Water-based conductive adhesive for lithium battery and preparation method thereof

A conductive adhesive and water-based adhesive technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of inability to fully utilize the conductive properties of the conductive agent on the positive or negative main material, and damage the capacity of the positive or negative main material Make full use of performance, uneven dispersion of conductive agent and binder, etc., to achieve the effect of being conducive to large-scale production, adapting to environmental protection trends, and saving pulping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

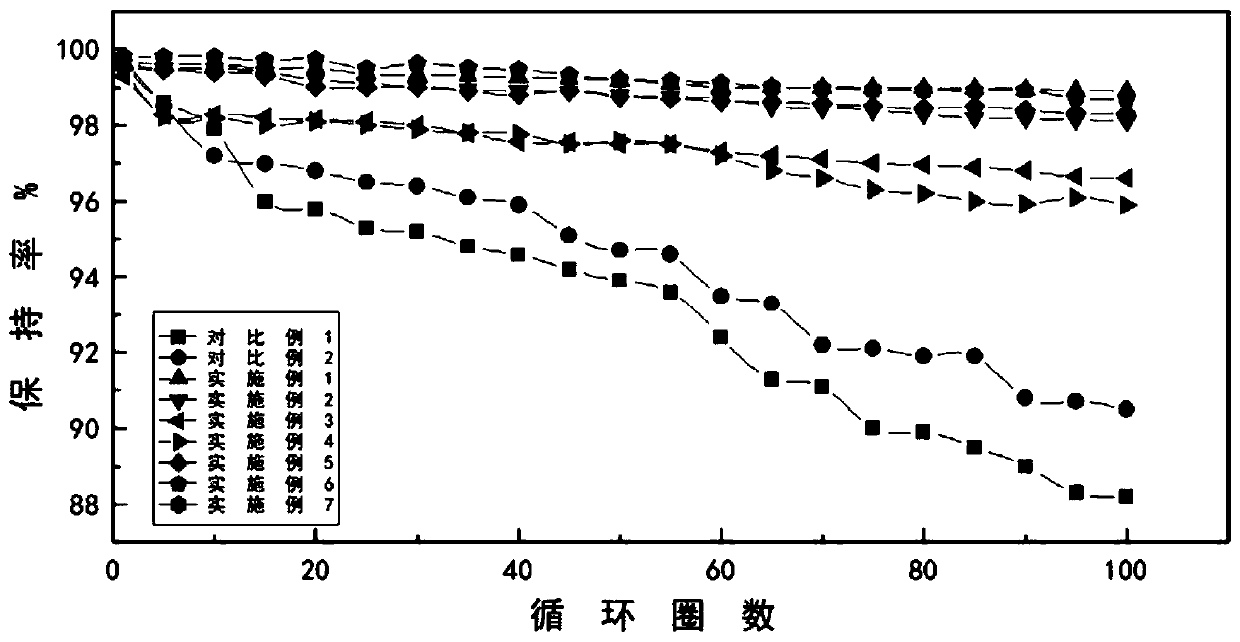

Embodiment 1

[0027] The invention provides a water-based conductive binder for lithium ions, including carbon nanotubes and a water-based binder, specifically, including 0.01-0.8 parts by weight of single-walled carbon nanotubes, 1-10 parts by weight of multi-walled carbon nanotubes and 10 to 50 parts by weight of water-based binder; the water-based binder includes PAA polyacrylic acid, PAN polyacrylonitrile, SBR styrene-butadiene rubber, CMC methylcellulose and other lithium-ion batteries with good dispersibility Water-based binder for positive and negative electrodes. In this specific embodiment, the water-based binder is PAA polyacrylic acid.

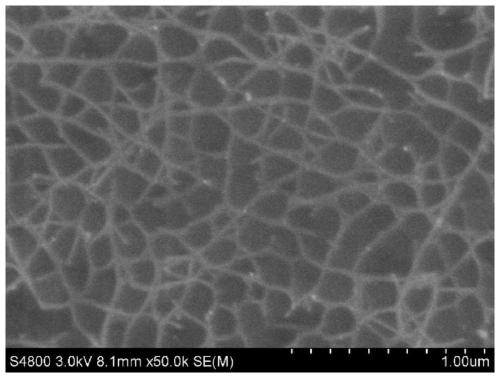

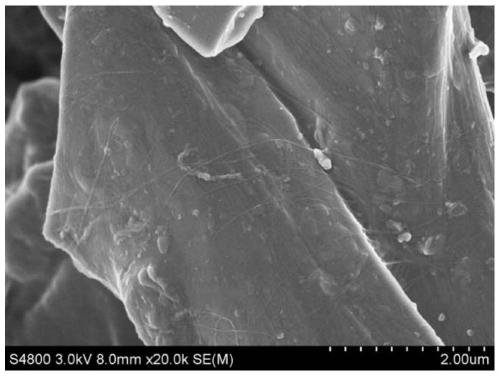

[0028] The outer diameter of the single-walled carbon nanotubes is 0.4 to 40 nm, and the wall thickness is Length ≥ 1 μm. The outer diameter of the multi-walled carbon nanotubes is 2 to 20 nm, and the thickness of the tube wall is The length is between 500nm and 10cm. The aspect ratio (ratio of length to diameter) of the single-walled carbo...

Embodiment 2

[0033] The difference between this embodiment 2 and the embodiment 1 is that the lithium ion water-based conductive binder of the present invention also includes a dispersant whose mass is 0.2-100 times the total amount of carbon nanotubes.

[0034] The dispersant is a nonionic polymer compound or ionic cellulose gum or ionic polyacrylic acid; the nonionic polymer compound adopts polyvinylpyrrolidone (PVP for short), and the ionic cellulose gum adopts carboxymethyl Base cellulose sodium (CMC-Na), the ionic polyacrylic acid adopts PAA mixture, and the PAA mixture adopts commercially available products, such as the LA133 product of Chengdu Yindile Power Technology Co., Ltd.

[0035] The present invention also provides a kind of preparation method of lithium ion water-based conductive binder, comprising the following steps:

[0036] Step 1. Take 0.4 parts by mass of single-walled carbon nanotubes and 5 parts of multi-walled carbon nanotubes, add them to a PVP dispersant whose mass ...

Embodiment 3

[0041] The difference between this specific embodiment 3 and embodiment 1 is: the lithium ion water-based conductive binder of the present invention also includes 0.5 to 10 parts by mass of auxiliary conductive materials, and the auxiliary conductive materials are graphene and vapor-phase grown carbon fibers. (VGCF), high density conductive carbon black (SP), at least one of conductive carbon black. In this specific embodiment, the auxiliary conductive material is graphene.

[0042] The present invention also provides a kind of preparation method of lithium ion water-based conductive binder, comprising the following steps:

[0043] Step 1. Take 0.01 parts of single-walled carbon nanotubes, 1 part of multi-walled carbon nanotubes, and 10 parts of graphene in parts by mass, and add them to 50 parts of water-based binder. Inject nitrogen to form a nitrogen atmosphere. The solution is impacted on one side by a low-pressure homogenizer at a low pressure of 200 bar to 1000 bar, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com