Patents

Literature

47results about How to "Retain softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame Retardant Bedding Product

InactiveUS20080254699A1Retain softnessRetains comfortablenessWarp knittingCircular knitting machinesPolyesterPolymer science

A bedding product, such as a pillow or cushion, that satisfactorily drawing out peculiar softness and comfort possessed by an internal filling material, realizes comfort and high flame retardance without detriment to the excellent drape and tactile sensation possessed by a fiber material of flame shielding cloth. There is provided a flame retardant bedding product comprising an internal filling material covered by a flame shielding cloth made of fibers containing 5 to 60 wt. % halogenous fiber (A), 5 to 60 wt. % flame retardant cellulose fiber (B), 0 to 75 wt. % cellulose fiber (C) and 0 to 50 wt. % polyester fiber (D).

Owner:KANEKA CORP

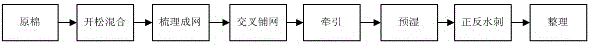

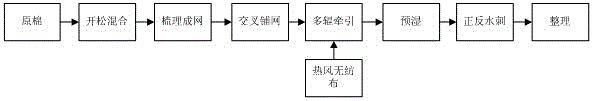

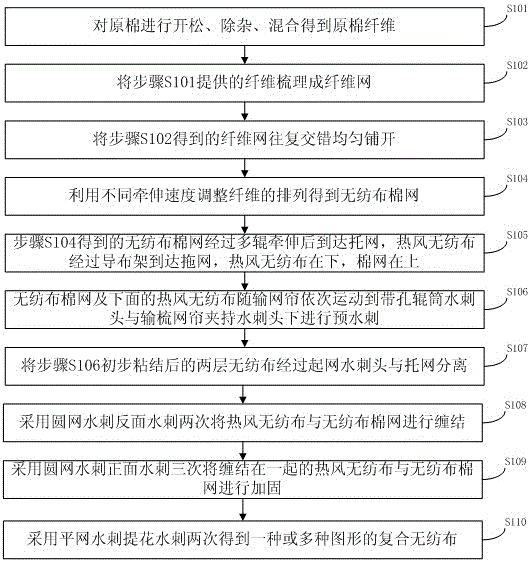

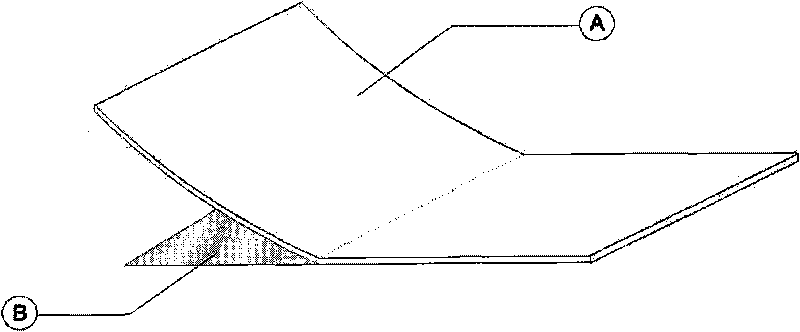

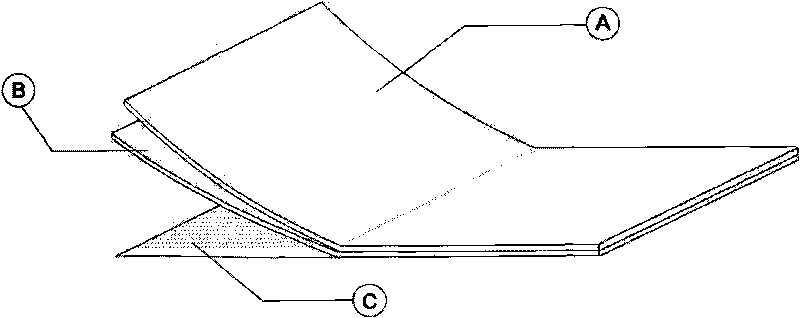

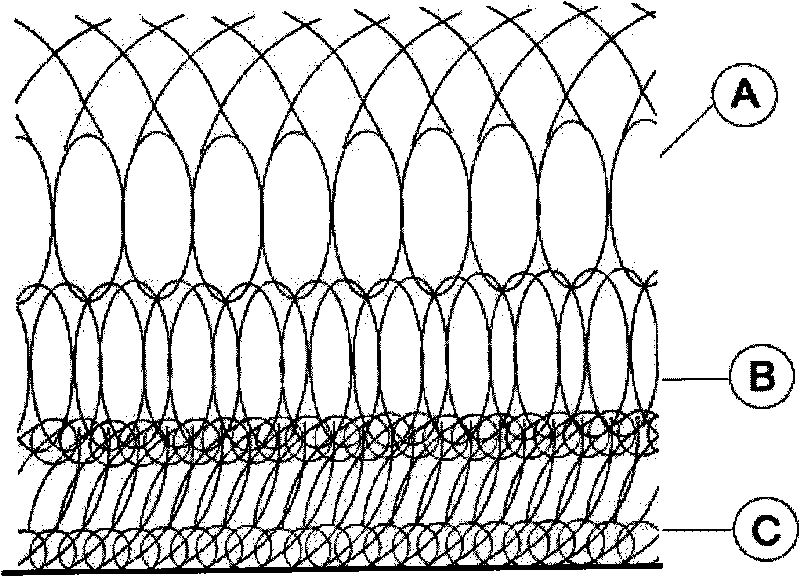

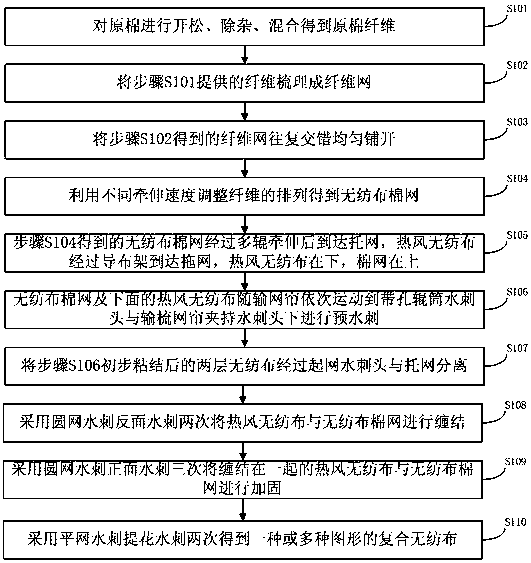

Compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric and production system thereof

ActiveCN106393945AComposite process advantagesRemove the phenomenon of bleedingLamination ancillary operationsLaminationPulp and paper industryNonwoven fabric

The invention discloses a compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric, and belongs to the technical field of nonwoven fabric production. The method comprises the following steps: taking hot air through nonwoven fabric as the bottom layer, laminating a nonwoven fabric-cotton mesh on the hot air through fabric, and carrying out pre-wetting and front-back spunlace laminating to obtain the product. According to the method, a spunlace method is used to replace chemical adhering to compound chemical fiber nonwoven fabric and all cotton spunlace nonwoven fabric; the advantages of all cotton nonwoven fabric such as softness, water absorbing property, breathability, and the like, are preserved, at the same time, the advantages of hot air through nonwoven fabric such as high filling power, good elasticity, soft hand feeling, strong warm keeping performance, air penetrating and water penetrating performance, and the like are also preserved; moreover, the glue leakage is prevented, and the peeling strength meets the requirement.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

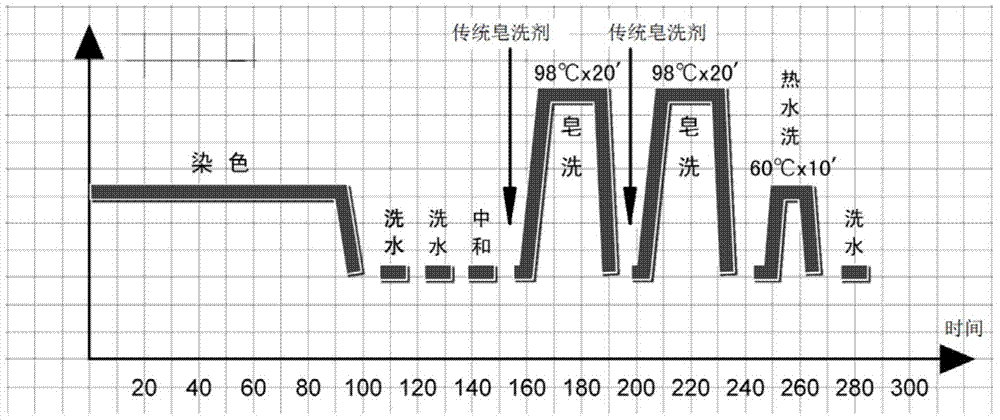

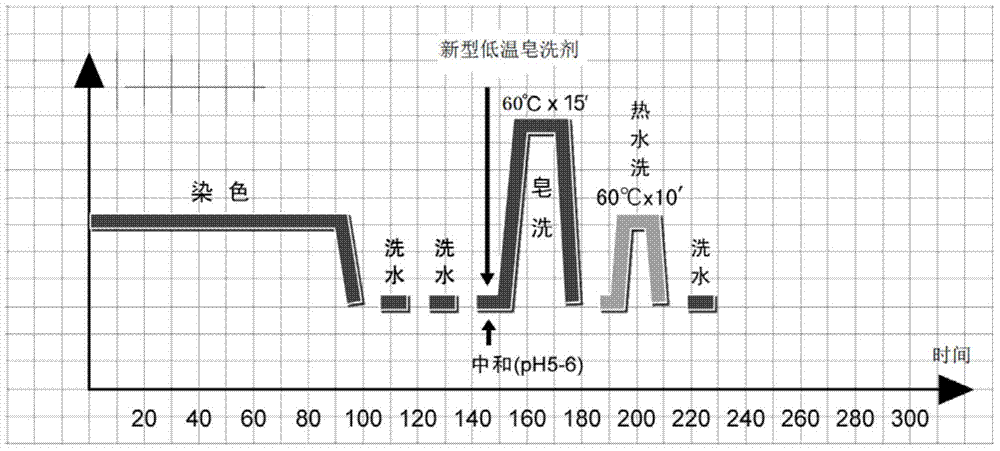

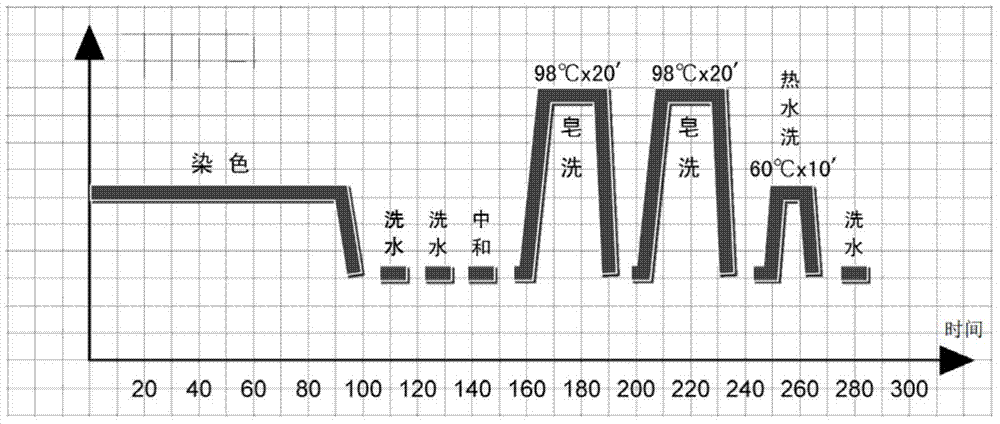

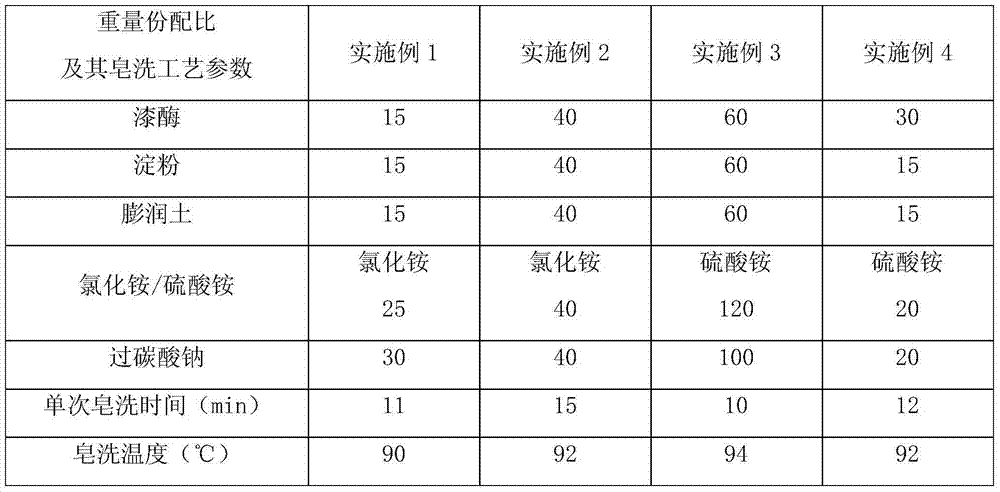

Novel cryogenic soaping agent and preparation method thereof

InactiveCN103571645AReduce dosageEffective dissolutionNon-ionic surface-active compoundsOrganic/inorganic per-compounds compounding agentsCarboxymethyl celluloseSulfate

The invention discloses a novel cryogenic soaping agent. The novel cryogenic soaping agent is characterized by comprising the following components in percentage by weight: 5-25% of laccase, 25-45% of persulfate, 15-35% of alkali, 15-25% of polyvinylpyrrolidone, 15-25% of sodium polyacrylate and 5-10% of sodium carboxymethyl cellulose. The novel cryogenic soaping agent is applied to a soaping process after reactive dyeing, and can effectively remove a flooding color, a paste material and an auxiliary agent on fabric at a relatively low temperature to improve the color brilliance, color fastness and cleanliness of the fabric.

Owner:上海德桑精细化工有限公司

Waterproof agent for fabrics and preparation method of waterproof agent

InactiveCN104611934AImprove yellowingImprove waterproof performanceFibre treatmentEpoxyPolymer science

The invention discloses a waterproof agent for fabrics. The waterproof agent comprises the following components: epoxy silicone oil modified vinyl / amino-functional silicone emulsion, carboxyl modified vinyl / amino silicon oil, amino-functional silicone emulsion, hydrogen-containing silicone emulsion and deionized water. The invention also relates to a preparation method of the waterproof agent for the fabrics; the method comprises the step of evenly mixing the epoxy silicone oil modified vinyl / amino-functional silicone emulsion, the carboxyl modified vinyl / amino silicon oil, the amino-functional silicone emulsion, the hydrogen-containing silicone emulsion and the deionized water at the mixing speed of 150-250r / min to obtain the waterproof agent for the fabrics. The waterproof agent for the fabrics is good in waterproofness, elasticity and hand feeling, has good softness, crease resistance and air permeability, and is non-toxic, odorless, free of skin irritation and harmless to the environment; furthermore, the preparation method of the waterproof agent for the fabrics is simple and easy to implement and high in safety during preparation, and does not cause environmental pollution.

Owner:SUZHOU CHENHENG WEAVING

Production method of yakwool/bamboo fiber blended yarn

The invention relates to a production method of a yakwool / bamboo fiber blended yarn, and the yakwool / bamboo fiber blended yarn is prepared by blending brown yakwool and bamboo fiber, wherein the brown yakwool with the average principal length being 37.4mm, the length discrete degree being 38.3% and the linear density being 4.23dtex is adopted. The method comprises the following steps: (1) preparing yakwool fiber into a yakwool combing sliver by adopting a wool spinning process of raw yakwool pretreatment, worsted carding, first gilling, combing and second gilling; (2) preparing the bamboo fiber into a bamboo fiber sliver by adopting a cotton spinning process of opening picking and cotton carding; (3) blending the yakwool combing sliver and the bamboo fiber sliver through first drawing of cotton spinning, then carrying out third gilling, recombing and regilling of wool spinning, and then carrying out second drawing, roving and spinning of the cotton spinning, thus finally obtaining the yakwool / bamboo fiber blended yarn. According to the production method, the yakwool and the bamboo fiber can be prepared into blended yarns with good quality, and the yarns ensure the yakwool fiber and the bamboo fiber to realize complementary optimization.

Owner:JIANGNAN UNIV

Modified chlorinated polyethylene waterproof roll and method for preparing same

InactiveCN101718078AImprove softnessHigh tensile strength at breakBridge structural detailsPlasticizerNational standard

The invention relates to a waterproof roll, in particular to a modified chlorinated polyethylene waterproof roll and a method for preparing the same, which solve the problems that the conventional waterproof roll cannot meet various performance indexes of products and the cost of formula is too high. The modified chlorinated polyethylene waterproof roll is prepared from an ethylene-octene copolymer, chlorinated polyethylene, linear high-pressure polyethylene, a filling reinforcing agent, a softening plasticizer, a phenolic antioxidant, a heat stabilizer, a lubricant and a light stabilizer. The method comprises the following steps of mixing and stirring various raw materials; pelleting the mixture by using a plastic mixing mill, a double roller and a pelletizer; putting granules into a single-screw extruder to extrude and then molding the granules through a die; and putting the molding materials into a three-roller cooling embossing machine to press the waterproof roll. The waterproof roll not only maintains specific flexibility, elongation and resilience of rubber, but also maintains higher tensile breaking strength of LLDPE; the waterproof roll has the advantages of good flexibility, flatness and evenness of the whole sheet, excellent ageing-resistance performance, physical performance and processing performance, and low production cost; and the performance indexes exceed national standards and relative standards of the Ministry of Railways.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

Waterproof rolled material and preparation method thereof

InactiveCN101845169AImprove softnessHigh tensile strength at breakFlat articlesPlasticizerAntioxidant

The invention relates to a waterproof rolled material, in particular to a modified chlorinated polyethylene waterproof rolled material and a preparation method thereof, which solve the problems that the traditional waterproof rolled material can not completely satisfy each performance index of a product and the formula cost is overhigh. The waterproof rolled material is prepared from an ethylene-octylene copolymer, chlorinated polyethylene, linear high-pressure polyethylene, a filler intensifier, a softener plasticizer, a phenol antioxidant, a heat stabilizer, a lubricant and a light stabilizer, and the preparation method thereof comprises the following steps: mixing and stirring various raw materials; granulating by sequentially adopting a plastic refining machine, a double-roll machine and a grain cutting machine; adding grain materials into a single-screw extruding machine for extrusion and molding through a mould; and adding the molded material into a three-roll cooling embossing machine for rolling to obtain the waterproof rolled material. Not only the peculiar softness, the elongation percentage and the rebound resilience of rubber are reserved, but also the higher breaking tensile strength of an LLDPE is reserved, the integral sheet material has good softness, flatness and evenness, the performance index exceeds a national standard and the related standard of a railway ministry, all the ageing-resistant performance, the physical performance and the processing performance are more excellent, and the production cost is low.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

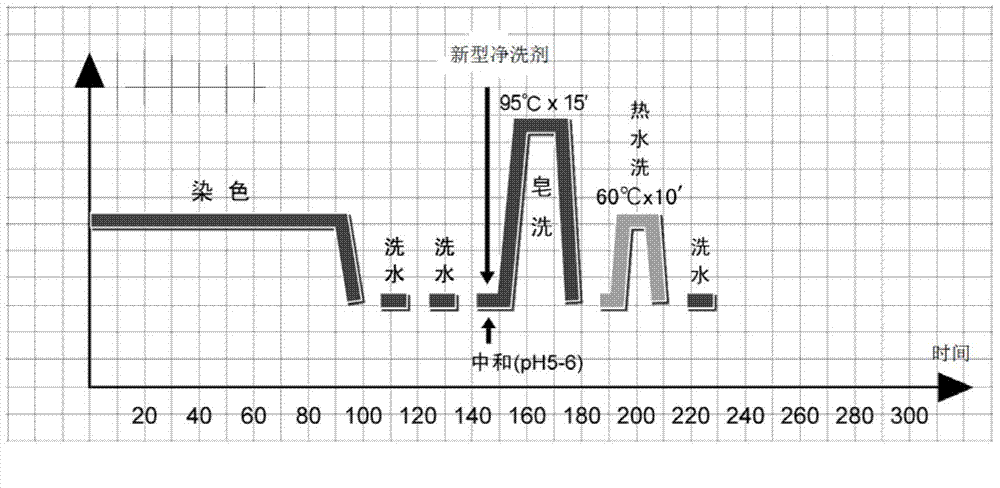

Novel detergent and preparation method thereof

InactiveCN103571654APlay a protective effectAvoid weight lossOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsPollutionAmmonium sulfate

The invention discloses a novel detergent. The novel detergent is characterized by comprising the following components in percentage by weight: 15-30% of laccase, 15-20% of starch, 15-25% of bentonite, 20-30% of ammonium chloride or ammonium sulfate, and 20-30% of sodium perborate or sodium percarbonate. The novel detergent is applicable to a cleaning process after dyeing of fabric, and is fully biodegradable, so that pollution to the environment is avoided and the ecological security is higher.

Owner:上海德桑精细化工有限公司

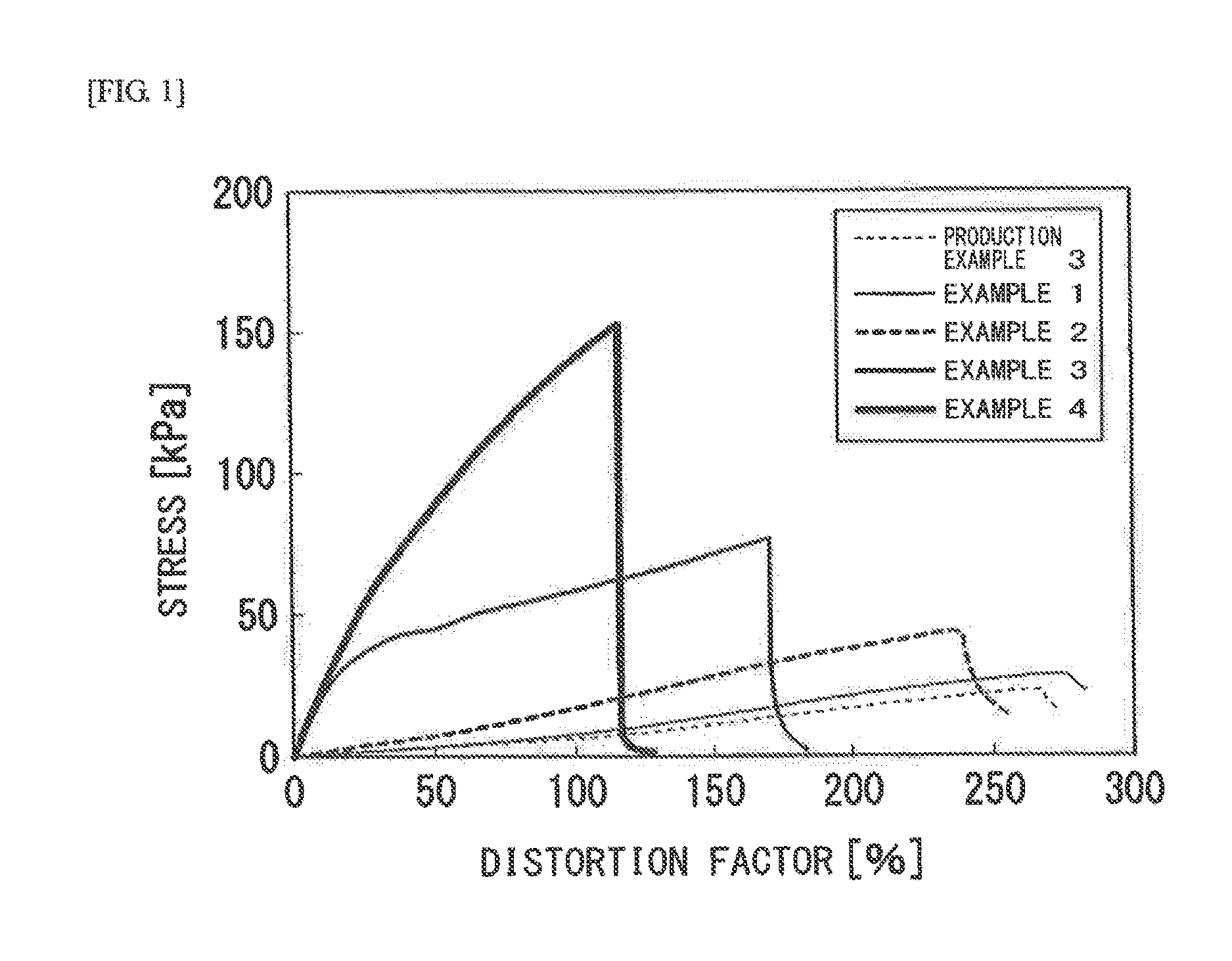

Method for producing gel

InactiveUS20170009024A1Improve operativityEnhance flowabilityCosmetic preparationsToilet preparationsSolventWater soluble

Method for producing a gel having a desired strength, by performing a step of removing a part or all of a solvent. Method for producing a gel containing a water-soluble organic polymer (A), a silicate salt (B), and a dispersant (C) for the silicate salt, including a desolvation step of removing a part or all of one or more solvents selected from the group consisting of water and a water-soluble organic solvent in the gel, or gelling a gel-forming composition containing the water-soluble organic polymer (A), the silicate salt (B), the dispersant (C) for the silicate salt, and one or more solvents selected from the group consisting of water and a water-soluble organic solvent and removing a part or all of the solvent in the composition.

Owner:NISSAN CHEM IND LTD

Method for preparing skin-care non-woven fabric through microemulsion atomization spraying process and application

InactiveCN109577016ALiquid adhesionUniform adhesionBiochemical fibre treatmentTextile treatment by spraying/projectingPreparing skinViscose

The invention relates to the field of sanitary products, and provides a method for preparing a skin-care non-woven fabric through a microemulsion atomization spraying process and application. A microemulsion atomization molecule infiltration process is adopted to coat the non-woven fabric with essence, and the non-woven fabric is prepared by using a viscose fiber as the main raw material in cooperation with a camellia fiber. The method for preparing the non-woven fabric through the microemulsion atomization spraying process causes little damage to the raw material fibers and preserves the color of the original fibers, and the product is soft and high in comfort, has the effects of resisting bacteria, nourishing and cleaning the skin and improving the skin and has broad application prospects in daily life.

Owner:ZHUZHOU QIANJIN PHARMA +1

Strong mesh cloth coating processing fabric

InactiveCN101736526AEnhance tension and adhesionSimple processing technologyLayered productsNon-woven fabricsTextileMetallurgy

The invention discloses strong mesh cloth coating processing fabric which has a double-layer structure or a three-layer structure, wherein each layer comprises at least one knitting mesh cloth and a compound fabric raw material. The strong mesh cloth coating processing fabric is prepared by blending and refining the following raw materials in percentage by weight: 20-50% of knitting mesh cloth and 50-80% of compound fabric, and the weight of the finished cloth is 200-250g / m. The invention has simple use of the processing technology, and can effectively increase the tension and adhesion of the fabric, thereby generating good drapability.

Owner:嘉兴市联诚制衣股份有限公司

Waterproof product containing linear low density polyethylene and preparation method thereof

InactiveCN101805477AHigh elongationHigh tensile strength at breakBridge structural detailsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a waterproof product containing linear low density polyethylene (LLDPE), in particular to a waterproof coiled material and a preparation method thereof, solving the problems of low performance index and high formulation cost of the waterproof coiled materials in the prior art. The waterproof coiled material is prepared by ethylene-octylene copolymers, chlorinated polyethylene, LLDPE, filling and reinforcing agents, softening and plasticizing agents, phenolic antioxidants, heat stabilizing agents, lubricants and light stabilizing agents. The method is characterized by mixing and stirring all the raw materials, adopting a plastic refining machine, a two-roll machine and a grain cutting machine in sequence for granulation, throwing the grains into a single screw extruder to be extruded and molding the grains with molds; and throwing the molded grains into a three-roll cooling embossing machine to be rolled, thus preparing the waterproof coiled material. The waterproof coiled material not only retains the special softness, elongation and resilience of the rubber, but also retains higher tensile strength at break of LLDPE, has good softness, straightness and flatness, has performance index in excess of the national standard and related standards of the Ministry of Railways, has excellent aging resistance, physical performance and processability and has low production cost.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

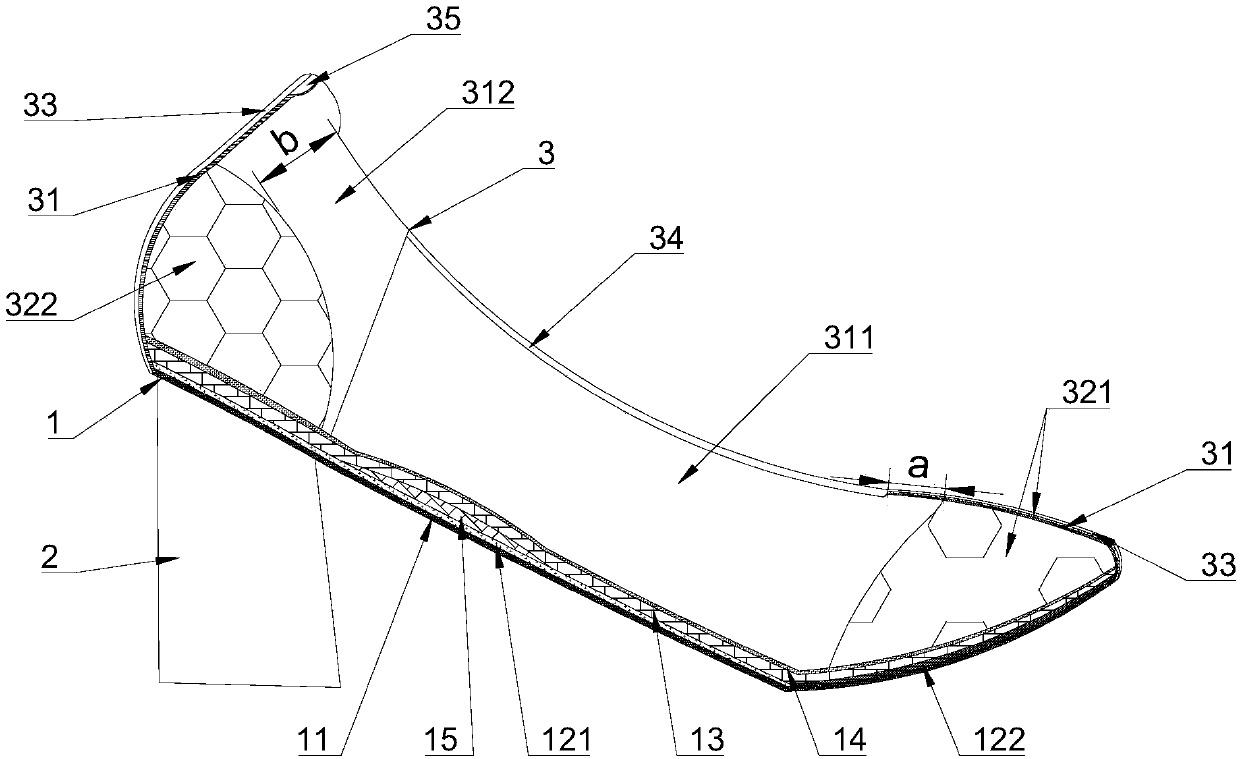

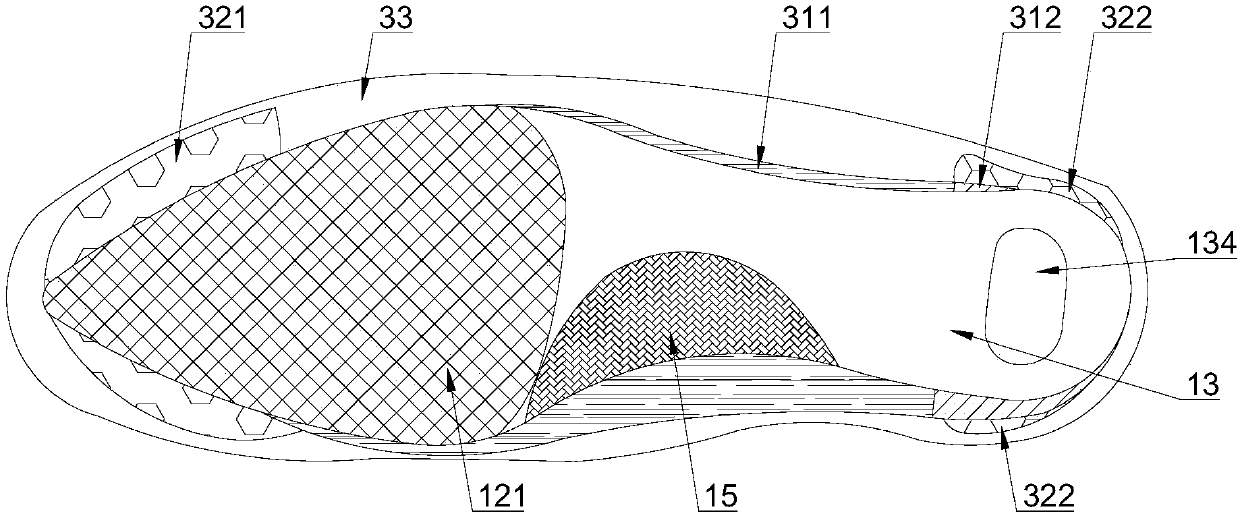

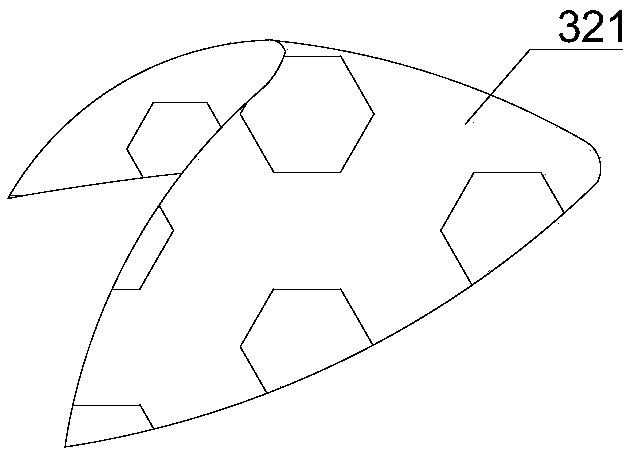

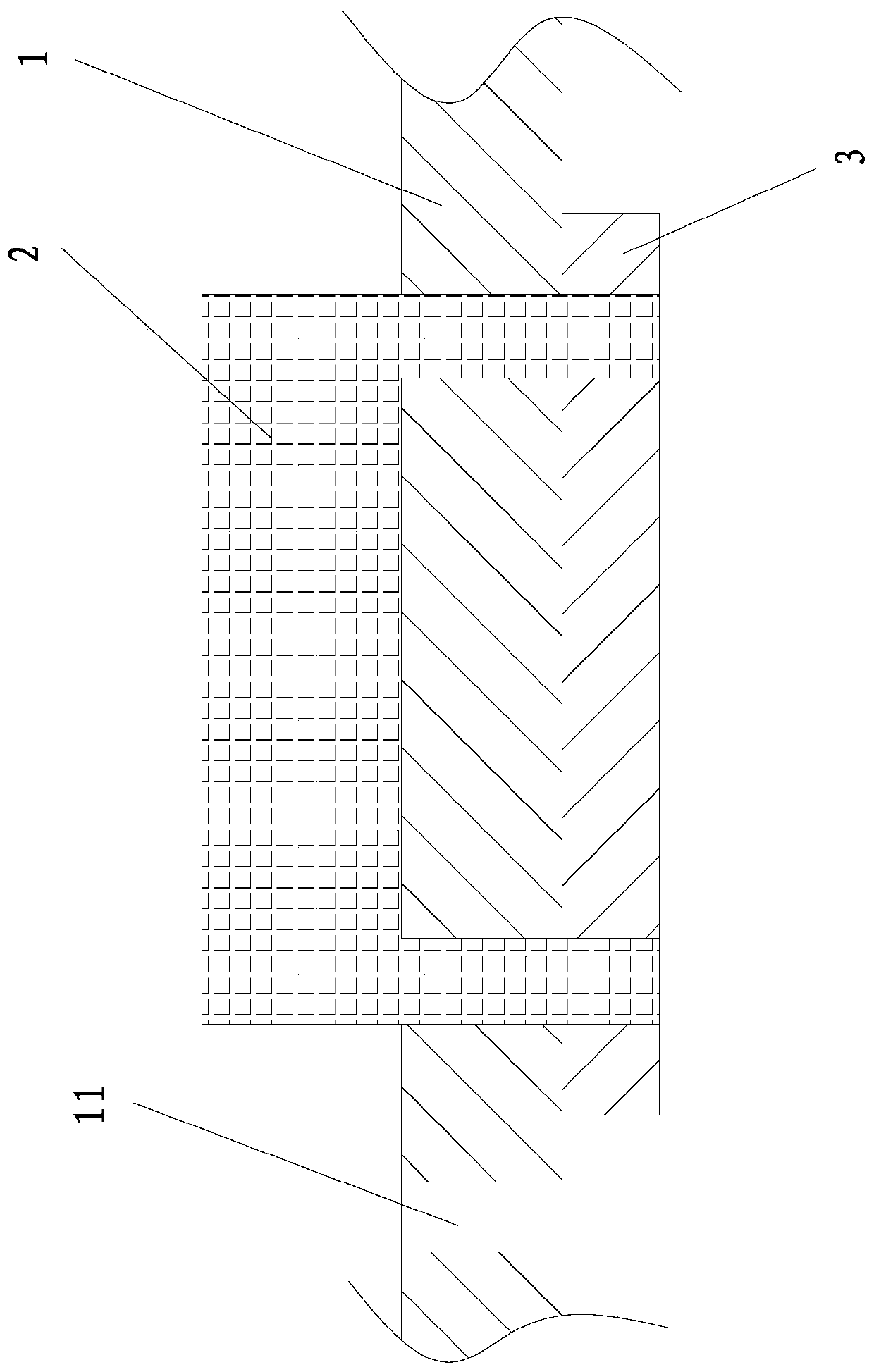

Soft and nondeformable shoe and production method thereof

The invention relates to a soft and nondeformable shoe and a production method thereof. The shoe comprises a sole, a heel and an upper, wherein the heel and the upper are respectively arranged on thesole; the sole comprises a sole pad, a middle bottom pad shaping layer, a shoe middle bottom and a sole inner layer which are sequentially arranged from bottom to top, a foot arch elastic body is arranged between the shoe middle bottom and the middle bottom pad shaping layer, the shoe middle bottom comprises a shoe middle bottom surface, a shoe middle bottom sponge layer and a shoe middle bottom inner surface which are sequentially arranged from bottom to top, and the thickness of the shoe middle bottom decreases progressively from the center to the periphery; and the upper comprises an upperinner layer, an upper shaping layer and an upper outer layer which are sequentially arranged from inside to outside, the upper shaping layer comprises toe cap shaping lining cloth and shoe heel shaping lining cloth, and an elastic covering edge is arranged on the upper outer layer along the edge of a shoe throat. Compared with the prior art, the soft and nondeformable shoe has the advantages thatthe shoe is soft, comfortable and does not deform, and the same shoe size is suitable for multiple shoe types.

Owner:FUZHOU LUYA SHOES

Preparation method of light and soft water-based spray painted textile cloth

InactiveCN109235054AReduce the probability of dust absorptionImprove flatnessCoatingsTextiles and paperWater basedSoft water

The invention provides a preparation method of light and soft water-based spray painted textile cloth. The preparation method comprises three technological steps: (1), ironing treatment of base cloth:the base cloth is fixed on an unwinding rack and subjected to unwinding, water is splashed on the surface of the base cloth, the base cloth enters a drying oven, creases on the base cloth are ironedunder the hot air action and the tensioning action, and the base cloth is wound for standby application; (2), surface treatment of the base cloth: the ironed base cloth is fixed on the unwinding rackand subjected to unwinding, and then the base cloth is soaked in a waterproof solution, taken out, dried and wound for standby application; (3), scrape coating of a water-based coating: a straight-knife platform is adopted for coating, water-based spray paint is applied to one side of the base cloth by scrape coating, and the base cloth is dried, cured and wound. The light and soft water-based spray painted textile cloth is light and soft and has a sustainable waterproof function.

Owner:SHANGHAI NAR INDAL

Fabric adopting TPU yarns for weaving surface and making method thereof

ActiveCN109722815AEfficient preparationThe production process is simple and economicalHeating/cooling textile fabricsEmbroidering machines apparatusYarnEngineering

The invention provides a fabric adopting TPU yarns for weaving a surface. The TPU yarns are embroidered at a local position of a bottom fabric layer and then molten through hot compression, and accordingly a TPU yarn layer with a protecting effect is formed on the surface of the bottom fabric layer and can enhance the abrasion resistance of the bottom fabric layer and keep the softness of the bottom fabric layer to a certain degree. Compared with leather and a hot molten membrane, the TPU yarn layer is lighter and can reduce the burden of a user. In addition, by adjusting the sparse and densespacing degree of embroidery textures of the TPU yarns, the air permeability of the fabric adopting the TPU yarns for weaving the surface can be improved. By matching TPU yarns with different colors and embroidering patterns with different textures, the TPU yarn layer can present a richer and more novel appearance effect compared with the leather and the holt molten membrane, and the fashion senseis higher. The invention further provides a making method of the fabric adopting the TPU yarns for weaving the surface.

Owner:SINCETECH FUJIAN TECH CO LTD

Waterproof product containing ethylene-octylene copolymers and preparation method thereof

InactiveCN101805478AHigh elongationHigh tensile strength at breakBridge structural detailsFlat articlesLinear low-density polyethyleneAging resistance

The invention relates to a waterproof product containing ethylene-octylene copolymers, in particular to a waterproof coiled material and a preparation method thereof, solving the problem that the existing waterproof coiled materials can not completely satisfy various performance indexes of the product and have excessively high formulation cost. The waterproof coiled material is prepared by ethylene-octylene copolymers, chlorinated polyethylene, linear low density polyethylene (LLDPE), filling and reinforcing agents, softening and plasticizing agents, phenolic antioxidants, heat stabilizing agents, lubricants and light stabilizing agents. The method is characterized by mixing and stirring all the raw materials, adopting a plastic refining machine, a two-roll machine and a grain cutting machine in sequence for granulation, throwing the grains into a single screw extruder to be extruded and molding the grains with molds; and throwing the molded grains into a three-roll cooling embossing machine to be rolled, thus preparing the waterproof coiled material. The waterproof coiled material not only retains the special softness, elongation and resilience of the rubber, but also retains higher tensile strength at break of LLDPE, has good softness, straightness and flatness, has performance index in excess of the national standard and related standards of the Ministry of Railways, has excellent aging resistance, physical performance and processability and has low production cost.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

Cotton fabric with different functions on two sides and preparation method thereof

ActiveCN112012011AImprove safety performanceGood durabilityStain/soil resistant fibresBiochemical fibre treatmentComposite materialAnti bacterial

The invention relates to a cotton fabric with different functions on two sides. One side of the fabric is an antibacterial finishing layer, and the other side of the fabric is an antifouling finishinglayer. The antibacterial finishing layer is made of polymethacryloyloxyethyl trimethyl ammonium chloride; and the antifouling finishing layer is made of polyethylene glycol-400 (PEG-400). The antibacterial finishing layer in the cotton fabric with different functions on the two sides is a non-skin contact layer and can effectively kill various bacteria and prevent bacterial adhesion, and the antifouling finishing layer is a skin contact layer and can prevent skin secretion adhesion, so that bacterial nutrition channels are cut off, and mildness and no irritation to the skin are guaranteed. The cotton fabric with the different functions on the two sides has efficient antibacterial capacity, excellent bacterial adhesion prevention capacity and excellent skin secretion pollution prevention capacity, is mild and non-irritant to the skin and has high safety.

Owner:ZHEJIANG SCI-TECH UNIV

Ethylene-octene copolymer waterproof coil and preparation method thereof

InactiveCN101831105AHigh elongationHigh tensile strength at breakFlat articlesLinear low-density polyethyleneOctene

The invention relates to a waterproof product, in particular to an ethylene-octene copolymer waterproof coil and a preparation method thereof, which solves the problem that the traditional waterproof coil can not completely satisfy various property indexes of the product and has high prescription cost. The coil is prepared from ethylene-octene copolymer, chlorinated polyethylene, linear high-pressure polyethylene, a filling strengthening agent, a softening plasticizer, a phenols antioxidant, a thermal stabilizer, a lubricating agent and a light stabilizer. The method comprises the following steps of: mixing and stirring various raw materials; granulating respectively by sequentially adopting a plastic refining machine, a double-roll press and a granulator; throwing the particles into a single screw extruder to be extruded, and forming by using a mould; and throwing the formed material into a three-roll cooling embosser to be rolled to form the waterproof coil. The waterproof coil maintains the specific softness, elongation and elasticity of rubber, also maintains higher break tension strength of LLDPE (Linear Low Density Polyethylene), and has good softness, flatness and smoothness, property indexes exceeding the national standard and the relevant standard of ministry of railway, better aging resistance property, physical property and processing property and lower production cost.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

Camellia fibre-containing antibacterial skincare soft cotton towel, and preparation method and application thereof

InactiveCN109363996AImprove water absorptionImprove performanceCosmetic preparationsToilet preparationsUltravioletCotton fibre

The invention provides a camellia fibre-containing antibacterial skincare soft cotton towel. In order to apply the camellia fibre-containing antibacterial skincare soft cotton towel successfully, cotton fibres are subjected to pre-bleaching treatment after being subjected to pre-treatment, and then the cotton fibres are matched with camellia fibres to prepare the camellia fibre-containing antibacterial skincare soft cotton towel. The camellia fibres are rich in camellia oil, has the effects of moisturizing, resisting oxidation, preventing sensitivity, preventing ultraviolet rays and inhibitingbacteria, can also eliminate fine wrinkles of skin, effectively delay skin aging and relieve part skin diseases, and has a broad application prospect in daily life.

Owner:ZHUZHOU QIANJIN PHARMA +1

Bacteriostatic skin care cotton soft towel based on multi-fiber blending and preparation method thereof

InactiveCN109589291AEliminate fine wrinkles on the skinDelay skin agingCosmetic preparationsBiochemical fibre treatmentPre treatmentCamellia sinensis

The invention relates to the field of sanitary articles, and provides a bacteriostatic skin care cotton soft towel based on multi-fiber blending. The bacteriostatic skin care cotton soft towel comprises the following raw materials: camellia fibers, avocado fibers, sunflower fibers, soybean fibers and cotton fibers; the bacteriostatic skin care cotton soft towel is prepared with the following method: pre-treating the raw material fibers separately; mixing the fibers after pre-treating to prepare a cotton soft towel; and evenly spraying a diluted plant essence fluid on the prepared cotton soft towel by adopting a microemulsion atomization molecular interpenetration method. According to the bacteriostatic skin care cotton soft towel and the preparation method thereof, the technical problem ofdifferent fiber blending is overcome, the prepared cotton soft towel combines the characteristics of five different fibers and has the advantages of softness, fineness and high comfort, the preparation method has little damage to the raw material fibers, and a product has the functions of resisting bacteria, and nourishing and cleansing skin.

Owner:ZHUZHOU QIANJIN PHARMA +1

Preparation method of hydrogel gauze capable of preventing blood adhesion

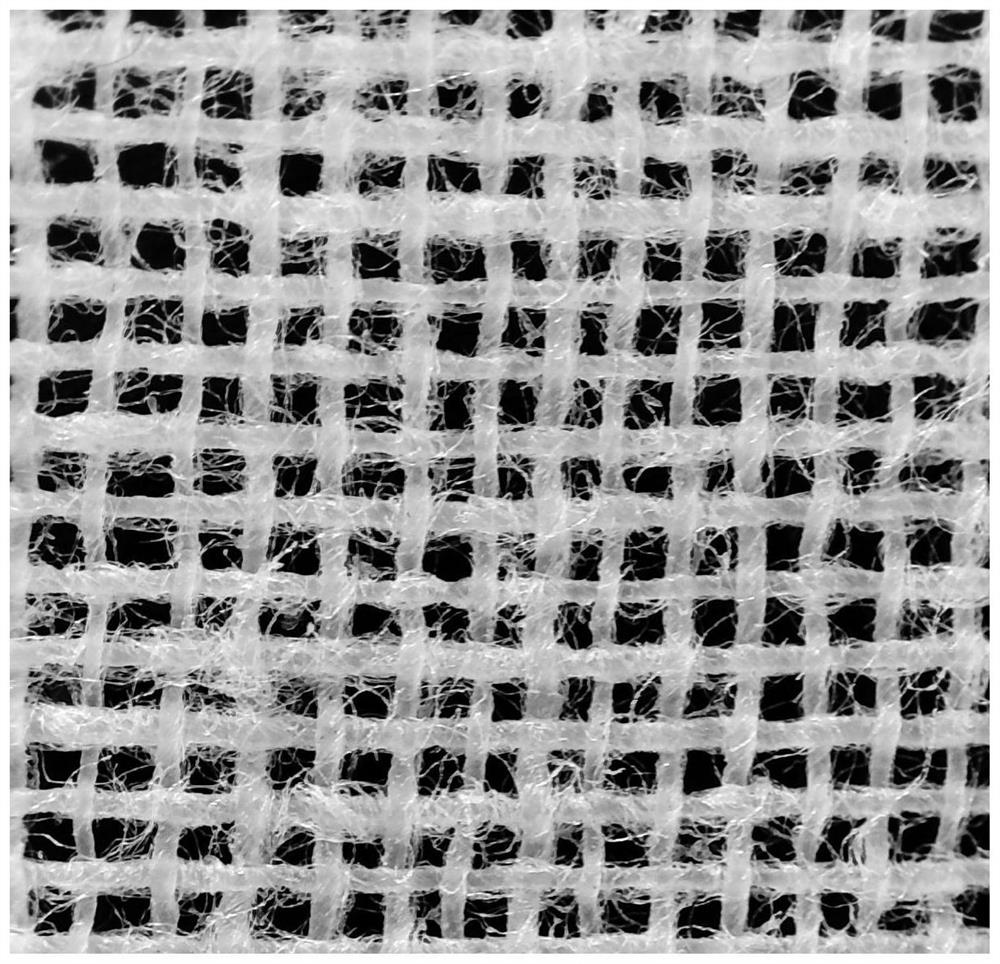

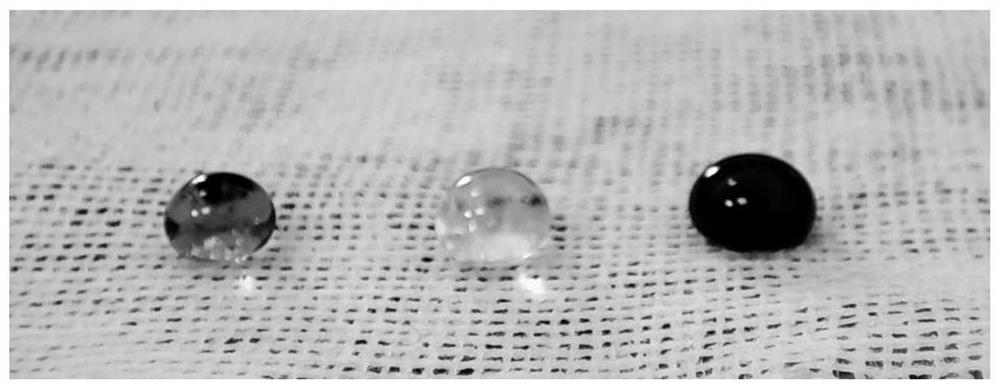

ActiveCN114045681AMaintain porous structureAir permeability effectPharmaceutical delivery mechanismAbsorbent padsPolymer scienceMeth-

The invention provides hydrogel gauze capable of preventing blood adhesion, and belongs to the technical field of biochemical engineering. The preparation method of the hydrogel gauze comprises the following steps: S1, adding a monomer and hydroxyl silicone oil into a solvent, and fully stirring and emulsifying to obtain a uniform emulsified solution; and adding a photoinitiator and N-aminoethyl-3-aminopropyl methyl dimethoxy silane, and fully stirring and mixing, so as to obtain a gel precursor solution, wherein the monomer is composed of a first monomer and a second monomer, the first monomer comprises acrylamide, and the second monomer comprises a silane coupling agent containing double bonds; S2, soaking gauze in the gel precursor solution, and enabling the soaked gauze to be subjected to light curing treatment to prepare the hydrogel gauze capable of preventing blood adhesion. The hydrogel gauze retains the softness and air permeability of original gauze, and meanwhile has a good anti-adhesion effect on solutions such as water, protein and blood.

Owner:GUANGZHOU UNIVERSITY

Waterproof product containing chlorinated polyethylene and preparation method thereof

InactiveCN101812198BHigh elongationHigh tensile strength at breakExtensibilityLinear low-density polyethylene

The invention relates to a waterproof product containing chlorinated polyethylene, in particular to a waterproof roll sheet containing chlorinated polyethylene and a preparation method, which solve the problem that the waterproof roll sheet in the prior art has low performance index and high formula cost. The waterproof product containing chlorinated polyethylene is prepared by the following steps: mixing and stirring an ethylene-octylene copolymer, the chlorinated polyethylene, linear high-pressure polyethylene, a filler intensifier, a soften plasticizer, phenol antioxidants, a heat stabilizer, a lubricating agent and light stabilizer; pelleting the raw materials with a plastics processing mill, a double-roller mill and a pelleter in sequence; feeding granules into a single screw extruder for extruding and forming by a die; and feeding formed materials into a three-roller cooling coining mill for rolling to form the waterproof roll sheet. The invention not only retains unique softness, extensibility and rebound elasticity of rubber, but also retains high tensile breaking strength of LLDPE (Linear Low Density Polyethylene); the whole sheet has good softness, glancing flatness and planeness; performance indexes exceed the national standard and relative standard of ministry of railways; the ageing resisting performance, physical performance and processing performance are excellent; and the production cost is low.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

Embroidery anti-fuzzing treatment method

PendingCN113957713AImproved anti-pilling propertiesReduce slipBiochemical fibre treatmentGrip property fibresChemistryComposite material

The invention relates to the technical field of embroidery, in particular to an embroidery anti-fuzzing treatment method. The embroidery anti-fuzzing treatment method comprises the following steps that step 1, an anti-fuzzing treatment agent is prepared; step 2, an embroidery product is put into the anti-fuzzing treatment agent prepared in the step 1, and soaked for 5-8 hours; step 3, the embroidery product soaked in the step 2 is dried with hot air at 50-80 DEG C; step 4, the dried embroidery product is washed, and after the embroidery product is washed, a post-treatment agent is sprayed onto an embroidery pattern by using a hand press type sprayer; and step 5, the embroidery product in the step 4 is baked by using hot air at 120-150 DEG C, and ironed by using an iron after the treatment is finished. According to the embroidery anti-fuzzing treatment method, a method of soaking with the anti-fuzzing treatment agent is adopted, a layer of soft and tough film is formed on the surface of the embroidery product, slippage of the barbed threads in the embroidery product is reduced, plush is not prone to forming by friction during use, the fuzzing and pilling resistance of the embroidery product is effectively improved, and the use effect of a user is improved.

Owner:宝应县顺扬刺绣厂

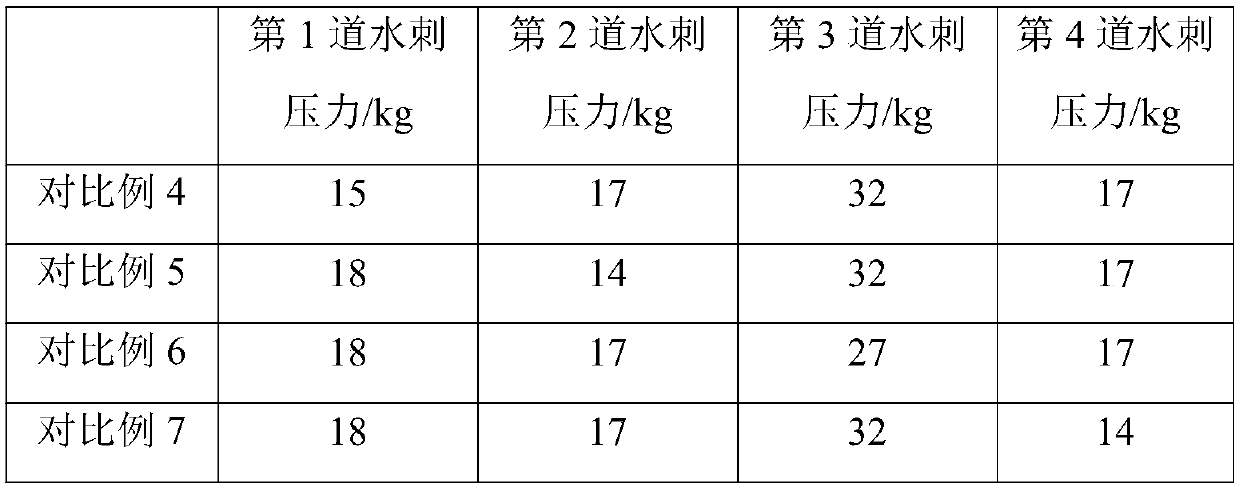

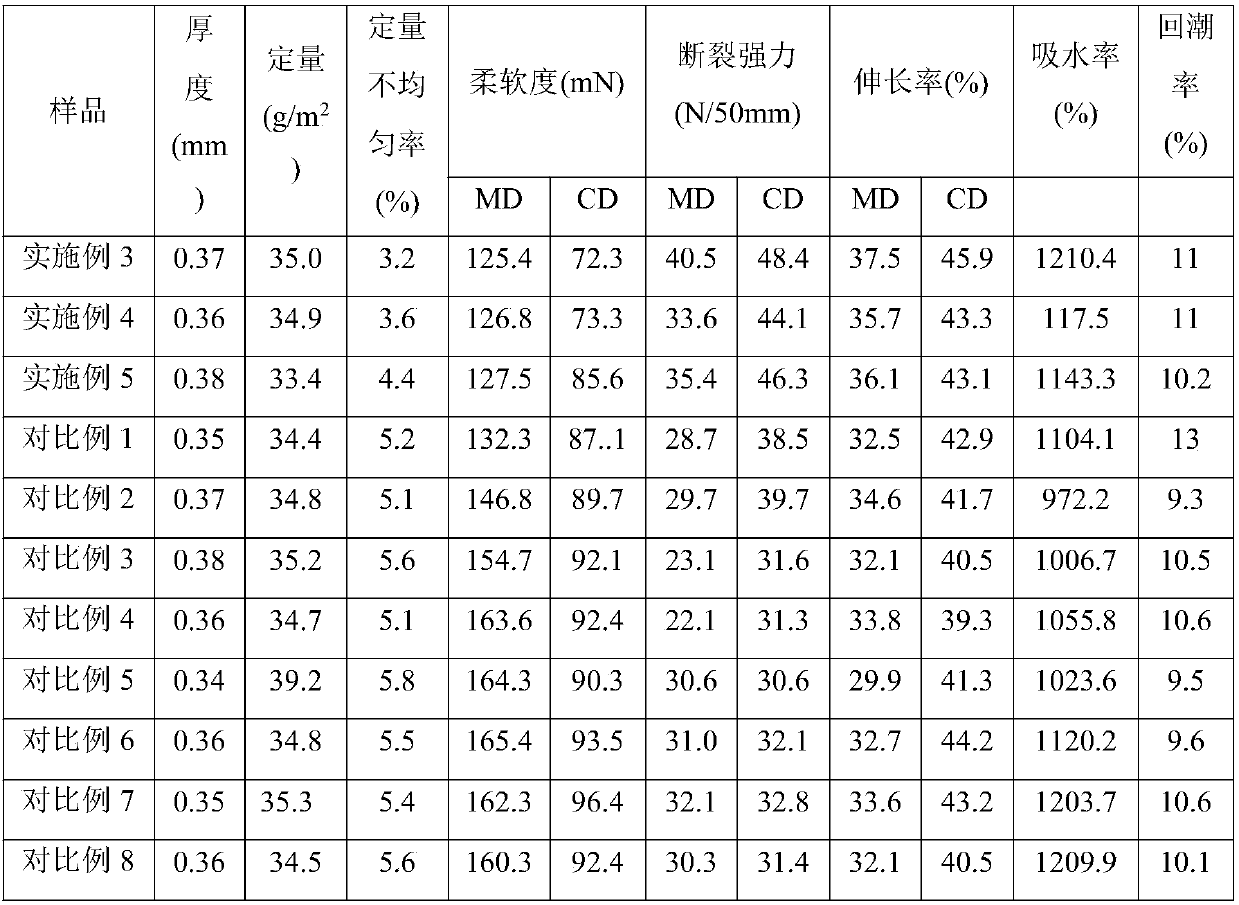

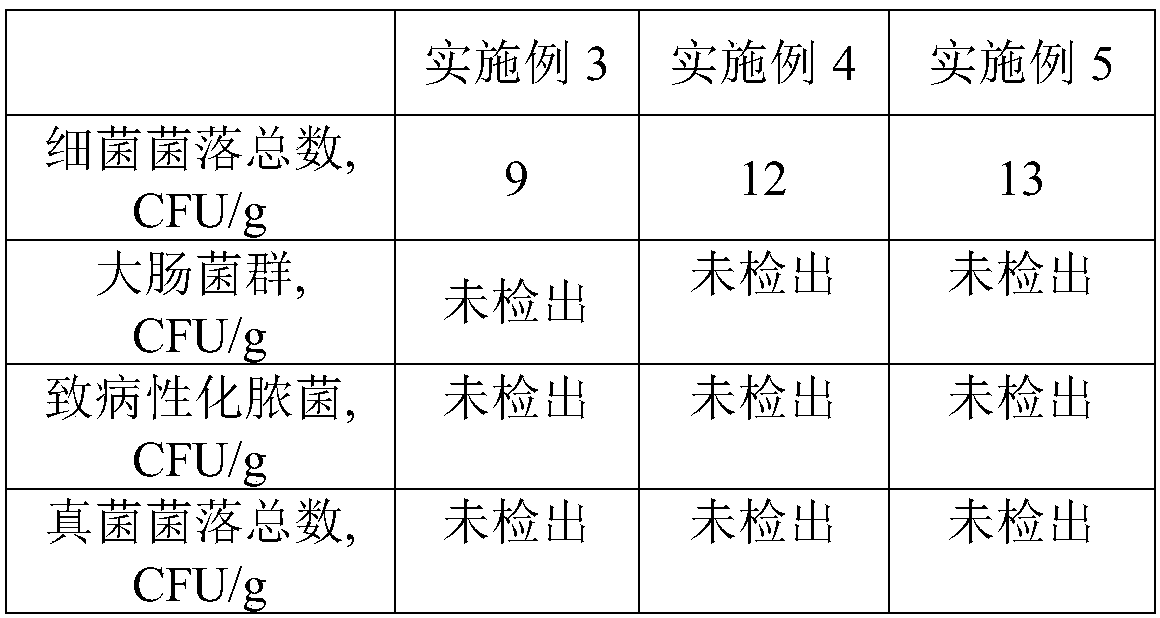

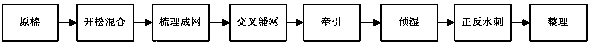

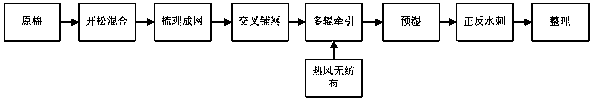

A composite method of hot-air non-woven fabric and cotton non-woven fabric and its production system

ActiveCN106393945BRetain softnessRetain water absorptionLamination ancillary operationsLaminationPulp and paper industryNonwoven fabric

The invention discloses a compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric, and belongs to the technical field of nonwoven fabric production. The method comprises the following steps: taking hot air through nonwoven fabric as the bottom layer, laminating a nonwoven fabric-cotton mesh on the hot air through fabric, and carrying out pre-wetting and front-back spunlace laminating to obtain the product. According to the method, a spunlace method is used to replace chemical adhering to compound chemical fiber nonwoven fabric and all cotton spunlace nonwoven fabric; the advantages of all cotton nonwoven fabric such as softness, water absorbing property, breathability, and the like, are preserved, at the same time, the advantages of hot air through nonwoven fabric such as high filling power, good elasticity, soft hand feeling, strong warm keeping performance, air penetrating and water penetrating performance, and the like are also preserved; moreover, the glue leakage is prevented, and the peeling strength meets the requirement.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

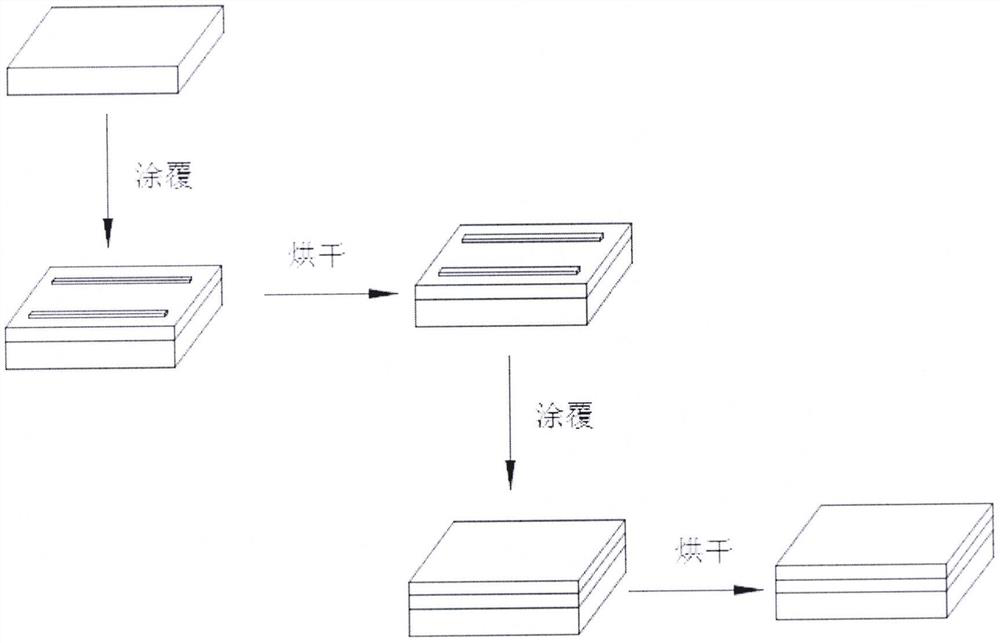

Coating decoration method for making high-grade waxing leather from low-grade leather

ActiveCN102827966BImprove waxing effectLow toxicityLeather manufacturingLeather surface finishingDefect repairLower grade

The invention relates to the technical field of a leather coating decoration method, and provides a coating decoration method for making high-grade waxing leather from low-grade leather with the advantages that the process is simple, the operation is convenient, used solvents have low toxicity, the natural attributives of softness, ventilation and the like of real leather are maintained, and the qualification rate is high. The method mainly comprises the following steps of leather blank preparation, defect repair, baking, plate pressing, polishing, mechanical foaming, falling, toggling, top coating, beating softening and sand plate pressing.

Owner:XINGYE LEATHER TECH CO LTD

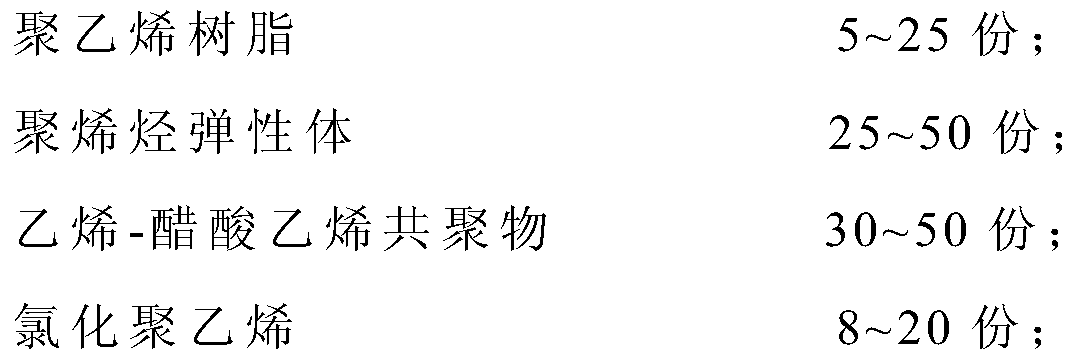

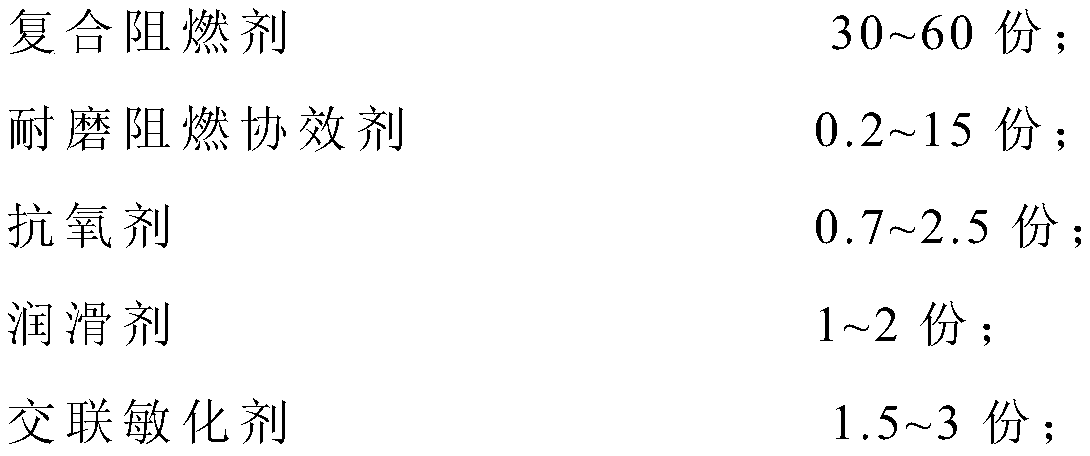

A kind of high flame-retardant composite material for new energy high-voltage line and preparation method thereof

ActiveCN107200917BImprove flame retardant performanceRetain softnessPlastic/resin/waxes insulatorsElastomerPolymer science

The present invention relates to a high flame retardancy composite material for a high voltage cable of a new energy automobile, the high flame retardancy composite material comprising the following raw materials in parts by weight: 5-25 parts of polyethylene resin; 25-50 parts of polyolefin elastomer; 30-50 parts of ethylene-vinyl acetate copolymer; 8-20 parts of chlorinated polyethylene; 30-60 parts of composite flame retardant; 0.2-15 parts of wear-resistant flame retardant synergist; 0.7-2.5 parts of antioxidant; 1-2 parts of lubricant; and 1.5-3 parts of cross-linking sensitising agent. The formulation of the present invention is improved, for example by using a mixture of bimodal polyethylene and high melt index high density polyethylene as a polyethylene resin and chlorinated polyethylene as a modifier, adding polyolefin elastomer and ethylene-vinyl acetate copolymer, and additionally adding a composite flame retardant, a flame retardant synergist, and an antioxidant, such that the composite material of the present invention has better flame retardancy properties and burns at a UL94 V0 grade whilst retaining the flexibility, high temperature resistance, oil resistance, and flame retardancy of high voltage cable material for use in a new energy automobile, and having excellent extrusion processing properties.

Owner:JIANGSU DEWEI ADVANCED MATERIALS

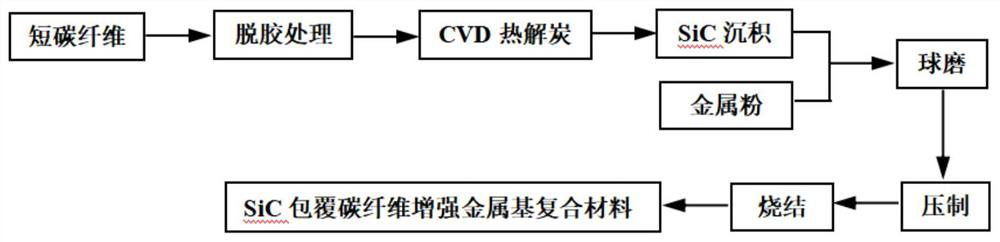

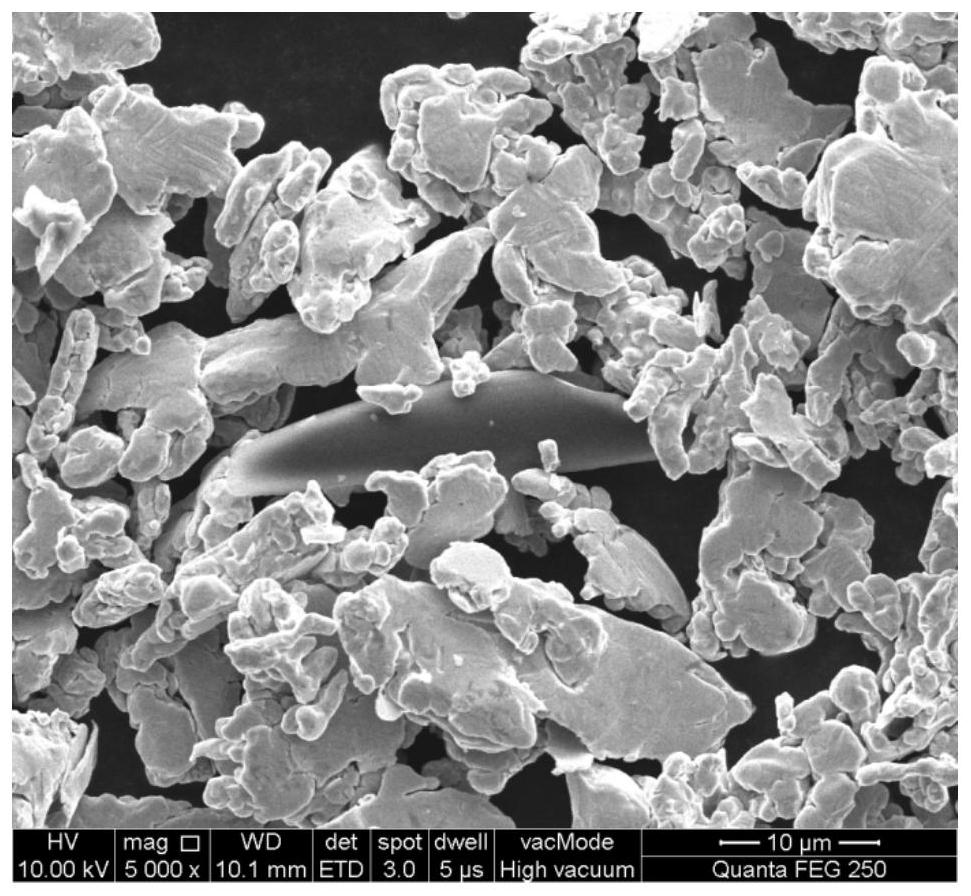

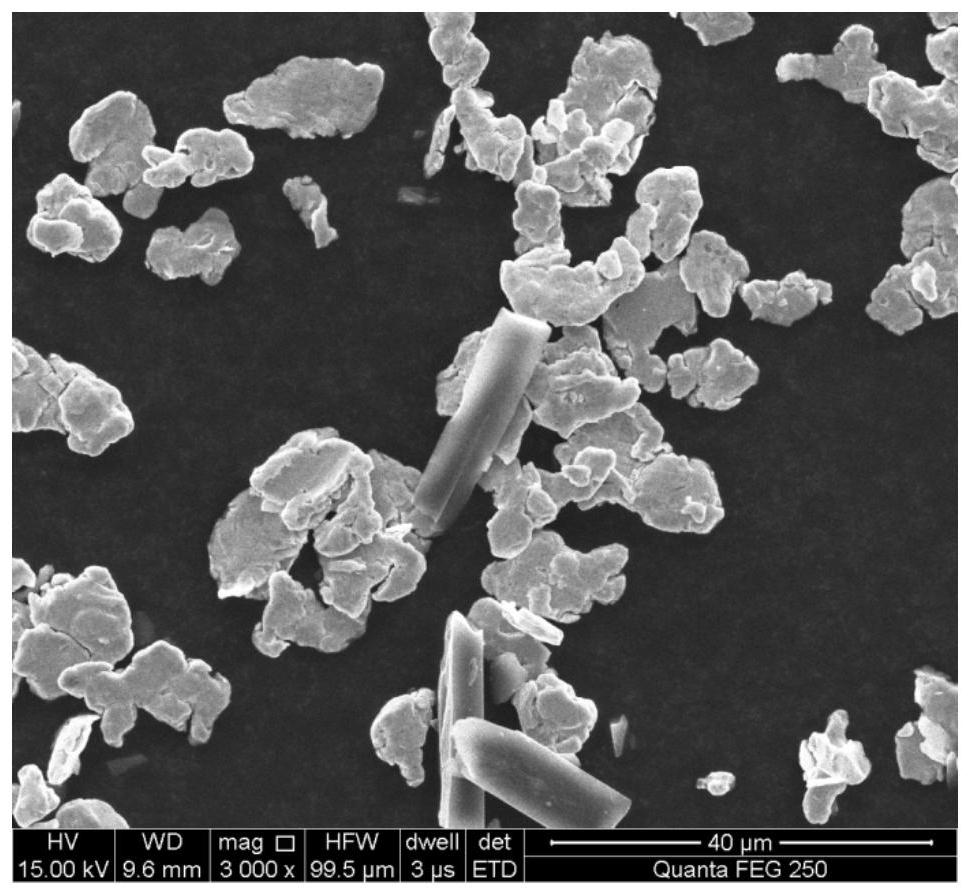

Preparation method for SiC coated carbon fiber reinforced metal based composite material

PendingCN112281085AImprove friction and wear performanceImprove wear resistanceCarbide siliconCarbon fibers

The invention relates to a preparation method for a SiC coated carbon fiber reinforced metal based composite material. The preparation method comprises the following steps: performing pyrolytic carbondeposition-silicon carbide deposition treatment on carbon fibers, coating the carbon fibers with phenolic resin, and ball-milling with a matrix metal ball to obtain uniformly mixed powder; and performing a pressing-sintering process to obtain the composite material. Wear resistance of the carbon fibers is remarkably improved through a pyrolytic carbon deposition-silicon carbide deposition treatment method, and the problems that the carbon fibers are easily wound, are unevenly dispersed in the material and are difficult to keep in a carbon fiber structure are successfully solved in combinationwith a phenolic resin coating and ball-milling process; moreover, the carbon fibers are coated with silicon carbide, so that the problems such as uncompact interface sintering due to poor intrinsic embrittlement of the CVD coated carbon fibers, and poor wettability with most of metals are solved, room-temperature and high-temperature mechanical properties of products are greatly improved while compact sintering is realized, and wear resistance of products is especially improved greatly.

Owner:CENT SOUTH UNIV

Ethylene-octene copolymer waterproof coil and preparation method thereof

InactiveCN101831105BHigh elongationHigh tensile strength at breakFlat articlesLinear low-density polyethyleneHigh pressure

The invention relates to a waterproof product, in particular to an ethylene-octene copolymer waterproof coil and a preparation method thereof, which solves the problem that the traditional waterproof coil can not completely satisfy various property indexes of the product and has high prescription cost. The coil is prepared from ethylene-octene copolymer, chlorinated polyethylene, linear high-pressure polyethylene, a filling strengthening agent, a softening plasticizer, a phenols antioxidant, a thermal stabilizer, a lubricating agent and a light stabilizer. The method comprises the following steps of: mixing and stirring various raw materials; granulating respectively by sequentially adopting a plastic refining machine, a double-roll press and a granulator; throwing the particles into a single screw extruder to be extruded, and forming by using a mould; and throwing the formed material into a three-roll cooling embosser to be rolled to form the waterproof coil. The waterproof coil maintains the specific softness, elongation and elasticity of rubber, also maintains higher break tension strength of LLDPE (Linear Low Density Polyethylene), and has good softness, flatness and smoothness, property indexes exceeding the national standard and the relevant standard of ministry of railway, better aging resistance property, physical property and processing property and lower production cost.

Owner:SHANXI SIFANG HENGTAI WATERPROOF MATERIALS

Method for preparing dermal transfer smearing

InactiveCN1321197CRetain softnessRetain breathabilityLiquid surface applicatorsSynthetic resin layered productsPlastic filmPolyresin

The invention relates to a manufacture method of coating for true leather transfering, which can be used in the leather precision work craft. The manufacture is: A, first use mending agent to scrape and mend the wound on the leather; B, the resin which can fuse below 130 DEG C is pressed on the thin film; C, spray the water resin fluid on the leather or the thin film coated with the resin in fog mode; D, between 100-110 DEG C temperature conditions, fold the thin film with the resin evenly on the leather, flat or roller press the resin layer with the pressure of 2 to 4 kilograms on to the leather and bond with it. Remove the plastic film to obtain the finished product.

Owner:邹恒余

Graphene heating fabric and preparation method thereof

InactiveCN112351521AImprove heating effectRetain softnessOhmic-resistance heatingConstructions elementsCopper foilSlurry

The invention relates to the technical field of electric heating materials, and particularly discloses a graphene heating fabric, which comprises a base material, a conductive graphene ink layer and acopper foil wire arranged on the base material, and an insulating glue layer coated on the surface of the conductive graphene ink layer. The invention further discloses a preparation method of the graphene heating fabric. According to the invention, the high-conductivity graphene slurry and the copper foil wire are arranged on the surface of the insulating film together based on the graphene electrifying heating technology, the insulating glue is coated for sealing after drying to obtain the graphene heating fabric; and the graphene heating fabric can be used for 5-36V direct-current voltageand has a good heating effect, can keep the flexibility and toughness of the heating film, can be compounded with wall cloth to replace indoor wall heating, can also be applied to special tents, carpets, mattresses, wooden heatable brick beds, clothes and other products to solve the heating problem of outdoor operators, and has wide market prospects.

Owner:陈建华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com