Patents

Literature

602 results about "Boiling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiling is the process of turning a liquid at its saturation temperature into vapor by applying heat. A similar process occurs when the pressure applied to a hot liquid is reduced: this would normally be called flashing.

Preparation method of nanometer carbon fiber material containing iron oxide

InactiveCN102634872ALow costImprove performanceElectro-spinningSpinning solutions preparationFiberCarbon fibers

The invention relates to a preparation method of a nanometer carbon fiber material containing iron oxides, which is characterized in that wood fiber resources are used as raw materials, and the method comprises the following steps: extracting lignin from wood fibers by a boiling process, removing impurities in the lignin by an organic solvent extraction method, mixing the purified lignin, high-molecular polymer, the organic solvent, and ferric acetylacetonate and dissolving, continuously injecting the mixed solution into a high pressure electrostatic spinning device, performing spinning to obtain nanometer fibers, finally preoxidizing the obtained nanometer fibers in air, and performing high temperature carbonization in the presence of protective gas to obtain the C / Fe3O4 nanometer fibers. The invention has cheap and easily available raw materials, a simple preparation process, easy operations, and good repeatability, and is easy to realize large scale production.

Owner:李翠花

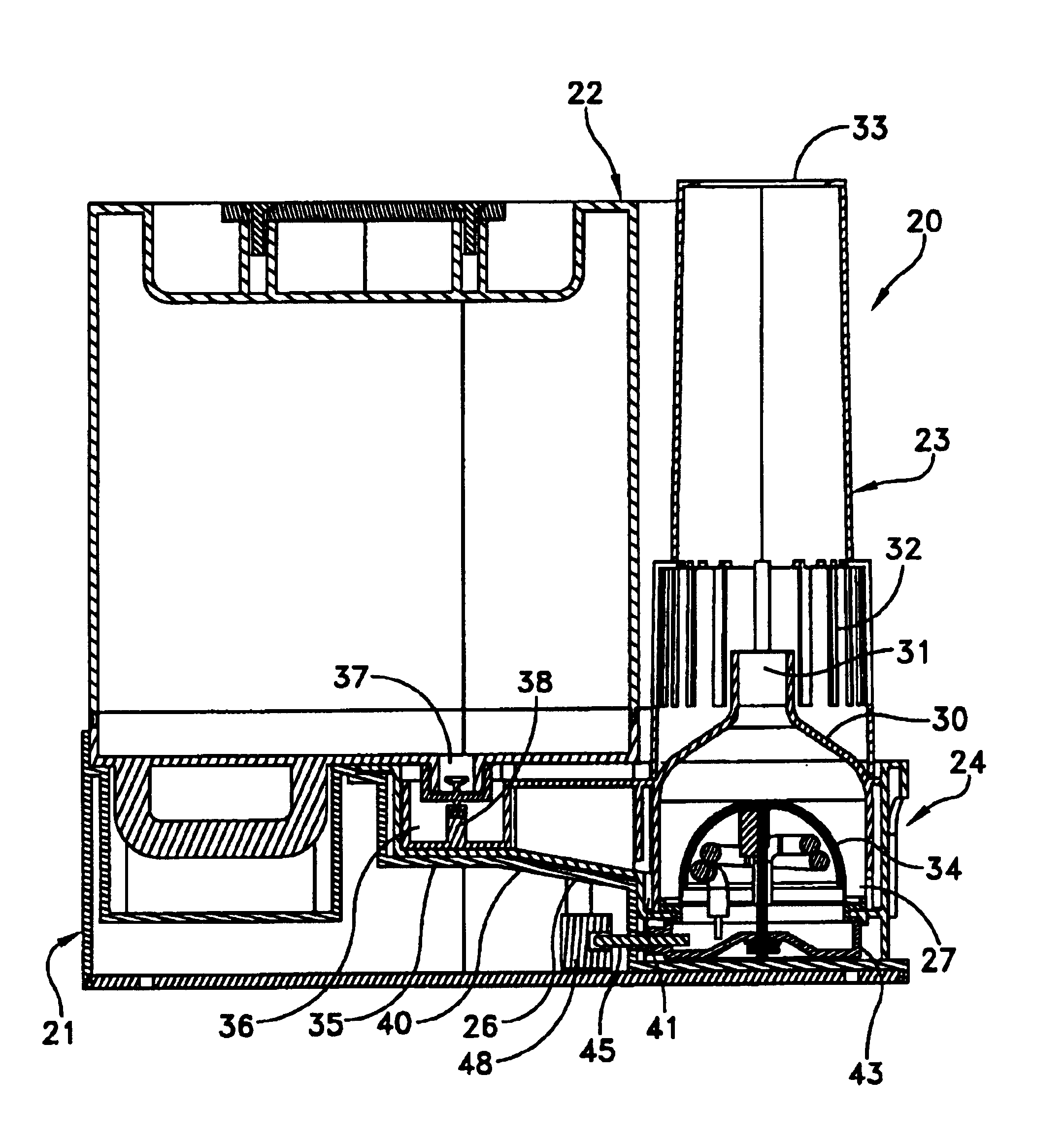

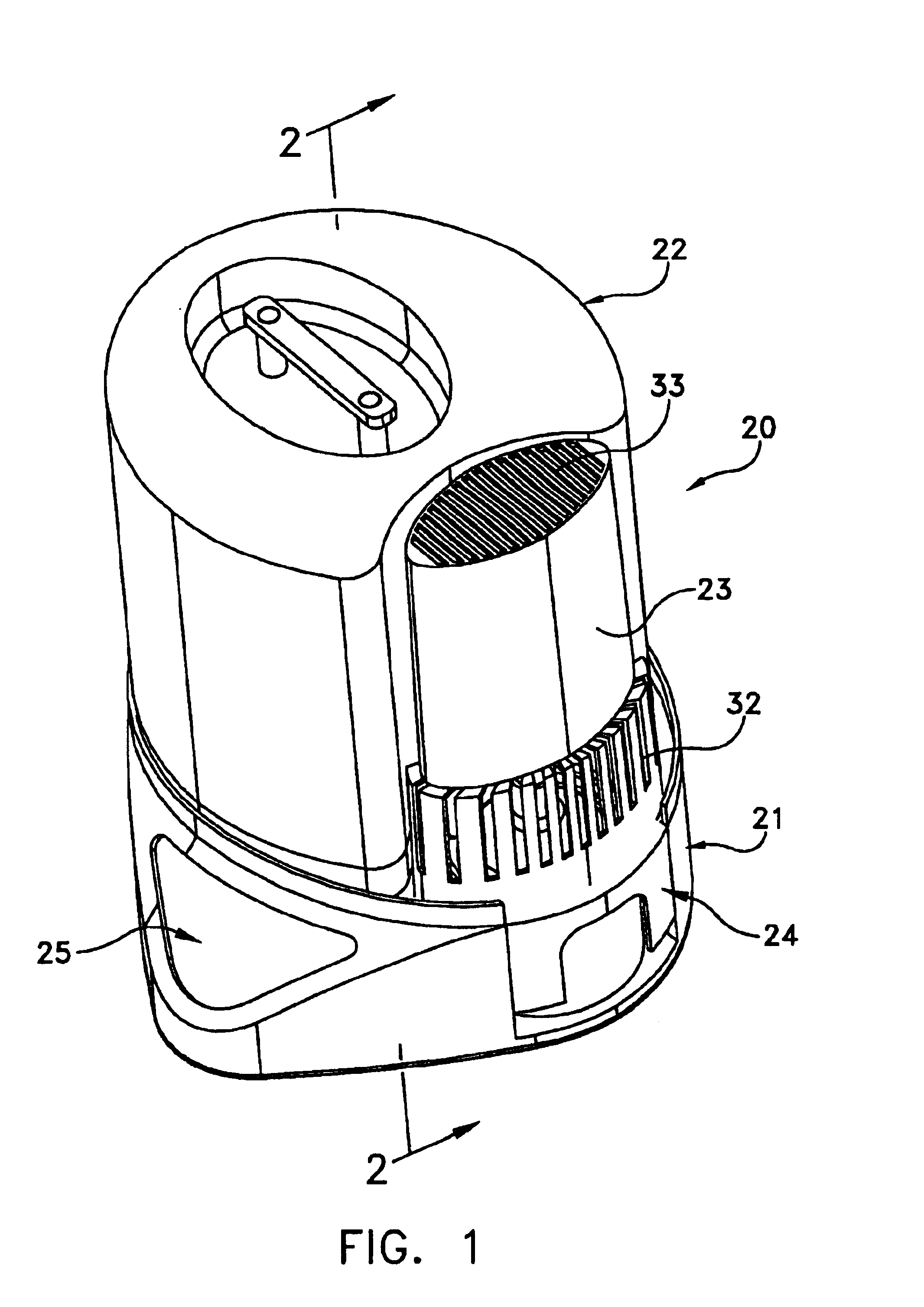

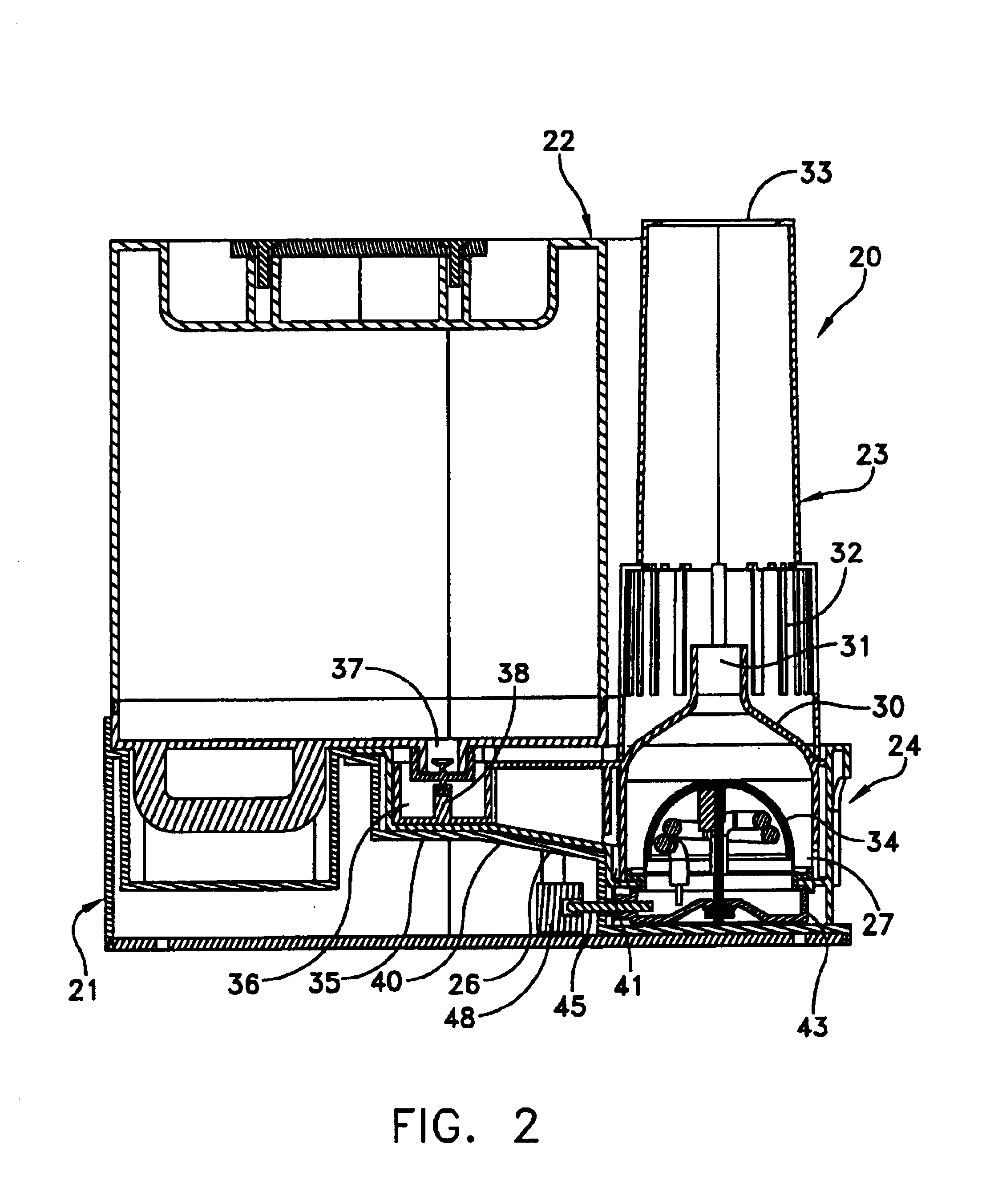

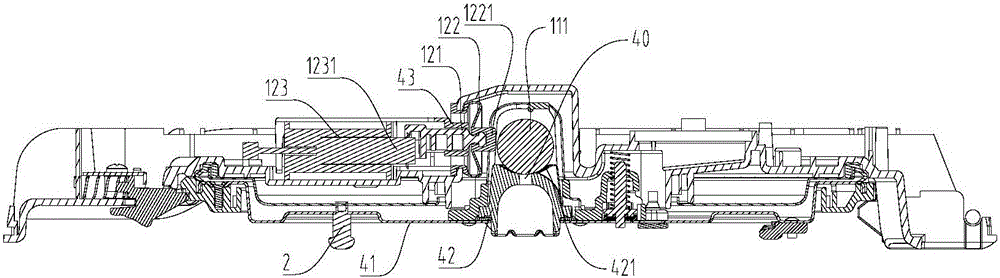

Apparatus for conditioning air

InactiveUS6938886B2Easy to cleanEasy to operateMixing methodsMachines/enginesBoiling processWater transfer

A humidifier including a steam generator with a container for water and an immersed heating module. The heating module has a spherical shape and is formed of a stainless steel outer surface and an aluminum inner body. Electrical heating coils are affixed to the aluminum body to heat the aluminum body and transfer heat through the stainless steel into water. The composite of the inner and outer bodies provides efficient heat transfer for boiling water. The stainless steel resists any permanent adherence of residue to the heating module during the boiling process. Steam from the boiling water transfers through a mixing stack to surrounding air in the humidifier.

Owner:APPLIANCE DEVMENT

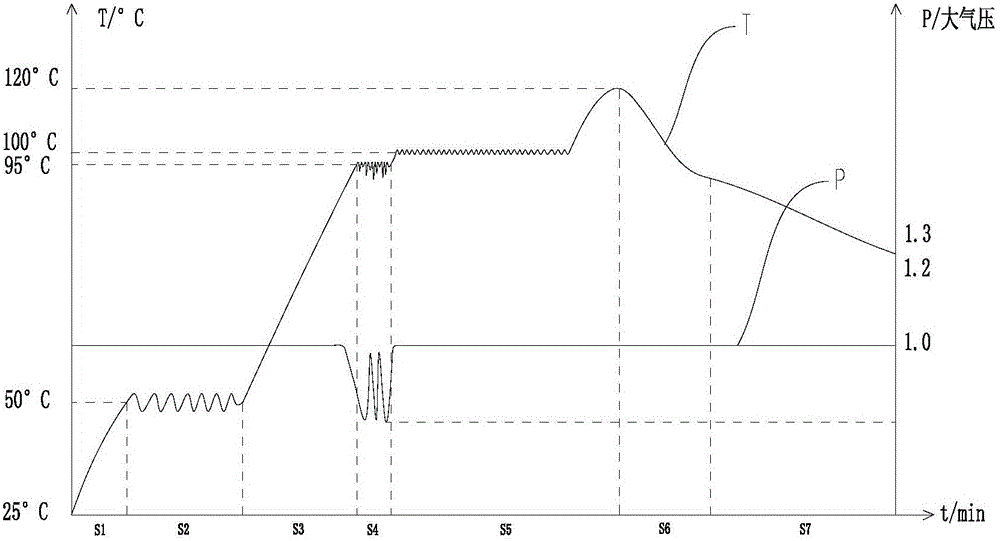

Electric rice cooker and cooking control method thereof

The invention discloses an electric rice cooker and a cooking control method thereof. The electric rice cooker comprises an air extracting device. The air extracting device is configured in a way that when the temperature of soup in a cooking cavity is increased to a sudden boiling temperature T(sudden boiling), the air extracting device extracts air in the cooking cavity to the outside, and therefore the soup in the cooking cavity suddenly boils, wherein T(sudden boiling)<T(boiling), and T(boiling) is the boiling temperature of the soup in the cooking cavity under the external air pressure of the electric rice cooker. When the air extracting device extracts air in the cooking cavity to the outside, the cooking cavity is isolated from the exterior of the electric rice cooker, and therefore the pressure in the cooking cavity is lower than the external air pressure of the electric rice cooker. With respect to the electric rice cooker, the sudden boiling process can be achieved, the caking problem of rice can be relieved, and mouthfeel and color of rice can be optimized.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

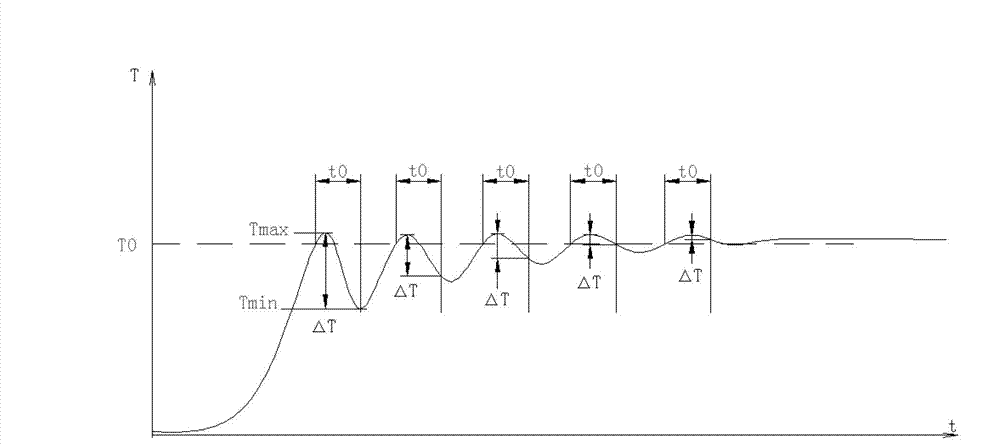

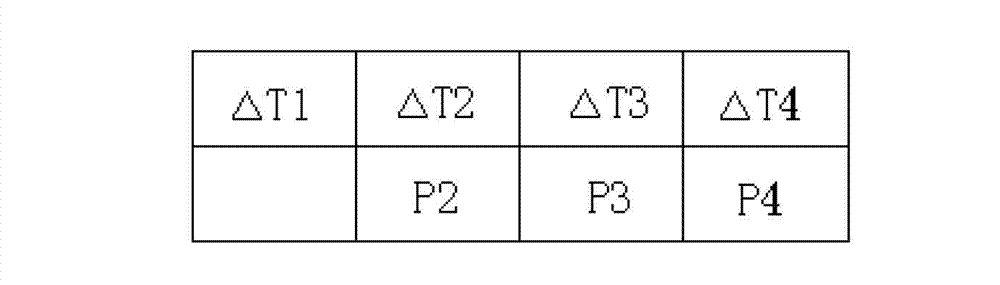

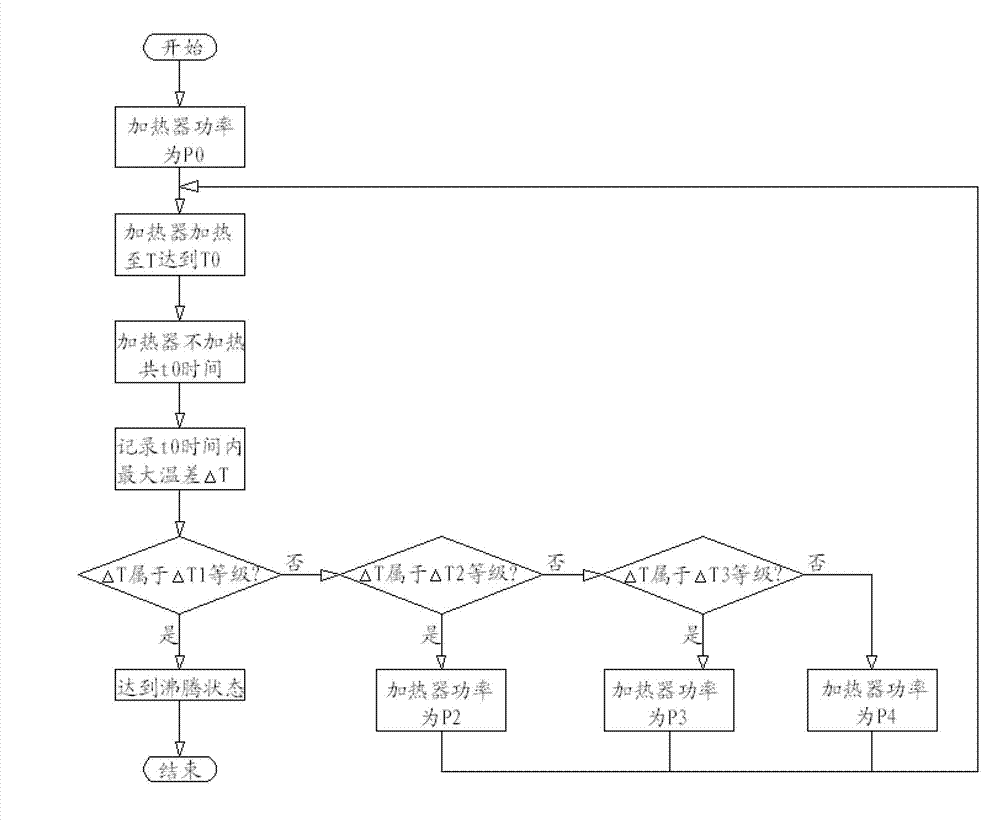

Water boiling judgment control method for heater

The invention discloses a water boiling judgment control method for a heater. The control method comprises the following steps that the heater starts working according to a preset power-regulating ratio; when the preset temperature is reached, the heater stops heating; the time of the heater stopping heating reaches the preset time, the maximum temperature value Tmax and the minimum temperature value Tmin in the present time are recorded, and the difference between the two values is worked out according to the formula of delta T=Tmax-Tmin; the delta T refers to the difference grade of the preset temperature, and based on the temperature difference grade in which the delta T falls, two boiling states are judged, namely the boiling state is judged to be reached and the boiling process is judged to be finished or the boiling state is judged not to be reached; and the heater works according to the preset power-regulating ratio corresponding to the temperature difference grade in which the delta T falls, and the whole process is repeated. The control method can accurately judge whether water in the heater is boiling, and when the boiling state is judged not to be reached, and additional heating with different heating capacity is performed, so that the phenomenon of overflow or insufficient heating when the heater works is effectively prevented.

Owner:MIDEA GRP CO LTD

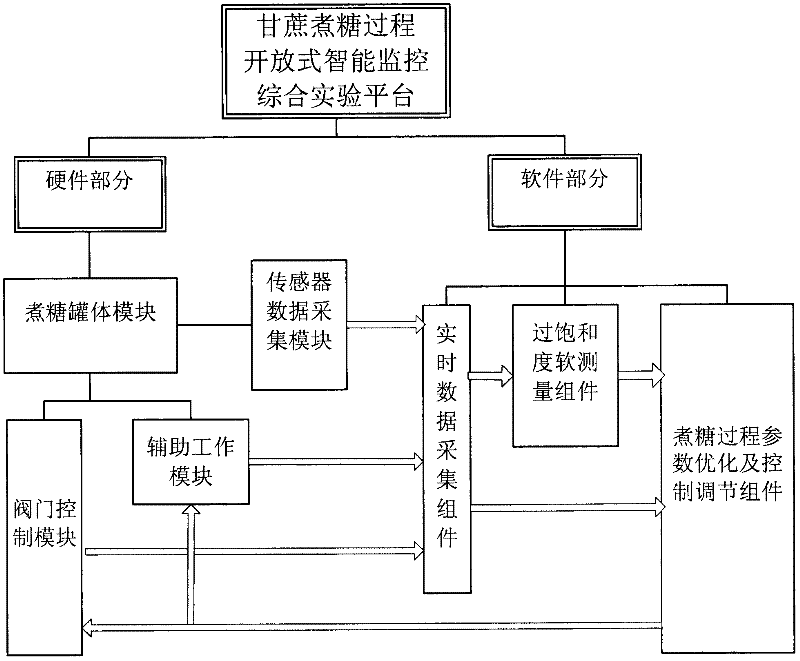

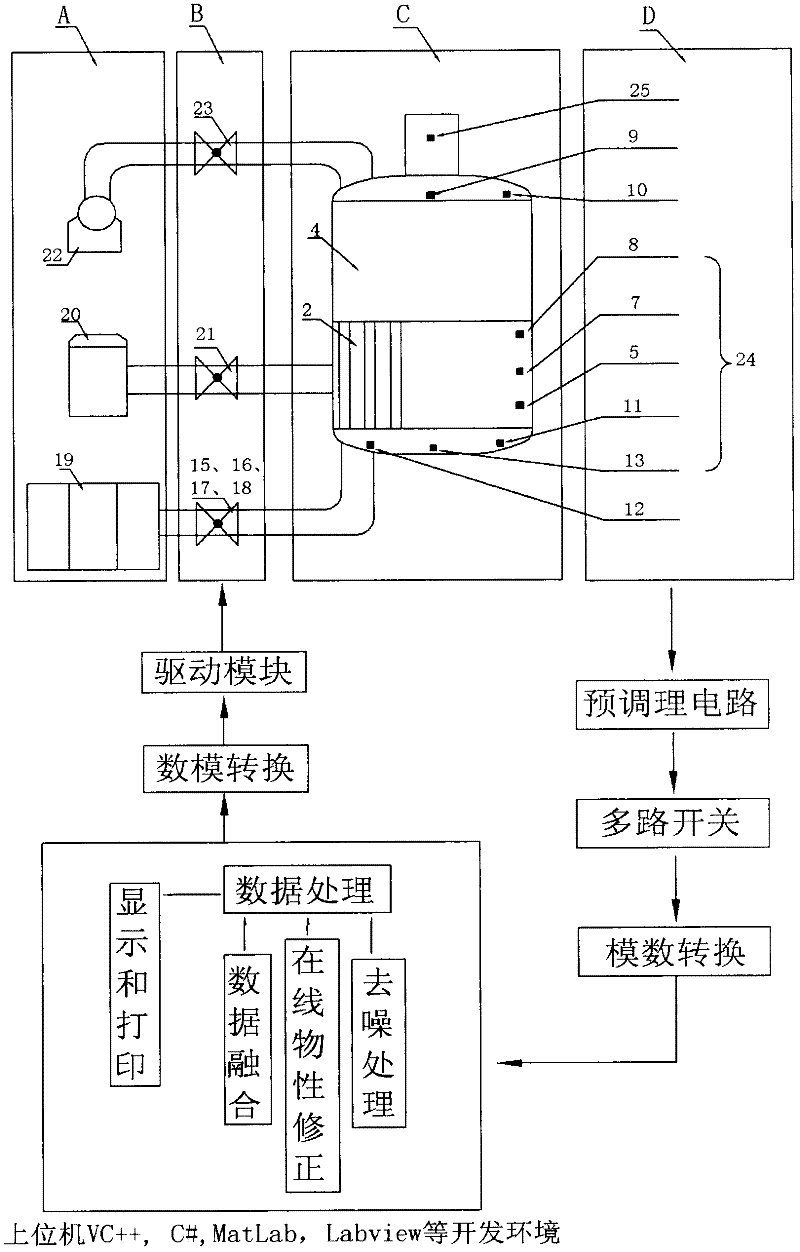

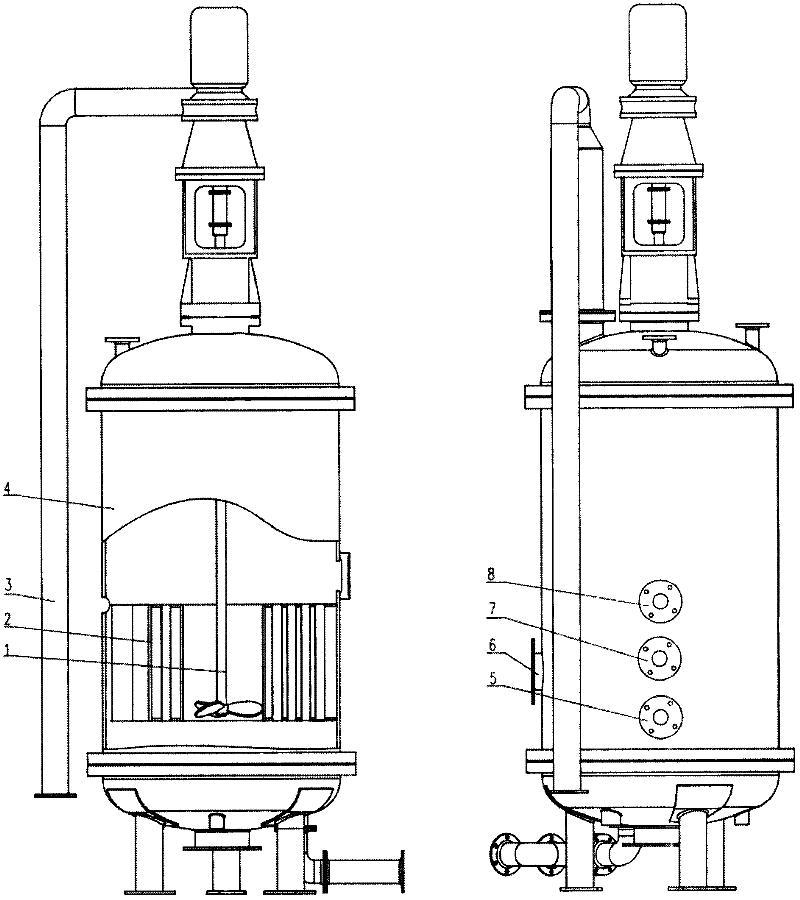

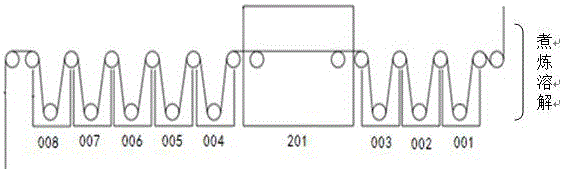

Open type intelligent monitoring comprehensive experiment platform in sugarcane sugar boiling process

ActiveCN102505048AReduce volumeLess materialSugar juice boiling/evaporationTotal factory controlArea networkReal-time data

The invention relates to an open type intelligent monitoring comprehensive experiment platform in the sugarcane sugar boiling process. The open type intelligent monitoring comprehensive experiment platform consists of a hardware part and a software part, wherein the hardware part comprises a sugar boiling tank body module, an auxiliary work module, a sensor data collecting module and a valve control module, the software part comprises a real-time data collecting assembly, a supersaturation degree soft measuring assembly and a sugar boiling process dynamic parameter optimizing and control regulation assembly, and the hardware part and the software part are connected with each other through a Mod bus and a controller area network (CAN) bus. The platform is used for scientific research, various kinds of monitoring method optimizing research are developed under various actual work conditions in the sugar boiling process, and the practical monitoring technology is provided in the actual sugar boiling process. The experiment platform can also be used as a comprehensive experiment teaching platform for students specialized in measuring control and sugar making, and relative comprehensive and design research teaching method research is developed.

Owner:GUANGXI UNIV

Method for producing high-elasticity bulked silk-cotton quilt

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

Processing method for cotton/hemp blended knitted fabric

InactiveCN101200845AEliminate internal stressReduce heavy metal contentWeft knittingBiochemical fibre treatmentYarnBoiling process

The invention discloses a processing method of cotton / ramie blended knitting fabric which adopts processing equipment of a cotton mill and adds yarn boiling and demineralizing processes before a weaving process. The whole technological process is from yarn boiling, demineralizing, weaving, mercerizing, bleaching and boiling, biological enzyme washing, and dyeing, softening, dehydration, width opening, drying and setting to preshrinking. The yarn boiling temperature in the yarn boiling process is 80 to 130 DEG C and the time is 10-30m. The demineralizing temperature in the demineralizing process is 30 to 90 DEG C and the time is 10-30m. In the demineralizing treatment, acid demineralizing agent and refining agent are used to remove heavy metal ions in cotton / ramie blended yarn. The invention has the advantages of ensuring the neat surface of the knitting fabric, comfort handle, light shrinkage and distortion and good durability with the added yarn boiling and demineralizing processes, eliminating the internal stress of the cotton / ramie blended yarn through the yarn boiling process, improving the toughness and the weaving efficiency of the knitting fabric, improving the insurance coefficient of the boiling and bleaching process through the demineralizing process and providing a guarantee for the strength of the knitting fabric.

Owner:宁波雅戈尔日中纺织印染有限公司

Preparation method of nanometer carbon fiber material containing polyvinylpyrrolidone

InactiveCN102634871ALow costImprove performanceFilament/thread formingFibre chemical featuresFiberCarbon fibers

The invention relates to a preparation method of a nanometer carbon fiber material containing polyvinylpyrrolidone, which is characterized in that wood fiber resources are used as raw materials, and the method comprises the following steps: extracting lignin from wood fibers by a boiling process, removing impurities in the lignin by an organic solvent extraction method, mixing the purified lignin, the organic solvent, and polyvinylpyrrolidone and dissolving, continuously injecting the mixed solution into a high pressure electrostatic spinning device, performing spinning to obtain nanometer fibers, finally preoxidizing the obtained nanometer fibers in air, and performing high temperature carbonization in the presence of protective gas to obtain the nanometer fibers. The invention has cheap and easily available raw materials, a simple preparation process, easy operations, and good repeatability, and is suitable for large scale production.

Owner:李翠花

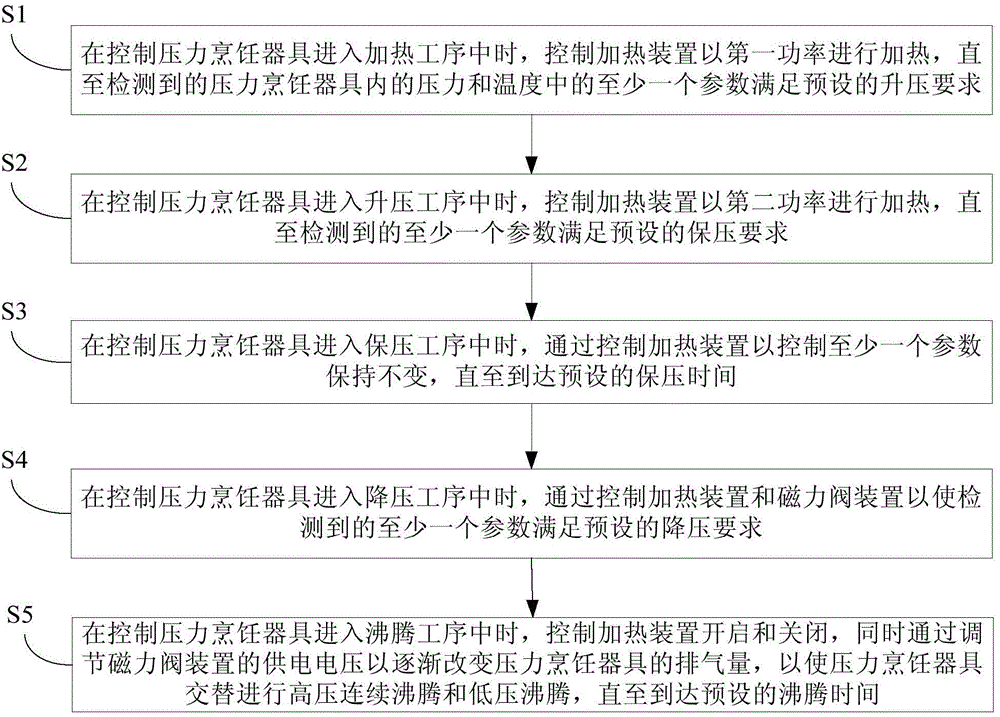

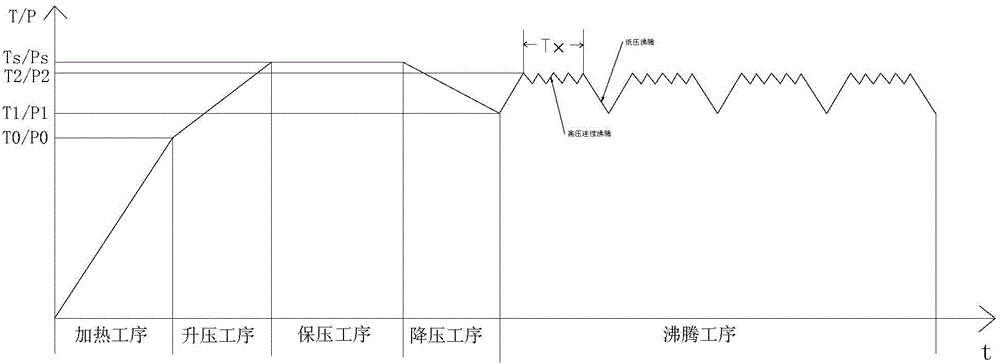

Pressure cooking appliance and cooking control method thereof

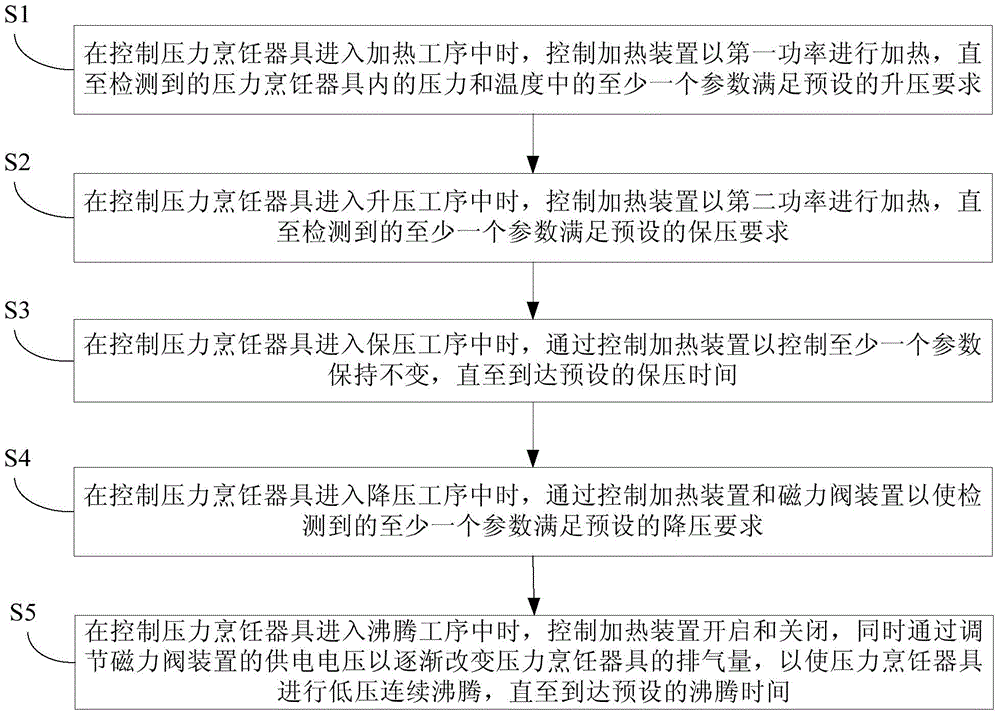

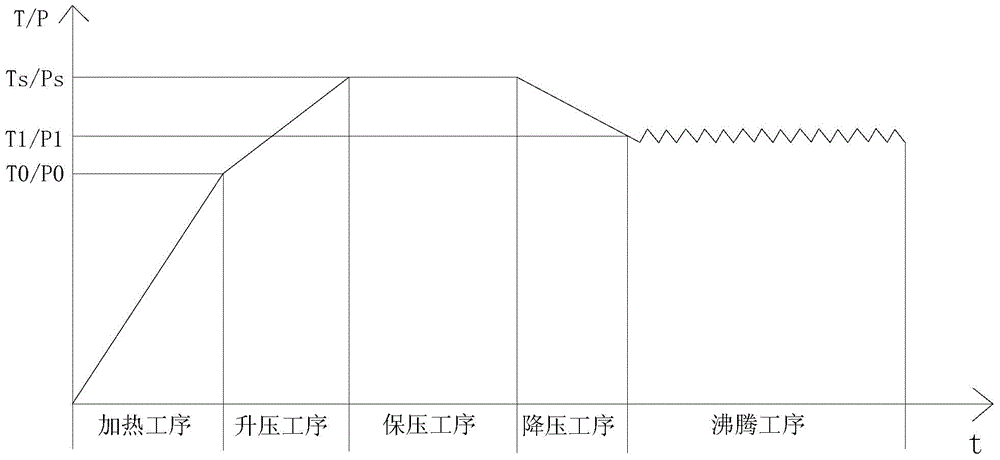

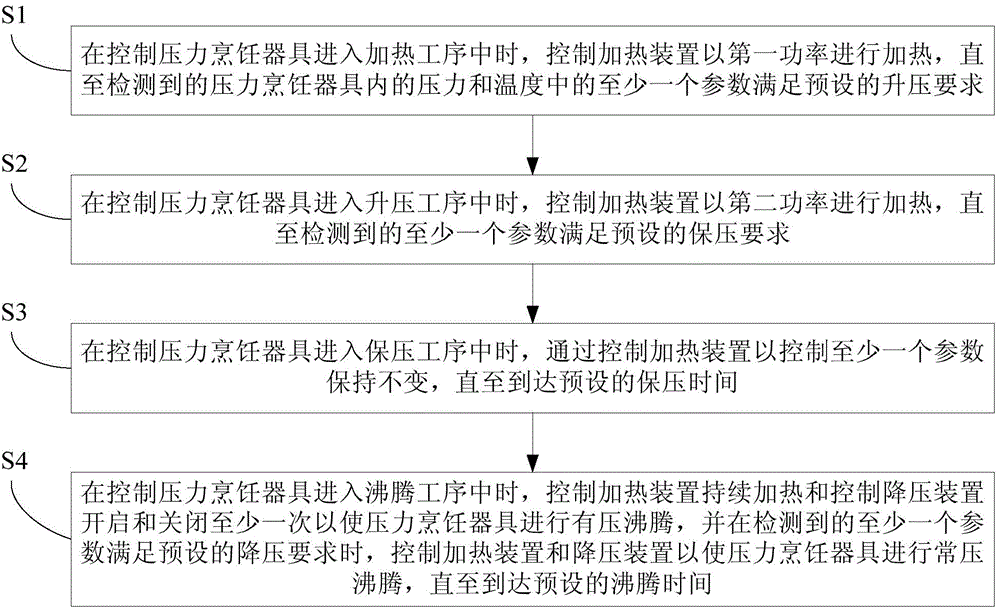

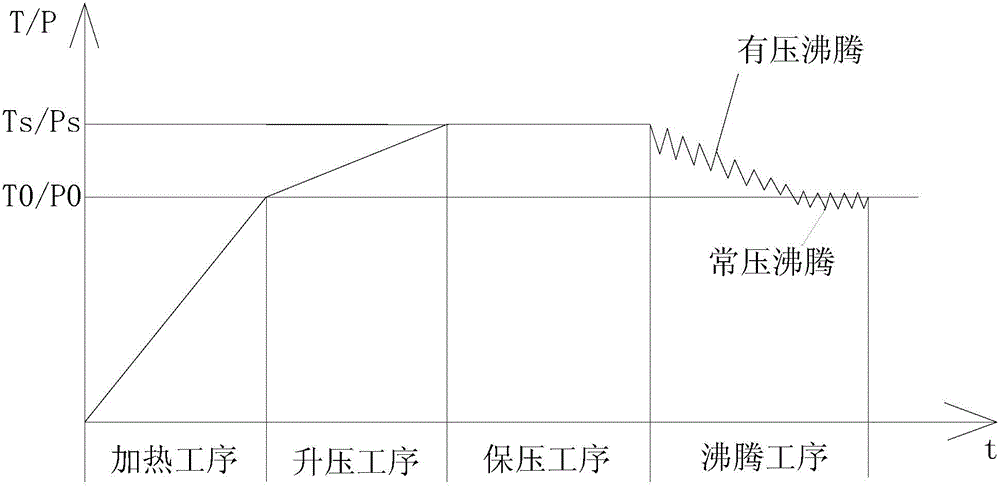

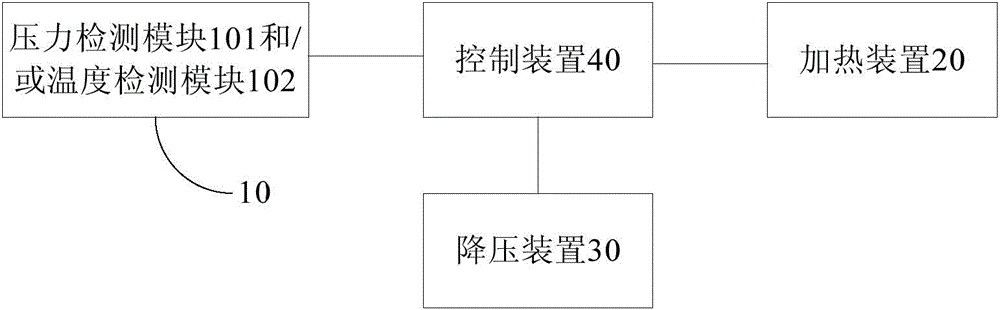

InactiveCN106136868AHigh nutritional valuePromote absorptionPressure-cookersWarming devicesNutrientBoiling process

The invention discloses a pressure cooking appliance and a cooking control method thereof. The cooking control method comprises the following steps: a heating process: controlling a heating device to conduct heating at first power until at least one parameter of the pressure and temperature in the appliance meets the preset pressure boosting requirement; a preset pressure process: controlling the heating device to conduct heating at second power until at least one parameter meets the preset pressure maintaining requirement; a pressure maintaining process: controlling the heating device to control at least one parameter to keep constant until the preset pressure maintaining time; a pressure reducing process: controlling the heating device and a magnetic valve device to enable at least one parameter to meet the preset pressure reducing requirement; a boiling process: controlling the magnetic valve device to enable the pressure cooking appliance to conduct low-pressure boiling until the preset boiling time. According to the cooking control method, food cooked by the pressure cooking appliance is rich in soup, and more nutrient substances are dissolved in the soup, and are convenient to absorb by a human body.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

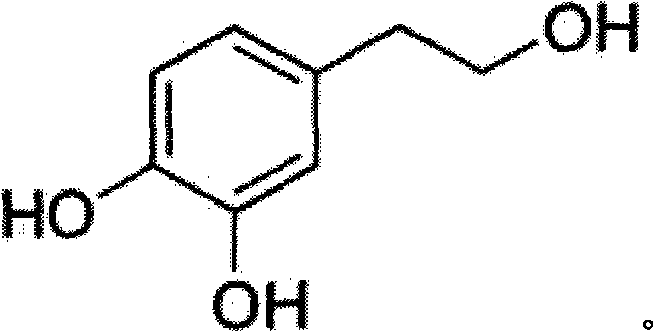

Method for extracting hydroxytyrosol

ActiveCN101973853AShort conversion timeShorten the production cycleOrganic chemistryOrganic compound preparationHydroxytyrosolBoiling process

The invention discloses a method for extracting hydroxytyrosol, which comprises the following steps of: preparing raw material extracting solution; taking one kind of extracting solution, adding concentrated hydrochloric acid to make the pH value thereof 0 to 2, boiling for 2 to 4 hours and hydrolyzing; allowing the hydrolyzate to pass through macroporous adsorption resin for column chromatography, eluting by using acid liquor with the pH value of 1 to 2, mixing the effluent liquid and pickling liquor, regulating the pH value to neutral, concentrating and filtering; making the filter liquor to pass through the macroporous adsorption resin for column chromatography, eluting by using 10 to 30 volume percent ethanol, collecting the eluent, concentrating, and drying to prepare the hydroxytyrosol. By acidifying the raw material extracting solution, the method realizes conversion of the hydroxytyrosol through the boiling process, greatly shortens the conversion time of the hydroxytyrosol, improves the conversion rate, integrally shortens the production cycle and saves the production cost. The hydroxytyrosol is prepared through separation and purification by the macroporous adsorption resin.

Owner:GUILIN NATURAL INGREDIENTS CORP

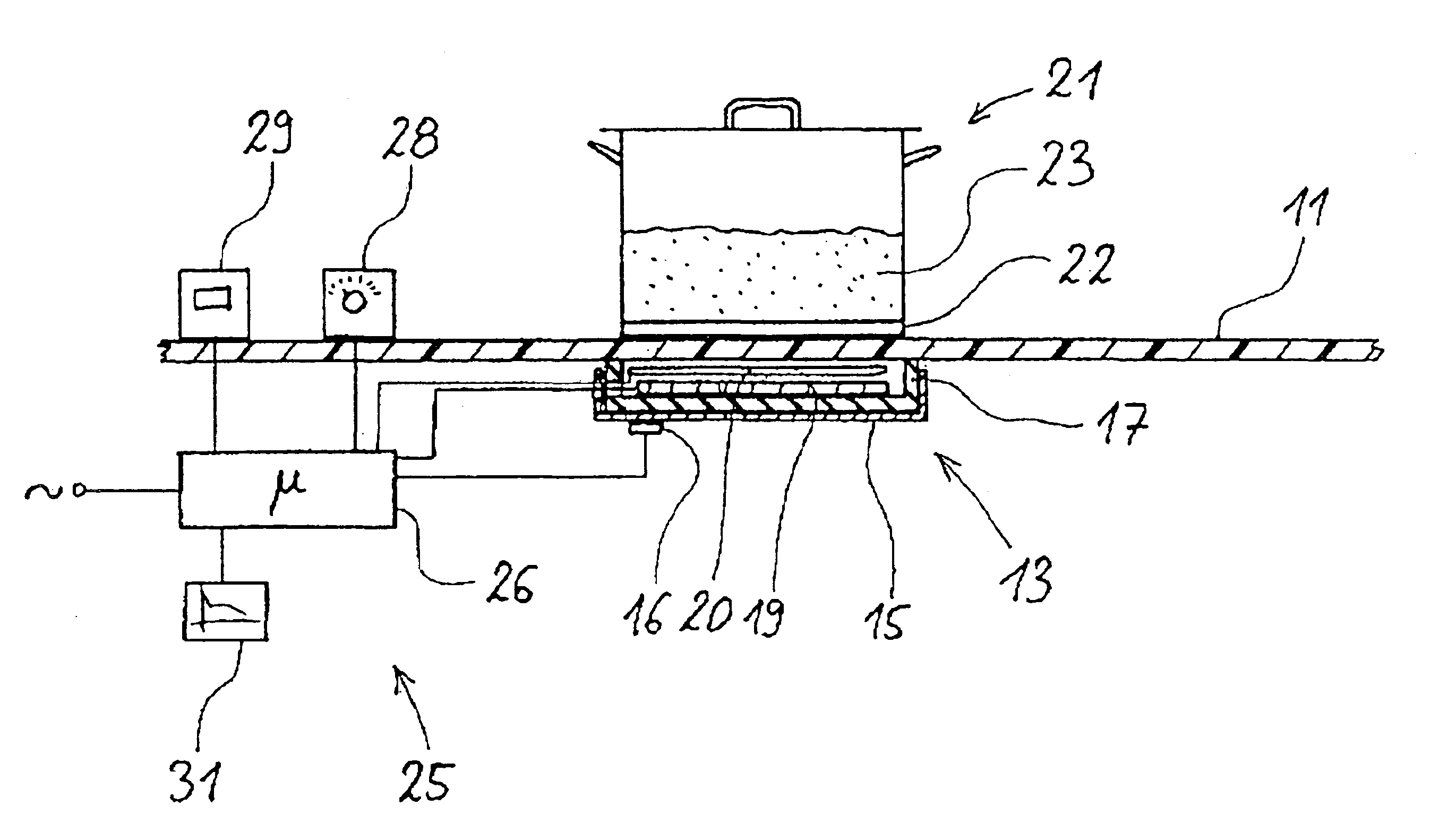

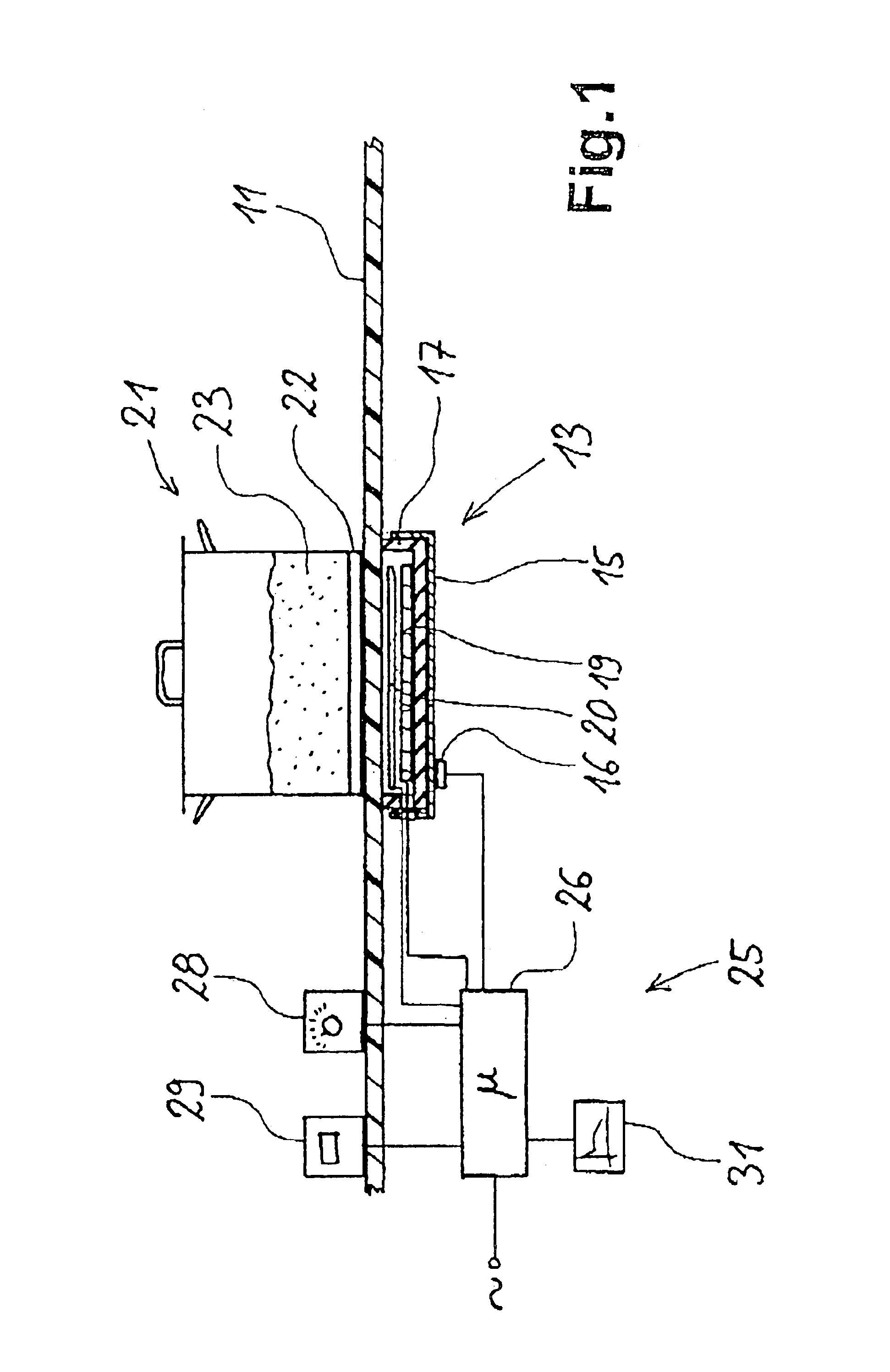

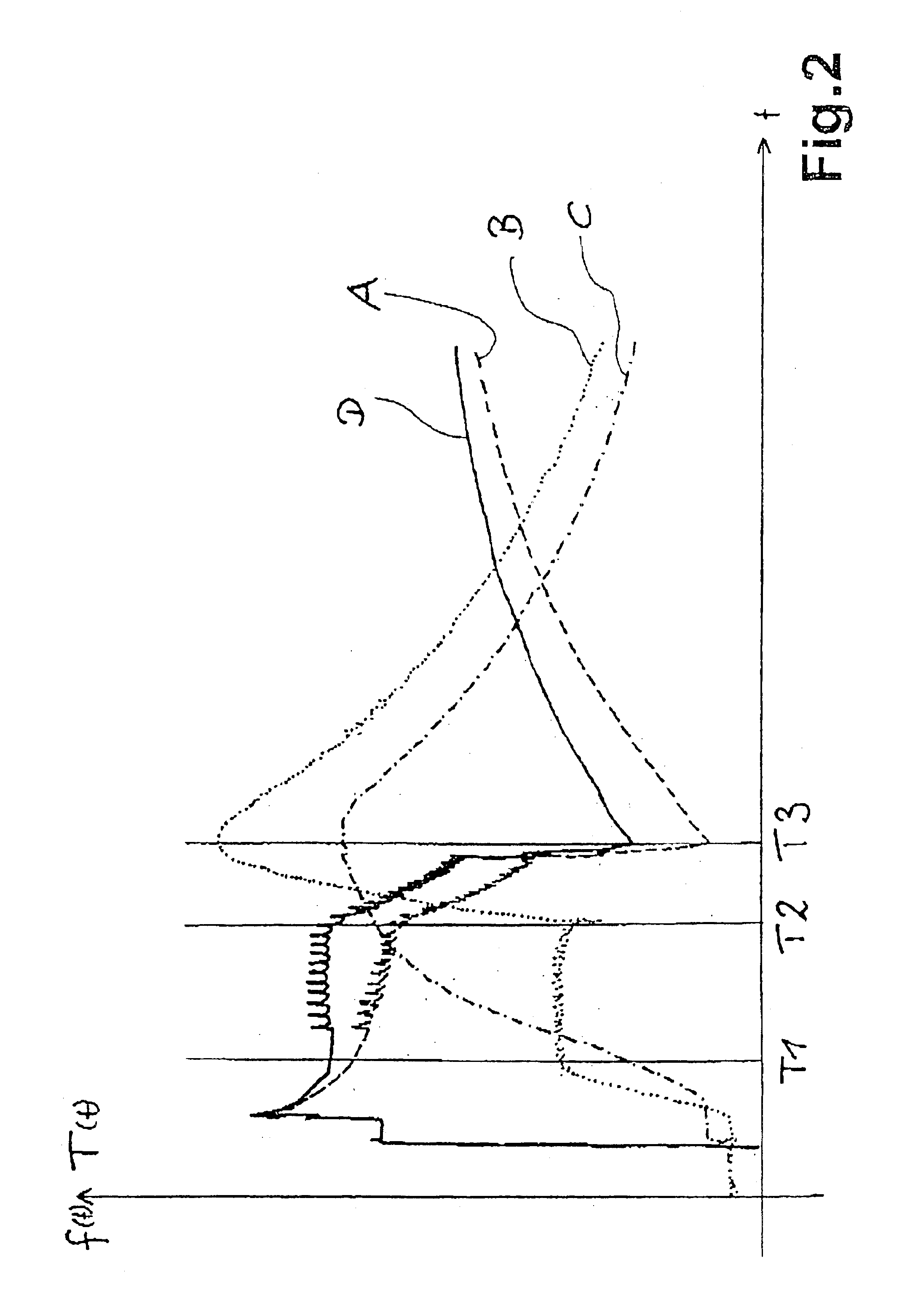

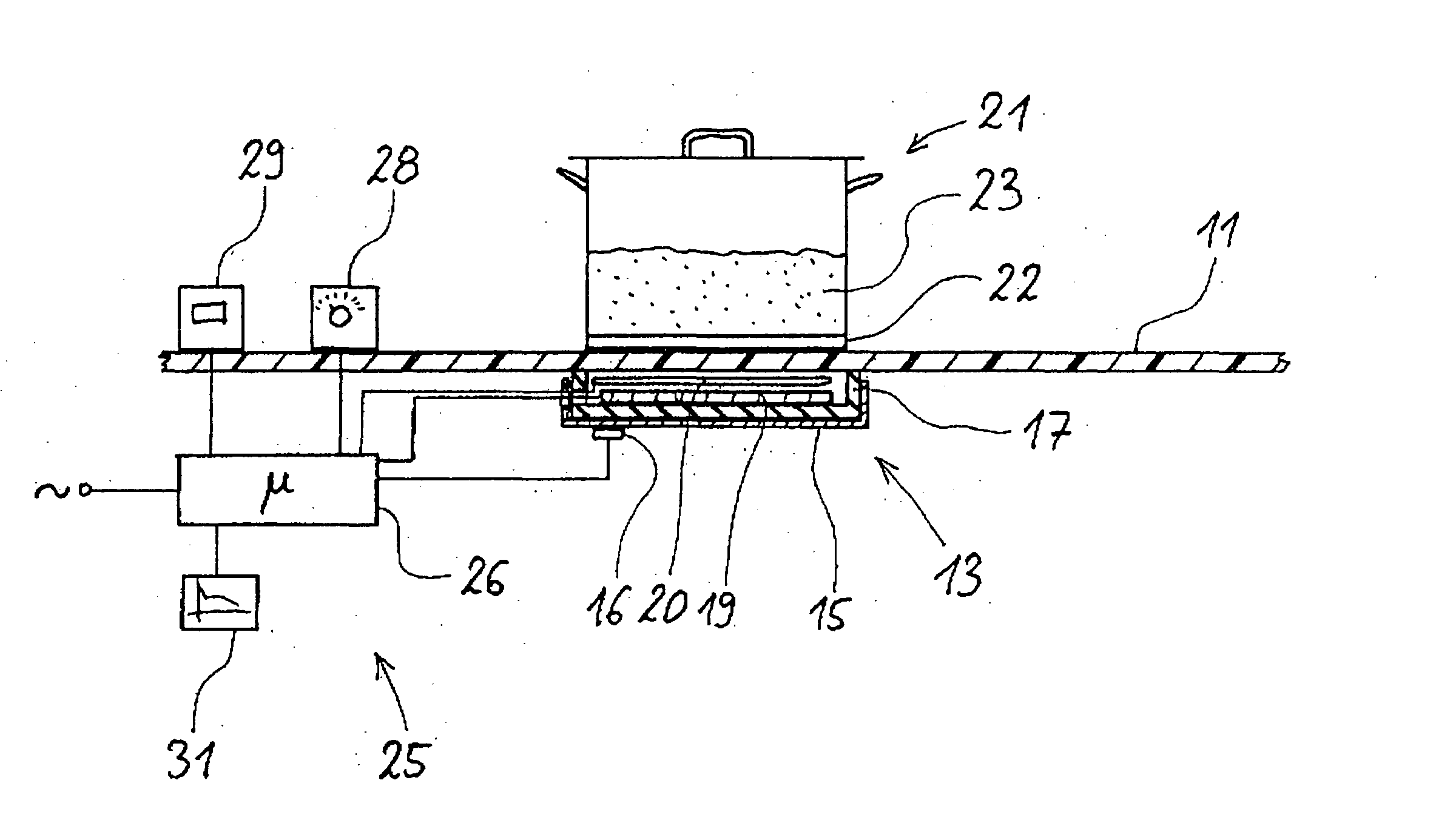

Method for measuring the temperature of a metal saucepan

InactiveUS6904378B2Value can be obtainedReduce further influenceThermometer detailsThermometers using material expansion/contactionRadiant heaterThermodynamics

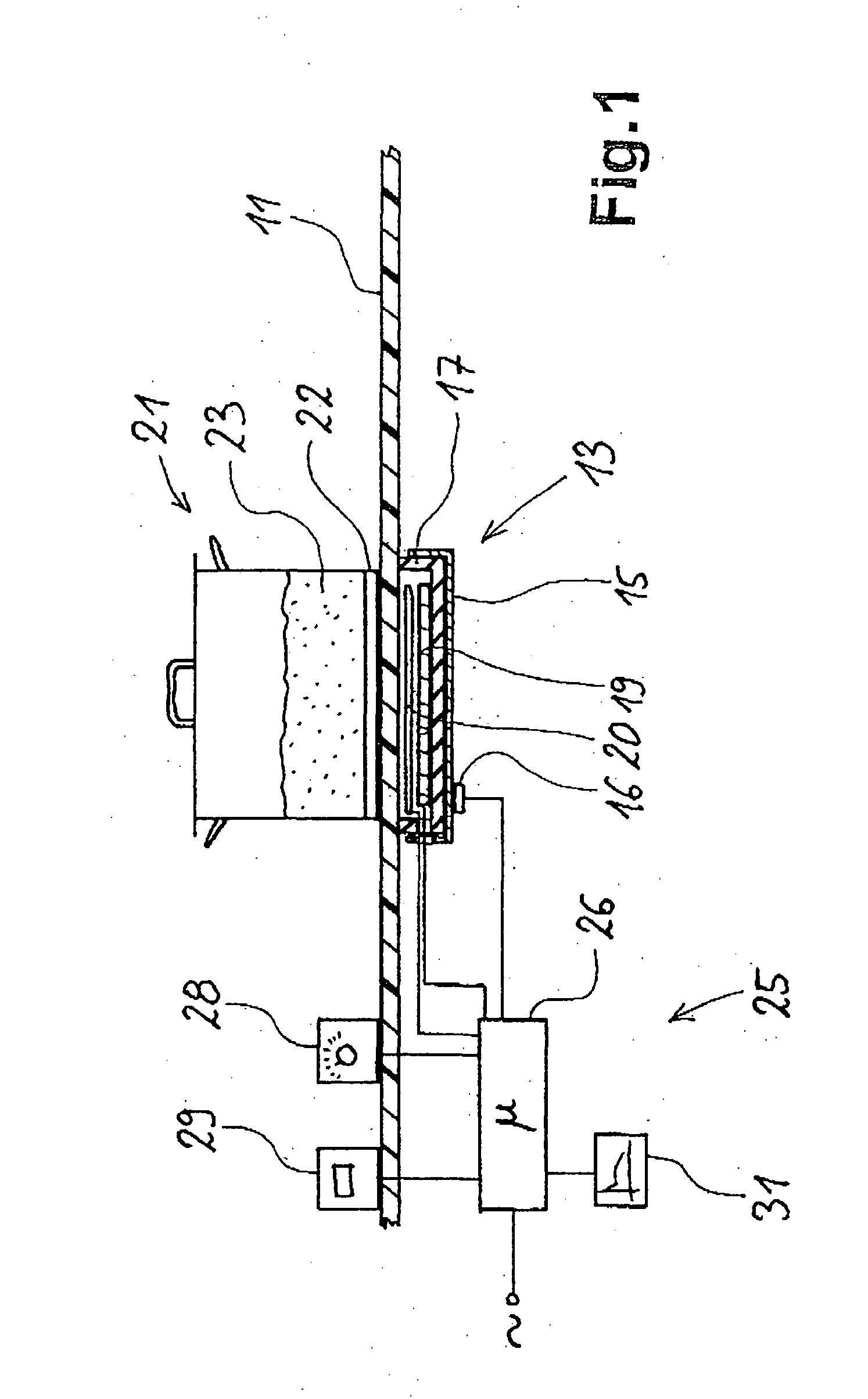

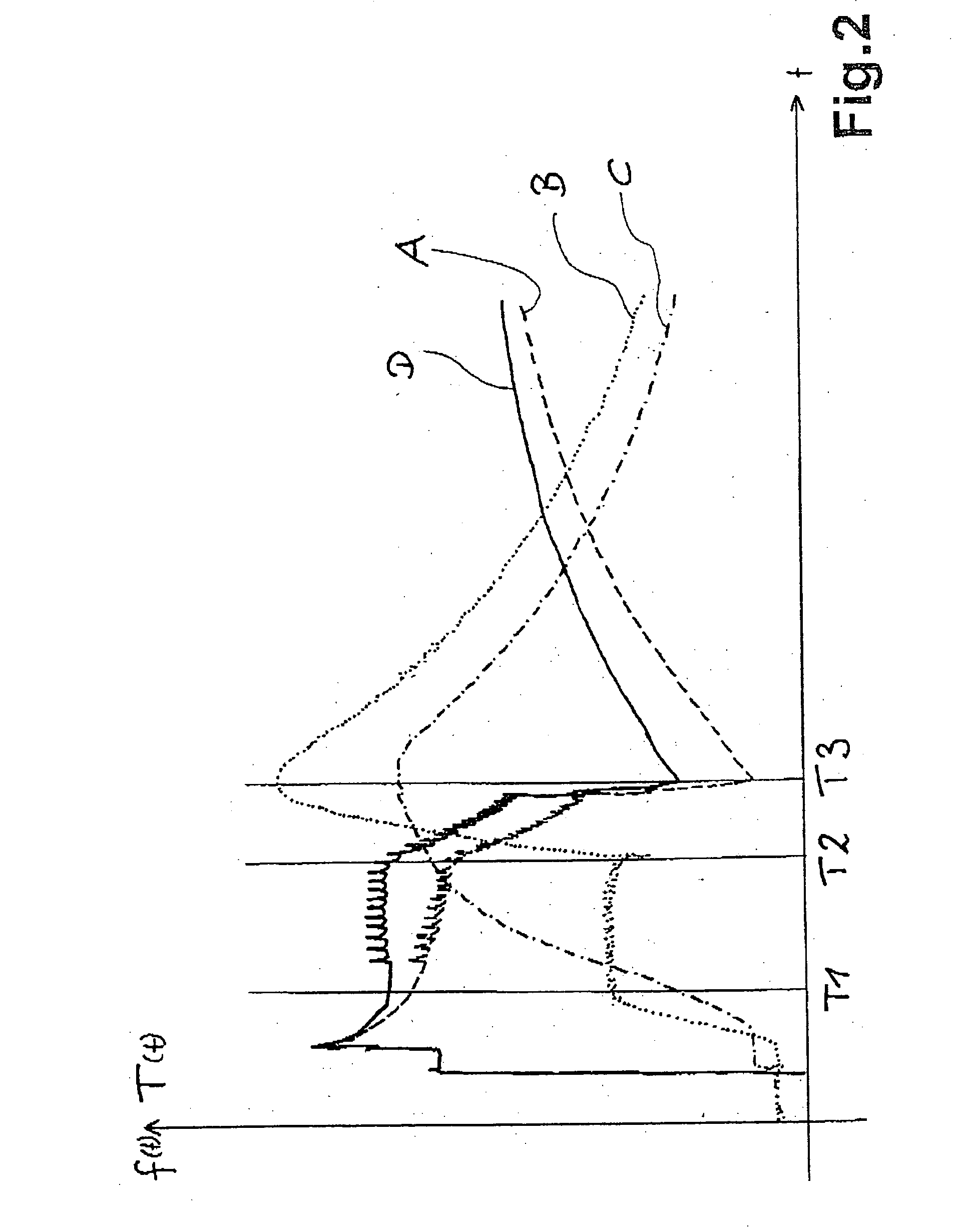

A method for measuring the temperature of a cooking vessel or saucepan using a radiant heater. The radiant heater has a heating coil with a corresponding control and an induction coil as an inductive sensor and which is located in a metal tray. With the inductive sensor, measurement takes place of the frequency of the inductive resonant circuit comprising saucepan, heating coil, induction coil and metal tray, which is dependent on the temperature of the components. In the control is stored known slopes or paths of the temperature and therefore the frequency of the metal tray over the time. From this the control gathers correction values in order to produce from the measured curve a compensated curve. At characteristic points, such as the start of a cooking or boiling process or an empty cooking or boiling of the saucepan, it is possible to detect the temperatures.

Owner:E G O ELEKTRO GERAETEBAU GMBH

Method for measuring the temperature of a metal saucepan

InactiveUS20040054486A1Value can be obtainedReduce further influenceThermometer detailsThermometers using material expansion/contactionRadiant heaterBoiling process

A method for measuring the temperature of a cooking vessel or saucepan by means of a radiant heater is described. The radiant heater has a heating coil with a corresponding control and an induction coil as an inductive sensor and which is located in a metal tray. With the inductive sensor, measurement takes place of the frequency of the inductive resonant circuit comprising saucepan, heating coil, induction coil and metal tray, which is dependent on the temperature of the components. In the control is stored known slopes or paths of the temperature and therefore the frequency of the metal tray over the time. From this the control means gathers correction values in order to produce from the measured curve a compensated curve. At characteristic points, such as the start of a cooking or boiling process or an empty cooking or boiling of the saucepan, it is possible to detect said temperatures.

Owner:E G O ELEKTRO GERAETEBAU GMBH

Bobbin dyeing technology

InactiveCN101736610AUniform dyeingSolve difficult dyeingBleaching apparatusDyeing processBobbinBoiling process

The invention discloses a bobbin dyeing technology, comprising the following steps: loose type spooling process, blanching pretreatment process, soap boiling process and drying process: putting prepared bobbin into a main cylinder of a dyeing machine, pouring water into the main cylinder until the bobbin is submerged; dyeing process: adding dyestuff into the main cylinder: 5g / L of sodium hydrosulfite and 1.5g / L of caustic soda; putting bobbin into the cylinder, then raising temperature to 50 DEG C and maintaining the temperature for 40min for carrying out full bath restoration, then discharging water when the full bath restoration is finished.The dyeing technology has the characteristics that use level of sodium hydrosulfite, caustic soda and temperature can be controlled, full bath restoration dyeing reaction can be adopted to ensure that the processed bobbin is evenly dyed, so that the problem that dyeing and flower dyeing are difficult.

Owner:QINGDAO XIYINGMEN GRP

Zero residual base normal-pressure or low-pressure boiling high-concentration pulp preparing method by using base process

InactiveCN101215794ARapid responseNo residual alkaliDigestersNon-macromolecular organic additionHigh concentrationSodium metasilicate

The invention relates to a method for boiling high concentration pulping in normal pressure or low pressure by an alkaline method with zero residual alkaline, and the method comprises adding accelerating agent in the boiling process and utilizing a double screw to rub and squeeze a pulper, leading pulp making and boiling process with an alkaline method to go on in normal pressure or low pressure, and leaving no residual alkaline in black liquor, leading pulp to always keep a higher density in the pulping process of boiling, washing and bleaching, and the pulp which is prepared can meets the requirement of paper making. Accelerating agent chooses one or a plurality of magnesium hydrate, potassium hydrate, sodium metasilicate, sodium sulfide, sodium sulfite, ammonium sulfite and carbamide. Special-purpose pulping boiling equipment and high-pressure boilers are not needed by pulping paper mills through utilizing the invention, in the process of pulping, pulp always keeps higher density, and black liquid has high density, little numbers and low energy consumption, alkaline recovery project with great investment is not needed to be built, and the invention enables black liquid to prepare fertilizer or other chemical products with high quality, and the invention is suitable for popularizing and applying.

Owner:晏永祥

Thermodynamic cycle system and method for ammonia water mixed working medium power cooling combined supply

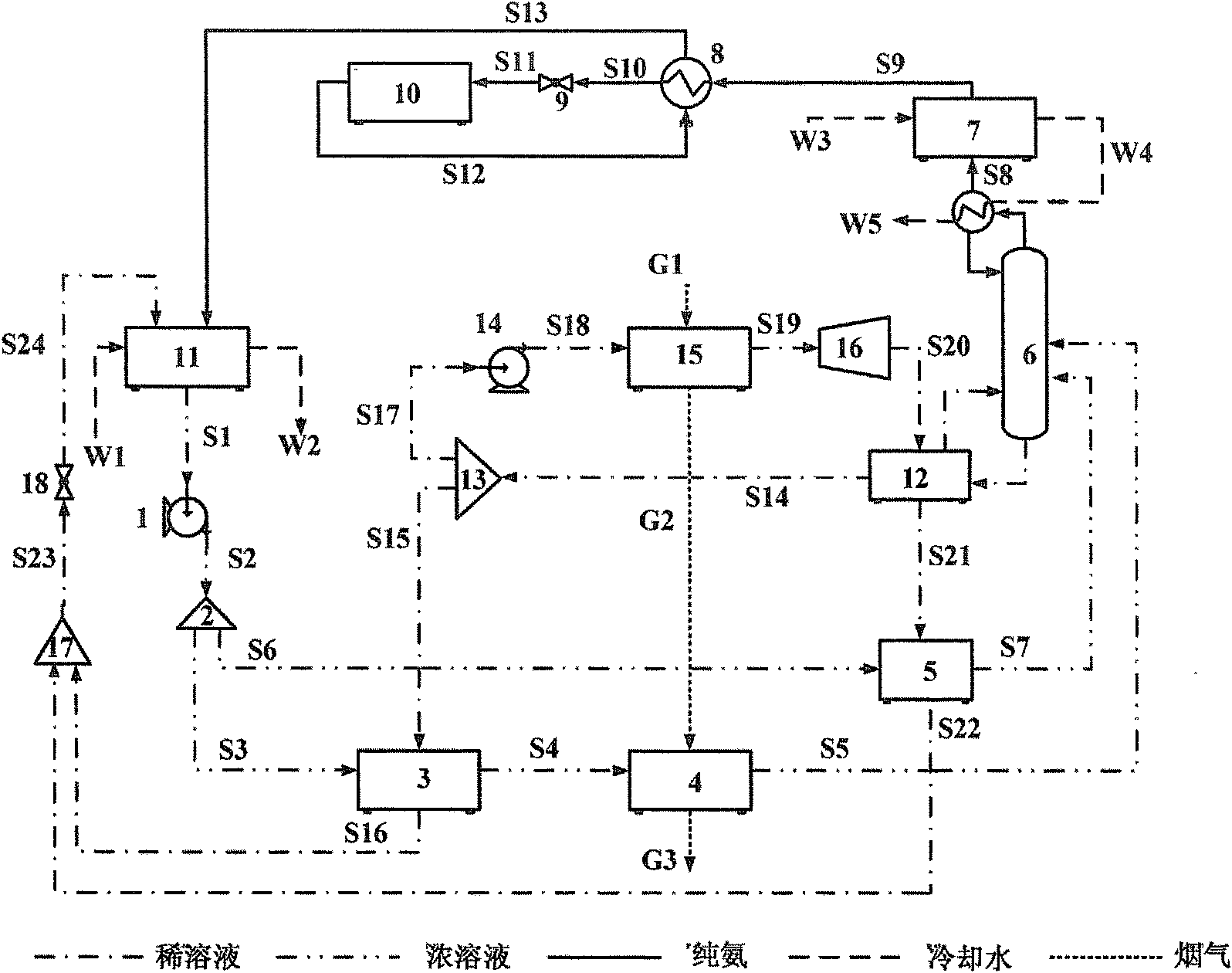

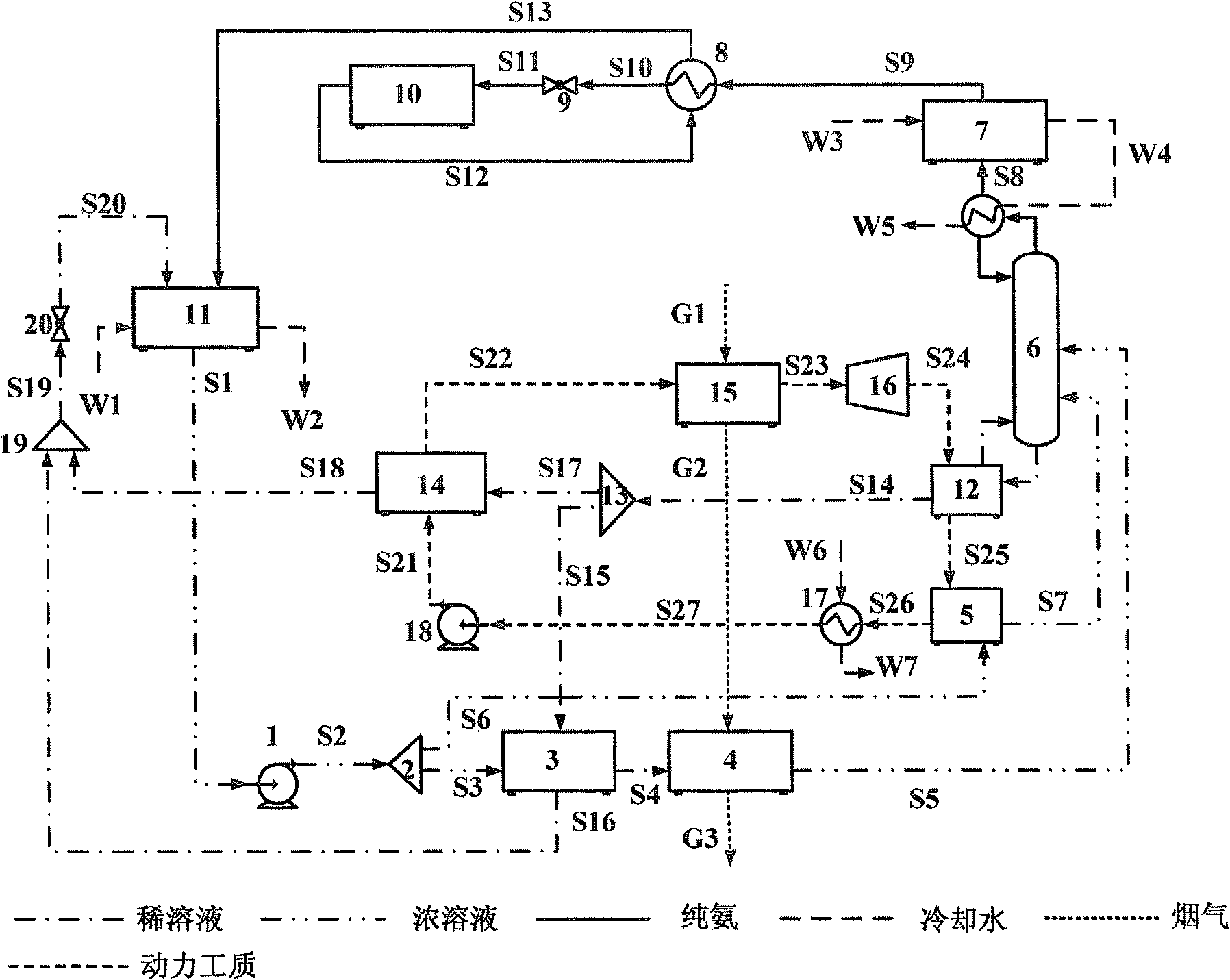

InactiveCN102721230AAchieve the goal of energy saving and emission reductionRealize cascade utilizationClimate change adaptationEnergy efficient heating/coolingSystem integrationBoiling process

The invention discloses a thermodynamic cycle system and method for ammonia water mixed working medium power cooling combined supply. Ammonia water mixture serves as a working medium, and medium-and-low temperature heat serves as a heat source; the thermodynamic cycle system includes a power cycle and a refrigerating cycle; and the power cycle taking the ammonia water mixture as the working medium, the characteristic of temperature-variable evaporation of the working medium is utilized to be excellently matched with a sensible heat source, meanwhile, the temperature-variable condensation of the working medium is utilized to provide heat for the re-boiling process of a tower kettle and the preheating process for partial feeding material of a rectifying tower of the refrigerating cycle. Through the system integration, the high-temperature part of the external heat source is utilized for power cycle, the low-temperature part of the external heat source and the heat extraction of the power cycle are utilized for the refrigerating cycle, the matched temperature and stepped utilization of heat are realized, and compared with the typical dividing system, the performance of the system is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

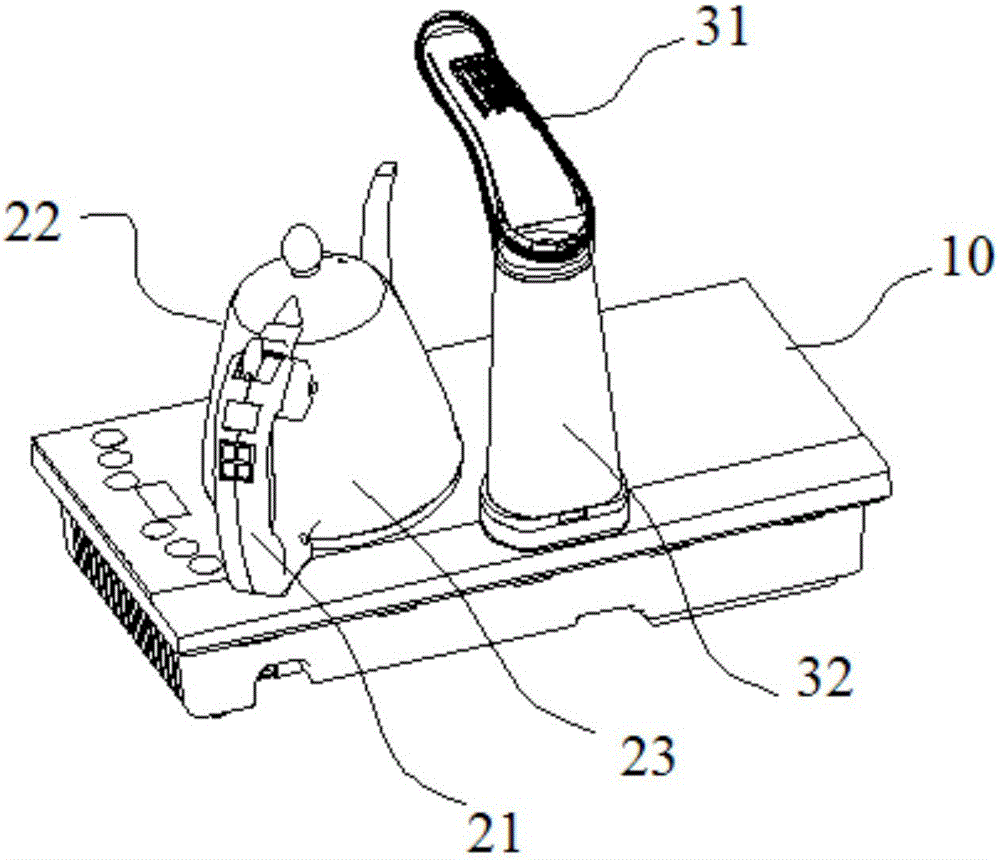

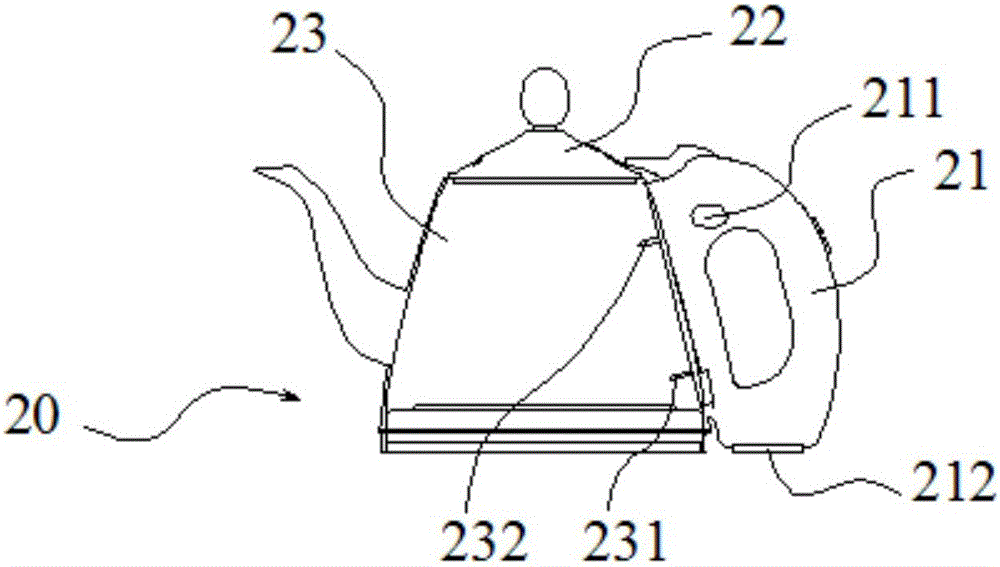

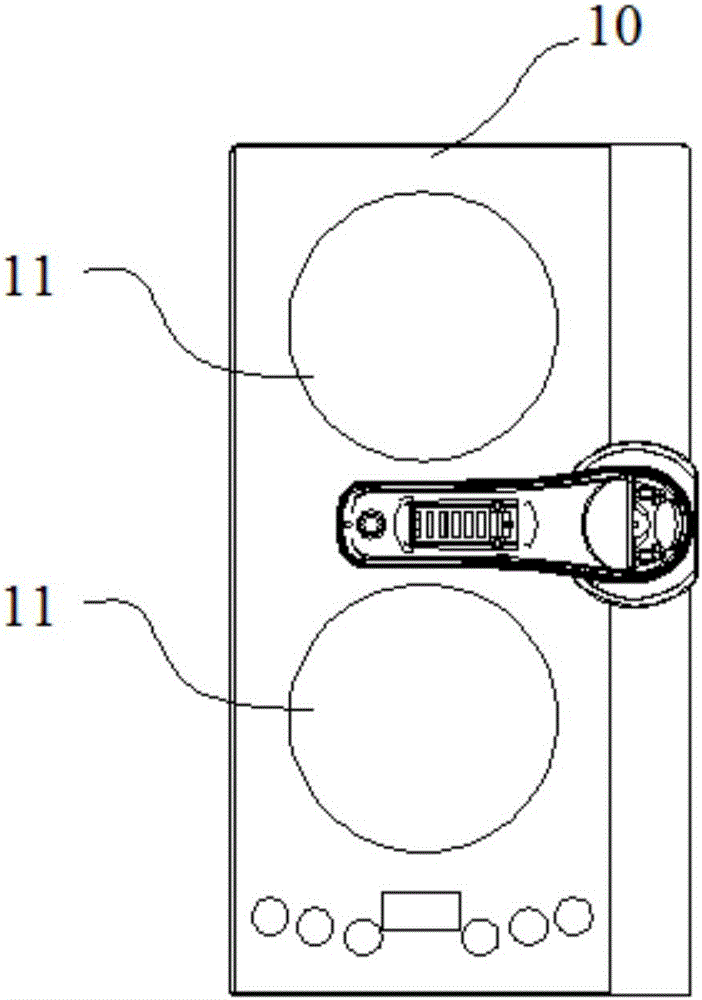

Complete-intelligent water-boiling device, water-boiling system and control method

The invention provides a complete-intelligent water-boiling device, a water-boiling system and a control method. The complete-intelligent water-boiling system and method are designed correspondingly by utilization of an automatic flipping device and an automatic rotary device for a water discharge elbow. By means of various man-machine interaction modes such as key operation of a teakettle or a heating base or operation of an intelligent mobile terminal, one-button intelligent water boiling is performed. The complete-intelligent water-boiling device, the water-boiling system and the control method have following beneficial effects: during the whole water-boiling process including water adding, heating or cooling by opening a cover, complete automation is achieved; a user does not need to perform other operation so that watering operation is performed easily and conveniently; and the complete-intelligent water-boiling device is much safer and more humanized.

Owner:XIAMEN YUEYI ELECTRONICS TECH

Blended yarn of flax and tencel and producing technology thereof

InactiveCN1920138ANo damage to physical and chemical propertiesHygroscopicYarnLiquid/gas/vapor textile treatmentYarnBoiling process

The invention relates to a blended yarn of flax and Tencel fiber, wherein the flax is 50-60%; the Tencel fiber is 40-60%; and its preparation comprises: (1) preparing the flax into blended yarn bar to be mixed with Tencel fiber into bar, and combining the bars into thick yarn; (2) boiling said thick yarn into thin yarn; (3) drying the thin yarn and winding to prepare the blended yarn; and the boiling process in the step (2) comprises: washing with hydric sulphate solution; bleaching with the mixture of sodium chlorite and sodium nitrate; first washing with water; oxygen bleaching with the mixture of sodium carbonate, caustic soda, sodium silicate and hydrogen dioxide solution; second washing with water. The inventive blended yarn has the advantages of two fibers, and the boiling process can increase the spinning number of flax; therefore, the product has crinkle resistance and better brightness, etc.

Owner:XINSHEN GROUP

Production technology for seasoned prawns with soft package

The invention discloses production technology for seasoned prawns with soft package, which is characterized in that the production technology comprises the steps of treating raw materials, pickling, brine boiling, deep frying, seasoning, packaging and the like. The technology saves a pre-boiling process, reduces the content of moisture, and better saves the delicate flavor of prawns and the flavor after the seasoning; the shelf life of products is prolonged through pickling and sterilization working procedures; the fishy smell is better removed; and the production technology has simple operation and easily realizes industrialized production. The seasoned prawns prepared by the technology have good color and luster and unique flavor, and are prawn leisure food which can be directly eaten.

Owner:连云港中医药高等职业技术学校

Method for preparing plant hemicellulose hydrolysis liquid and method for extracting xylose and gum sugar

InactiveCN101880329AAchieve mass productionSolve the capacity problem of popular applicationChemical recyclingHigh concentrationLiquid ratio

The invention provides a method for preparing plant hemicellulose hydrolysis liquid and a method for extracting xylose or gum sugar. The method for preparing the hemicellulose hydrolysis liquid comprises the steps of soaking, acid liquid pretreatment, heating hydrolysis, washing and the like. The problems of low sugar liquid concentration and large acid liquid reclaiming amount caused by a large liquid ratio when flowing water is boiled are solved by adopting a flowing water-free wet material boiling method; and on the other hand, reduction of sugar liquid concentration and dilution of acid liquid caused by changing water vapor into condensed water during directly heating the water vapor and preserving the heat are also avoided by adopting an indirect heating mode in a heat preservation boiling process so as to obtain high-concentration sugar liquid and reduce the concentration of the acid liquid used at initial soaking.

Owner:陈培豪

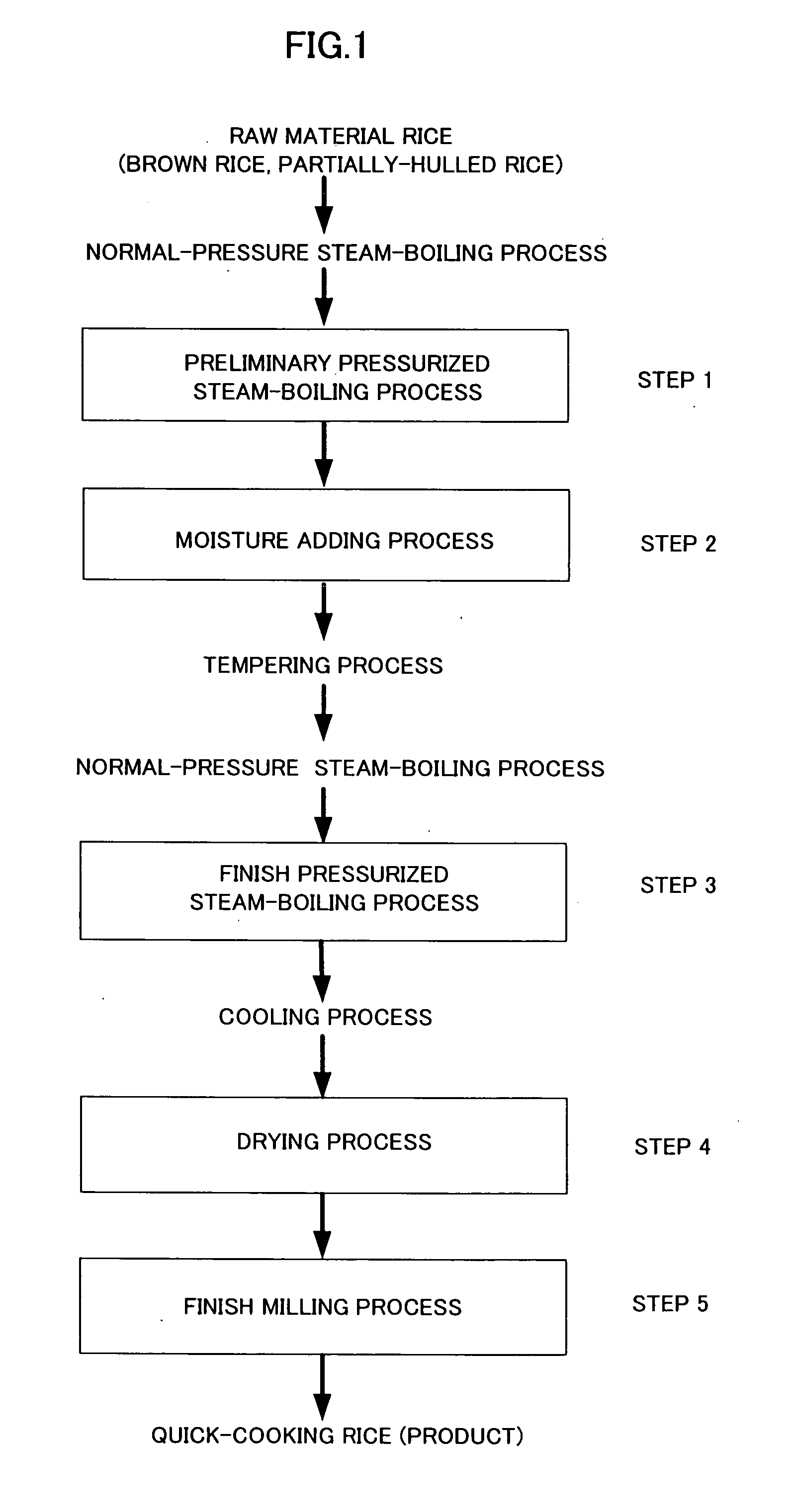

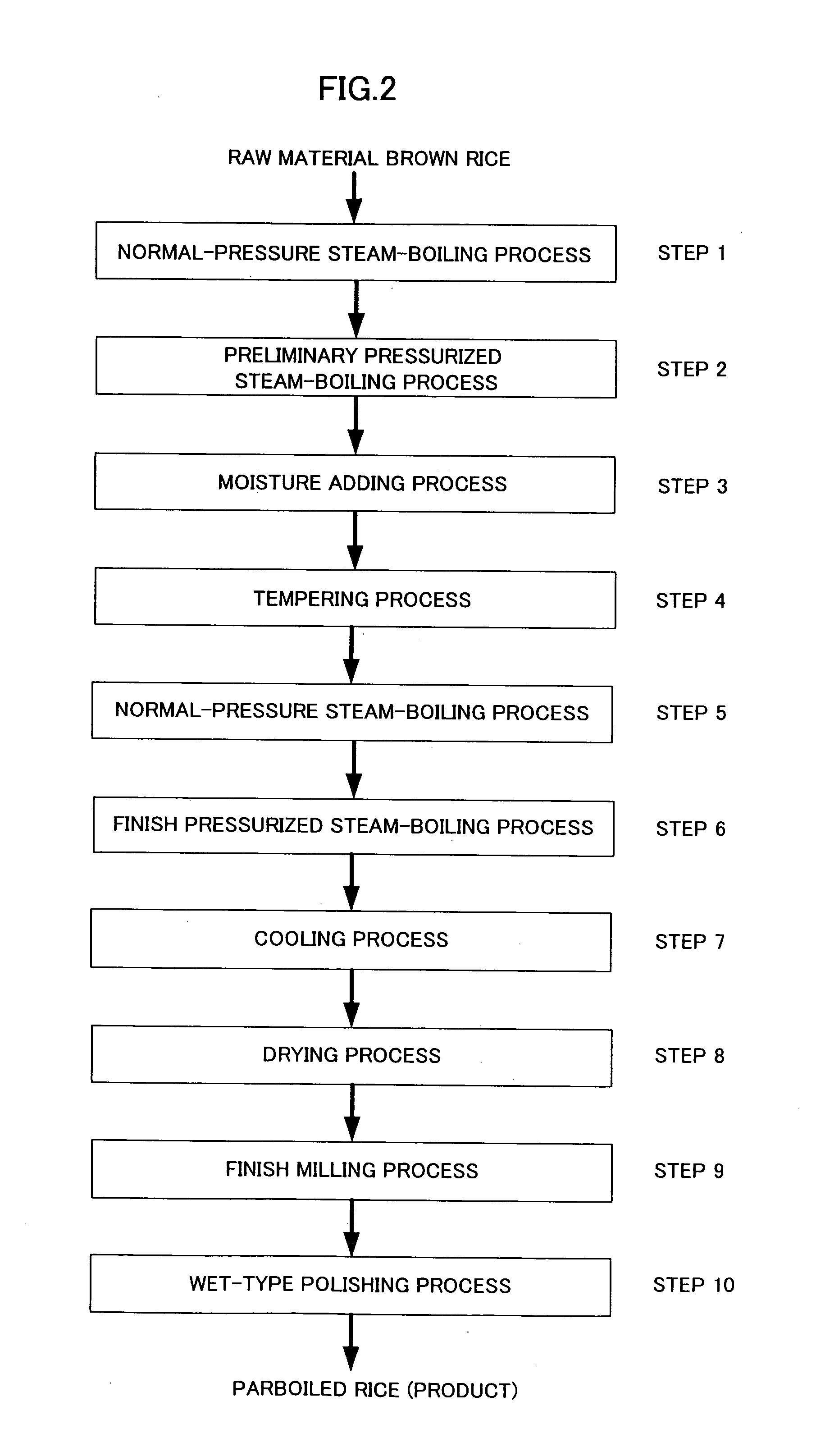

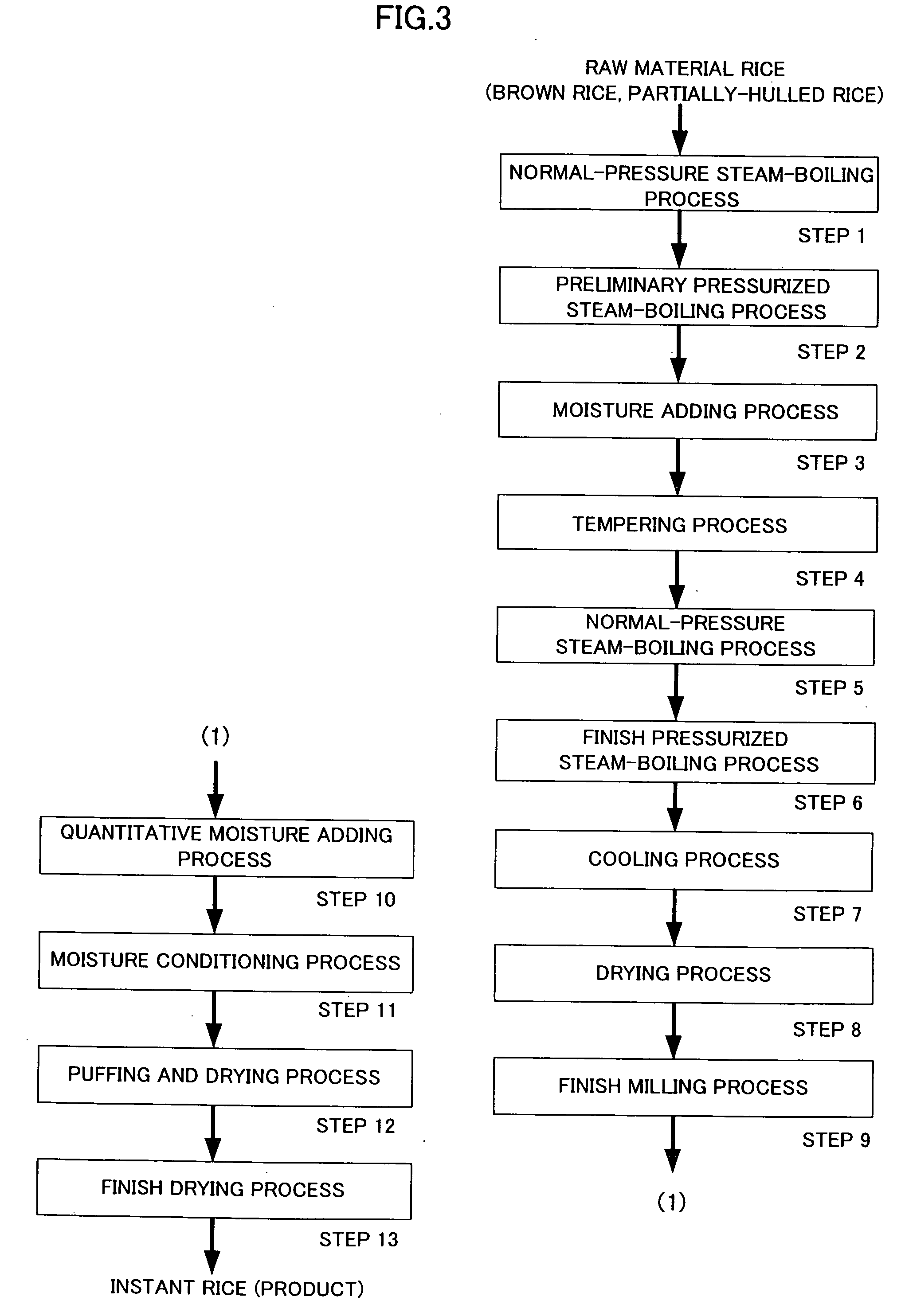

Method for producing quick-cooking rice and quick-cooking rice produced by the method

InactiveUS20100323087A1Quality improvementExtension of timeMeat/fish preservation by heatingFood shapingRice dishesBoiling process

Raw material rice (brown rice and partially-milled rice) is subjected to a preliminary pressurized steam-boiling process to form an alpharized layer on the surface of the raw material rice, and then a moisture adding process is performed. Since the surface of the raw material rice is alpharized to become stiff with the preliminary pressurized steam-boiling process, even rapid moisture addition does not cause a crack in the raw material rice. Therefore, water absorption can be quickly achieved to a target moisture content, thereby reducing a moisture adding time. Also, with no crack, quick-cooking rice with an excellent outer appearance of rice as a product and without a drain of nutrients in rice grains at the time of rice cooking.

Owner:SATAKE CORP

Small brown sugar preparation method

InactiveCN106435043AGreat tastePure tasteSugar productsSugar juice boiling/evaporationFlavorBoiling process

Provided is a small brown sugar preparation method. The method comprises the steps of squeezing sugar cane juice, boiling the juice in a series of pots, controlling the flame in the direction air stove, granulating, and putting the granule sugar in different models for cooling and shape forming to acquire the purely manual brown sugar of different flavors and different shapes. The detailed method comprises the steps of firstly preparing sugar cane juice, then boiling the sugar can juice, at last conducting the shape forming of the brown sugar. The method applies the series pots and direct air stove. The series pot uses five consecutive pots to boiling the sugar cane juice in sequence for multiple cycles. The direct air stove is used to control the heating degree and heating duration to make the heating process to be stable and orderly in the boiling process. The small brown sugar of various shapes processed by various models is both beautiful and attractive. Different spices are positioned under each model to greatly enhance the mouthfeel of the small brown sugar in the tea serving.

Owner:何启华

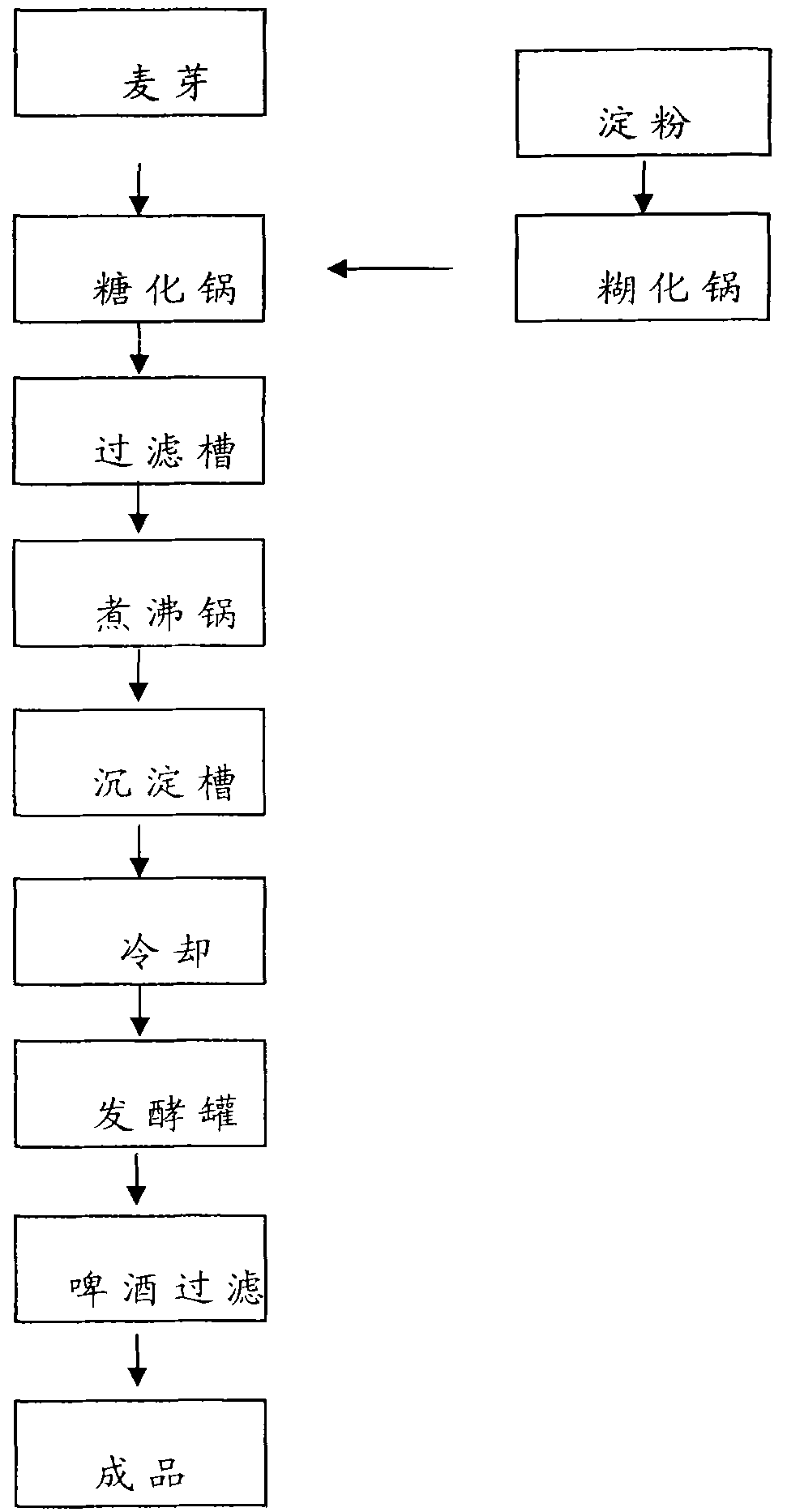

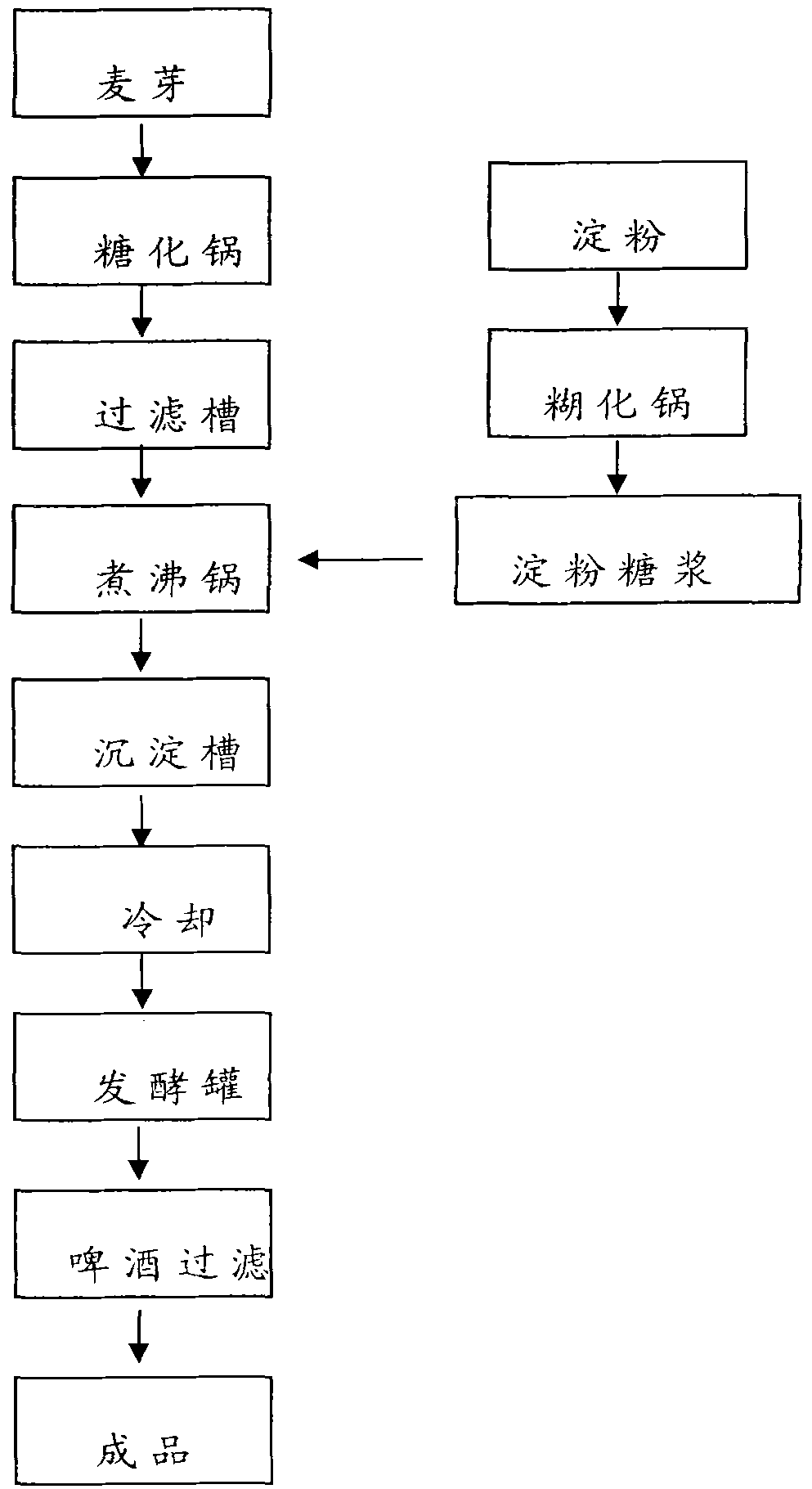

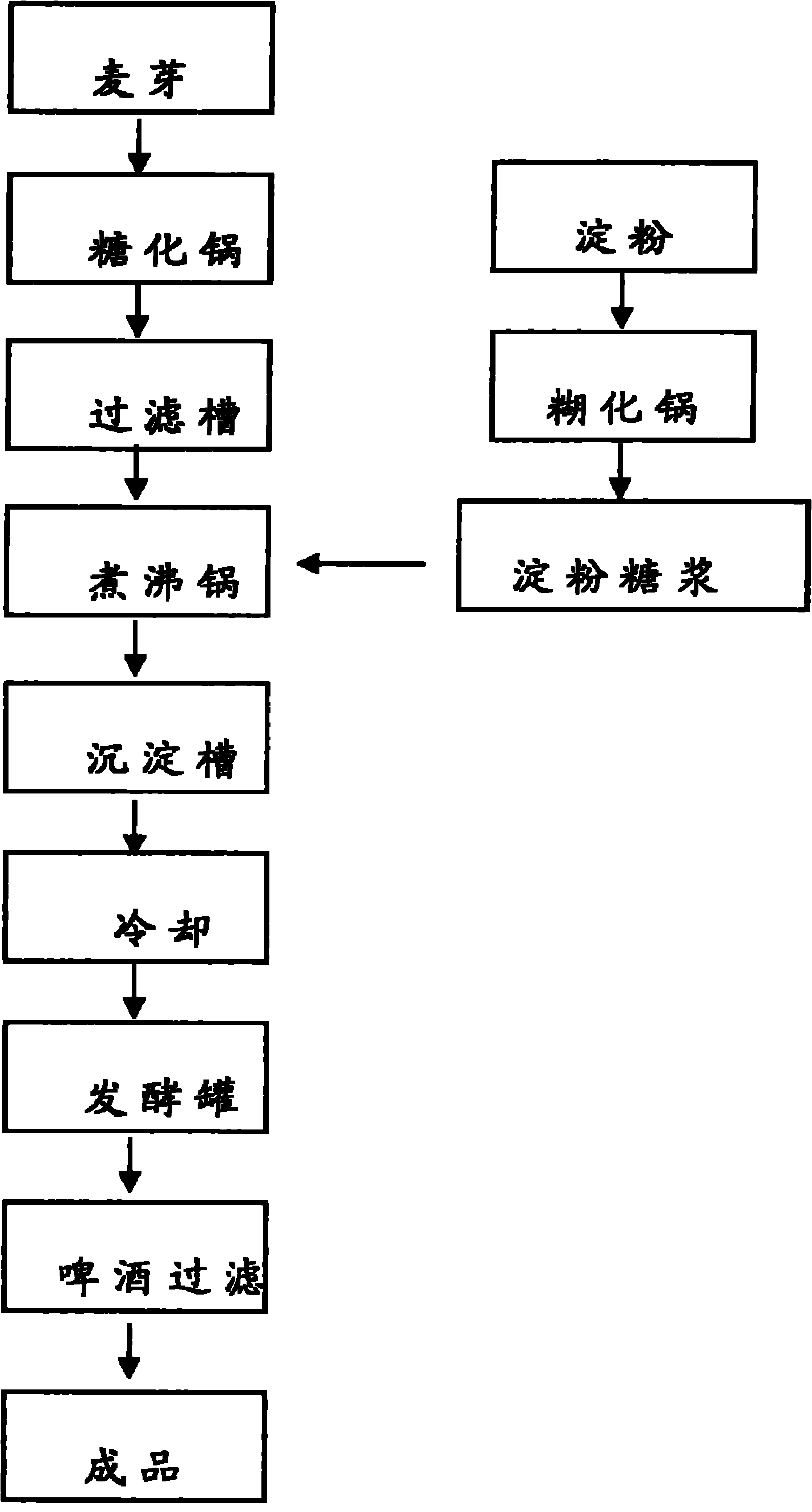

Preparation method of high-concentration malt wort

ActiveCN101845371AIncreased efficiency of conversion to syrupReduce manufacturing costWort preparationHigh concentrationBoiling process

The invention relates to a preparation method of high-concentration malt wort, which comprises the following steps of: boiling the filtered malt wort in a boiler; adding syrup for beer prepared from starch by specific processes and hydrolysis of multiple enzyme preparations in a mash boiler in advance before the boiling process is finished; and then, depositing by rotating and cooling the hot malt wort mixed by the boiler to obtain the high-concentration malt wort. The malt wort of the invention has short preparation period and short conversion time, thereby greatly improving the efficiency for converting starch into syrup. In addition, specific starch decomposition processes are adopted by the invention, the step of secondary liquefaction is increased, and the syrup converted by the compounding technology of three kinds of amylolytic enzyme preparations meets the requirements of beer brewing, thus a brewery can save the transportation cost of syrup purchase and a large amount of energy consumption in the processes of preparation and concentration of bought-in syrup. Meanwhile, the syrup for beer brewing, which is prepared from starch, is directly added into the boiler and does not need to participate in the whole process of boiling malt wort, thereby reducing the production cost of beer malt wort, and saving the energy consumption.

Owner:TSINGTAO BREWERY

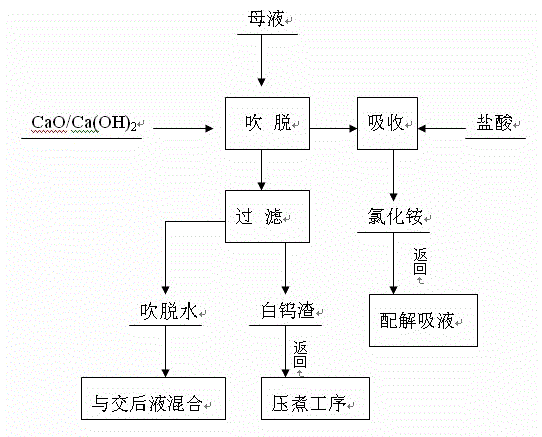

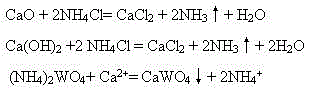

Method for recycling tungsten and ammonia in one step from ammonium paratungstate crystallization mother solution smelt through tungsten

InactiveCN102910648ALow costMature smelting technologyTungsten oxides/hydroxidesAmmonia preparation/separationBoiling processSlag

The invention discloses a method for recycling tungsten and ammonia in one step from an ammonium paratungstate crystallization mother solution smelt through tungsten. After the ammonium paratungstate (APT) is subjected to evaporative crystallization, a mother solution is pumped into a reaction kettle for stripping treatment, calcium oxide with content above 90% or calcium hydroxide with content above 95% are added into the mother solution, a stripping process which is commonly used in the crystallization mother solution in the APT preparation process is utilized to recycle the ammonia, the reaction temperature is in a range from 25 DEG C to 90 DEG C, when the ammonia is subjected to gas-liquid separation through condensation concentration, the ammonia is sprayed with a hydrochloric acid to prepare ammonium chloride to return to a main process to prepare an analytical solution, white tungsten slag returns to a pressure boiling process, when a potential of hydrogen (pH) value of a reaction system is maintained in a range from 9 to 11 and concentration of ammonia nitrogen in water is reduced to about 30mg / L, the reaction is finished, and a waste liquid free of the ammonia nitrogen is subjected to a mixing treatment with an ion exchange post-liquid which is generated in the main process working procedure. The method has the advantages that the process procedures are greatly simplified, the tungsten deposition rate is high, the process is simple, the operation is easy, and the treating cost is slightly low.

Owner:ZHONGXIANG TUNGSTEN IND

Soft and insulation high wet-absorption fabric and preparation method thereof

InactiveCN105803635AImprove water absorptionImprove quick-drying performanceSucessive textile treatmentsWoven fabricsBoiling processEngineering

The invention relates to a soft and insulation high wet-absorption fabric, which is prepared by postprocessing including boiling gray fabric, wherein the gray fabric is prepared by interweaving warp yarns and weft yarns; the warp yarns and / or the weft yarns adopt covering yarns with yarn cores being modified polyester fiber; the modified polyester fiber is dissolved during the boiling process to enable the warp yarns and / or the weft yarns adopting the covering yarns to have a hollow structure finally; the modified polyester fiber is modified polyester filament yarns dissolved under the alkaline condition. According to the fabric provided by the invention, the conduction of heat can be reduced, and more heat can be reserved, and a heat insulation function is realized. According to the hollow structure, the comfort in wearing and use is improved, meanwhile, the water absorbing capacity and the quick dry capacity of the fabric are improved, and better comfortable and good feeling is brought.

Owner:JIANGSU HONGLIU BEDSHEET LIMITED

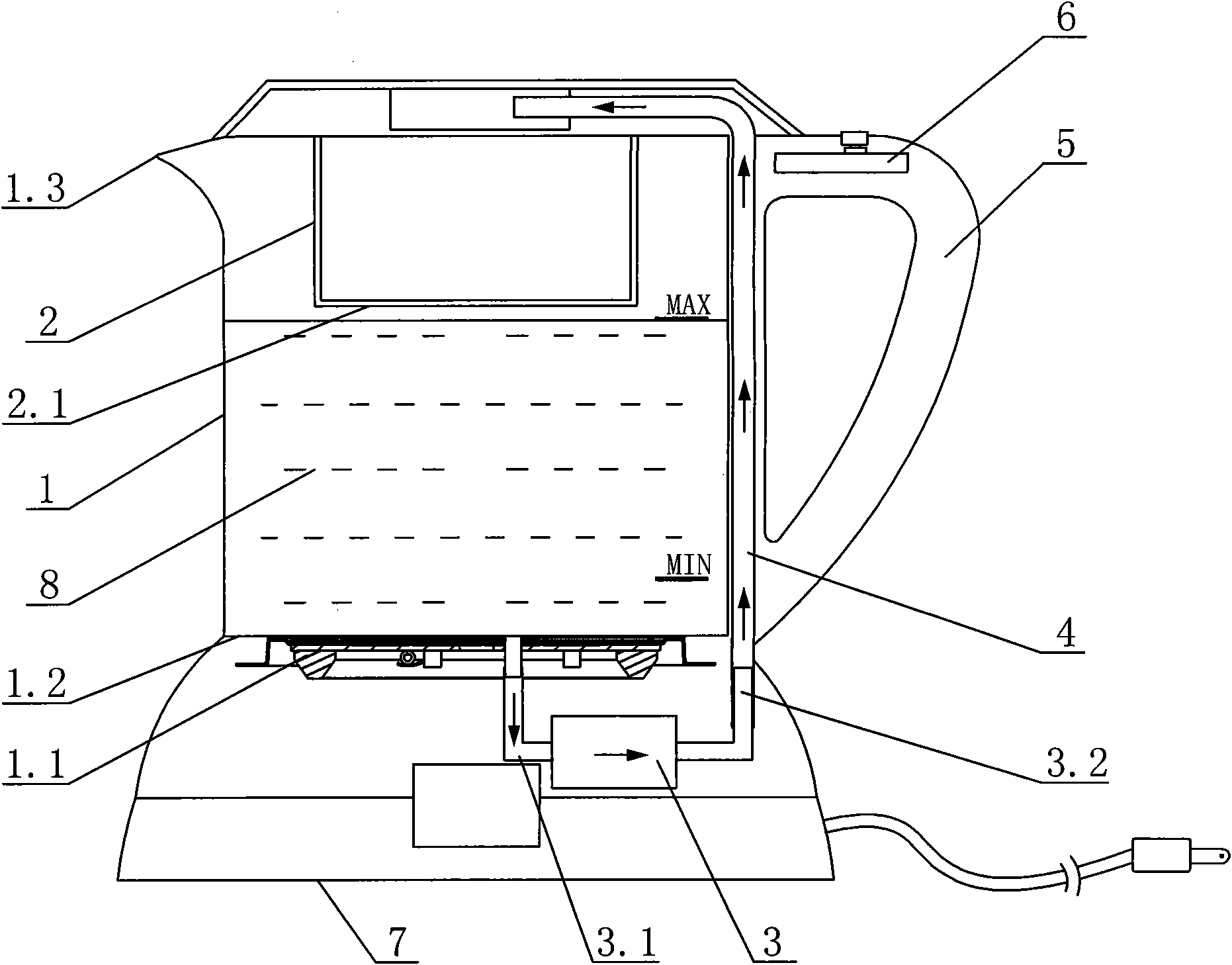

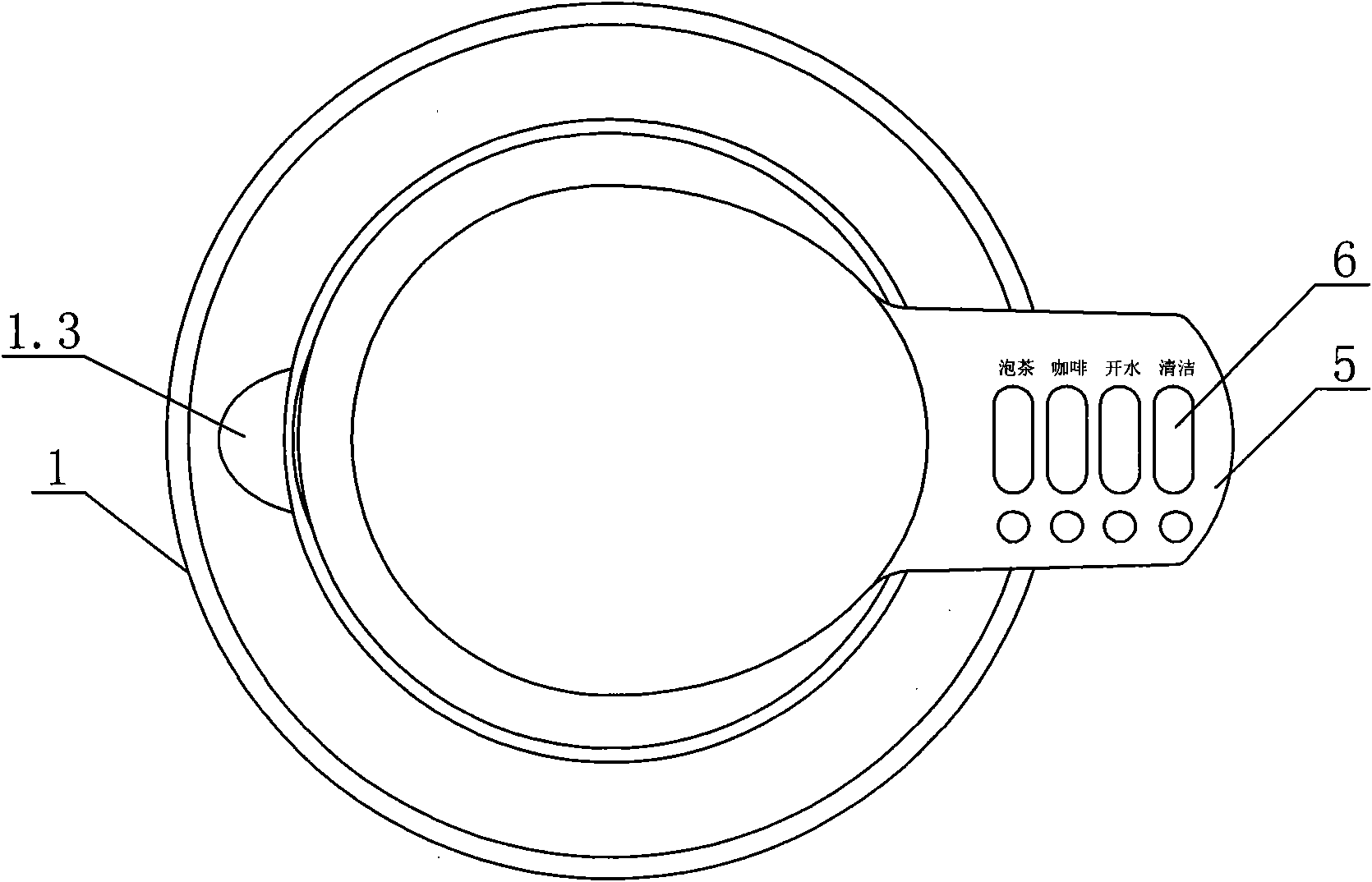

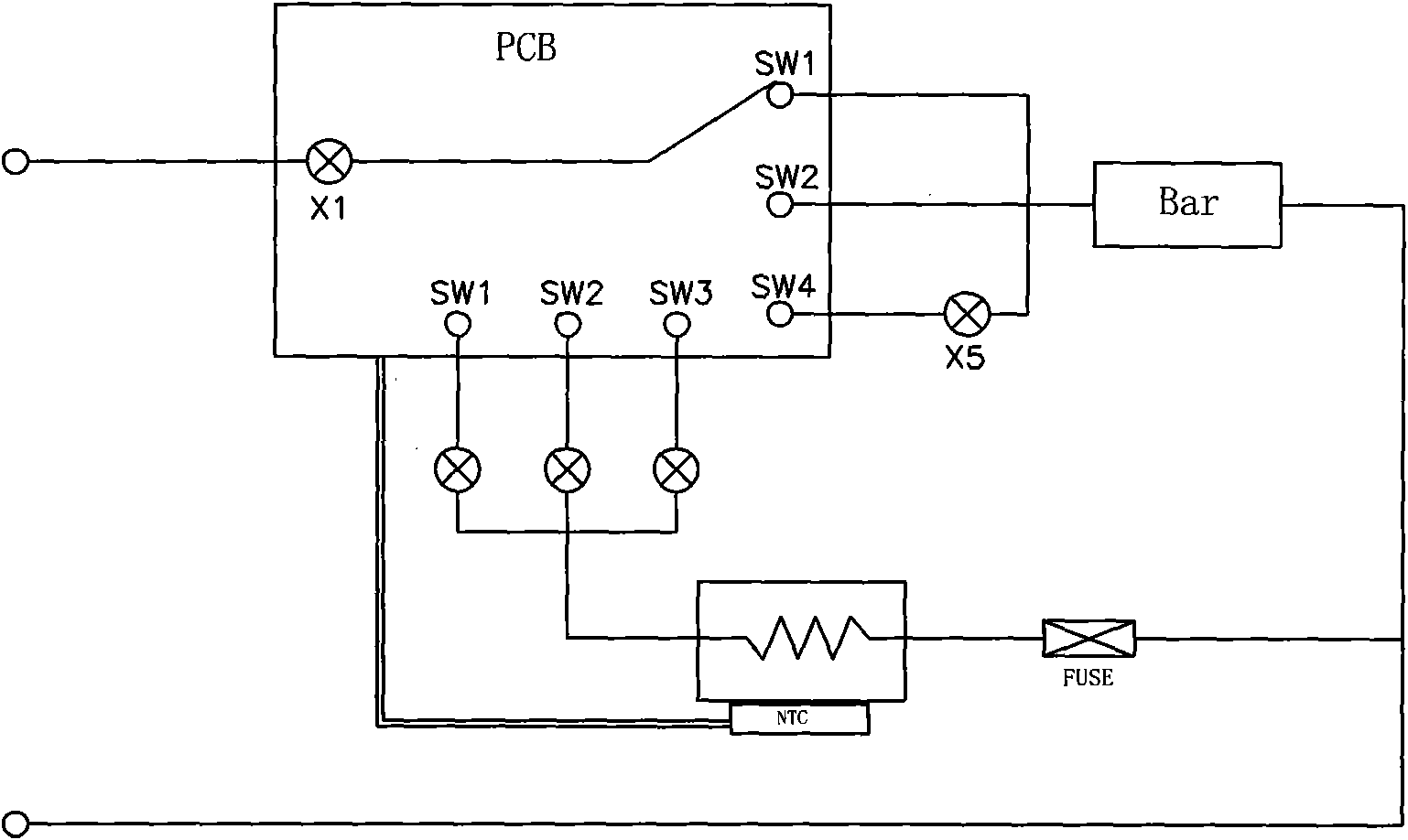

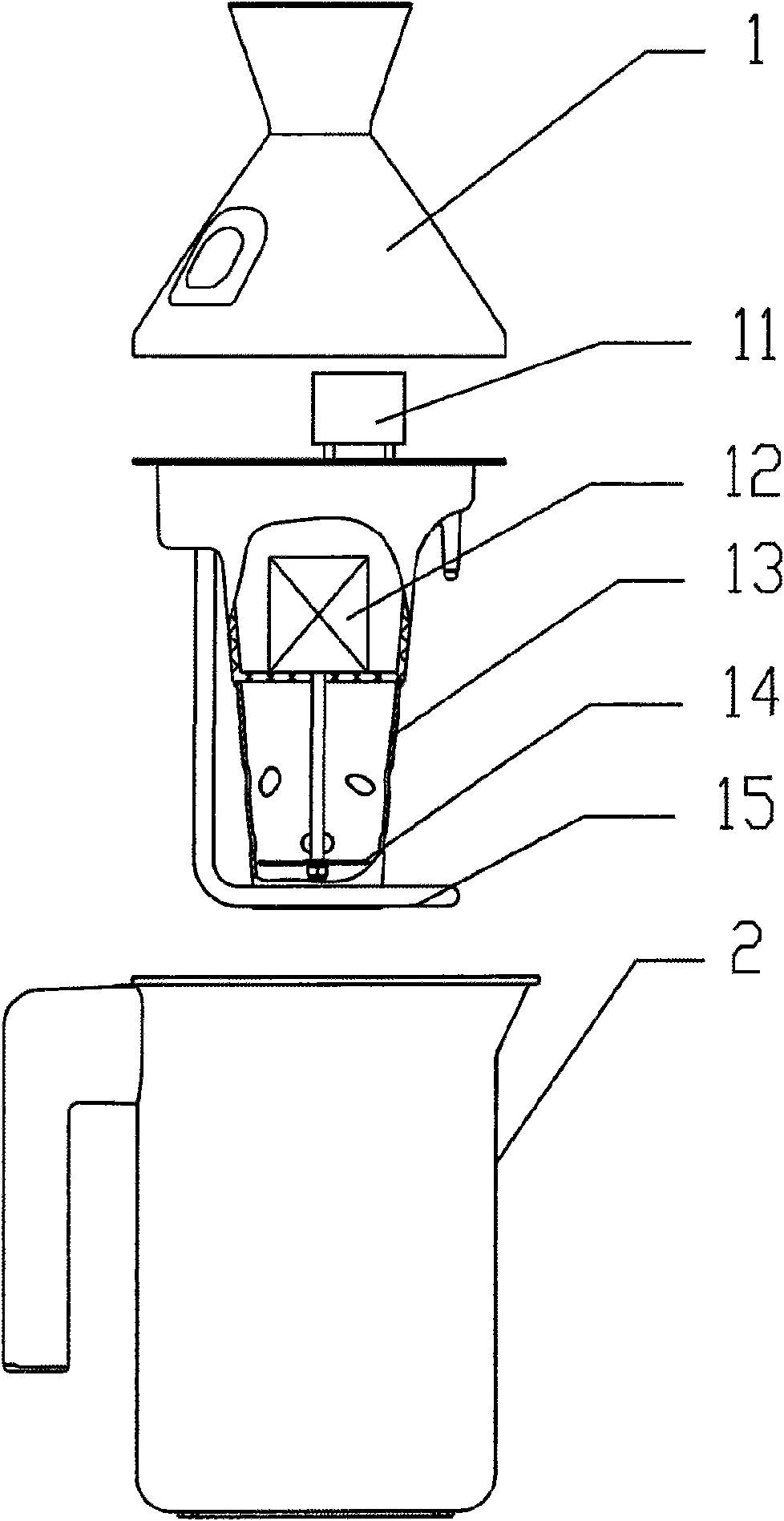

Full-automatic beverage brewing machine

InactiveCN102178455AInhibition releaseFit for drinkingBeverage vesselsBoiling processAdditive ingredient

The invention relates to a full-automatic beverage brewing machine, comprising a pot body and a power supply base, wherein the pot body comprises a heating cavity and a brewing cavity movably connected with the heating cavity, a circulating assembly is arranged between the brewing cavity and the heating cavity to jointly form a water loop. The circulating assembly comprises a water pump and a water circulation pipeline connected with the water pump. In the invention, the circulating assembly is additionally arranged to jointly form the water loop, and a gap is kept between the brewing cavity and the highest water level line MAX of the heating cavity, thus the heating cavity is separated from the brewing cavity, a brewed matter is ensured to be not in direct contact with the heating cavity in a water boiling process, and the brewed matter can be effectively prevented from releasing harmful ingredients after being soaked at high temperature for a long time; and the active ingredients of the brewed matter can be rapidly extracted, and the extraction concentration can be controlled, thus brewed beverage is applicable to the crowd with different tastes. By adopting the full-automatic beverage brewing machine, coffee and tea can be brewed, milk powder can be mixed, or a traditional Chinese medicine can be decocted, thus different beverages can be obtained; and the full-automatic beverage brewing machine has the characteristics of simple and reasonable structure, low cost, simplicity and convenience in operation and convenience in processing and production, multiple purposes of the machine can be achieved, and the practicability of a product is increased.

Owner:廖志文

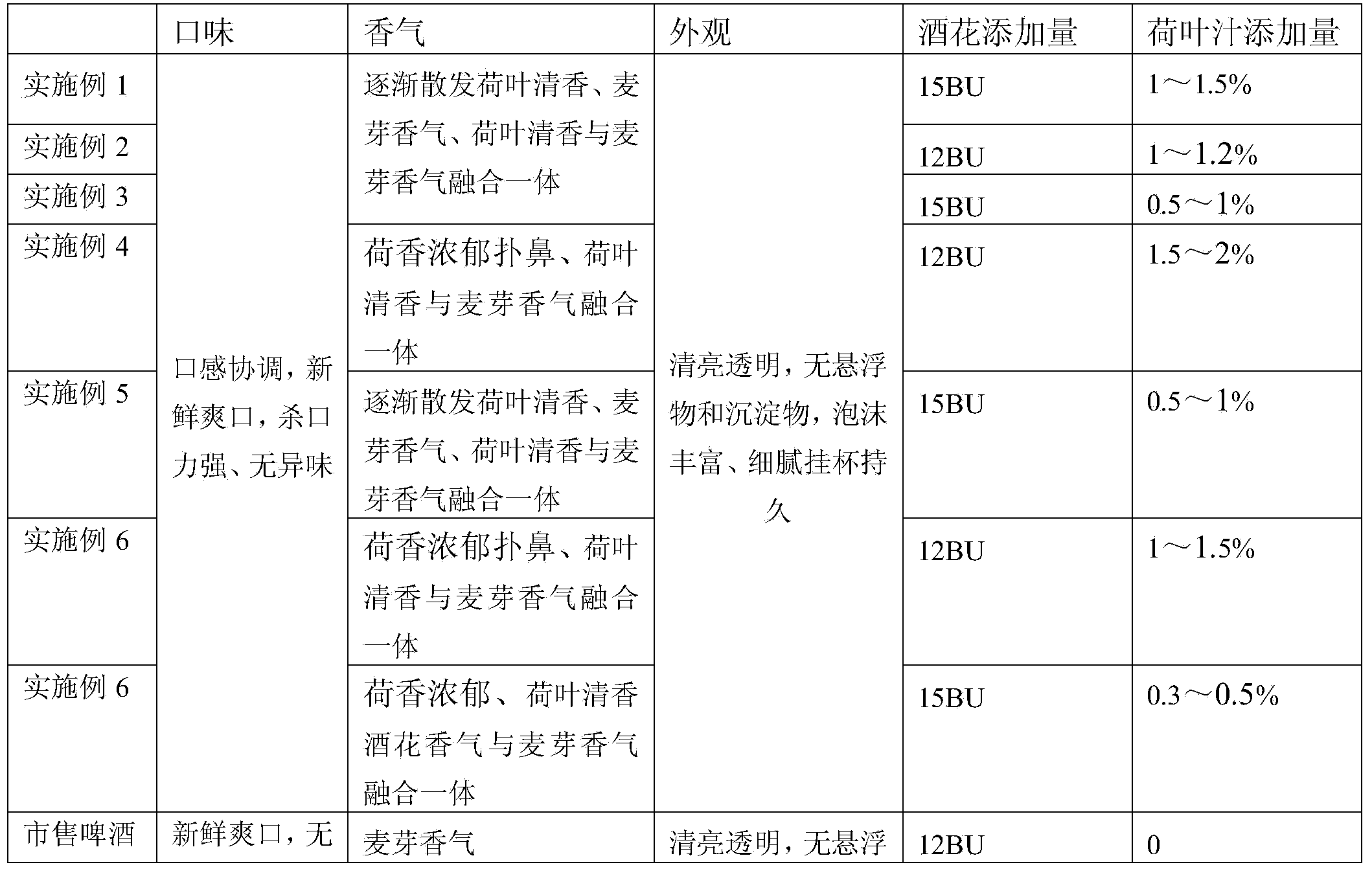

Preparation method for lotus leaf health-care beer

The invention relates to a preparation method for lotus leaf health-care beer. The preparation method comprises the following steps: juicing lotus leaves to obtain lotus leaf juice; mixing and crushing barley malt and wheat malt, and then adding water to obtain mixed mash; saccharifying the mixed mash at the temperature of 44-78DEG C; after the saccharification is ended, filtering, boiling, precipitating, cooling, oxygenating, performing primary fermentation, diacetyl reduction, cooling, post fermentation, post storage and filtering, and operating according to a conventional preparation process of beer fermentation; adding the lotus leaf juice in the boiling process or after post storage and before filtering beer; filling and sterilizing to obtain the lotus leaf health-care beer. According to the preparation method disclosed by the invention, the usage amount of hops is reduced; the stability of wort is improved by using polyphenol in the lotus leaves, so that the forming degree of the beer is improved; the lotus leaf juice is added in the beer during the boiling of the wort or before filtering, so that the faint scent of the lotus leaves and the beer can be better fused together; the prepared lotus leaf health-care beer retains the flavor of fresh malt beer, has faint scent and lotus fragrance of the lotus leaves and has the advantages of pure flavor, freshness, tasty and unique taste; besides, the staying power of beer foam is improved.

Owner:山东巴克斯啤酒有限公司

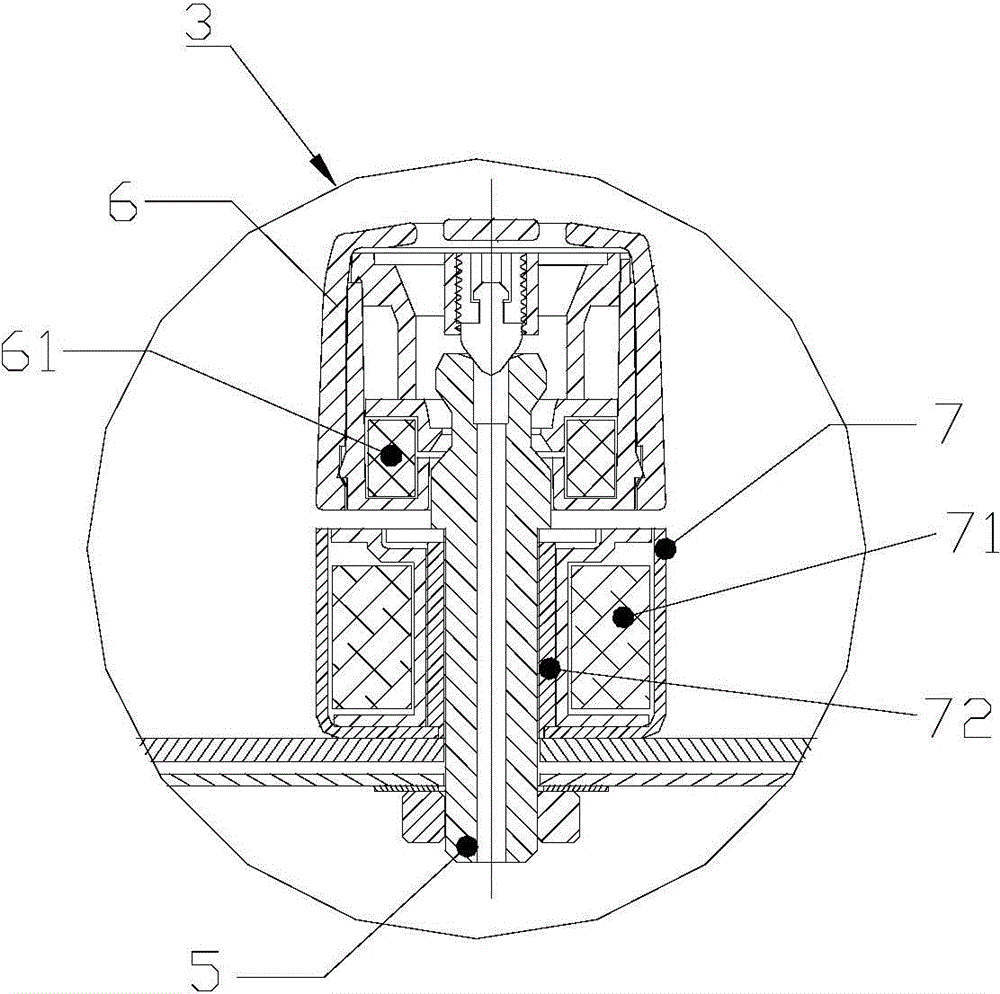

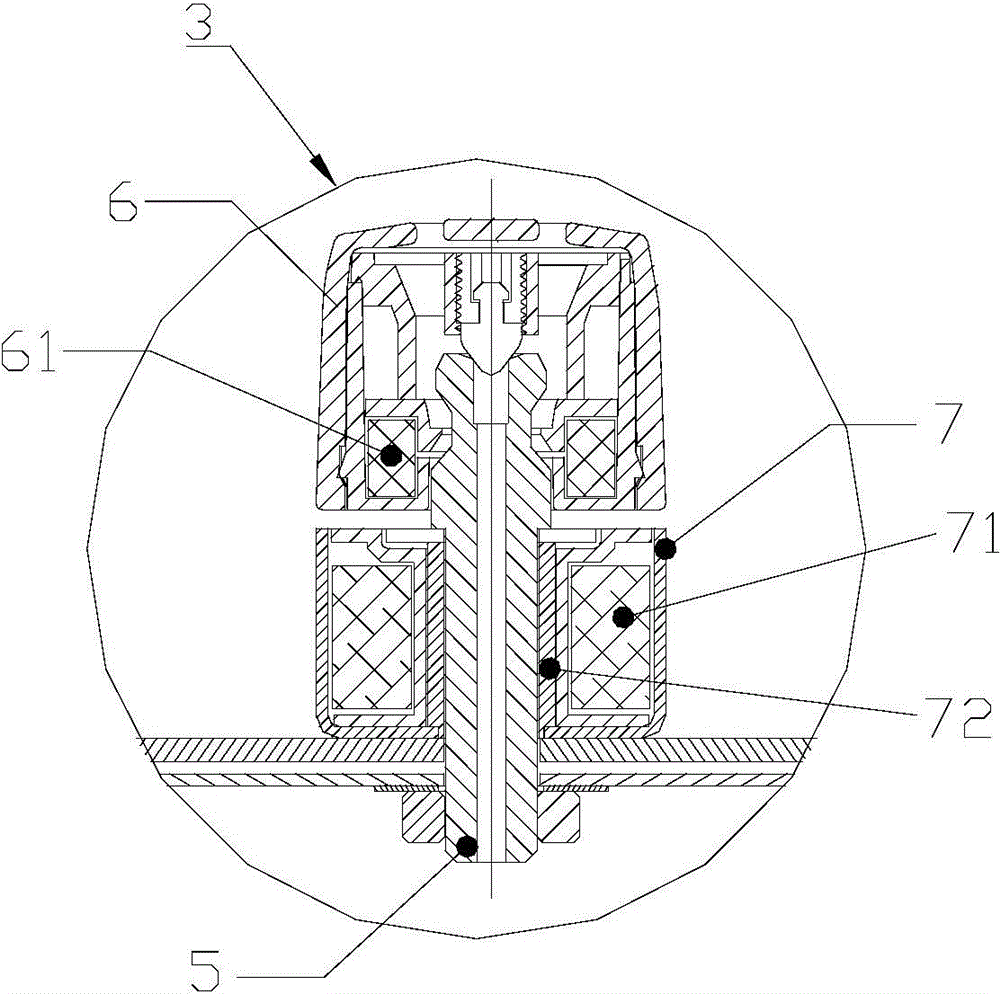

Pressure cooking appliance and cooking control method thereof

InactiveCN106136869ASolve the problem of not thickPromote absorptionPressure-cookersBoiling processMagnetic valve

The invention discloses a pressure cooking appliance and a cooking control method thereof. The cooking control method comprises the following processes: a heating process: controlling a heating device to conduct heating at first power until at least one parameter of pressure and temperature in the appliance meets the preset pressure boosting requirement; a preset pressure process: controlling the heating device to conduct heating at second power until at least one parameter meets the preset pressure maintaining requirement; a pressure maintaining process: controlling the heating device to control at least one parameter to keep constant until the preset pressure maintaining time; a pressure reducing process: controlling the heating device and a magnetic valve device to enable at least one parameter to meet the preset pressure reducing requirement; a boiling process: controlling the magnetic valve device to enable the pressure cooking appliance to alternatively conduct high-pressure continuous boiling and low-pressure boiling until the preset boiling time. According to the cooking control method, food cooked by the pressure cooking appliance is rich in soup, and more nutrient substances are dissolved in the soup, and are convenient to absorb by a human body.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

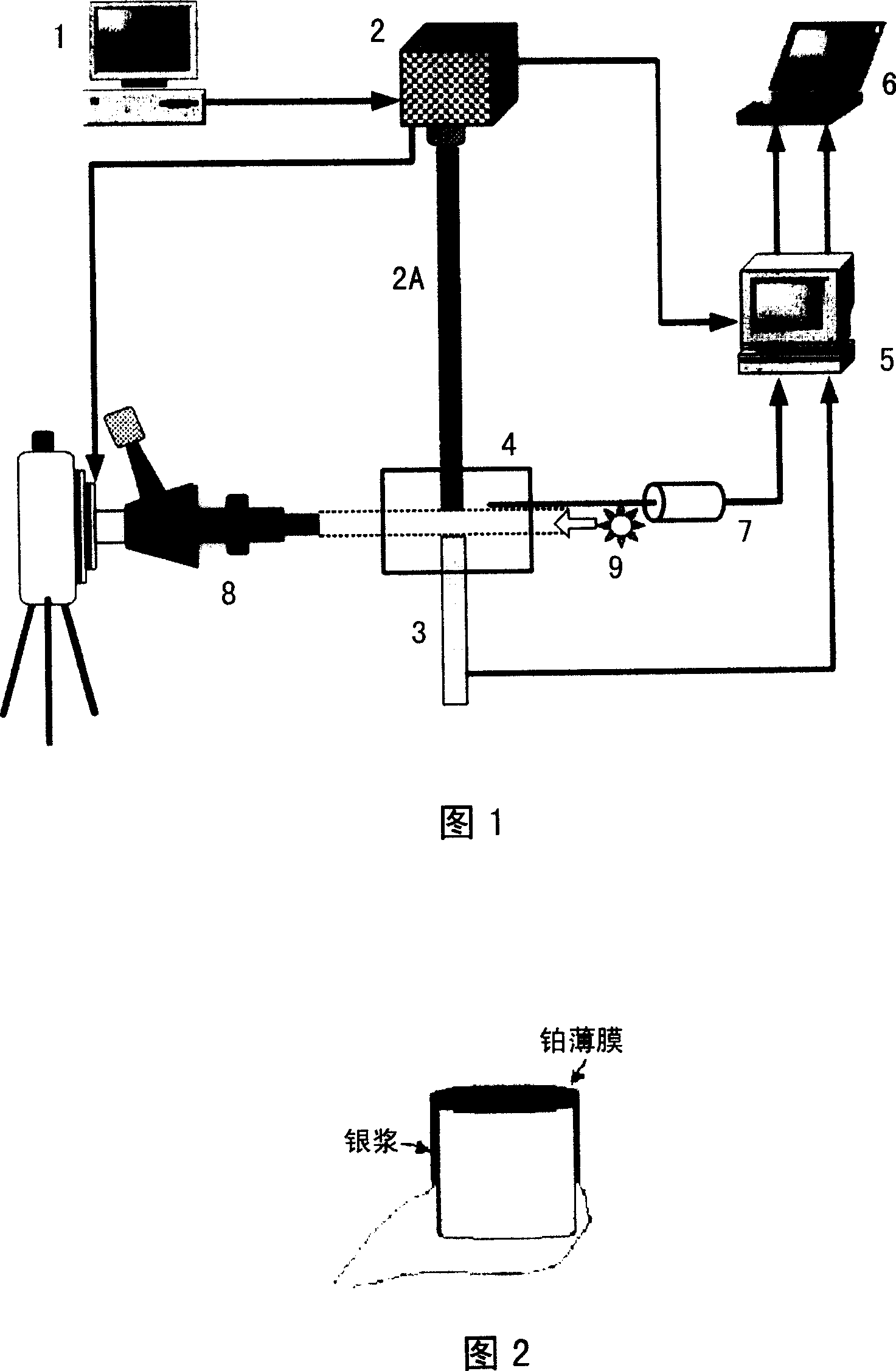

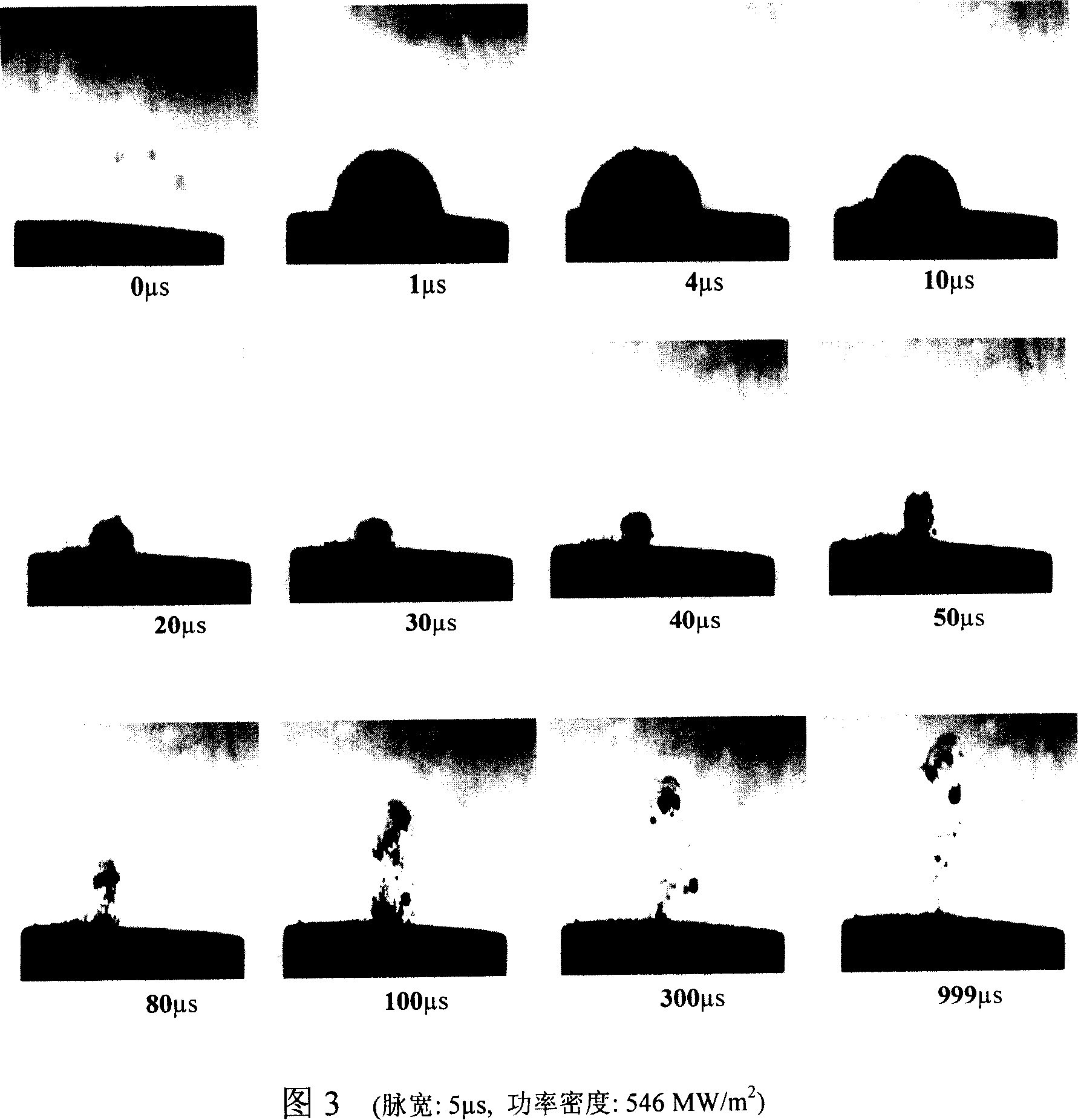

Visual inspection and transient measurement system for micro-scale explosive boiling process

InactiveCN1995985AGuaranteed instantaneousGuaranteed accuracyMaterial analysis by optical meansInvestigating phase/state changeCamera lensBoiling process

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

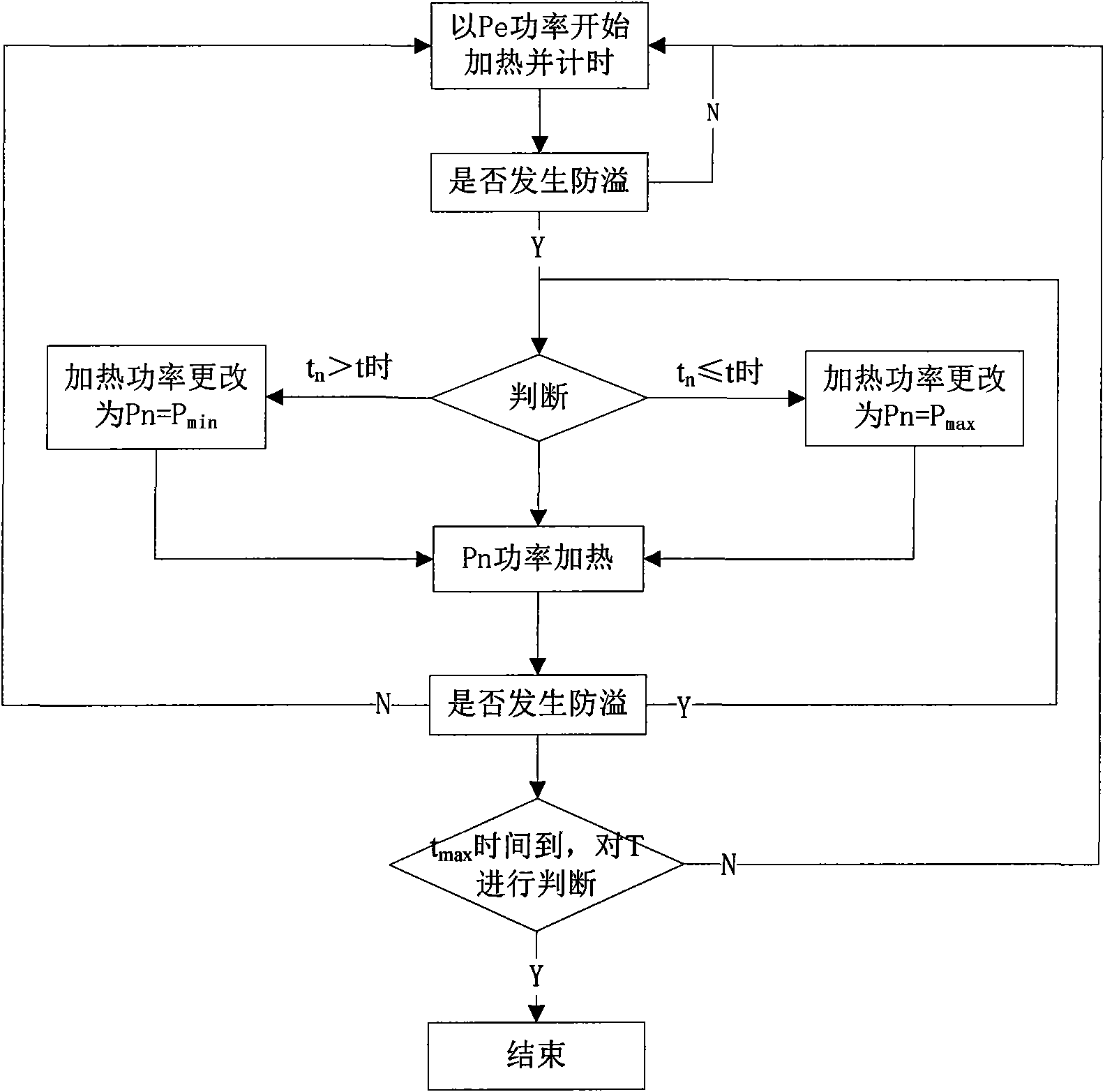

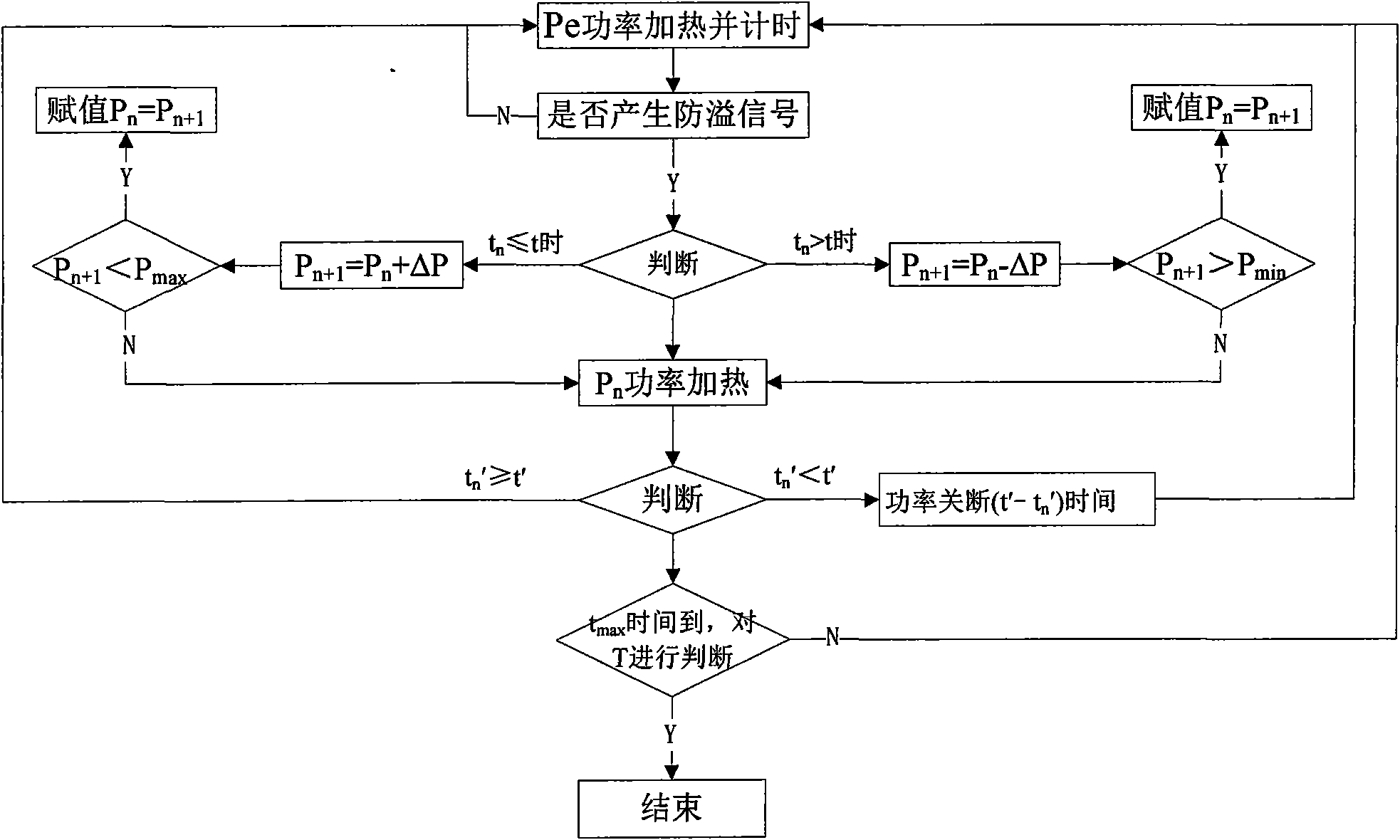

Soymilk boiling method and soymilk making machine

The invention relates to a boiling method for beverage and a food processing machine for realizing the boiling method, in particular to a soymilk boiling method and a soymilk making machine. The soymilk boiling method comprises a process of heating soymilk by a heating device and a control process for preventing the soymilk from overflowing, wherein the rated power of the heating device is Pe, the reference value of the overflowing time of the soymilk is t, and the actual value of the overflowing time of the soymilk is tn. The soymilk boiling method is characterized in that the soymilk boiling method has a process for judging the tn after the soymilk touches an anti-overflowing electrode, and the method determines the actual heating power Pn for heating the soymilk by the heating device through the judgment of tn so that the soymilk is in a heating state all the time during the whole soymilk boiling process. The invention provides the soymilk boiling method with high soymilk boiling efficiency and good mouthfeel of the soymilk, and the soymilk making machine for realizing the soymilk boiling method with simple structure and convenient operation.

Owner:JOYOUNG CO LTD

Pressure cooking utensil and cooling control method thereof

InactiveCN105877475AReduce the hassle of cleaningSolve the problem of not thickPressure-cookersPressure riseBoiling process

The invention discloses a cooling control method of a pressure cooking utensil. The method comprises the following steps: a heating process: controlling a heating device to perform heating at a first power till at least one parameter of pressure and temperature in the utensil meets a preset pressure rising requirement; a pressure rising process: controlling the heating device to perform heating at a second power till at least one parameter meets a preset pressure maintaining requirement; a pressure maintaining process: controlling at least one parameter to remain unchanged by controlling the heating device till a preset pressure maintaining time is achieved; a boiling process: controlling the pressure cooking utensil to perform pressure boiling, and controlling the pressure cooking utensil to perform normal pressure boiling when at least one parameter meets a preset pressure dropping requirement till a preset boiling time is achieved. The method can solve the problem that food soup cooked by the existing pressure cooking utensil is not thick, and ensures that more nutrient substance is dissolved in the soup and is convenient for human body to absorb. The invention further discloses a pressure cooking utensil.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com