Patents

Literature

39results about How to "Avoid softness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

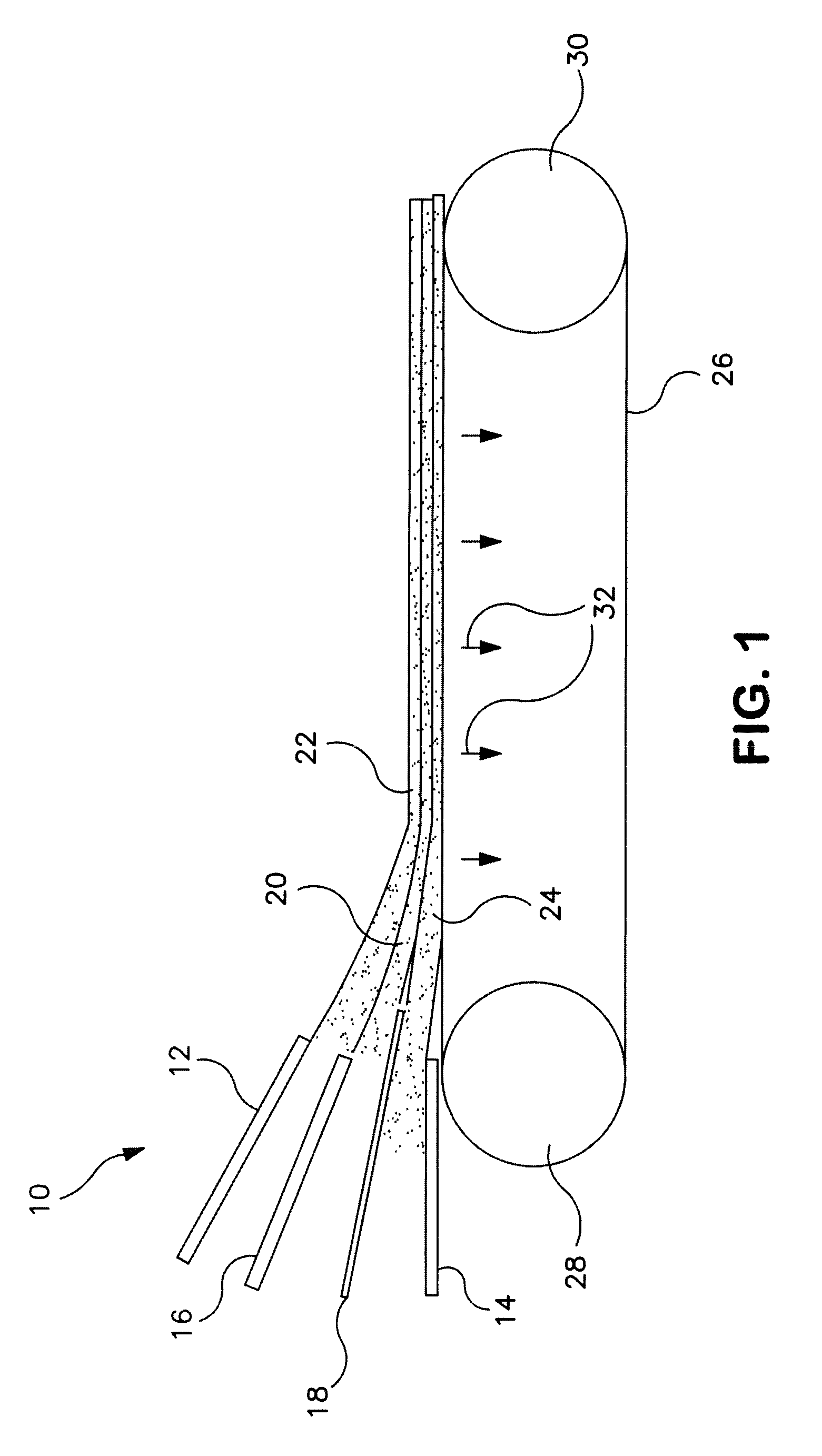

Embossed tissue products

InactiveUS20070137813A1Preserve strengthHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

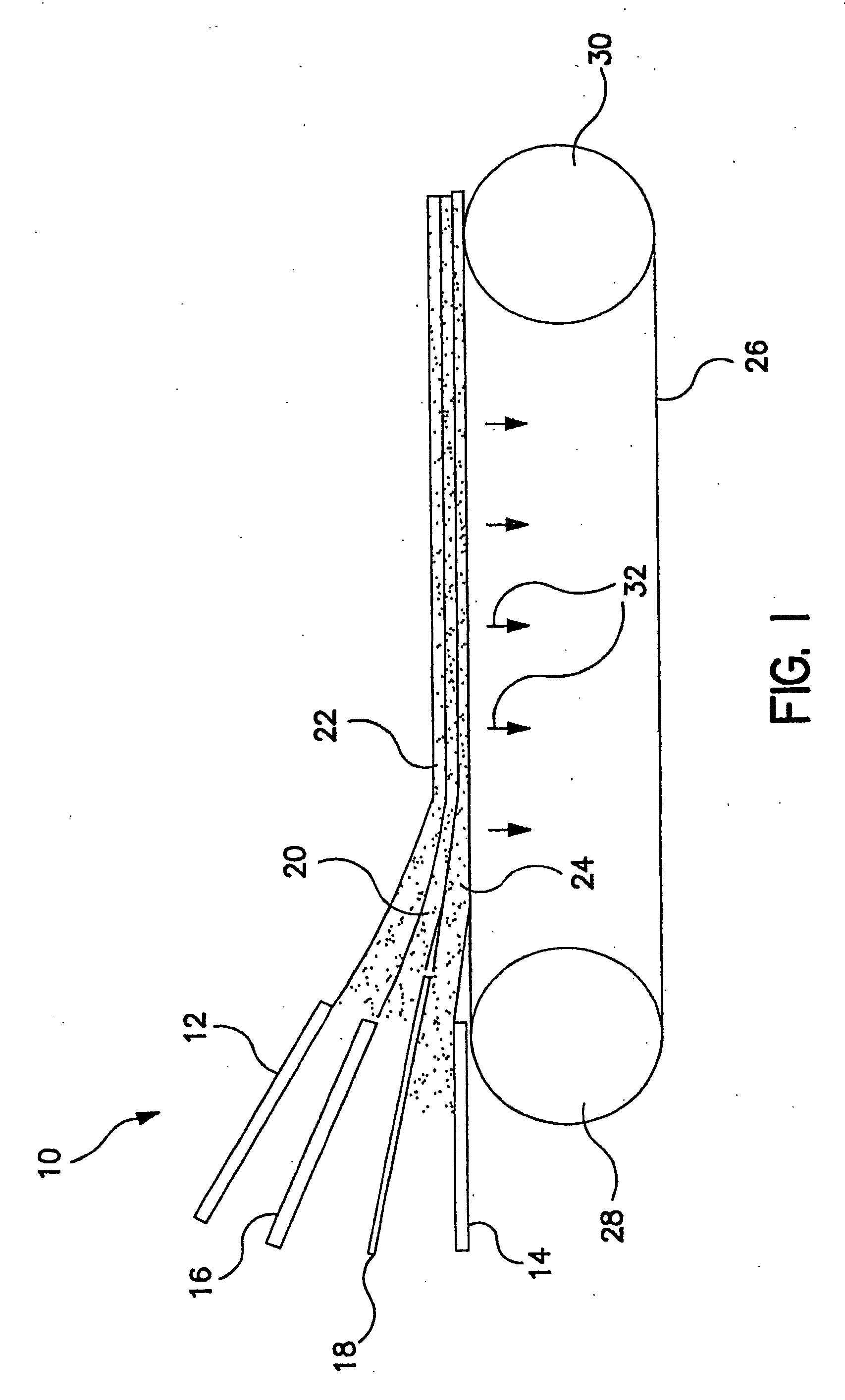

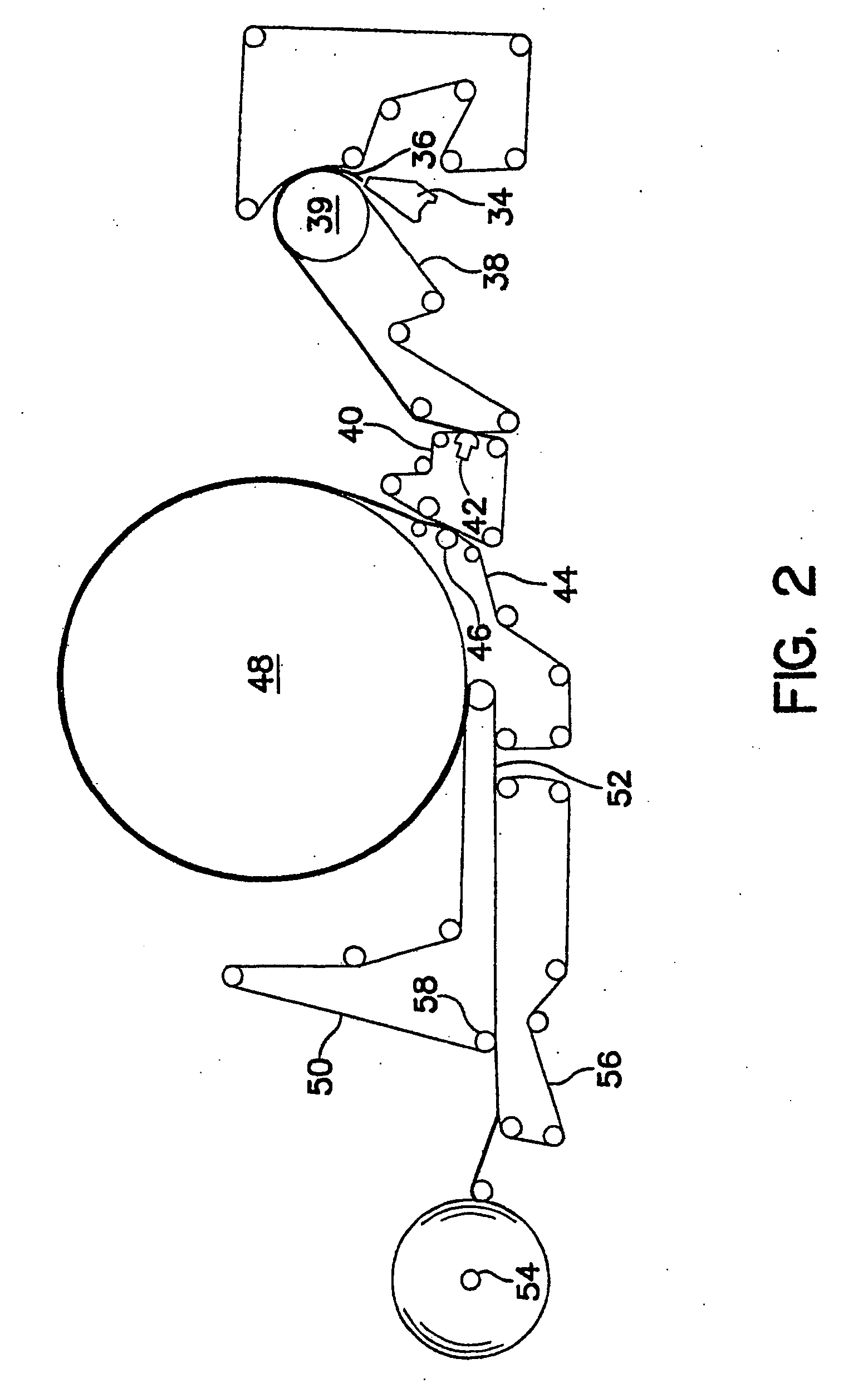

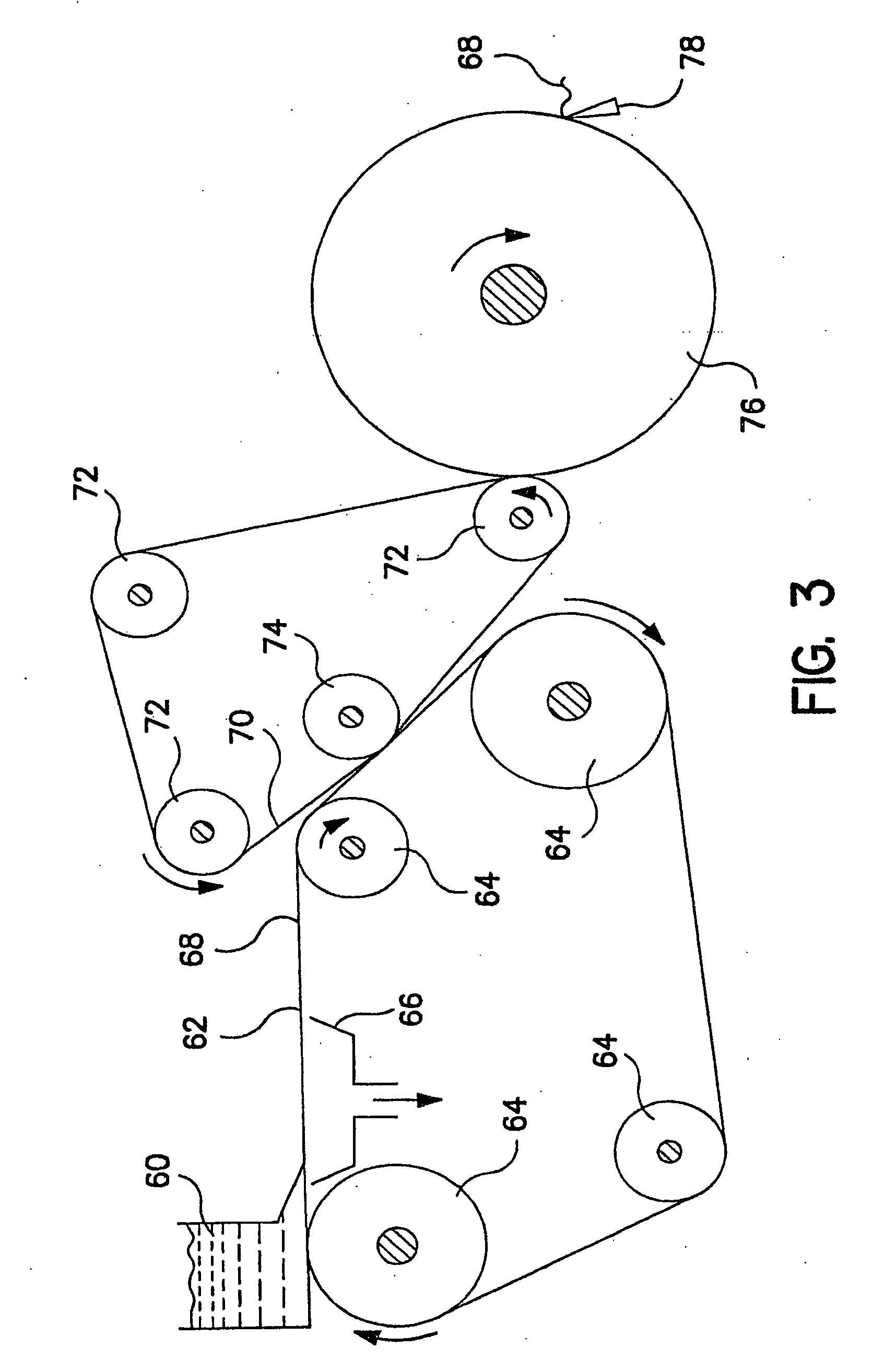

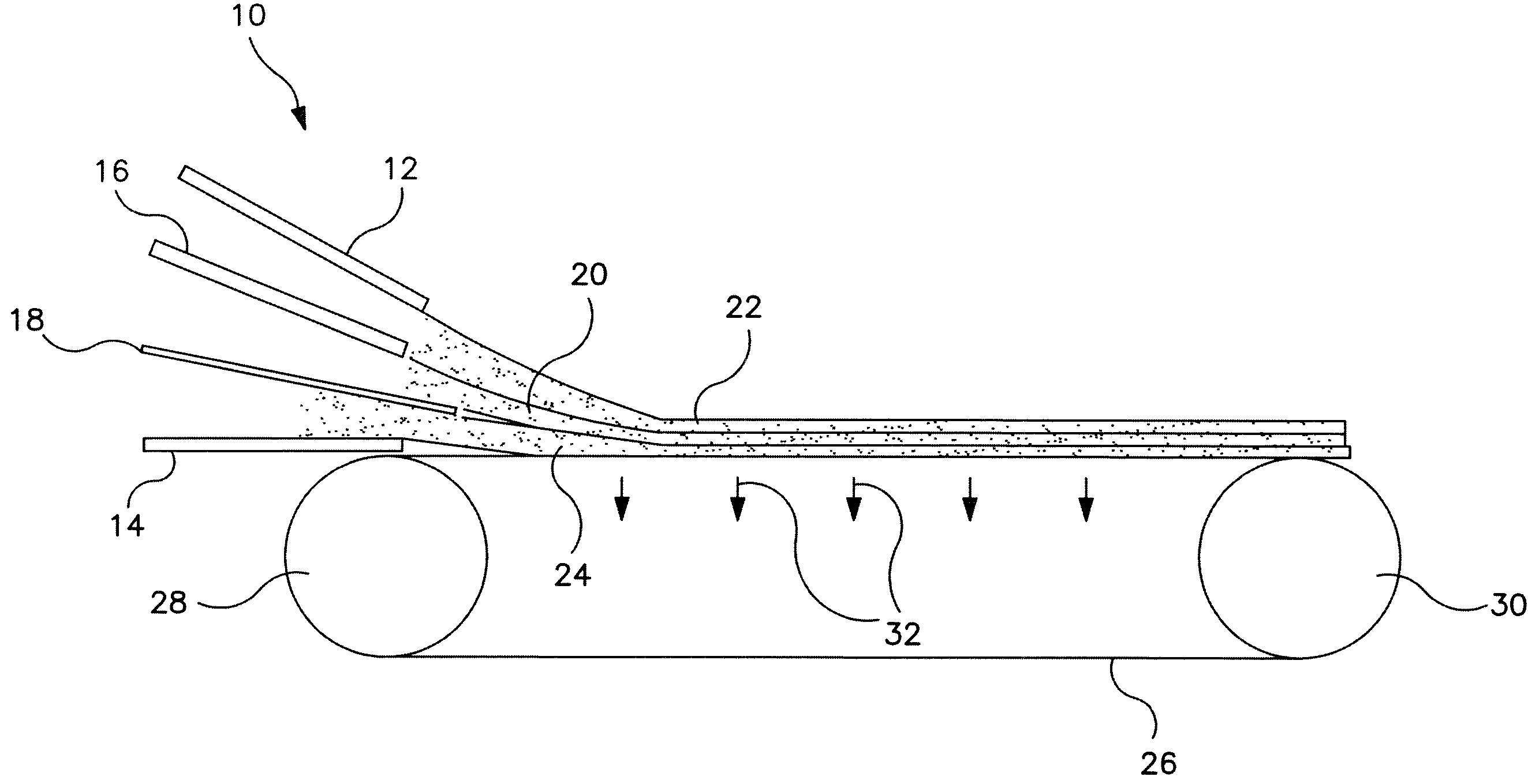

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. After the additive composition is applied to the web or otherwise incorporated into the tissue web, the tissue web is embossed. During embossing, the additive composition forms well defined embossments in the web that are water resistant. In one embodiment, the additive composition may also be used to bond multiple tissue webs together to form a multiple ply product during the embossing operation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Embossed tissue products

InactiveUS7842163B2Preserve strengthHigh strengthNatural cellulose pulp/paperMechanical working/deformationFiberCarboxylic acid

Owner:KIMBERLY-CLARK WORLDWIDE INC

Agent containing fat (oil), which contains onion extract, the production and use thereof for caring, preventing or treating damaged skin tissue, especially scarred tissue

The invention relates to a novel agent containing fat (oil), which contains onion extract, in addition to the production and use thereof for caring, preventing or treating damaged skin tissue, such as after operations, biopsies, wounds, burns and other accidents, and especially scarred tissue, stretch marks, degenerative skin conditions and others. The agent is characterised in that the base thereof is based on oil, which can be used to produce, for example, cream, lotion, fluid, massage, or balm based products which contain fail (oil). Surprisingly, the onion extract, which contains water, alcohol or water-alcohol, can be integrated into a base containing oil without the effectiveness thereof being reduced or a phase separation being produced. The effectiveness thereof could be proved when the medical application thereof was monitored.

Owner:MERZ PHARMA GMBH & CO KGAA

Antistaling process and agent

InactiveUSRE38507E1Inhibition formationAvoid softnessMilk preparationDough treatmentBiotechnologyAmylase

The staling of leavened baked products such as bread is retarded by adding an enzyme with exoamylase activity to the flour or dough used for producing the baked product in question.

Owner:NOVOZYMES AS

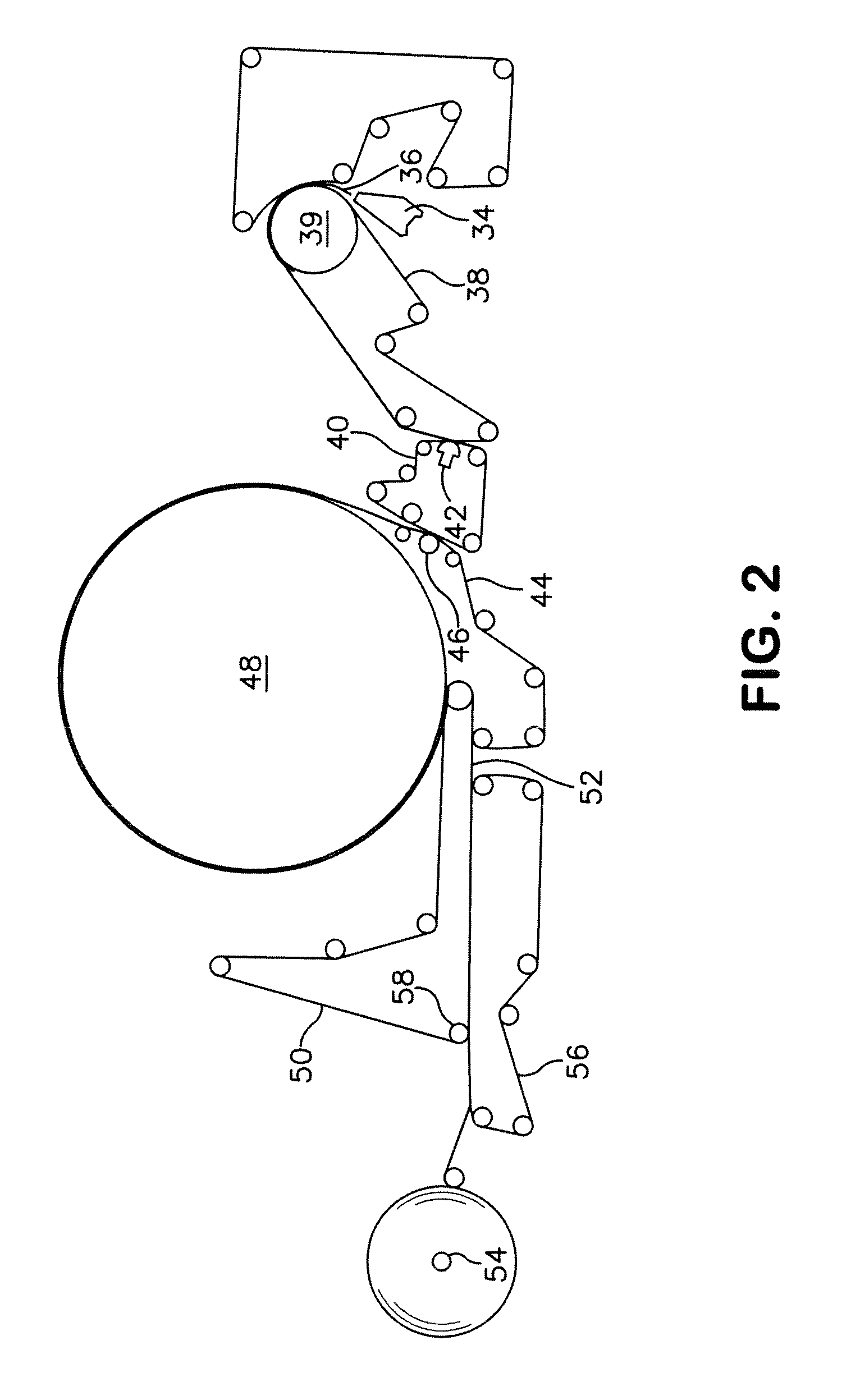

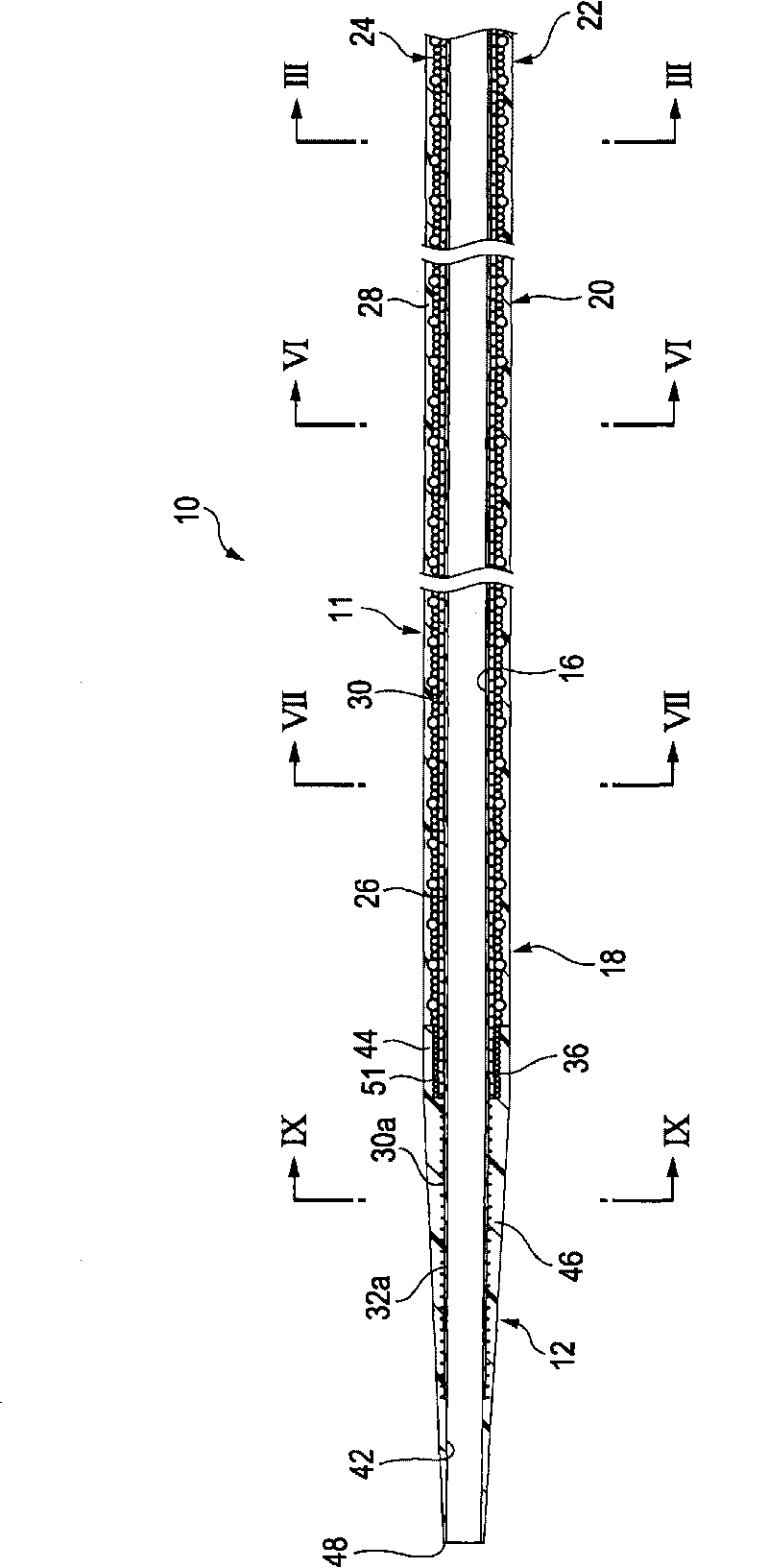

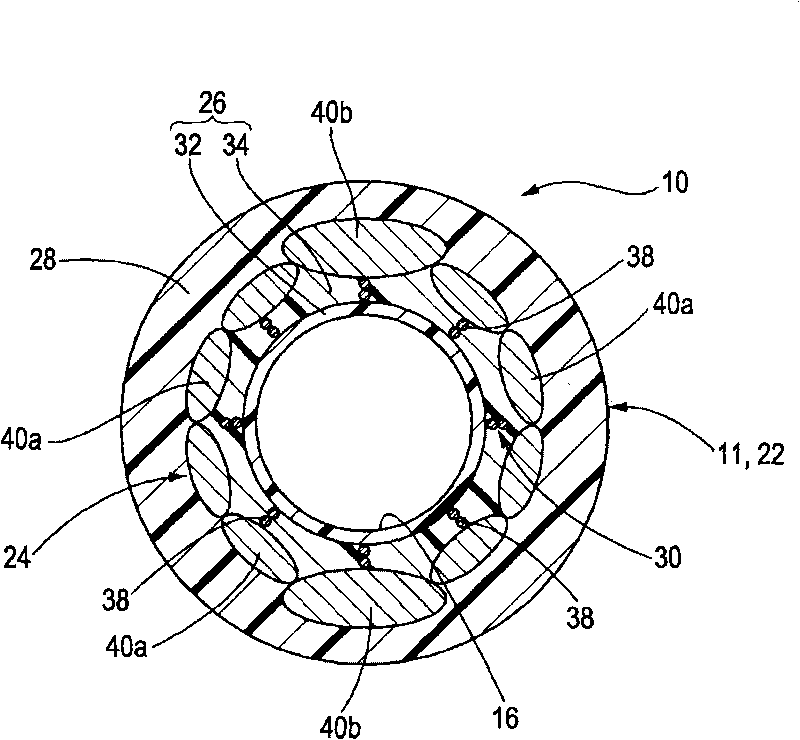

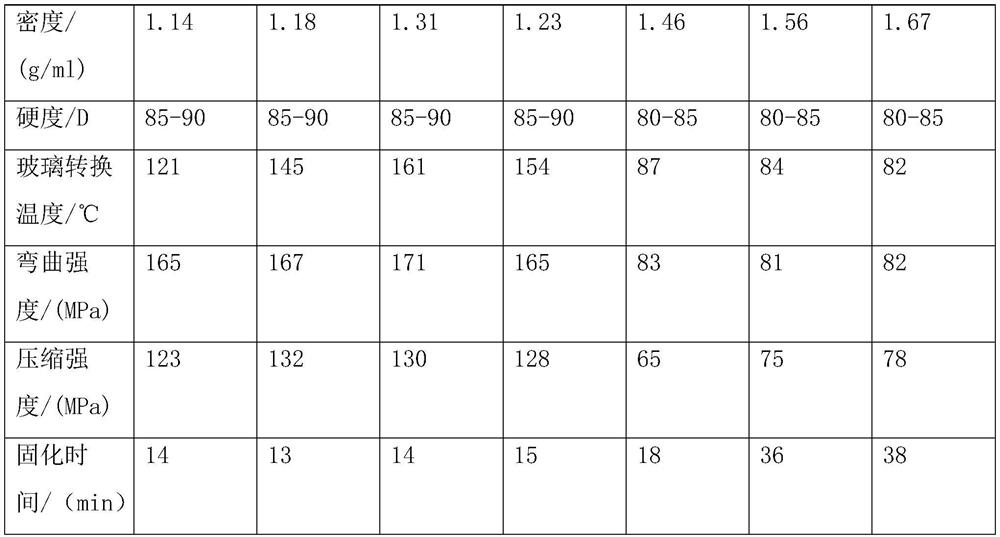

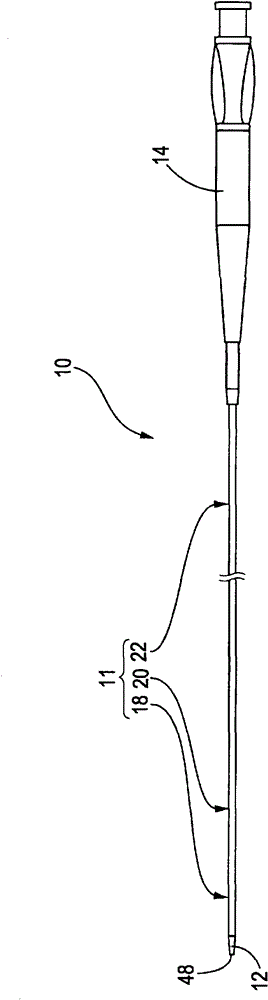

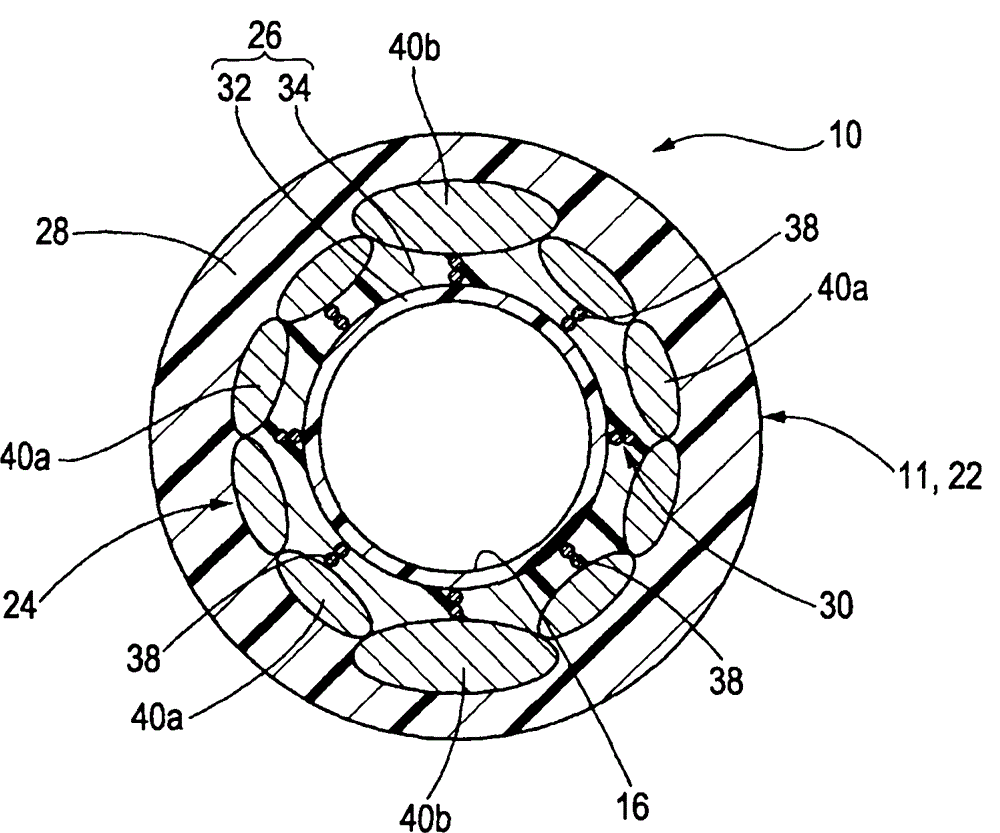

Catheter

ActiveCN101721770AImprove flexibilityExcellent torque transmittanceCatheterSurgeryStress concentrationMedicine

The invention discloses a catheter, which has a structure that a catheter body 11 includes a hollow coil 24 whose outer and inner surfaces are coated with outer and inner resin layers 28 and 26. A resin tip 12 is provided at a distal end 48 of the catheter body. The tip 12 has a tapered section 46 at a distal end of the tip. Also, an axially extending braid is embedded in the catheter body 11 andthe tip 12 to extend from the catheter body 11 to the tip 12 in the axial direction. The inventive catheter has plasticity, can reduce the stress concentration of the boundary part between the catheter body and the tip, and can exert higher torque transmissibility at the boundary part.

Owner:ASAHI INTECC CO LTD

Flame-retardant low-resilience urethane foam cushion

InactiveUS20090311933A1Prevent spreadExcellent texture and comfortPillowsStuffed mattressesPolyesterCushion

A low-resilience urethane foam cushion that is comfortable and has high flame retardancy. It sufficiently retains the unique texture and comfort inherent in low-resilience urethane foam materials for use as cushions or pillows. It further retains the intact excellent texture, touch feeling, and other properties inherent in fibrous materials. The low-resilience urethane foam cushion is obtained by covering a low-resilience urethane foam with a flame-barrier fabric made of at least two members selected from the group consisting of halogenated fibers (A), flame-retardant cellulosic fibers (B), cellulosic fibers (C), and polyester fibers (D), wherein the sum of (A) and (B) is 25 to 75 wt. % of the flame-barrier fabric, the sum of (B) and (C) is 30 wt. % or more of the flame-barrier fabric, the amount of (C) alone is up to 75 wt. % of the flame-barrier fabric, and the amount of (D) alone is up to 30 wt. % of the flame-barrier fabric.

Owner:KANEKA CORP

White goat-breeding feed and preparation method thereof

InactiveCN107647125AIncreased hungerIncrease appetiteFood processingAnimal feeding stuffGizzardLicorice roots

The invention discloses white goat-breeding feed and belongs to the technical field of goat breeding. The feed includes the following raw materials in parts by weight: straw 8-10, white radishes 5-8,wheat seedlings 8-12, chicken gizzard-membrane 3-5, fructus aurantii 2-3, licorice roots 1-3, salt 6-8 and brewer's grain 4-7. According to the invention, on the condition of guaranteeing sufficient nutrients, the feed also strengthens gastrointestinal digestion and absorption capability, improves feed palatability and increases the feed intake of white goats so as to achieve the effect of fast fattening. Except for the condition of feeding different feed, based on a same weight gain standard after feeding, adopting the feed provided by the technical solution meets the standard 2-3 months earlier than adopting traditional feed. In addition, the wheat seedlings having the functions of decreasing blood lipids and blood glucose are added into the feed to avoid unhealthy obesity caused by excessive feed intake so as to guarantee the healthy of the white goats.

Owner:务川自治县宏牧羊业有限公司

Soft antibacterial non-woven fabric and preparing method thereof

InactiveCN111705423AIncrease softnessHigh speedFabric breaking/softeningTextile treatment machine arrangementsPolymer scienceCotton fibre

The invention belongs to the technical field of non-woven fabric preparing, and particularly relates to soft antibacterial non-woven fabric and a preparing method thereof. The soft antibacterial non-woven fabric is formed through mixing of cotton fibers and polypropylene staple fibers, the proportion of the cotton fibers in the soft antibacterial non-woven fabric is 75 to 80wt%, and the balance isthe polypropylene staple fibers; the polypropylene staple fibers are fine denier fibers, and contain a silver-loaded chitosan antibacterial agent, the adding amount of the silver-loaded chitosan antibacterial agent in the polypropylene staple fibers is 5 to 10wt%, the prepared non-woven fabric has the good antibacterial property, meanwhile, through soft arranging in the physical manner, softnessis good, treatment without a softening agent is achieved, and no softening agent remains.

Owner:张小艳

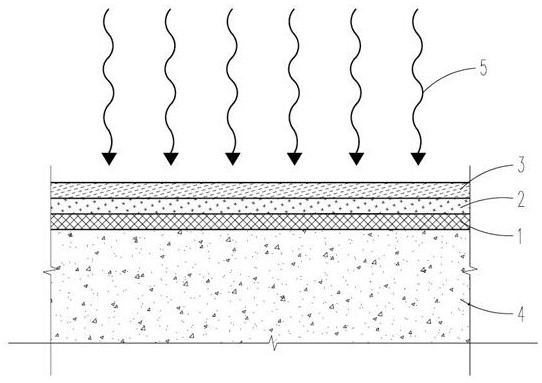

Building radiation cooling coating structure and manufacturing method thereof

PendingCN114716860AEasy to operateEasy to implementClimate change adaptationHeat proofingPolymethyl methacrylateEngineering

The invention discloses a building radiation cooling coating structure which covers the outer surface of a building and comprises a coupling agent layer, a solar spectrum radiation total reflection layer and an infrared emission layer from inside to outside. In particular to an infrared emission layer containing a polydimethylsilane and polymethyl methacrylate composite cooling material, which not only ensures a radiation cooling function, but also ensures the mechanical stability of a formed film. Sunlight is reflected through the solar spectrum radiation total reflection layer, absorption of energy in the sunlight is reduced, heat of a building is radiated outwards through the infrared emission layer, radiation absorption of sunlight in the daytime is reduced, meanwhile, release of infrared radiation with the wavelength of 8-13 micrometers at night is enhanced, and therefore the overall temperature of the building is reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

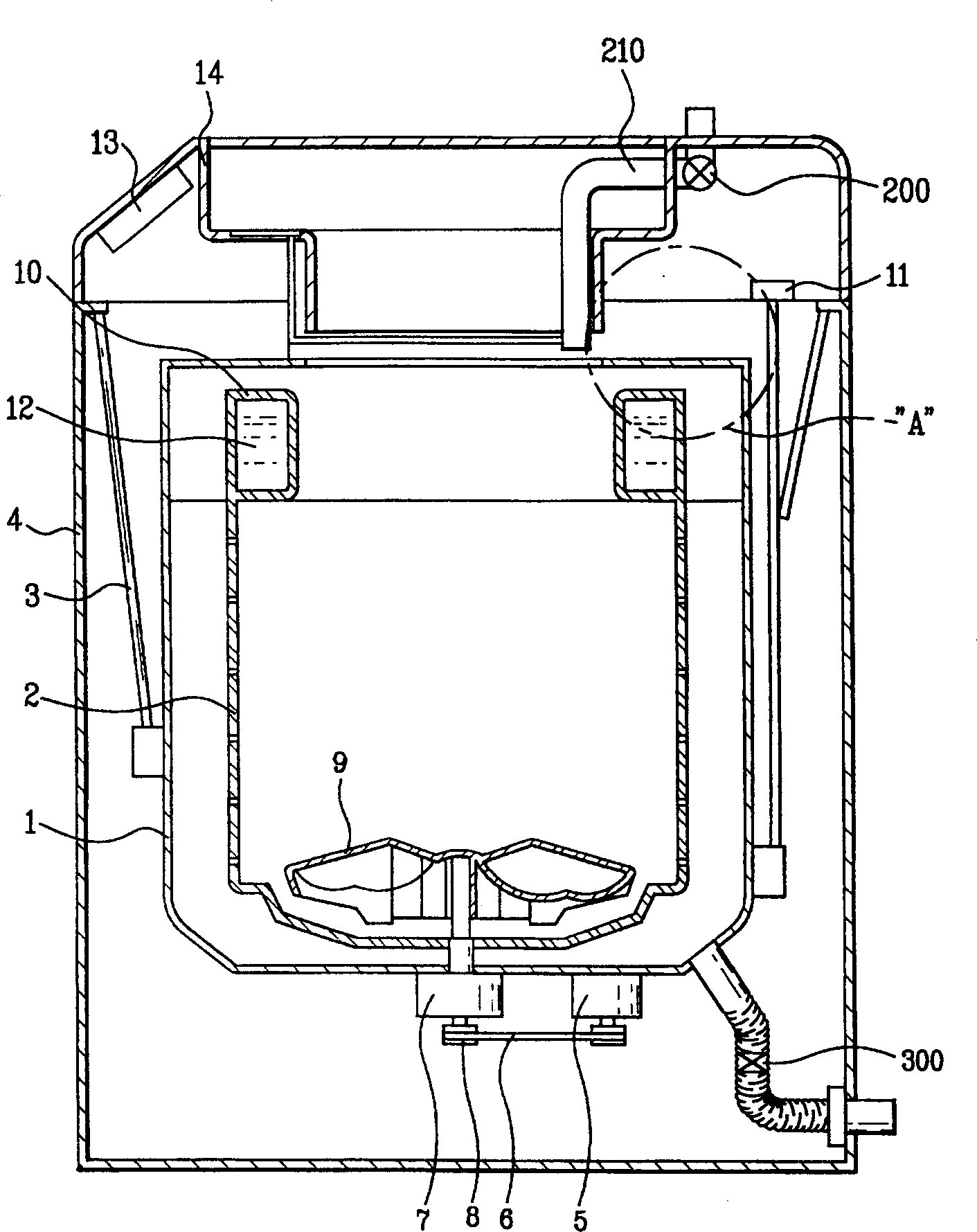

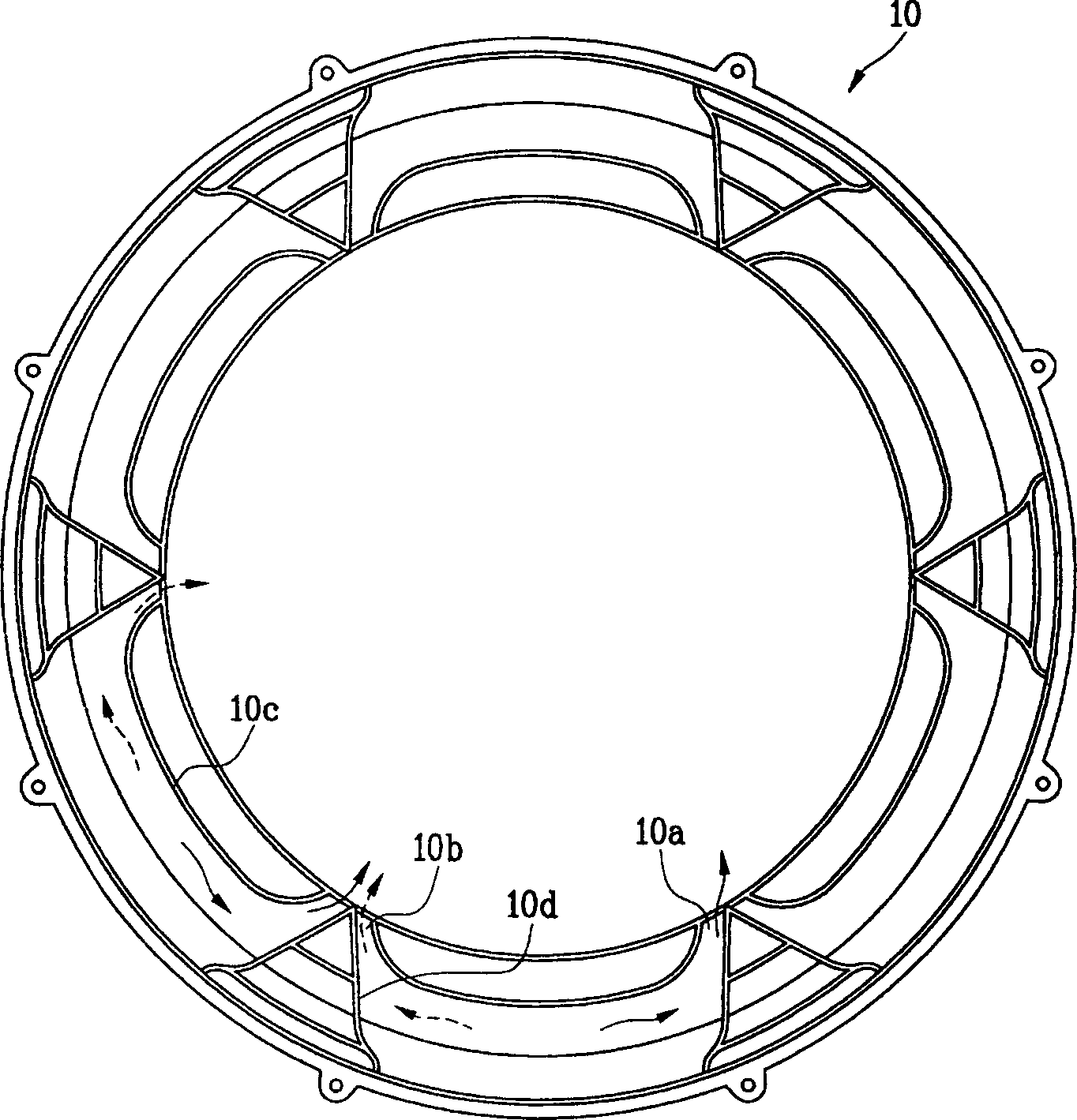

Washing machine set with additive adding structure

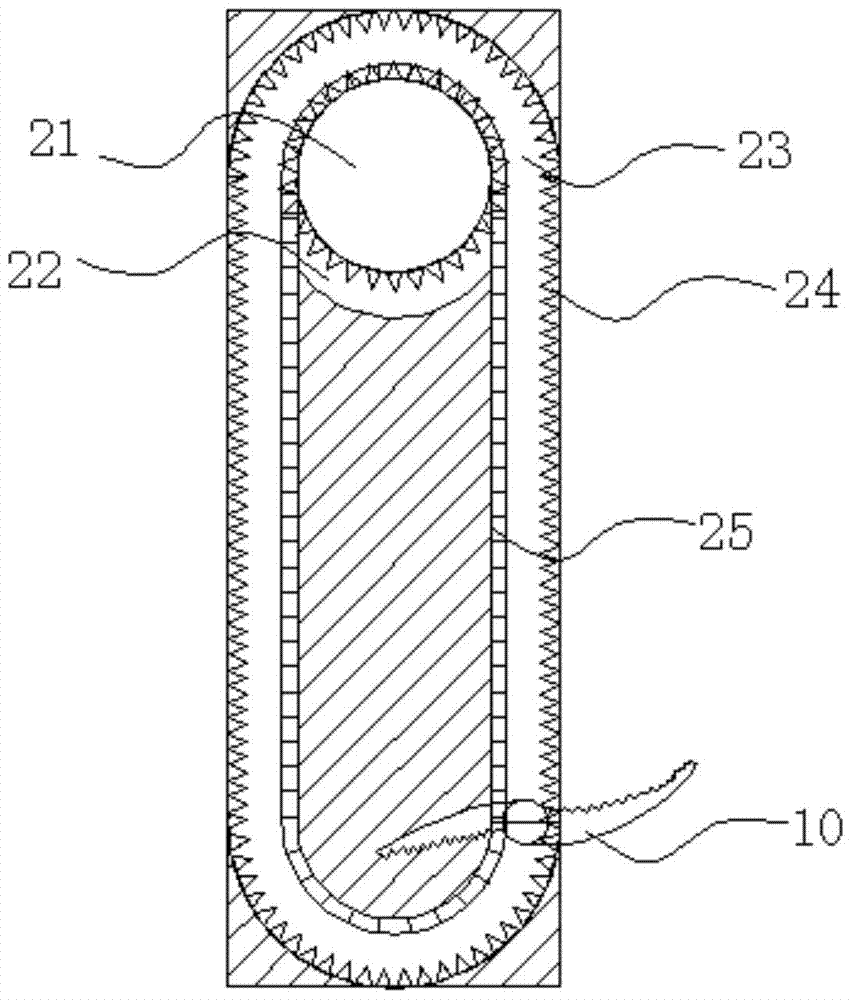

InactiveCN1508348APrevents backflow to above sink coverAvoid softnessOther washing machinesTextiles and paperCounter currentCircular surface

The invention provides a transmission washing machine, comprising external box, external tank, washing tank, top cover, additive holding room, washing tank cover and counter-current preventing equipment. The external tank is set inside the external box; the washing tank can be rotatablely set inside the external tank, formed with many through holes on the external circular surface; the top cover is installed on the top of the box; the holding room set on the top cover to hold bleaching agent or fiber softening agent, etc; the washing tank cover set at the upper end of the external tank and formed with additive inflow holes to make the additive flow into the lower space from the holding room; the counter-current preventing instrument preventing the washing water from reversely flow to the periphery of the additive inflow holes when the transmission washing executed.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Outdoor towel fabric

ActiveCN110295445AAppearance plump and thickFeel comfortableBiochemical treatment with enzymes/microorganismsGrip property fibresEnzymatic hydrolysisPolyamide

The invention discloses an outdoor towel fabric which comprises a base layer, a skin-friendly layer and a terry layer. The terry layer is formed on the surface of the base layer, the skin-friendly layer is directly formed on the other side opposite to the terry layer on the base layer, polyamide, spandex, viscose and chitosan fibers are blend to form the skin-friendly layer, bast fiber mixture istreated by enzymatic hydrolysis and ultraviolet isolation factor filling, the treated bast fiber mixture, cotton fibers and bamboo fibers are blend to form warp yarns, the bast fiber mixture and the cotton fibers are blend to form weft yarns, and the warp yarns and the weft yarns are woven to form the base layer. The fabric is full and thick in appearance and comfortable in hand feeling has high toughness and anti-ultraviolet and antibacterial effects.

Owner:YUEYANG BAOLI TEXTILE

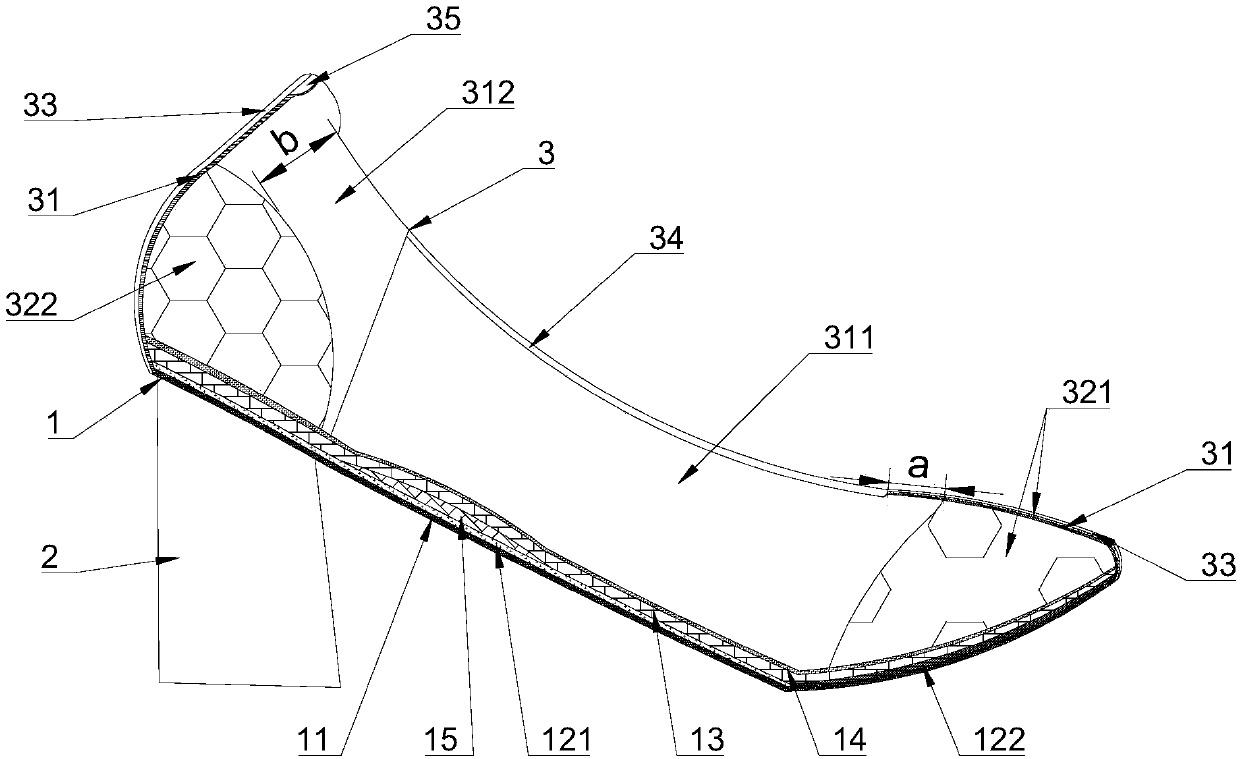

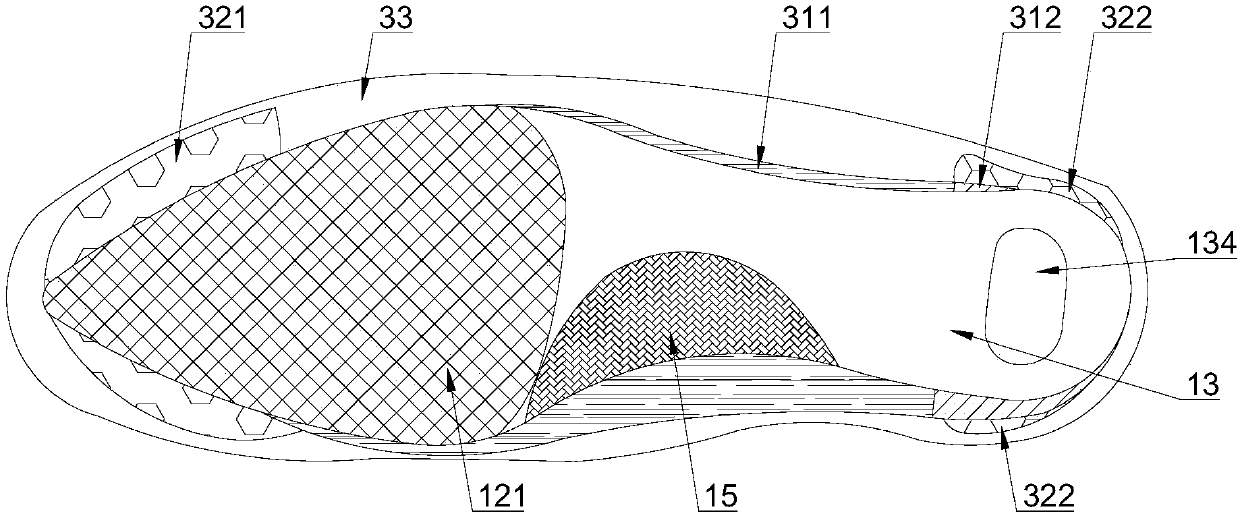

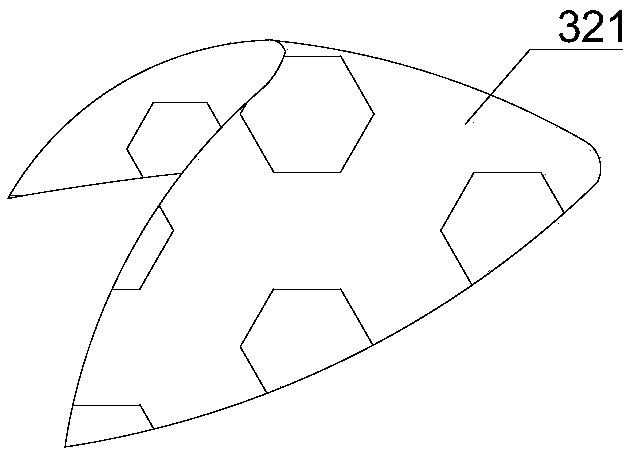

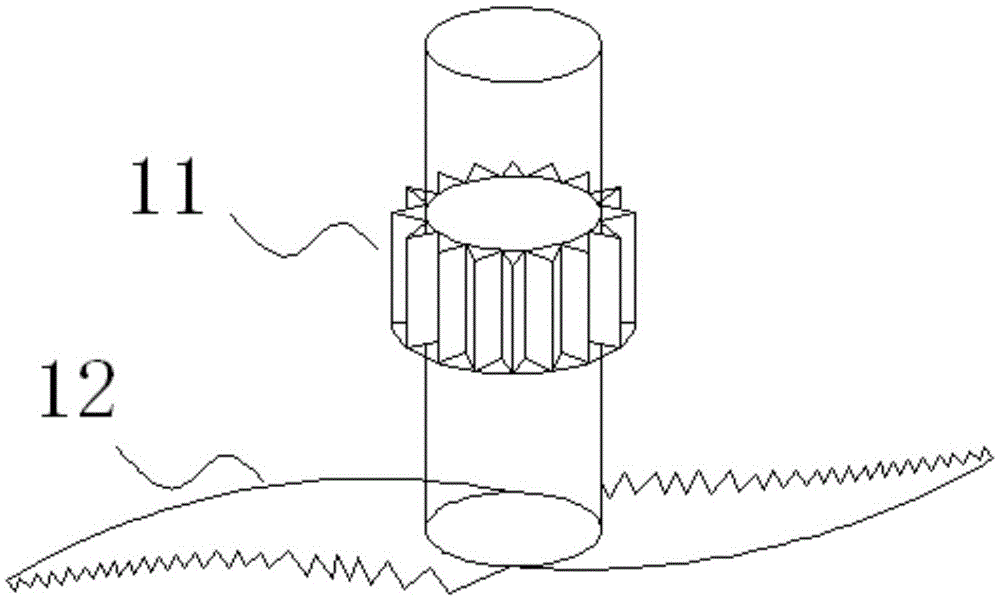

Soft and nondeformable shoe and production method thereof

The invention relates to a soft and nondeformable shoe and a production method thereof. The shoe comprises a sole, a heel and an upper, wherein the heel and the upper are respectively arranged on thesole; the sole comprises a sole pad, a middle bottom pad shaping layer, a shoe middle bottom and a sole inner layer which are sequentially arranged from bottom to top, a foot arch elastic body is arranged between the shoe middle bottom and the middle bottom pad shaping layer, the shoe middle bottom comprises a shoe middle bottom surface, a shoe middle bottom sponge layer and a shoe middle bottom inner surface which are sequentially arranged from bottom to top, and the thickness of the shoe middle bottom decreases progressively from the center to the periphery; and the upper comprises an upperinner layer, an upper shaping layer and an upper outer layer which are sequentially arranged from inside to outside, the upper shaping layer comprises toe cap shaping lining cloth and shoe heel shaping lining cloth, and an elastic covering edge is arranged on the upper outer layer along the edge of a shoe throat. Compared with the prior art, the soft and nondeformable shoe has the advantages thatthe shoe is soft, comfortable and does not deform, and the same shoe size is suitable for multiple shoe types.

Owner:FUZHOU LUYA SHOES

Shelduck feed for improving quality of duck meat

InactiveCN105028924AHigh in collagenFresh fleshAnimal feeding stuffAnimal scienceAdditive ingredient

The invention discloses a shelduck feed for improving the quality of duck meat. The shelduck feed for improving the quality of the duck meat comprises, by weight, 30-40 parts of corn, 15-20 parts of rice bran, 8-12 parts of puffed full-fat soybean, 10-15 parts of green bean powder, 15-20 parts of linseed meal, 0.5-1 part of chitin, 0.6-0.8 part of fish solubles, 2-4 parts of linoleic acid, 0.2-0.3 part of choline chloride, 1-2 parts of chilli powder, 0.06-0.08 part of methionine, 0.02-0.06 part of lysine, 0.02-0.06 part of threonine and 0.2-0.4 part of calcium hydrophosphate. Compared with the prior art, the shelduck feed for improving the quality of the duck meat has the advantages that the duck meat can be fresh in meat color by changing the proportions of nutritional ingredients of the feed and appropriately adding corresponding additives, the water-holding capacity is improved, the collagen content of the duck meat is increased, and the quality of the duck meat is improved.

Owner:杨珊洪

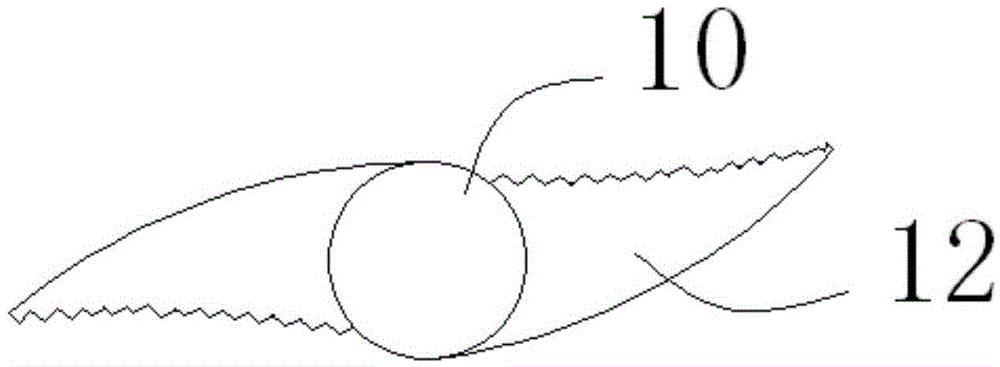

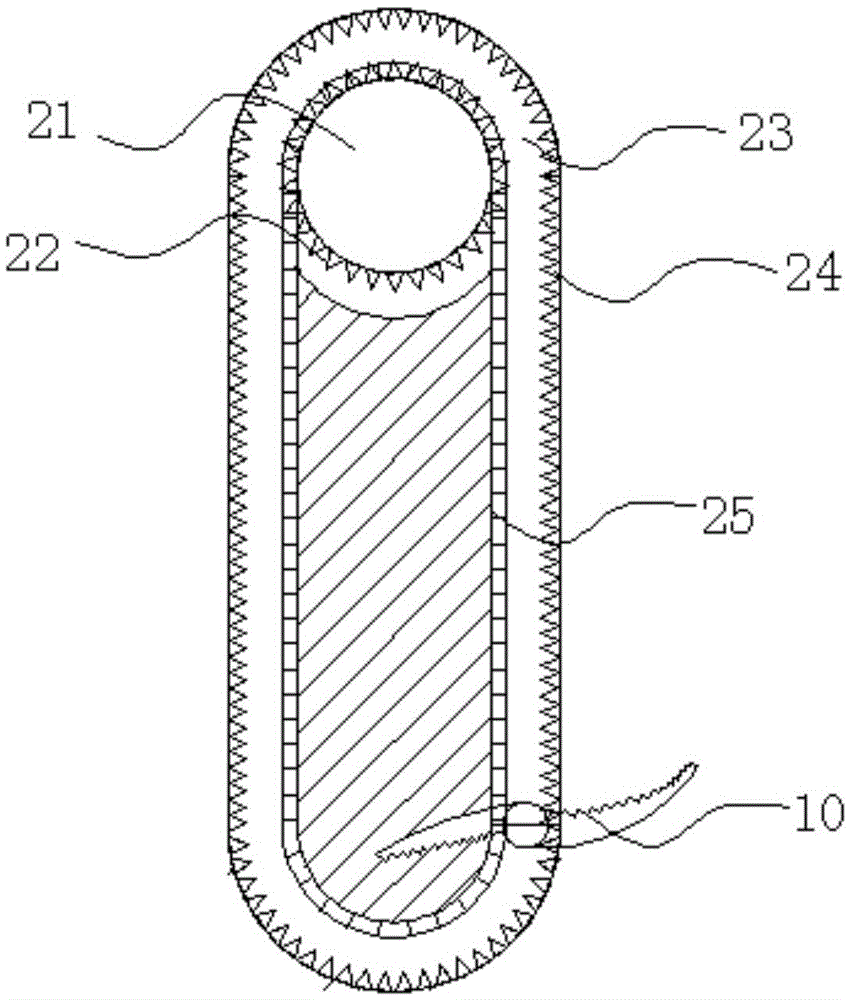

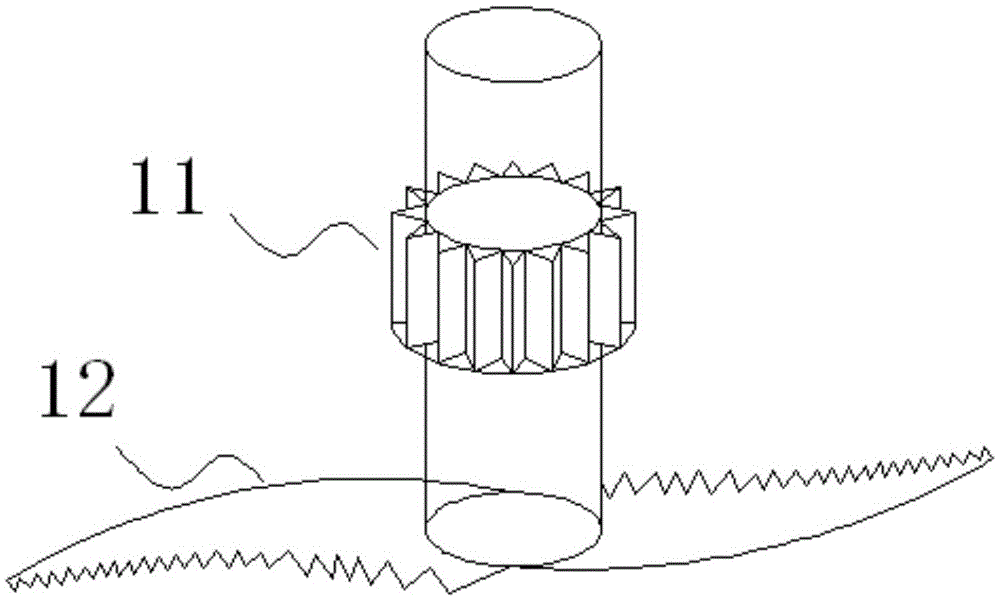

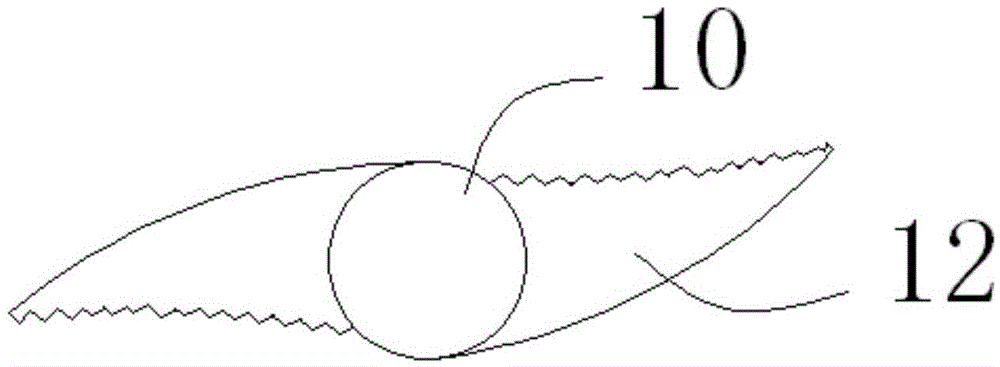

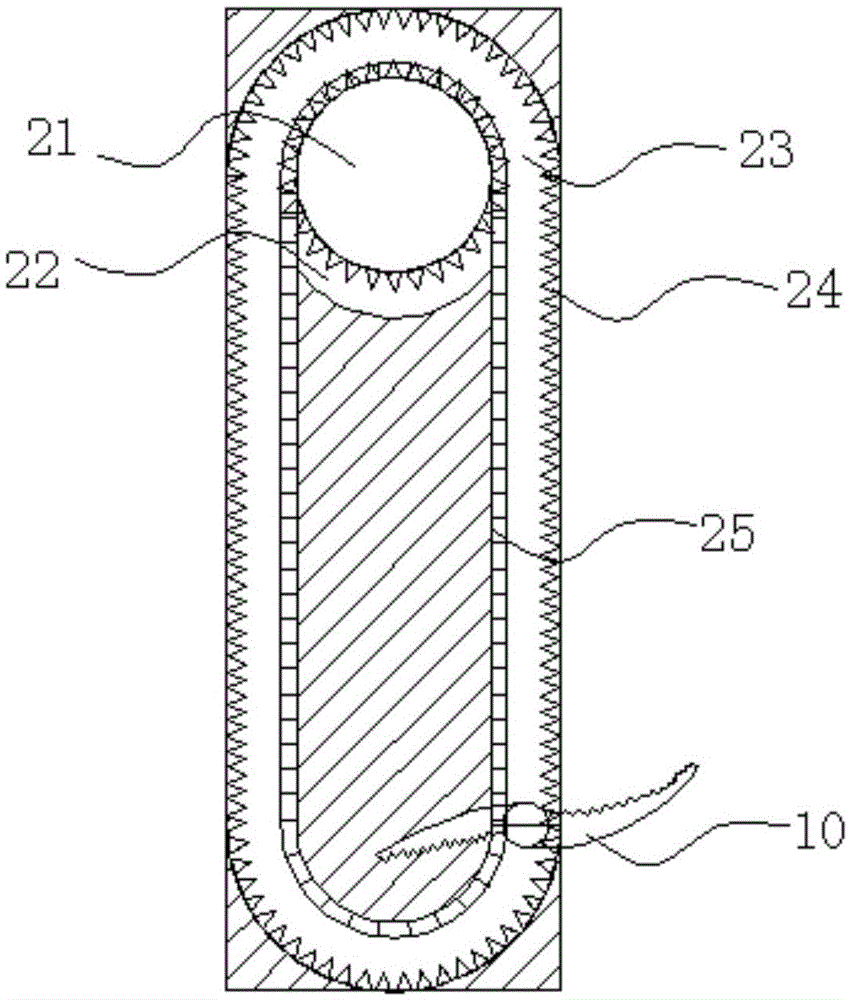

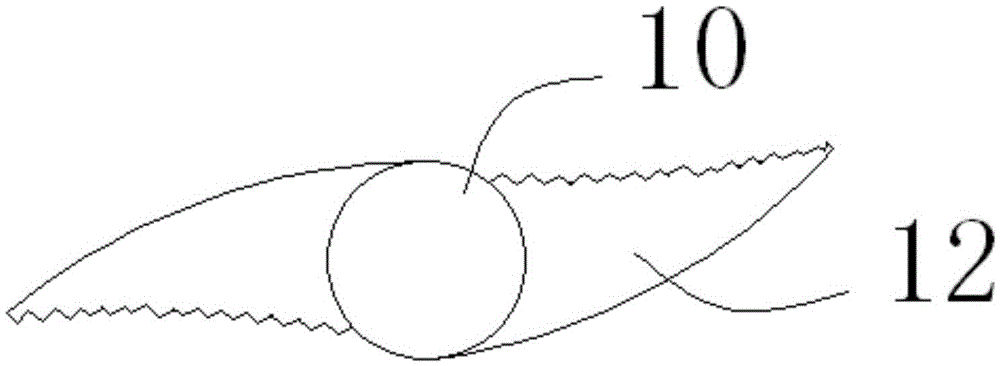

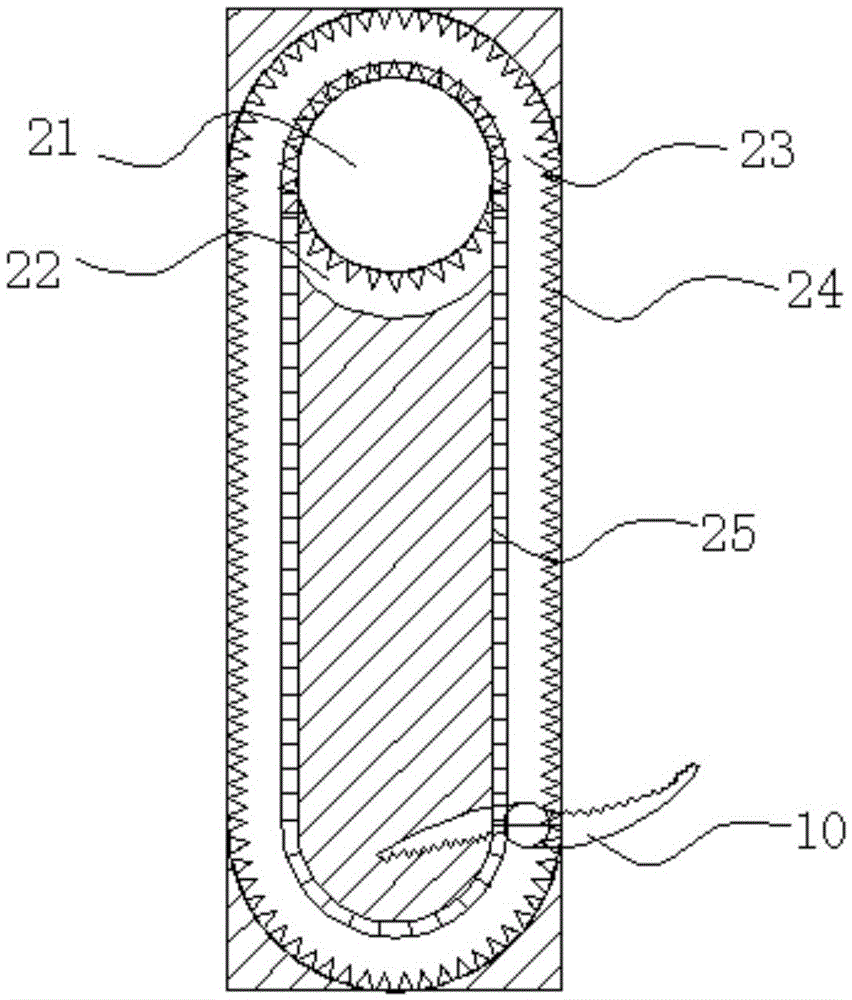

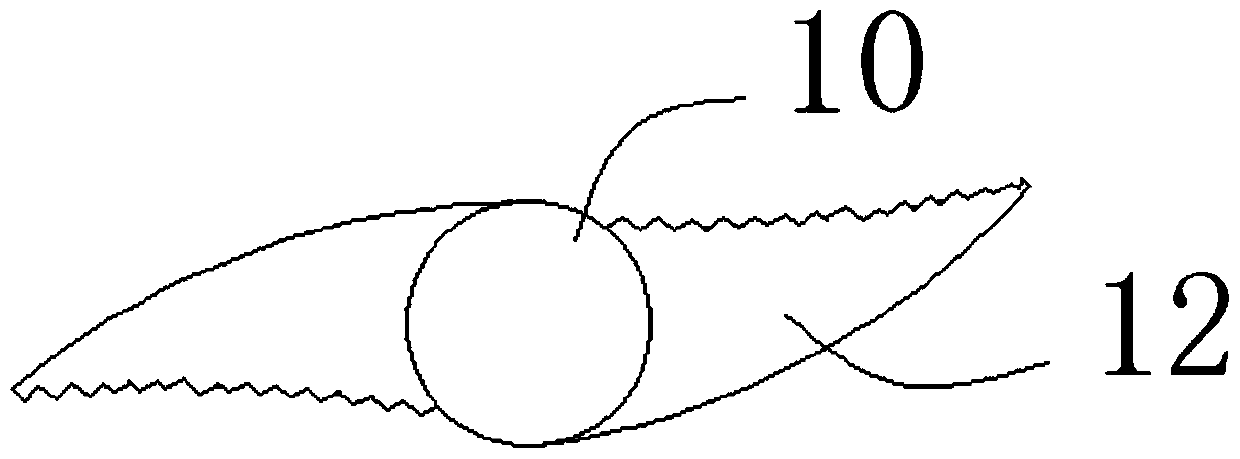

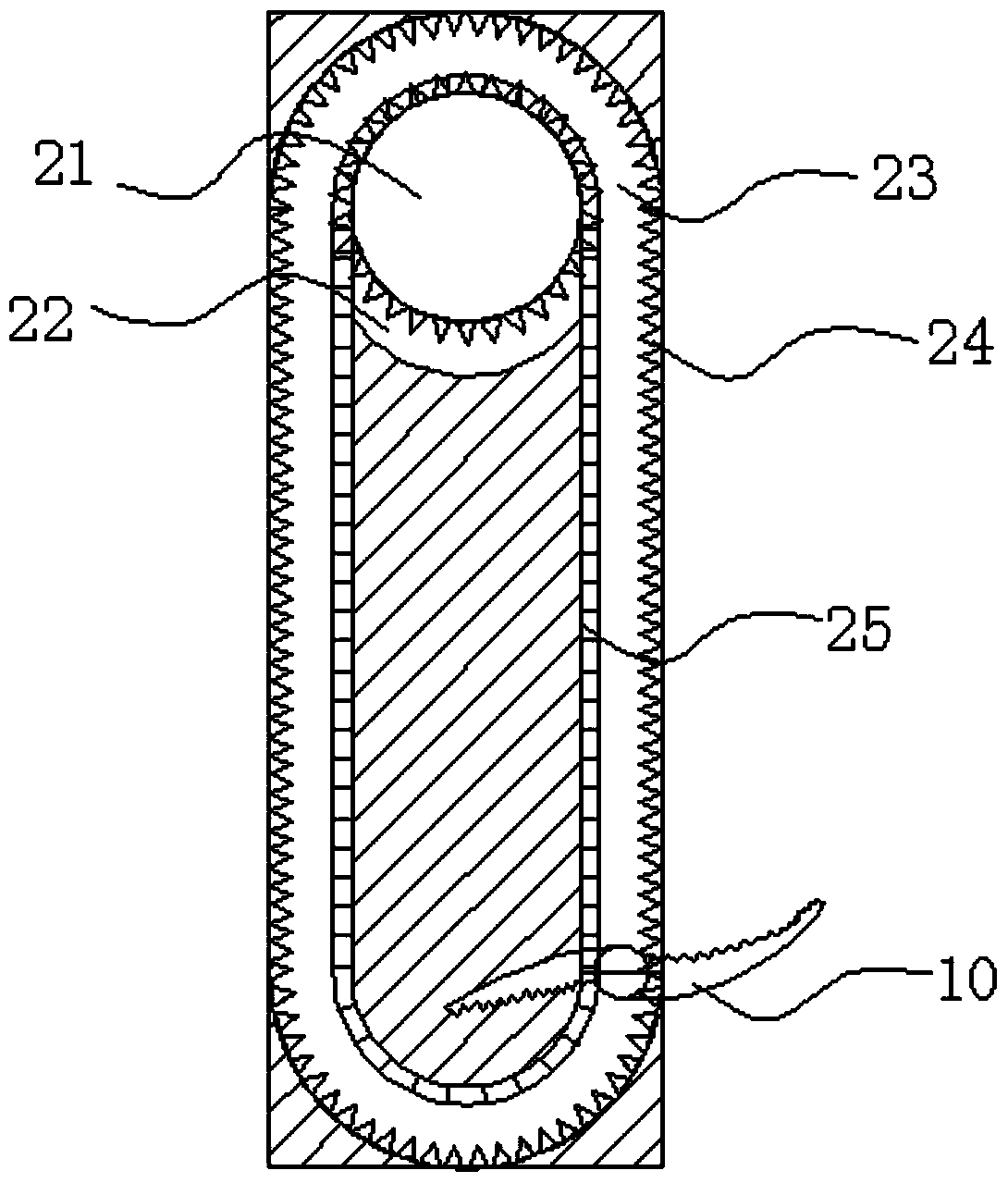

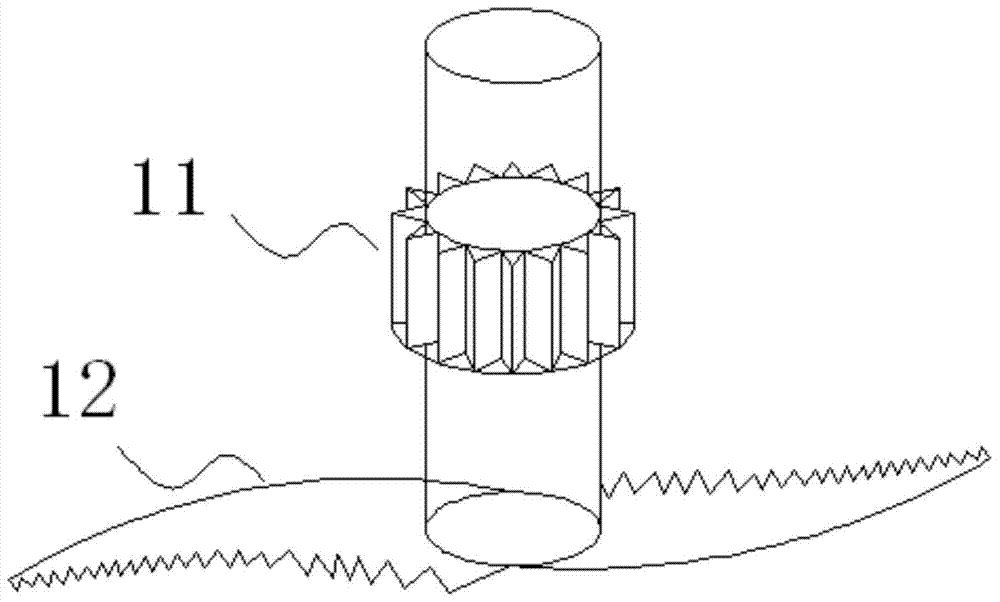

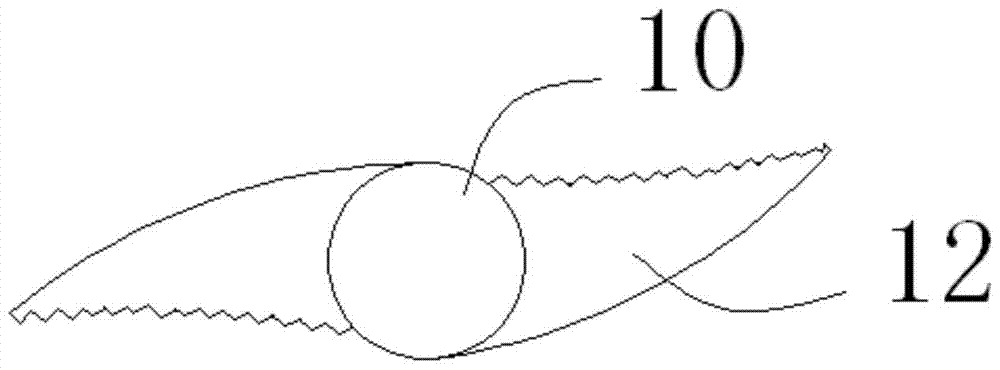

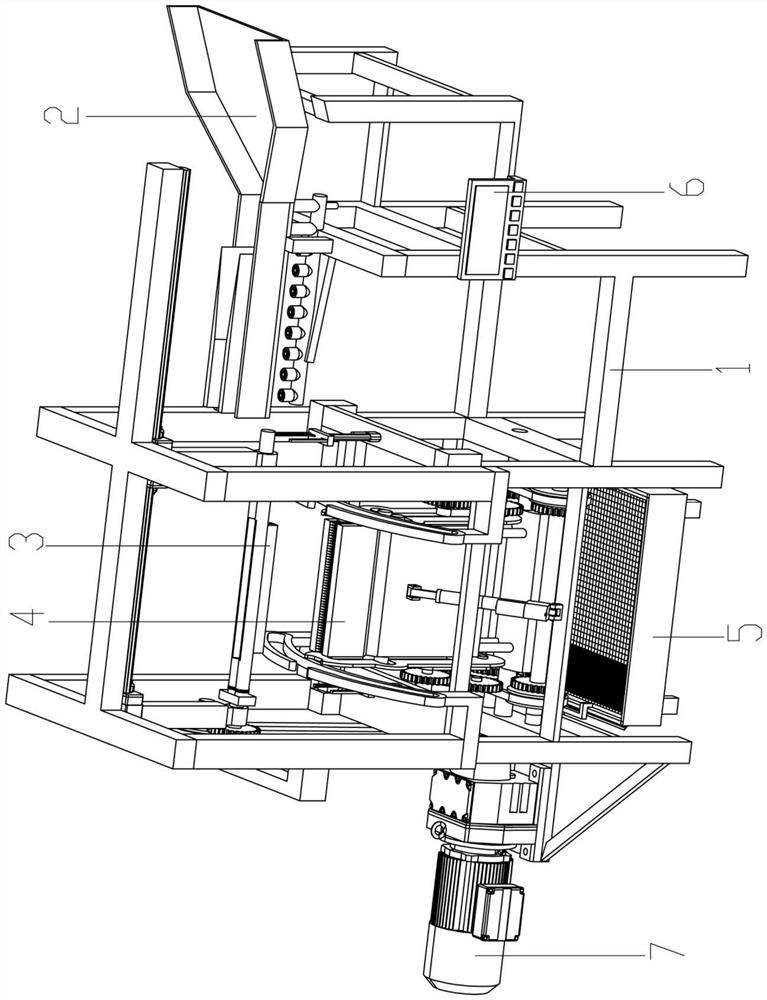

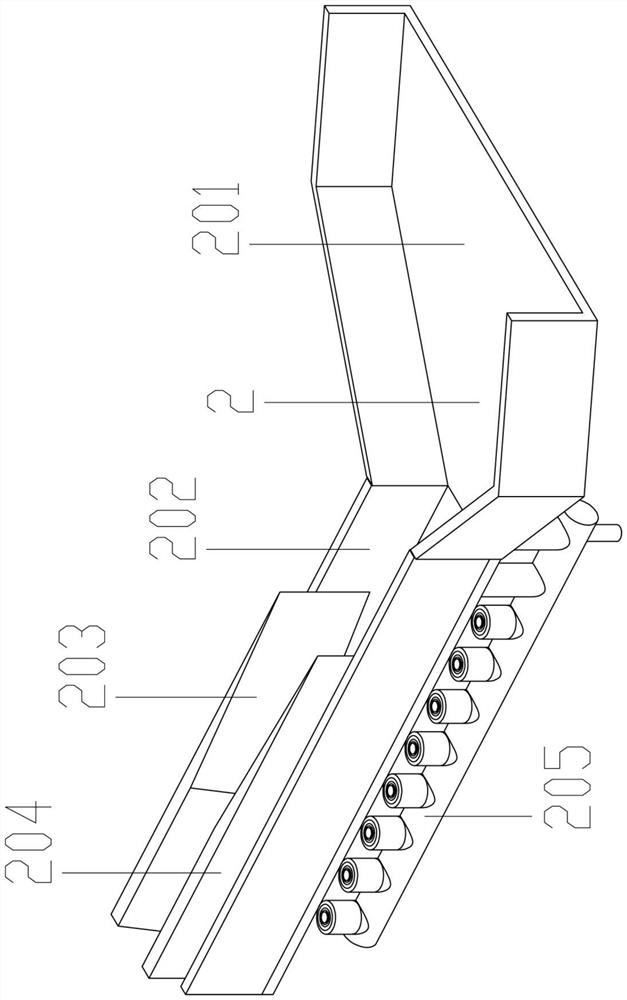

Gardening pruning device facilitating rapid forming

ActiveCN105557341AReduce rework rateImprove efficiencyCuttersMotor driven pruning sawsPruningMotor drive

The invention discloses a gardening pruning device facilitating rapid forming. The pruning device comprises a rotating cutter, a first drive device, a filleted cuboid with rails inside and a second drive device, wherein the rotating cutter comprises cutter blades and a rotary shaft, the rotary shaft is a cylinder provided with a gear, the cutter blades are arranged on the front end surface of the rotary shaft, and the planes of the blades are axially perpendicular to the rotary shaft; the first drive device comprises a chain which is a transmission chain, a first gear and a first motor, the first gear is meshed with the chain, and the first motor drives the first gear to rotate, so that the chain can move; the second drive device comprises a roller, a second motor, an outer ring, an inner ring, a handle and a hard rod, wherein a boss facing the circle center is arranged on one end surface of the outer ring, the handle is fixed to the outer ring of the second drive device, one end of the hard rod is fixed to the inner side of the inner ring, the other end of the hard rod is hinged with the first drive device, and bulges are arranged on the edge of the boss. The gardening pruning device facilitating rapid forming is simple to manufacture, convenient and flexible to operate, high in pruning efficiency and suitable for multi-angle pruning of plants.

Owner:王文强

Medical sanitary non-woven fabric

ActiveCN111529209AExtended service lifeImprove impermeabilityAbsorbent padsBaby linensPolymer scienceAdhesive

The invention belongs to the technical field of non-woven fabrics, in particular to a medical sanitary non-woven fabric. The fabric comprises a surface layer, an intermediate layer and a contact layer, wherein the surface layer is arranged above the intermediate layer; the contact layer is arranged under the intermediate layer; the surface layer is a non-woven fabric; the contact layer is a non-woven fabric; the intermediate layer is high-molecular water-absorbing resin. The medical sanitary non-woven fabric has a simple structure, and the production process is simple and implementable; besides, the use of an adhesive is omitted, the production cost is effectively reduced, strength of the product is improved by pressed lines formed by ultrasonic pressing, dislocation and aggregation of composition of the product can be avoided, and performance of the product is ensured.

Owner:济南瑞凝医药科技有限公司

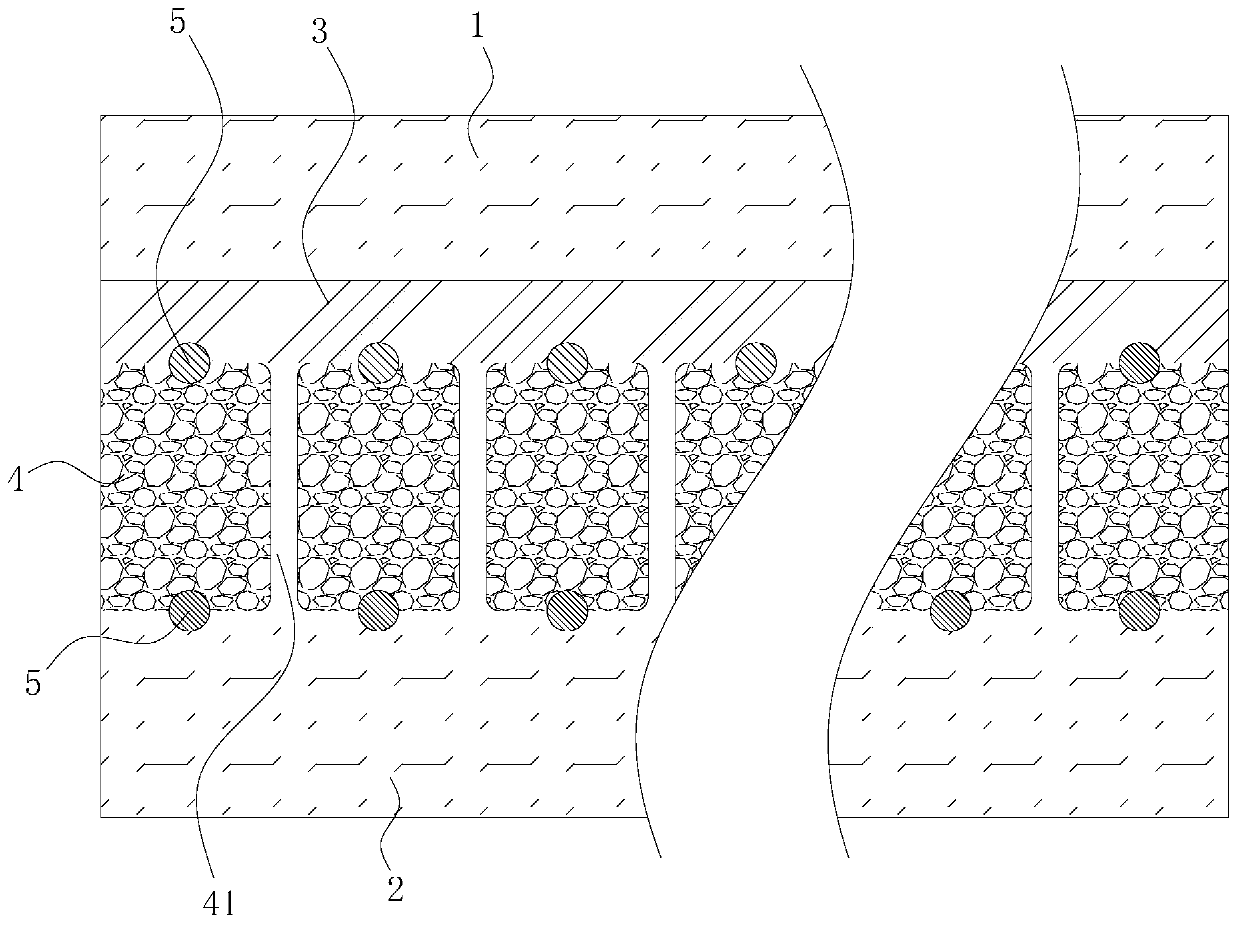

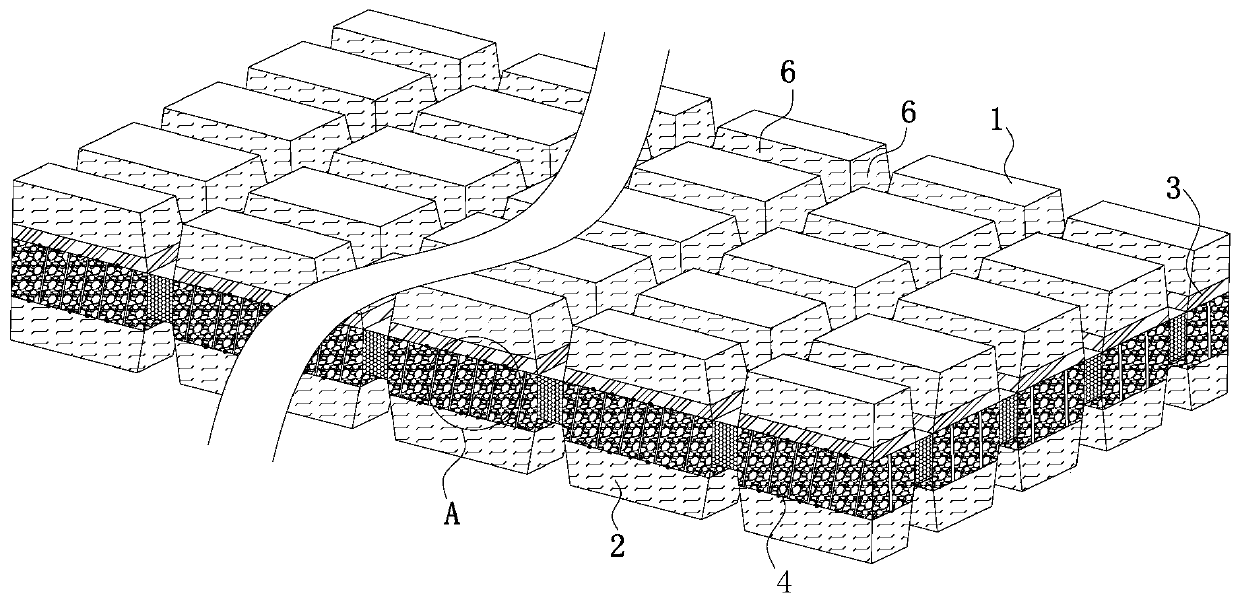

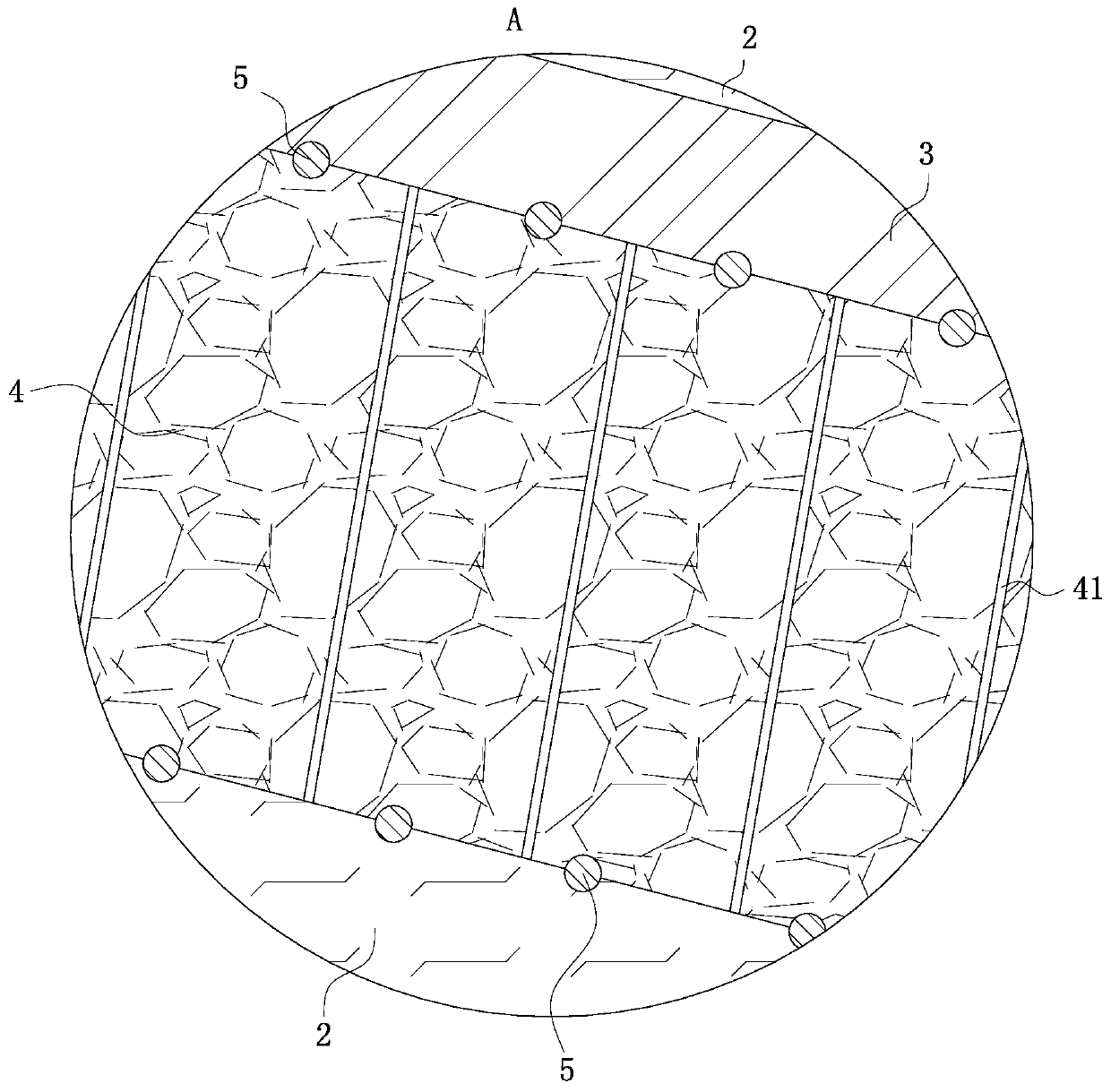

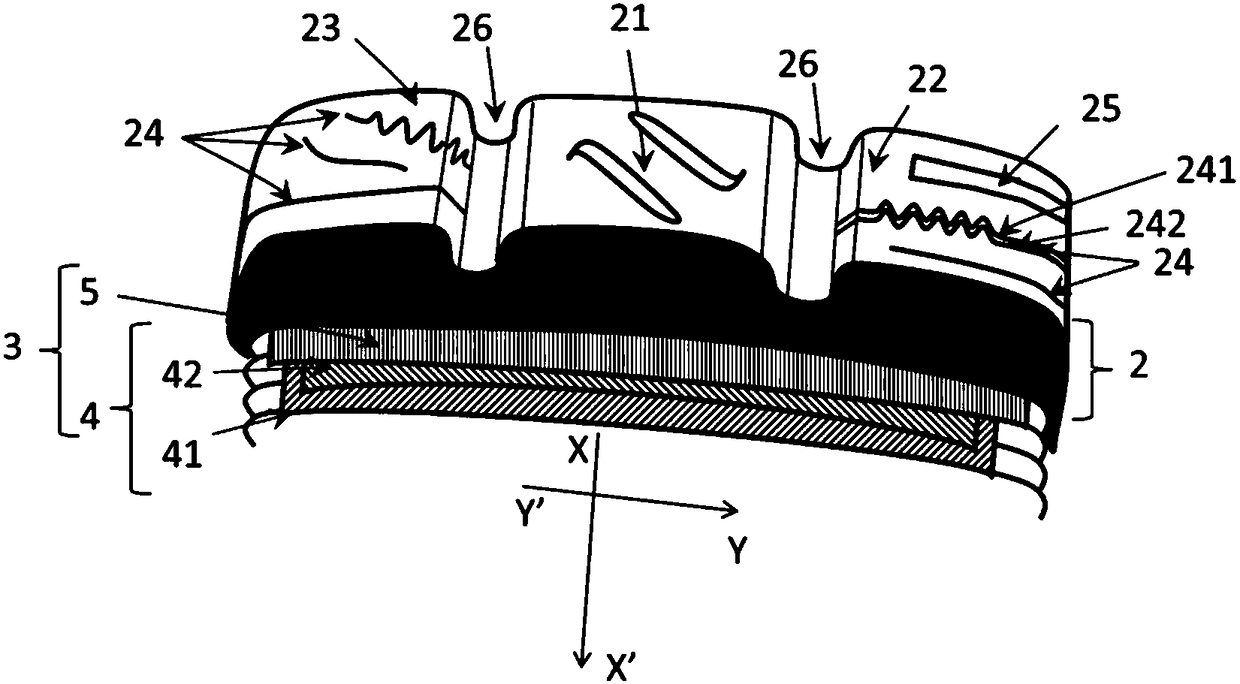

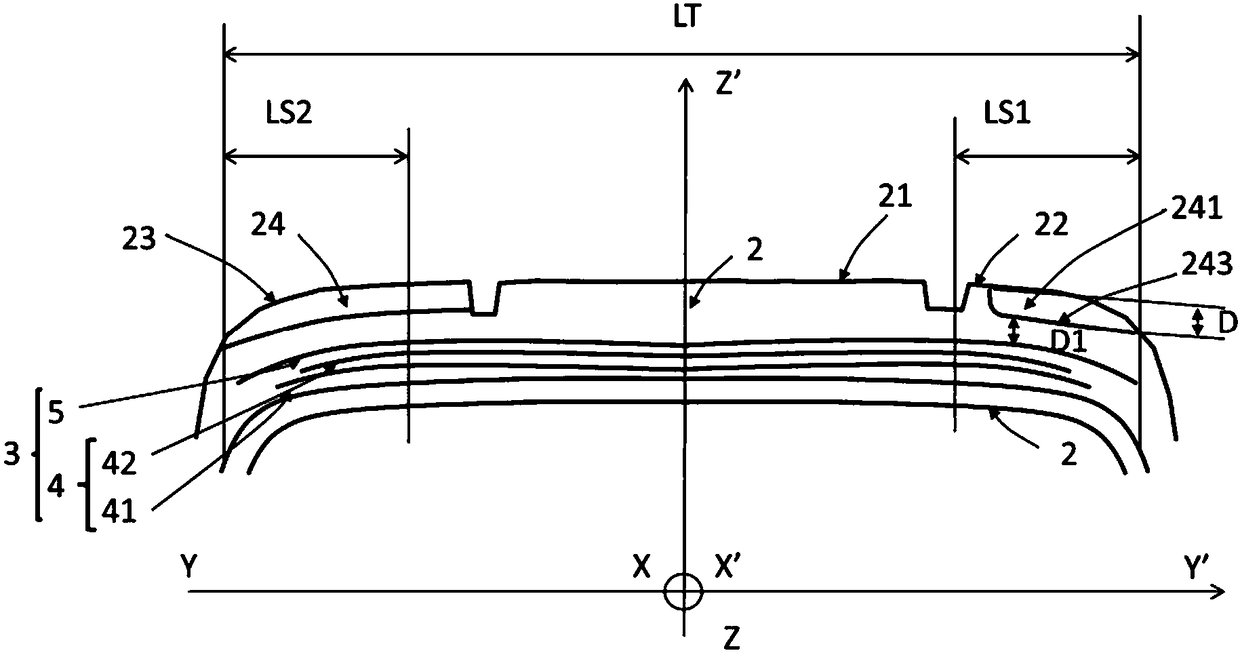

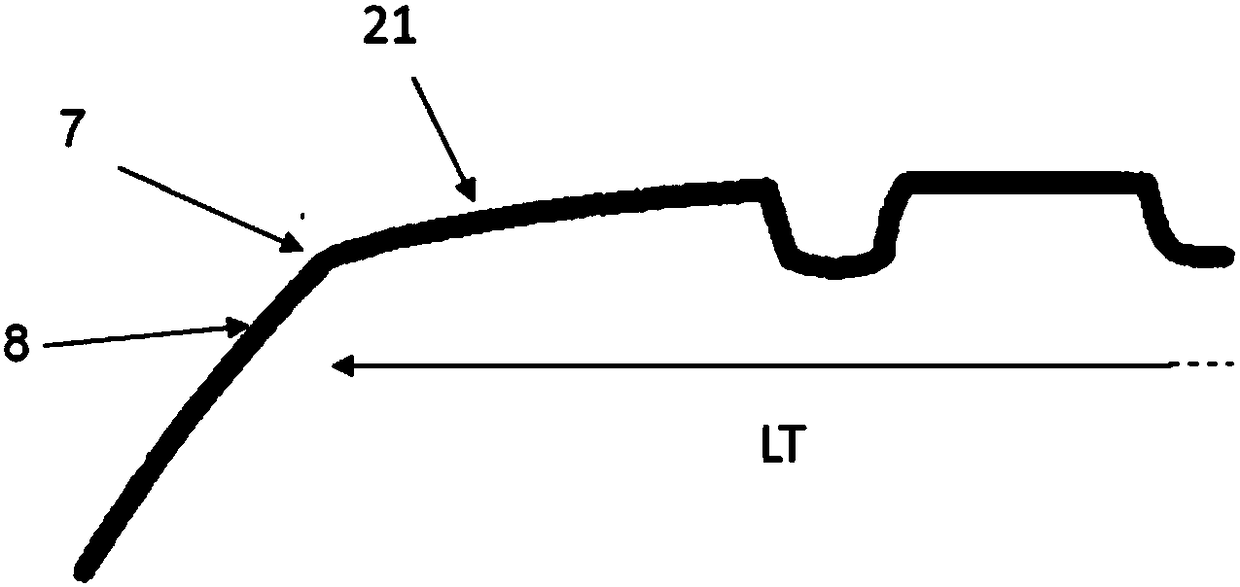

Pneumatic tire, having working layers comprising monofilaments and a tire tread with incisions

ActiveCN108136855ABlock water flowAvoid softnessPneumatic tyre reinforcementsTyre tread bands/patternsTire beadEngineering

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

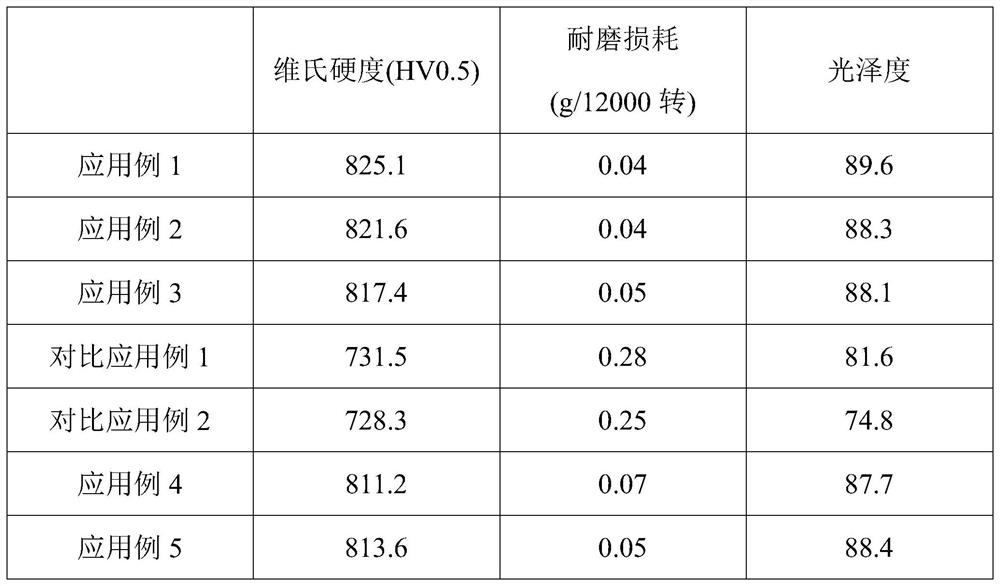

Wear-resistant glaze material as well as preparation method and application thereof

ActiveCN113105266AAvoid softnessImprove wear resistanceCeramic materials productionClaywaresFiberGlass fiber

The invention provides a wear-resistant glaze material as well as a preparation method and application thereof. The wear-resistant glaze material comprises quartz, kaolin, dolomite, calcined talcum powder, corundum, fluorite, borax, a binder and reinforced fibers. According to the wear-resistant glaze material, albite is not added, so that the problem that a glaze surface is soft is avoided; meanwhile, a proper amount of fluorite and borax are added, so that the effect of a low-temperature fluxing agent is exerted, separation of crystals in the glaze is facilitated, and it is guaranteed that the wear resistance of the glaze is improved; a proper amount of fluorite and borax are added to induce crystal precipitation, so that the addition range of corundum is expanded, and the problem of wear resistance reduction caused by corundum addition amount control deviation in the actual application process is avoided; the binding agent is matched with the reinforced fibers, so that the wear resistance of the obtained wear-resistant glaze material is improved; and the glass fiber, corundum and quartz are uniformly dispersed in the slurry in the pulping process, so that the uniformity and consistency of the wear resistance of the obtained glaze surface are ensured, and the glaze surface has wear resistance and structural strength.

Owner:亚细亚新材料科技股份公司

Gardening pruning tool facilitating rapid forming

The invention discloses a gardening pruning tool facilitating rapid forming. The pruning tool comprises a rotating cutter, a first drive device, a cuboid with rails inside and a second drive device, wherein the rotating cutter comprises cutter blades and a rotary shaft, the rotary shaft is a cylinder provided with a gear, the cutter blades are arranged on the front end surface of the rotary shaft, and the planes of the blades are axially perpendicular to the rotary shaft; the first drive device comprises a chain which is a transmission chain, a first gear and a first motor, the root diameter of the first gear is 3-4 times of that of the gear of the rotary shaft, the first gear is meshed with the chain, and the first motor drives the first gear to rotate, so that the chain can move; the second drive device comprises a roller, a second motor, an outer ring, an inner ring, a handle and a hard rod, a boss facing the circle center is arranged on one end surface of the outer ring, one end of the hard rod is fixed to the inner side of the inner ring, and the other end of the hard rod is hinged with the first drive device. The gardening pruning tool facilitating rapid forming is simple to manufacture, convenient and flexible to operate, high in pruning efficiency and suitable for multi-angle pruning of plants.

Owner:王文强

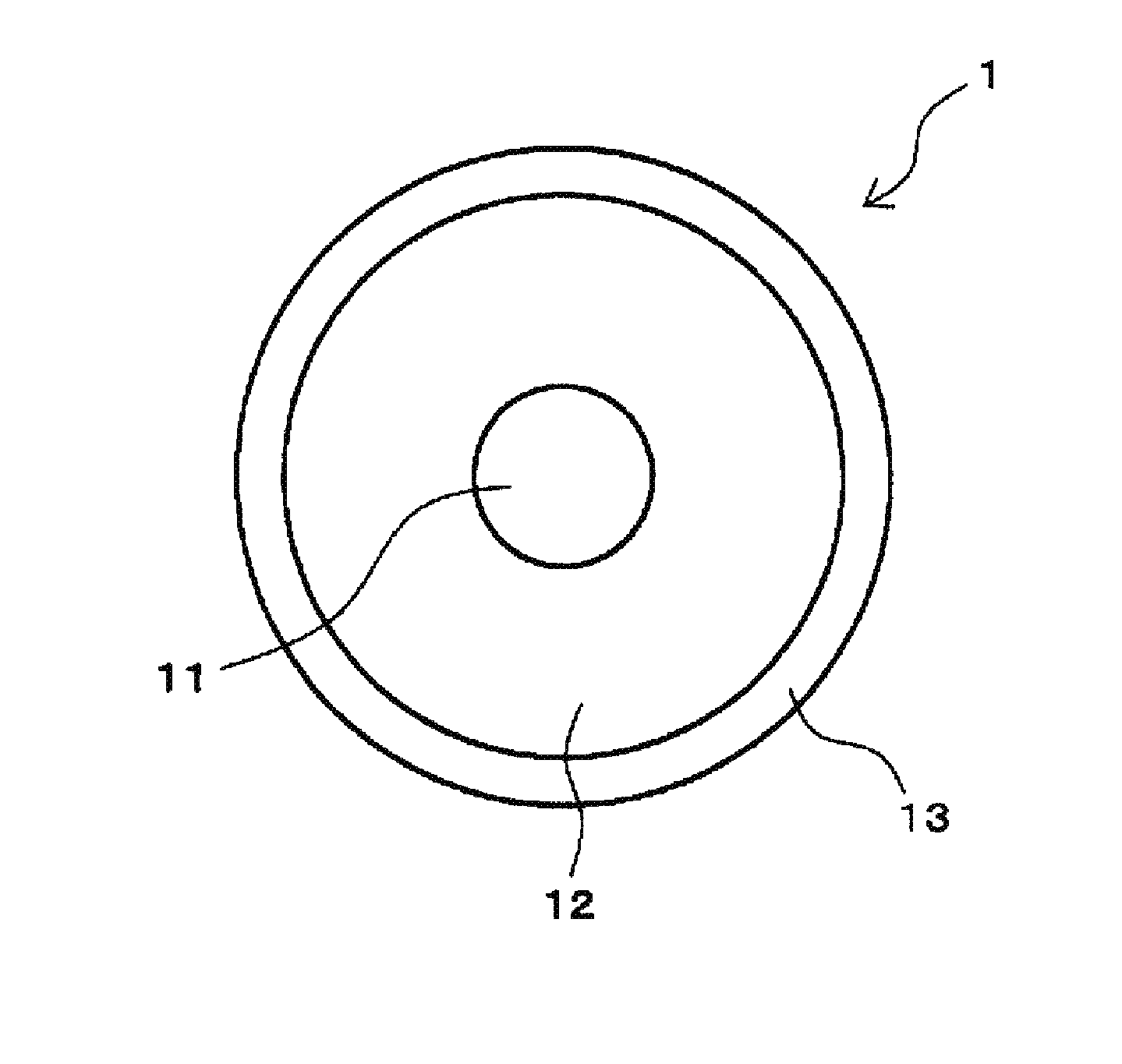

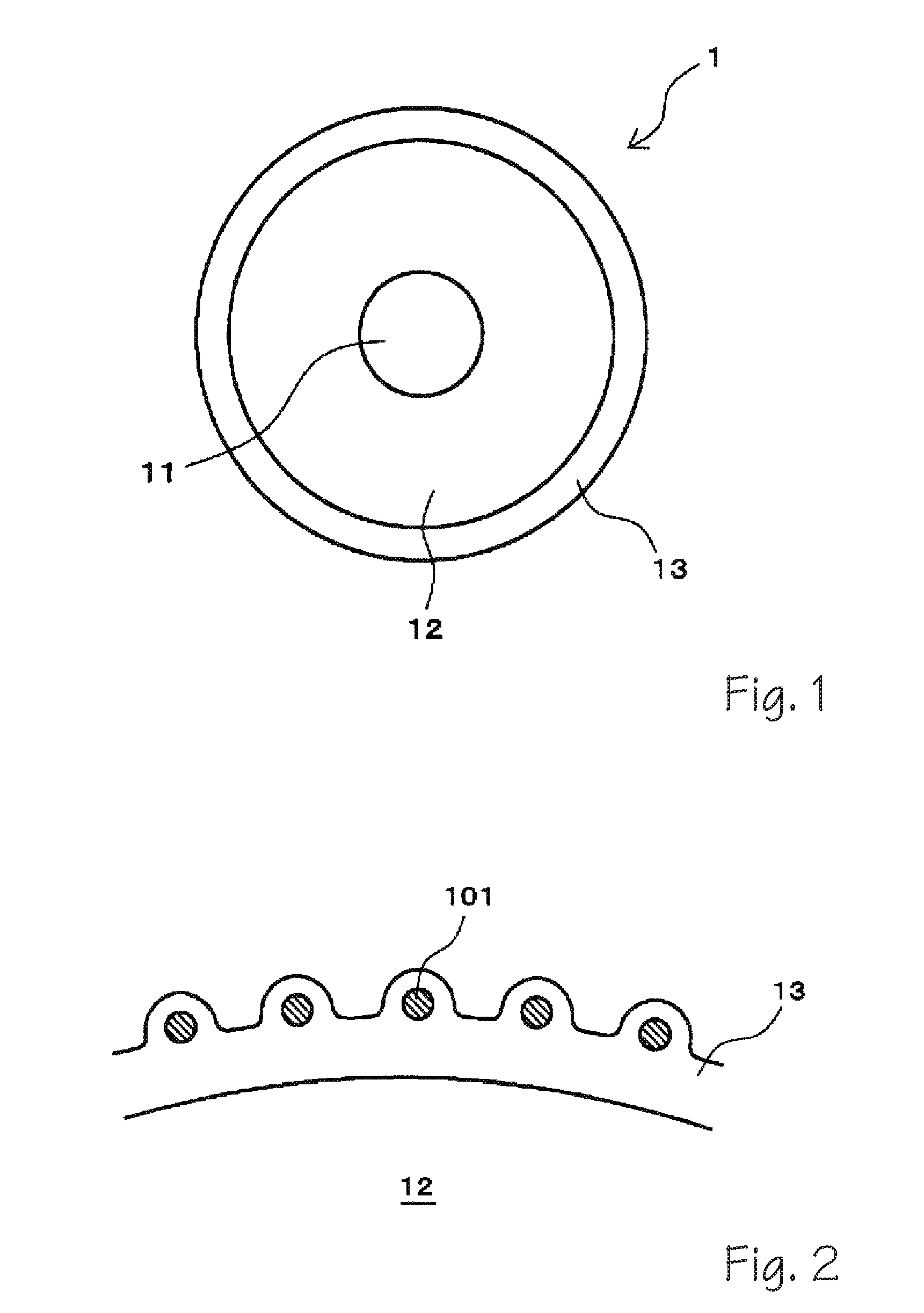

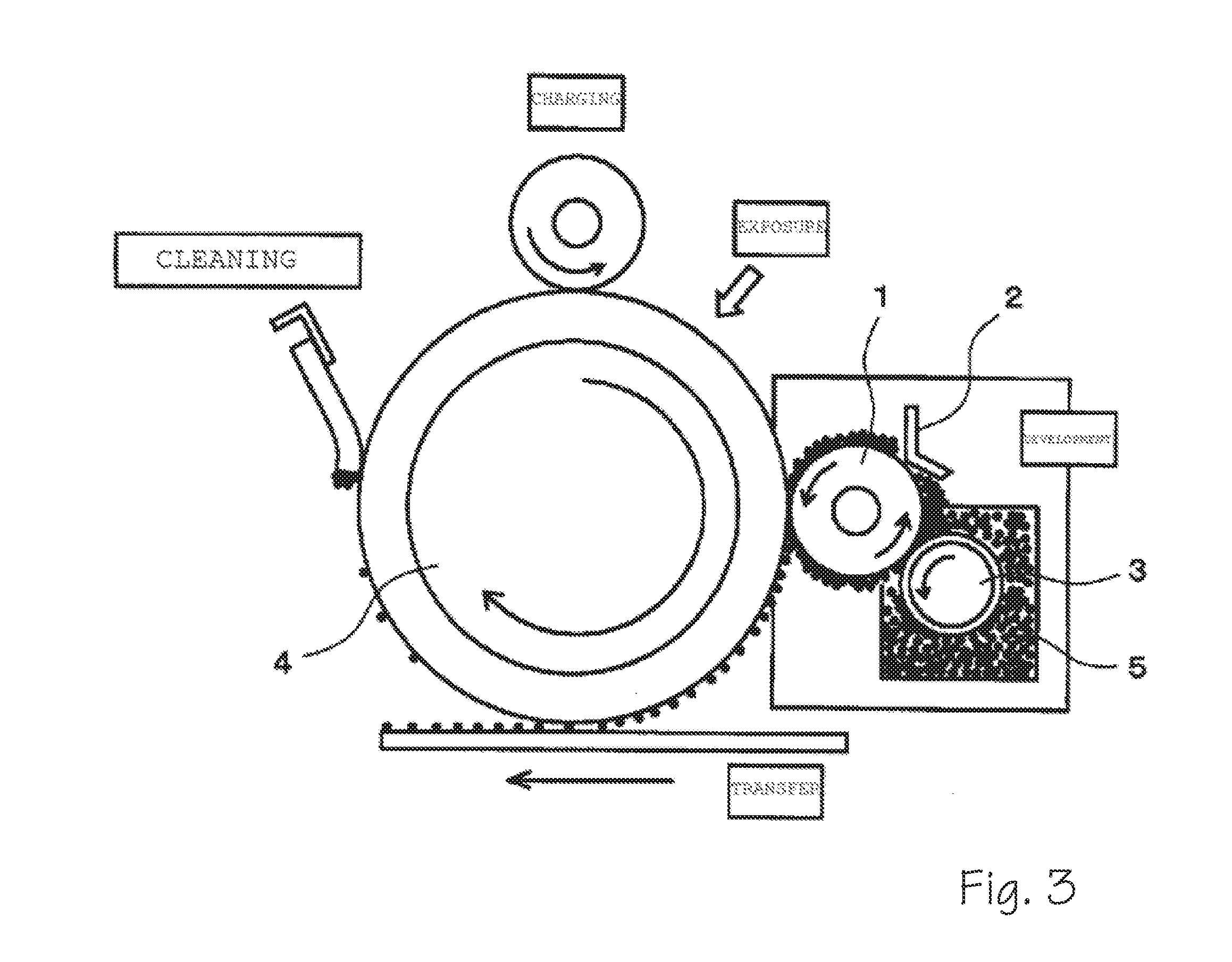

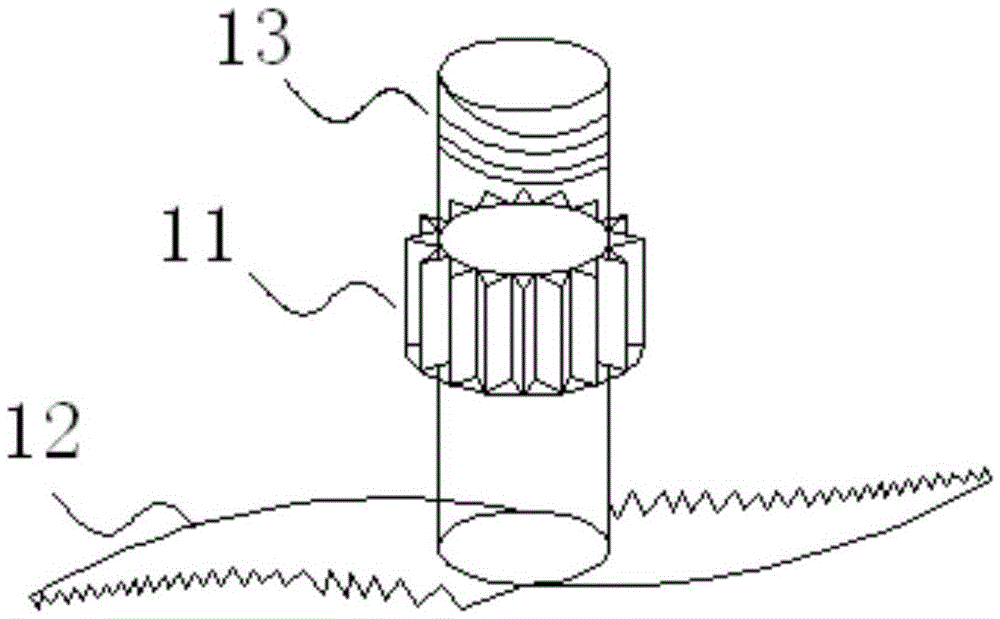

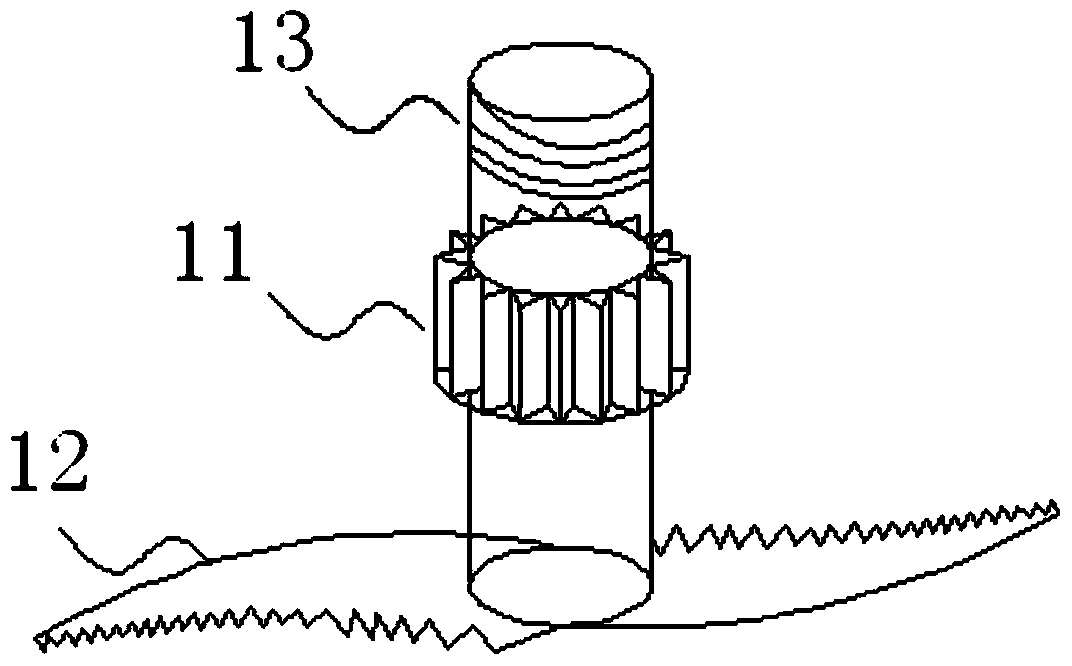

Rubber Member for Coating Developing Roll and Manufacturing Method of Developing Roll for Image Forming Apparatus

ActiveUS20170045840A1Stay flexibleReduce frictionElectrographic process apparatusChemical vapor deposition coatingRough surfacePolyol

An object is to provide a rubber member for coating a developing roll which is formed a uniform rough surface at a surface of the developing roll, does exert neither damage nor toner stress to the mating member or the toner while maintaining flexibility, is possible to secure a thickness which can sufficiently avoid the effect of the rubber, and can realize non-tackiness and low friction, which can be solved by a rubber member for coating a developing roll which is the rubber member for coating a developing roll obtained by coating a coating layer 13 component at around a developing roll having a rubber substrate layer 12 and curing the same, wherein the coating layer 13 component comprises a liquid binder which contains at least a polyol, an isocyanate compound and reactive silicone oil, silicone rubber particles 101 having a hardness (JIS K6253: 1997) by Durometer A (instantaneous) of 20 to 80 degree and a rubber particle size of 0.2 to 10 μm, and a diluting solvent, and a ratio of a thickness of the coating layer 13 after curing and a diameter of the rubber particles 101 satisfies rubber particles 101 diameter / coating layer 13 thickness <0.3.

Owner:NOK CORP +1

Durable gardening pruning tool

ActiveCN105475007APrevent the rotary knife from falling offReduce rework rateCuttersCutting implementsMotor driveEngineering

The invention discloses a durable gardening pruning tool. The tool comprises a rotating cutter, a rotating shaft, a drive device, a cuboid and a handle, wherein the rotating cutter comprises a blade; the rotating shaft is a cylinder provided with a gear, the blade is arranged on the front end face of the rotating shaft, the plane of the blade is perpendicular to the rotating shaft in the axial direction, an external thread is arranged at the rear end of the blade, the gear of the rotating shaft is arranged in the middle of the rotating shaft, and the diameter of the rotating shaft is equal to the root diameter of the gear of the rotating shaft; the drive device comprises a chain, a gear and a motor, the root diameter of the gear is 3-4 times that of the gear of the rotating shaft, the gear is meshed with the chain, and the motor drives the gear to rotate to enable the chain to move; a track is arranged in the cuboid; the handle is fixed to one end of the driving device, and the handle is provided with a button for controlling the driving device to work. The tool is easy to manufacture, convenient to operate, high in pruning efficiency, suitable for pruning vegetation in a multi-angle mode, and flexible to operate.

Owner:王文强

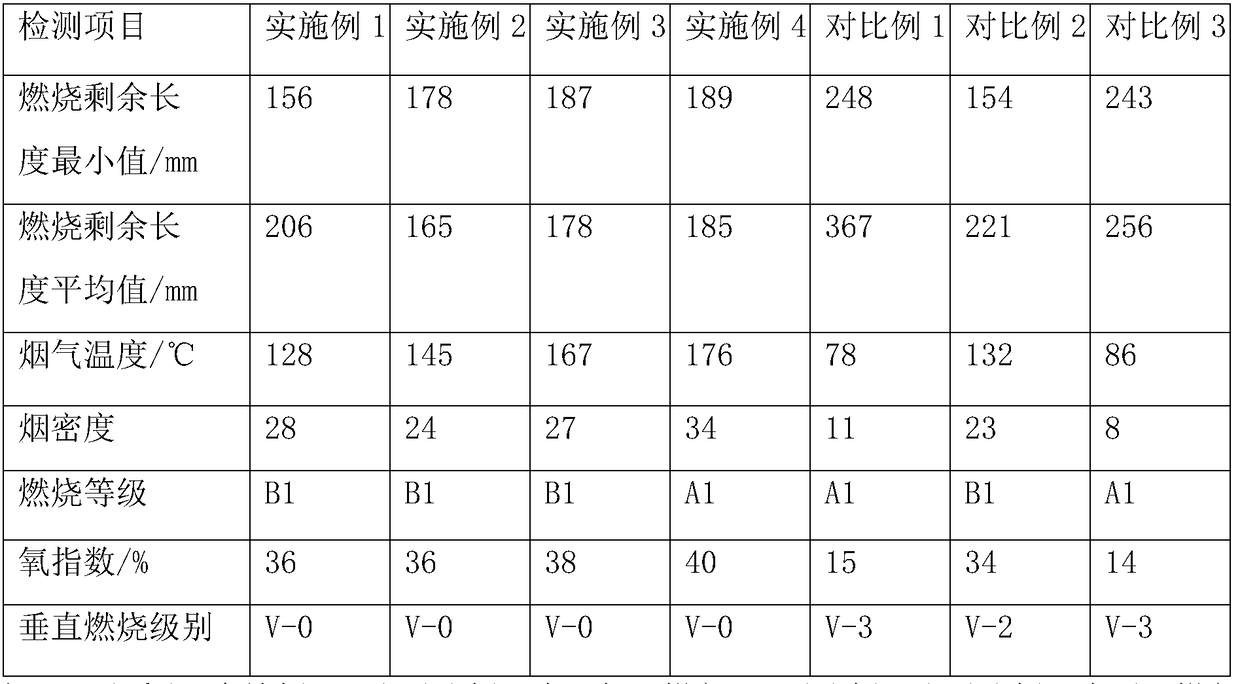

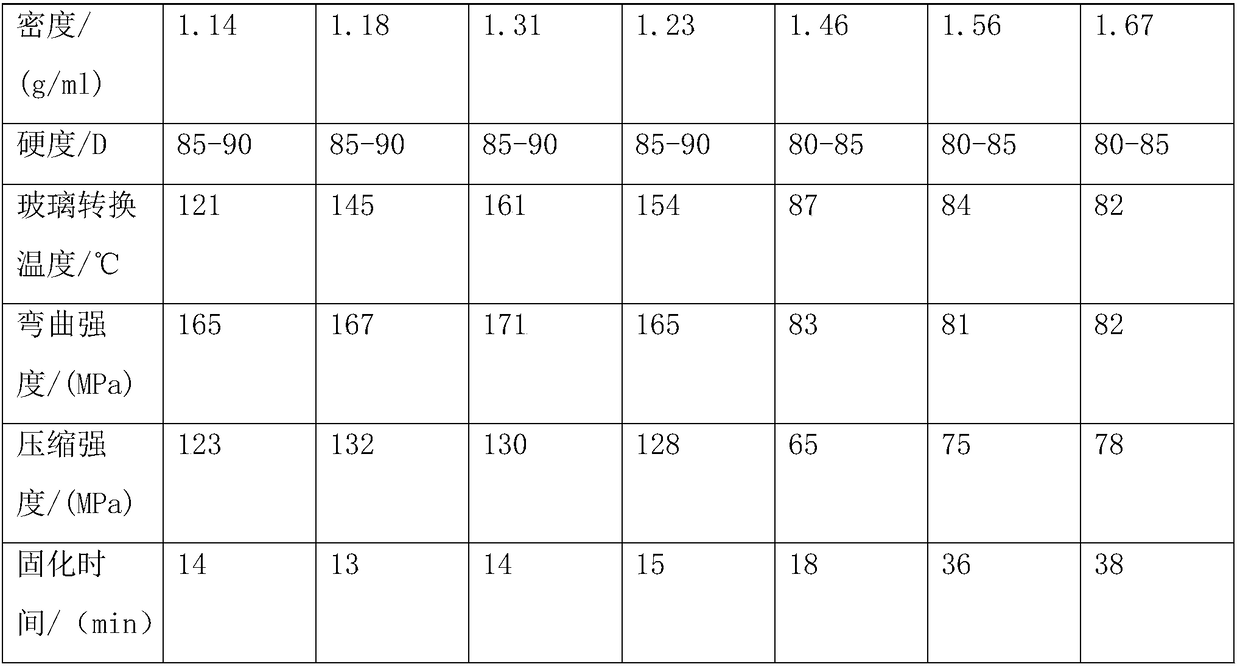

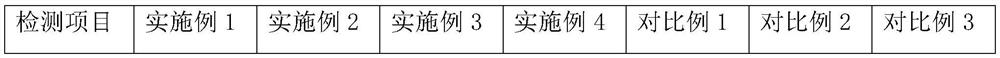

Gel coat resin, preparation method thereof and racer barrel seat using gel coat resin

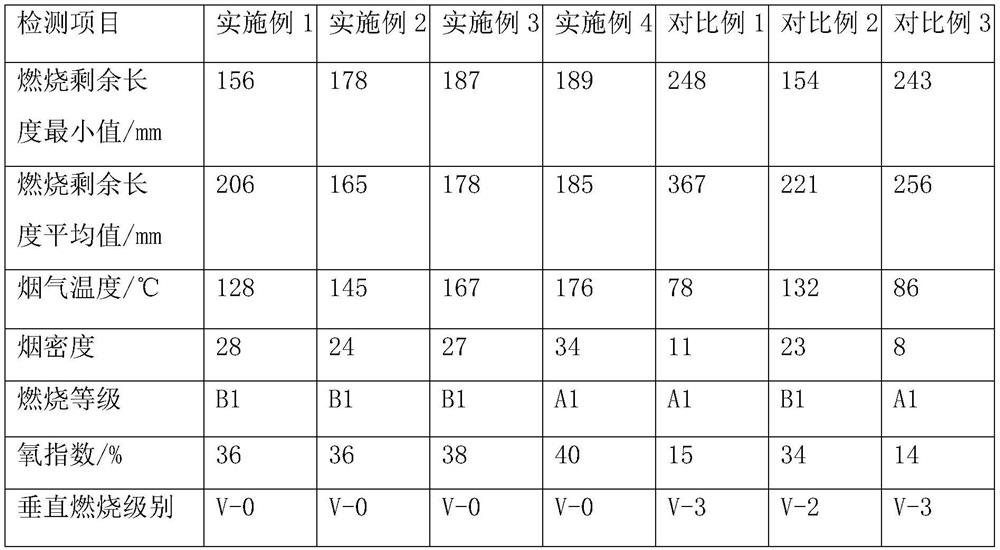

The invention discloses gel coat resin, a preparation method thereof and a racer barrel seat using the gel coat resin, and relates to the technical field of gel coat resin preparation. The gel coat resin is prepared from the following components in parts by weight: 40-80 parts of matrix resin, 20-60 parts of a flame retardant, 10-30 parts of a curing agent and 12-24 parts of an aid; the matrix resin is prepared from the following substances in parts by weight: 30-45 parts of tetrabromo anhydride, 20-22 parts of propylene glycol, 5-10 parts of m-phthalic anhydride, 10-15 parts of cis-butenedioic anhydride, 8-14 parts of styrene and 5-8 parts of a polymerization inhibitor; the flame retardant is prepared from the following substances in parts by weight: 20-36 parts of antimony trioxide, 17-28 parts of zinc borate, 15-27 parts of attapulgite, 10-15 parts of triphenyl phosphate, 8-16 parts of magnesium hydroxide, 5-14 parts of aluminum hydroxide and 9-15 parts of polyborosiloxane. The problems of poorer flame retardancy and longer curing time of gel coat resin are solved; the flame retardant and the curing agent are added to the matrix resin, the gel coat resin can be endowed with flame retardancy, curing time of the gel coat resin is shortened, and working efficiency is improved.

Owner:厦门拓达复材科技有限公司

Agent containing fat (OIL), which contains onion extract, the production and use thereof for caring, preventing or treating damaged skin tissue, especially scarred tissue

The invention relates to a novel agent containing fat (oil), which contains onion extract, in addition to the production and use thereof for caring, preventing or treating damaged akin tissue, such as after operations, biopsies, wounds, burns and other accidents, and especially scarred tissue, stretch marks, degenerative skin conditions and others. The agent is characterised in that the base thereof is based on oil, which can be used to produce, for example, cream, lotion, fluid, massage, or balm based products which contain fail (oil). Surprisingly, the onion extract, which contains water, alcohol or water-alcohol, can be integrated into a base containing oil without the effectiveness thereof being reduced or a phase separation being produced. The effectiveness thereof could be proved when the medical application thereof was monitored.

Owner:LAB HRA PHARMA SA

Preparation method of preserved fresh curcuma alismatifolia flowers and matched reagent

InactiveCN113767897AAvoid Petal StickingAvoid being too softDead plant preservationHorticultureChemistry

The invention discloses a preparation method of preserved fresh curcuma alismatifolia flowers and a matched reagent. The preparation method comprises the following steps: 1) dehydrating and decoloring of fresh curcuma alismatifolia flowers via a dehydrating and decoloring solution: soaking the fresh curcuma alismatifolia flowers in a good state into the dehydrating and decoloring solution for decoloring for 24-48 hours, wherein the dehydrating and decoloring solution comprises 60% by volume of absolute ethyl alcohol, 30% by volume of methanol and 10% by volume of isopropanol; 2) soaking treatment via an organic substitute solution: quickly soaking the dehydrated and decolored fresh curcuma alismatifolia flowers into the organic substitute solution for 24-48 hours so as to allow the processed fresh curcuma alismatifolia flowers to be refilled and plump to present a natural ornamental state, wherein the formula of the organic substitute solution comprises 50% of absolute ethyl alcohol, 20% of glycerol, 20% of polyethylene glycol 200 and 10% of polyethylene glycol 400; and 3) drying the preserved fresh curcuma alismatifolia flowers. The method can effectively solve the problems that the preserved fresh curcuma alismatifolia flowers are incomplete in dehydration and decoloration, too soft and too crisp, and the like, and the finished preserved fresh flowers have tough texture and beautiful flower types.

Owner:浙江省园林植物与花卉研究所

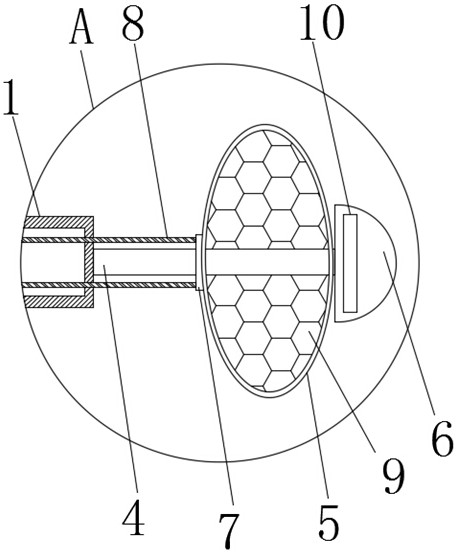

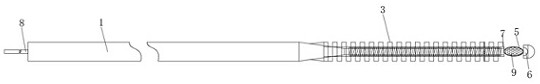

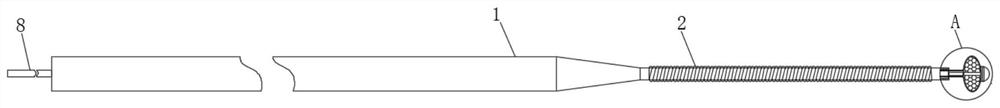

Micro guide wire with nickel-titanium hose

PendingCN113893443AAvoid damageAvoid surgical failureGuide wiresMedical devicesBlood vessel injuryApparatus instruments

The invention relates to the technical field of medical instruments, and discloses a micro guide wire with a nickel-titanium hose, the hose body is inserted into a blood vessel, and the head end of the hose enters the blood vessel, so that the micro guide wire is more durable and not easy to deform in complex nerve and blood vessel intervention; vascular injury and operation failure caused by shadow change of an instrument in an operation are avoided to a great extent, the problems that the outer layer of the far end of the core wire generally only has a single winding wire, the flexibility and durability are poor, and the core wire is more durable and can deform easily in complex nerve and blood vessel intervention are avoided, and the success rate of the operation is increased; the push tube is pushed, slides at the right end of the core wire body rod body and drives the sliding block to slide on the surface of the connecting rod, so that the sliding block extrudes the net-shaped woven ball body to bulge, the outside of the net-shaped woven ball body is tightly attached to the inside of a blood vessel, and tortuosity and stenosis of the blood vessel, such as intracranial blood vessels and difficult operation of feeding a micro guide wire to the far end of the blood vessel, are avoided; complications are easily caused, and the operation effect is improved.

Owner:深圳麦普奇医疗科技有限公司

Gardening tool capable of quickly conducting trimming

The invention discloses a gardening tool capable of quickly conducting trimming. The gardening tool comprises a rotary cutter, a driving device and a handle. The rotary cutter comprises blades and a rotating shaft which is a cylinder with a gear, the blades are arranged on the front end face of the rotating shaft, and the plane where the blades are located is perpendicular to the axial direction of the rotating shaft. The driving device comprises a chain which is a transmission chain, a gear, a motor and a cuboid, wherein the diameter of the tooth root circle of the gear is 3-4 times that of the tooth root circle of the gear of the rotating shaft, the gear is meshed with the chain, the motor drives the gear to rotate to enable the chain to move, and the cuboid is internally provided with a track. The handle is fixed to one end of the driving device and provided with a button used for controlling the driving device to work. The gardening tool is easy to manufacture, convenient to operate, high in trimming efficiency, suitable for trimming vegetation in multiple angles and flexible in operation.

Owner:王文强

A rapid prototyping durable garden pruning tool

The invention discloses a durable gardening trimming tool capable of quickly achieving forming. The durable gardening trimming tool comprises a rotary cutter, a first driving device, a second driving device and a handle. The rotary cutter comprises blades and a rotating shaft which is a cylinder with a gear, the blades are arranged on the front end face of the rotating shaft, the plane where the blades are located is perpendicular to the axial direction of the rotating shaft, an external thread is arranged at the rear end of the rotating shaft, the gear of the rotating shaft is arranged in the middle of the rotating shaft, and the diameter of the rotating shaft is equal to the diameter of the tooth root circle of the gear of the rotating shaft. The second driving device comprises a rolling body, a second motor, an outer ring and an inner ring, wherein a boss facing the circle center is arranged on one end face of the outer ring. The durable gardening trimming tool is easy to manufacture, convenient to operate, high in trimming efficiency, suitable for trimming vegetation in multiple angles and flexible in operation.

Owner:王文强

A rapid prototyping garden pruning tool

The invention discloses a gardening pruning tool facilitating rapid forming. The pruning tool comprises a rotating cutter, a first drive device, a cuboid with rails inside and a second drive device, wherein the rotating cutter comprises cutter blades and a rotary shaft, the rotary shaft is a cylinder provided with a gear, the cutter blades are arranged on the front end surface of the rotary shaft, and the planes of the blades are axially perpendicular to the rotary shaft; the first drive device comprises a chain which is a transmission chain, a first gear and a first motor, the root diameter of the first gear is 3-4 times of that of the gear of the rotary shaft, the first gear is meshed with the chain, and the first motor drives the first gear to rotate, so that the chain can move; the second drive device comprises a roller, a second motor, an outer ring, an inner ring, a handle and a hard rod, a boss facing the circle center is arranged on one end surface of the outer ring, one end of the hard rod is fixed to the inner side of the inner ring, and the other end of the hard rod is hinged with the first drive device. The gardening pruning tool facilitating rapid forming is simple to manufacture, convenient and flexible to operate, high in pruning efficiency and suitable for multi-angle pruning of plants.

Owner:王文强

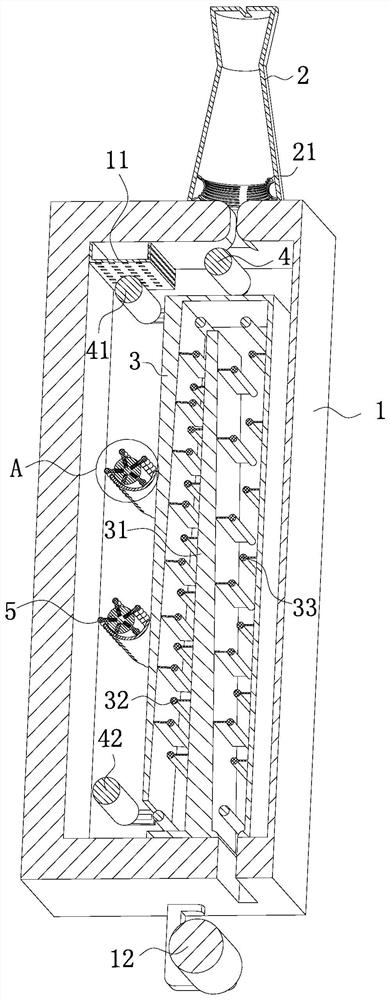

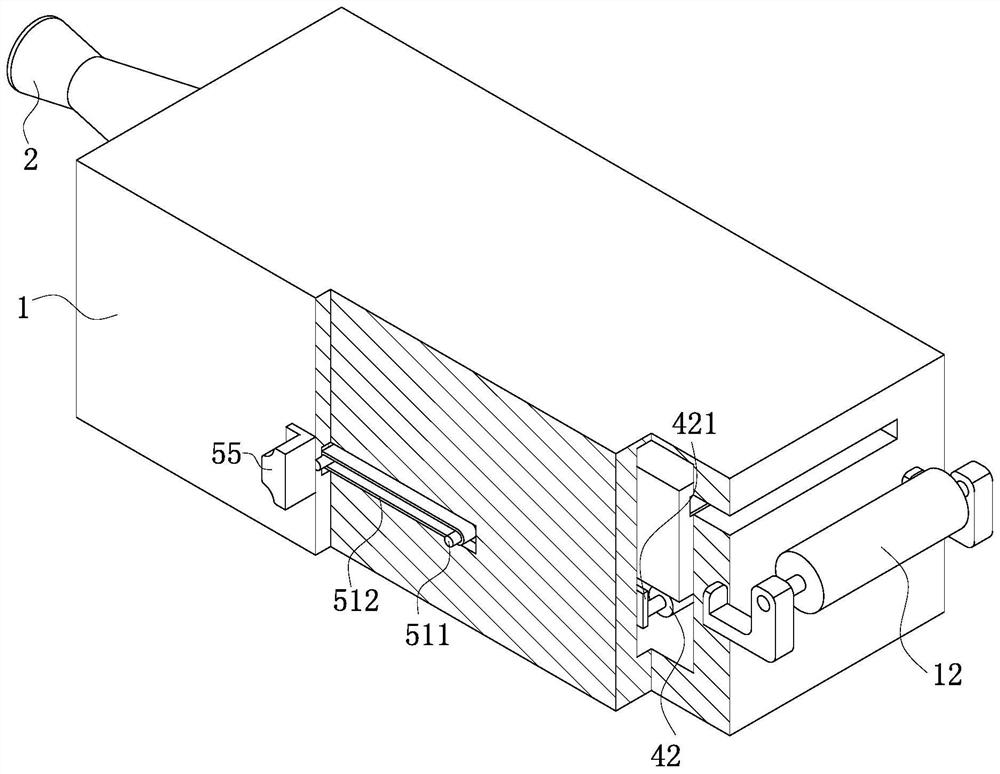

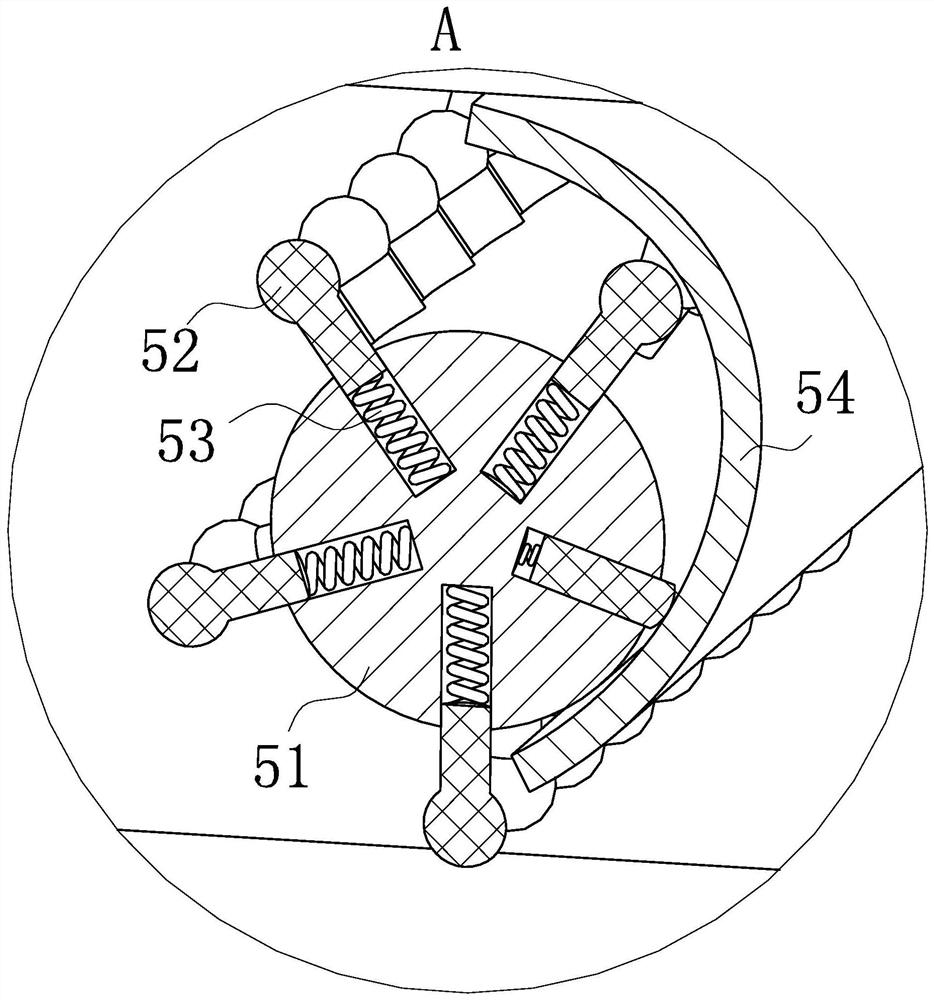

A kind of enzyme raw material preparation device

ActiveCN111482387BAchieve stretchAvoid softnessCleaning using toolsLoading/unloadingControl switchEnzyme

The invention relates to an enzyme production, in particular to an enzyme raw material preparation device. The technical problem to be solved by the present invention is to provide an enzyme raw material preparation device. An enzyme raw material preparation device, including an installation frame, a vertical leaf feeding mechanism, a double-rod splint reversing mechanism, a double-sided lodging and brushing mechanism, a fluff deposition box, a control switch and a servo motor; the right part of the top of the installation frame and the vertical leaf feed The material mechanism is welded; the top left part of the installation frame is provided with a double-rod splint reversing mechanism; the left middle part of the installation frame is provided with a double-sided lodging brush mechanism. The invention achieves cleaning of the blades so that they are pulled outwards to keep the blades stretched. At the same time, only one side of the blades is brushed in a single operation to prevent the blades from being too soft and curled after brushing, which cannot achieve the cleaning effect. At the same time, it prevents the brushed fluff from clogging the outlet hole and affecting the discharge of sewage.

Owner:GUANGDONG ZHENGDANGNIAN BIO TECH CO LTD

A kind of gel coat resin and its preparation method and racing bucket seat using the gel coat resin

The invention discloses gel coat resin, a preparation method thereof and a racer barrel seat using the gel coat resin, and relates to the technical field of gel coat resin preparation. The gel coat resin is prepared from the following components in parts by weight: 40-80 parts of matrix resin, 20-60 parts of a flame retardant, 10-30 parts of a curing agent and 12-24 parts of an aid; the matrix resin is prepared from the following substances in parts by weight: 30-45 parts of tetrabromo anhydride, 20-22 parts of propylene glycol, 5-10 parts of m-phthalic anhydride, 10-15 parts of cis-butenedioic anhydride, 8-14 parts of styrene and 5-8 parts of a polymerization inhibitor; the flame retardant is prepared from the following substances in parts by weight: 20-36 parts of antimony trioxide, 17-28 parts of zinc borate, 15-27 parts of attapulgite, 10-15 parts of triphenyl phosphate, 8-16 parts of magnesium hydroxide, 5-14 parts of aluminum hydroxide and 9-15 parts of polyborosiloxane. The problems of poorer flame retardancy and longer curing time of gel coat resin are solved; the flame retardant and the curing agent are added to the matrix resin, the gel coat resin can be endowed with flame retardancy, curing time of the gel coat resin is shortened, and working efficiency is improved.

Owner:厦门拓达复材科技有限公司

Catheter

ActiveCN101721770BAvoid stress concentrationIncreased torque transfer capabilityCatheterSurgeryCatheter

A catheter body includes a hollow coil whose outer and inner surfaces are coated with outer and inner resin layers. A resin tip is provided at a distal end of the catheter body. The tip has a tapered section at a distal end of the tip. Also, an axially extending braid is embedded in the catheter body and the tip to extend from the catheter body to the tip.

Owner:ASAHI INTECC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com