Soybean milk making machine, and method for making soybean milk by using it

A soymilk machine and soymilk technology, which are applied in beverage preparation devices, applications, dairy products, etc., can solve problems such as increased cost, more foam, and reduced pulping efficiency, improve the phenomenon of bottom paste and overflow, and save heating. time, and the effect of increasing the concentration of soy milk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

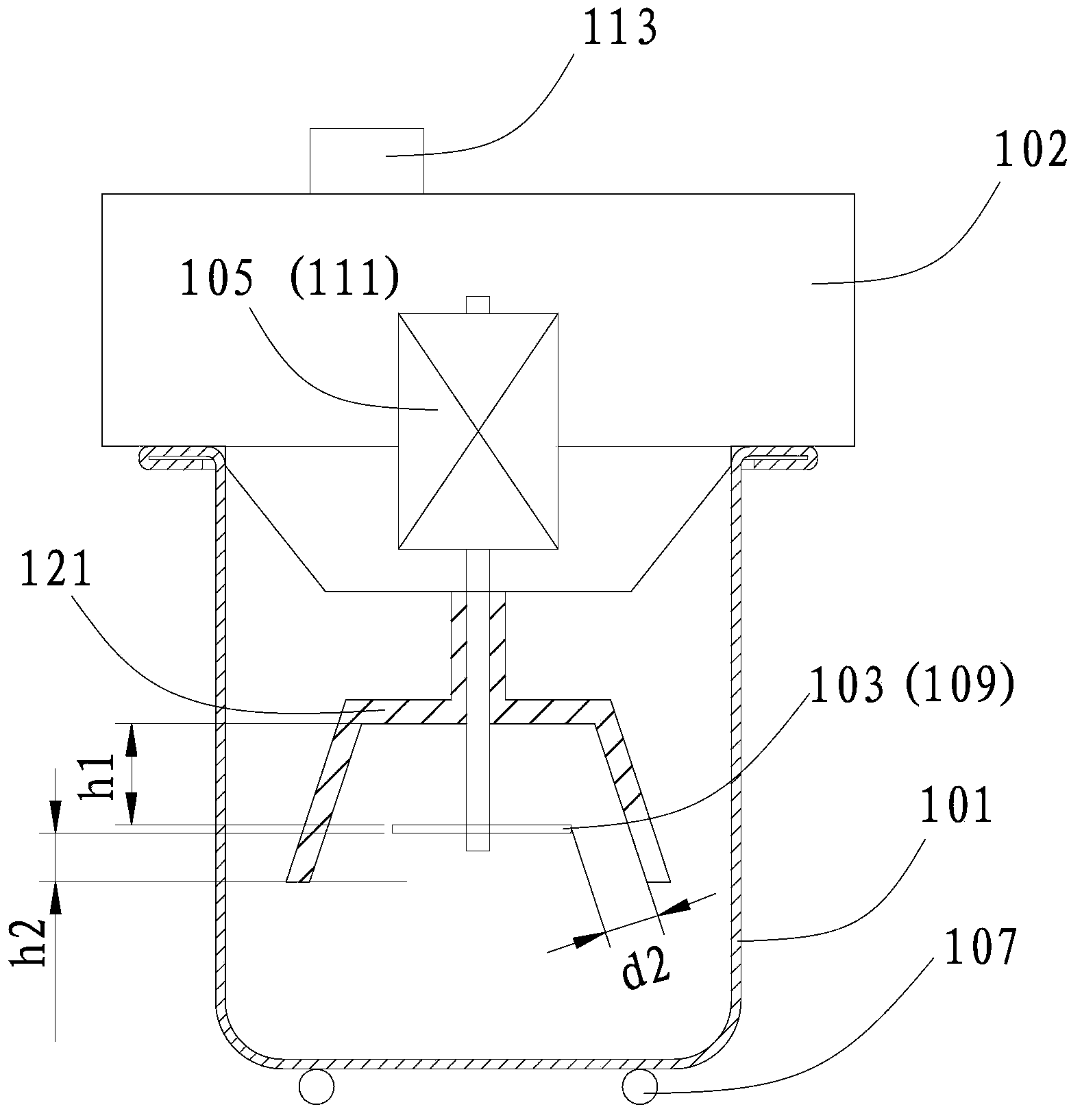

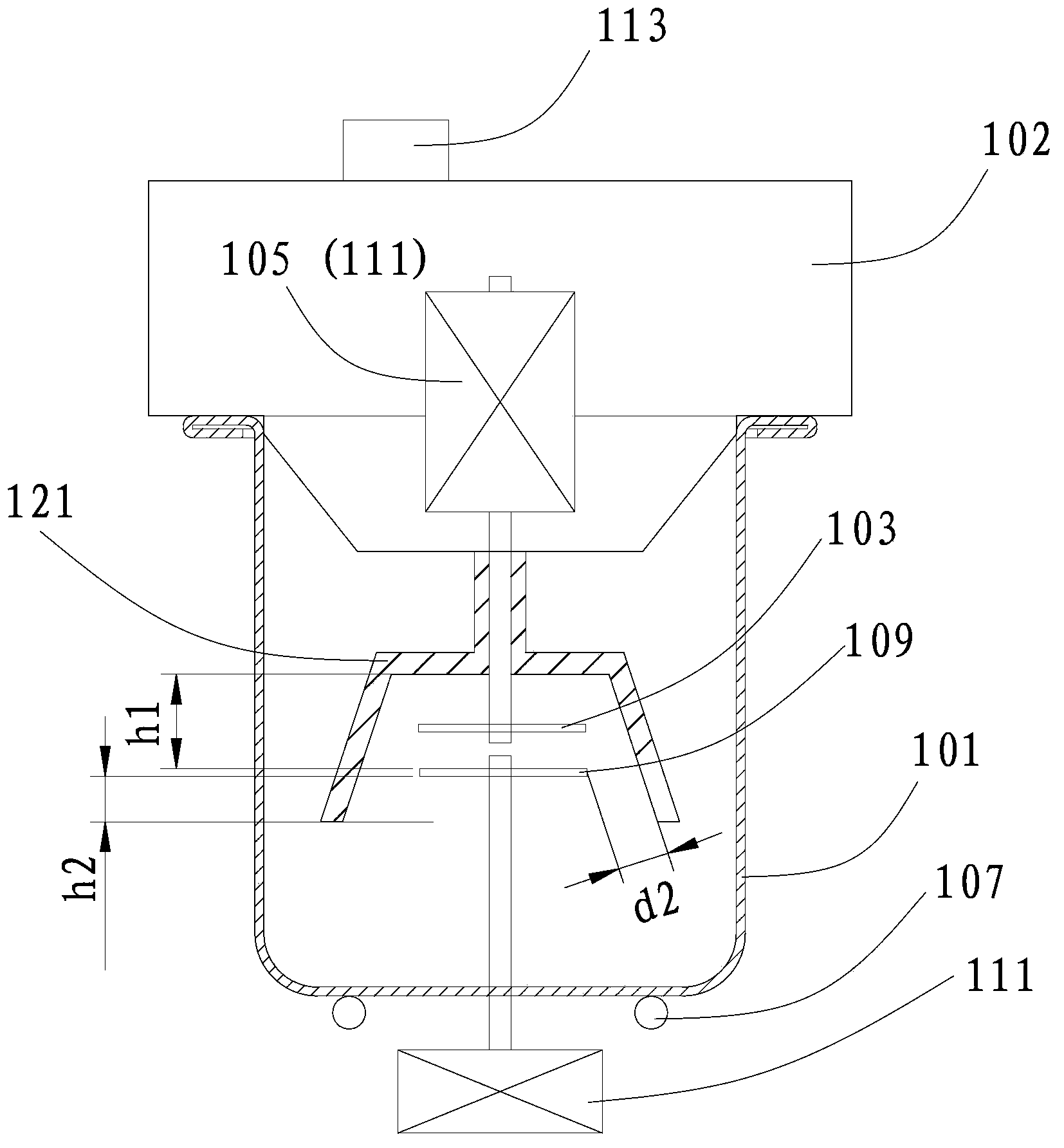

[0102] image 3 A process flow diagram corresponding to this example is shown. In this embodiment, the crushing step can be crushed intermittently, that is, the crushing motor 105 of the soybean milk machine is controlled to rotate intermittently, and the crushing is carried out in an intermittent manner, which can improve the mechanical life of the crushing motor 105 and avoid crushing the motor 105. Damage caused by continuous high-speed operation for a long time.

[0103] For example, the controller can control the crushing motor 105 to rotate at speed V1 for N cycles T, and the crushing motor 105 stops between two adjacent cycles T for a predetermined interval M, where: 1≤N≤50, 5 seconds≤T≤ 40 seconds, 10 seconds ≤ M ≤ 20 seconds.

[0104] For example, taking N=10, T=20 seconds, and M=15 seconds as an example, then the controller controls the crushing motor 105 to rotate at speed V1 for 10 cycles, each cycle is 20 seconds, and the crushing between two adjacent cycles Th...

Embodiment 2

[0119] Figure 4 A process flow diagram corresponding to this example is shown. The inventors found that the stirring speed V2 and the distance h2 between the lower surface of the stirrer 109 and the lower end surface of the spoiler 121 can also change the degree of bottom paste during the cooking process. The inventor obtained through a large number of experiments: in the heating and boiling process, the stirring speed V2 and h2 satisfy the following relationship: 20 revolutions / (minute*mm)≤V2 / h2≤2500 revolutions / (minute*mm), which can be well improved The concentration of the soy milk is obtained, and the sticky bottom phenomenon in the pulping process is further improved, and the foam in the boiling process is also greatly reduced, so that the subsequent defoaming process can be facilitated.

[0120] Further, the inventors found that during the heating and boiling process, the stirring speed V2 and h2 further satisfy the following relationship: 20 rpm / (min*mm)≤V2 / h2≤1000 r...

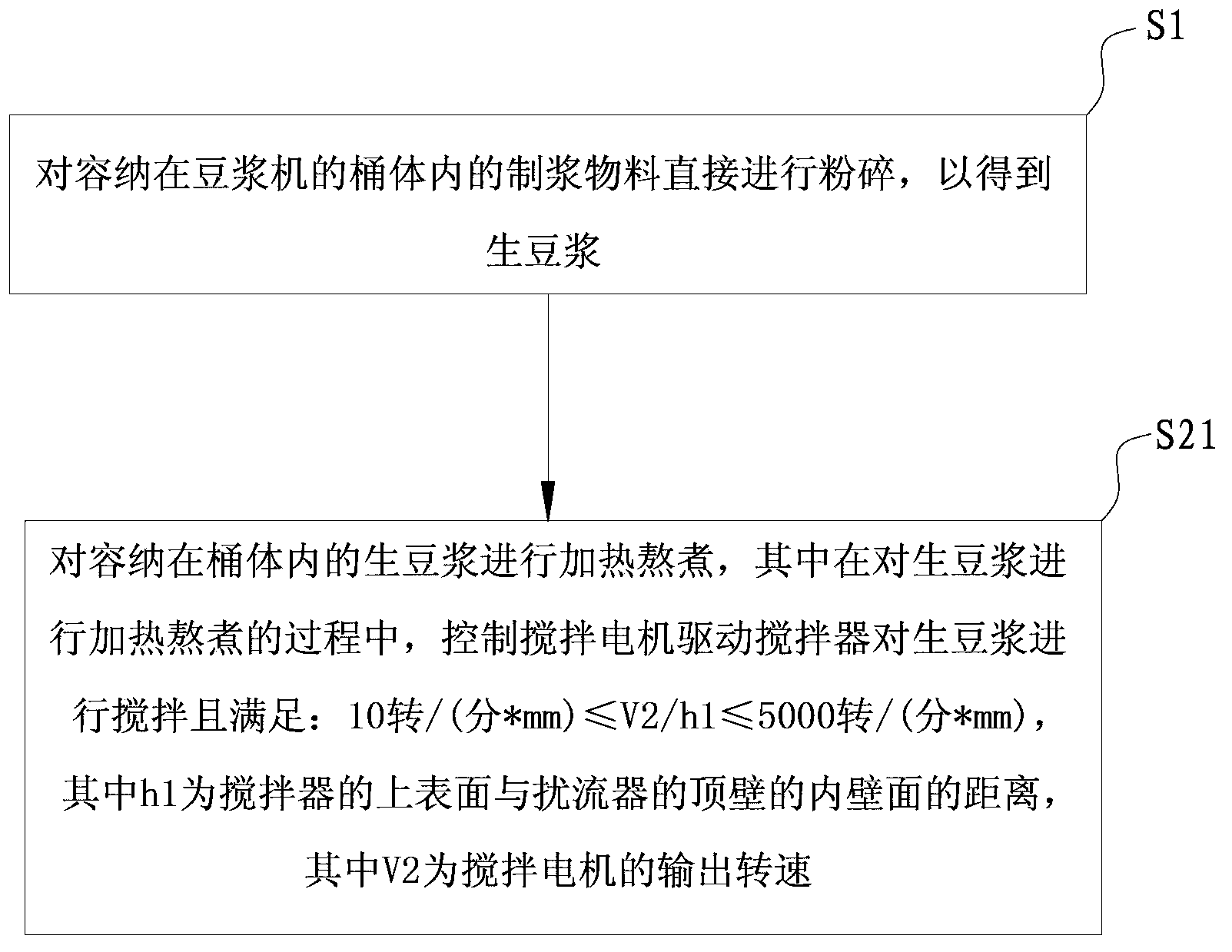

Embodiment 3

[0125] Figure 5 A process flow diagram corresponding to this example is shown. The inventors found that the stirring speed V2 and the distance d2 between the outermost side of the stirrer 109 in the radial direction and the inner wall surface of the peripheral wall of the spoiler 121 are also related to the degree of bottom paste during the boiling process. The inventor obtained through a large number of experiments: in the heating and boiling process, the stirring speed V2 and d2 satisfy the following relationship: 20 revolutions / (minute*mm)≤V2 / d2≤2500 revolutions / (minute*mm), which can be well improved The concentration of the soy milk is obtained, and the sticky bottom phenomenon in the pulping process is further improved, and the foam in the boiling process is also greatly reduced, so that the subsequent defoaming process can be facilitated.

[0126] Further, the inventors found that during the heating and boiling process, the stirring speed V2 and d2 further satisfy the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com