Vaporization coating template and application thereof

A template and evaporation technology is applied in the field of preparing multi-color display organic electroluminescent devices, which can solve the problems of mask deformation, difficulty in improving resolution, difficulty, etc., and achieve the effects of simple structure, easy cleaning, and non-deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

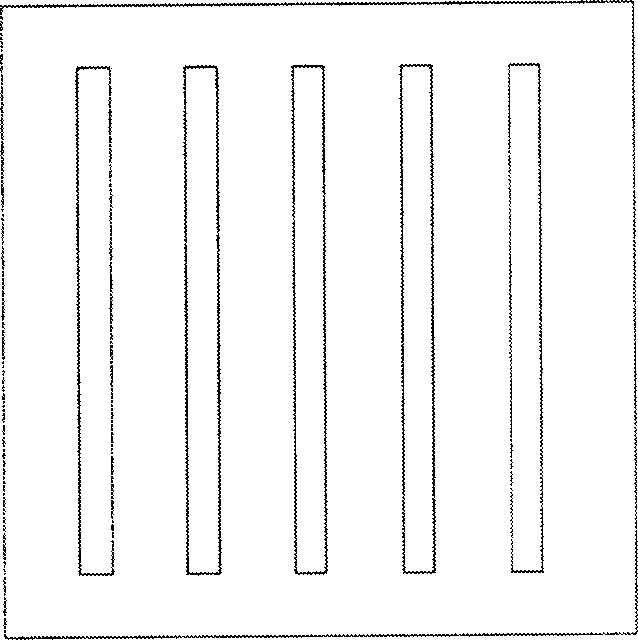

[0041] First, prepare a limit shielding evaporation template:

[0042] Coating a layer of photoresist with a thickness equal to the thickness of the barrier on the template substrate of quartz glass, and then accurately exposing the substrate to obtain a limiting column with a width equal to one sub-pixel;

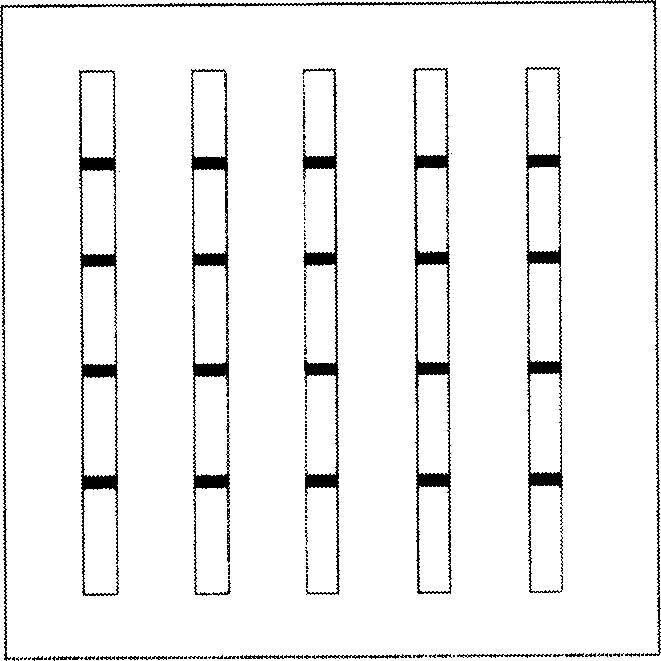

[0043] After the substrate is dried, cover the entire substrate with cobalt metal particles as a magnetic substance, and then vibrate the substrate. After the cavity formed by the limiting pillars is filled with cobalt metal particles, use a flat plate to block the evaporation template with a limit. Scrape to remove remaining cobalt particles.

[0044] Then, the limit-shielding evaporation template is used for evaporation to realize the full-color display organic electroluminescent device in RGB mode, including the following steps:

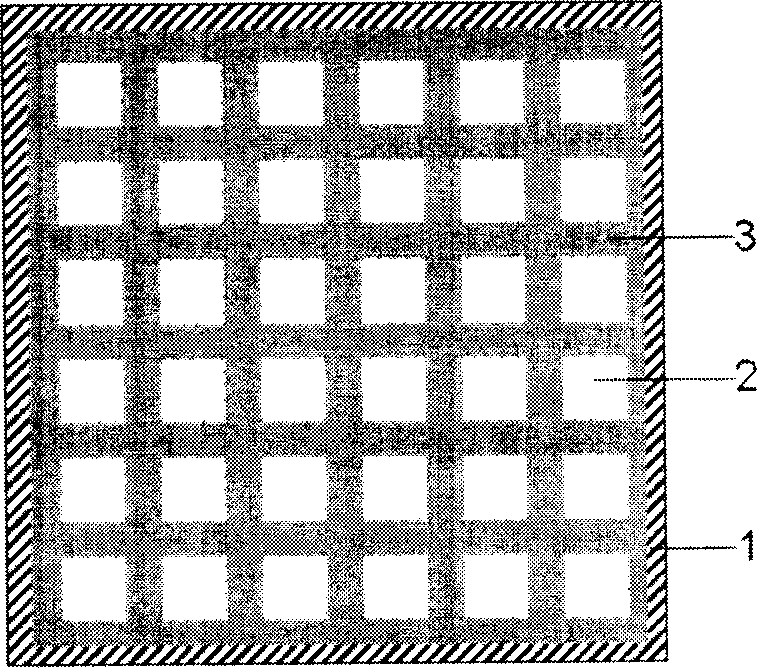

[0045] (a) The limit template is aligned with the substrate through the alignment system in the evaporation device, and the limit template i...

Embodiment 2

[0053] First, prepare a limiting shielding evaporation template according to the method of Example 1. The difference is that the cobalt particles as a magnetic substance are replaced with iron particles as a charged substance covering the entire substrate, and then the substrate is vibrated, and then the substrate is vibrated by the limiting column. After the formed cavity is filled with iron particles, use a flat plate to scrape the limit-shield evaporation template to remove the rest of the iron particles.

[0054] Then, the limit shielding evaporation template is used for evaporation to realize the full-color display organic electroluminescent device of RGBW mode, including the following steps:

[0055] (f) The limit template is aligned with the substrate through the alignment system in the evaporation device, and the limit template is bonded to the substrate after alignment (such as Figure 3A shown);

[0056] (g) Apply an electric field in the upper space of the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com