Patents

Literature

348results about "Upholstery filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

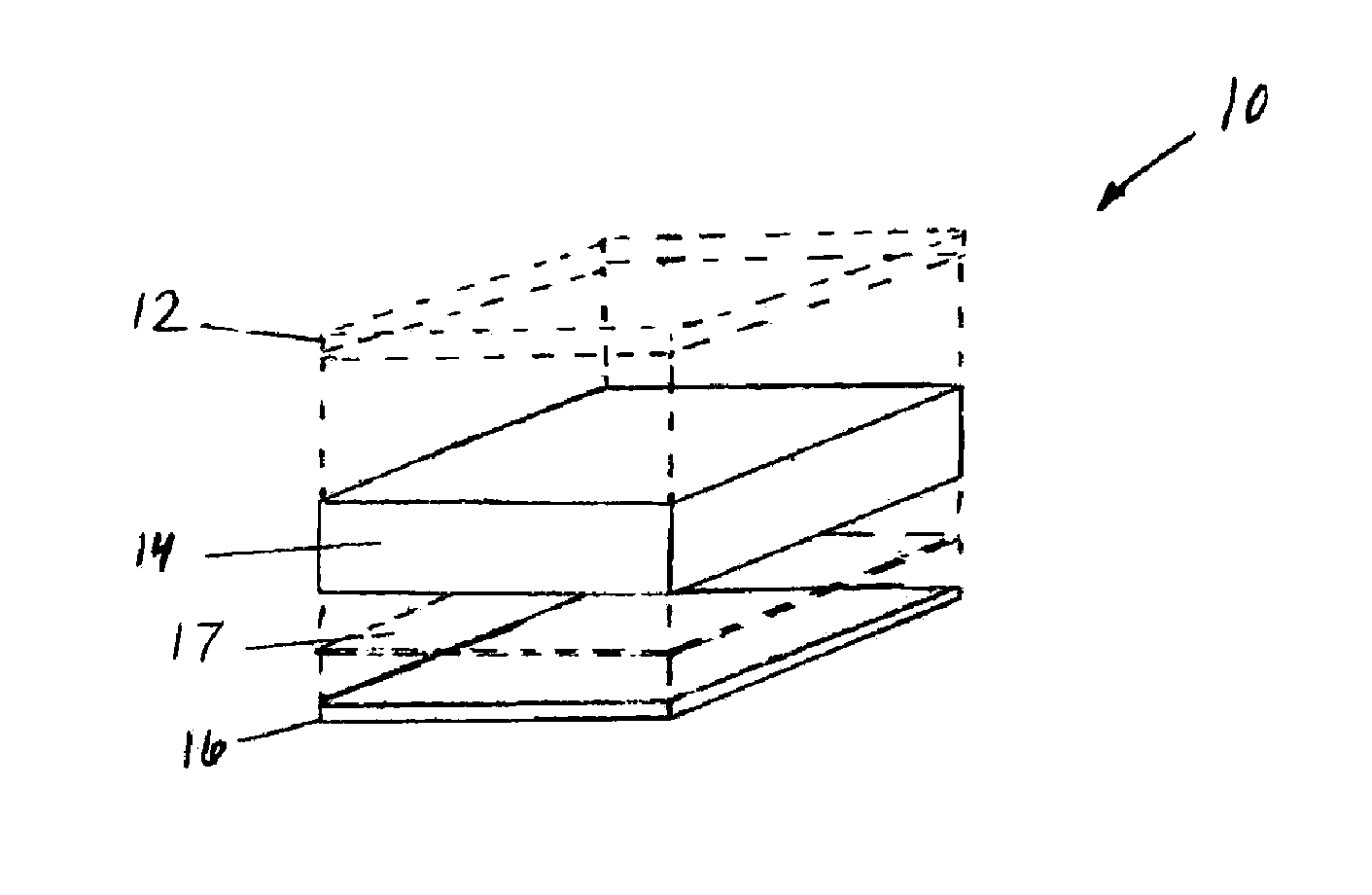

Comfort pillow

Owner:TEMPUR WORLD

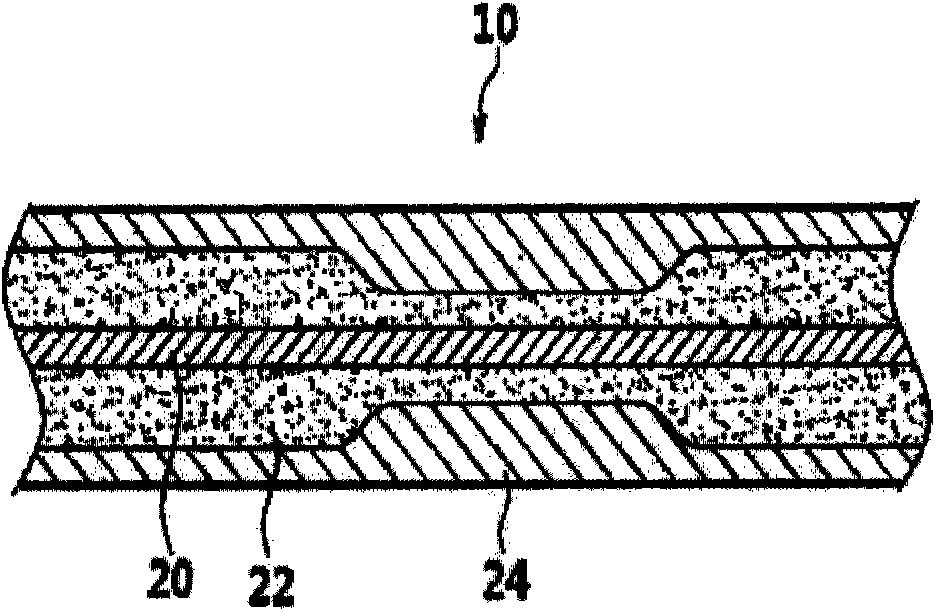

Component with multiple layers

Owner:SERTA

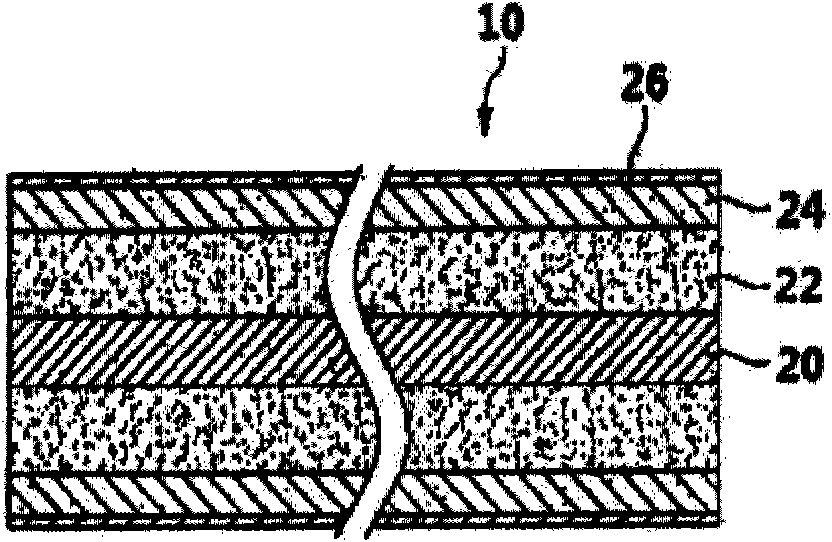

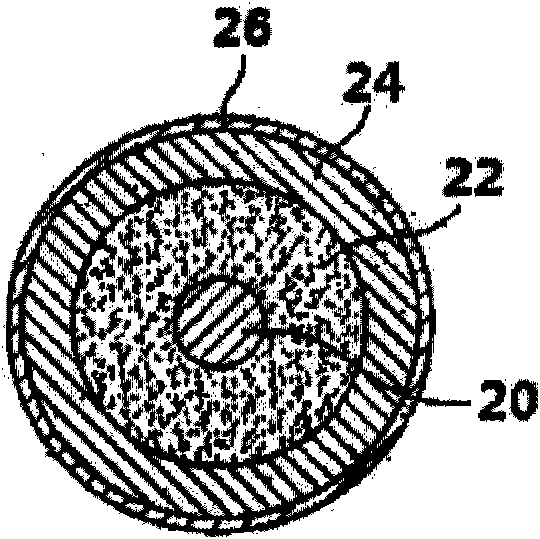

Slickened or siliconized flame resistant fiber blends

InactiveUS20060160454A1Extinguish any residual flameMinimal shrinkageDomestic upholsteryFibre treatmentFiberPolymer science

The invention relates to slickened or siliconized flame resistant fiber blends that are well suited for use in mattresses, boxsprings, upholstered furniture, fiber-filled bed clothing, transportation seating or any end use application where a soft materials are desired for flame resistant (FR) purposes. Some of the fibers in the blend are slickened. The FR fibers incorporated into these blends include both char forming FR fibers and oxygen depleting FR fibers. FR char-forming fibers are those which exhibit little shrinkage when exposed to direct flame and are not spun from polymers manufactured with halogenated monomers. Oxygen depleting FR fibers are spun from polymers manufactured with halogenated monomers.

Owner:BEIJING CARINAE MATERIAL TECH CO LTD

Comfort pillow

Owner:TEMPUR WORLD

Reticulated open cell filling material

InactiveUS7255917B2Readily filter outEliminates warm and damp conditionPillowsBlanketMicroorganismFilling materials

Flexible filtering filling material consisting of pieces that are 100% open cell reticulated polyurethane foam. The pieces filter out the damp warm condition within the filling, haltering the proliferation of microorganisms, giving the product a more sanitary and longer life.

Owner:ROCHLIN SCOTT +2

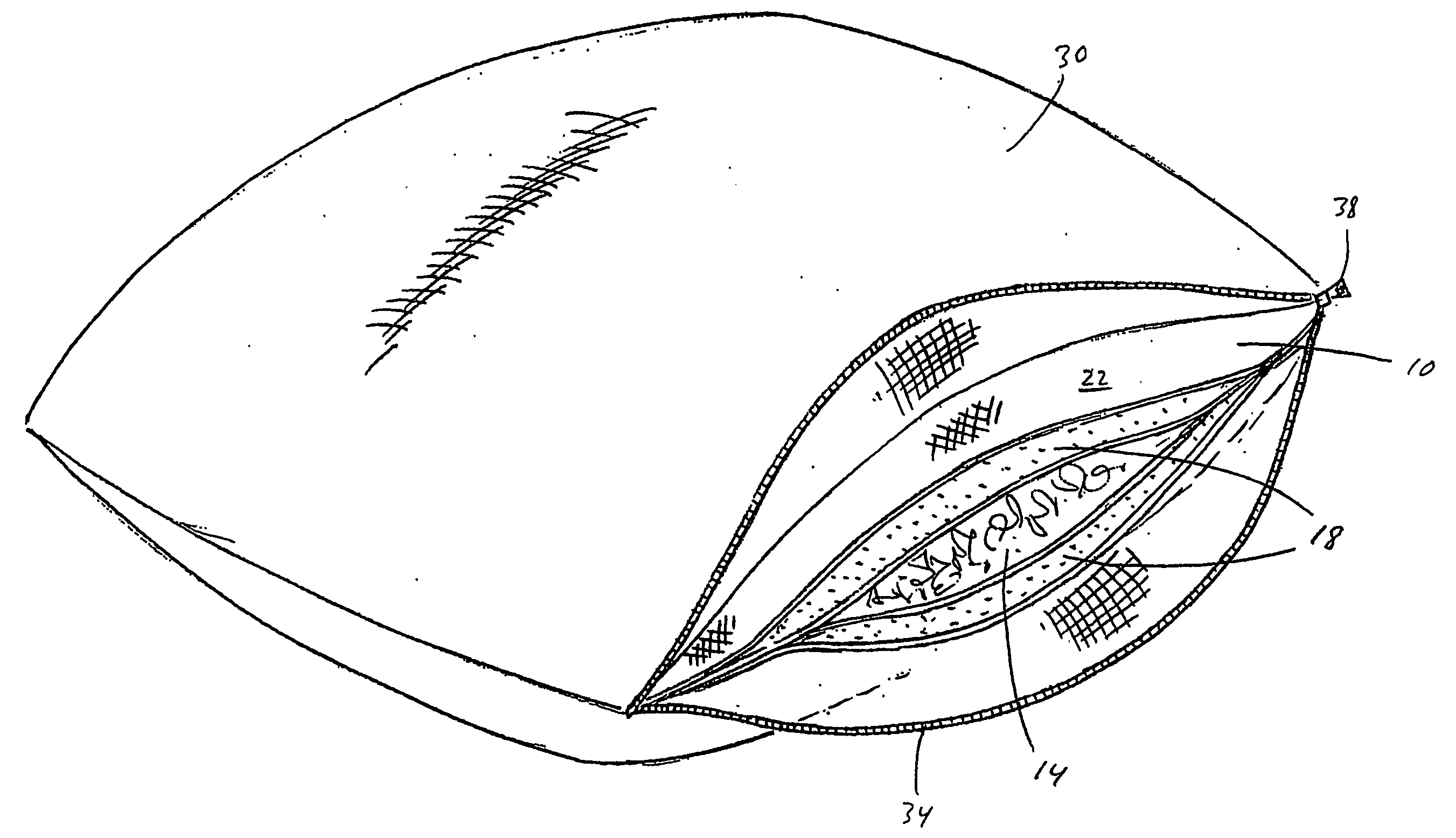

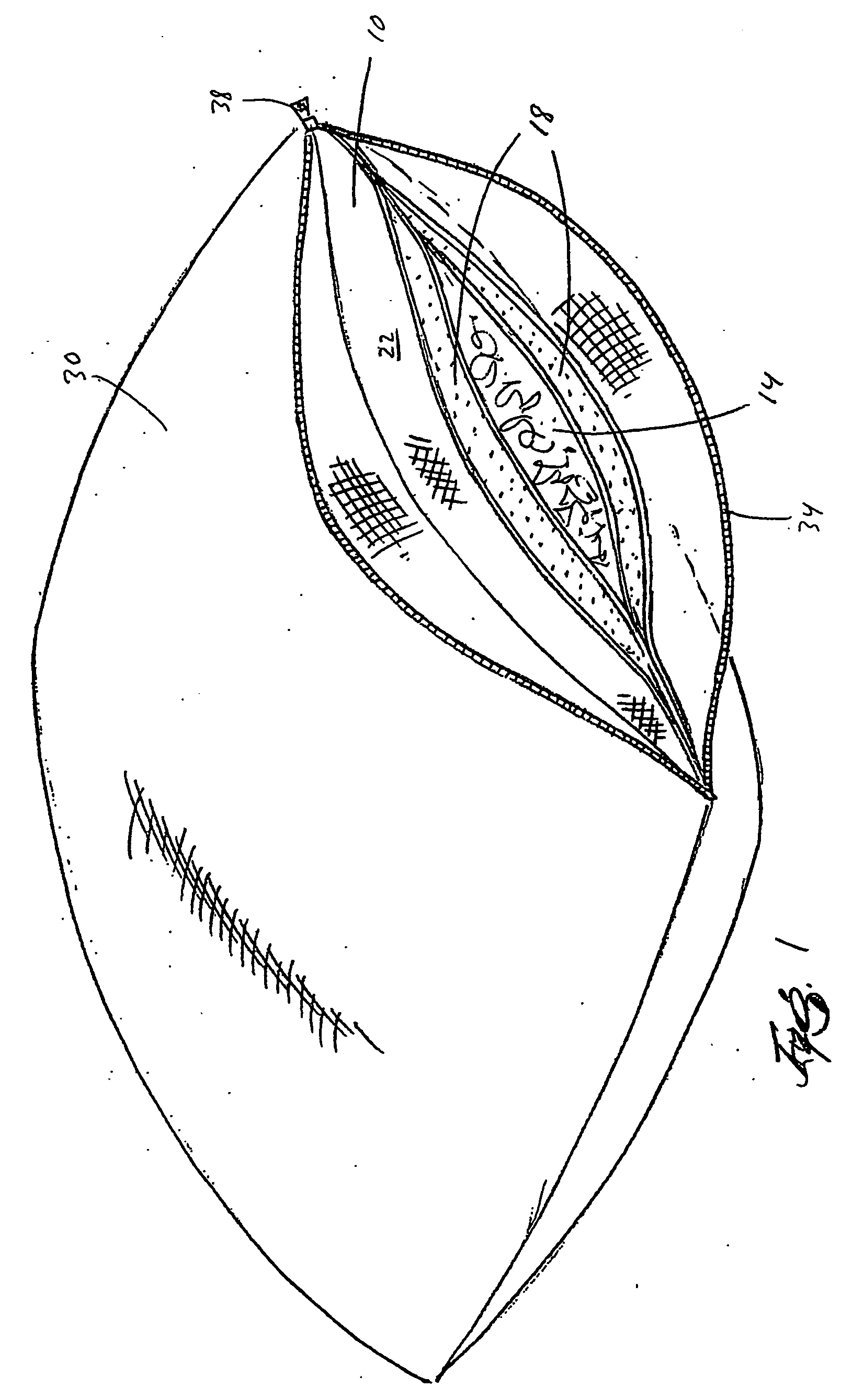

Down feather sheet

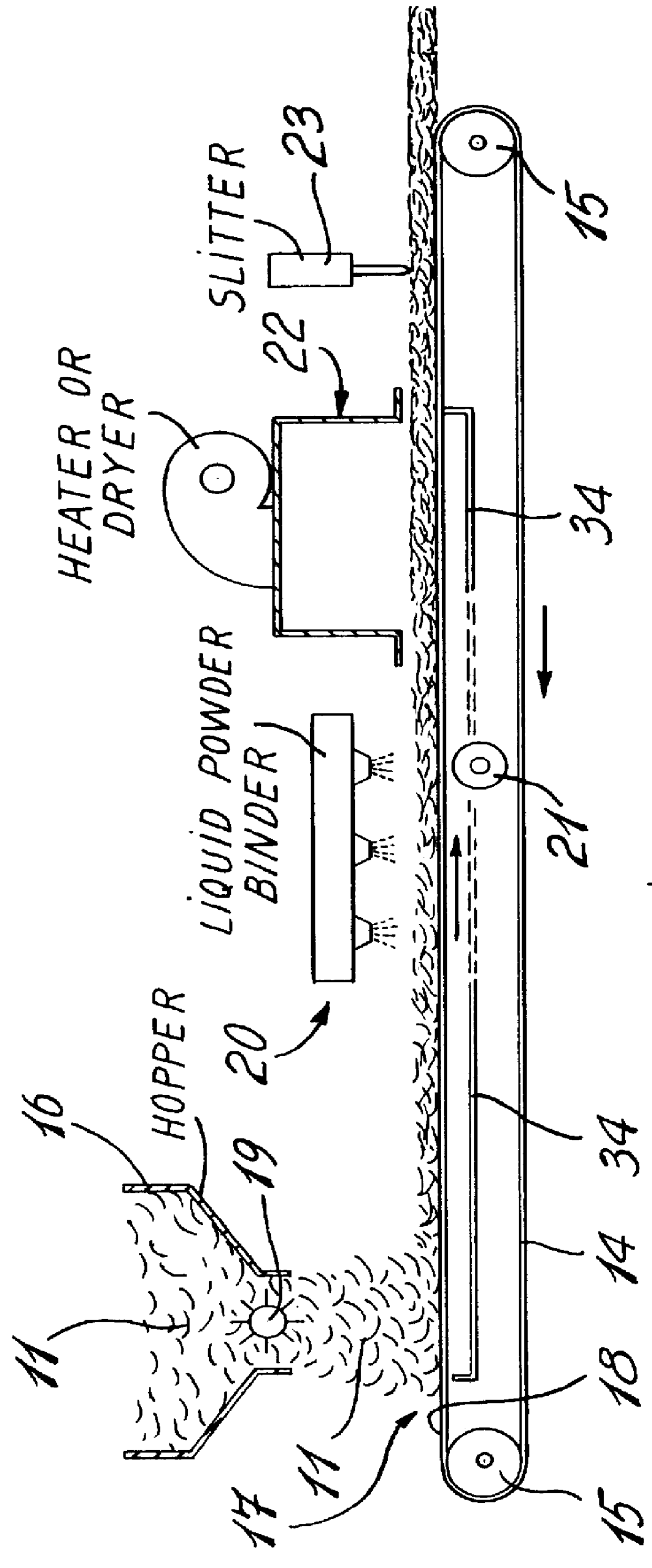

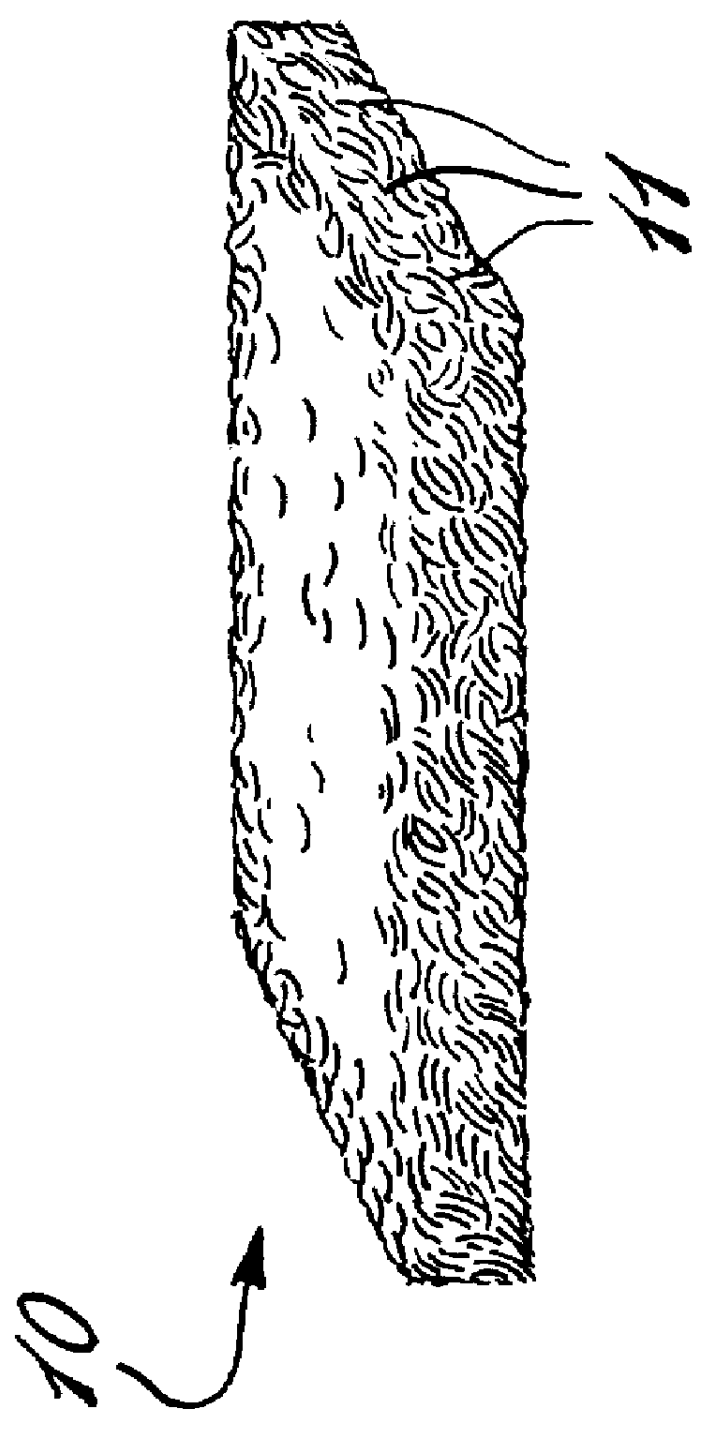

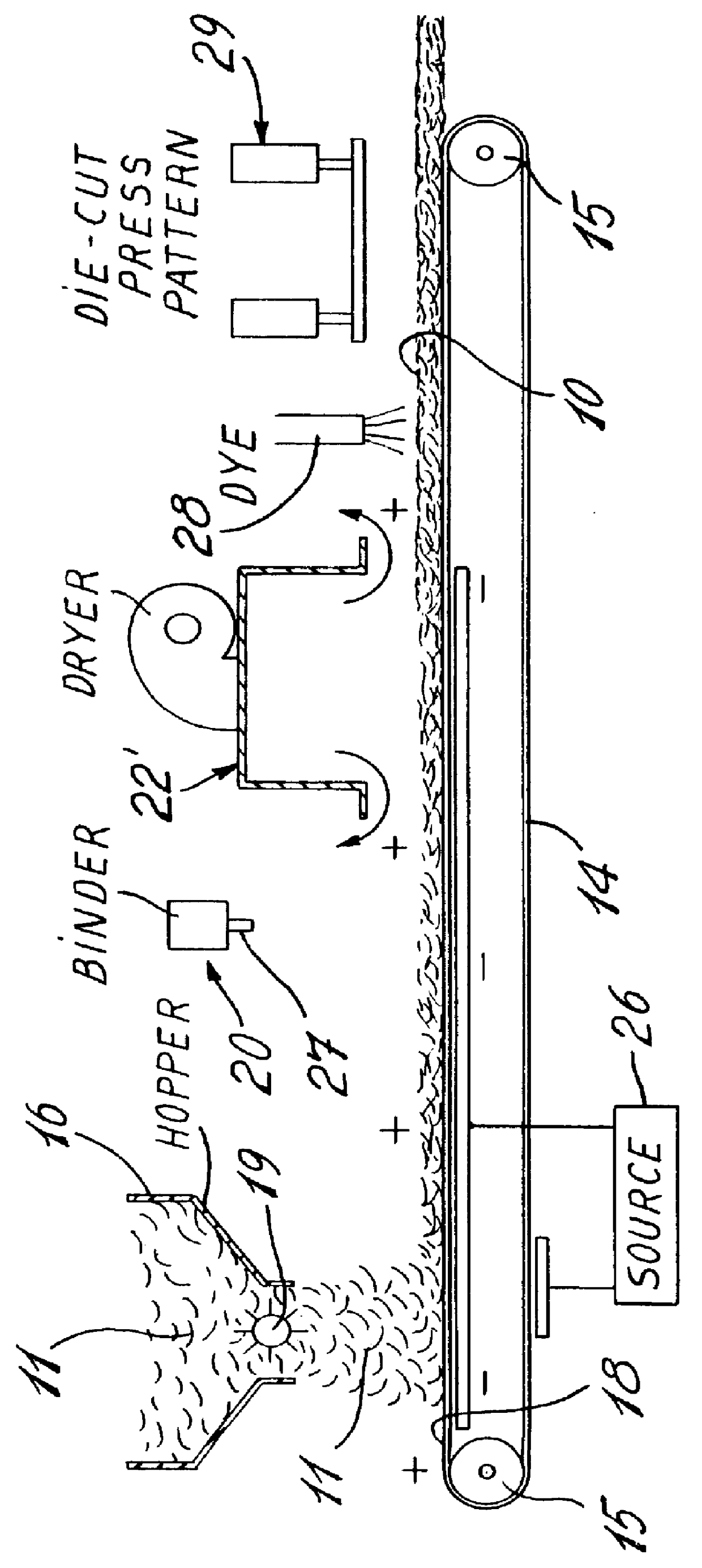

A method of fabricating a down feather sheet is described and it comprises forming a sheet of down feathers having been treated whereby to retain a homogeneous form. A binder is associated with the down feathers whereby they are retained together in sheet form. The down feather sheet product is also described.

Owner:7513194 CANADA

Contourable inflatable orthopedic pillow

InactiveUS20020078507A1Inexpensive to produceInstallation economyPillowsStuffed mattressesOrthopedic pillowSoft materials

A pillow that includes an inflatable bladder surrounded by a resilient layer. The bladder may be inflated to various levels to achieve a desired level of orthopedic support. In some embodiments of the invention, the pillow may include an outer comfort layer of softer material than the firm inner core. Optionally, an integral hand pump may be included on the pillow for inflation purposes.

Owner:EDIZONE LC

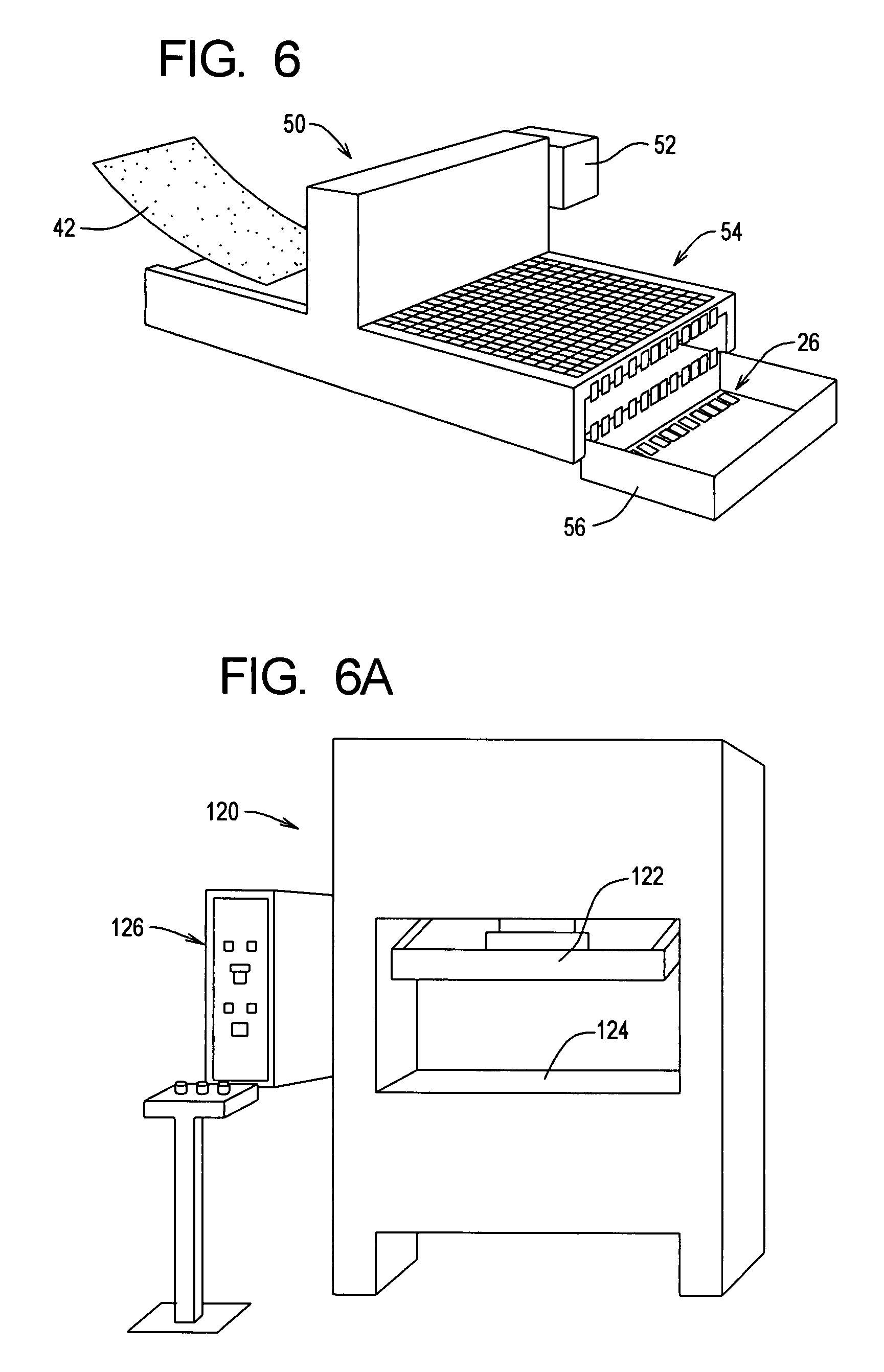

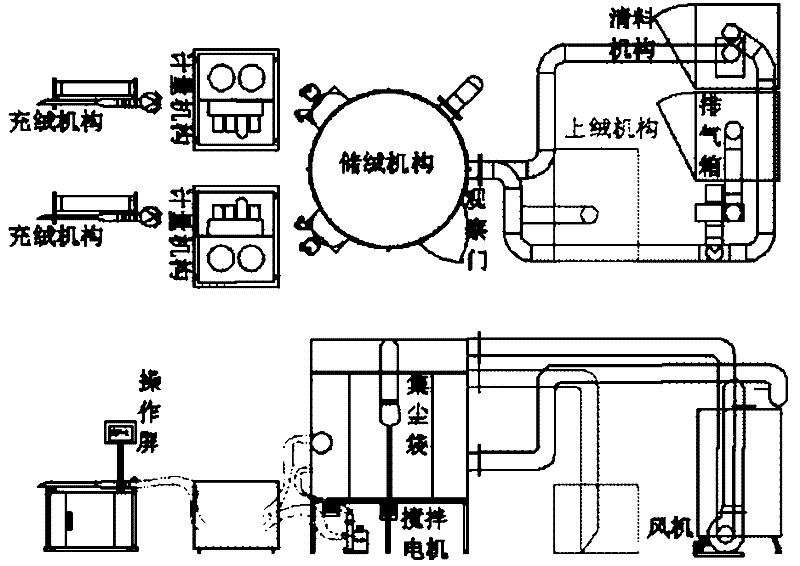

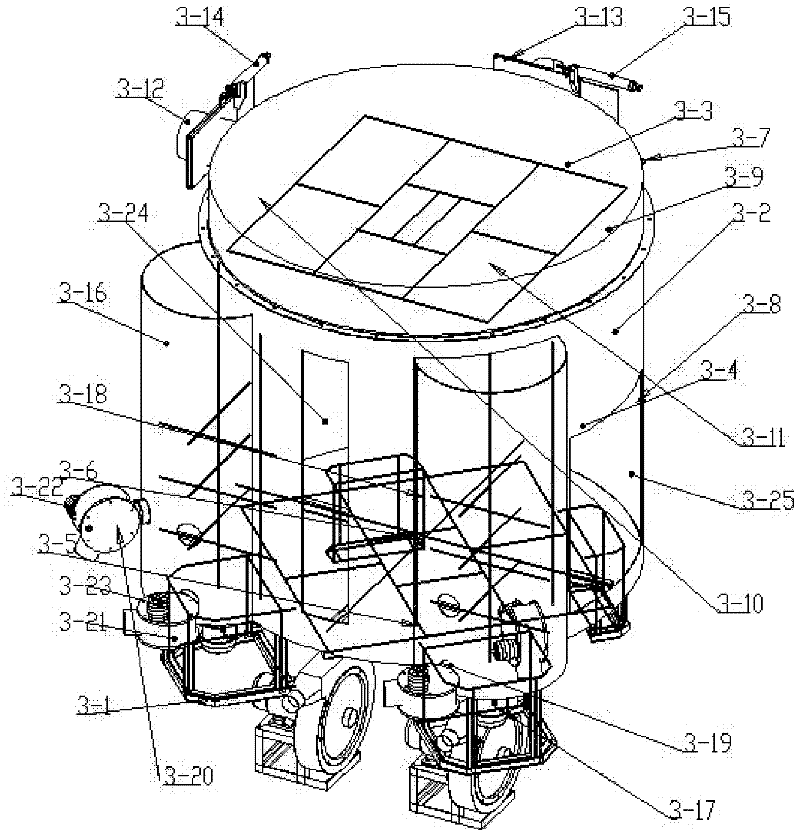

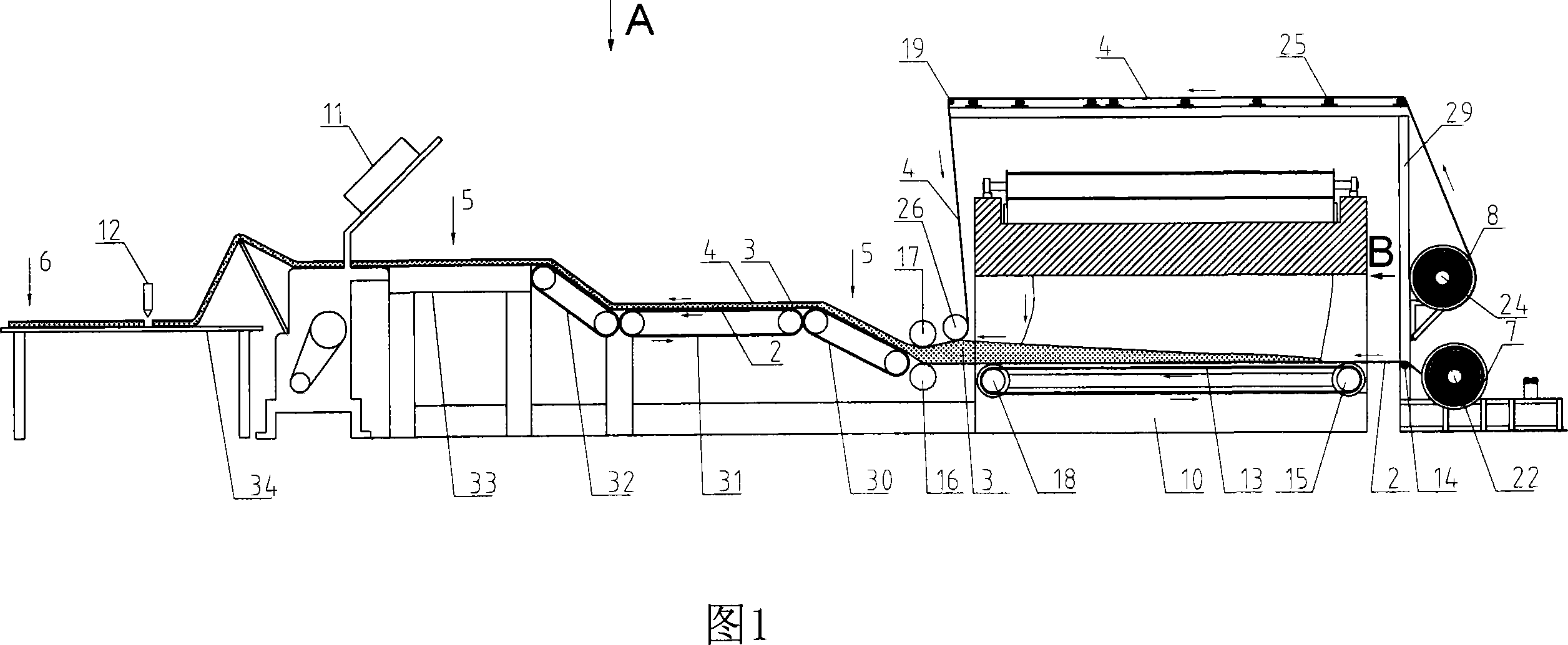

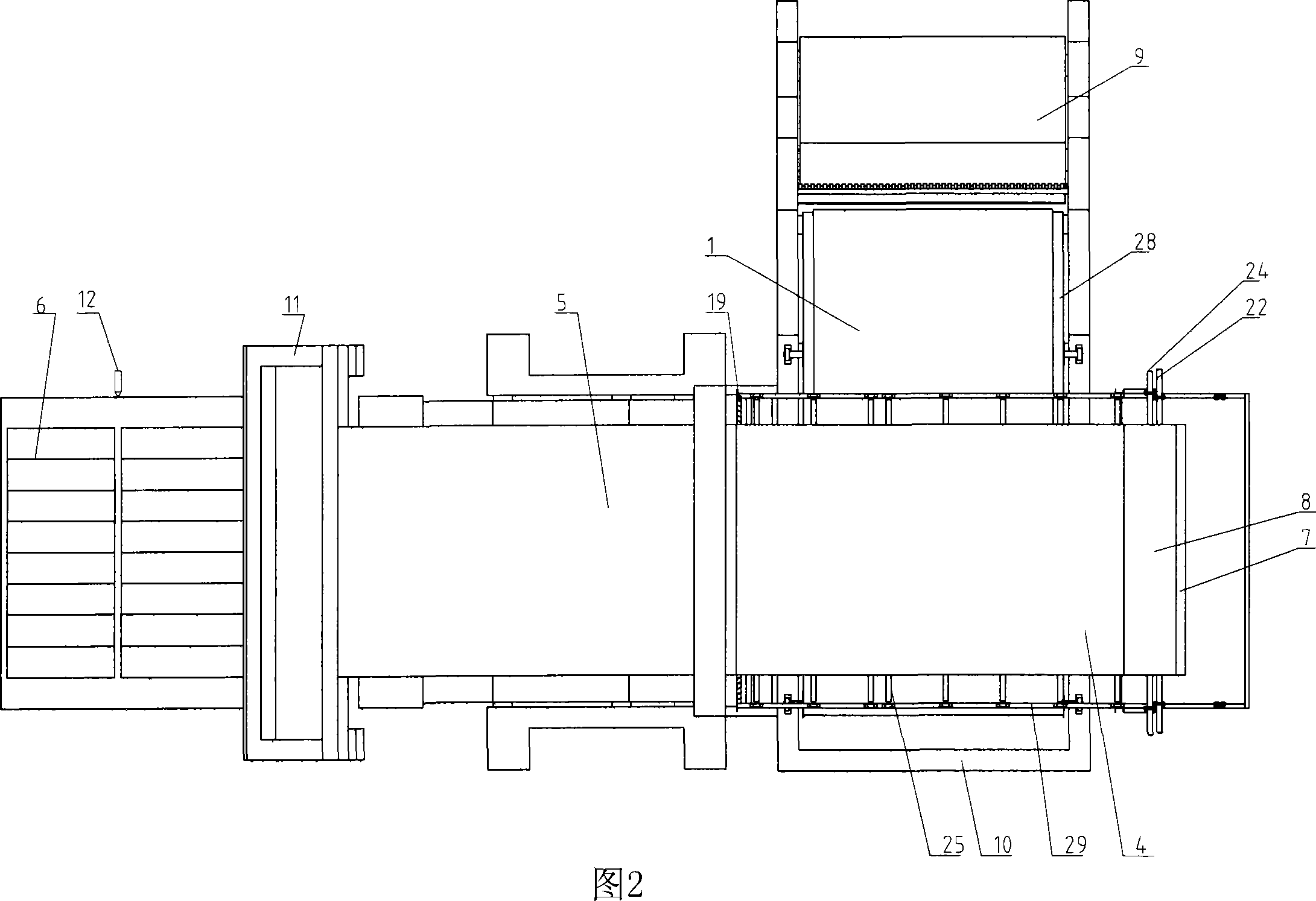

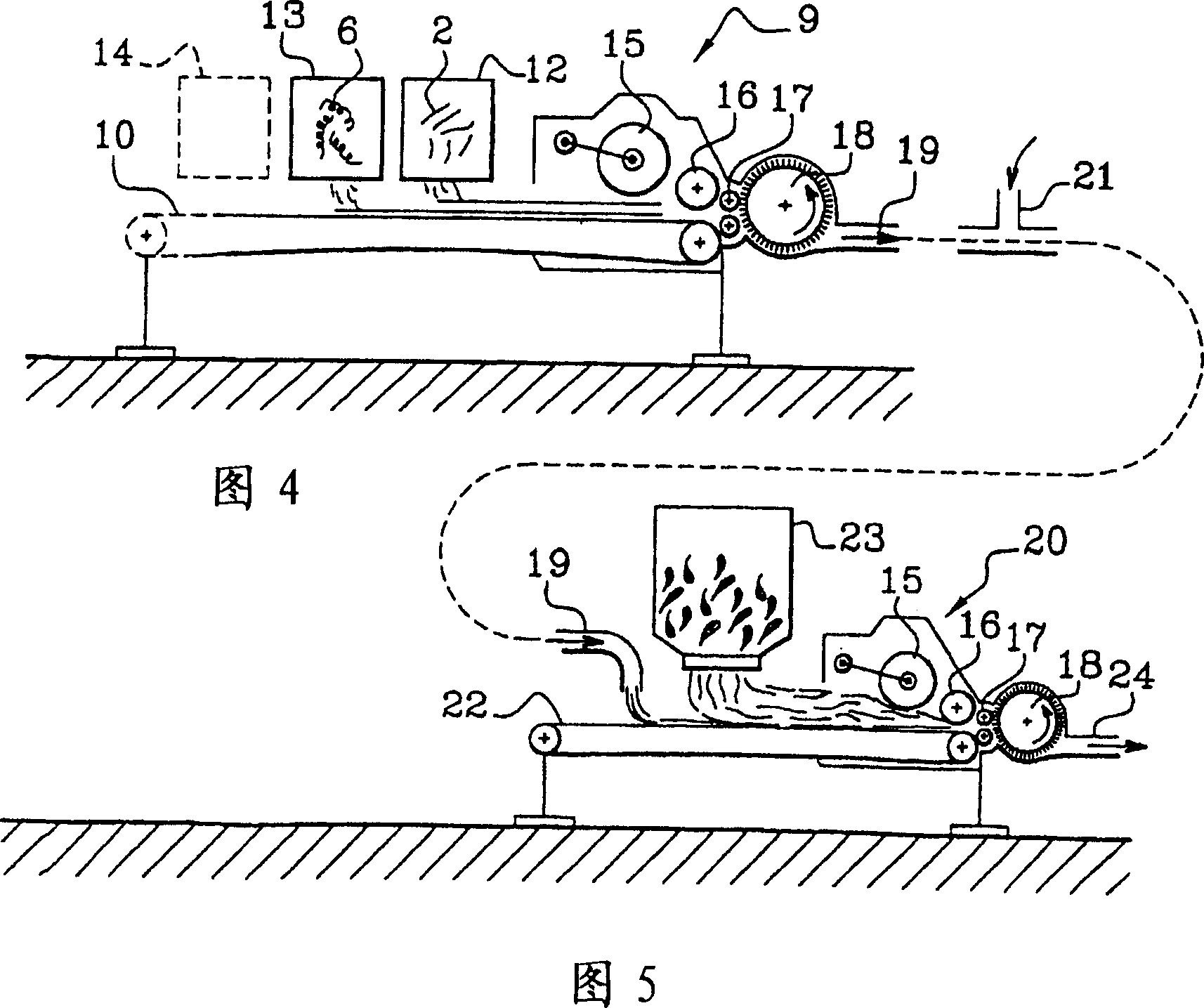

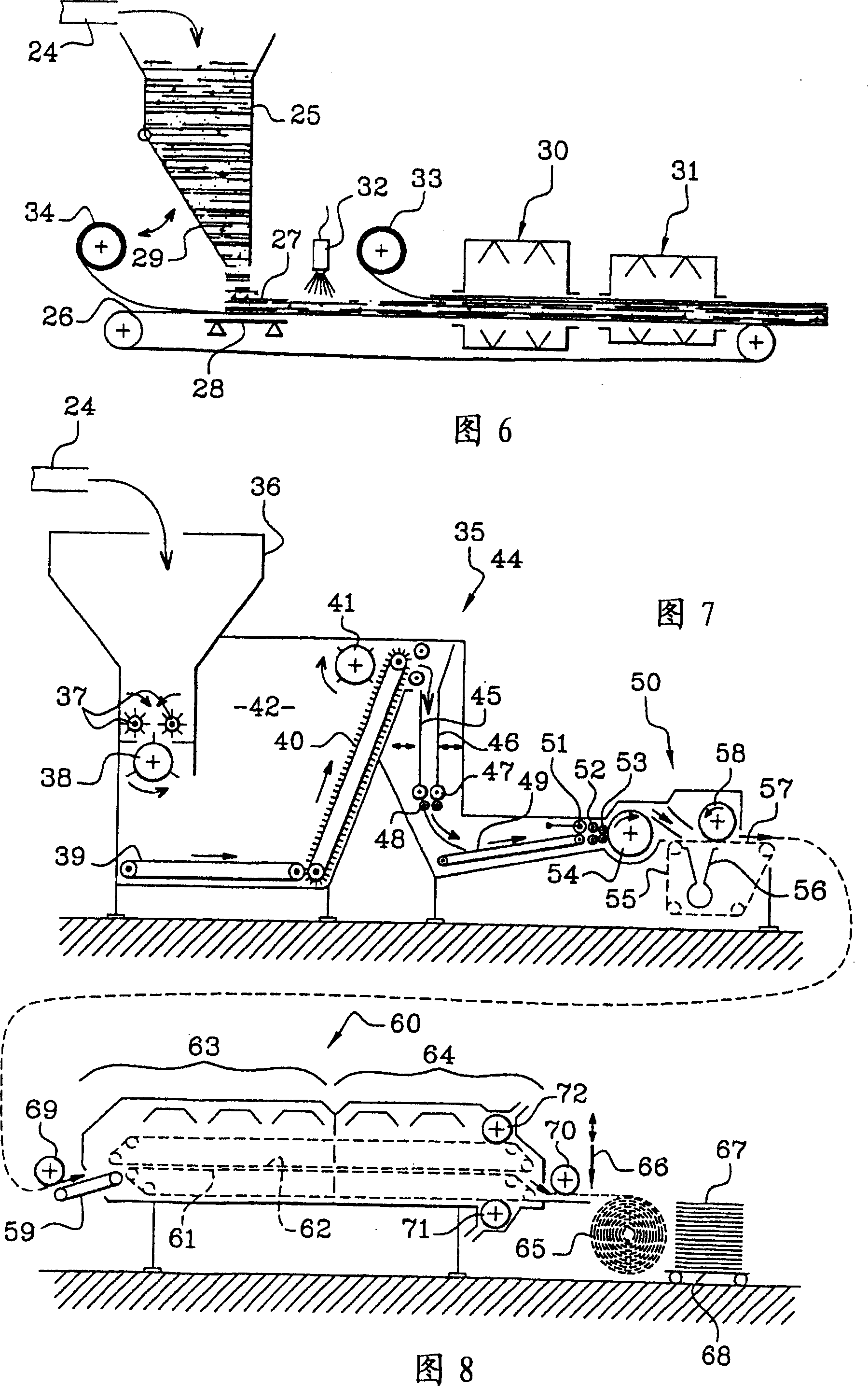

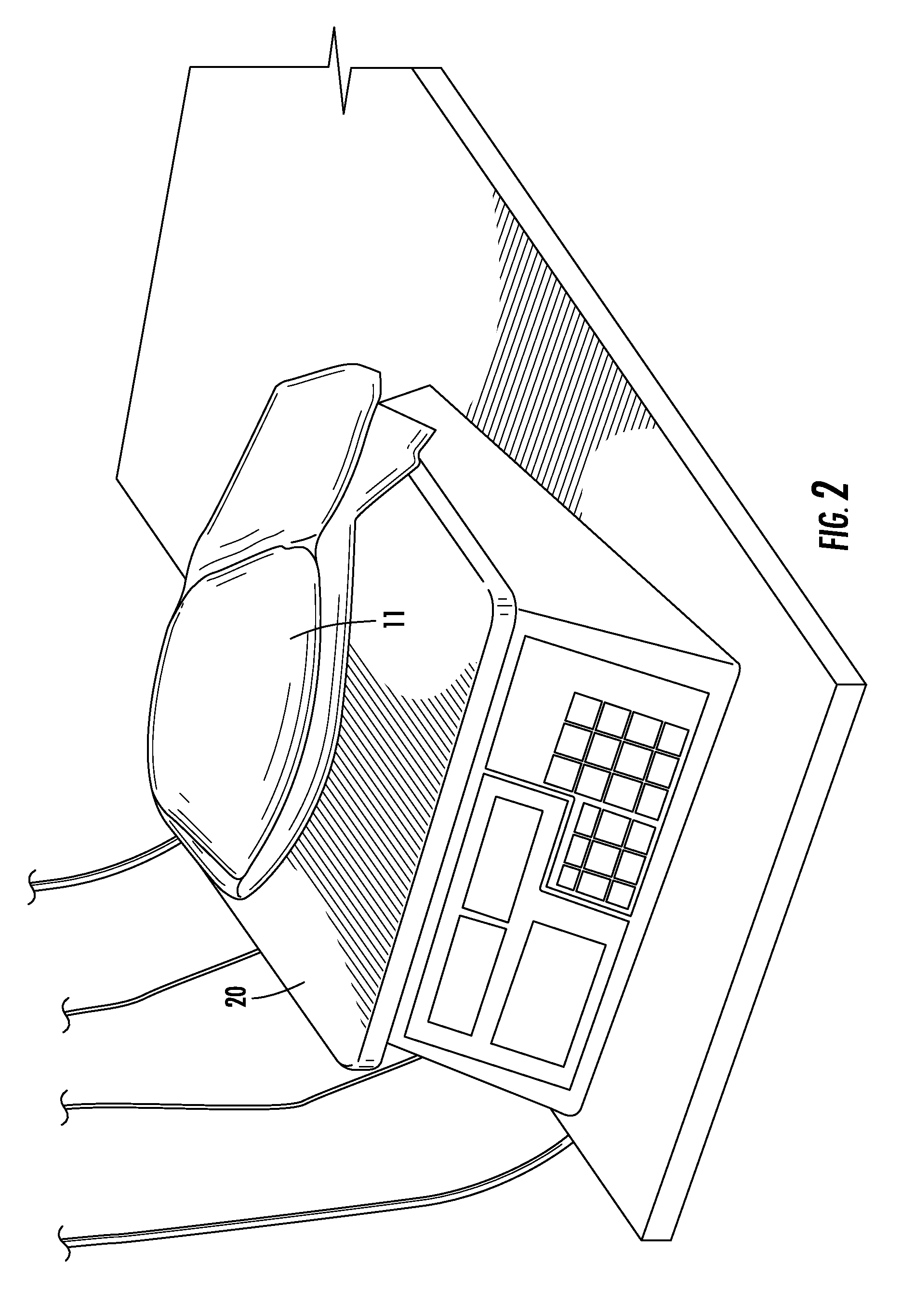

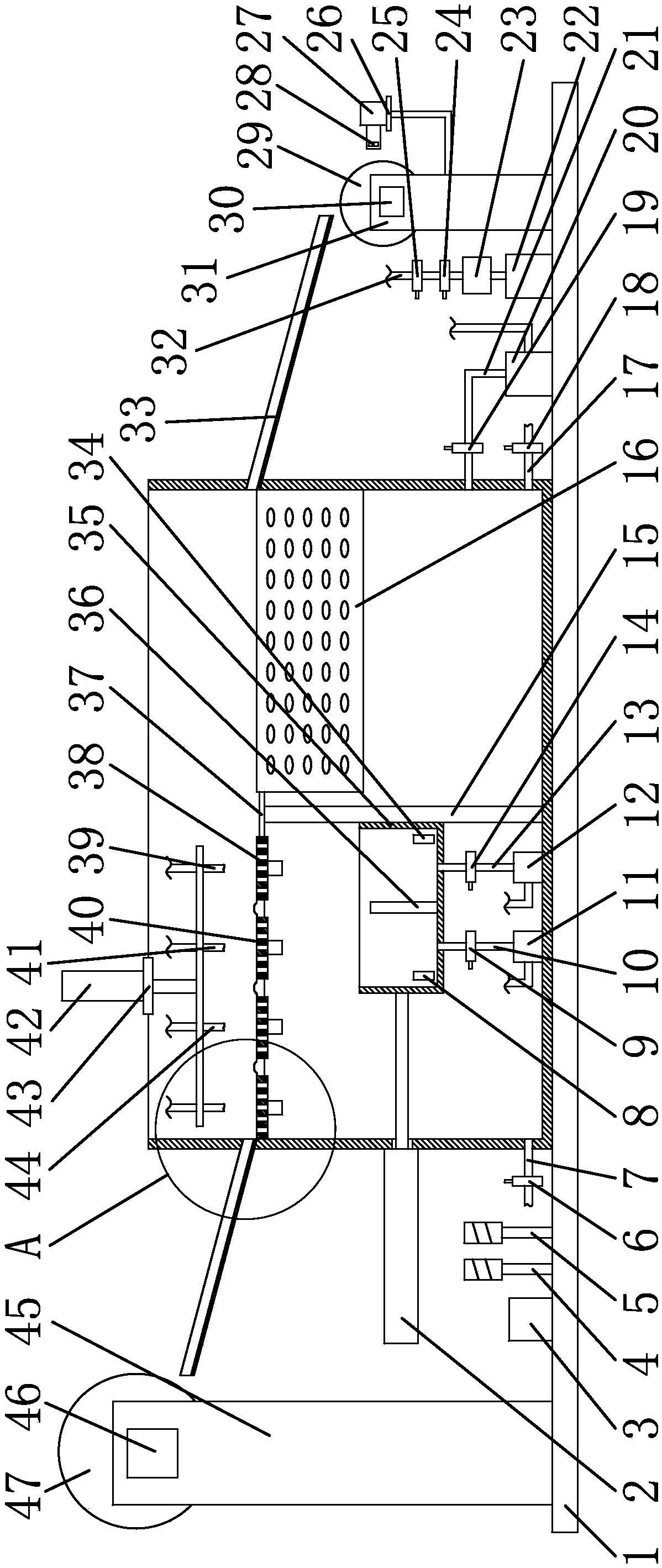

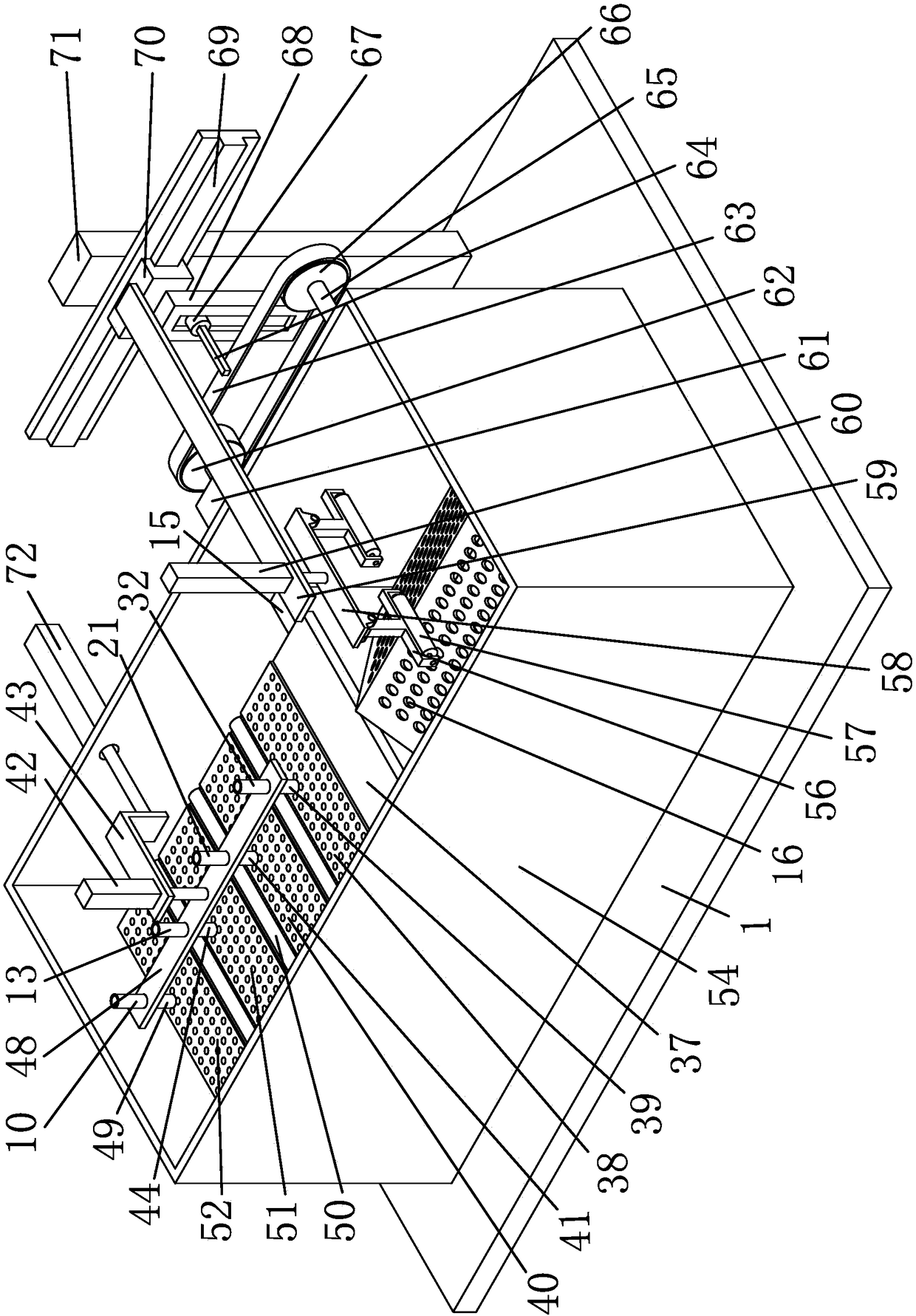

Full-automatic down feather filling machine

InactiveCN102303838AReduce wasteImprove working environmentUpholstery manufactureUpholstery fillingWorking environmentEngineering

The invention discloses a full-automatic down feather filling machine, which consists of a fan, a material loading mechanism, a down feather storage mechanism, a metering mechanism, a down feather filling mechanism and a material cleaning mechanism. The air inlet of the fan is connected with the material loading mechanism, the material loading mechanism is connected with the down feather storage mechanism, the down feather storage mechanism is connected with the metering mechanism, the metering mechanism is connected with the down feather filling mechanism, the down feather filling mechanism is connected with the material cleaning mechanism, and the material cleaning mechanism is connected with the air outlet of the fan. The working mode of manually filling down feather is replaced by the full-automatic down feather filling machine with the structure, and the down feather flows in a full-enclosed environment in the overall process, so that the working environment of staff is improved, labor intensity is lowered, the waste of the down feather is reduced, and working efficiency is improved. In addition, the full-automatic down feather filling machine has the advantages that: the machine has a simple structure and a rational design and is convenient to use.

Owner:天津艾瑞克机械设备有限公司

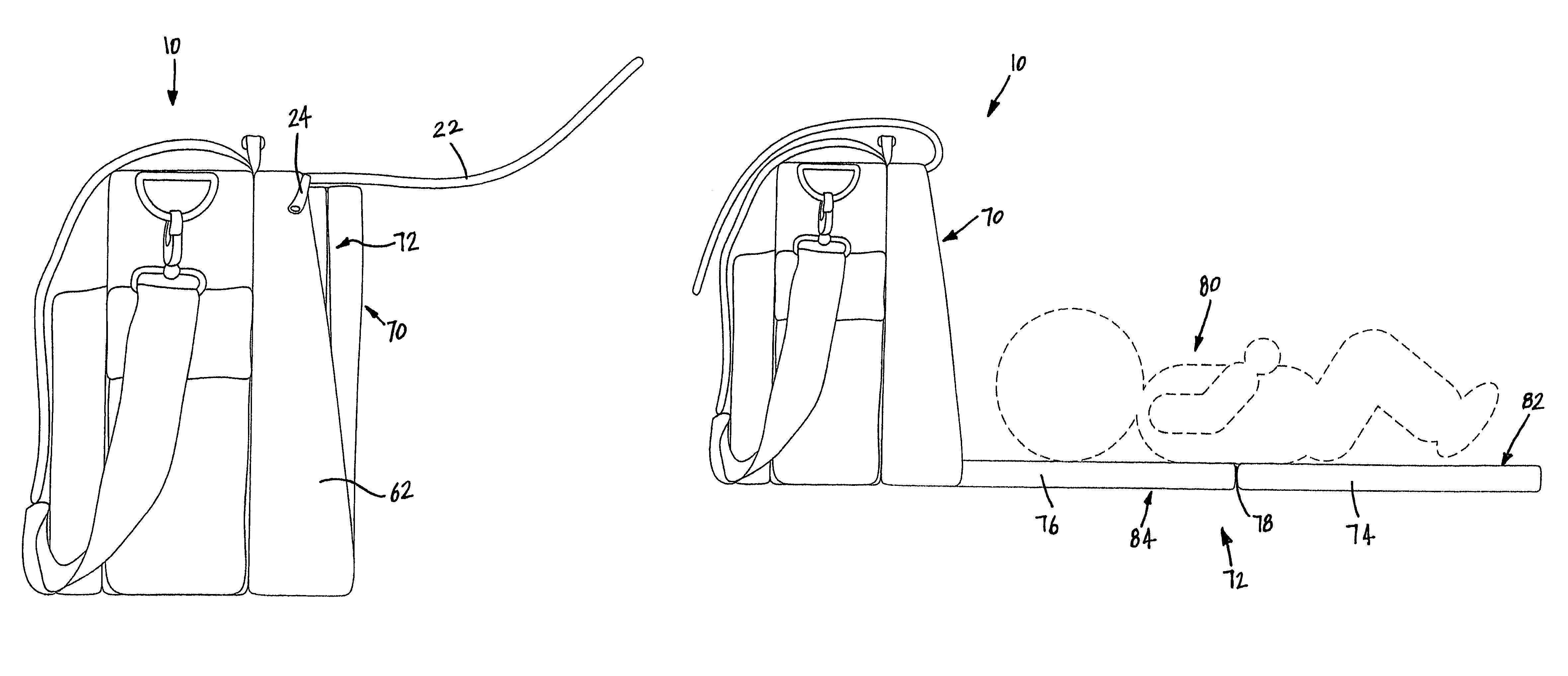

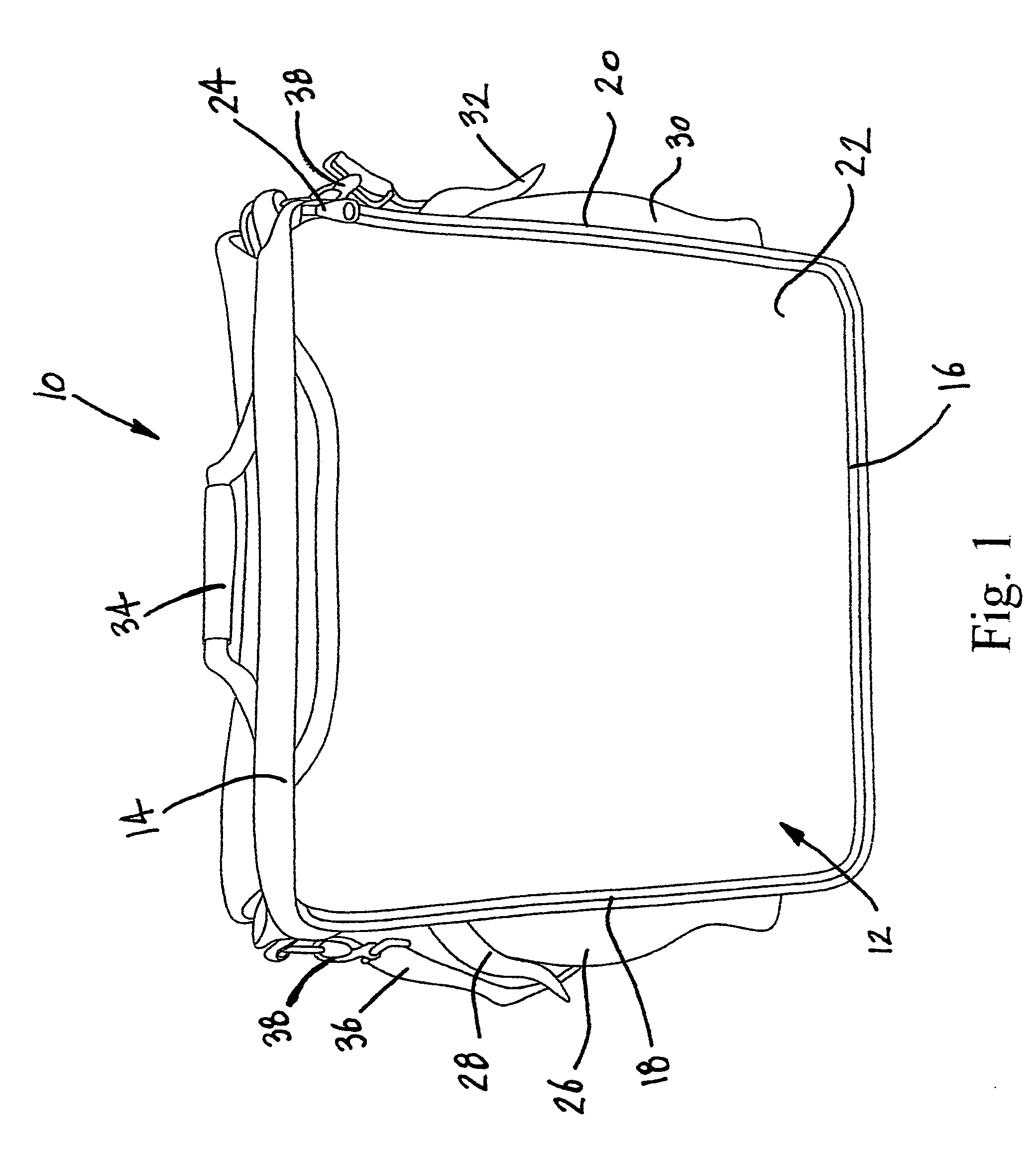

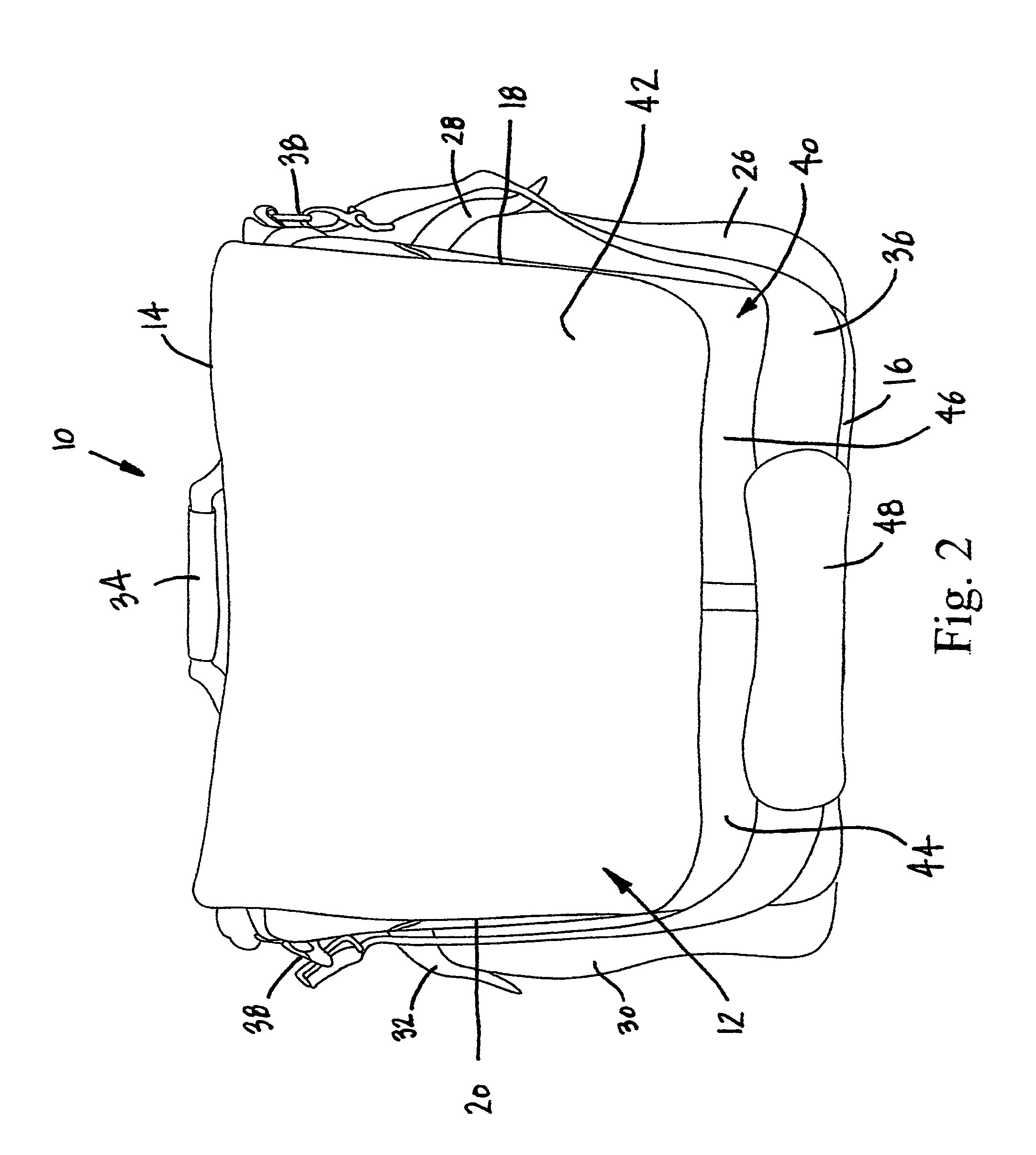

Diaper bag having an integral changing pad

InactiveUS8490230B2Additional cleanlinessImprove comfortTravelling sacksDressing tableEngineeringMechanical engineering

Owner:ROVIN SCOTT A

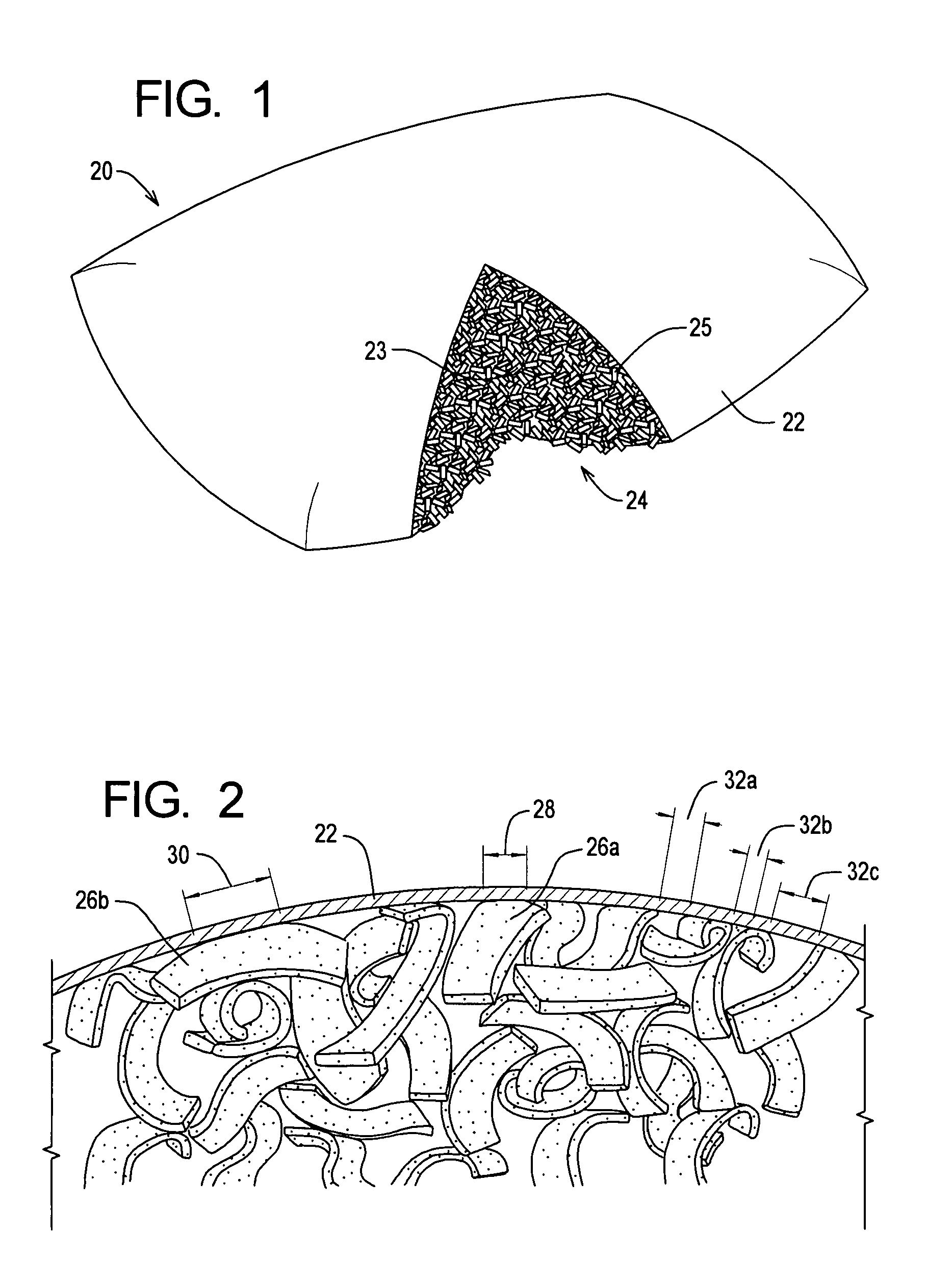

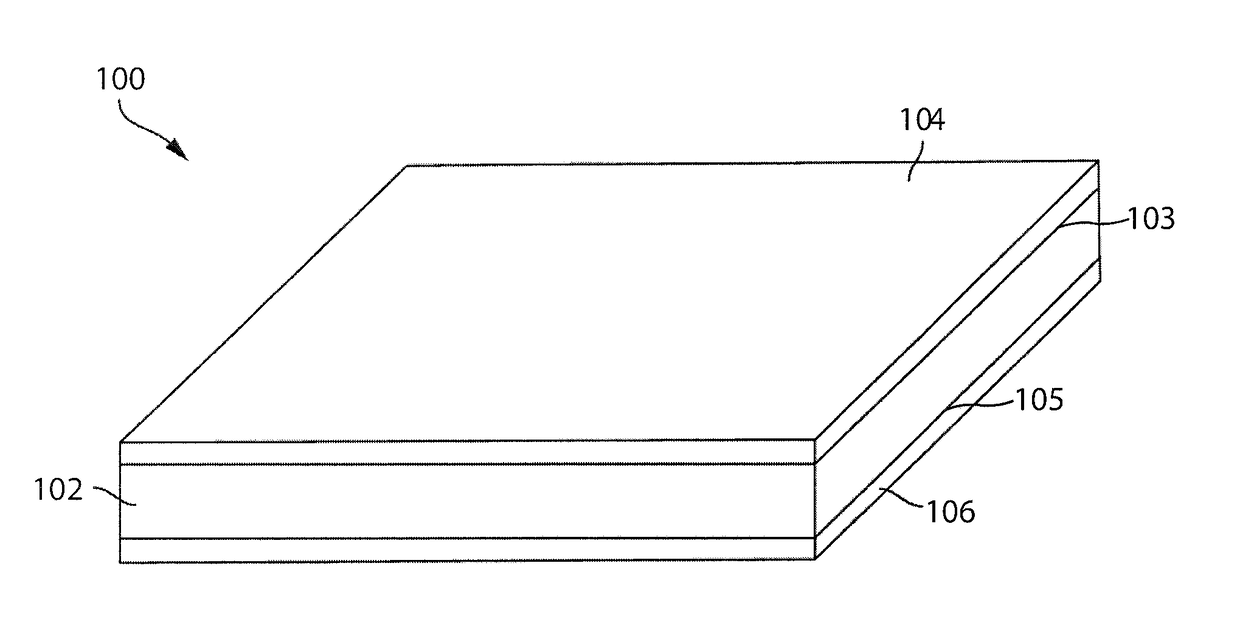

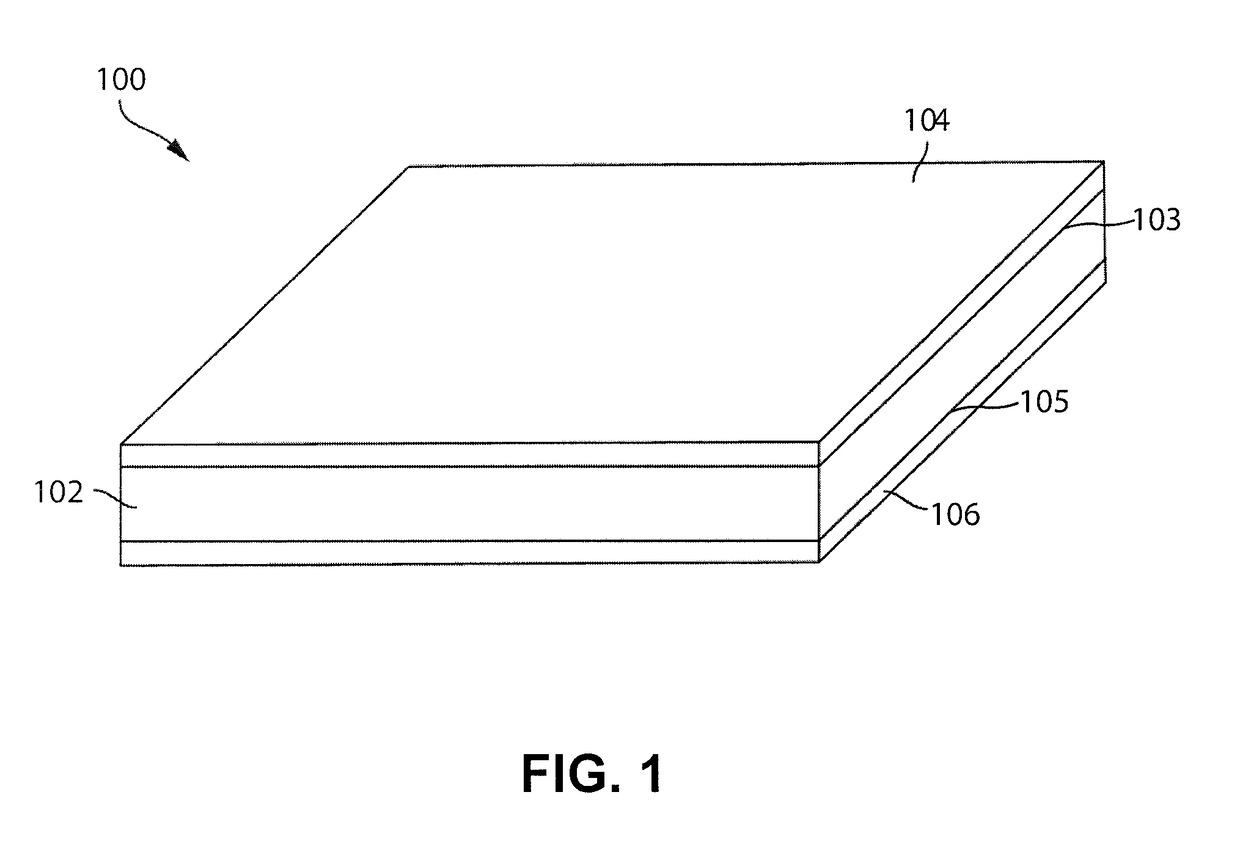

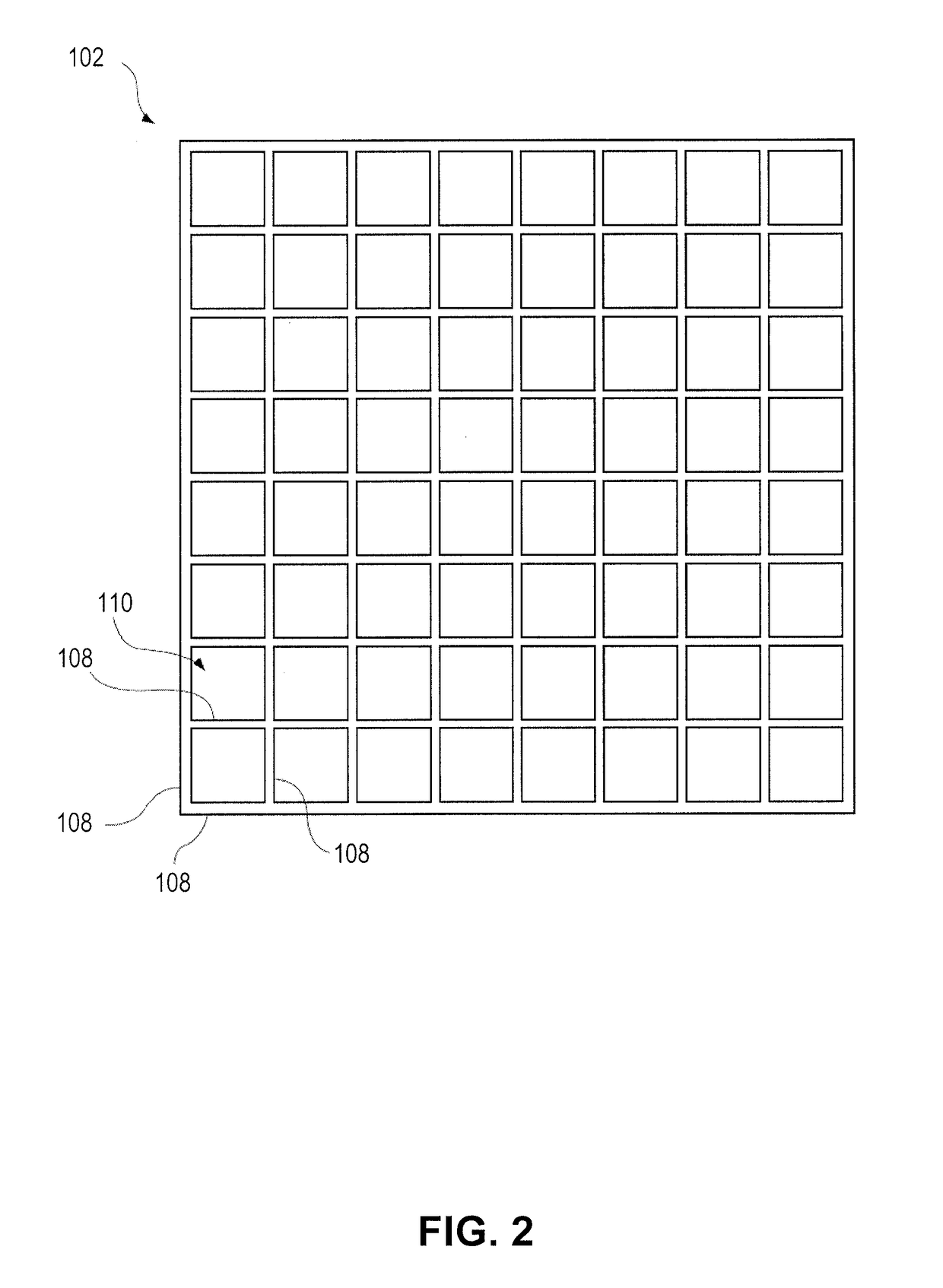

Cushions including a coated elastomeric cushioning element and related methods

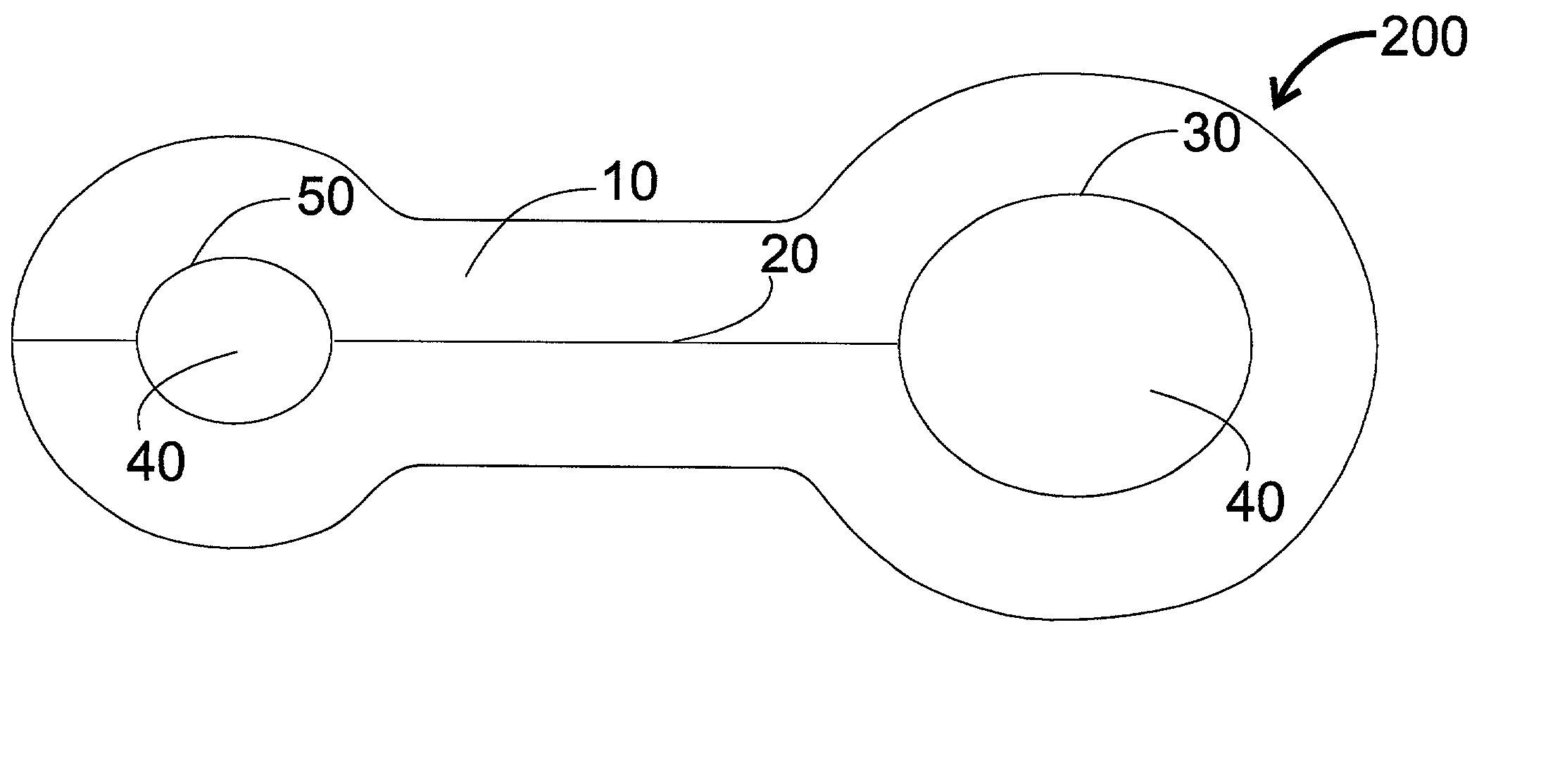

A cushion includes a cushioning element and a coating provided on a surface of the cushioning element. The cushioning element comprises an elastomeric material forming a plurality of intersecting buckling walls defining a plurality of hollow columns in an expanded form. The elastomeric material comprises an elastomeric polymer and a plasticizer. The coating comprising an olefin powder formulated to hinder adhesion of the elastomeric material when the cushioning element is in a compressed form such that the plurality of intersecting buckling walls is pressed together. The cushioning element is configured to be compressed by a roll-packing machine into the compressed form and subsequently released from the compressed form to transform to the expanded form. Methods of forming the cushion include forming the cushioning element comprising an elastomeric material, coating a surface of the cushioning element with olefin powder, and compressing the cushioning element into a compressed form.

Owner:PURPLE INNOVATION LLC

Method for producing high-elasticity bulked silk-cotton quilt

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

Comfort pillow

Owner:TEMPUR WORLD

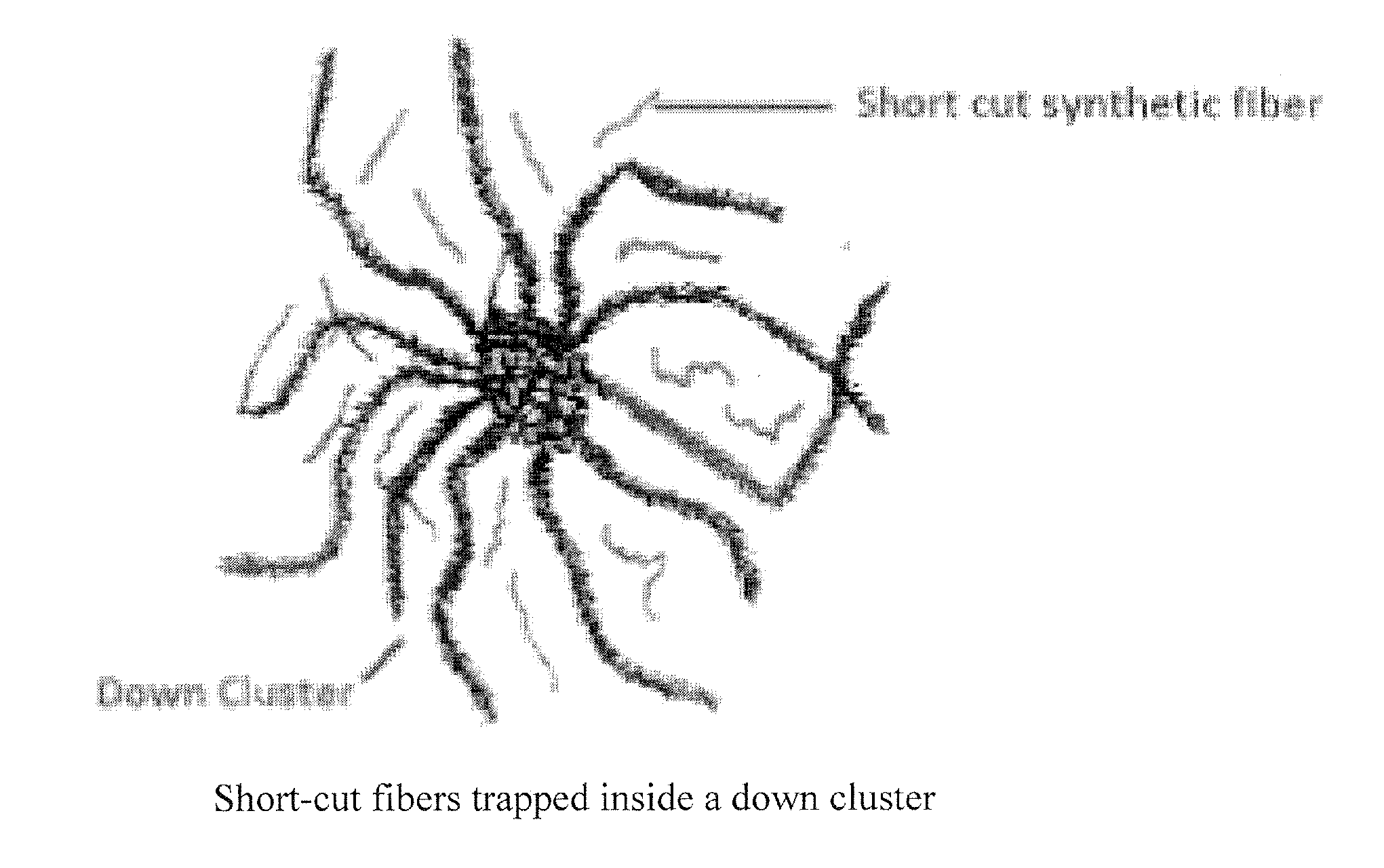

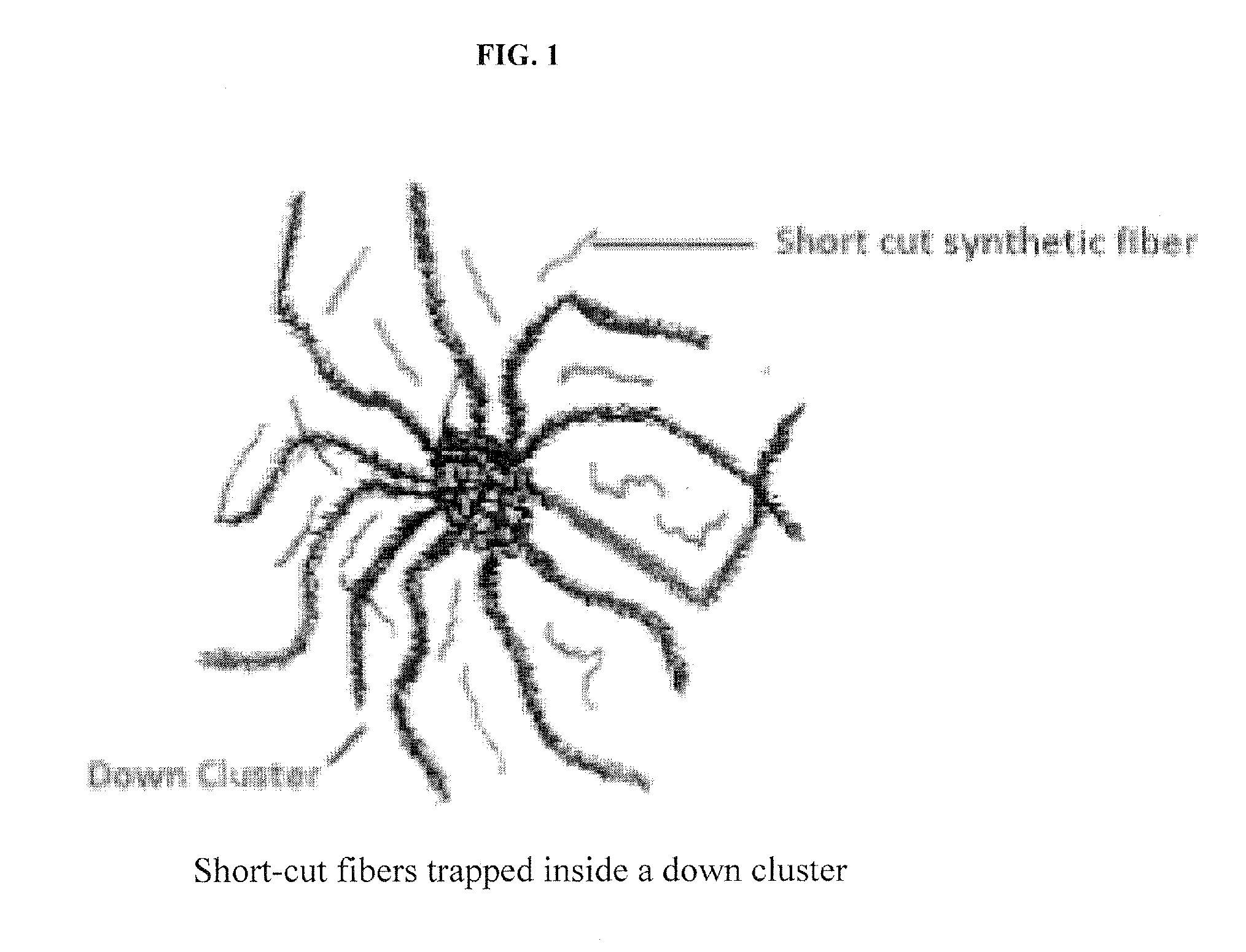

Blowable insulation material with enhanced durability and water repellency

ActiveUS20140206796A1Impart water repellencyImprove structural durabilityPhysical treatmentProtein adhesivesNatural fiberWater repellent

A blowable insulation material comprising natural fibers and short cut synthetic fibers or fiber balls. The natural fibers and short cut synthetic fibers or fiber balls are individually treated with a water repellent to impart water repellency to the fibers, and later aerodynamically blended together. The water repellent fibers constitute a part or most of the blowable insulation material, thus enhancing the durability of the structure as well as water repellency, which may be advantageous during washing or laundering.

Owner:PRIMALOFT

Method for preparation of quilt and device for actualizing said method

ActiveCN101095589AIncrease productivityLower skill requirementsUpholstery manufactureBed-coversBiomedical engineeringBlanket

The invention relates to a method for producing quilt, and the employed device. The invention is to solve problems of low quilt production efficiency and bad quilt quality. The method comprises following steps: carding cotton; laying cotton on the bottom surface; covering face fabric on quilt core, quilting, cutting, and tipping. The quilt is characterized by increased production efficiency and improved quilt quality.

Owner:李佑安

Silk-floss wadded quilt producing process

The present invention discloses silk-floss wadded quilt producing process, and aims at providing one kind of silk-floss wadded quilt capable of resisting vacuum compression. The silk-floss wadded quilt producing process includes the steps of: soaking silkworm cocoon in hot water, machine drawing silk, boiling, high temperature refining, cold rinsing, neutralizing to soften, adding special puffing agent and drying agent, quick high temperature roasting, physical puffing, making wadding, vacuuming and sealing, and packing the product. The silk-floss wadded quilt product has small size and after unpacking, it restores its puffed soft ventilating state.

Owner:潘新平

Slickened or siliconized flame resistant fiber blends

InactiveUS7589037B2Desirable soft and comfortable propertyLess testingDomestic upholsteryFibre treatmentFiberPolymer science

Owner:BEIJING CARINAE MATERIAL TECH CO LTD

Method for manufacturing silk quilt

InactiveCN101744484AQuality improvementImprove performanceUpholstery manufactureHand sewingHuman bodyBiomedical engineering

The invention relates to a method for manufacturing a silk quilt, which comprises the following process steps: purchasing raw materials and manufacturing silk floss; sewing a silk floss sleeve; and manufacturing the silk quilt. The silk quilt manufactured by the method is natural and environmental-friendly, and has reliable quality, stable performance and durability; the inner floss is not rolled, exposed or shrunk; and the silk quilt also has the effects of preventing insects, moulds and dusts and resisting static. The silk quilt has the characteristics of fine, smooth, fluffy and soft feelings, coolness in summer and warmness in winter, and affinity with skin, capacity of nourishing cells, promoting the blood circulation, improving the sleeping state, being beneficial to a human body after long-time use, and a best healthcare product in the modern house.

Owner:隋日宽

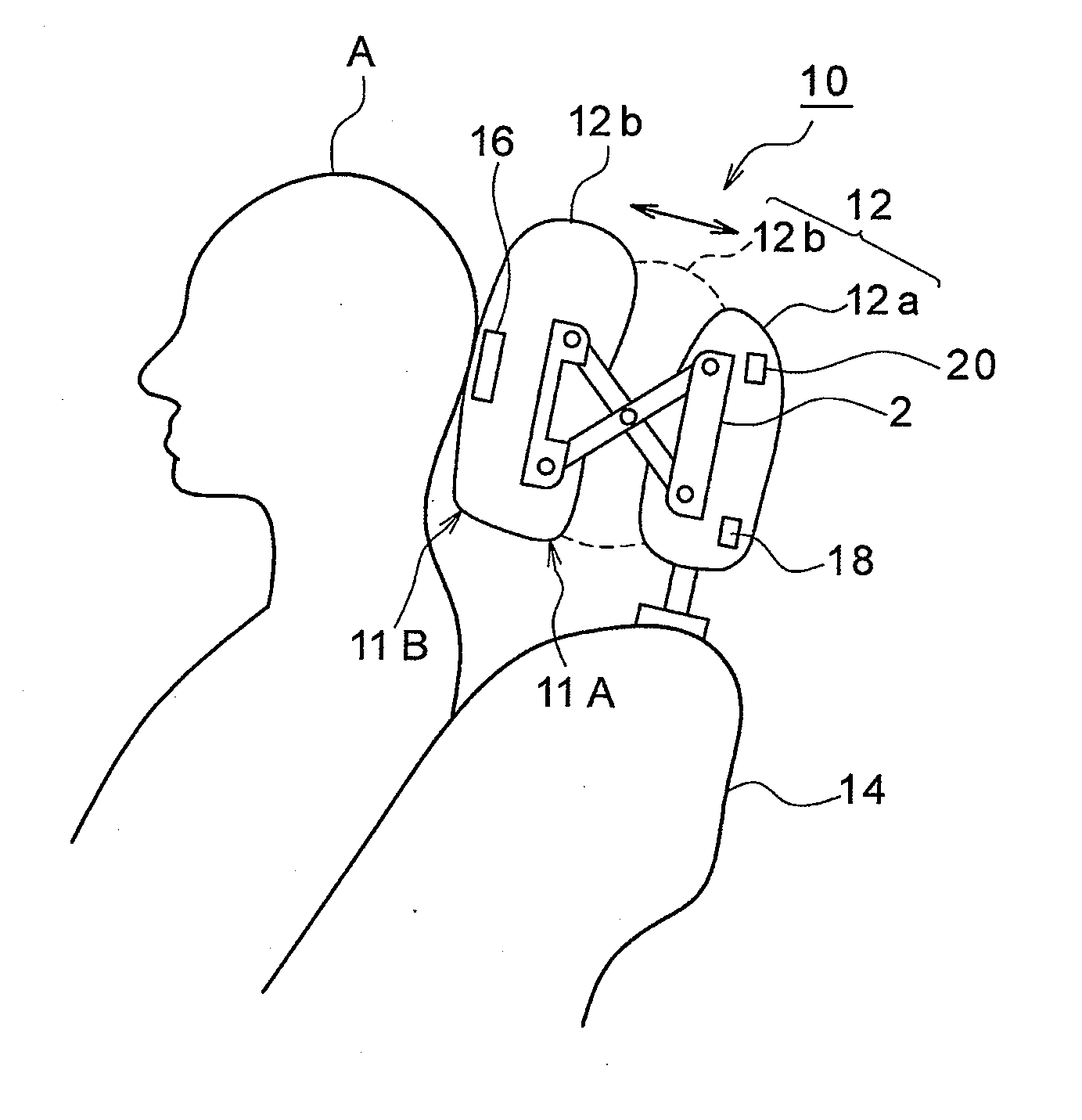

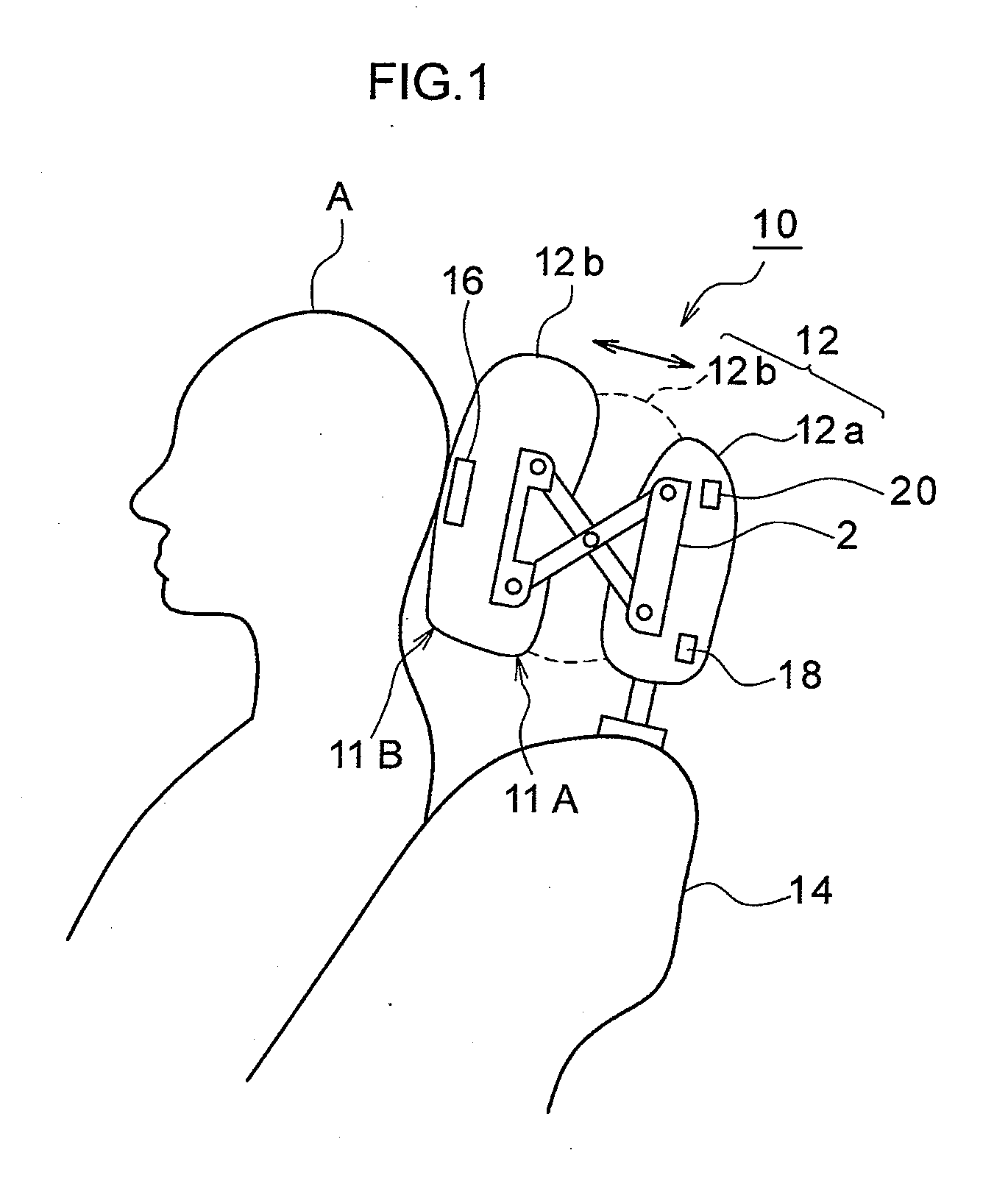

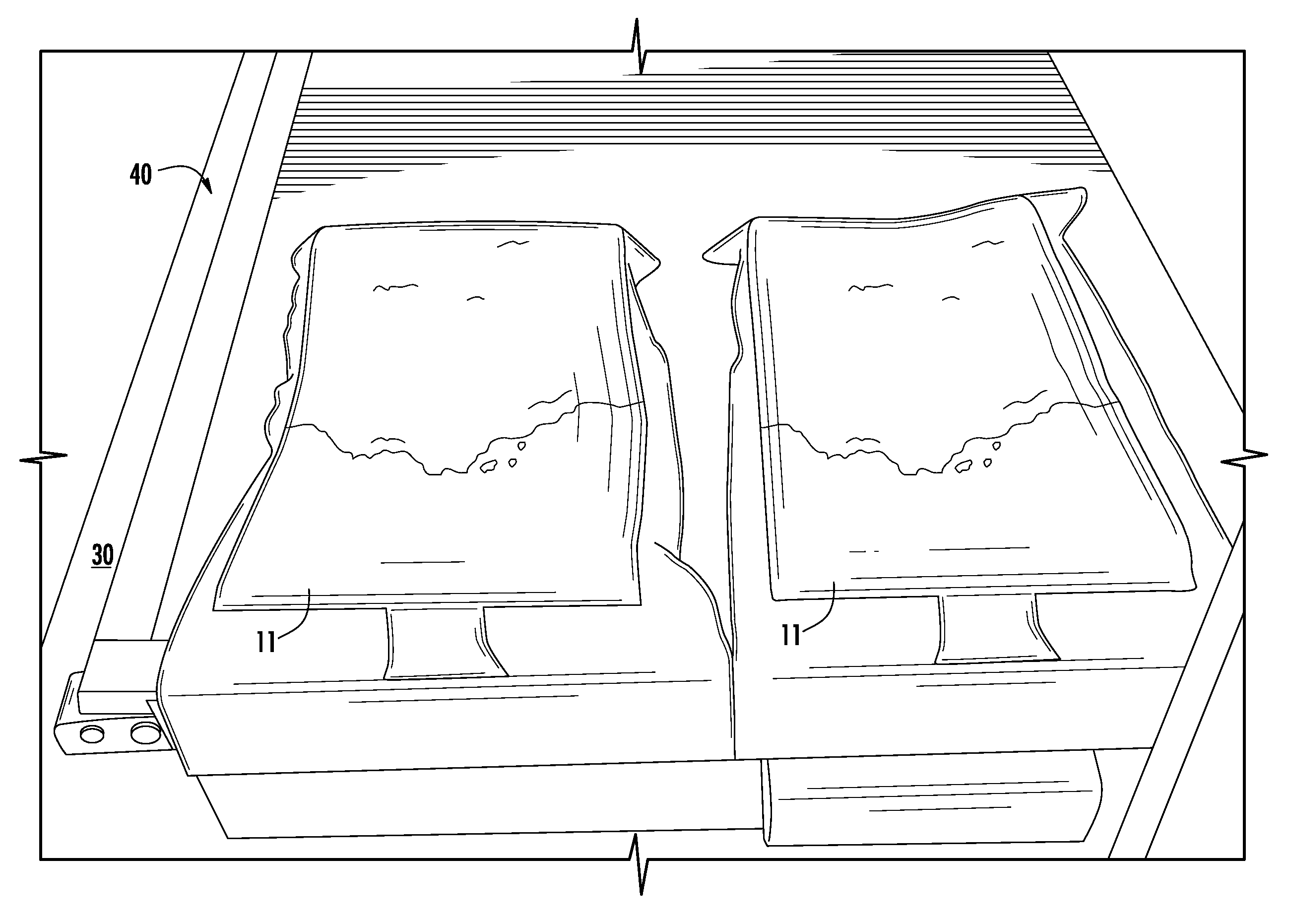

Headrest Apparatus, Method of Adjusting Headrest Position, Vehicle Seat

ActiveUS20110316318A1Regulation stabilityCost-effective structureVehicle seatsOperating chairsEngineeringMechanical engineering

Owner:NHK SPRING CO LTD

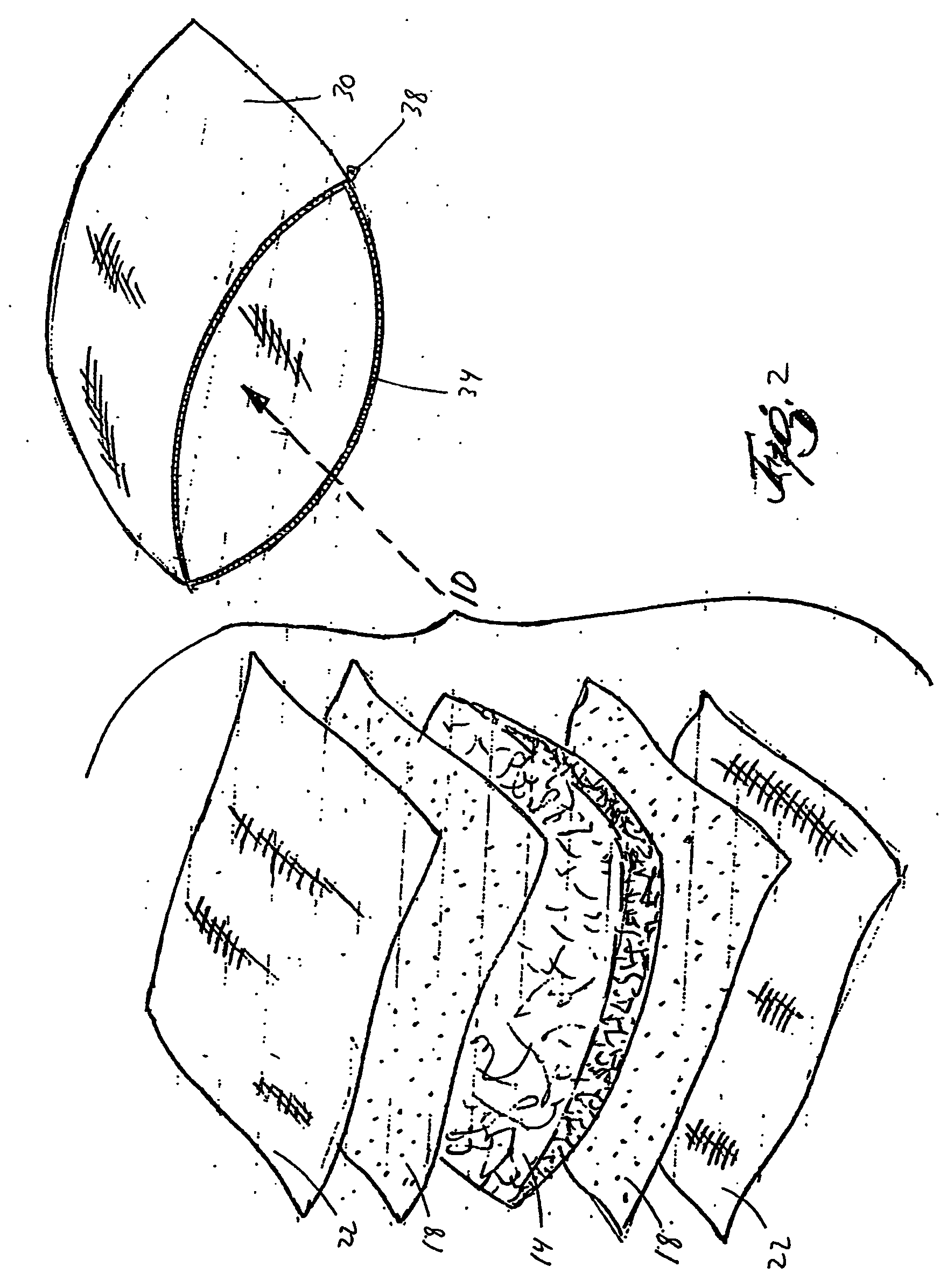

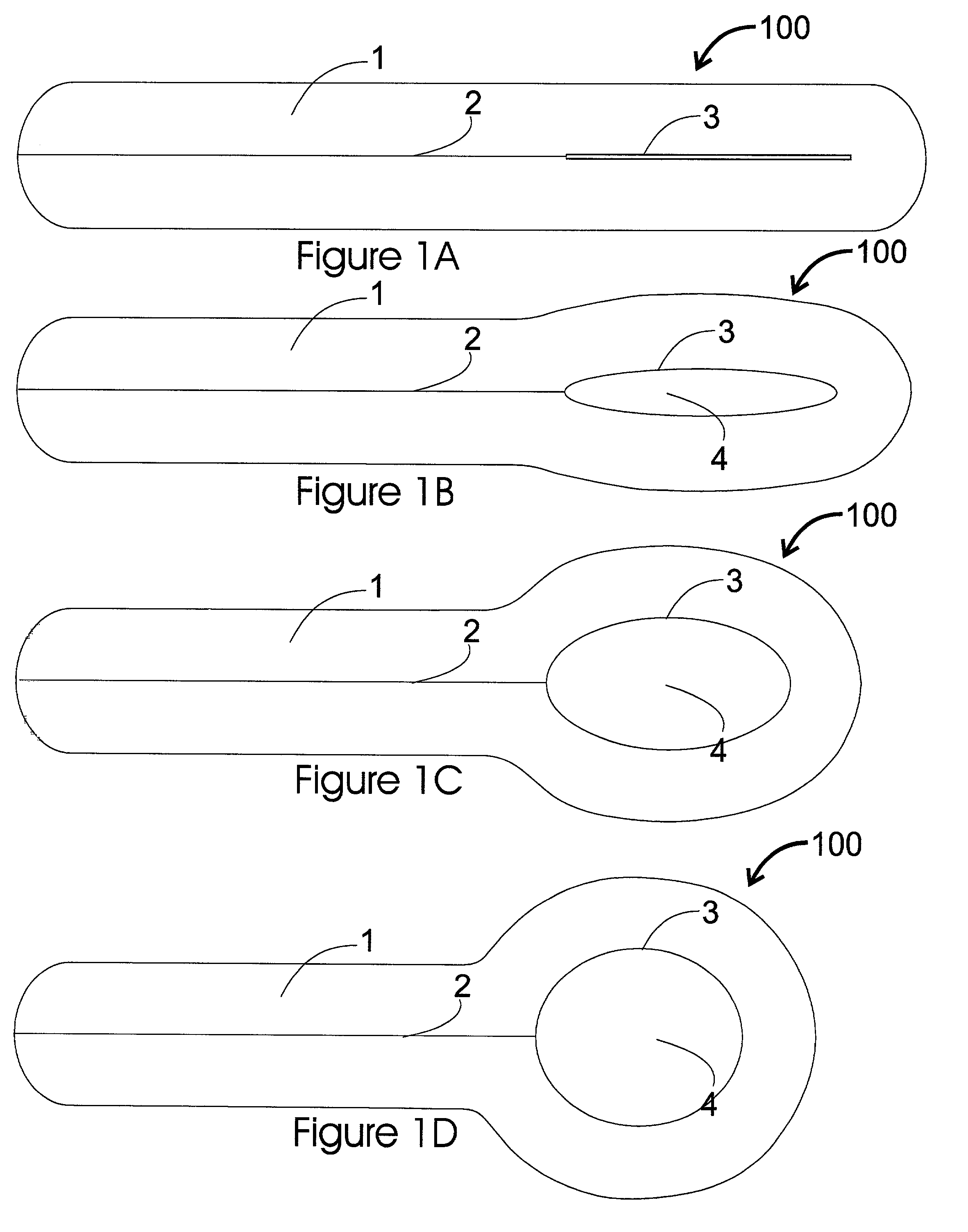

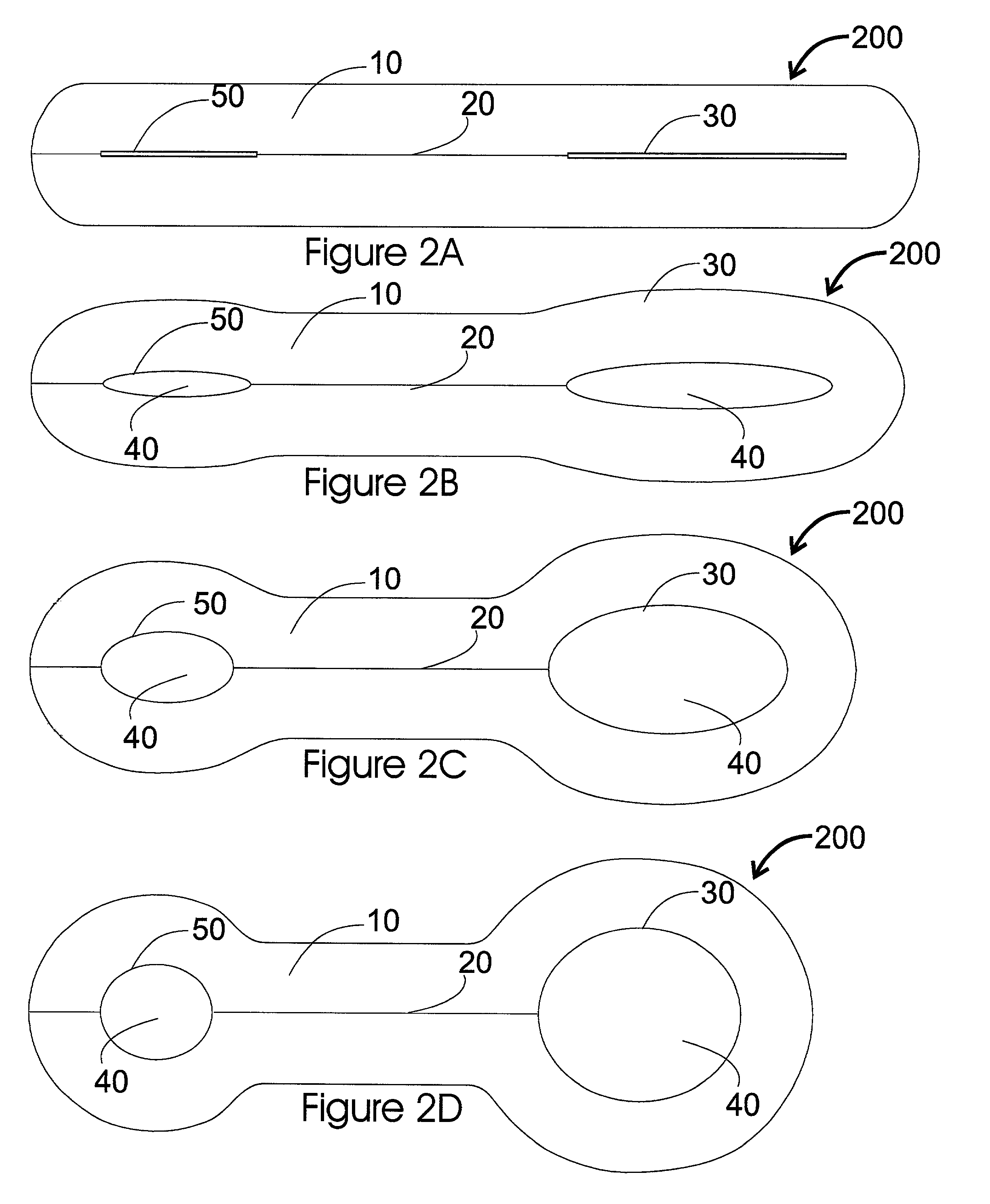

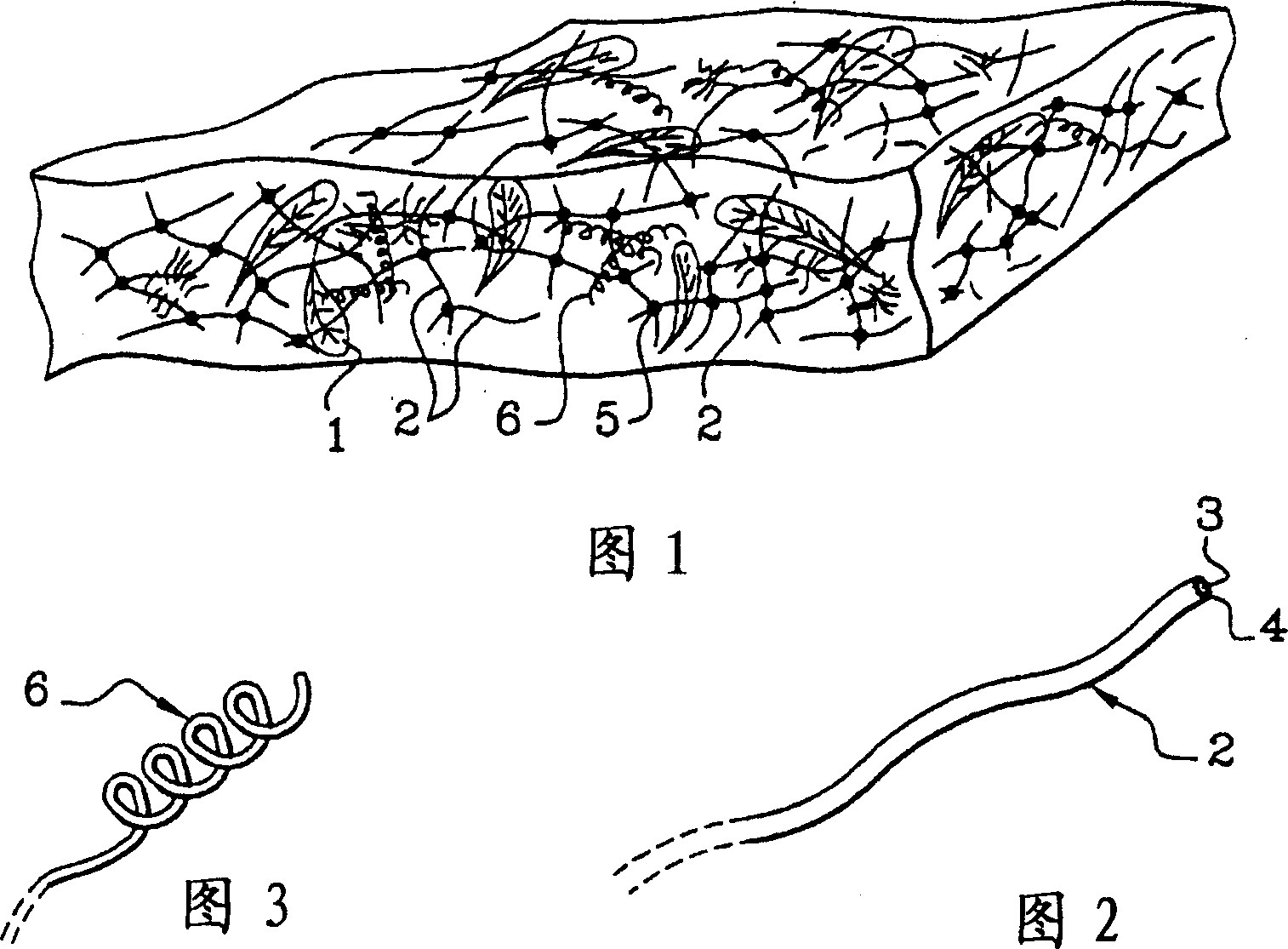

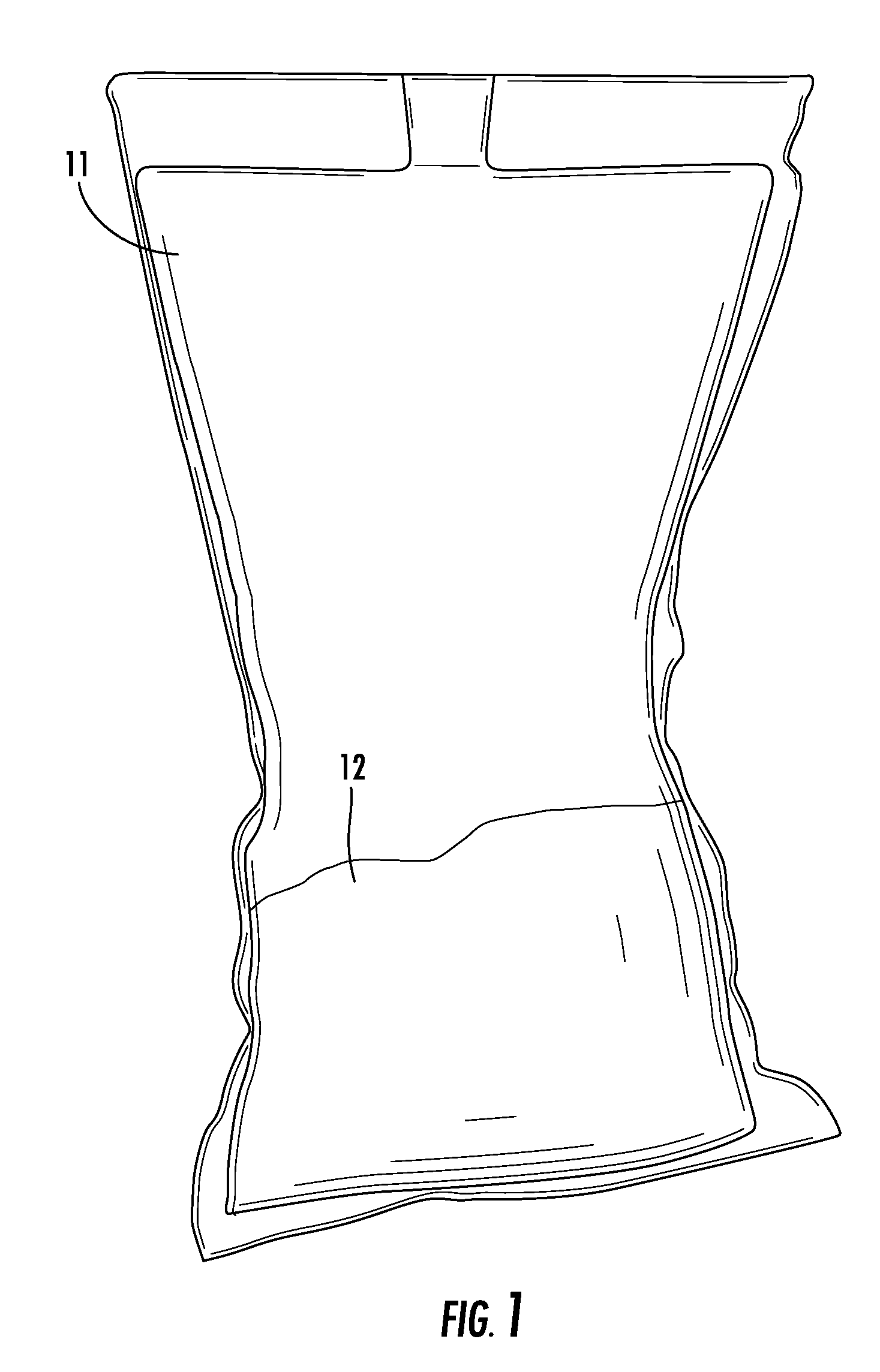

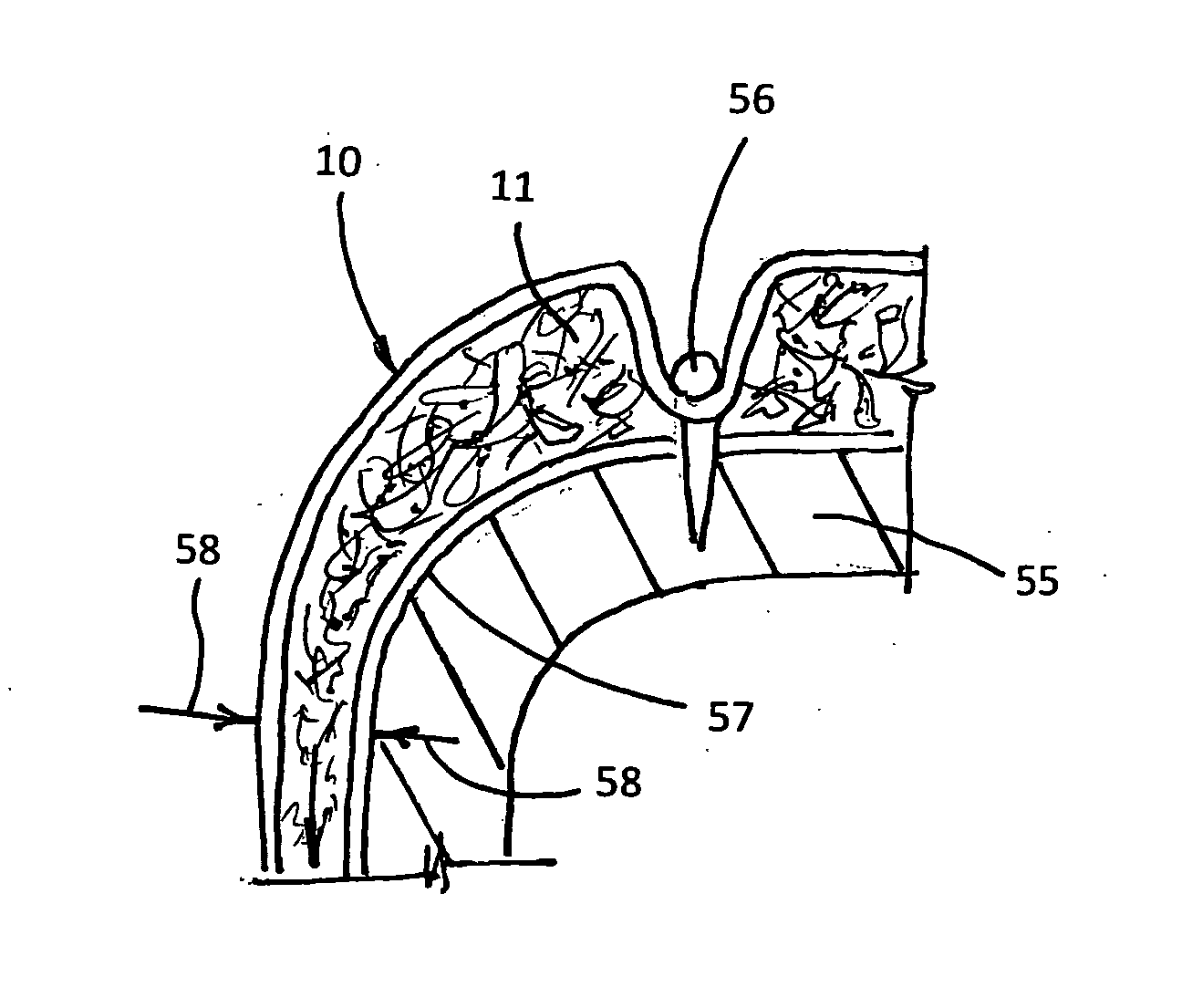

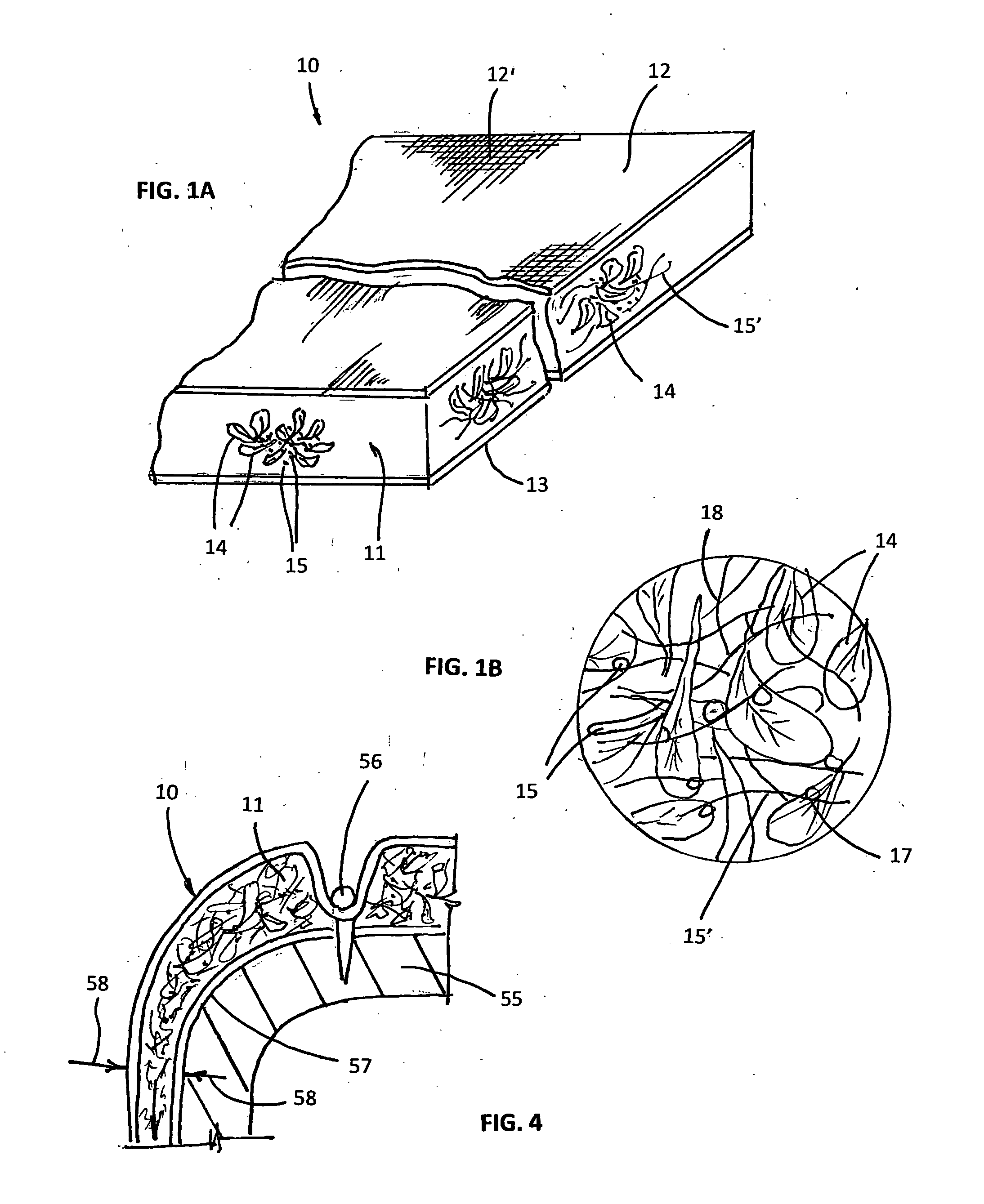

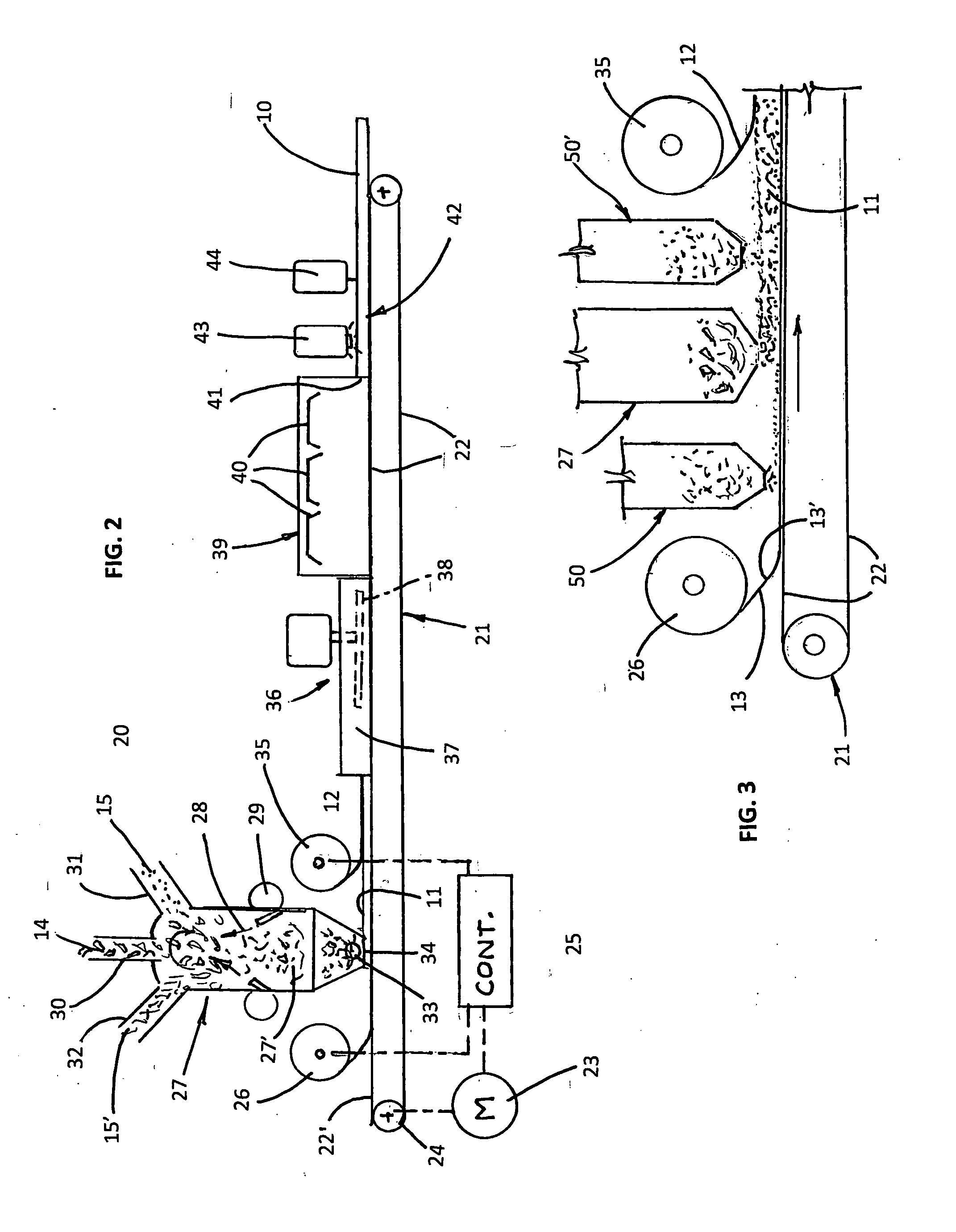

Feather-based padding product, preparation method and installation for implementing said method

The invention concerns a feather-based padding product having a coherent shape resulting from the presence of a structure in the form of a three-dimensional network; said network consists of mutually bound thermoplastic fibres (2), which enclose said feathers. Said fibres (2) are first mixed with the feathers, then with appropriate heat treatment, said fibres are bonded at their contact points (5). The padding product is thus in the form of a web and it is packed in rolls or in the form of slabs.

Owner:ナプテュラル

Plane cocoon warm-keeping type bedding and clothing and method for preparing the same

The present invention is one kind of plate cocoon quilt and its making process. The plate cocoon quilt is made with natural plate cocoon as main material, and through softening, puffing, shrinkproof setting treatment and a conventional process. During its making, natural plate cocoon is first softened through soaking in softening liquid comprising environment friendly softening agent BS-1 in 0.1-0.6 wt%, environment friendly marseilles soap 0.1-0.6 wt% and water 98.8-99.8 wt%, washing and drying; and then shrinkproof set through soaking in shrinkproof setting liquid comprising polyacrylate 5-20 wt% and water 80-95 wt% and drying. The plate cocoon quilt has excellent warming, moisture permeating and air permeating performance, possesses health functions of resisting fungi, resisting oxidation and preventing ultraviolet, and is comfortable.

Owner:丁志强

Flame Retardant Bedding Product

InactiveUS20080254699A1Retain softnessRetains comfortablenessWarp knittingCircular knitting machinesPolyesterPolymer science

A bedding product, such as a pillow or cushion, that satisfactorily drawing out peculiar softness and comfort possessed by an internal filling material, realizes comfort and high flame retardance without detriment to the excellent drape and tactile sensation possessed by a fiber material of flame shielding cloth. There is provided a flame retardant bedding product comprising an internal filling material covered by a flame shielding cloth made of fibers containing 5 to 60 wt. % halogenous fiber (A), 5 to 60 wt. % flame retardant cellulose fiber (B), 0 to 75 wt. % cellulose fiber (C) and 0 to 50 wt. % polyester fiber (D).

Owner:KANEKA CORP

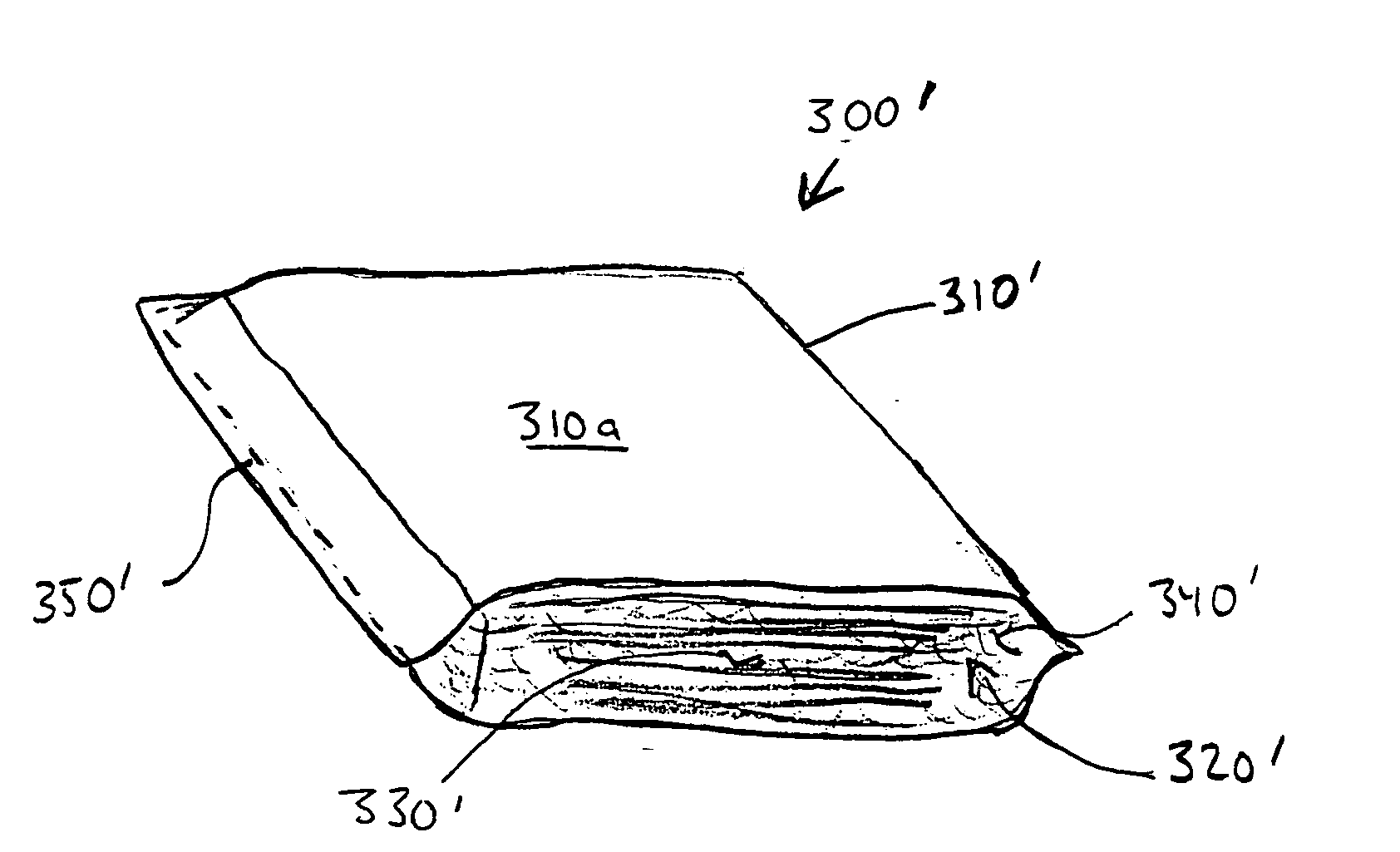

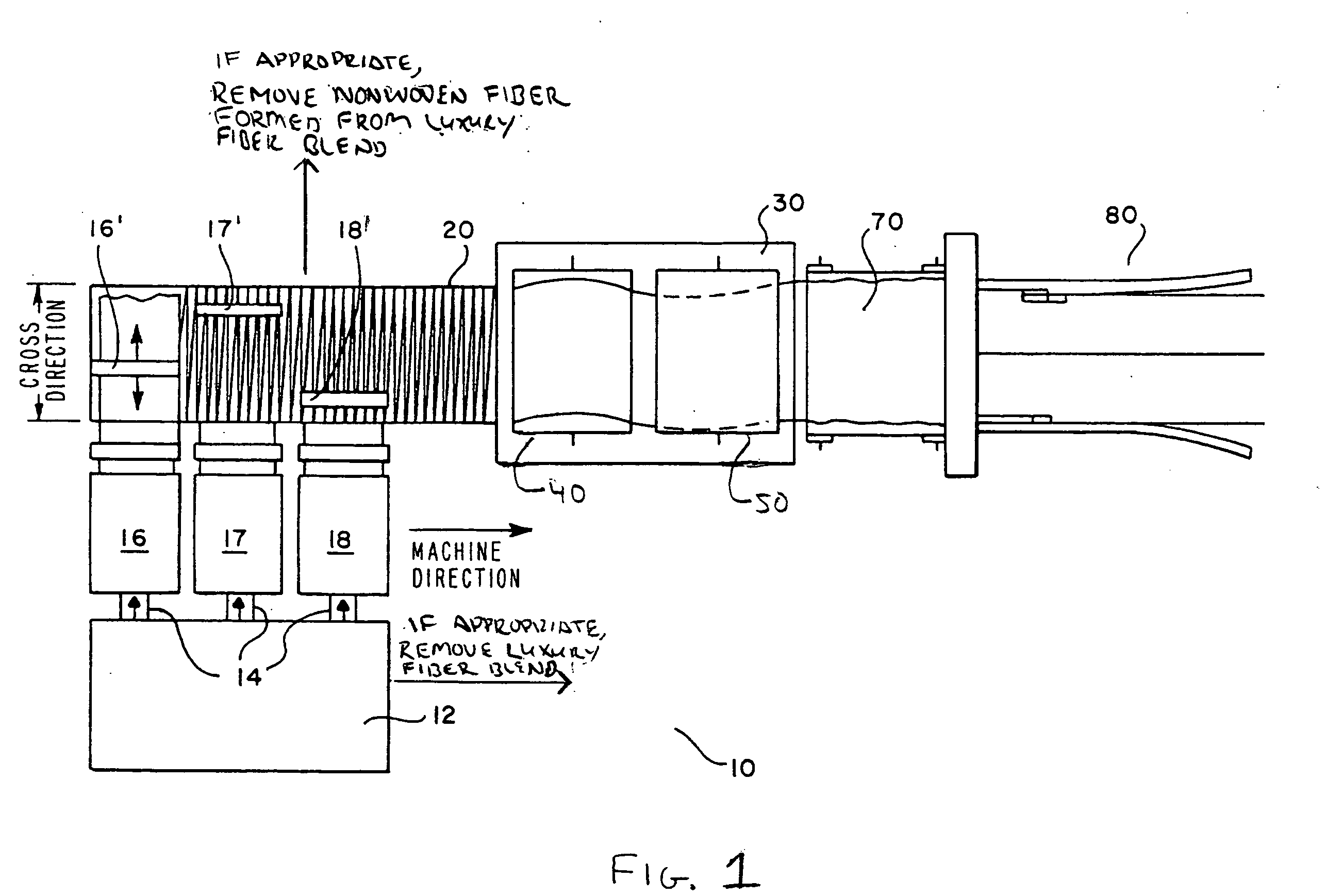

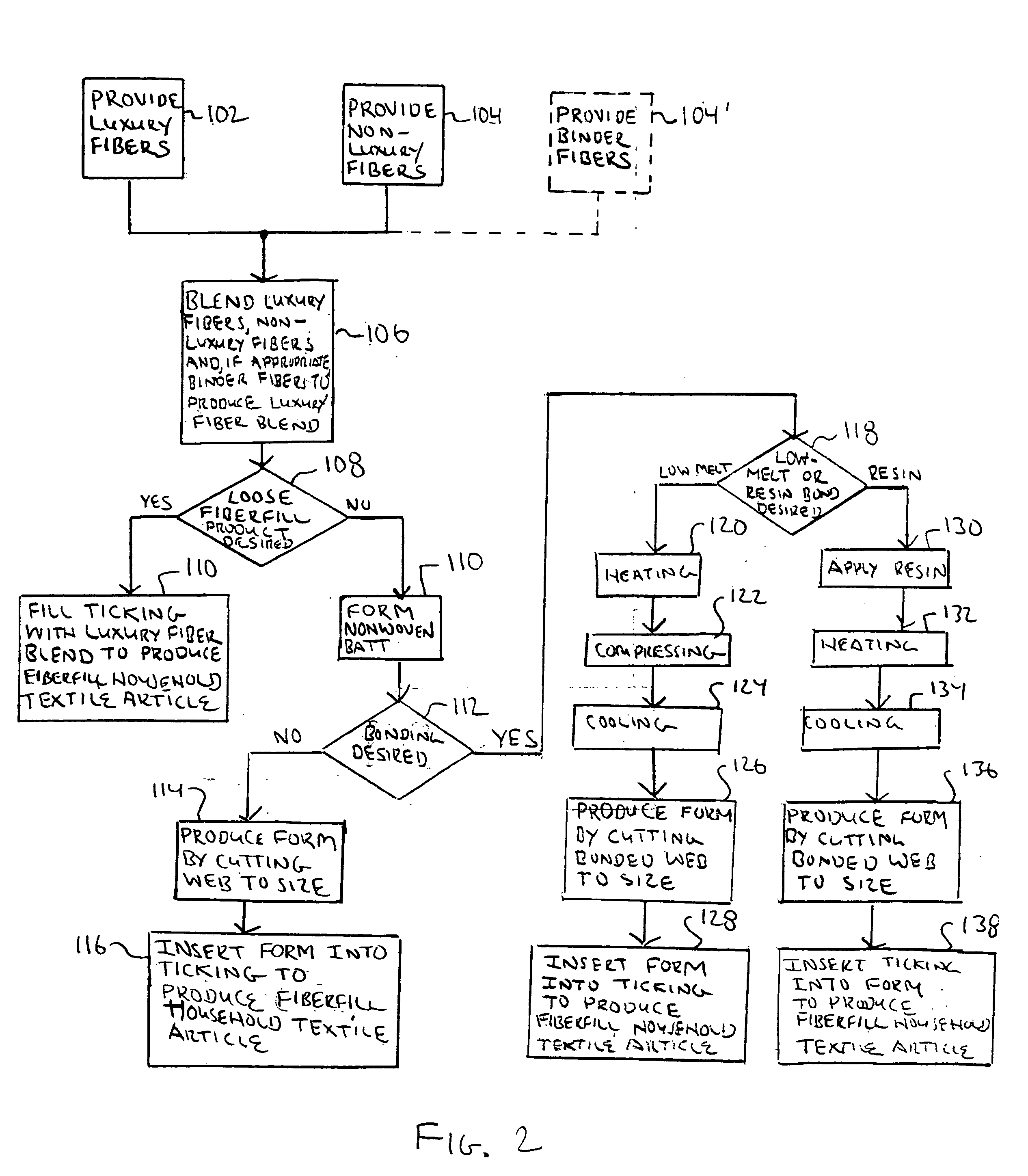

Luxury fiber blend for use in fiberfill household textile articles

A pillow, pillow form, quilt or other household textile article is comprised of a ticking having a fiberfill inserted into an interior space thereof. The fiberfill is comprised of a luxury fiber blend in the form of either loose fibers or a nonwoven fiber batt. The luxury fiber blend is comprised of a first amount, preferably, five percent by weight, of a luxury fiber such as silk or cashmere and a second amount, preferably ninety-five percent by weight, of a non-luxury fiber such as polyester.

Owner:POLYESTER FIBERS LLC A DELAWARE LLC

Method and system of changing flow characteristics of a support

ActiveUS20120311787A1Increase heightMaintain support effectSofasCouchesEngineeringParticulate material

The present invention provides a method and system for customization of flow characteristics of a support using permanent and controlled evacuation of interstitial gas during the manufacturing process. The flow characteristics can be customized to provide a stiffer or less stiff support by a comparative degree. The flow characteristics can be permanently changed. The support includes a bladder filled with a fluidized particulate material. The medium of the fluidized particulate material includes interstitial spaces. A predetermined amount of gas can be removed to provide a support having a desired specific support characteristic.

Owner:MOLNLYCKE HEALTH CARE AB

Antibacterial thermal down quilt manufacturing method

InactiveCN108100984AEasy to manufactureGuaranteed cleanlinessUpholstery manufactureBiochemical fibre treatmentFiberManufacturing engineering

The invention provides an antibacterial thermal down quilt manufacturing method and solves technical problems of excessive procedures, manufacturing complexity and the like of existing manufacturing methods. The manufacturing method includes steps: S1, selecting down filler for manufacturing down quilts; S2, subjecting the down filler in the step S1 to pretreatment; S3, drying the down filler subjected to pretreatment in the step S2; S4, adopting an ultraviolet sterilization device for sterilizing the down filler dried in the step S3; S5, mixing heating fibers and antibacterial fibers into mixed filler, soaking the mixed filler into finishing liquid by consumption of 10-30g / L, and keeping the temperature at 70-80 DEG C for 10-60min, wherein a pH value is 6.5-7.5; S6, subjecting the mixed filler treated by the finishing liquid in the step S5 to compression shaping, and cleaning for 10-30min in a cleaning device. The antibacterial thermal down quilt manufacturing method has advantages ofsimplicity and convenience in manufacturing.

Owner:海宁市锦涤化纤有限公司

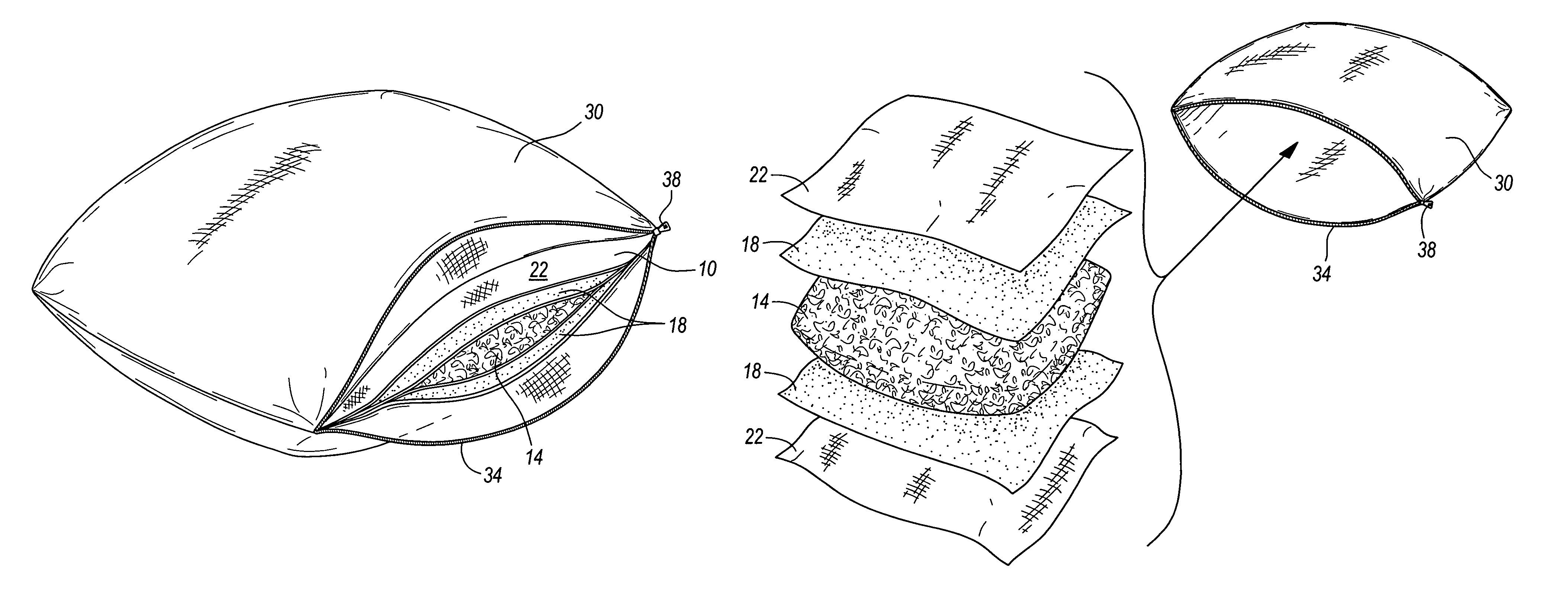

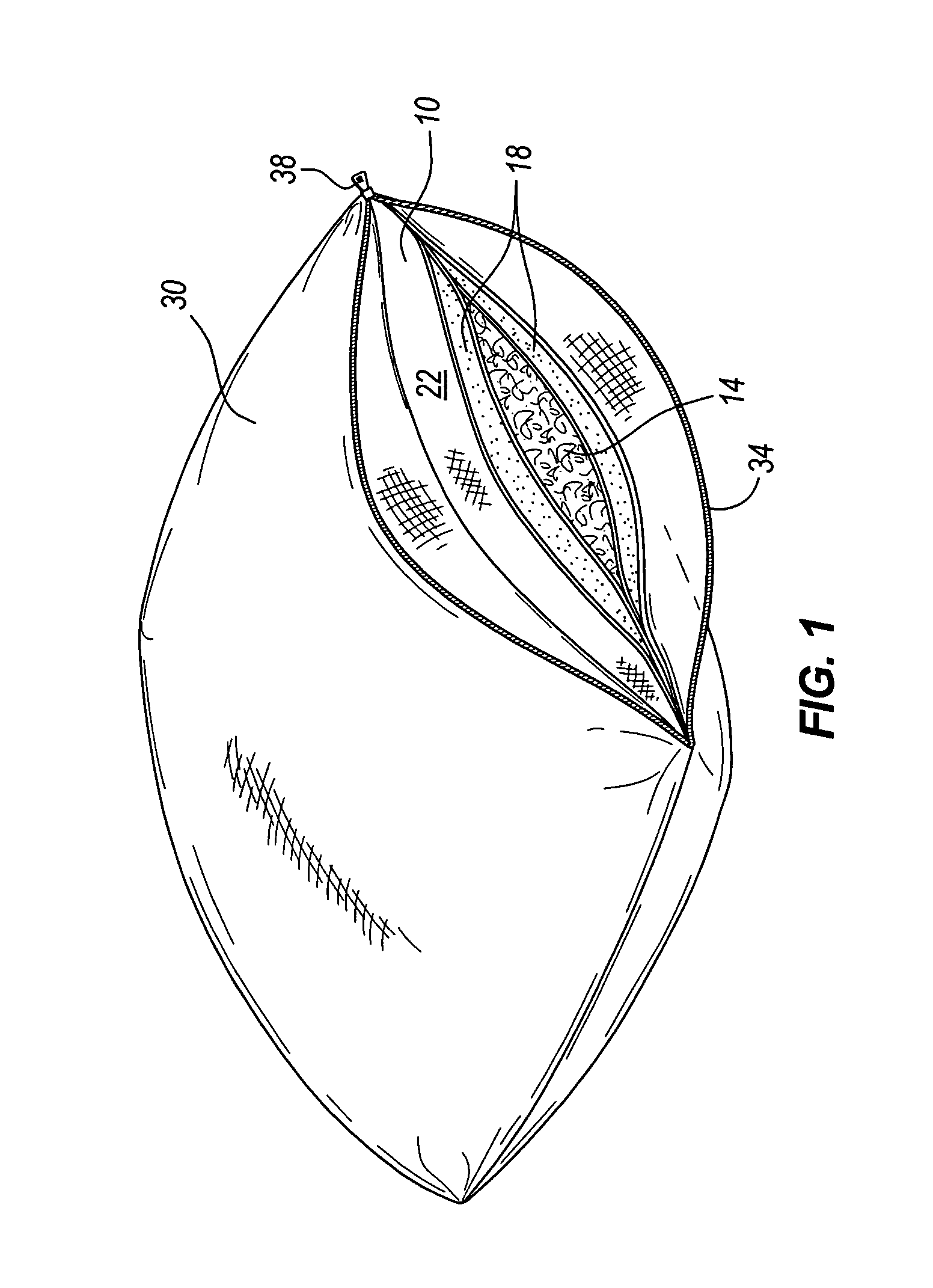

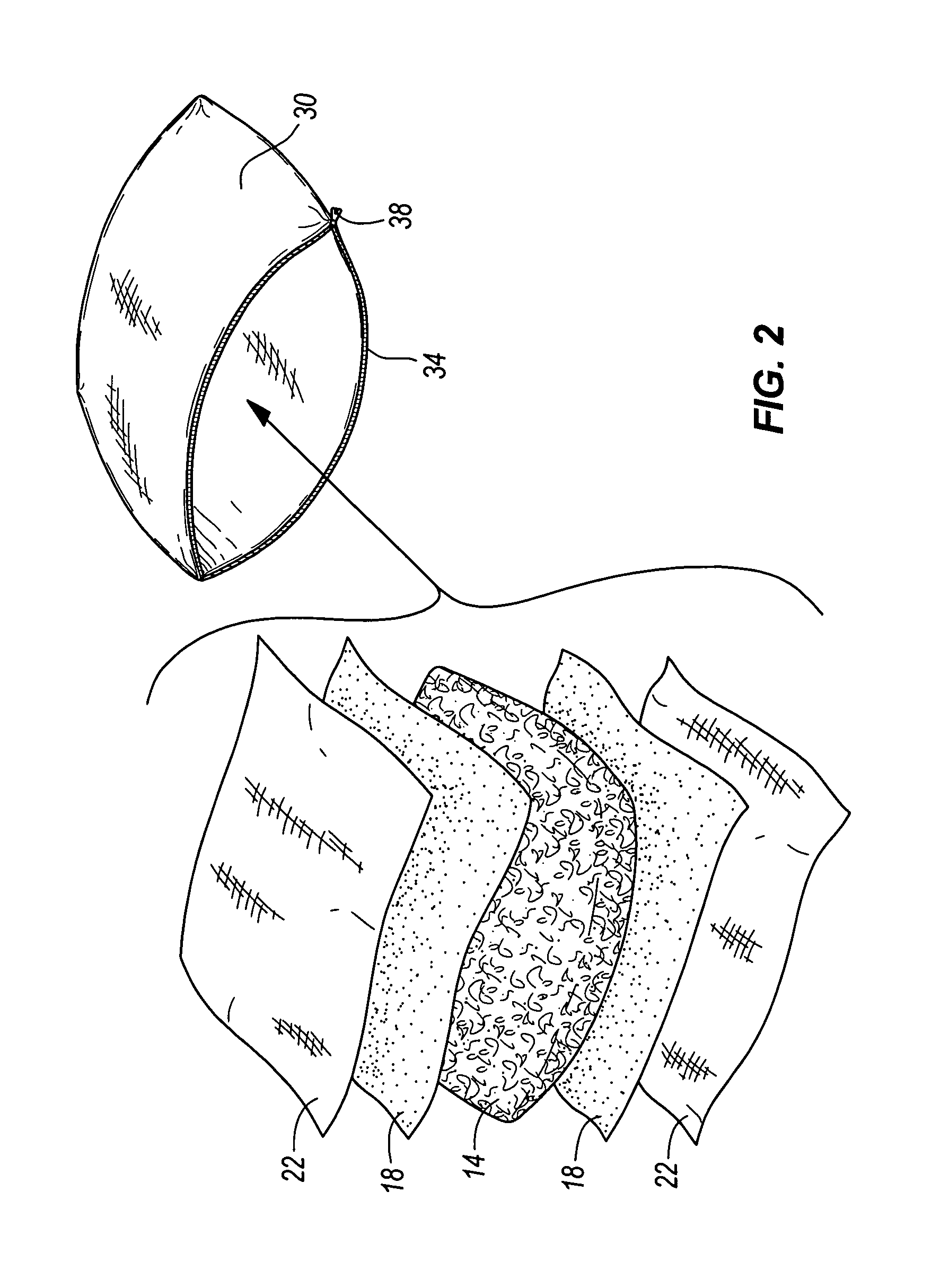

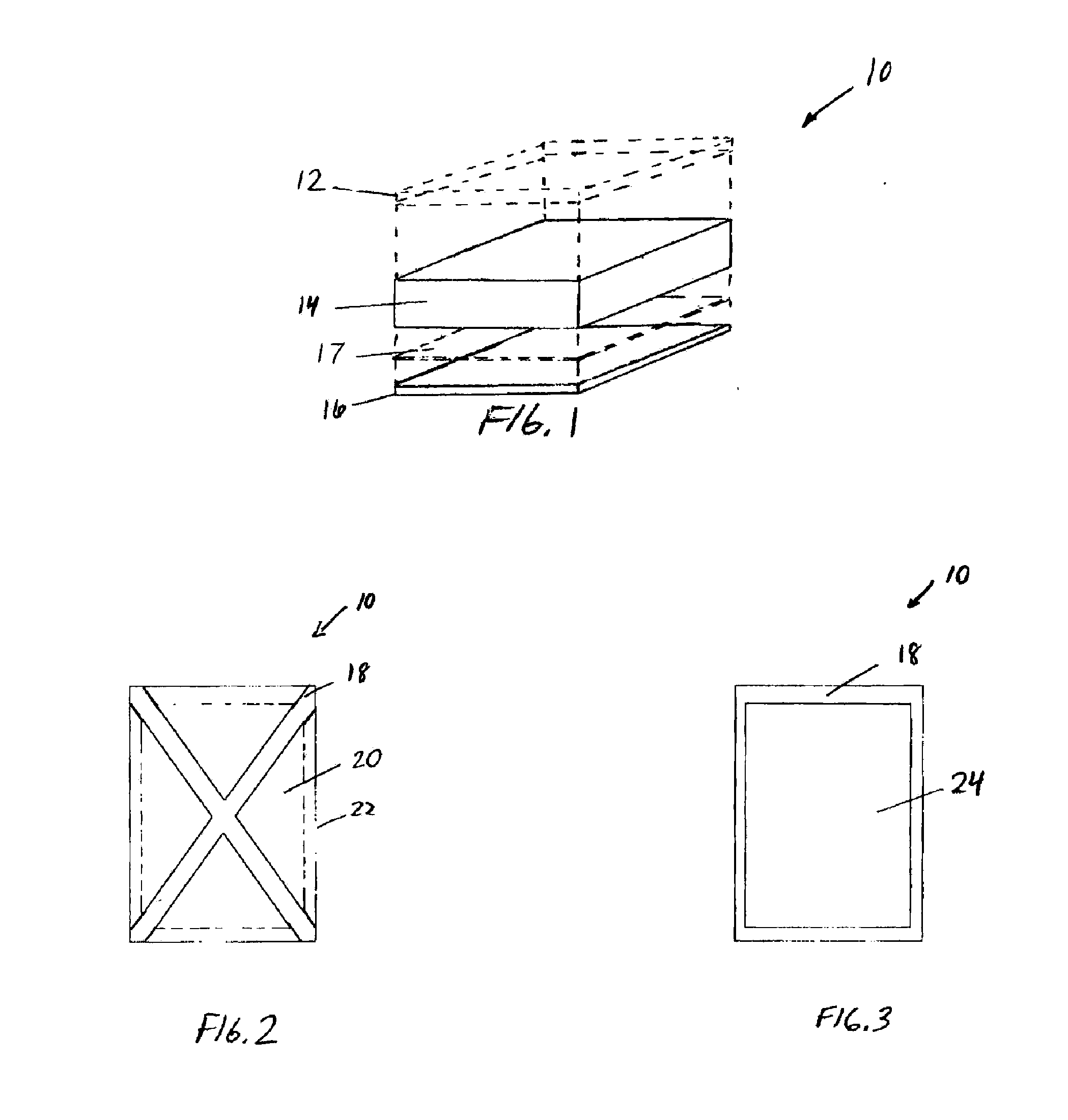

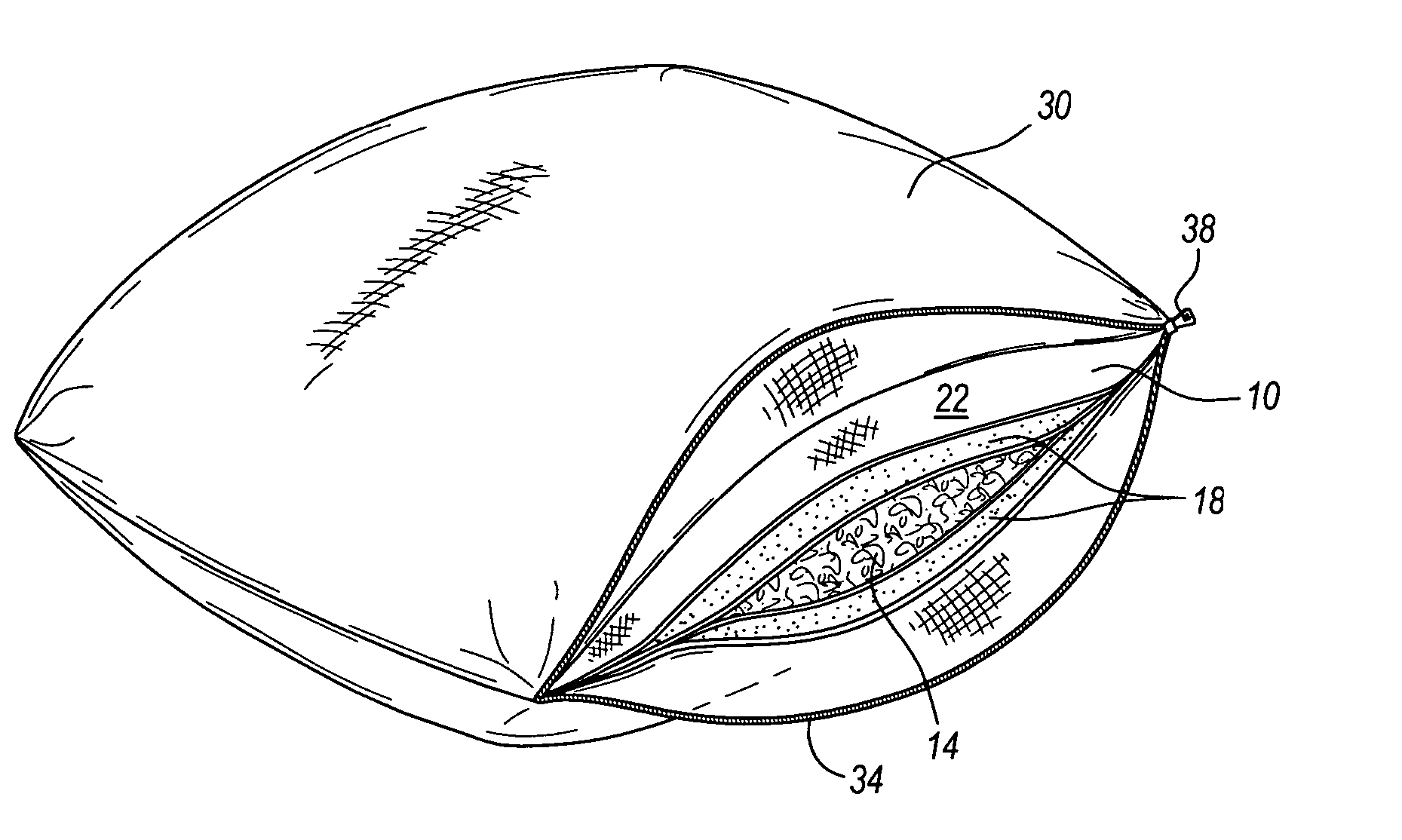

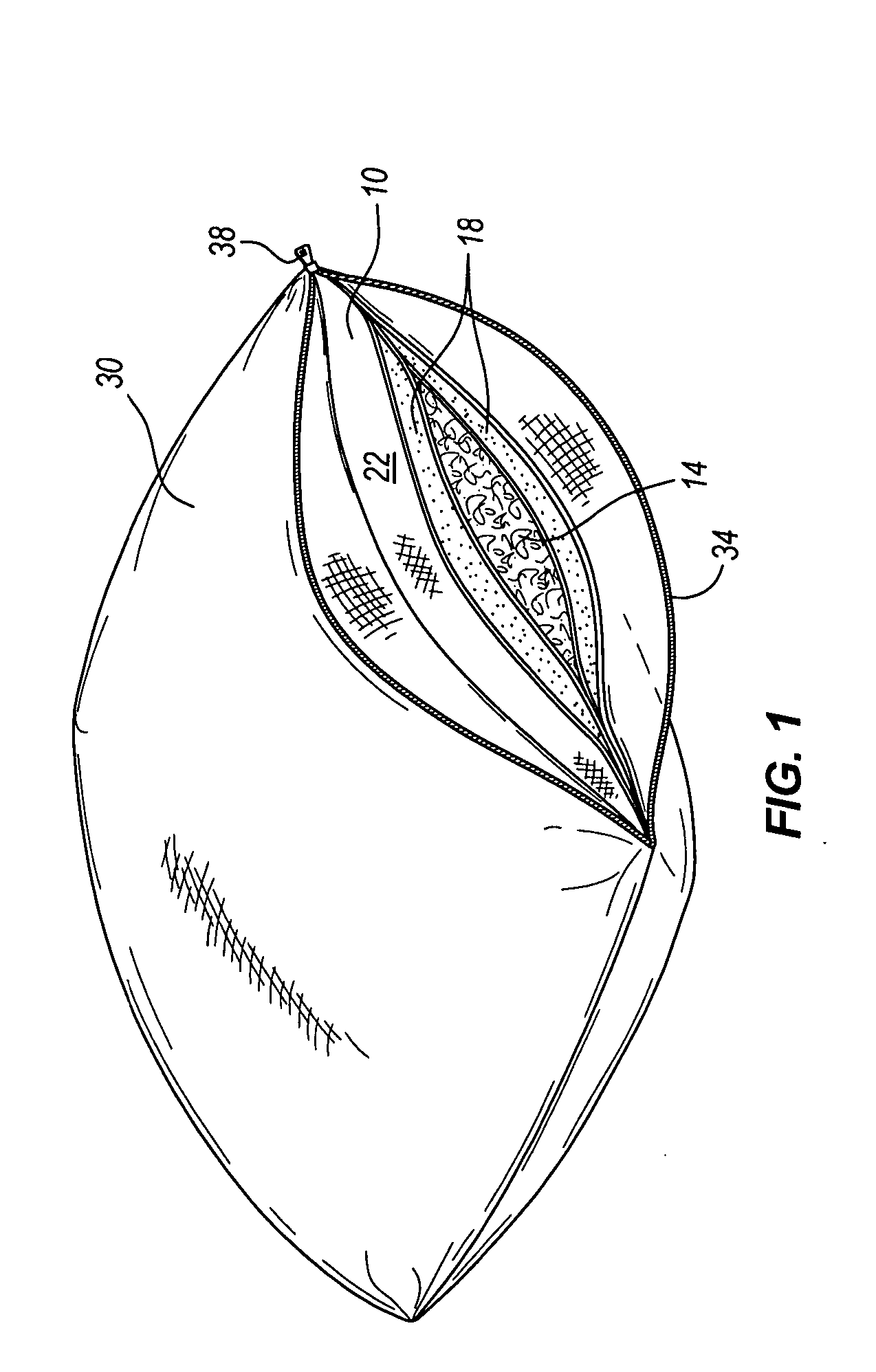

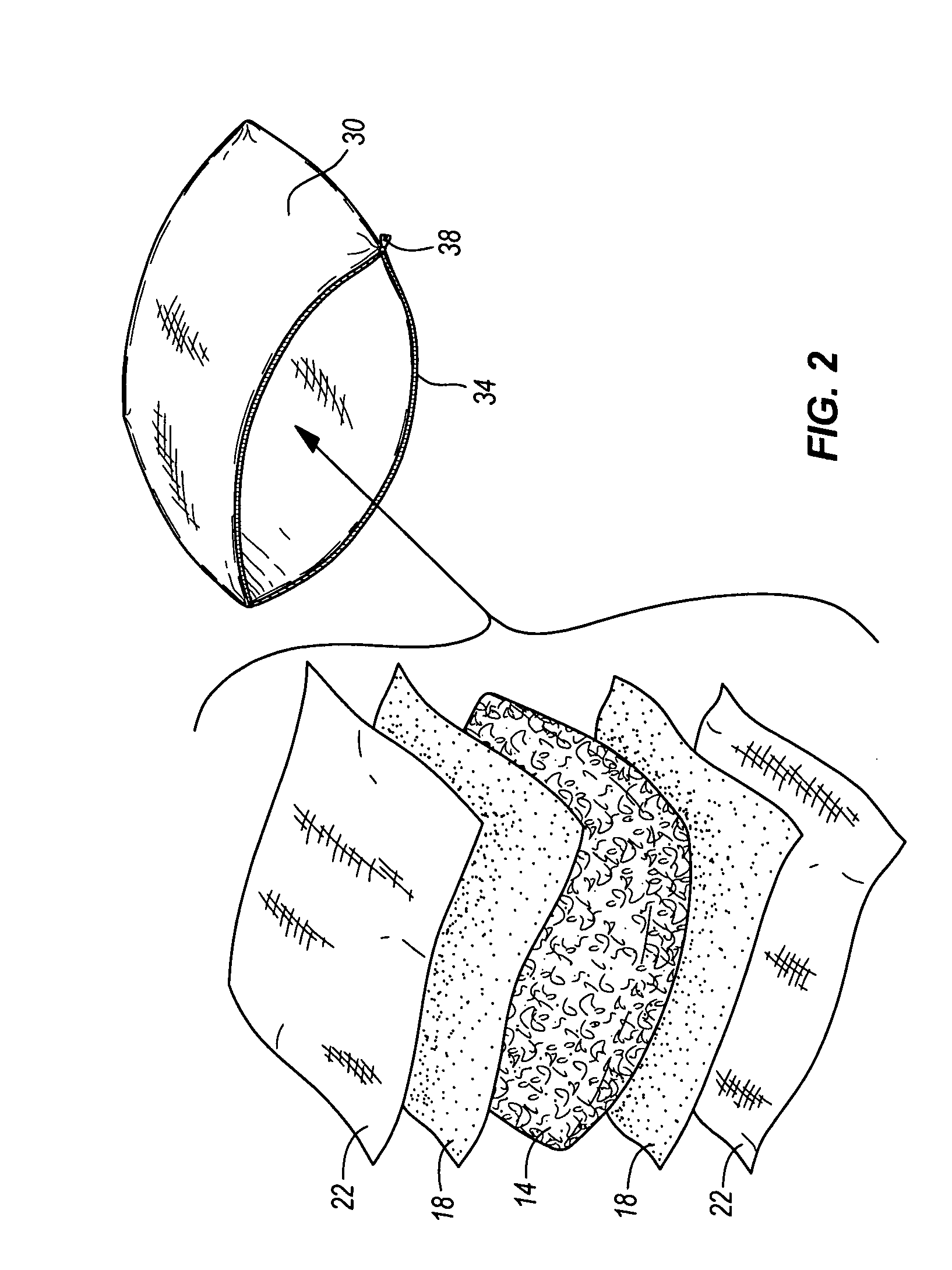

A pillow with multi-layered structure

Provided is a pillow which is manufactured by reflecting the structure of an arm pillow of a user, and provides various functions and advantages by using a multi-layered structure in which the respective layers have different compressibility and are deformed differently. The pillow with a multi-layered structure includes an intermediate layer and an outer layer, and may further include a core. The core supports the cervical vertebrae when the head is laid on the pillow. The outer layer includes a first support section formed to cover the intermediate layer and support the cervical vertebrae, and a second support section formed to extend from the first support section and support the head. The outer layer is formed of a soft material, and the internal structure of the pillow is formed of materials whose elasticity and hardness increase toward the center of the pillow. Therefore, the pillow provides softness and elasticity like a person's arm. Further, the shape of the pillow is constantly maintained, so that the normal posture of the cervical vertebrae can be maintained.

Owner:吴锡宽

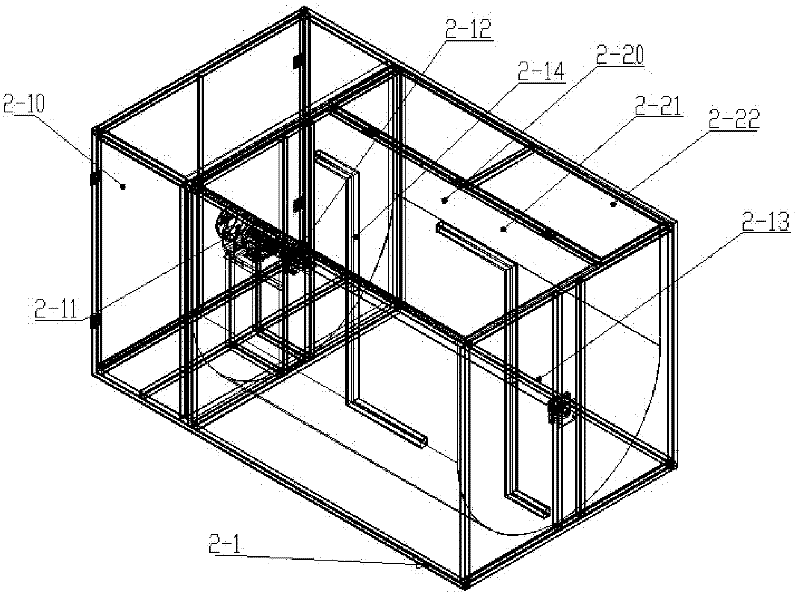

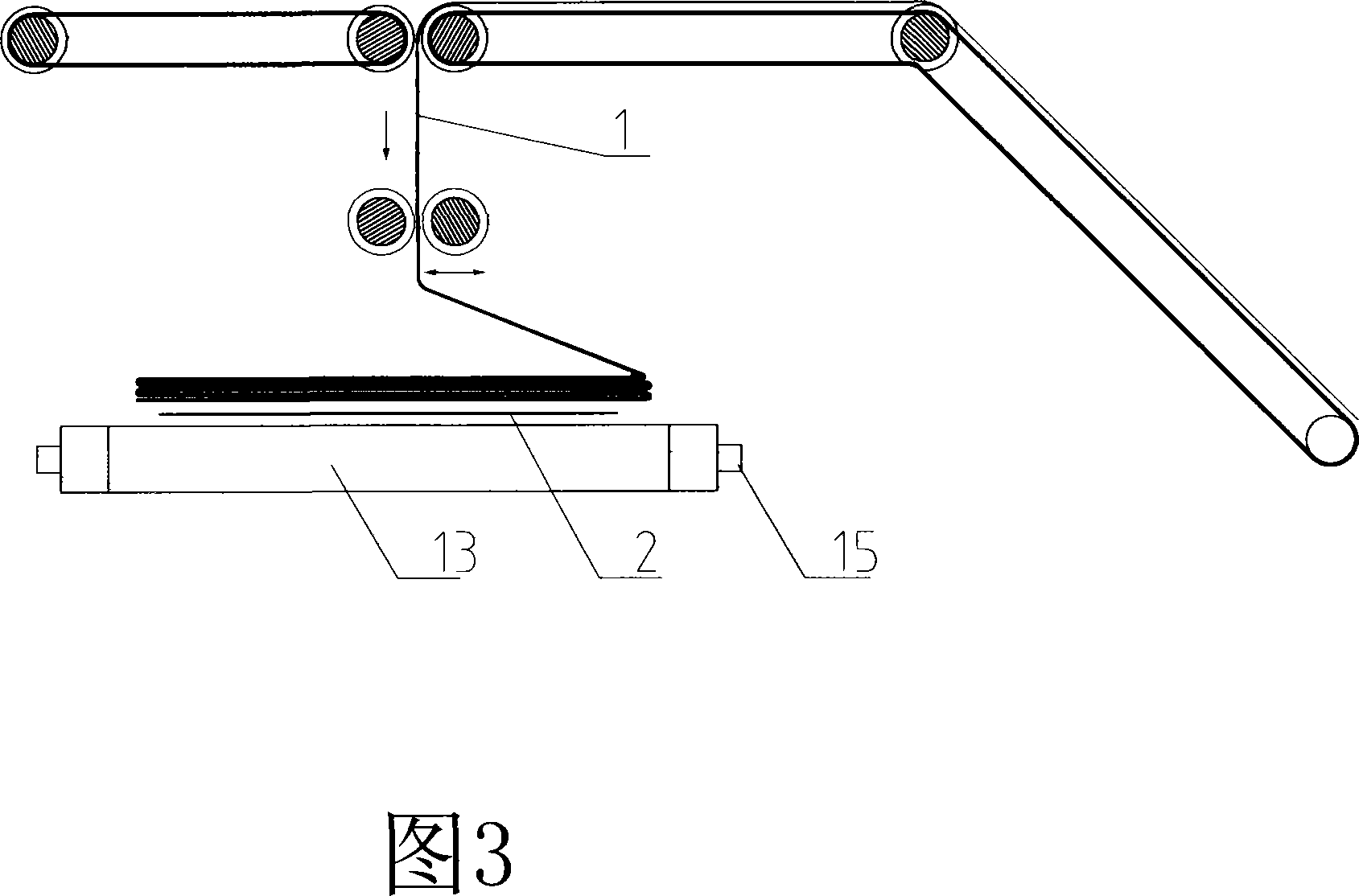

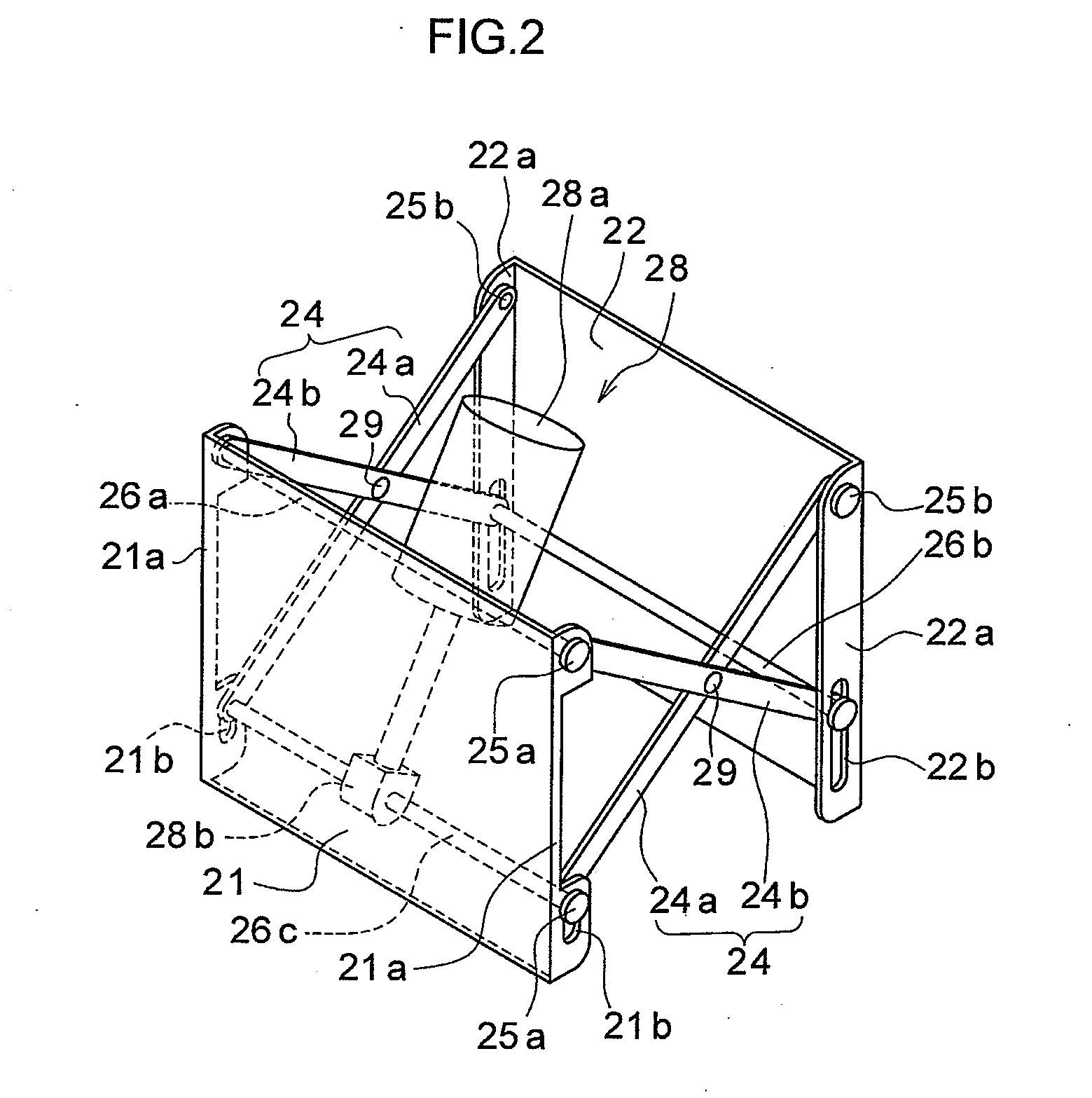

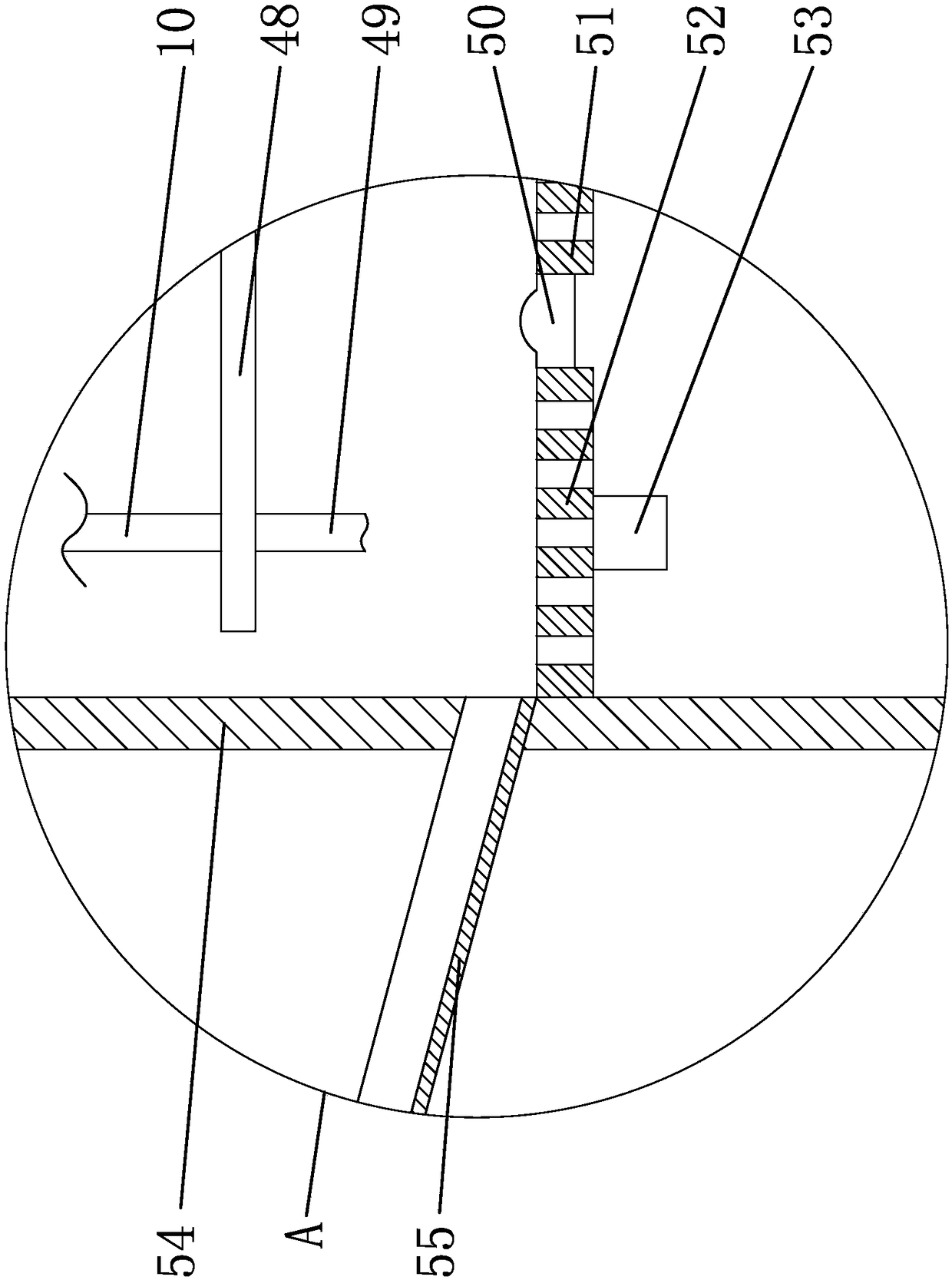

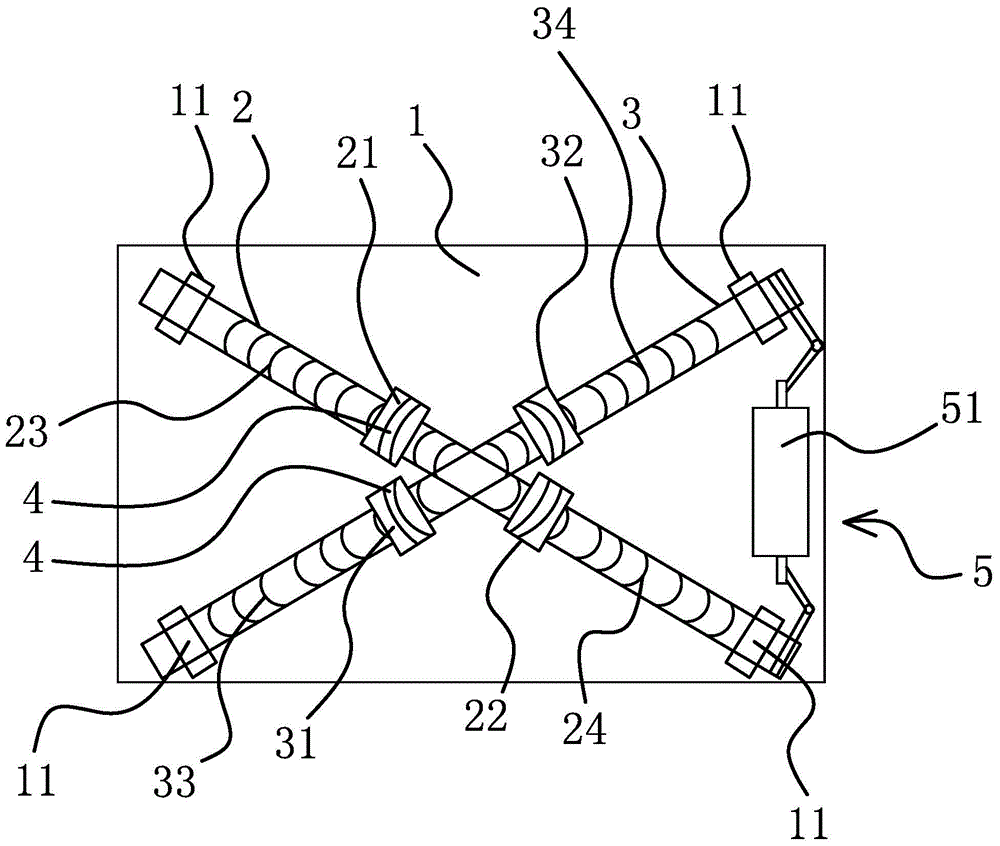

Silk drawing driving mechanism for silk liner in silk quilt

ActiveCN104528628AUniform thicknessIncrease productivityGearingUpholstery fillingEngineeringMechanical engineering

The invention relates to a silk drawing driving mechanism for a silk liner in a silk quilt. The silk drawing driving mechanism solves the problem that the design in the prior art is not reasonable enough. The silk drawing driving mechanism comprises a rack; a first driving rod and a second driving rod are arranged on the rack; the middle of the first driving rod and the middle of the second driving rod are arranged in an intersected mode; a first movement sleeve and a second movement sleeve are arranged on the first driving rod; a third movement sleeve and a fourth movement sleeve are arranged on the second driving rod; each of the first movement sleeve, the second movement sleeve, the third movement sleeve and the fourth movement sleeve is provided with a silk drawing block; each of the first driving rod and the second driving rod is connected with a driving assembly; a first connecting structure is arranged on the first driving rod; and a second connecting structure is arranged on the second driving rod. The silk drawing driving mechanism has the beneficial effects that the structure is simple; stability is good; coincidence in all directions in the silk drawing process can be guaranteed; the thickness of the silk liner in the finished product is uniform; the production efficiency is high; and the cost is low.

Owner:浙江爱尚家科技股份有限公司

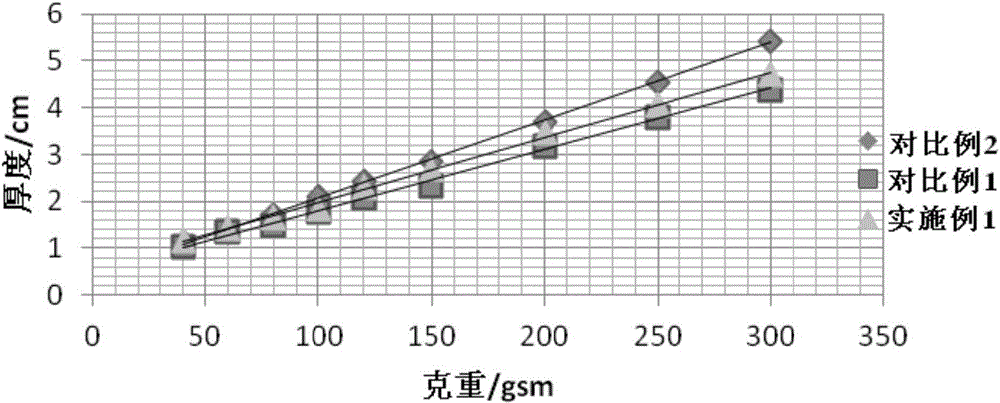

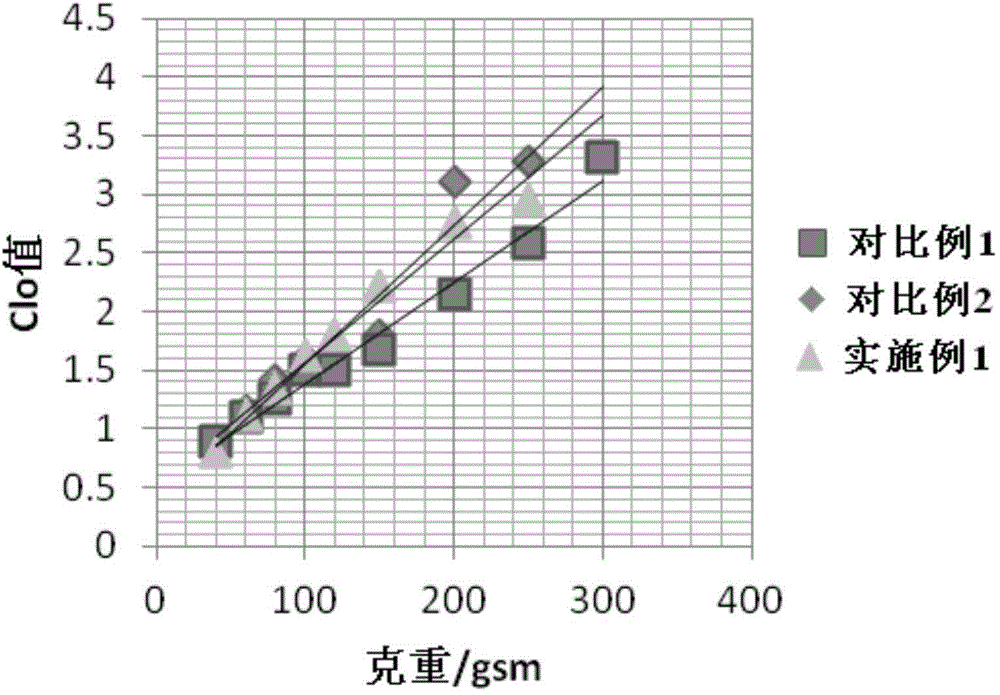

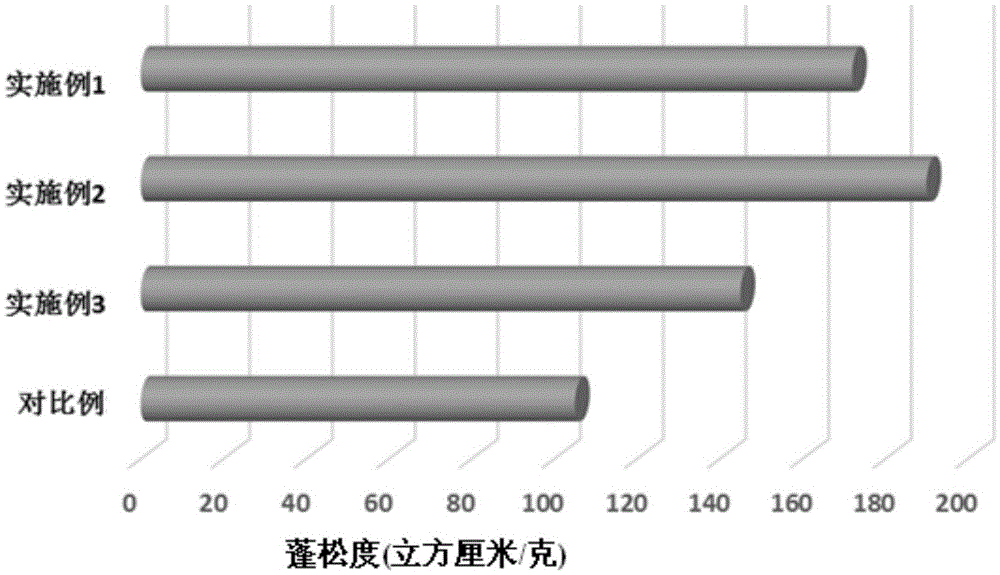

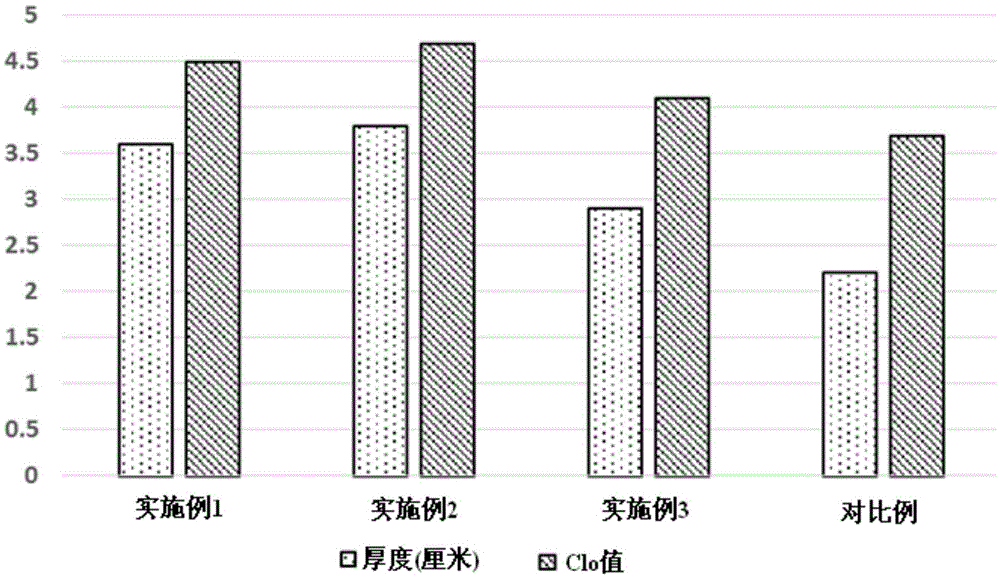

Insulating packing material, preparation method thereof and insulating product comprising same

The embodiment of the invention provides an insulating packing material, a preparation method thereof and an insulating product comprising the same, and belongs to the technical field of insulating packing materials. The insulating packing material comprises loose fibers and spherical fiber assemblies. The weight ratio between the loose fibers and the spherical fiber assemblies ranges from 20:80 to 80:20. On the premise of keeping the good heat retention property and fluffiness of the insulating packing material, the water resistance of the insulating packing material is substantially improved.

Owner:3M INNOVATIVE PROPERTIES CO

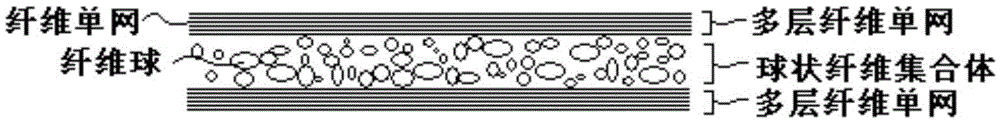

Heat preservation flocculus material, preparing method of heat preservation flocculus material and heat preservation product

InactiveCN105463697AFluffiness is goodGood compression resiliencePillowsSleeping rugSingle fiberMaterials science

The invention provides a heat preservation flocculus material, a preparing method of the heat preservation flocculus material and a heat preservation product, and belongs to the technical field of heat preservation flocculus materials. The heat preservation flocculus material comprises a plurality of stacked single fiber nets and spherical fiber assemblies at least distributed between part of the adjacent single fiber nets. The heat preservation flocculus material has the excellent comprehensive performance such as filling power, compression rebound resilience, heat preservation performance and washing resistance.

Owner:3M INNOVATIVE PROPERTIES CO

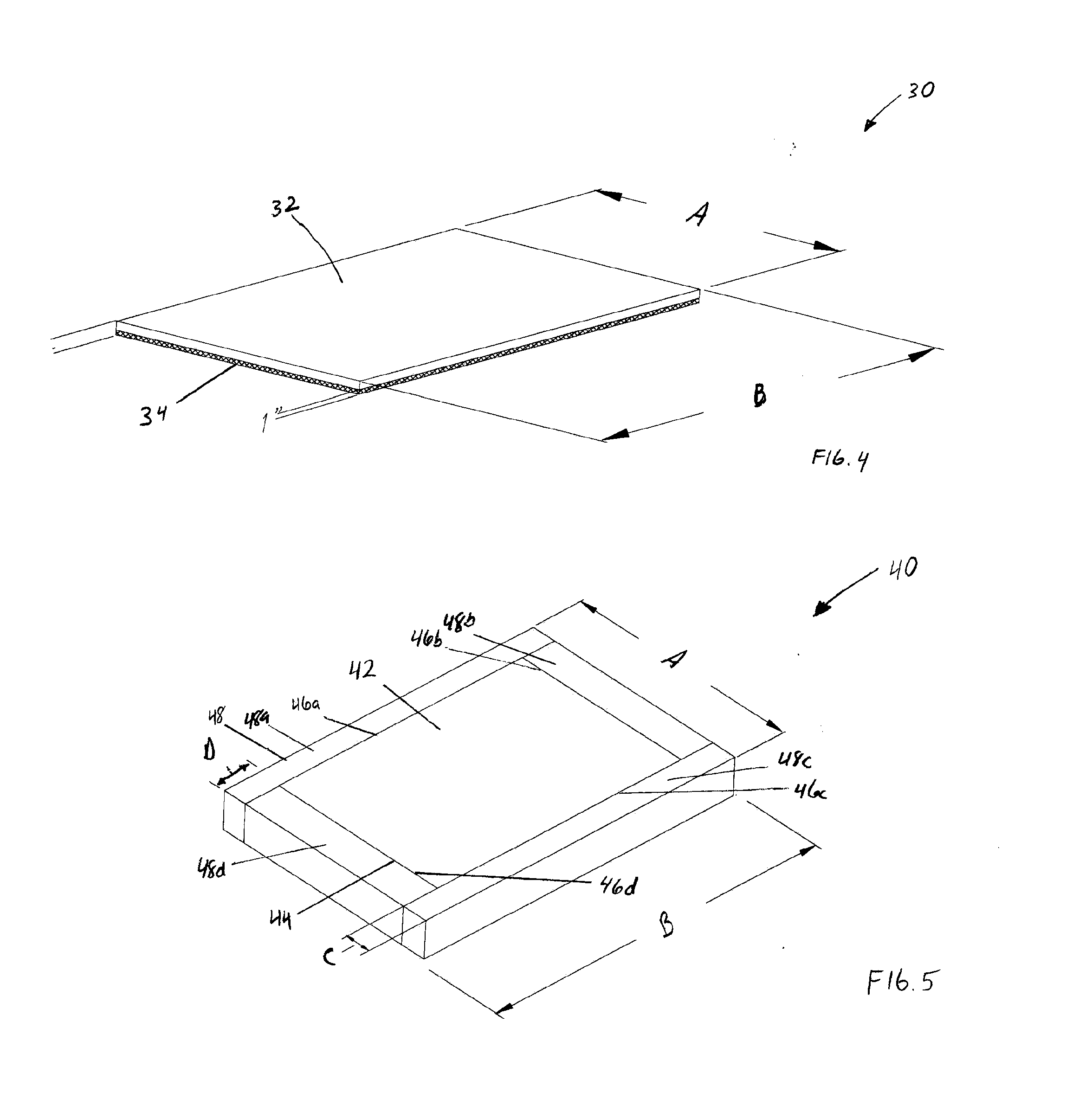

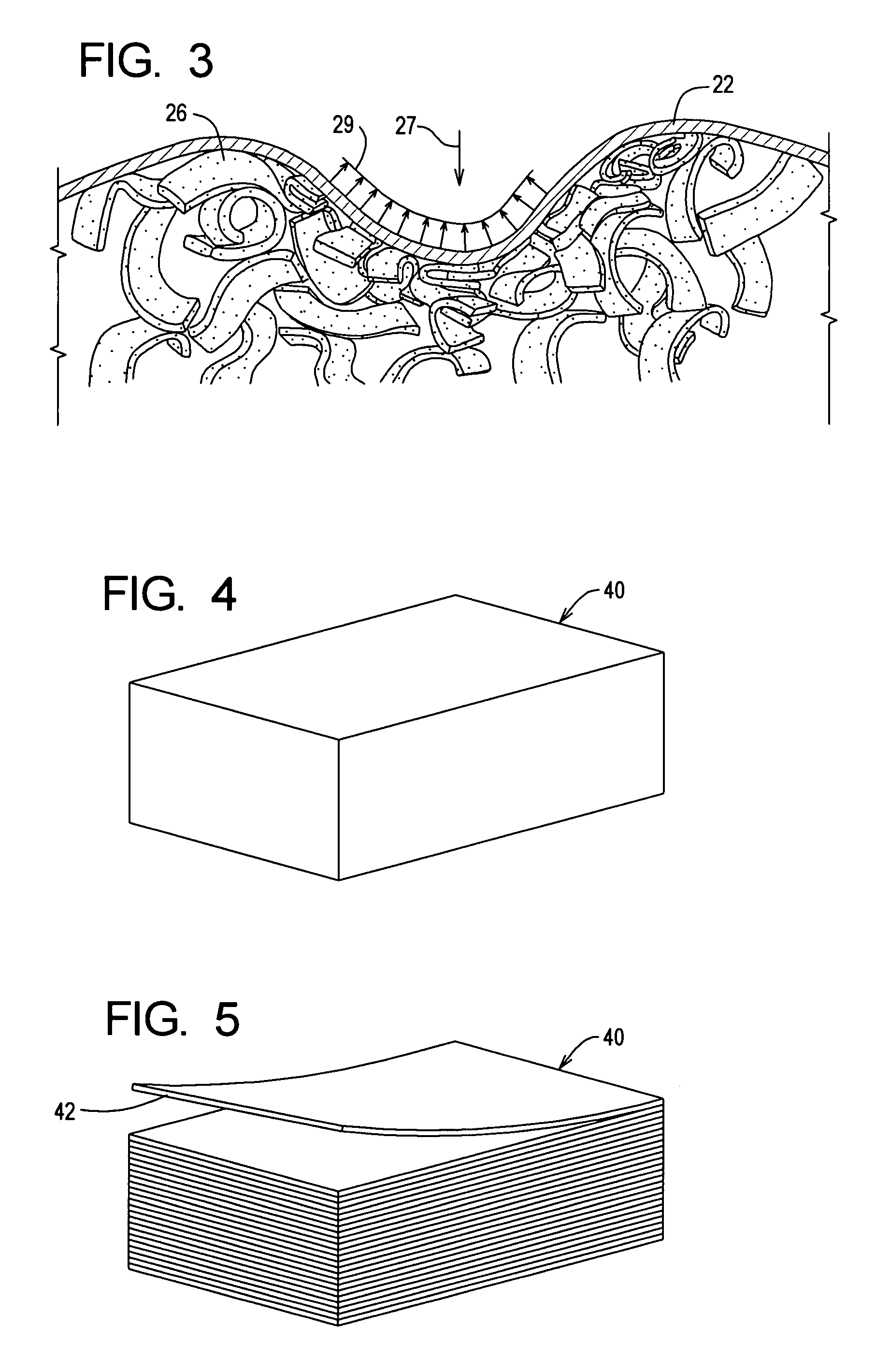

Thermally Insulating Stretchable Down Feather Sheet and Method of Fabrication

A thermally insulating stretchable down feather sheet and its method of manufacture is described. The core of the sheet is comprised of down feathers mixed with a binder which exhibits elastic properties. The core is sandwiched between a top and bottom stretchable elastomeric sheet having multi-directional stretchability. The core down feathers and the binder as well as the elastomeric sheet and bound together by heat treatment to provide a down feather insulating sheet which is stretchable in all directions without fractioning the sheet.

Owner:7513194 CANADA

Coconut palm fiber elastic cushion

InactiveCN1579927AModerate elasticityUniform densityUpholstery manufactureNatural rubber adhesivesEngineeringPalm fiber

A stretch cushion is made of coir fiber. After steamed under a high pressure, carded by mechanism, sprayed glue (which is mixed by natural lactoprenes), dried, sulfuration and other processing technics, the cushion has a good air permeability, hydraulic permeability, and hygroscopicity. Also its processing technic is simple. It is warm in winter while cold in summer. With this character, it fits to make bed-cushion and seating cushion, and also it can be used as sound-proof, non-hygroscopic and packaging materials.

Owner:黄志平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com