Soft and nondeformable shoe and production method thereof

A soft and upper technology, applied to uppers, shoes, soles, etc., can solve the problems of unfavorable long-term walking, hard shoe-making fabrics, and wrong shoe sizes, so as to achieve the goal of not easily deforming, improving support, and compact size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

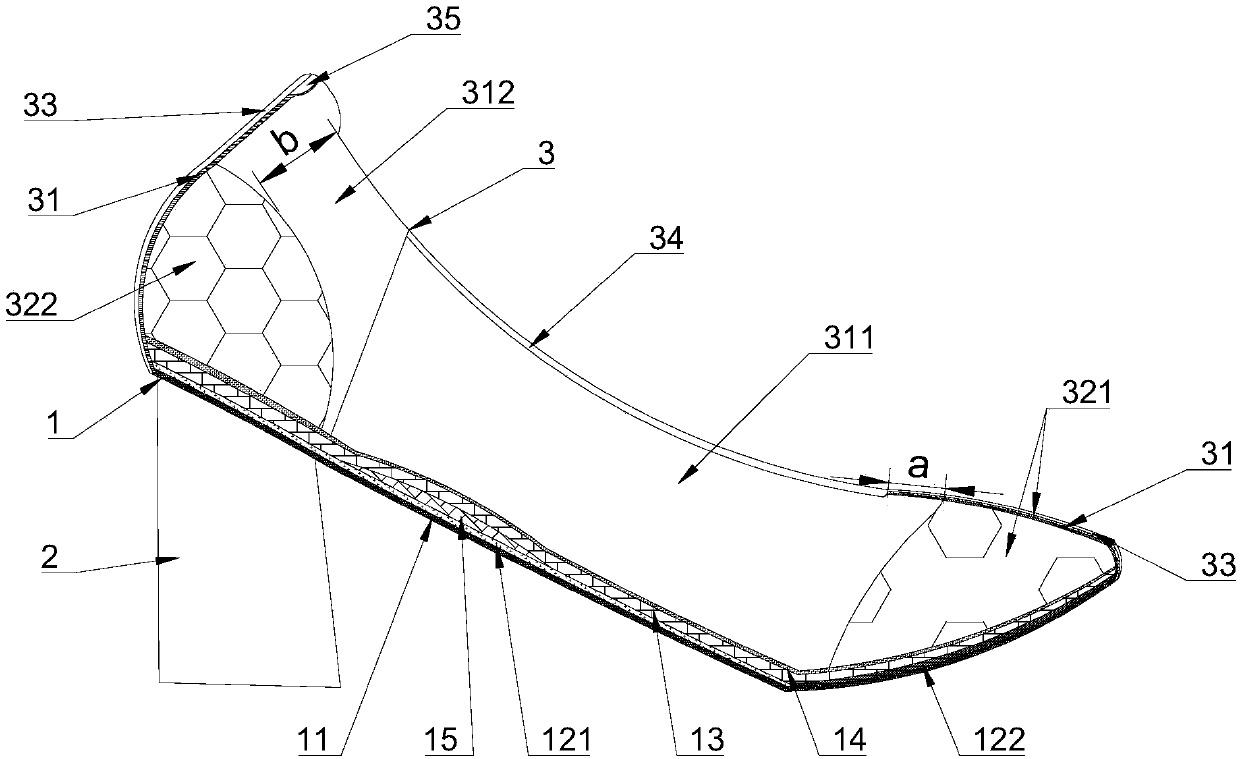

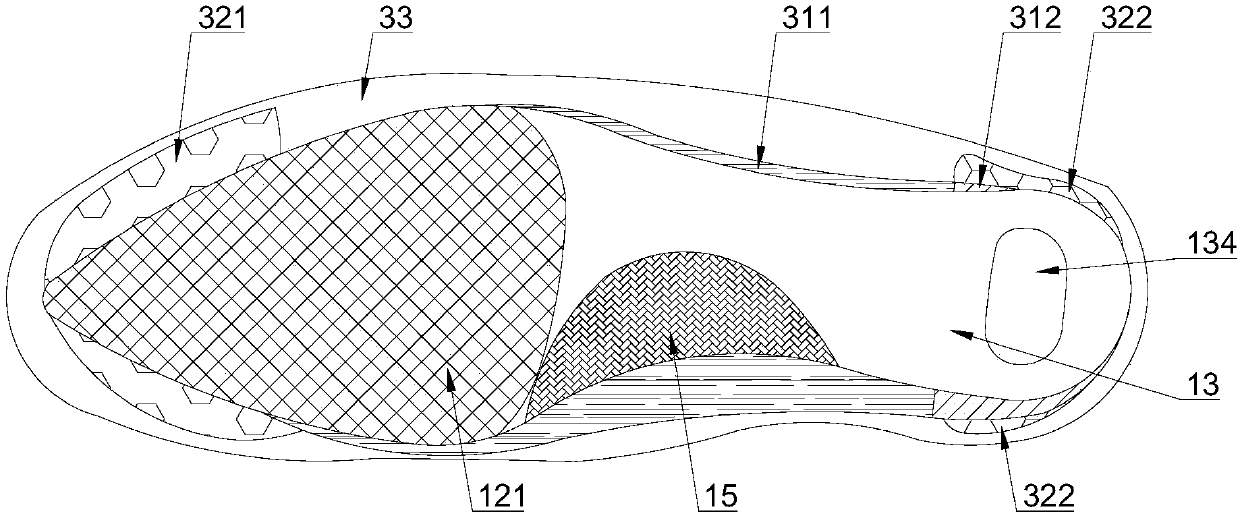

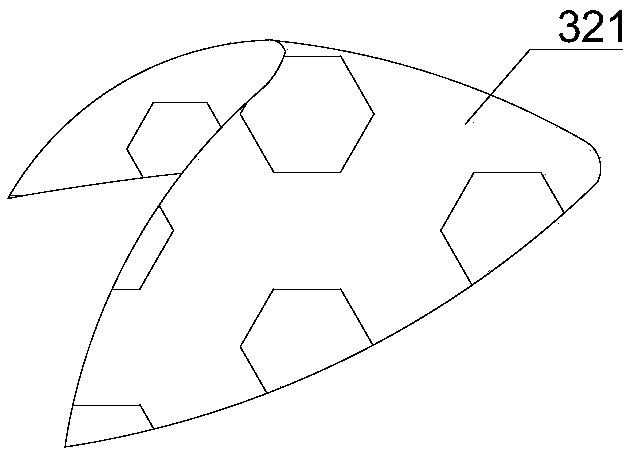

[0042] Such as figure 1 and figure 2 As shown, a soft and non-deformable shoe includes a sole 1, a heel 2 and a vamp 3 respectively arranged on the sole 1, and the specific structure is as follows:

[0043] The sole 1 includes a sole pad 11, a midsole pad shaping layer, a shoe midsole 13, and a sole inner layer 14 arranged sequentially from bottom to top. , shape, and size match the raised arch elastic body 15, the arch elastic body 15 has the effect of supporting the sole of the foot to protect the arch of the foot, can maximize the supporting effect, slow down the occurrence of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com