Patents

Literature

80results about How to "Shorten pulping time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of stable slurry of lithium ion battery

The invention discloses a preparation method of stable slurry of a lithium ion battery. The preparation method comprises the steps of: preparing mixed material and glue from an active substance, a conductive agent, a bonding agent, a dispersing agent, a solvent and other additives by a few steps of dry mixing, wet mixing and glue preparation, and then subjecting the mixed material and the glue to wet mixing by a stirrer to obtain mixed slurry, and further comprises the steps of: (1) dispersing the mixed slurry for 10 to 20 minutes by a high speed dispersing machine of 15 to 50m / s, and storing the slurry in a storage tank upon the completion of the dispersion; (2) returning the slurry in the storage tank to the stirrer and then dispersing the slurry for 10 to 20 minutes by the high speed dispersing machine according to the step (1); (3) circularly repeating the step (1) and the step (2) 2 to 5 times; and (4) after the dispersion is completed, performing defoaming, filtration and iron impurity removal on the slurry based on the prior art to obtain the finished product. The slurry in the invention is homogeneous in dispersion and can be stable for a long time; and compared with the traditional way that the stirrer is used to stir for a quite long time, the method can shorten the time for slurry preparation greatly and is favorable for automatic continuous production.

Owner:HUNAN FENGYUAN YESHINE KINGCO NEW ENERGY

Straw bio-enzyme degradation aid and degradation pulping process

InactiveCN102230288AThe role of strong biological enzymesHigh activityPulp bleachingAlkylphenolStrong acids

The invention relates to a straw bio-enzyme degradation aid in the technical field of straw degradation, which comprises the following components in percentage by weight: 8 to 10 percent of cellulase, 6 to 11 percent of lipase, 6 to 10 percent of alpha-1,4-glucose hydrolase, 4 to 10 percent of catalase, 6 to 20 percent of urea, 6 to 16 percent of magnesium sulfate, 8 to 15 percent of fatty alcohol-polyoxyethylene ether, 11 to 15 percent of alkylphenol polyoxyethylene ether OP and the balance of excipient. A degradation pulping process for the straw bio-enzyme degradation aid comprises the following steps of: cleaning straw, cutting into segments, putting the segments into a quick pulping machine, adding water and the straw bio-enzyme degradation aid, mixing uniformly, and heating to the temperature of between 50 and 60 DEG C in the quick pulping machine for rubbing to perform reaction for 1 to 1.5 hours; and adding hydrogen peroxide for bleaching, and when the whiteness is more than 70 percent which is required by International standard organization (ISO), stopping the reaction to obtain paper pulp. The degradation pulping process is non-pollution, thermophilic digestion is avoided, strong base and strong acid are not used, the requirement of environment-friendly pulping is met, waste water is not discharged during pulping, a large amount of water for production and energy canbe saved, the production cost is reduced, and the pulping speed is accelerated.

Owner:TAIAN QINENG CHEM TECH

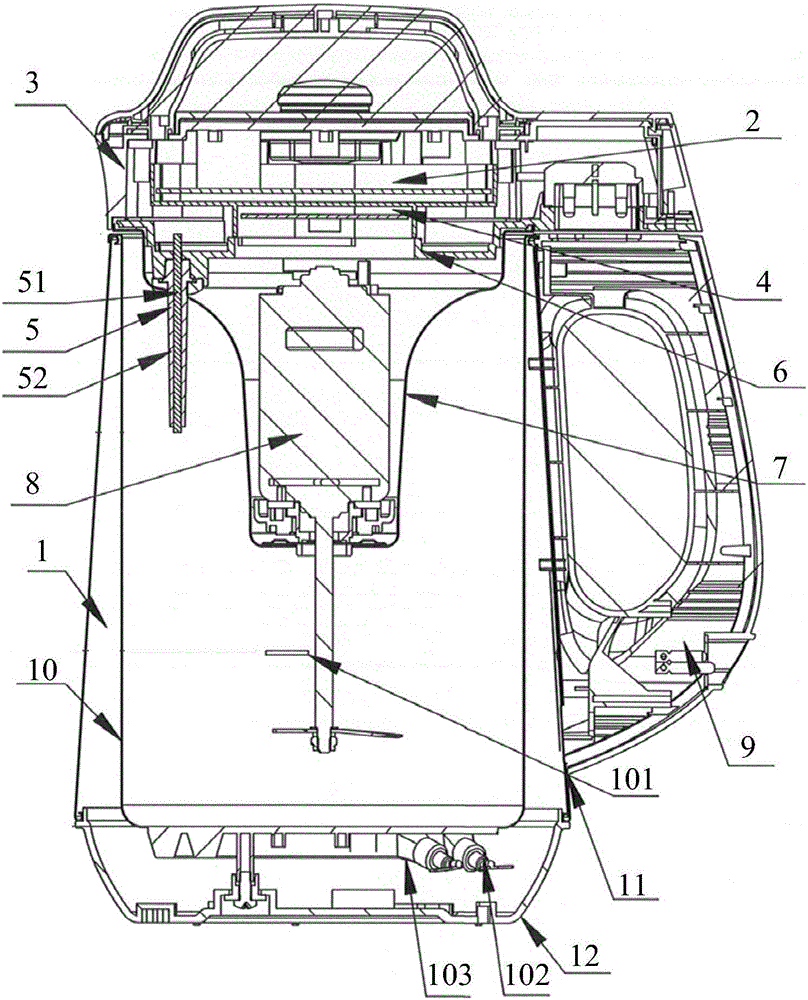

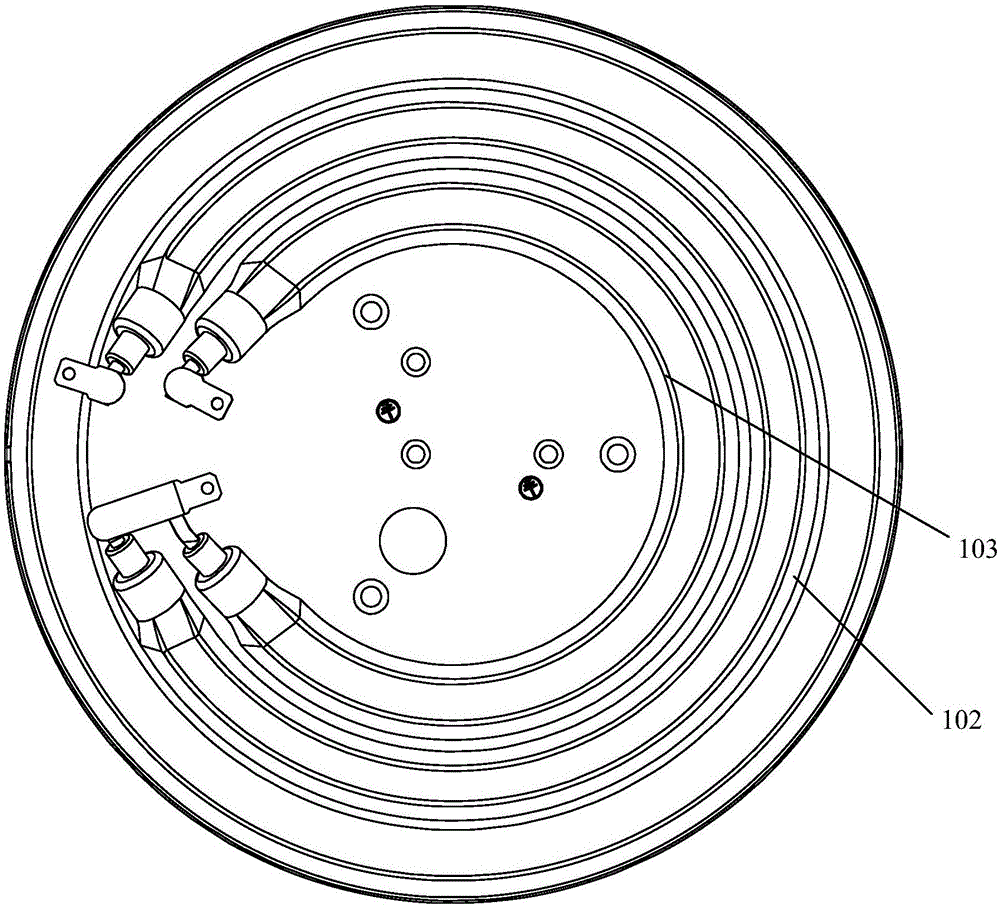

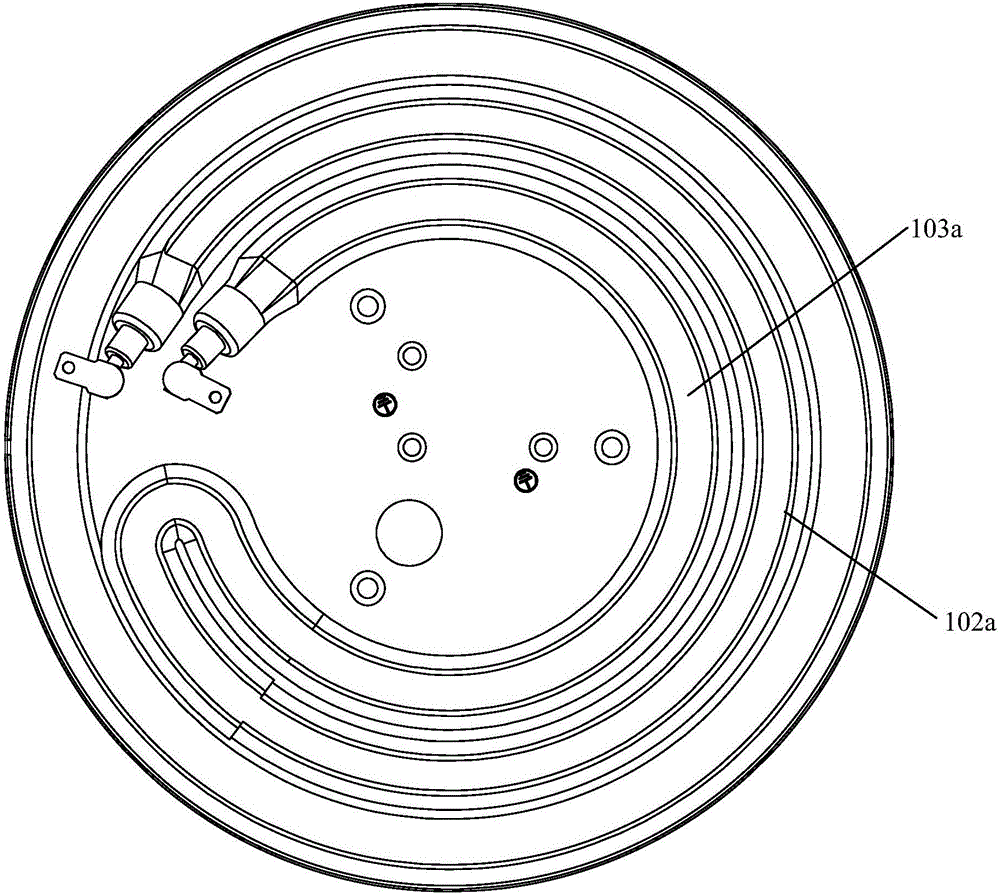

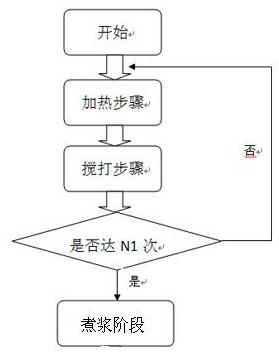

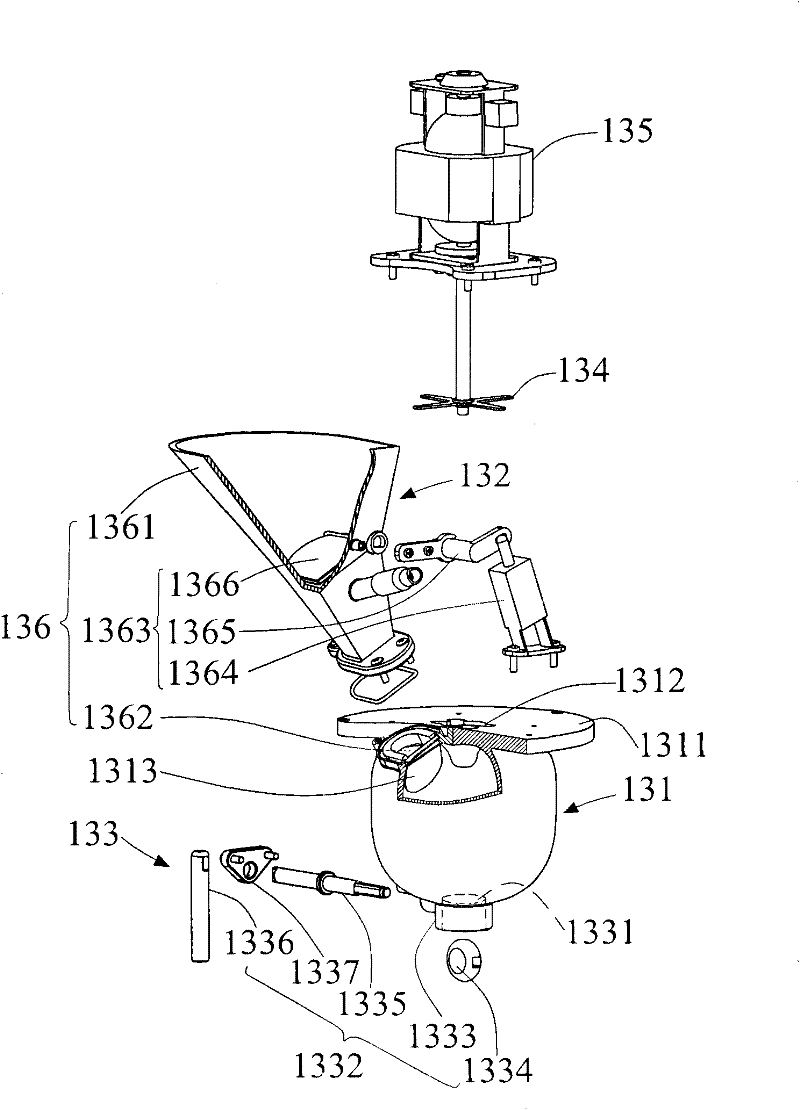

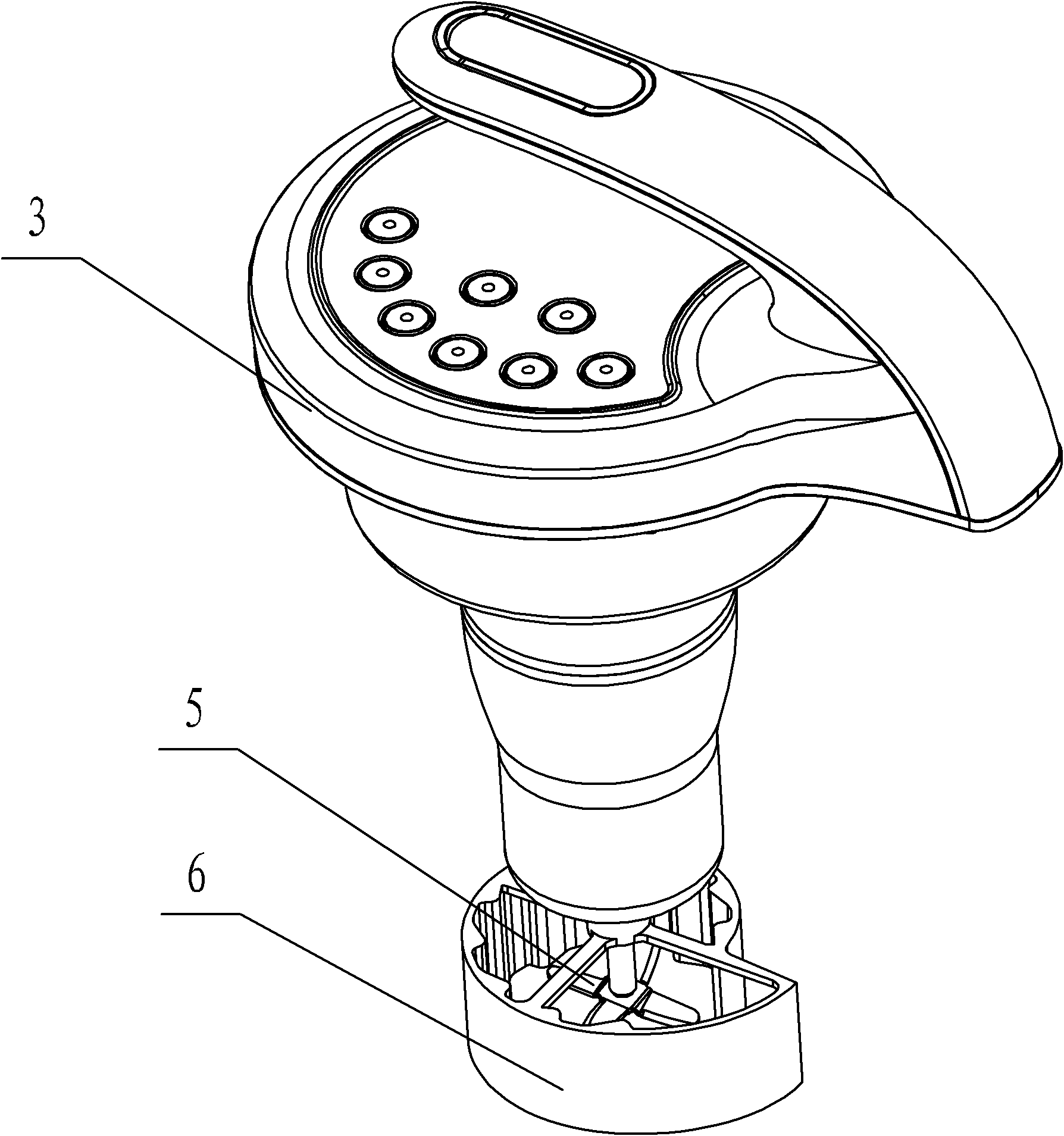

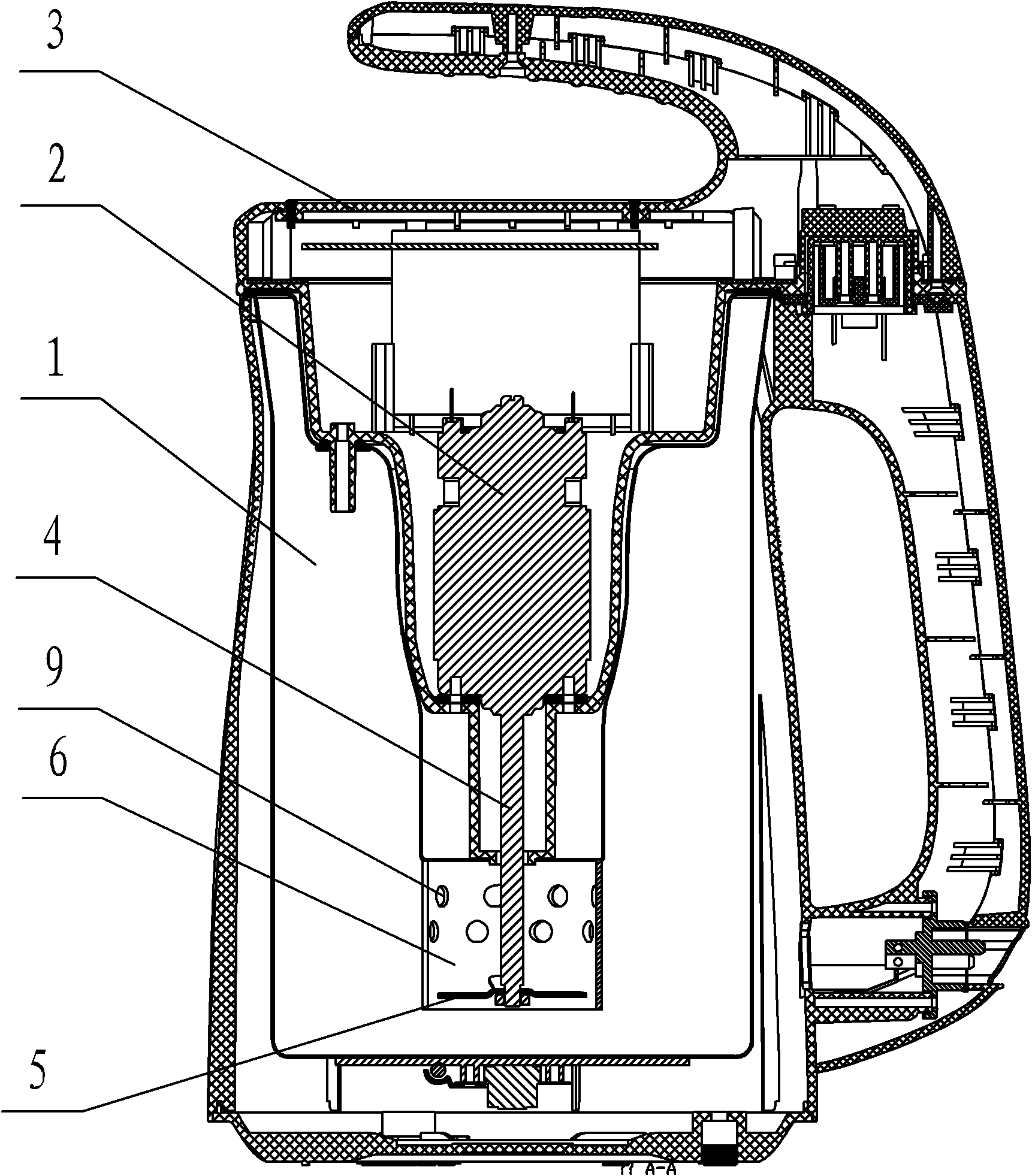

Pulp food processor and pulping method adopted by same

The invention aims at providing a pulp food processor and a pulping method adopted by the pulp food processor, aiming at shortening the preparation time of pulp food. According to the pulp food processor and the pulping method, an electric heating device heats food materials in an inner barrel to a first preset temperature at the full heating power, then the heating power is reduced to a second heating power, so that the food materials in the inner barrel are heated to a second preset temperature, then a motor is started for carrying out pre-grinding at the first motor power, meanwhile, the heating power of the heating device is reduced to a third heating power for heating till the food materials in the inner barrel achieve the third preset temperature or above; then grinding is carried out at the increased second motor power, and the heating device carries out heating at the reduced fourth heating power within the set time; and finally, the motor carries out grinding at the full power, and meanwhile, the heating device carries out heating at the reduced fifth heating power.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

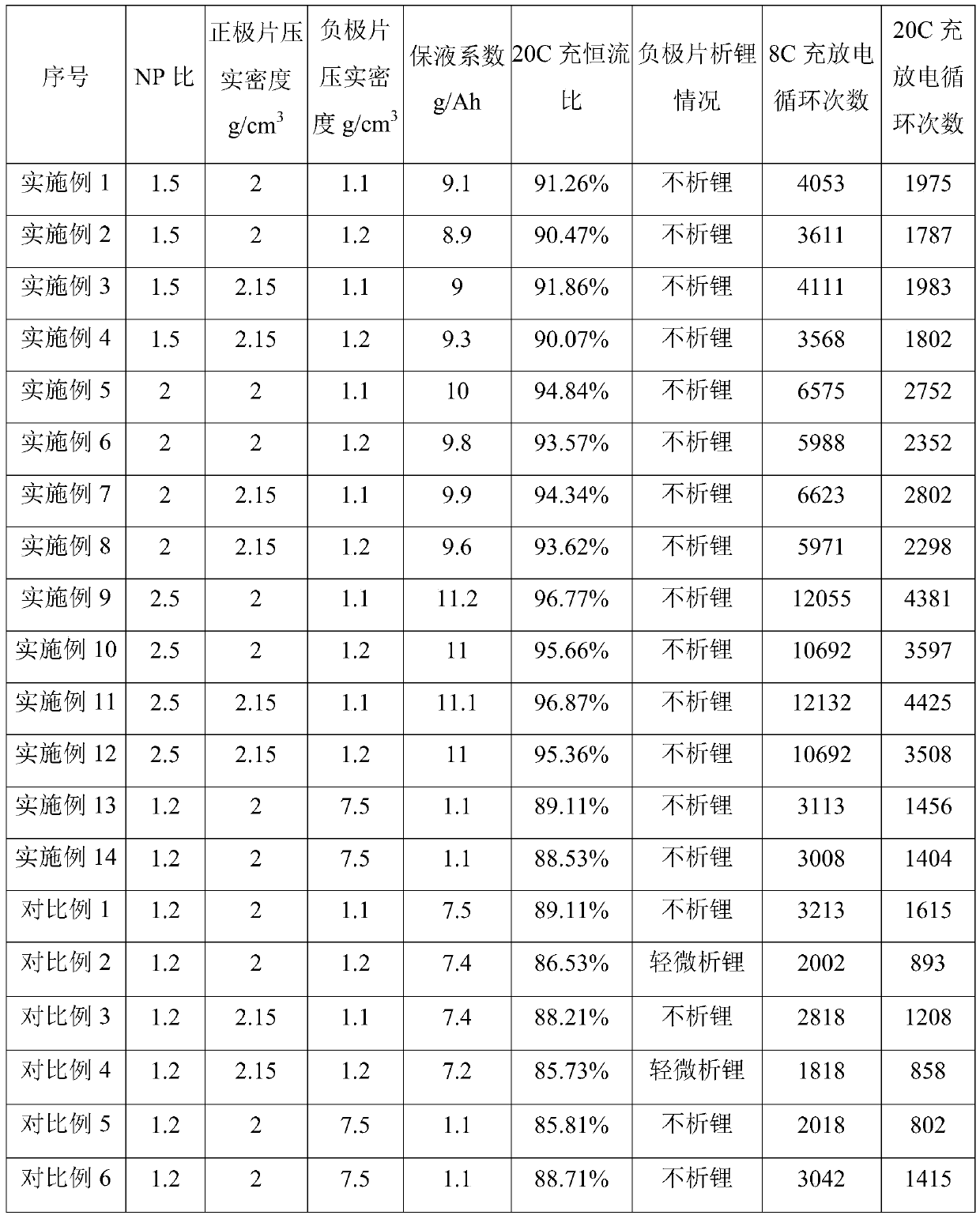

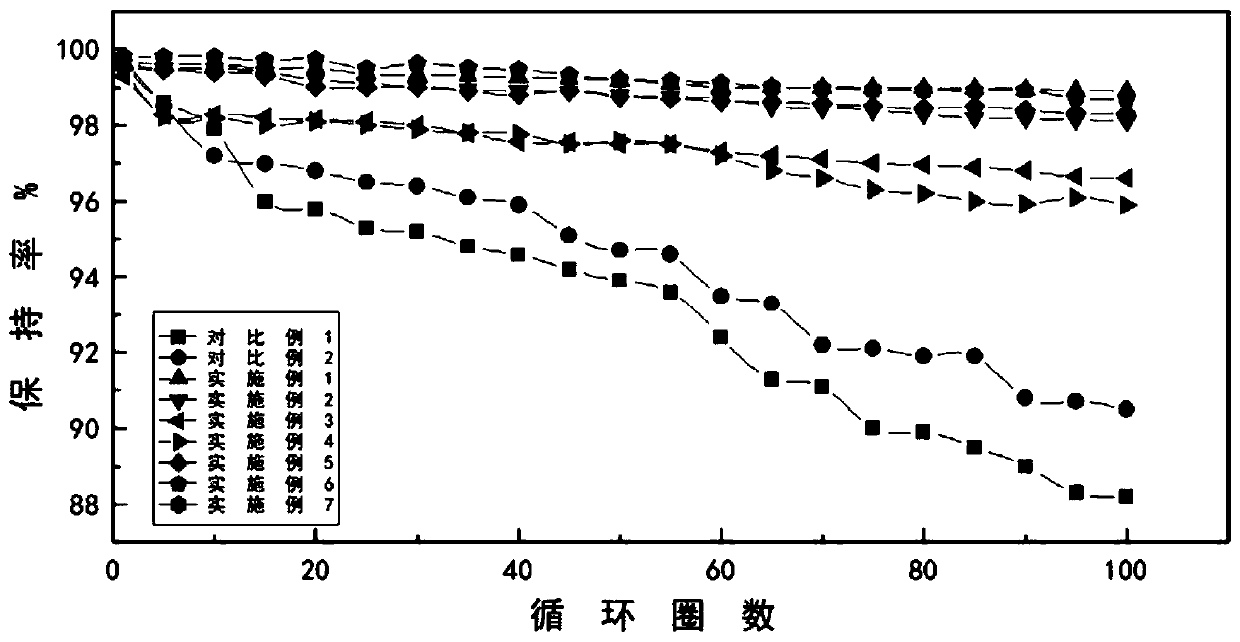

Lithium ion battery and preparation method thereof

PendingCN111403801AImprove cycle performanceImprove securityFinal product manufactureElectrode carriers/collectorsPhysical chemistryPositive current

The invention relates to the technical field of batteries, in particular to a lithium ion battery and a preparation method thereof. The lithium ion battery is characterized in that the lithium ion battery comprises a positive plate, a negative plate, a diaphragm, an electrolyte and a battery housing. The positive plate comprises a positive current collector and positive slurry, and the negative plate comprises a negative current collector and negative slurry, wherein the ratio of the capacity of the negative plate to the capacity of the positive plate is 1.41-9.41. According to the lithium ionbattery, the ratio of the capacity of the negative plate to the capacity of the positive plate in the battery is optimized, the surplus capacity is supplemented through a lithium supplementing technology, and the parameters of the positive plate and the negative plate are optimized, so that the cycle performance, the safety performance and the rate charging performance of the lithium ion batteryare improved, and the lithium ion battery has the characteristics of high rate and long service life.

Owner:FARASIS TECH (GANZHOU) CO LTD

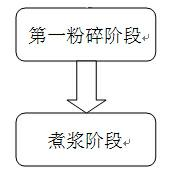

Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

InactiveCN102144889ANot easy to burnImprove homogeneityBeverage vesselsMilk substitutesFlavorLiquid temperature

The invention relates to an originally ground soybean milk preparation method of a soybean milk grinder, which comprises: (a) a first grinding stage and (b) a boiling stage, wherein in the first grinding stage, materials for preparing soybean milk are ground by a grinding blade under the driving of an electric motor of the soybean milk grinder, and the liquid temperature during the first grinding stage is not more than 70 DEG C; and in the boiling stage, the soybean milk is heated by a heating component of the soybean milk grinder until the soybean milk is boiled up, and the heating component is used for persistently or interruptedly heating the materials in a cup during the first grinding stage. The soybean milk prepared according to the soybean milk preparation method has bean flavor and better mouthfeel.

Owner:JOYOUNG CO LTD

Food processing method of food processor and food processor

InactiveCN108652478ALower oxygen levelsReduce churnVessels with intergral heatingVacuum pumpingStopped work

The invention discloses a food processing method of a food processor and the food processor, and relates to the field of food processing. The food processor comprises a machine base provided with a motor and a circuit board, a vacuum pump, a mixing cup, a grinding cutter, a pressure relief module used for pressure relief of the mixing cup and a sealing module used for sealing the mixing cup. The circuit board is provided with a control circuit. The food processing method at least comprises the steps that a intermittent vacuum extraction step is performed, specifically, the sealing module sealsthe mixing cup, then the vacuum pump works to extract air in the mixing cup to enable the mixing cup to be in a negative pressure state and then the vacuum pump stops working, then the pressure relief module performs pressure relief on the mixing cup, and the intermittent vacuum pumping step is executed repeatedly; and a crushing step is performed, specifically, the motor drives the grinding cutter to rotate to crush materials in the mixing cup. According to the food processing method, no burnt bottom and less foam are achieved, and the noise is low.

Owner:JOYOUNG CO LTD

Method for making soybean milk with soybean milk machine and the soybean milk machine

InactiveCN102845527AShorten pulping timeNo harm to human healthBeverage vesselsMilk substitutesHuman healthSoybean oil

The invention provides a method for making soybean milk with a soybean milk machine and the soybean milk machine. The method includes sequentially performing soybean milk making and boiling. The boiling includes heating pulverized raw material, and performing ultrasonic defoaming on foams generated during heating. The defoaming treatment includes detecting foam volume and ultrasonically defoaming when abnormal foam volume is detected. The soybean milk machine includes a control module, a foam detection module and an ultrasonic defoaming device. The soybean milk machine allows the foam detection module to detect foams generated during soybean milk boiling and to transmit a signal when abnormal foam volume is detected to the control module, which sends an instruction to start the ultrasonic defoaming device for rapid defoaming through ultrasonic wave generated by the ultrasonic defoaming device. The method shortens soybean milk making time, has no foam in produced soybean milk, is convenient, rapid and safe, and has no danger to human health.

Owner:BYD CO LTD

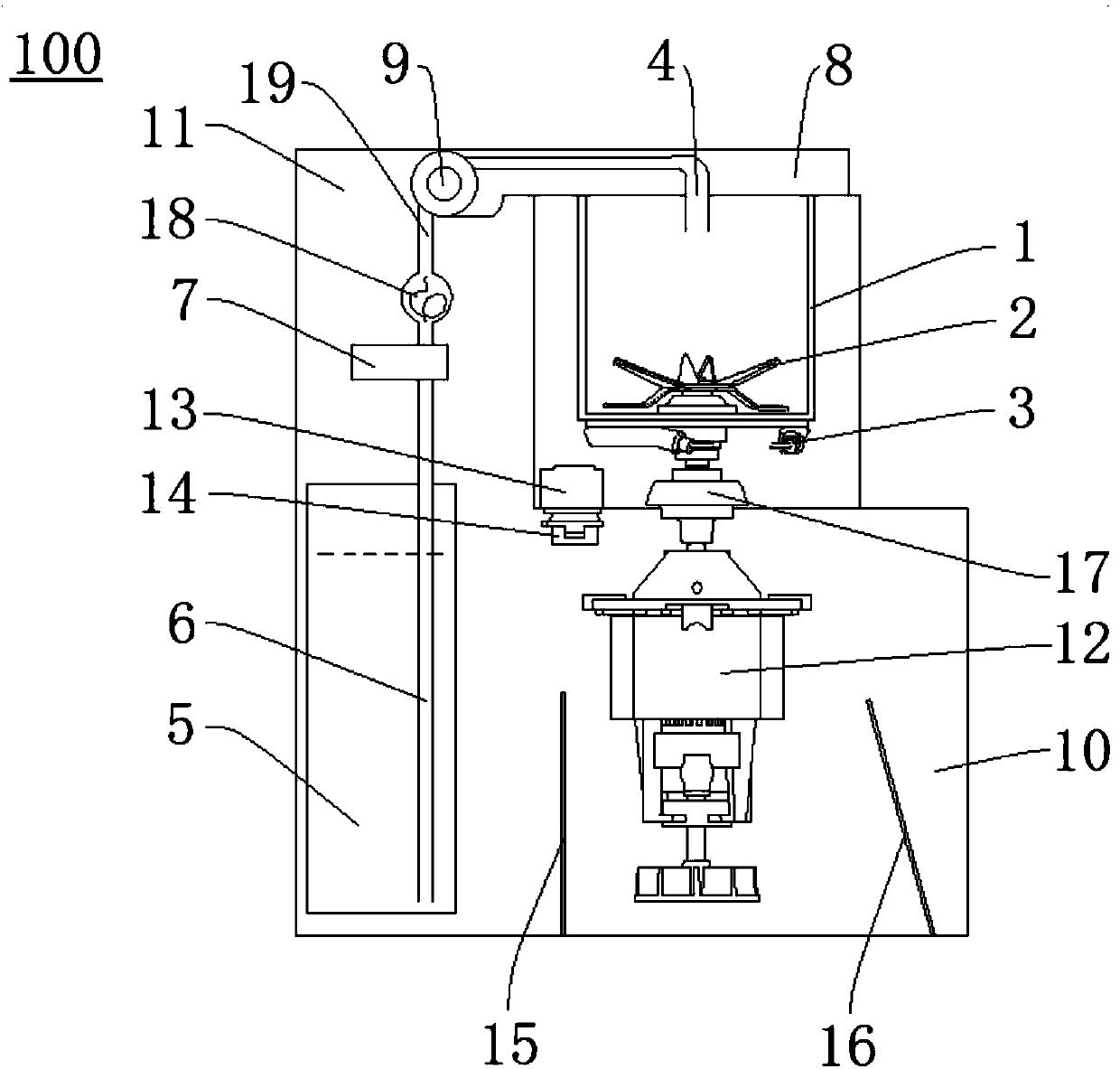

Rapid soybean milk machine

ActiveCN103300726AWon't burnQuality improvementBeverage vesselsMilk substitutesProcess engineeringFood science

The invention relates to a rapid soybean milk machine, in particular to a rapid soybean milk machine with a cup barrel for crushing and soymilk boiling and a motor arranged at the upper part. The rapid soybean milk machine is characterized in that an inner cup can be sleeved and overlapped in the cup barrel; after water serving as a heat-conducting medium is added between the cup barrel and the inner cup, crushing and soymilk boiling operations are performed in the inner cup; in a soymilk preparation control process, the inner cup is applied to boiling and preparing soymilk in at least one working process; and under the condition that the inner cup is not used, a machine head and a cup body are combined, the machine is a common soybean milk machine with a larger volume. After the inner cup is additionally arranged, the machine head, the cup body and the inner cup are combined, so that the new type rapid soybean machine with a soymilk boiling and preparing function and a smaller volume is formed.

Owner:福建秉德培青科技有限公司

Environment friendly pulping process

ActiveCN101591864AShorten pulping timeLess investment in equipmentPulp bleachingPulping with inorganic basesFiberPulp and paper industry

The invention belongs to the technical field of improved pulping process, and particularly relates to an environment friendly pulping process. The environment friendly pulping process is characterized by comprising the following steps: (1) chopping and dust removal of pulping materials; (2) material mixing by adding water and medicaments; (3) primary grinding; (4) primary thermal insulating bleaching; (5) pulp extruding and washing; (6) secondary medicament addition; (7) secondary thermal insulating bleaching; (8) pulp extruding; (9) pulp washing; and (10) the production of organic fertilizer by recycling non-fiber materials. The pulping process has the advantages of pulping time conservation, no discharge of pulping water, odorlessness, high efficiency, energy conservation, low equipment investment, high white pulp yield and whiteness, low cost, and no brightness reversion of the paper pulp; and the pulp prepared by the process is better than the full chemical pulp.

Owner:刘长如

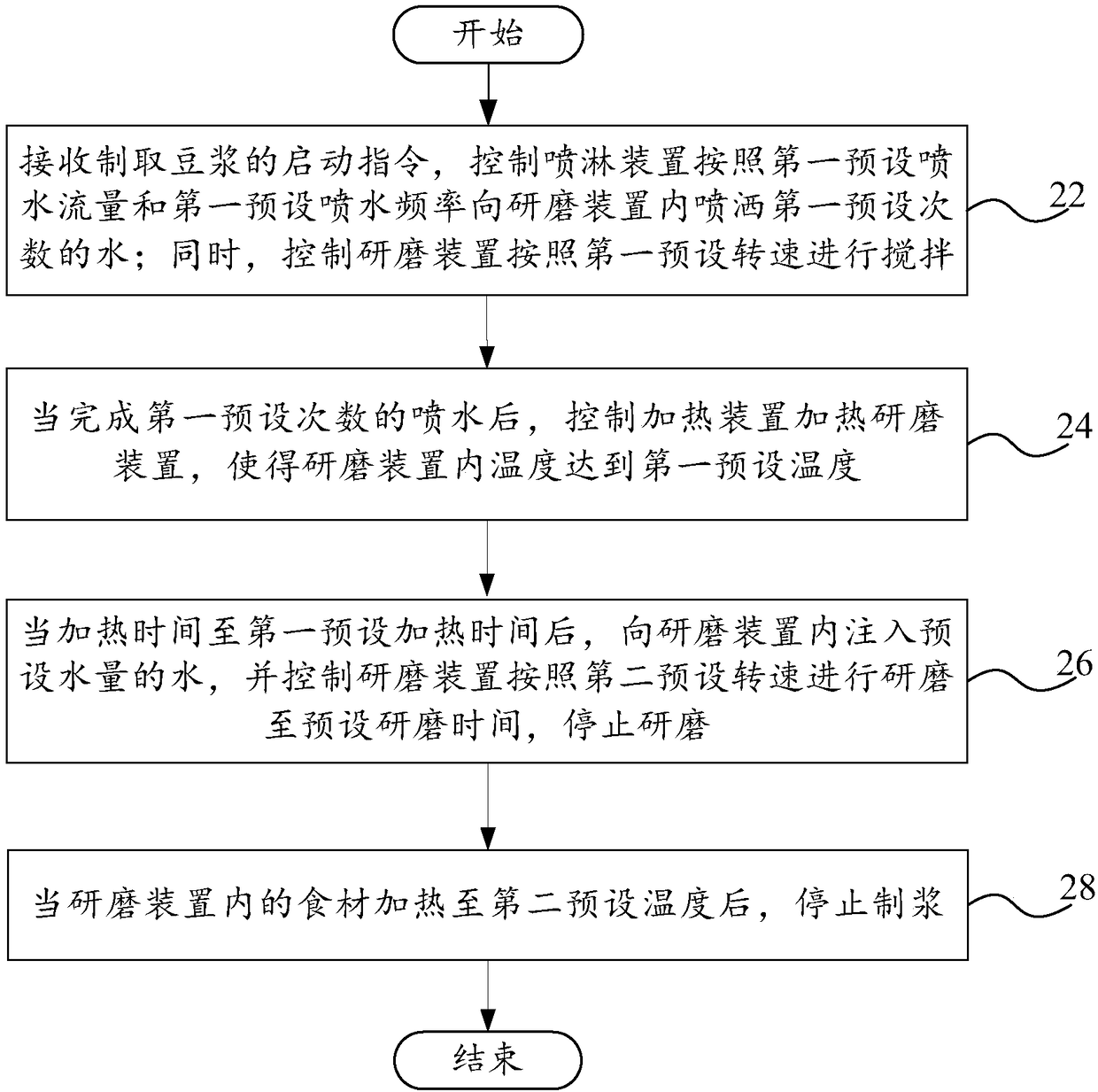

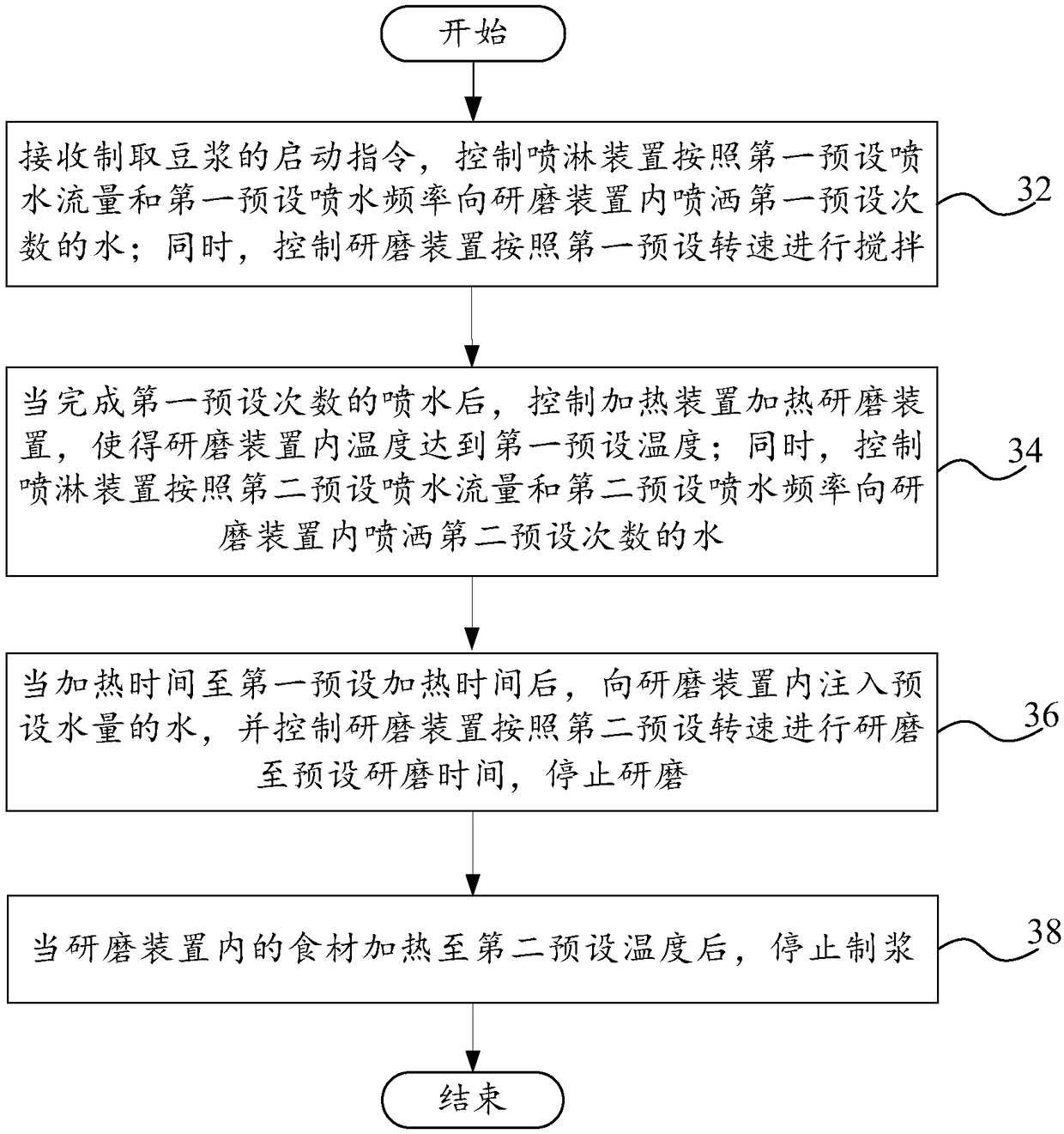

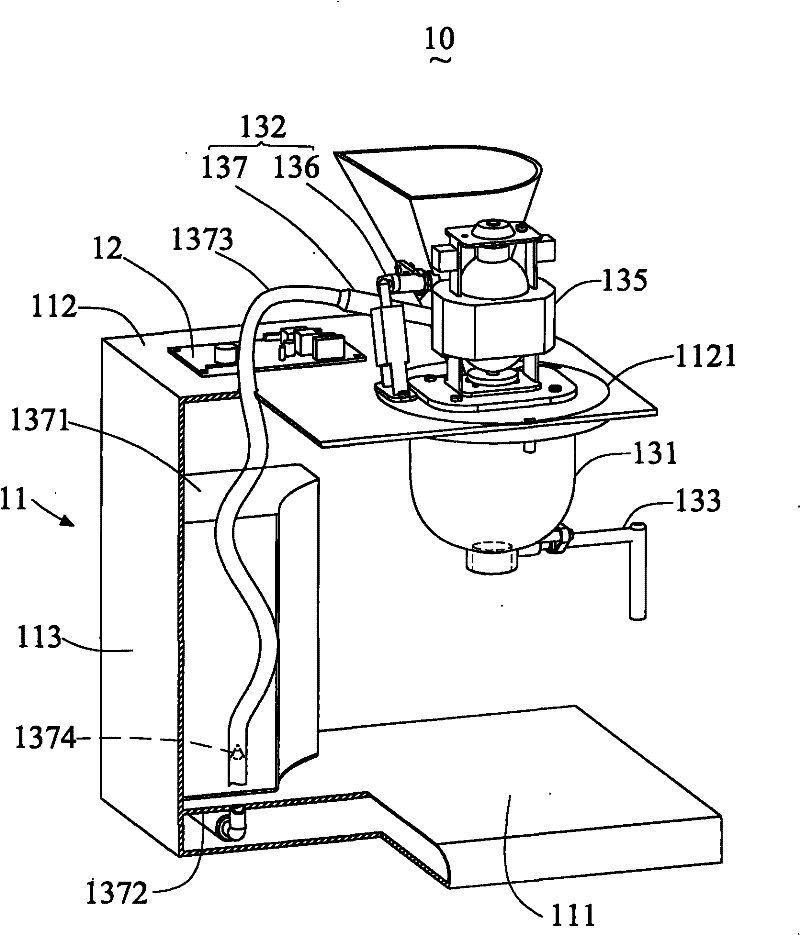

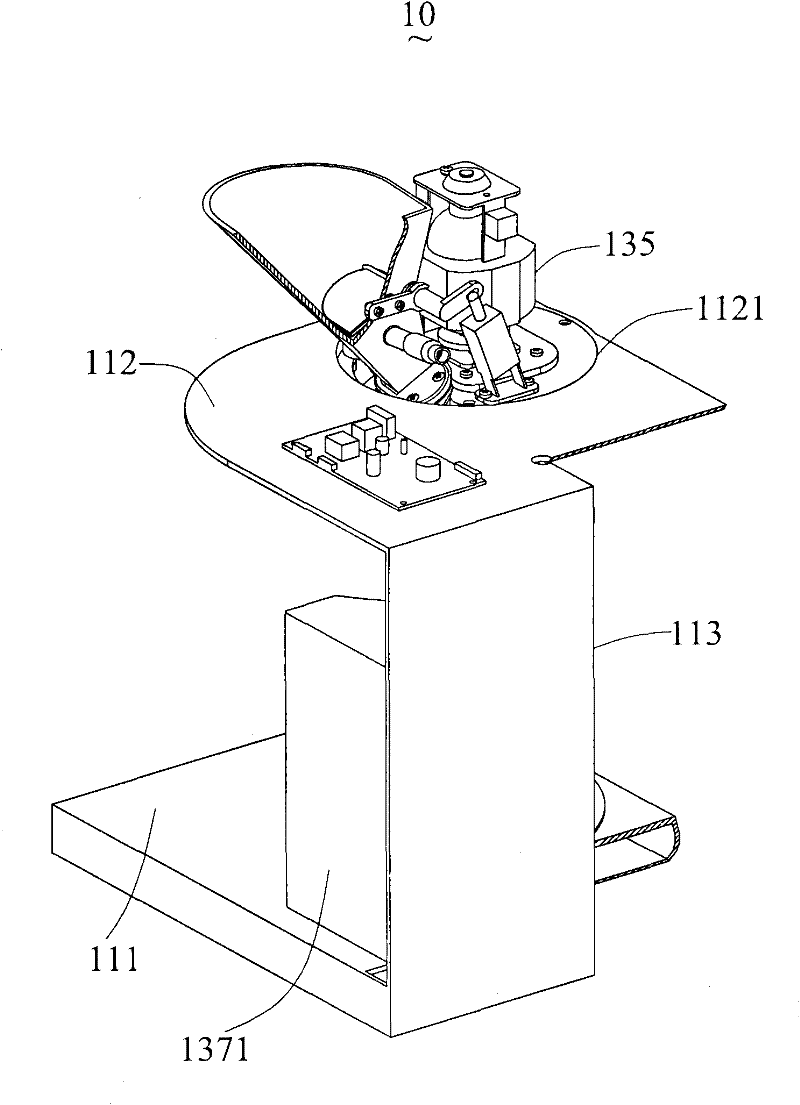

Cooking utensil, soybean milk making method and computer device

PendingCN109419387AImprove satisfactionHigh nutritional valueKitchen equipmentFood scienceEngineeringFood material

The invention provides a cooking utensil, a soybean milk making method, a computer device and a computer readable storage medium. The cooking utensil comprises a shell, a grinding device in the shell,a spraying device in the shell and a heating device in the shell, wherein the spraying device is located above the grinding device and provided with a water spraying opening; the heating device is located below the grinding device. According to the cooking utensil, the spraying device sprays water into the grinding device through the water spraying opening to make food materials wetted, and the heating device is used for heating the wetted food materials in the grinding device to generate wet hot steam for enzyme deactivation treatment of the food materials, so that the enzyme deactivation speed is increased, the cooking time is shortened, the application range of the cooking utensil is enlarged, and the use satisfaction degree of users is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

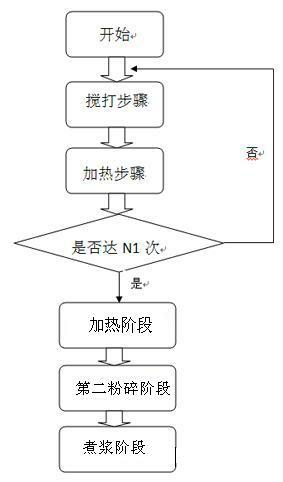

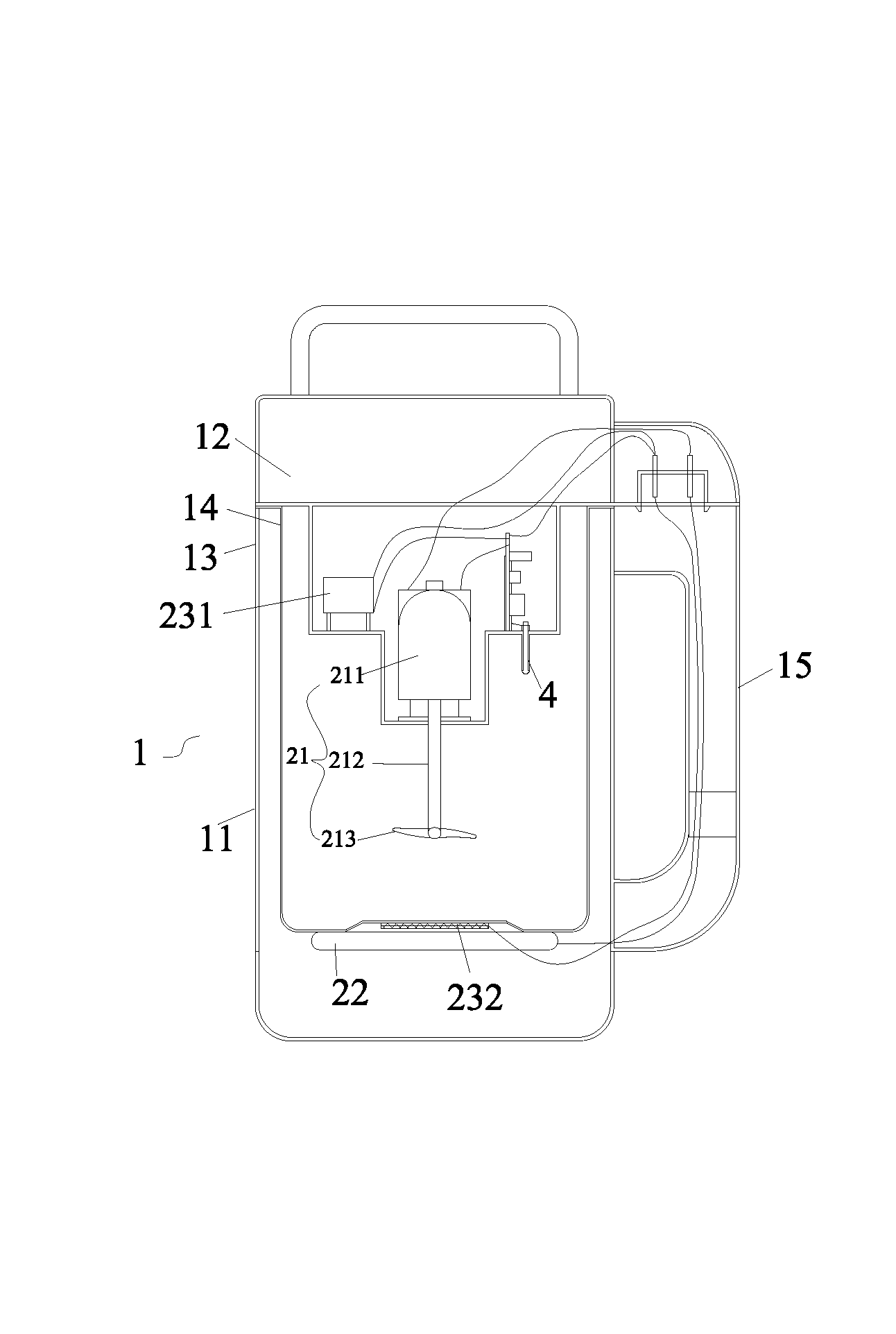

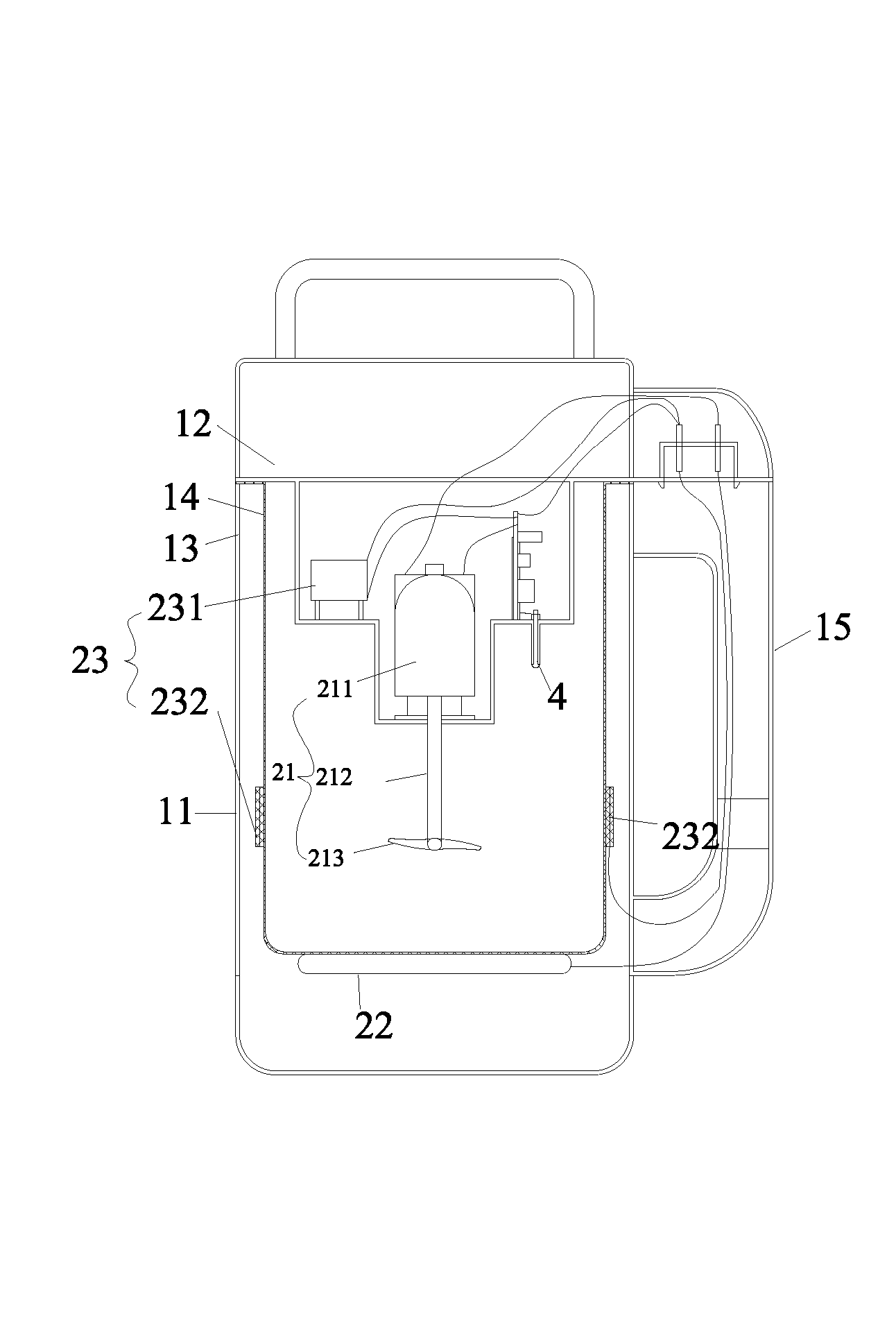

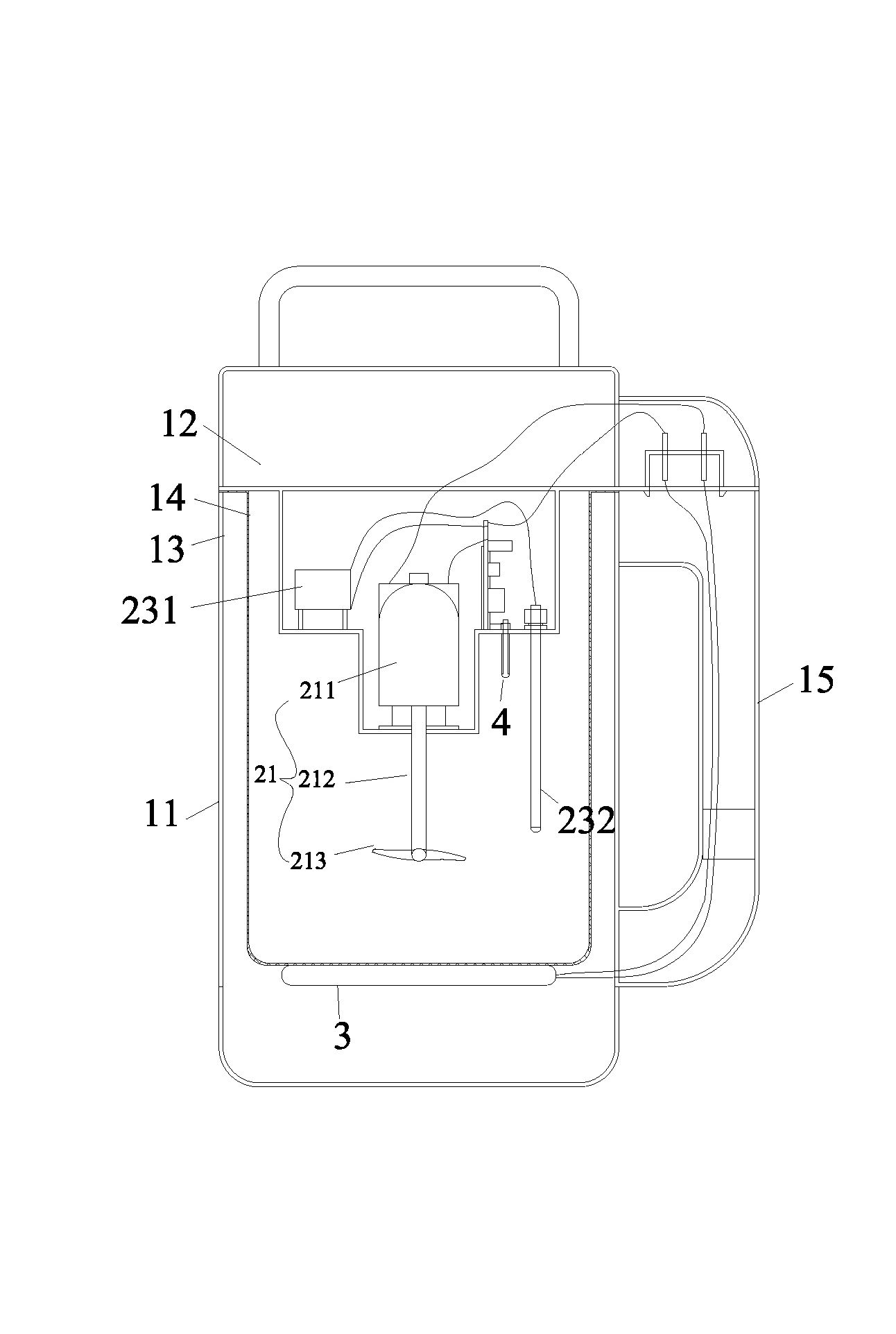

Soya-bean milk machine capable of quickly making milk

ActiveCN102204789AReduce cooking timeImprove the crushing finenessBeverage vesselsMilk substitutesEngineeringSlurry

The invention relates to a soya-bean milk machine capable of quickly making milk. The soya-bean milk machine comprises a machine seat, a control unit, a smashing cutter, a motor for driving the smashing cutter to rotate, a smashing ager and a pre-heating device; the motor or the shaming ager is installed on the machine seat; the motor is electrically connected with the control unit; the smashing cutter is positioned in the smashing ager; materials and water are mixed in the smashing ager and are smashed by the smashing cutter into pulp / paste, heat is generated by mutual friction among the pulp / paste, the smashing cutter and the smashing ager to raise the temperature of the pulp / paste until curing; and the pre-heating device is used for heating the water and / or the materials before smashing and curing. By adopting a smashing and curing unit with higher smashing efficiency in the soya-bean milk machine, the time of comprehensively making the milk is greatly shortened, and the milk can be made only within 10 minutes.

Owner:JOYOUNG CO LTD

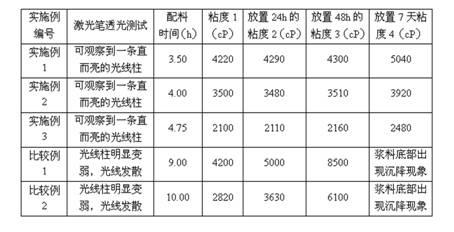

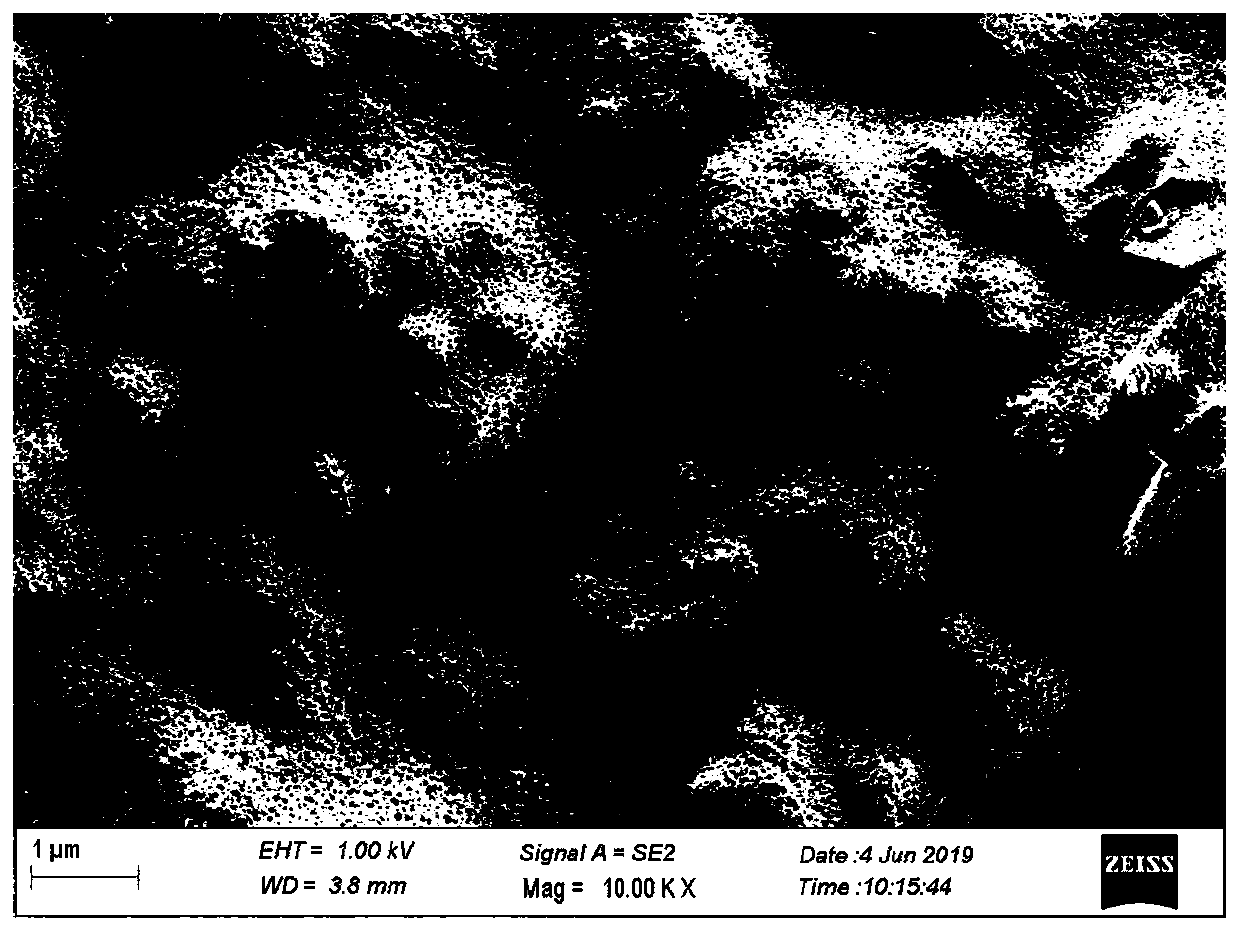

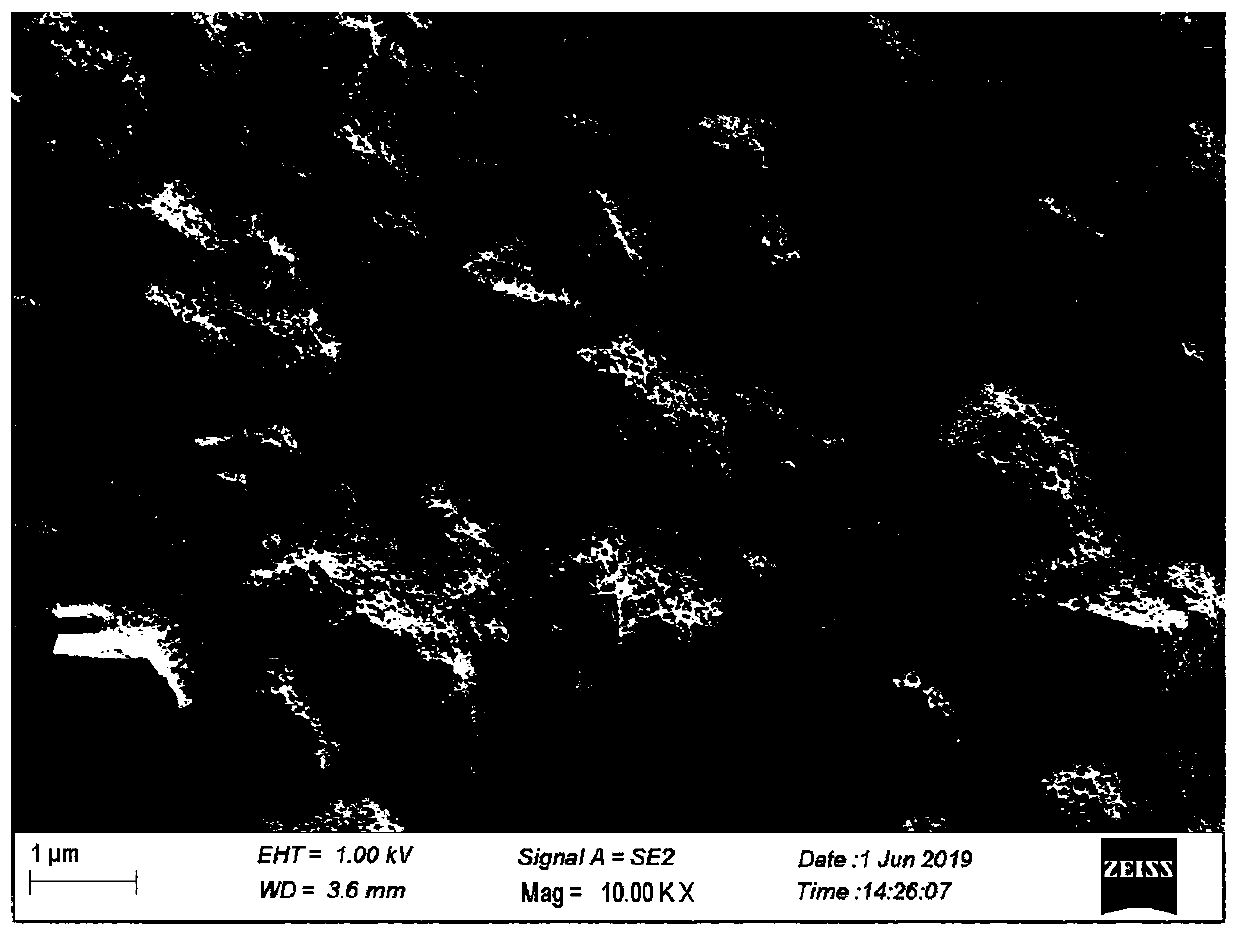

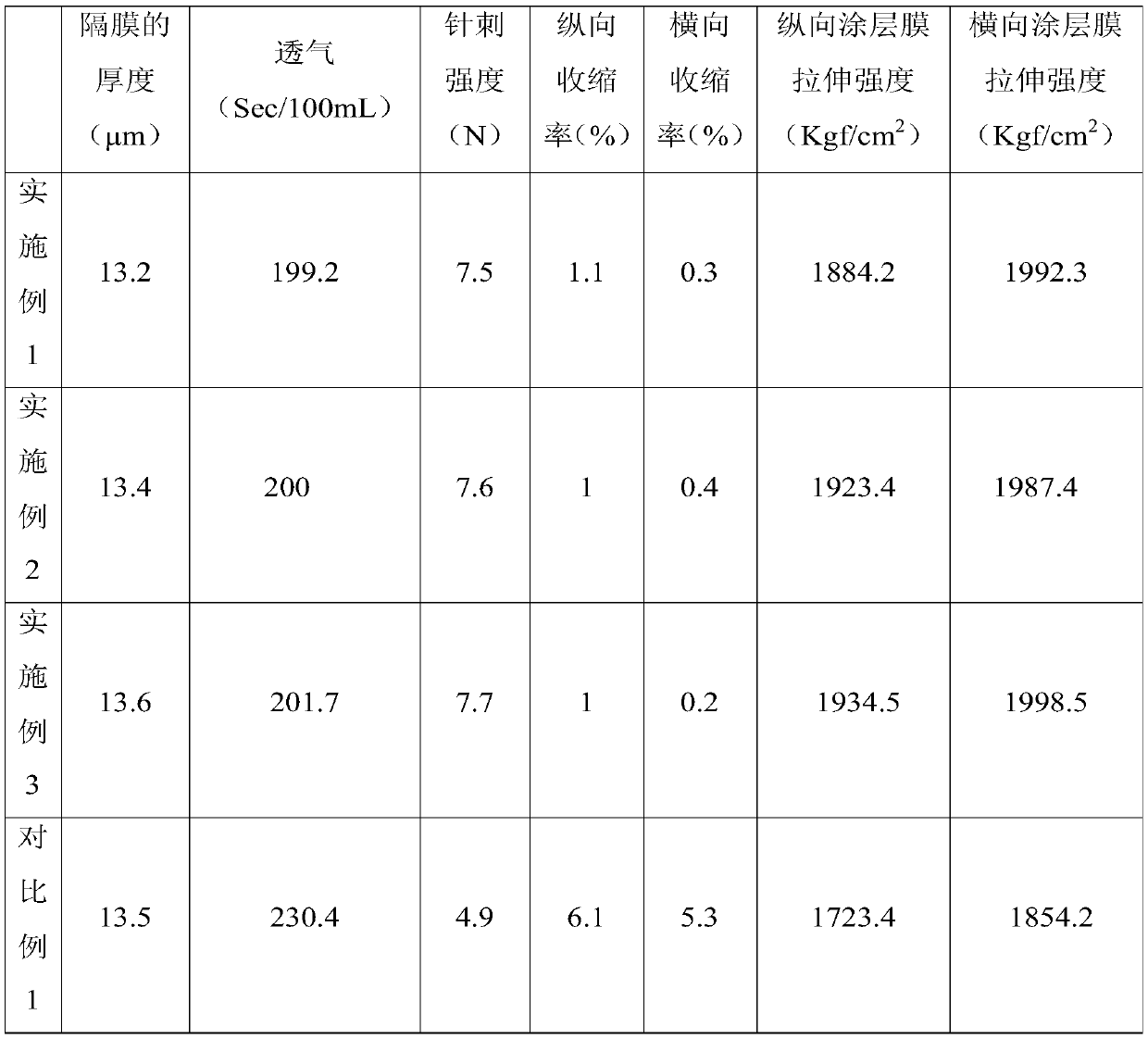

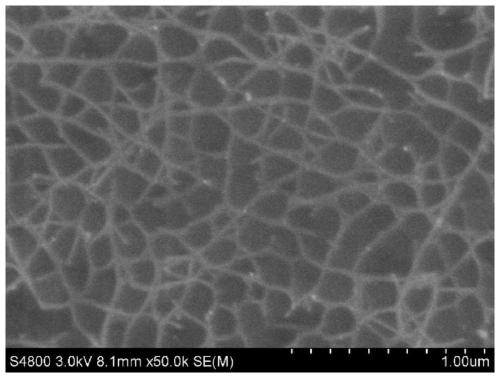

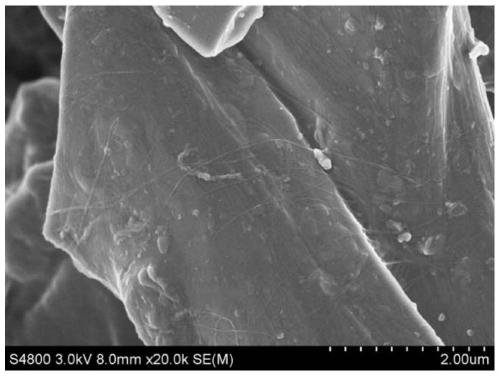

Aramid fiber coating liquid, preparation method thereof, diaphragm based on aramid fiber coating liquid and application

ActiveCN110707265AImprove diaphragm shrinkageImprove acupuncture strengthCell component detailsFiber coatingCeramic particle

The invention discloses an aramid fiber coating liquid, a preparation method thereof, a diaphragm based on the aramid fiber coating liquid and application, the preparation method comprises the following steps: stirring and sanding ceramic particles and dimethylacetamide to obtain a first mixture; under the atmosphere of nitrogen or inert gas, stirring the first mixture and m-phenylenediamine, cooling to 0-5 DEG C after stirring, adding isophthaloyl dichloride, stirring, heating to 78-90 DEG C after stirring, adding calcium hydroxide, and stirring to obtain a second mixture; and mixing and stirring the second mixture and an organic matter, and adjusting the viscosity to 280-400 mpa.s to obtain the aramid fiber coating liquid. Starting from the synthesis direction, substances required by a diaphragm coating are added in the synthesis process, so that the pulping time is shortened while the cost is saved, and the safety performance of thermal shrinkage, needling and the like of the aramidfiber diaphragm is improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

Preparation method of dry lotus root vermicelli

The invention discloses a preparation method of dry lotus root vermicelli. The preparation method of the dry lotus root vermicelli comprises the following steps: 1) cleaning dry lotus roots, and slicing the dry lotus roots; 2) carrying out ultrasonic grinding pulping on dry lotus root slices by using an ultrasonic grinder; 3) carrying out two-step centrifugation on pulp obtained in the step 2) so as to obtain dry lotus root starch pulp; and 4) pouring the dry lotus root starch pulp into a steamer basket to obtain dry lotus root starch peel, drying the dry lotus root starch peel until the water content is 20% to 30%, cutting into dry lotus root starch peel strips, and then drying by using a drying oven until the water content is lower than 5% (weight) so as to obtain the dry lotus root vermicelli. According to the preparation method, a centrifugal manner is used instead of natural precipitation, and the pulping time of dry lotus roots is obviously shortened, so that the efficiency for preparing the dry lotus root vermicelli is improved; and the dry lotus root pulp prepared in the centrifugal manner is purer, and the prepared dry lotus root vermicelli is crispy and tasty.

Owner:广西钱隆投资管理有限公司

Environment-friendly pulping technology

InactiveCN105463892AShorten pulping timeLess investmentFibrous raw materialsFiberPulp and paper industry

The invention belongs to the technical field of improved technology for a pulping technology and in particular relates to an environment-friendly pulping technology. The environment-friendly pulping technology is characterized by comprising the following steps of (1) cutting out and dedusting for pulping raw material, (2) adding water and medicine to mix, (3) grinding for the first time, (4) conducting heat-preservation bleaching for one time, (5) shoving and washing, (5) adding medicine for the second time, (7) conducting the heat-preservation bleaching for the second time, (8) shoving, (9) washing and (10) recovering non-fiber material to produce organic fertilizer. Pulping time can be reduced and non water is discharged; no smell is caused; the pulping technology is high efficient and energy-saving; low equipment investment is required; high white pulp yield and whiteness degree can be achieved; low cost is demanded; and yellowing of the paper pulp can be avoided, so the pulp manufactured by the pulping technology is better than full-chemical pulp.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

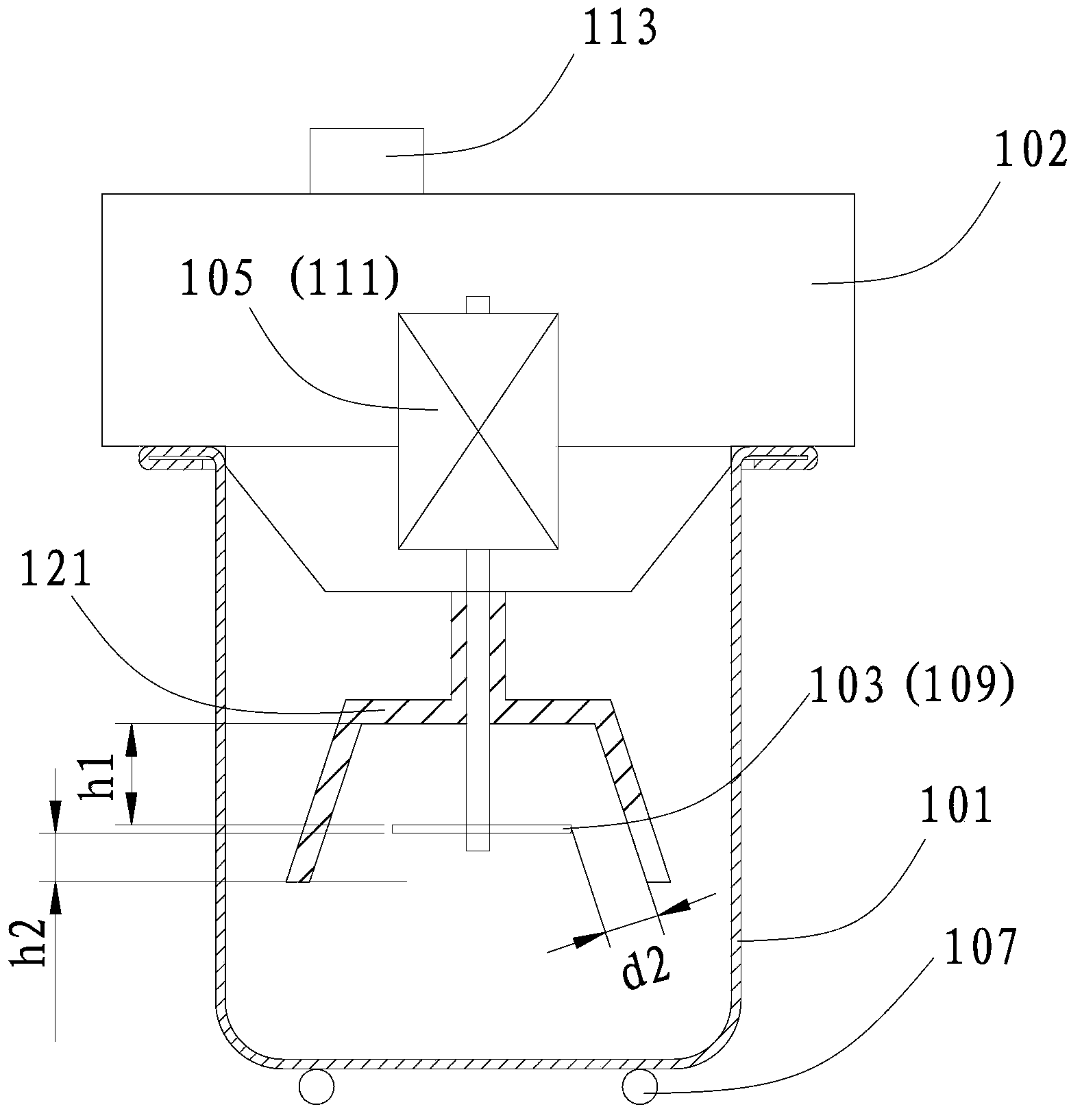

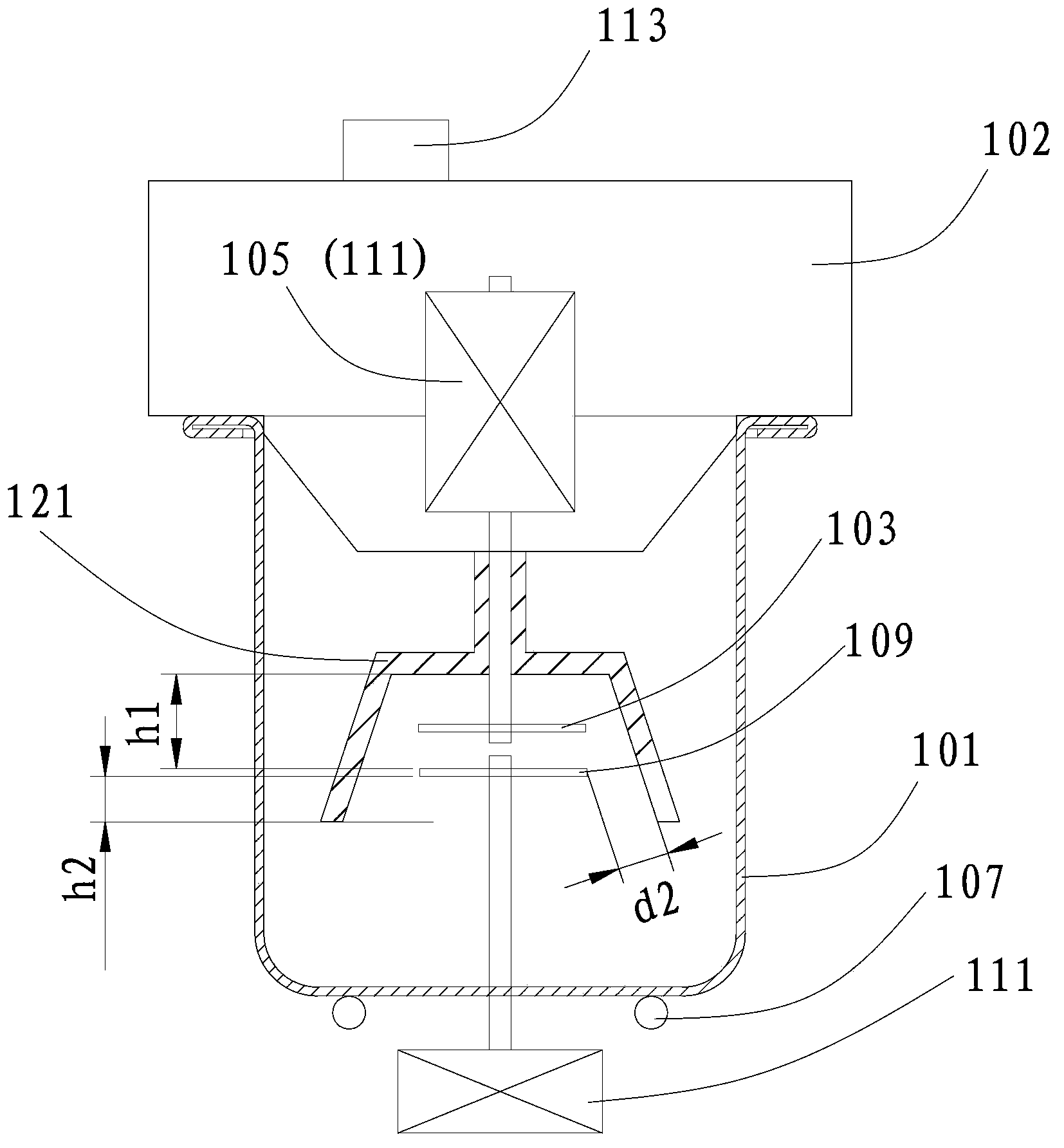

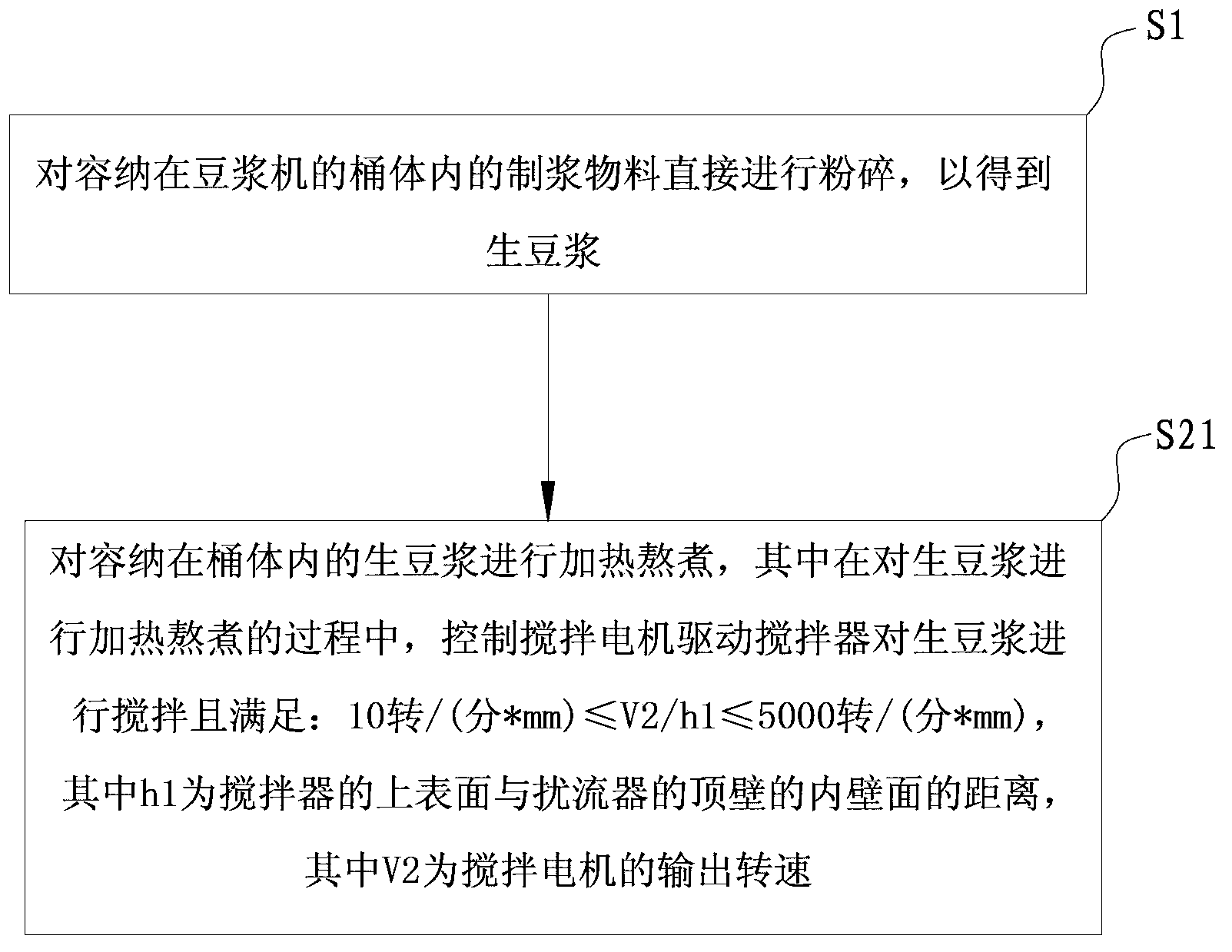

Soybean milk making machine, and method for making soybean milk by using it

ActiveCN104115937AIncrease concentrationExtend your lifeBeverage vesselsMilk substitutesEngineeringProcess engineering

The embodiment of the invention discloses a soybean milk making method and an apparatus thereof. The method includes the following steps: directly crushing a soybean milk material by controlling a crushing motor of a soybean milk making machine (the apparatus) to drive the crusher of the soybean milk making machine to obtain raw soybean milk; and heating the raw soybean milk for boiling while stirring by a stirrer arranged in a barrel, wherein stirring satisfies a condition that V2 / h1 is not less than 10r / (min*mm) and not more than 5000r / (min*mm), h1 is a distance from the upper surface of the stirrer to the inner wall surface of a spoiler, and V2 is the output speed of a stirring motor. The soybean milk making method disclosed in the embodiment of the invention improves the soybean milk making efficiency, greatly improves the concentration of the made soybean milk, and greatly prolongs the service life of each of the above motors.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

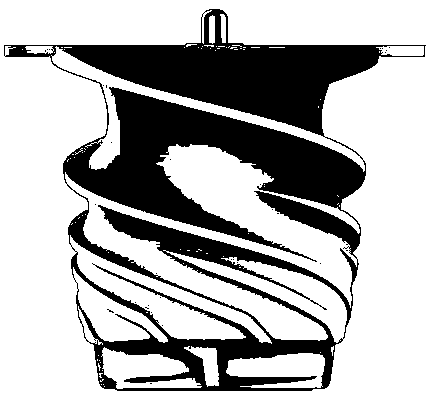

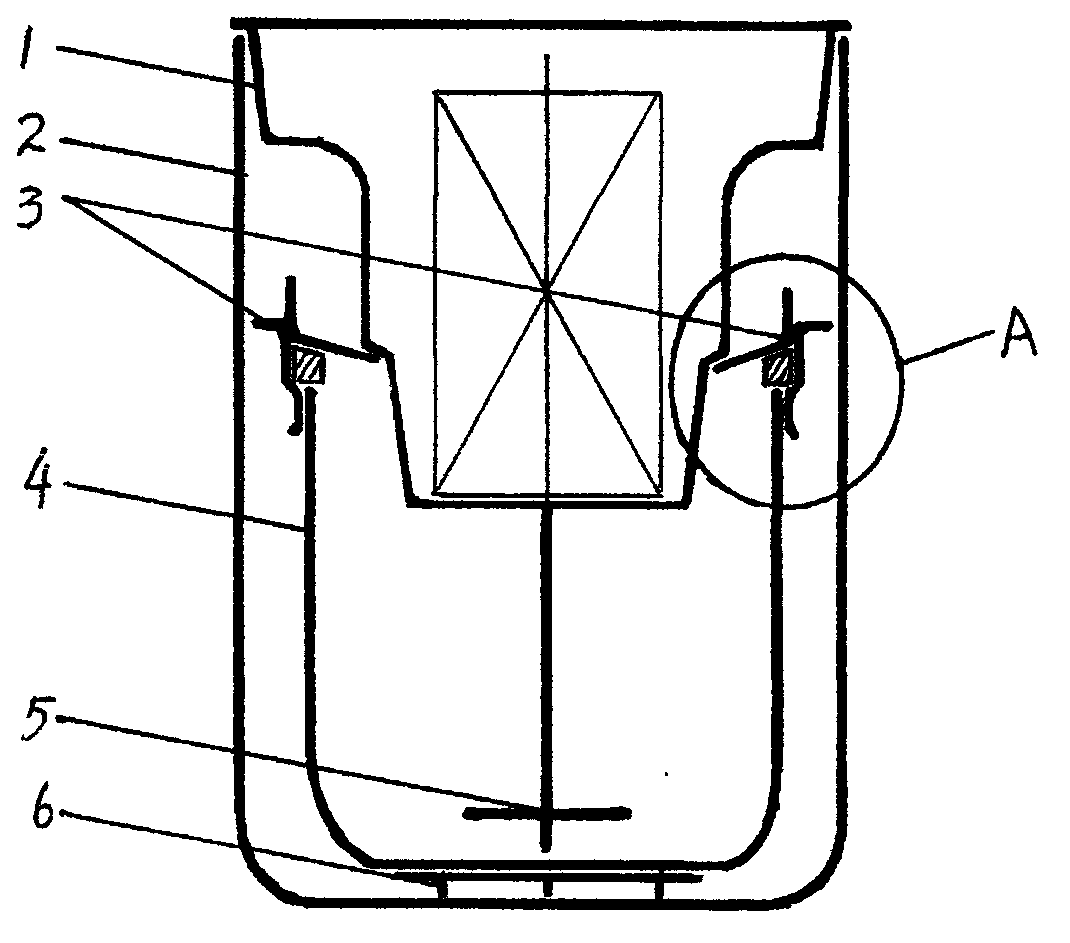

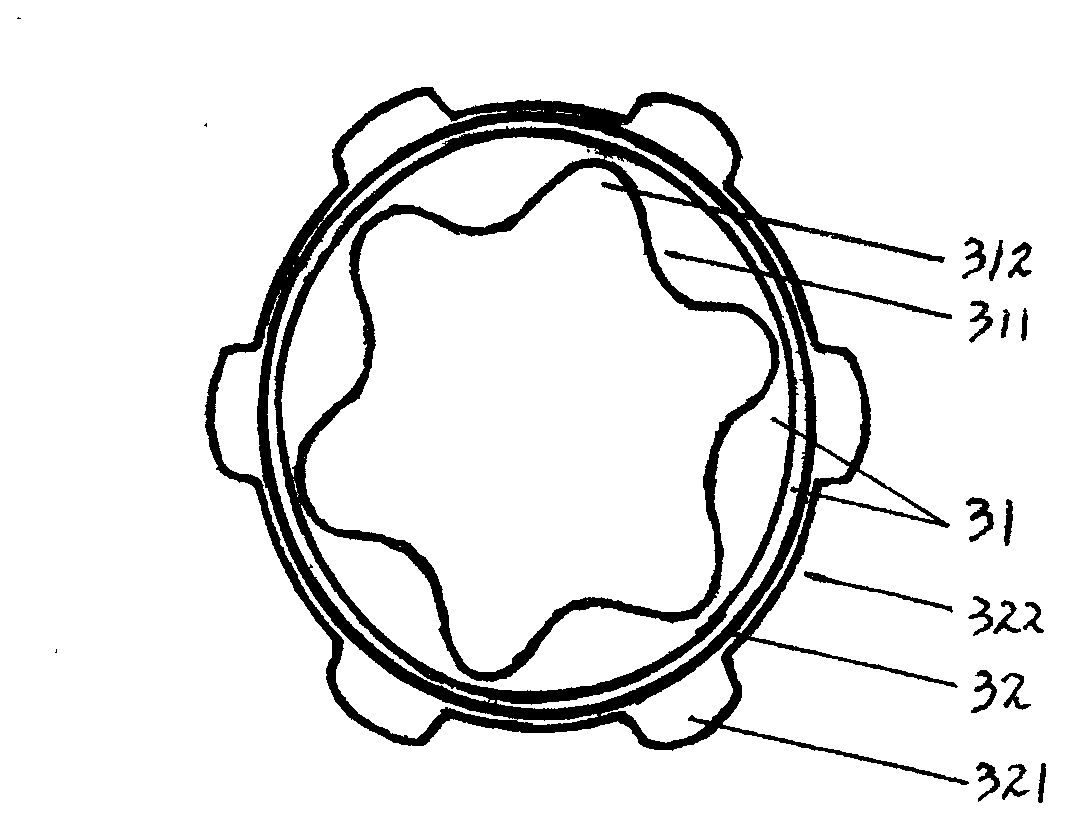

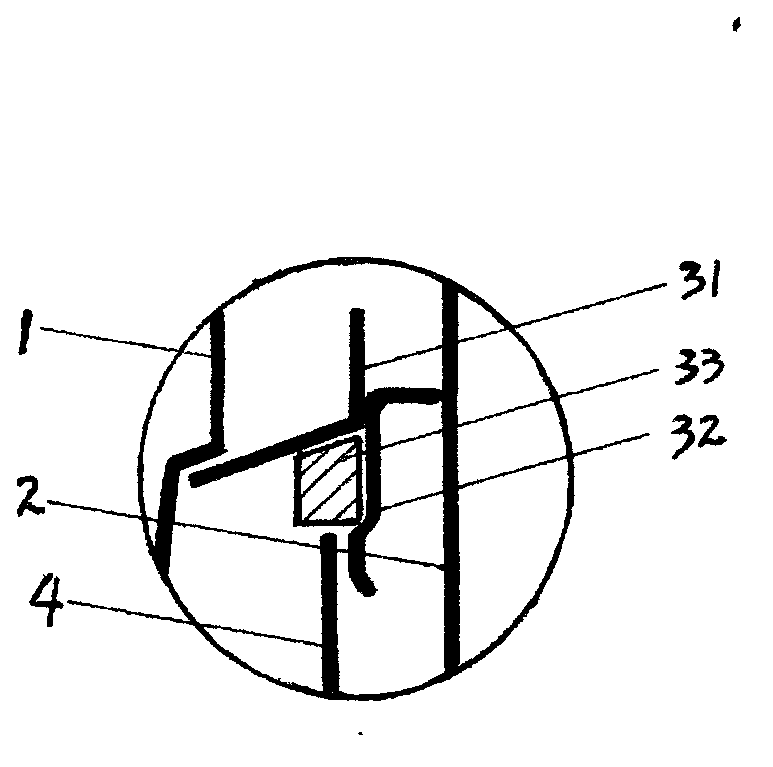

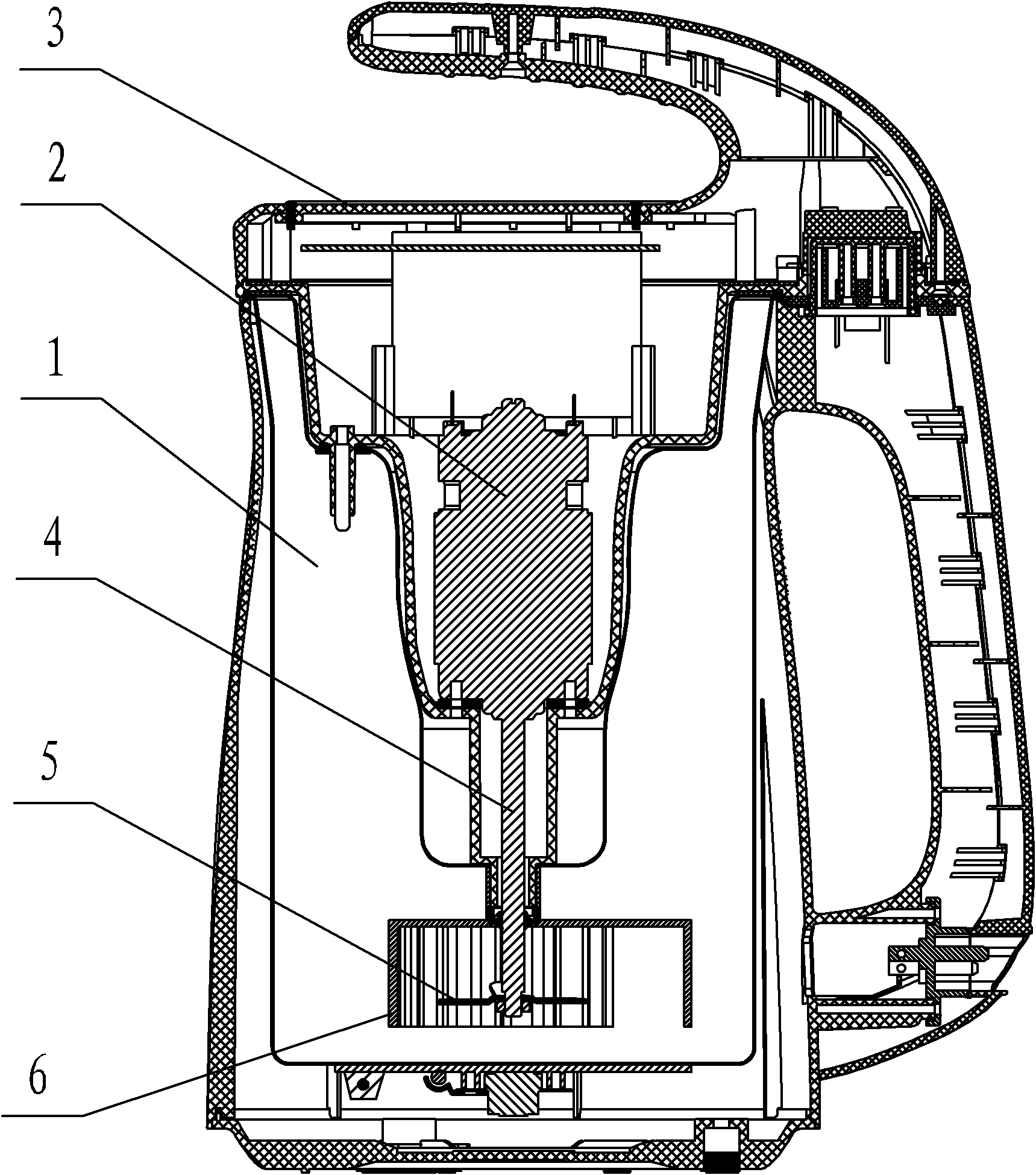

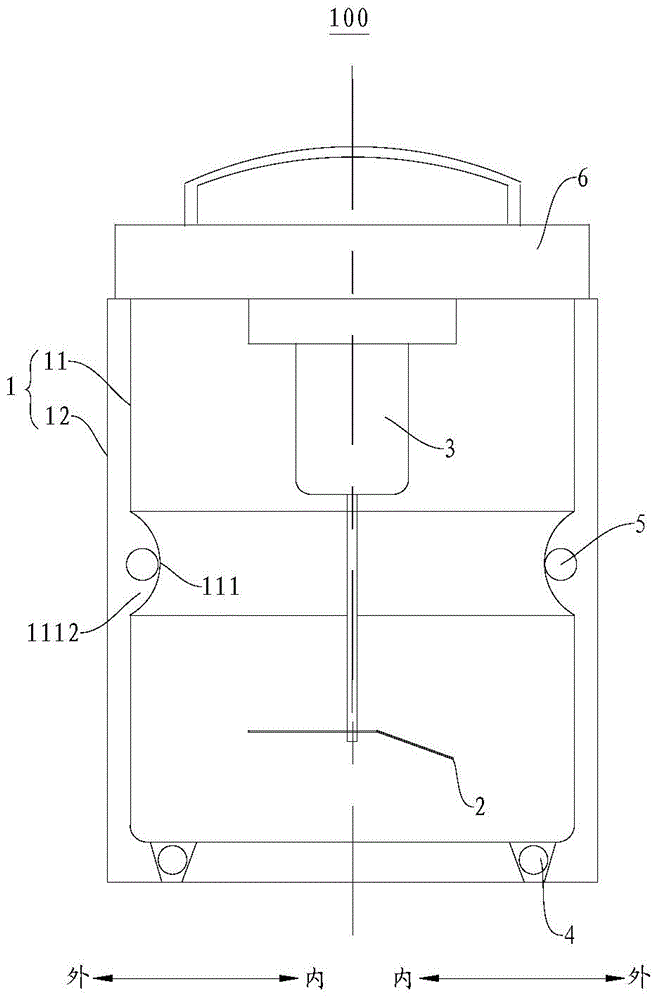

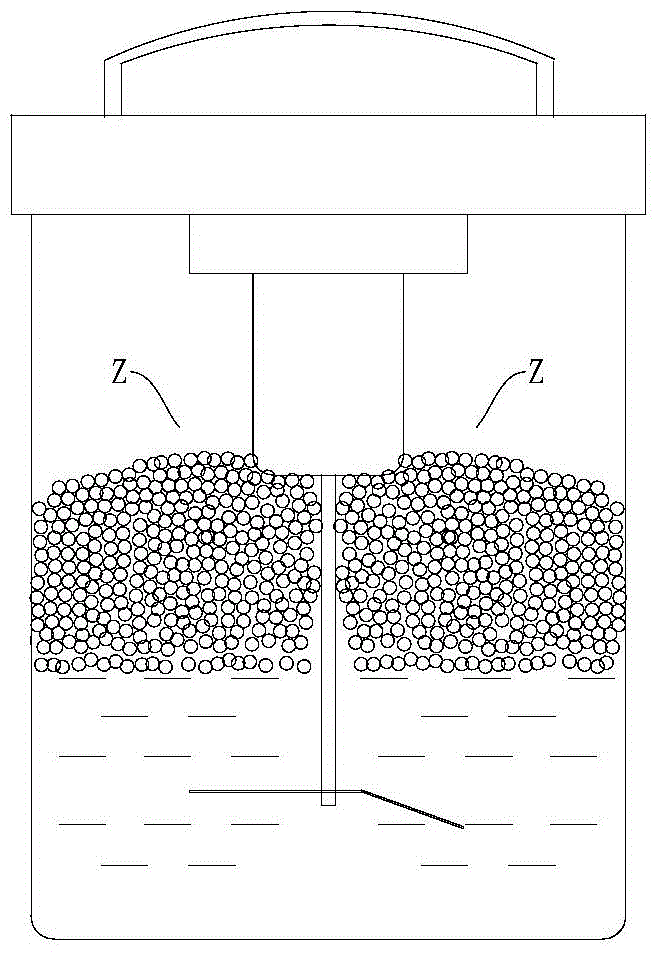

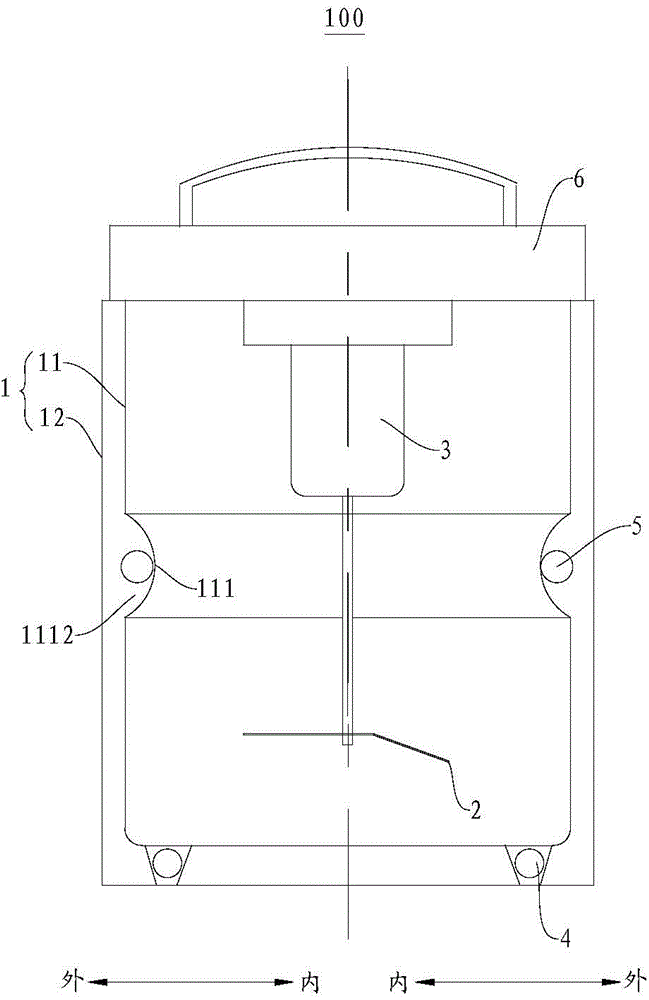

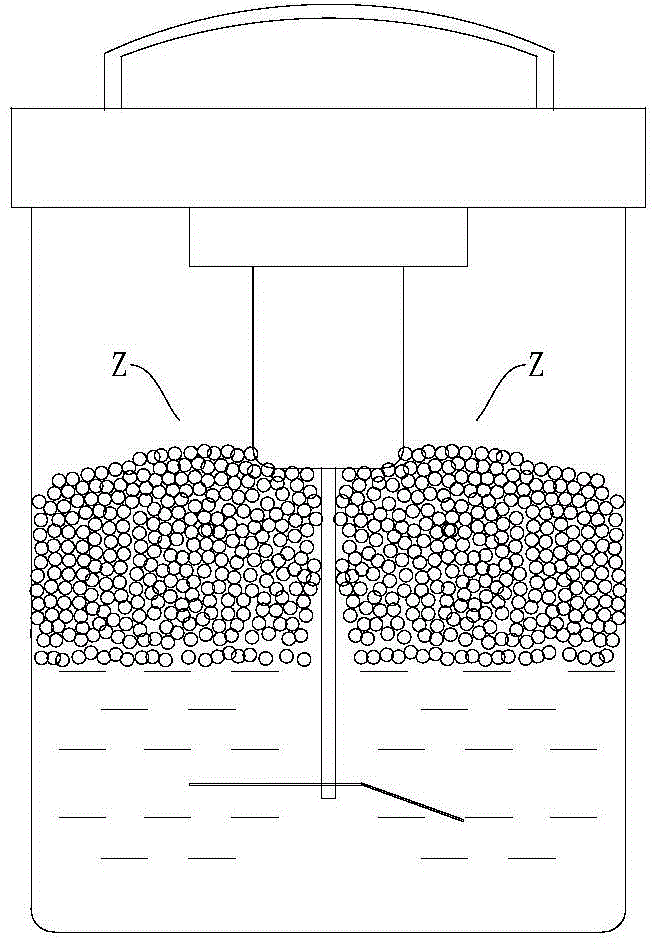

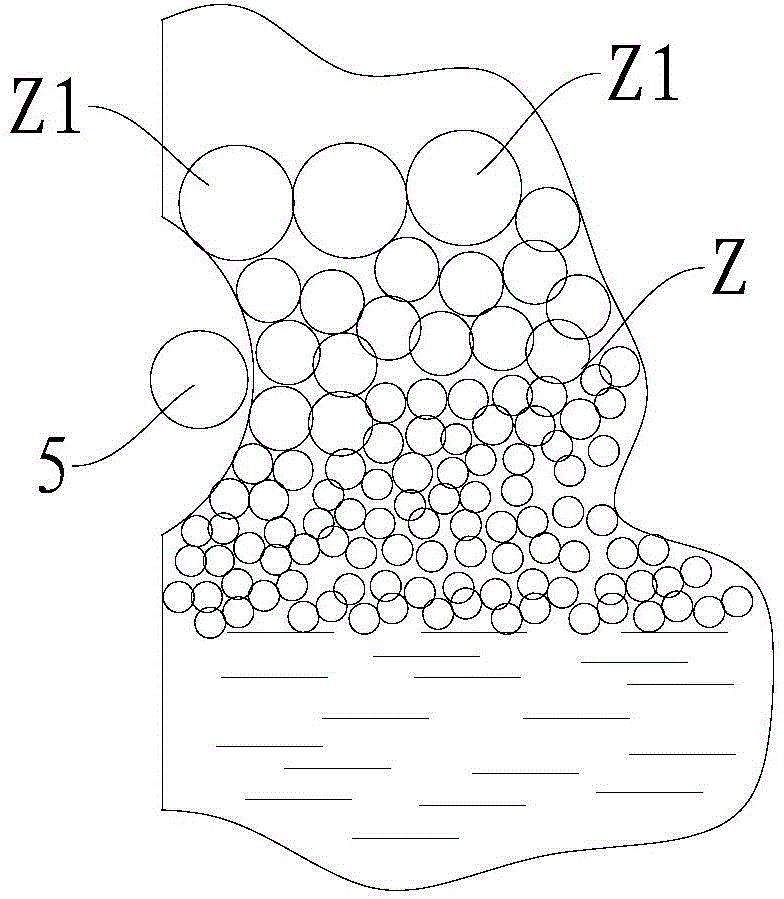

Soybean milk machine

ActiveCN102008243AEasy to disassembleEasy to cleanBeverage vesselsMilk substitutesWater flowEngineering

The invention discloses a soybean milk machine, comprising a soybean milk container (1) the top of which is provided with an opening, and a motor (2) which is used as a power source, wherein the motor (2) is contained in a motor shell (3); an output shaft (4) of the motor (2) penetrates through the motor shell and extends into the soybean milk container (1); and the tail end of the output shaft (4) is connected with a grinding knife (5). The invention is characterized in that the soybean milk machine also comprises a turbolator (6) which is positioned around the grinding knife (5), wherein the turbolator (6) extends along the semi-enclosed curve integrally. Due to design of the turbolator and the relevant structure, soybeans can gather together at the center along with water flow. Compared with the prior art, the soybean milk machine has the advantages that the pulping effect is increased; and since the turbolator is convenient for processing and manufacturing, the soybean milk machine in the technical scheme has great superiority in the manufacturing cost.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Water-based conductive adhesive for lithium battery and preparation method thereof

InactiveCN111129499AGood dispersionImprove cycle performanceMaterial nanotechnologyCell electrodesAdhesiveInternal resistance

The invention provides a water-based conductive adhesive for a lithium battery, and the adhesive comprises 0.01-0.8 part of single-walled carbon nanotube, 1-10 parts of multi-walled carbon nanotube and 10-50 parts of water-based adhesive, wherein the outer diameter of the single-walled carbon nanotube is 0.4-40nm, and the thickness of the tube wall of the single-walled carbon nanotube is greater than or equal to 1[mu]m; the outer diameter of the multi-walled carbon nanotube is 2-20nm, and the thickness of the tube wall of the multi-walled carbon nanotube is 500nm-10cm; and the length-diameterratio of the single-walled carbon nanotube to the multi-walled carbon nanotube is greater than or equal to 1,000nm. The water-based conductive adhesive for the lithium battery, which is prepared by adopting a simple process of one-step synthesis and one-step dispersion, has the properties of electric conduction, adhesion and dispersion, is low in dosage, and can reduce the internal resistance of the battery, improve the adhesion force of a pole piece and improve the cycle performance of the battery; in addition, the preparation cost of the water-based conductive adhesive is low, water is usedas a solvent in the whole process, and the water-based conductive adhesive conforms to the trend of environmental protection.

Owner:YANYI NEW ENERGY TECH CO LTD

Novel process for preparing soybean milk

InactiveCN102177972AShorten pulping timeImprove water retentionMilk substitutesFood sciencePetalSoybean meal

The invention relates to a novel process for preparing soybean milk. The process comprises a raw material supply stage at which a soybean raw material is provided, and a user side pulverization and pulping stage, wherein the raw material supply stage comprises the steps of crushing whole soybeans into a plurality of soybean petals and curing the soybean petals; and the user side pulverization and pulping stage comprises the steps of mixing the soybean petals and water, pulverizing and pulping. By the novel preparation process, the soybean petals are cured in the raw material supply stage, so that a step of boiling the soybean milk is not required in the user side pulverization and pulping stage, namely when people want to prepare the soybean milk, the cured soybean petals provided in the raw material supply stage are directly mixed with water for pulverization and pulping, so that the pulping time of a user side is greatly shortened.

Owner:JOYOUNG CO LTD

Method for rapidly forming hole by using rotary drilling rig to penetrate through drift sand layer

InactiveCN102433875AIncrease friction load capacityReduce the amount of pouringBulkheads/pilesWater useWater source

The invention discloses a method for rapidly forming a hole by using a rotary drilling rig to penetrate through a drift sand layer. The method comprises the following steps of: (1) preparation of chemical polymer slurry; (2) shield-tube burying; (3) drilling for hole formation; (4) reinforcement cage lifting and lowering; (5) secondary hole cleaning; and (6) underwater concrete pouring. In the chemical polymer slurry preparing process, water used as a raw material is clean tap water; the pH value of the water source is tested by using pH test paper before the water is used; a small amount of dietary alkali is added according to a testing result; and the pH value of a slurry system is adjusted to be 9-10; 2-3% of chemical polymer is added to water with pH value of 9-10 to prepare an aqueous solution with mass concentration of 0.1-0.5%. The relative density of the slurry is 1.15-1.18, the viscosity of the slurry is 17-20 and the sand content of the slurry is not more than 3%; and before concrete casting, the relative density of the slurry is 1.03-1.1, the viscosity of the slurry is 18-19 and the sand content of the slurry is not more than 0.5%. The polymer slurry boring mud has the advantages of rapidness for precipitation and less sediment.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

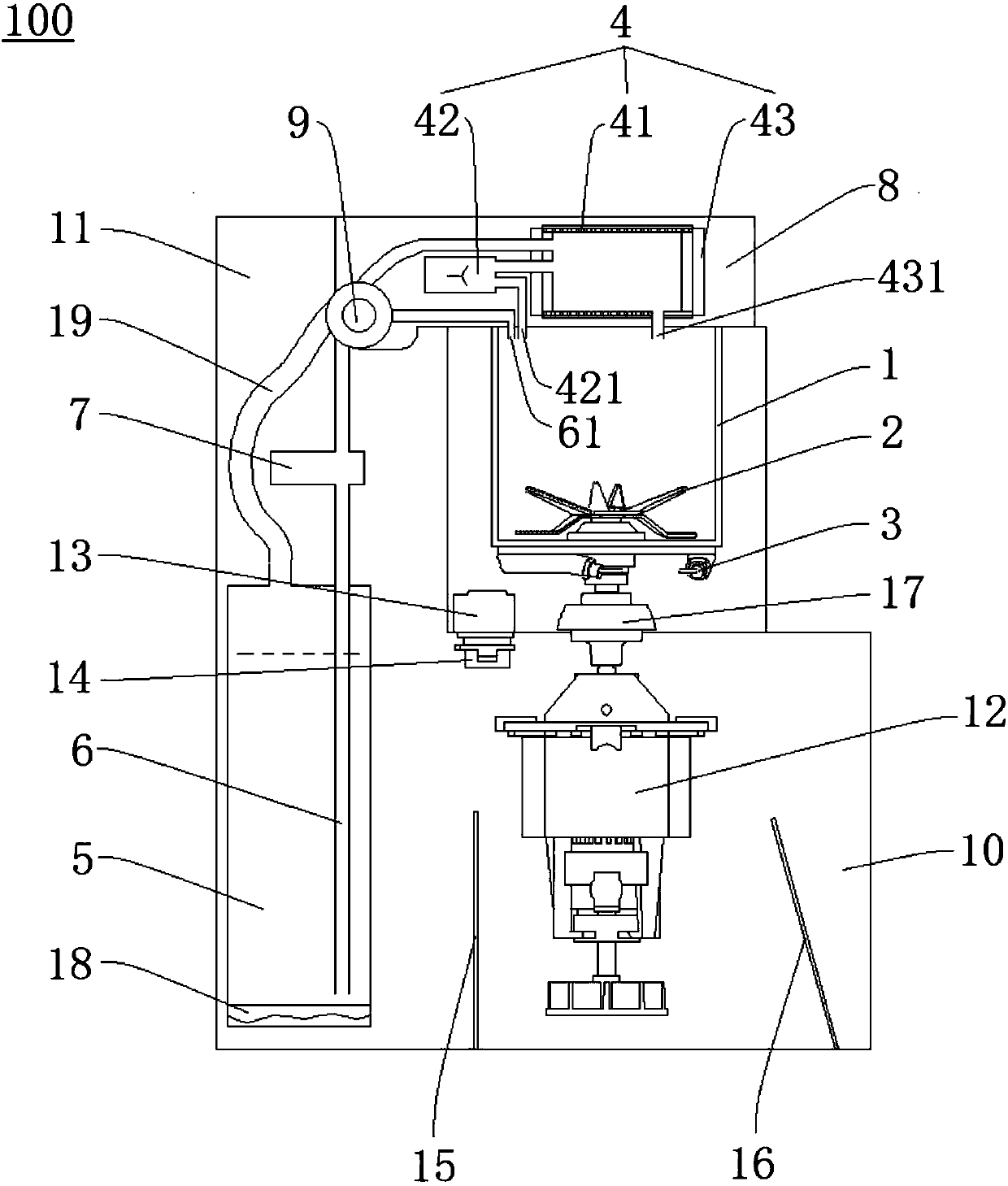

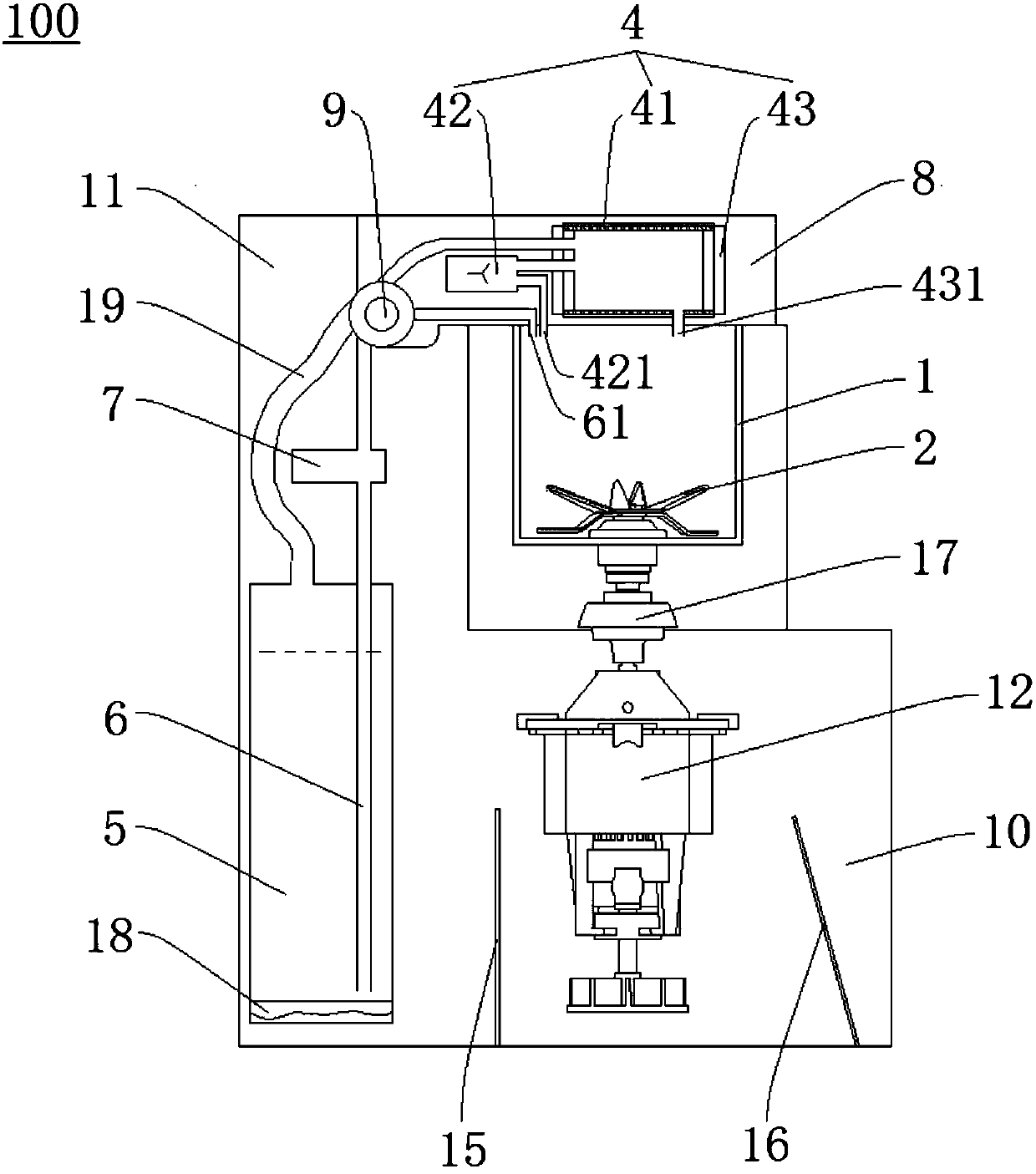

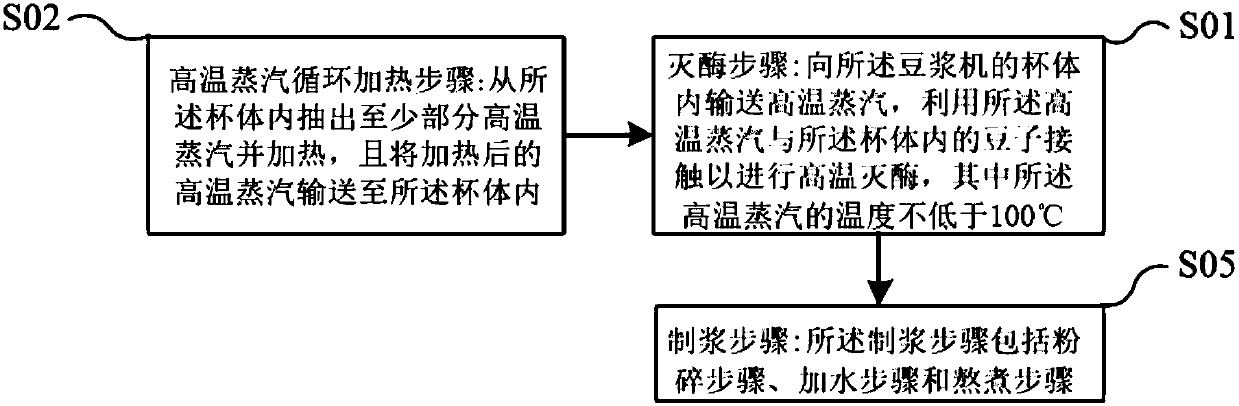

Soybean milk machine and milk making method of soybean milk machine

The invention discloses a soybean milk machine and a milk making method of the soybean milk machine. The soybean milk machine includes a cup body, a crushing device, a high-temperature steam generating device and a high-temperature steam cyclic heating device; the crushing device is arranged in the cup body and used for crushing beans in the cup body; the high-temperature steam generating device is used for generating high-temperature steam, the high-temperature steam can be in contact with the beans before the beans are crushed by the crushing device, the beans are subjected to high-temperature enzyme deactivation accordingly, and the temperature of the high-temperature steam is not lower than 100 DEG C; the high-temperature steam cyclic heating device conducts cyclic heating on the high-temperature steam in the cup body. According to the soybean milk machine, through the arrangement of the high-temperature steam generating device, the high-temperature steam can be generated and conveyed into the cup body, the beans can be subjected to high-temperature steam enzyme deactivation before being crushed, and the milk making time is conveniently saved. Meanwhile, through the arrangementof the high-temperature steam cyclic heating device, the high-temperature steam in the cup body can be subjected to cyclic heating, so that the steam in the cup body is continuously kept at high temperature, and the improvement of the high-temperature enzyme deactivation effect is facilitated.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

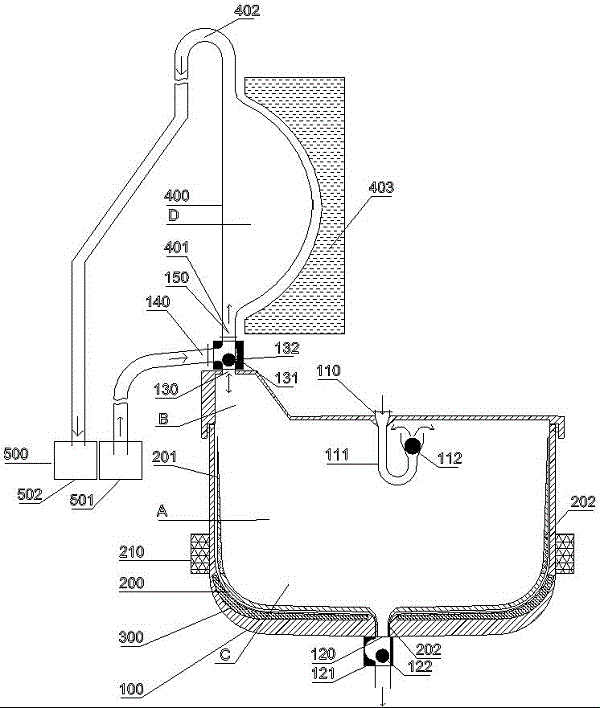

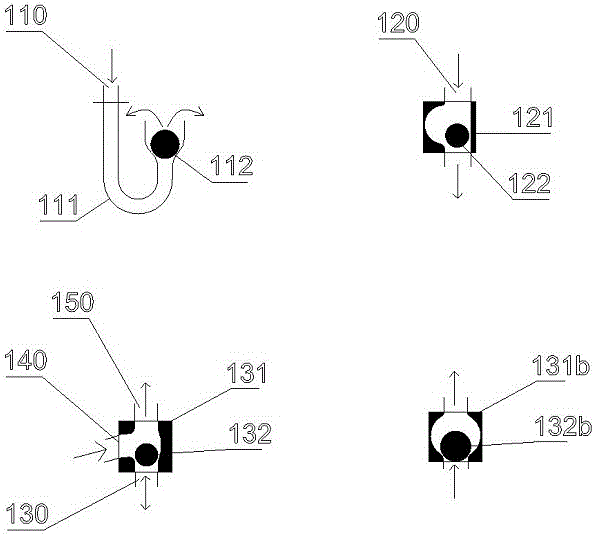

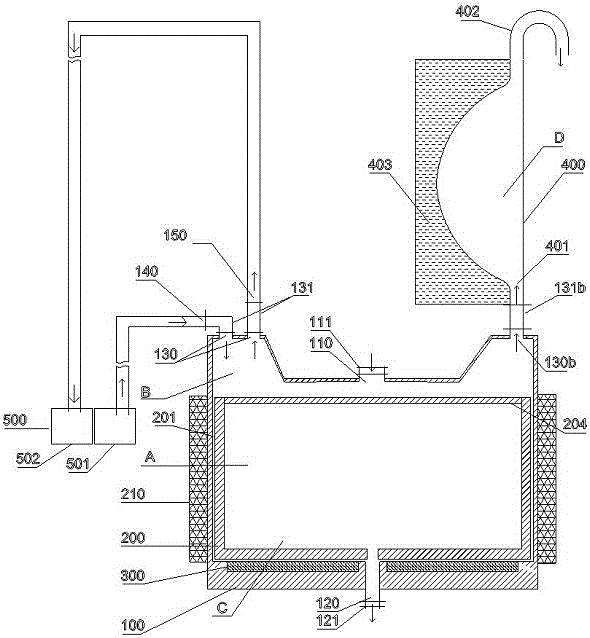

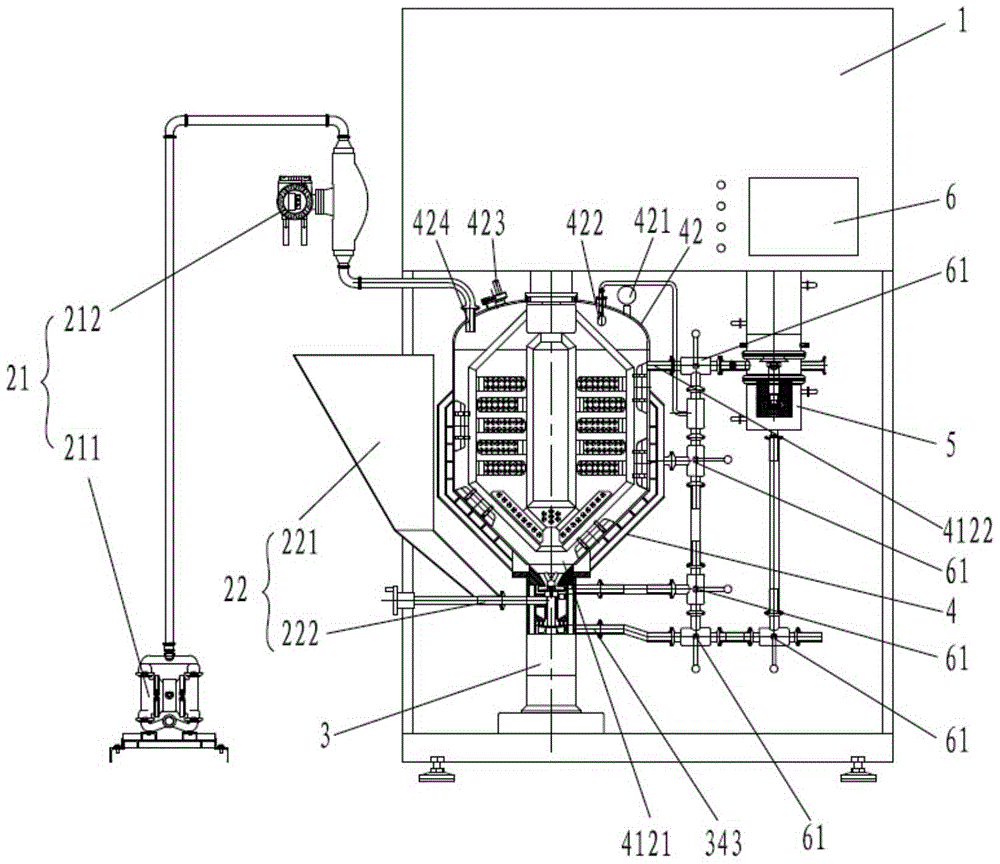

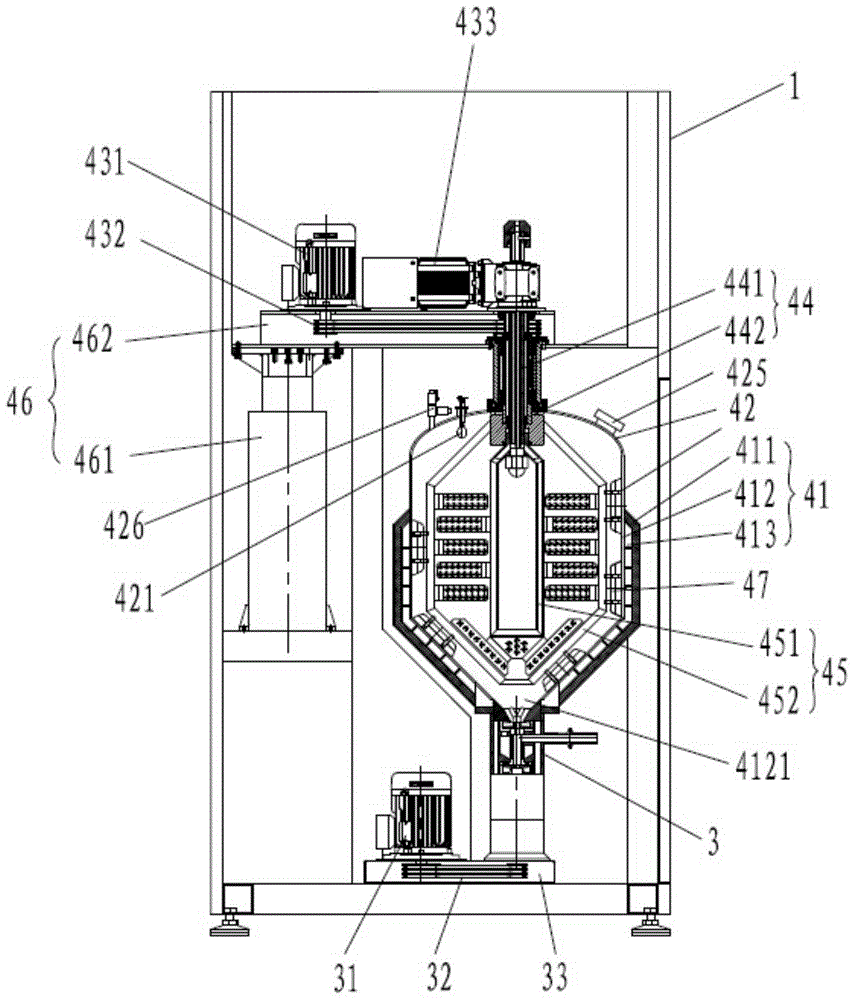

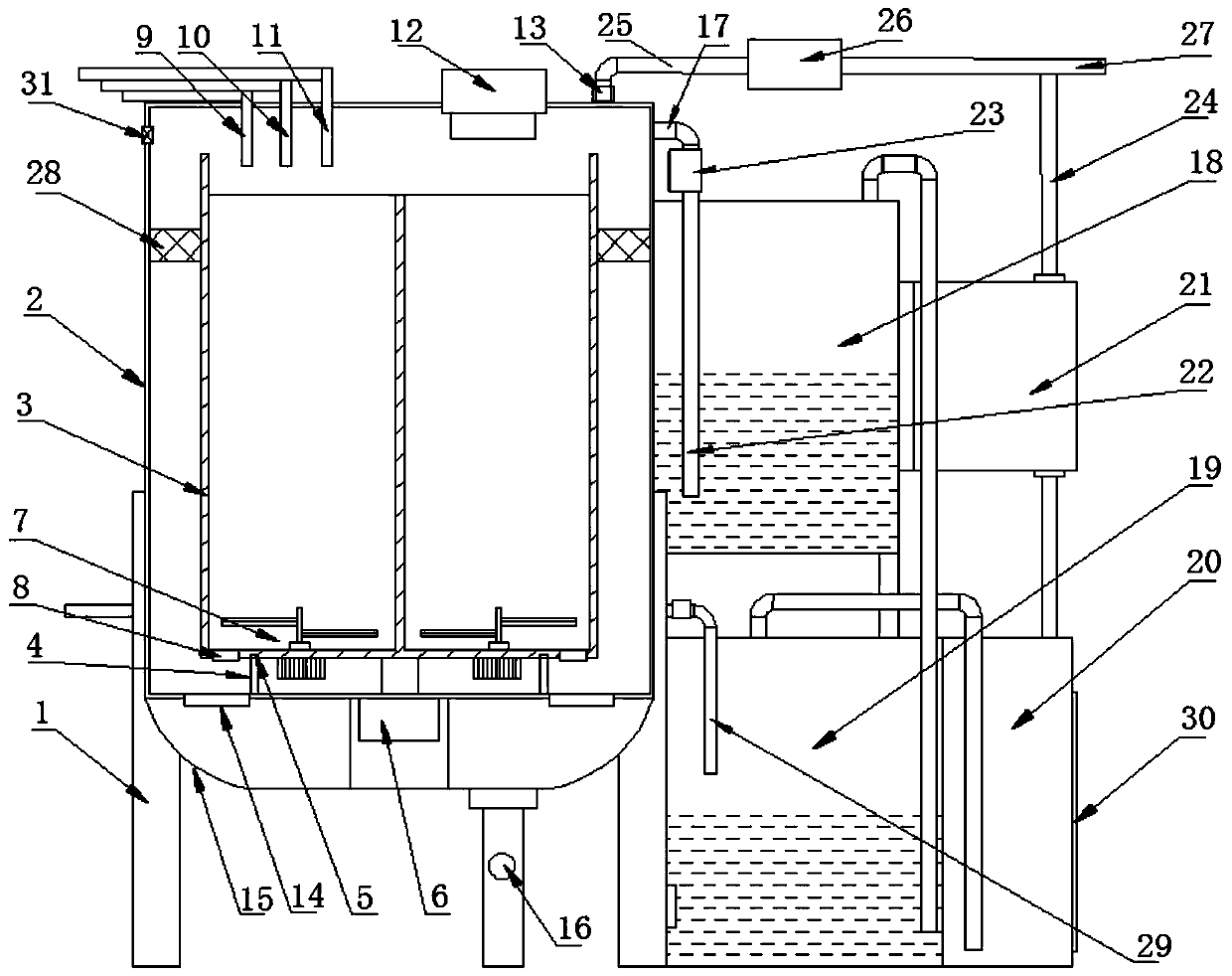

Stirring pulp cooking and air-controlled pulp inlet and outlet device and stirring pulp cooking and air-controlled pulp inlet and outlet method

ActiveCN106260006AEvenly heatedAvoid cakingPaper recyclingFood shapingPulp and paper industryControl valves

The invention relates to a stirring pulp cooking and air-controlled pulp inlet and outlet device for pulp food, and the stirring pulp cooking and air-controlled pulp inlet and outlet device comprises a pulp cooking barrel, a stirring device, a heating device, an overflowed pulp return device, and an air pressure control device, wherein the pulp cooking barrel is provided with a pulp inlet, a pulp outlet, and an air port, the stirring device comprises a stirrer and a stirring driver, the air pressure control device comprises a steam generator and a sucking device, a closed cavity is formed inside the pulp cooking barrel, the pulp inlet of the pulp cooking barrel is provided with a control valve which can be automatically opened or closed according to the pressure of the pulp cooking barrel, the air port of the pulp cooking barrel is provided with a control valve connected with the air pressure control device, and is also connected with overflowed pulp return device, the inner wall of the overflowed pulp return device is smooth and is provided with a return cavity with unidirectional slope, the low point of the return cavity is provided with a first connection port connected with the pulp cooking barrel, the overflowed pulp return device is also provided with a second connection port, one connection port of the overflowed pulp return device is provided with a control valve which can be automatically opened or closed according to the pressure of the pulp cooking barrel, the stirrer is arranged in the pulp cooking barrel, the stirring driver is arranged outside the closed cavity, and a coupling action force is formed between the stirrer and the stirring driver. According to the stirring pulp cooking and air-controlled pulp inlet and outlet device, pollution-free, rapid and safe heat processing treatment on the pulp food can be realized by closed pulp cooking, isolated stirring, overflowed pulp return and air-controlled pulp inlet and outlet.

Owner:上海洛瓷动力科技有限公司

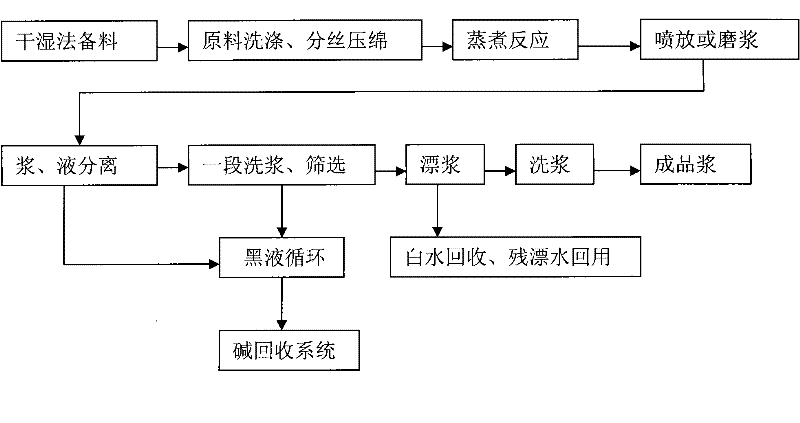

Pulping agent and method for applying same to production

ActiveCN102454133AChange the traditional pulping processQuality improvementWashing/displacing pulp-treating liquorsPulp bleachingFiberChlorine dioxide

The invention relates to an energy-saving and emission-reducing pulping agent and a method for applying the same to production. The pulping agent used in a pulping method consists of sodium carbonate, NaOH, a cooking aid, chlorine dioxide and a silicate stabilizer. The pulping method for applying the pulping agent to a production flow comprises the following steps of: 1, preparing materials with a dry-wet process, washing raw materials and pressing cotton; 2, undergoing a cooking reaction, spraying or grinding into a thick liquid; 3, separating pulp and recycling a black liquor; 4, recovering an alkali; and 5, bleaching and washing the pulp. Due to the adoption of the pulping method, energy saving and emission reduction are realized for the papermaking industry by controlling pollution from a source, and the technical problem of pulping of agricultural straw and grass fibers is solved; the pulping agent is nontoxic, harmless and non-corrosive, and can be cooked at the normal temperature and under the normal pressure; the generating capacity of the black liquor per ton is reduced by 80 percent compared with that of the black liquor per ton by using the conventional pulping method; crude pulp is easy to clean and bleach, bleaching water can be recycled, and the water consumption and drainage per ton of pulp are reduced by 70 percent compared with those of the conventional pulp; the steam consumption is reduced by one third; foul odor generated by total reduced sulfur is eliminated; the investment can be saved by one third compared with that made by a similar-sized pulping plant; and industrial production can be realized.

Owner:庞少静

Soybean milk making machine

ActiveCN105193256AImprove foam breaking efficiencyImprove foam breaking abilityBeverage vesselsBoiling processEngineering

The invention discloses a soybean milk making machine which comprises a barrel, a crushing device, a crushing motor, a boiling heating component and a foam breaking heating component. Annular foam breaking ribs protruding out of the inner wall face of the side wall of the barrel are constructed on the side wall of the barrel. The crushing device is arranged inside the barrel. The crushing motor is connected with the crushing device. The boiling heating component is at least used for heating and boiling raw soybean milk. The foam breaking heating component is not lower than the highest liquid level inside the barrel in the heating and boiling process so as to heat and break foams generated in the heating and boiling process. The foam breaking ribs are not lower than the highest liquid level. Due to the fact that the independent foam breaking heating component is arranged on the soybean milk making machine, and foams are broken in a heating mode through the foam breaking heating component, the foam breaking efficiency is improved, and the foam breaking effect is better due to the facts that the foam breaking ribs are arranged and can effectively stop and extrude the foams and the foam breaking heating component is arranged in a matched mode.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

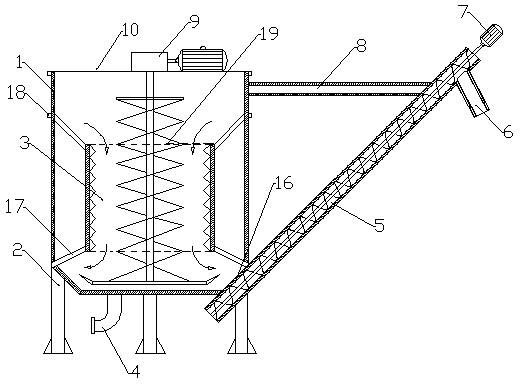

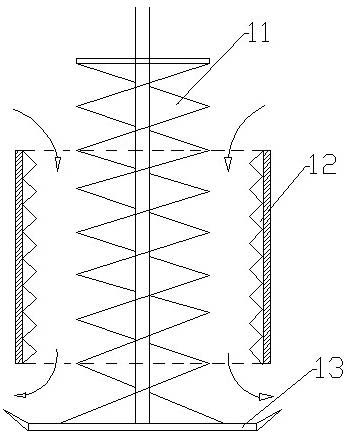

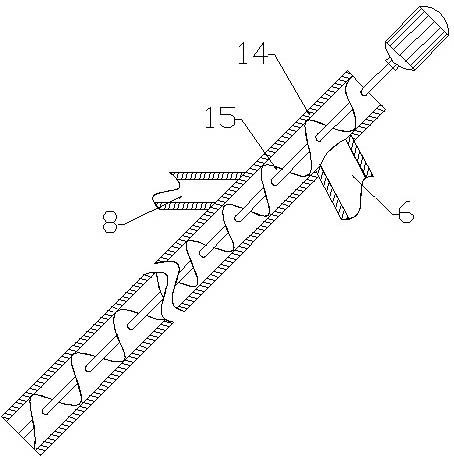

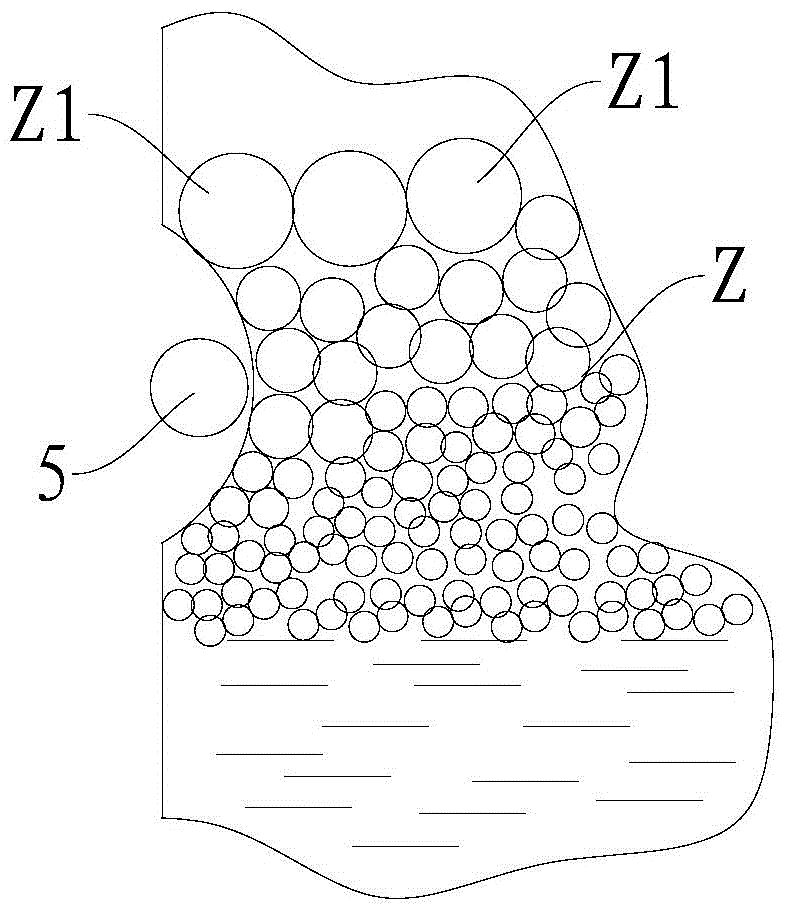

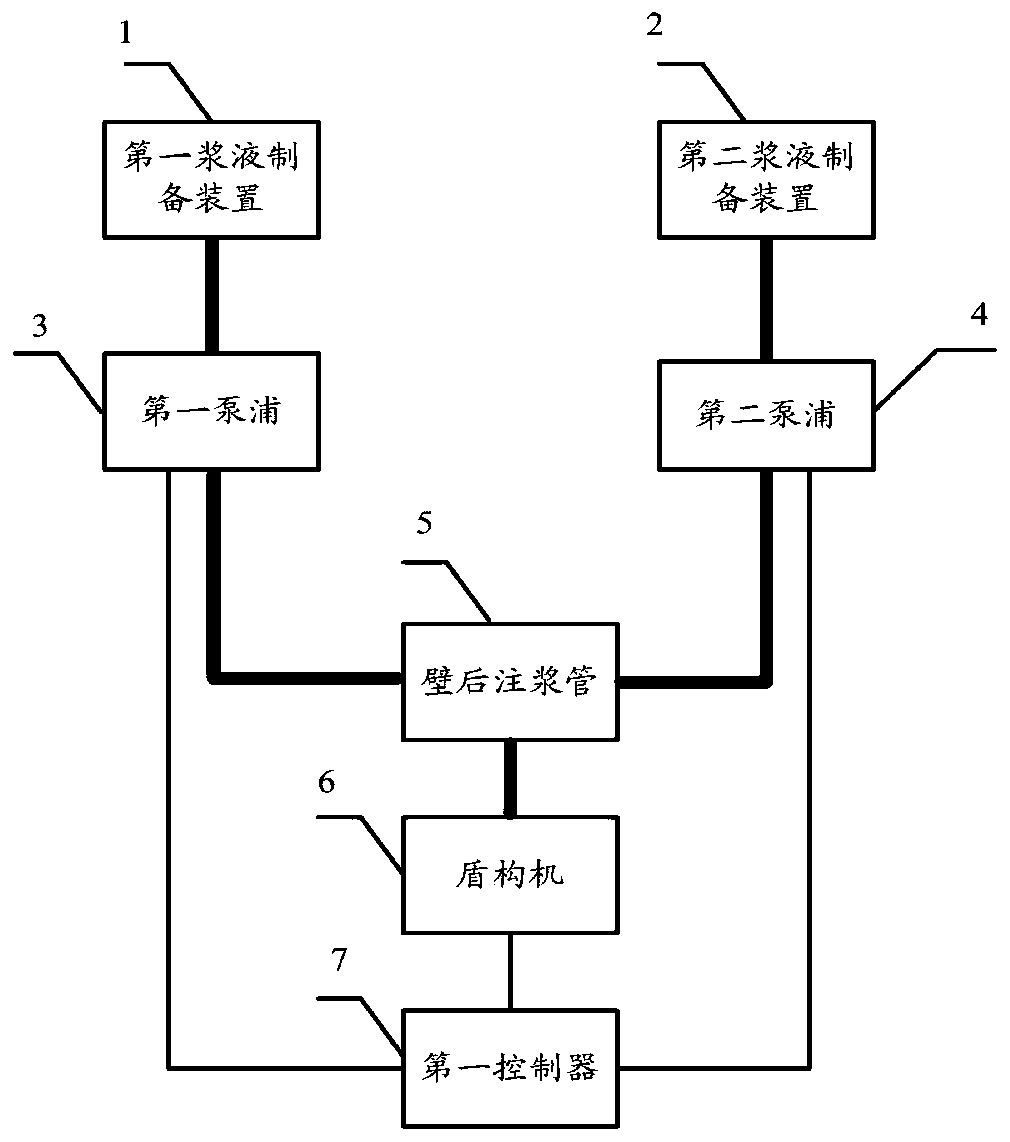

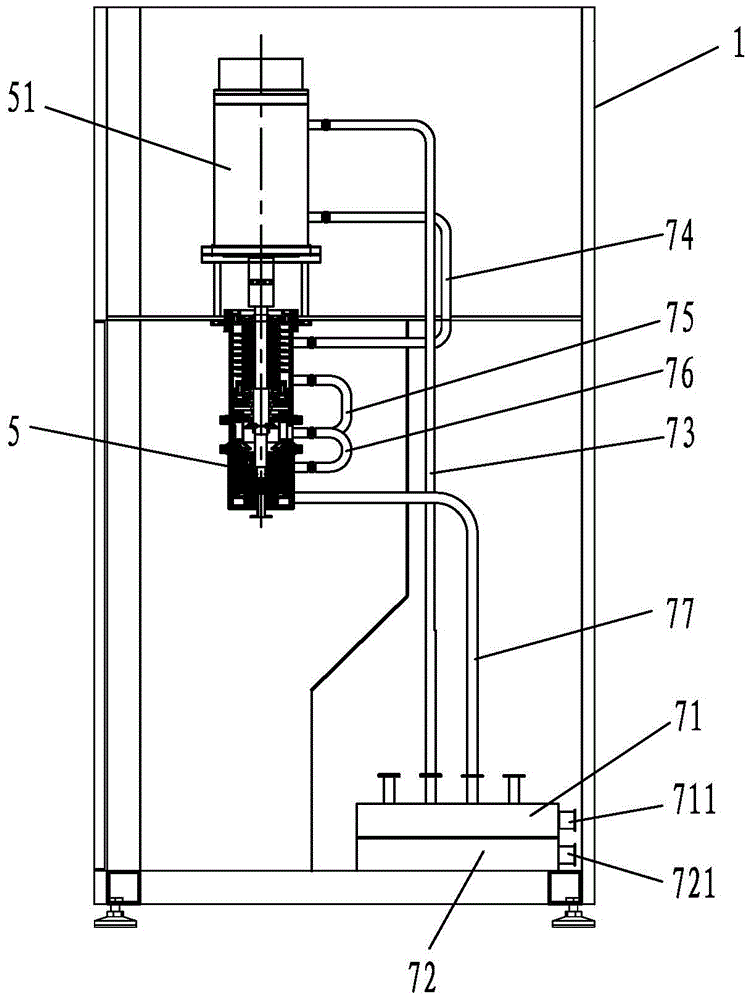

Double-liquid-wall post-grouting device

PendingCN110552721AShorten mixing timeShorten pulping timeUnderground chambersTunnel liningSlurryEngineering

The invention discloses a double-liquid-wall post-grouting device which includes a first grout preparation device, a second grout preparation device, a first pump, a second pump, a backfill grouting pipe and a first controller; the first grout preparation device is used for preparing first grout and is in communication with the backfill grouting pipe through the first pump; the second grout preparation device is used for preparing second grout and is in communication with the backfill grouting pipe through the second pump; the backfill grouting pipe is used for mixing the first grout and the second grout; and the first pump, the second pump and a shield tunneling machine are connected to the first controller, and the first controller is used for controlling the working rate of the first pump, the working rate of the second pump and the advancing rate of the shield tunneling machine. The double-liquid-wall post-grouting device provides the grout fluidity and the grouting efficiency.

Owner:YANGTIE MACHINERY HANGZHOU CO LTD

Soybean milk machine and milk making method of soybean milk machine

The invention discloses a soybean milk machine and a milk making method of the soybean milk machine. The soybean milk machine includes a cup body, a crushing device and a high-temperature steam generating device; the crushing device is arranged in the cup body and used for crushing beans in the cup body; the high-temperature steam generating device includes a high-temperature steam generating part, the high-temperature steam generating part is used for generating high-temperature steam and conveying the high-temperature steam into the cup body, the high-temperature steam is in contact with thebeans before the beans are crushed by the crushing device, and the beans are subjected to high-temperature enzyme deactivation by utilizing the high-temperature steam accordingly, wherein the temperature of the high-temperature steam is not lower than 100 DEG C. According to the soybean milk machine, through the arrangement of the high-temperature steam generating part, the high-temperature steamcan be generated and conveyed into the cup body, a high-temperature steam environment is formed in the cup body accordingly, thus, the beans can be subjected to high-temperature steam enzyme deactivation before being crushed, and therefore the milk making time is significantly saved.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD

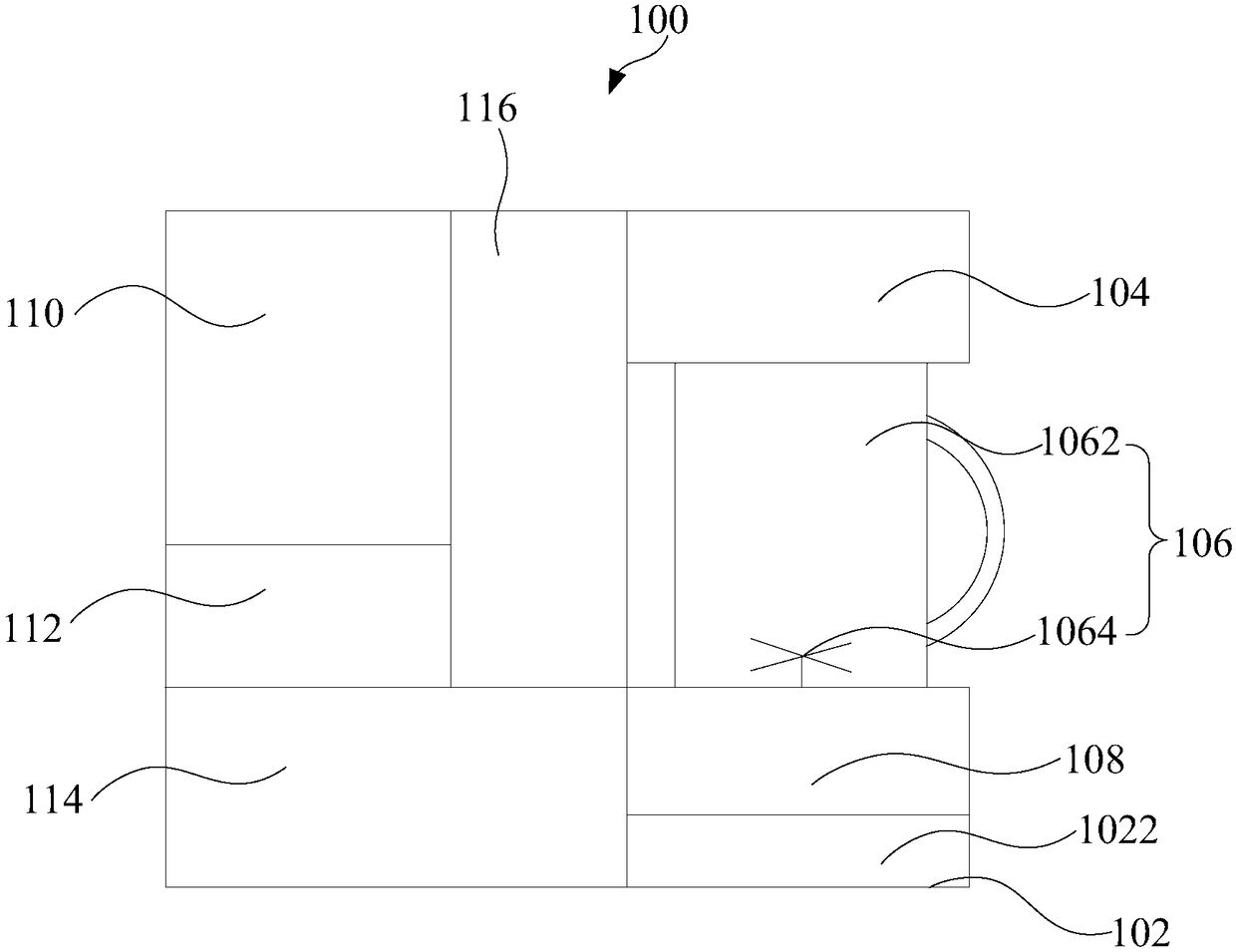

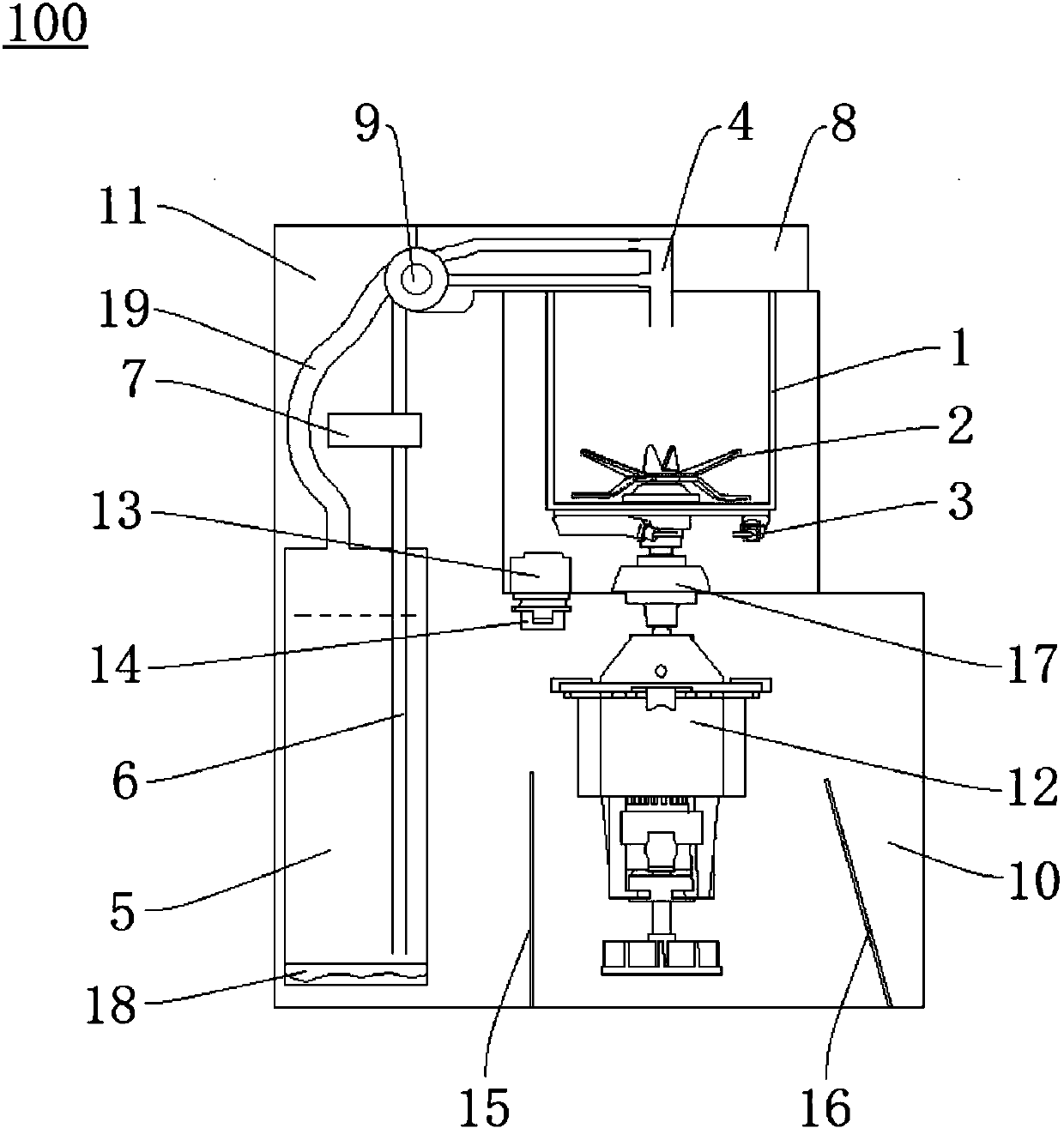

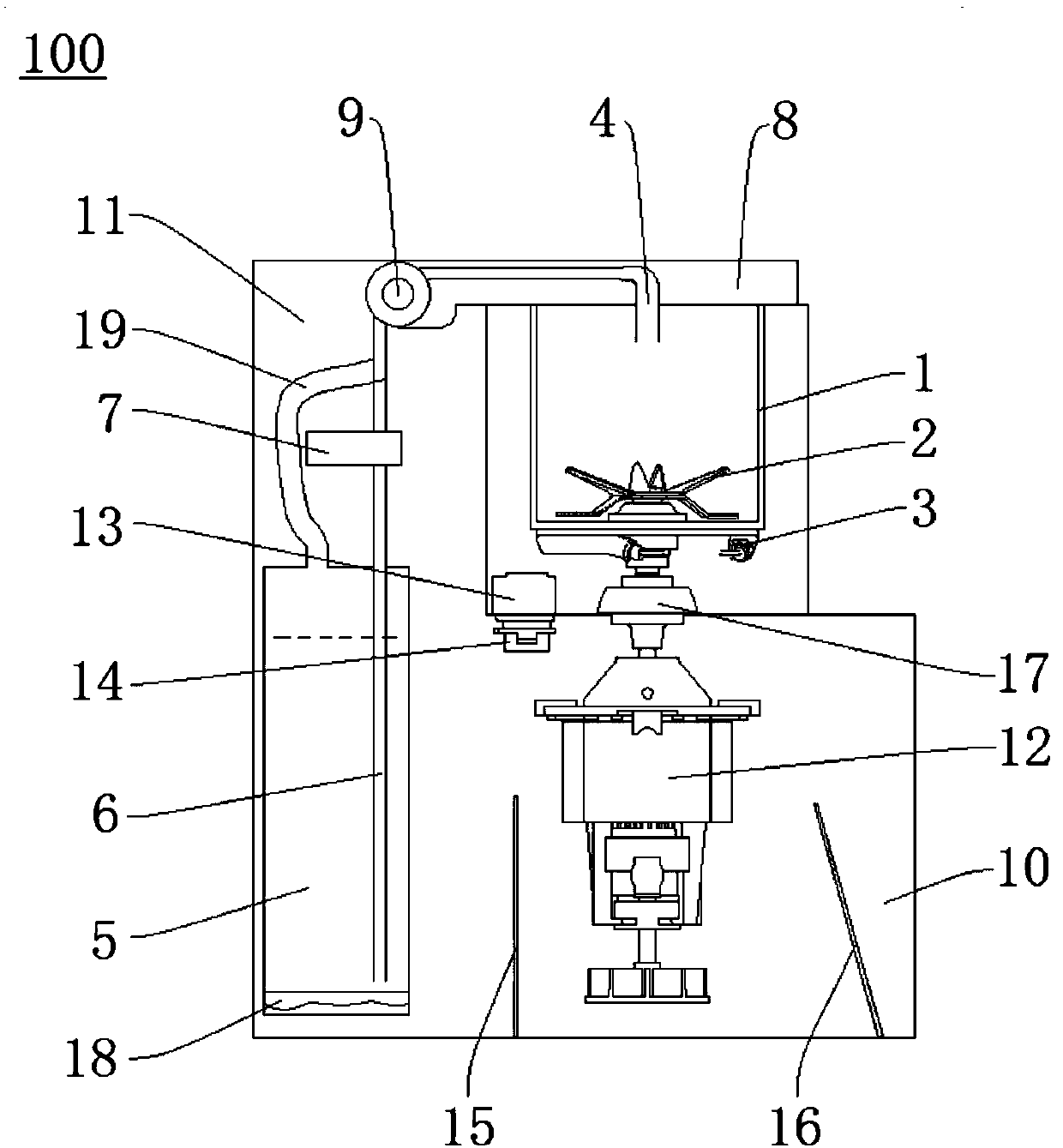

Integrated pulping device

ActiveCN104096506BEnsure consistencyHigh speed mixingTransportation and packagingMixing methodsElectrical controlControl cell

Owner:SHENZHEN SHANGSHUI INTELLIGENT CO LTD

Environmentally friendly pulping process

InactiveCN105463894AShorten pulping timeLess investmentPulping with inorganic basesNon-woody plant/crop pulpThermal insulationPulp and paper industry

The present invention belongs to the technical field of pulping process improvement, and particularly relates to an environmentally friendly pulping process.. The environmentally friendly pulping process is characterized by comprising the following steps: (a) cutting off and dedusting a pulping raw material; (2) adding water and dosing, and blending; (3) conducting a first defibrination; (4) conducting a first thermal insulation bleaching; (5) squeezing pulp and washing; (6) dosing for the second time; (7) conducting a secondary thermal insulation bleaching; (8) squeezing pulp; (9) washing the pulp; and (10) recycling non-fibrous materials for production of organic fertilizers. The process has the advantages of pulping time saving, no discharge of the pulping water, no gas or odor, high efficiency, energy saving, low investment in equipment, high yield of white pulp, high whiteness, low cost and no brightness reversion of paper pulp; and the prepared pulp is superior to the whole chemical pulp.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Soybean milk making machine

The invention discloses a soybean milk making machine which comprises a barrel, a crushing device, a crushing motor, a boiling heating component, a foam breaking heating component and an anti-overflowing structure. Annular foam breaking ribs protruding out of the inner wall face of the side wall of the barrel are constructed on the side wall of the barrel. The crushing device is arranged inside the barrel. The crushing motor is connected with the crushing device. The boiling heating component is at least used for heating and boiling raw soybean milk. The foam breaking heating component is not lower than the highest liquid level inside the barrel in the heating and boiling process. The foam breaking ribs are not lower than the highest liquid level. The anti-overflowing structure is arranged inside the barrel and is not lower than the highest liquid level. Due to the fact that the independent foam breaking heating component is arranged on the soybean milk making machine, and foams are broken in a heating mode through the foam breaking heating component, the foam breaking efficiency is improved, and the foam breaking effect is better due to the facts that the foam breaking ribs and the anti-overflowing structure are arranged and the foam breaking heating component is arranged in a matched mode.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

Method for preparing high-hardness pulp by using grass type plants as raw materials

ActiveCN101451314AHigh yieldReduce lossesDigestersNon-macromolecular organic additionKappa numberState of art

The invention discloses a method for preparing high-hardness pulp by taking a grass plant as a raw material. The method comprises the steps of material preparation and stewing, the prepared raw material is conveyed into a digester to be stewed into the high-hardness pulp of which the hardness has a potassium permanganate value of between 16 and 28 and is equivalent to a Kappa number of between 24 and 50, a stewing method comprises that the grass plant raw material is prepared and then enters an impregnation screw to be conveyed into the digester, and a stewing reagent is added into the digester; steam is aerated to heat, and the thermal insulation is performed for the needed time when the needed pressure is achieved by heating. Compared with the prior art, the stewing and thermal insulation time of the method is greatly shortened, which greatly reduces energy consumption for enterprises and improves production efficiency; and the prepared high-hardness pulp can be taken as a raw material for preparing bleached chemical pulp.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Recovery device for valuable metals in waste foamed nickel

ActiveCN110699549AImprove leaching rateReduce productionMeasurement devicesProcess efficiency improvementSodium chlorateMonitoring system

The invention provides a recovery device for valuable metals in waste foamed nickel, and is suitable for the field of heavy metal recovery. The recovery device comprises a material barrel, a pure water inlet, a sodium chlorate solution inlet, a dilute sulfuric acid inlet, a feeding port and a safety valve are formed in the top of the material barrel, a material stirring barrel is arranged inside the material barrel, and a collecting box is arranged below the material barrel. According to the recovery device, the material stirring barrel is partitioned, continuous oxidation acid leaching operation can be carried out, the reaction time is greatly shortened, the reaction efficiency is improved, the leaching rate of metal is obviously improved, the nickel leaching rate can reach 99% or above,the treatment effect is obvious, in addition, an online monitoring system is introduced for flammable and explosive hydrogen gas, it is guaranteed that the reaction can be conducted safely and continuously, the reaction safety coefficient is improved, and the possibility of accident occurring is reduced.

Owner:JINGMEN GEM NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com