Soya-bean milk machine capable of quickly making milk

A soymilk machine and pulping technology, applied in dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of reducing the number of collisions between materials and pulverizing tools, long cooking time for soymilk, and prolonging pulping time. The effect of cooking time, shortening pulping time, and increasing bean content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

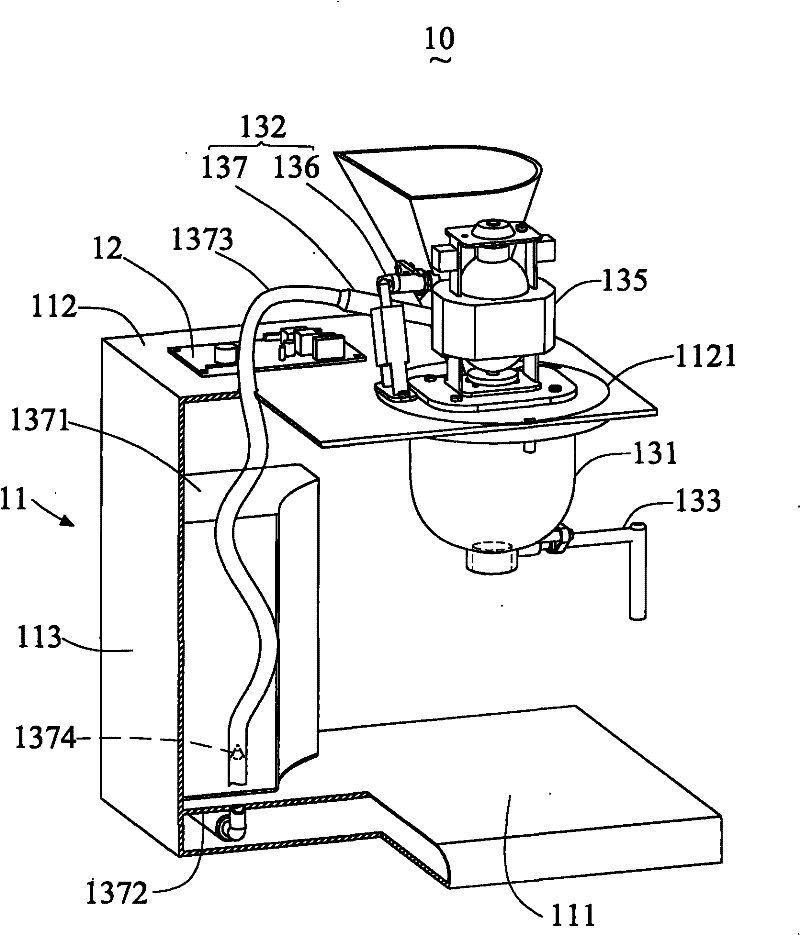

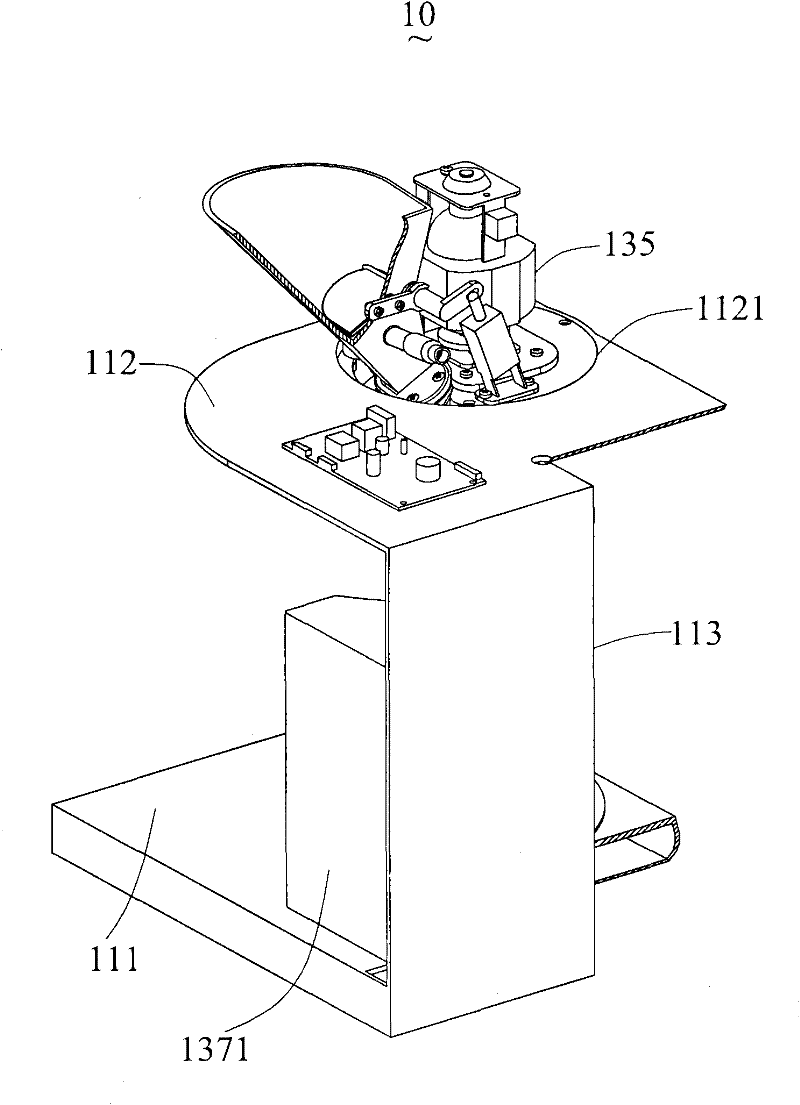

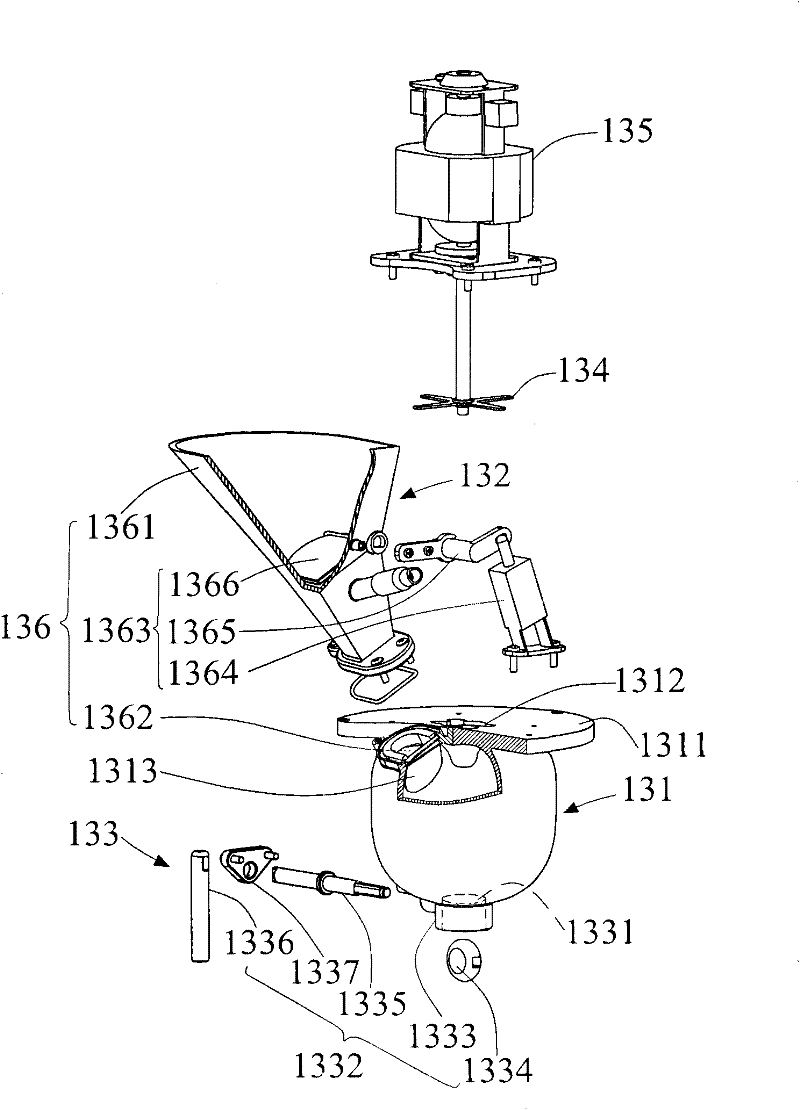

[0044] see Figure 1 to Figure 3 Shown is the first preferred embodiment of the rapid pulping soybean milk machine of the present invention, the rapid pulping soybean milk machine 10 includes a machine base 11, a control unit 12, a crushing and cooking device 131, a feeding mechanism 132, and a pulp discharging mechanism 133 , the crushing cutter 134, the motor 135 and the preheating device that drive the crushing cutter 134 to rotate. The feeding mechanism 132 and the pulp discharging mechanism 133 communicate with the pulverizing and ripening device 131 respectively. The crushing cutter 134 is located in the crushing and ripening device 131 . The crushing cutter 134 stirs the material and water to circulate in the crushing and ripening device 131 for crushing and pulping. The preheating device heats water and / or materials before crushing and curing. The motor 135 or the crushing and ripening device 131 are installed on the machine base 11 .

[0045] The base 11 is roughl...

Embodiment approach 2

[0067] see Figure 4 Shown is the second preferred embodiment of the rapid pulping soybean milk machine of the present invention, the difference between the rapid pulping soybean milk machine 90 and the rapid pulping soybean milk machine 10 is: the rapid pulping soybean milk machine 90 also Including a pulp cooking container 14 and a heating unit 15, the pulp cooking container 14 is detachably placed on the base 111 of the machine base 11, and is located downstream of the crushing and cooking device 131, and is used to receive soybean milk flowing out from the crushing and cooking device 131, The heating unit 15 is arranged on the pulp cooking container 14 and is electrically connected with the control unit 12 .

[0068] The soymilk machine 90 for rapid pulping can further mature the soymilk matured in the pulverizing and ripening device 131 by adding the boiling vessel 14 and the heating unit 15 .

[0069] It can be understood that the heating unit can also be an electromagn...

Embodiment approach 3

[0072] see Figure 5 Shown is the third preferred embodiment of the crushing and cooking device of the instant pulping soybean milk machine of the present invention, the difference between the crushing and cooking device 231 and the crushing and cooking device 131 is that the crushing and cooking device 231 includes a first housing 2311 and a second casing 2312. The first housing 2311 and the second housing 2312 are fastened together by a plurality of locking structures 2313 , thereby enclosing the crushing and ripening device 231 . In this embodiment, the locking structure 2313 is two ribs 2314 and several screws, one rib 2314 is fixedly connected with the first housing 2311, and the other rib 2314 is fixedly connected with the second housing 2312. The first housing 2311 and the second housing 2312 are locked together with the second ribs 2314 by screws. The two ribs 2314 can also be sealed by a sealing ring 2315 . By adopting the split-type crushing and maturing device 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com