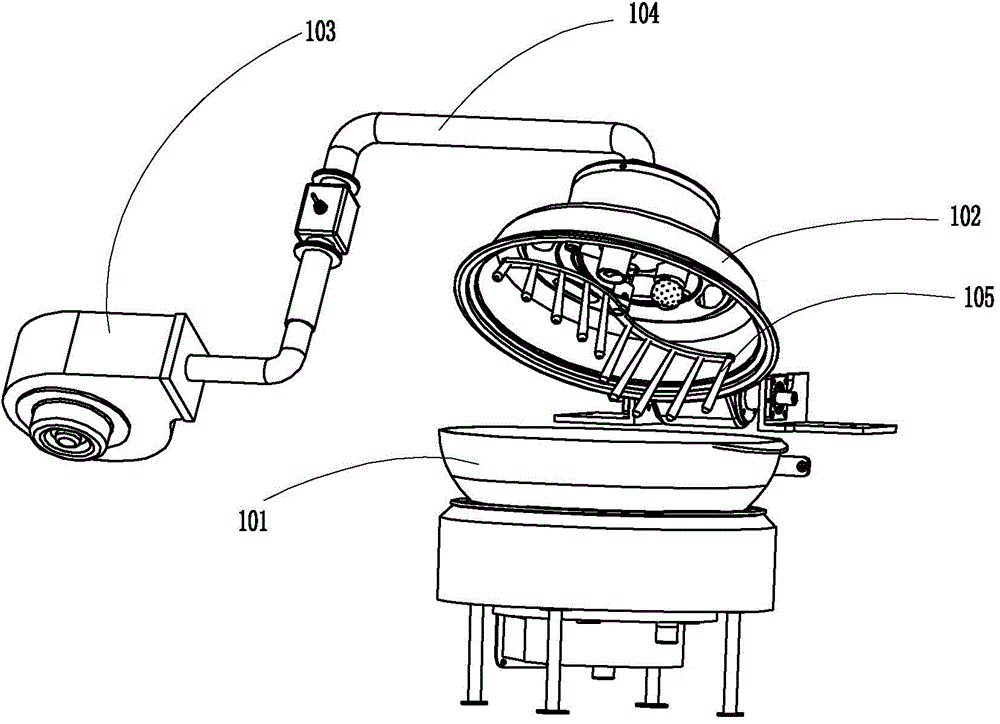

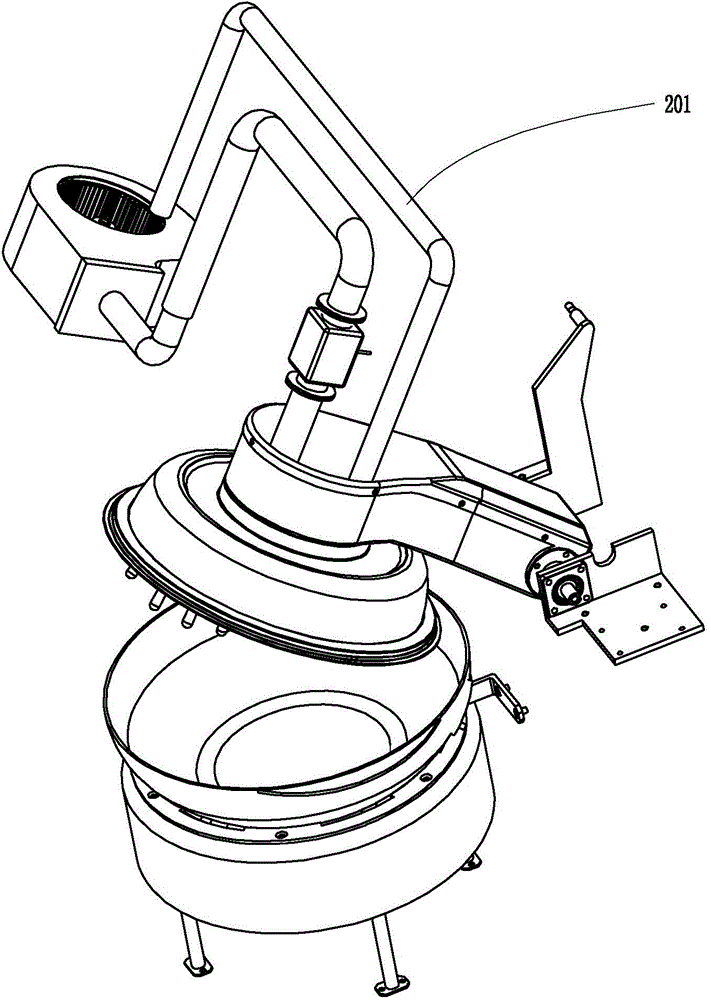

Double-heat source heating cooking method

The present invention provides a double-source heating cooking method. The cooking method herein comprises the following steps: (1) start a first heater at the beginning of the cooking to supply heat to a cooking utensil body from below or the peripheral of the cooking utensil body; (2) put cooking objects such as meat or vegetables to the cooking utensil; (3) at the time right before or after step (2), more particularly the initial stage after step (2), start a second heater or increase heating intensity of the second heater, preferably increase heating power of heat sources so as to perform direct heating on cooking objects inside the cooking utensil from above the cooking utensil, the first and the second heaters having different heat sources; (4) after heating at intervals, close the second heater or decrease heating intensity of the second heater, preferably decrease heating power of heat sources. The present invention by adopting hot wind, infrared or light wave and the like in heating assistance can supply heat to the surface of cooking objects via air-flow or radiation, and facilitate surface maturing of the cooking objects to a certain extent so as to lock internal water of the cooking objects. The double-source heating cooking method also has the surface treatment effect on the cooking objects.

Owner:AIC ROBOTICS TECH

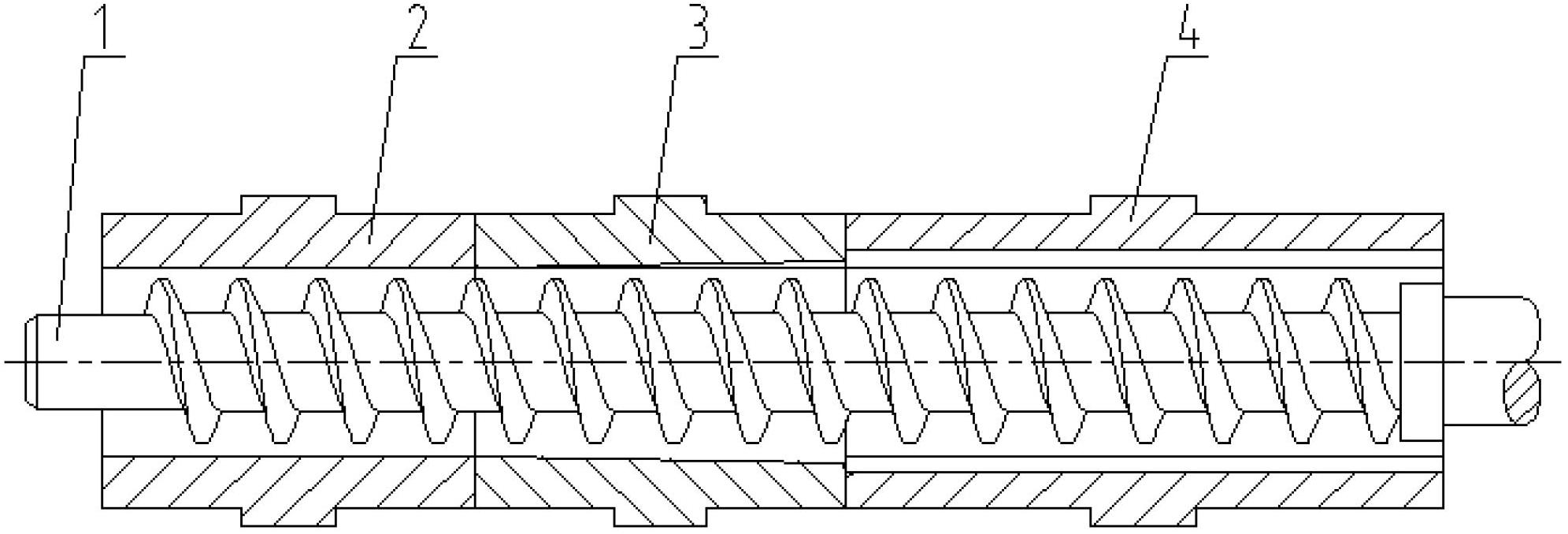

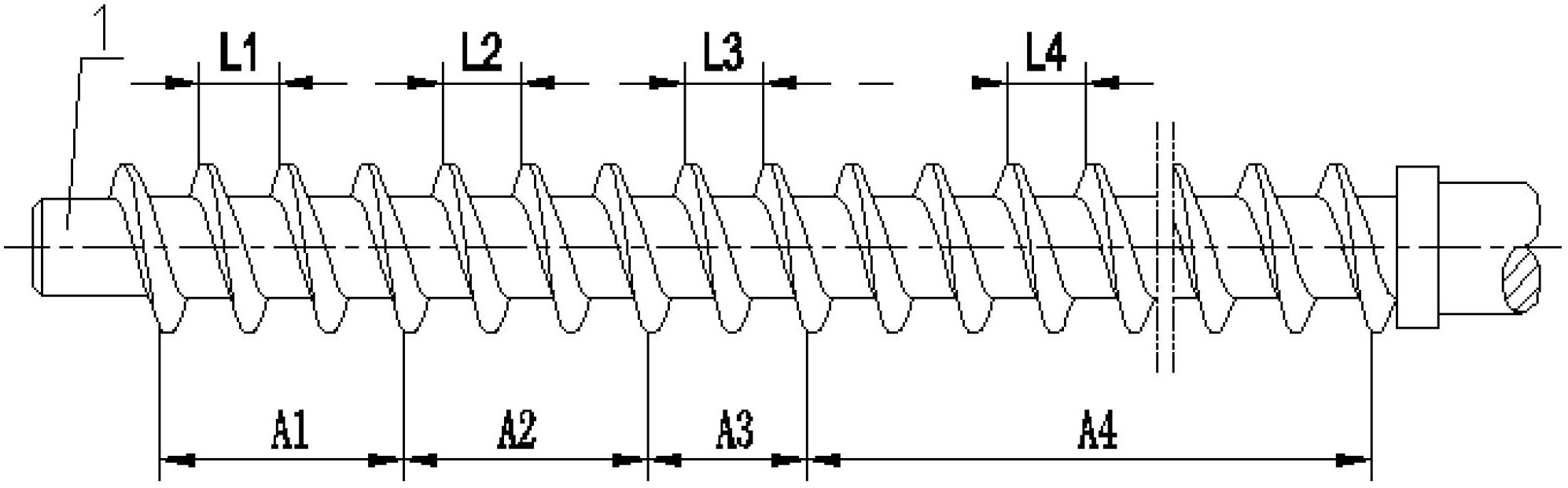

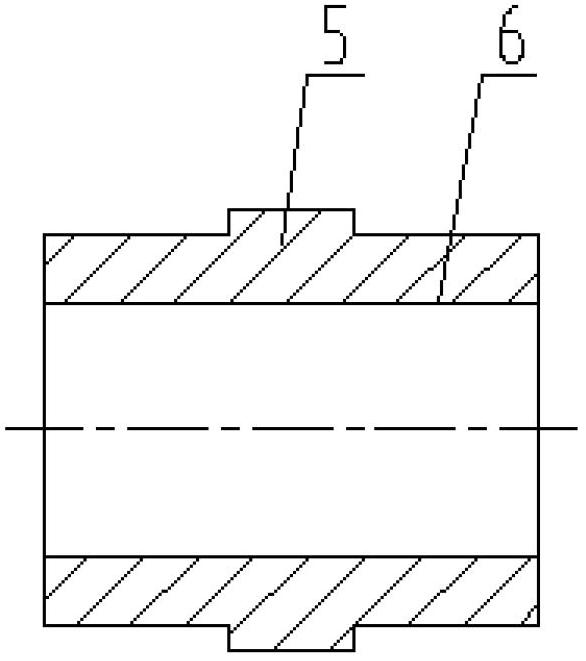

Screw propulsion device of bulking machine

InactiveCN102669805ASimple structureGood production effectPressurized chemical processFeeding-stuffAerospace engineeringProduction effect

The invention discloses a screw propulsion device of a bulking machine. The screw propulsion device comprises a propulsion screw and a bushing, wherein the propulsion screw is connected with a driving shaft, the bushing is installed on the external circumference of the propulsion screw, and the outer ring of the bushing is fixed in a bulking cavity of a casing. The screw propulsion device is characterized in that the propulsion screw adopts a segmental structure, the thread numbers of the segments are different, and the pitches of the segments are different; and the bushing is multi-segmented, and comprises a smooth bushing with a smooth inner ring and / or a groove bushing, a plurality of grooves are distributed on the internal circumference of the groove bushing, and the multi-segmented bushing is directly sleeved on the external circumference of the propulsion screw. The screw propulsion device has the characteristics of simple structure, good production effect, stable equipment operation, high part durability, wide applicability, high extrusion efficiency and the like.

Owner:GUIGANG RUIKANG FEED

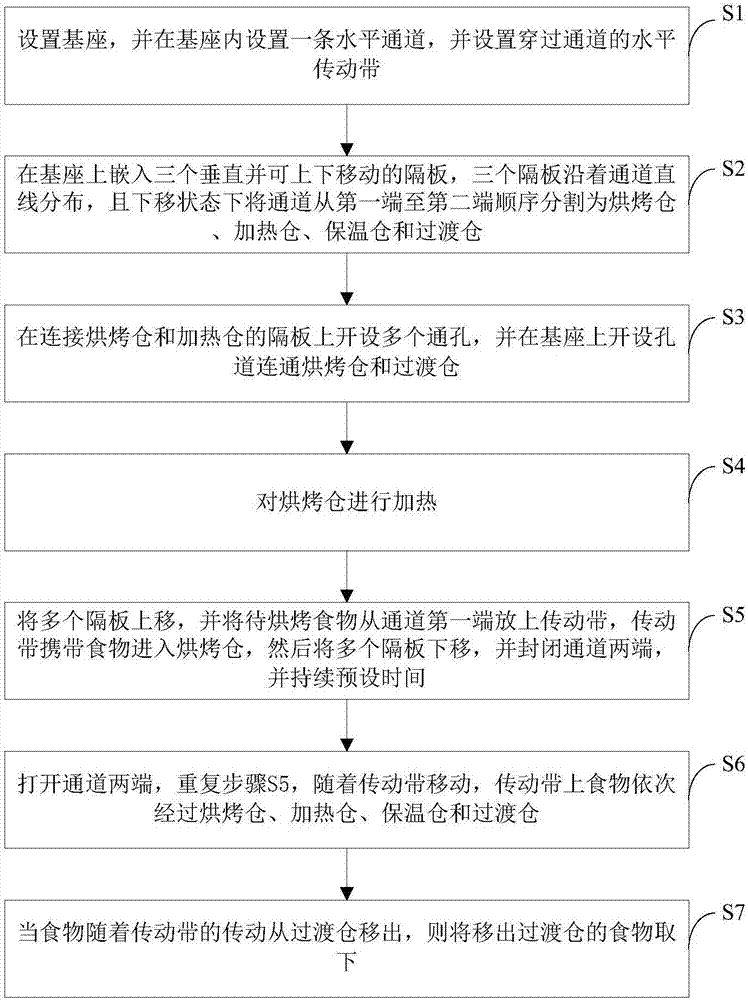

Food temperature segmental baking method

The invention discloses a food temperature segmental baking method. Food to be baked stays in a baking bin for a preset time so that the food can become quickly non-raw through high temperature heating; then, the food enters a heating bin, and through low-level high temperature heating and cooked, not only is the coked food caused by a high temperature avoided, but also it is guaranteed that the food is evenly cooked from inside to outside; then the cooked food enters a heat preservation bin, and through high temperature stewing, it is beneficial to improvement of the mouthfeel of the food; finally, the food enters a transition bin, since the temperature is low in the transition bin, the food is buffered in the transition bin, and the food can be prevented from being cooled suddenly after being separated from a channel, so that the mouthfeel does not get bad.

Owner:WUHU FEIYUE FOOD

Coke oven burner double-flue supplemental heating method

ActiveCN101979464BSolving insufficient heating conditionsImprove the coefficient of uniformityCombustible gas coke oven heatingVena contracta diameterCombustion

The invention relates to a coke oven burner double-flue supplemental heating method, which belongs to the field of heating combustion of a recuperative heat coke oven and a lean-gas-burning single heat coke oven. In the method, auxiliary afterflaming is performed in two sets of vertical flues in the burner on the machine and coke side of a lean gas heating coke oven in a coke oven rich gas lower-jet mode; a rich gas main pipe is arranged as a coke oven rich gas pipeline for supplemental heating; two rich gas distribution pipes are led out from the rich gas main pipe on the oven machine and coke side respectively and connected with lower jet pipes of the vertical flues in the burner; a copper ball valve and a stainless steel orifice plate are arranged on each jet pipe for regulating gas volume entering the flues; and the gas exchange is realized by a coke oven exchange and transmission device. The method can effectively solve the problem of insufficient heat supply to the burner when the lean gas is burnt in the coke oven, and the burner temperature is improved so as to meet the requirements of the technology. Therefore, the uniformity coefficient of the burner temperature is improved, the uniformity of whole oven temperature is ensured, the uniformity and maturity of the burner coke and whole oven coke are guaranteed, and the service life of the coke oven is prolonged.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com