Pneumatic tire, having working layers comprising monofilaments and a tire tread with incisions

A working layer, tire technology, applied in the direction of tire tread/tread pattern, reinforcement layer of pneumatic tires, tire parts, etc., can solve the problems of buckling, insufficient tire durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

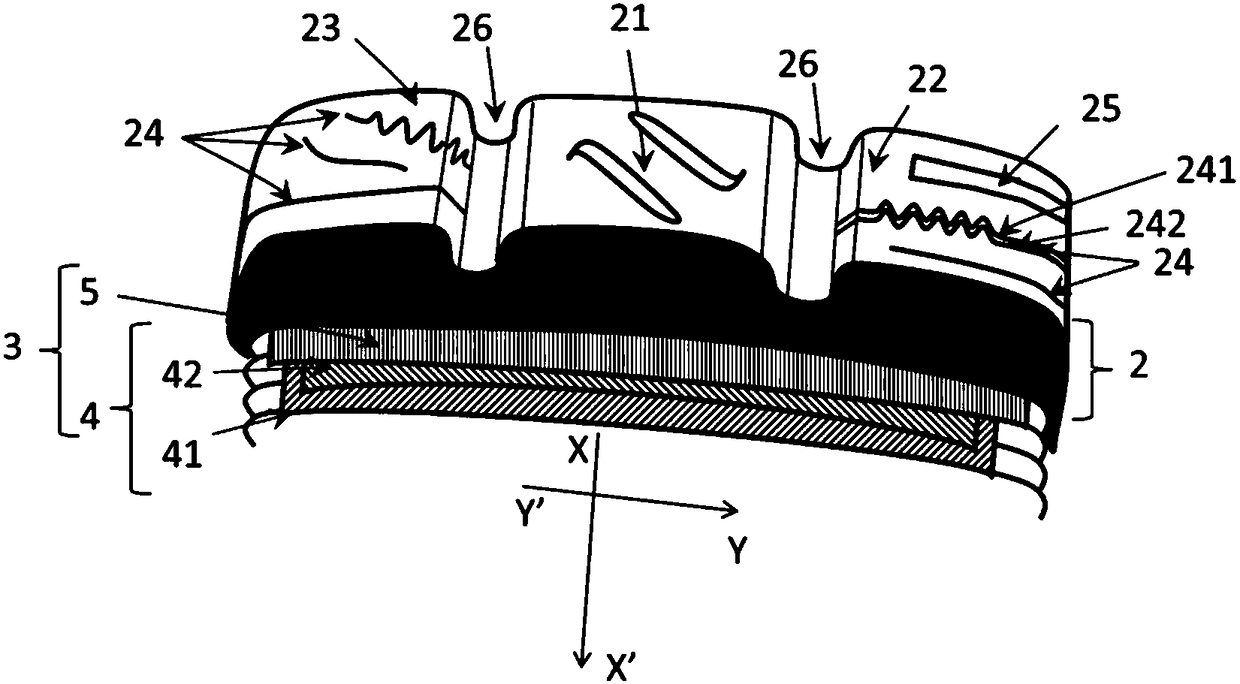

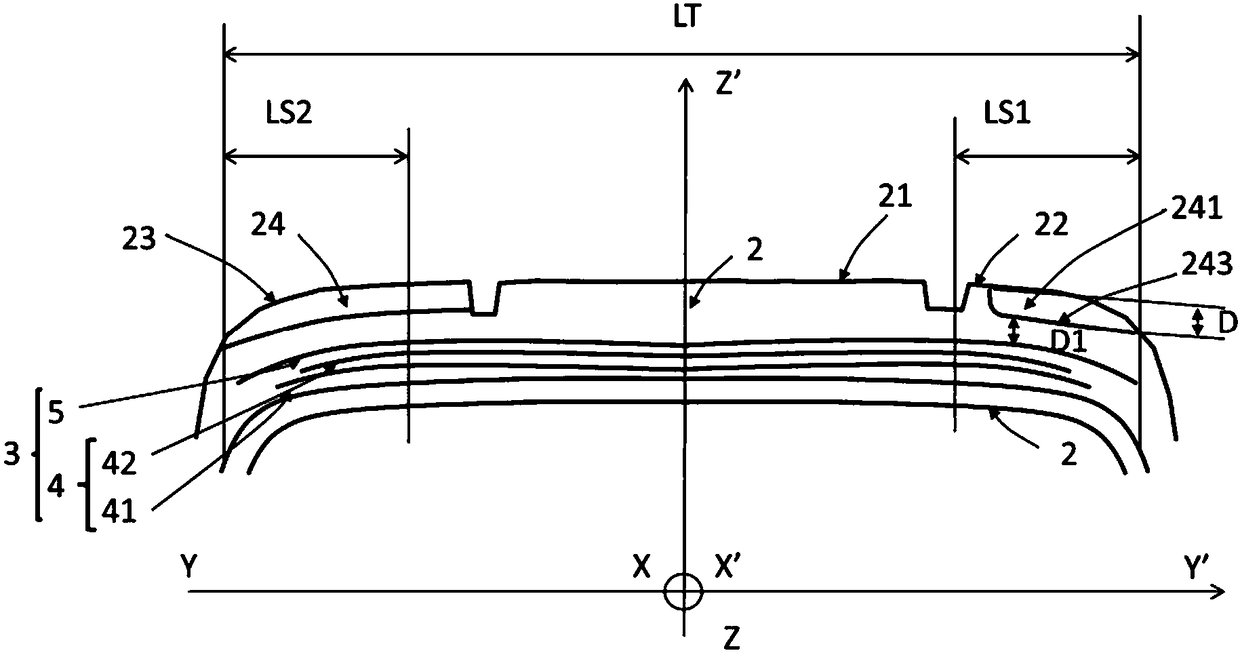

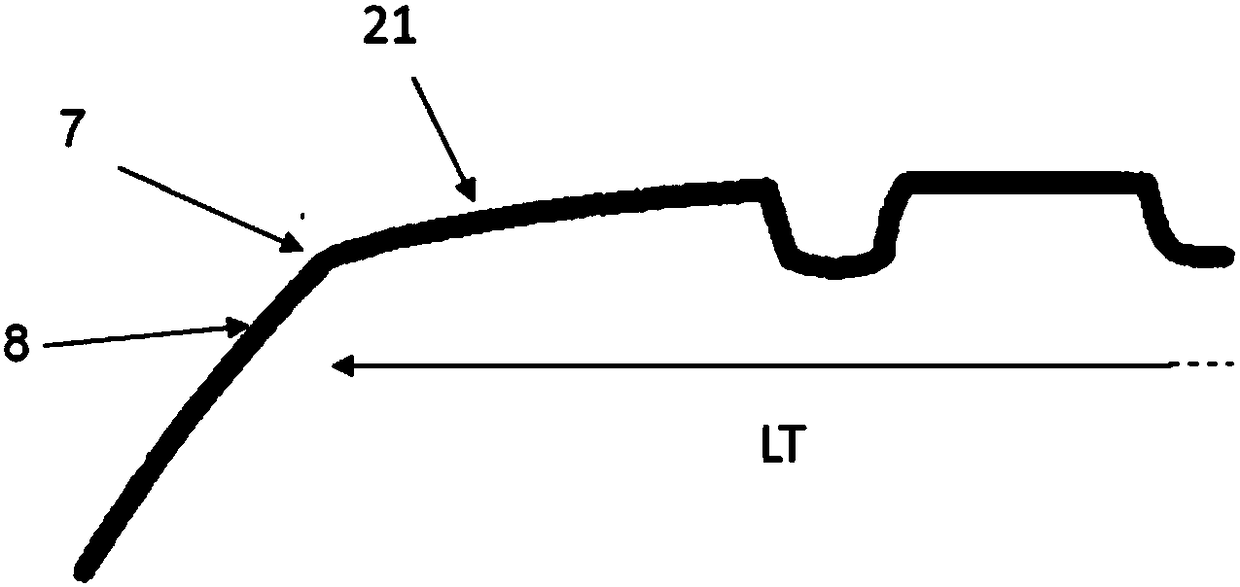

[0070] figure 1 The crown portion of the tire is shown. The tire comprises a tread 2 intended to come into contact with the ground via a tread surface 21 . In the axially outer portions 22 and 23 of the tread there are axially outer cuts comprising sipes 24 and grooves 25 . The tire further has a crown reinforcement 3 comprising a working reinforcement 4 comprising two working layers 41 and 42 and a hooping reinforcement 5 . figure 1 Further shown are simple and complex blind grooves, double blind grooves and cutouts axially leading to the outside or inside (i.e. with parallel side surfaces in the main direction of the cutout or in its depth direction or with zigzag or sinusoidal sections The cutout of the side surface), thereby preventing some relative movement of the two side surfaces.

[0071] figure 1 Only the axially outer grooves extending along the axial axis (YY') are shown in the axially outer portions 22 and 23 of the tread. In fact, the figure is only for re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com