Patents

Literature

299results about How to "Not easily deformed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing technology of shell of wind-driven generator

ActiveCN101814808ASimple manufacturing methodNot easily deformedManufacturing dynamo-electric machinesWind drivenManufacturing engineering

The invention discloses a manufacturing technology of a shell of a wind-driven generator, comprising the following steps: processing the shell firstly, and then processing a rotor, processing an end cover finally and assembling the shell, the rotor and the end cover. The shell of the wind-driven generator is easy to manufacture and is not easy to deform.

Owner:NANTONG HONGFENG ELECTRO MECHANIC

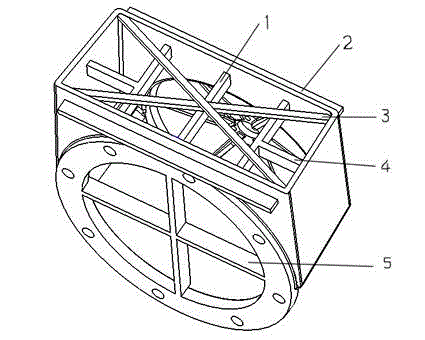

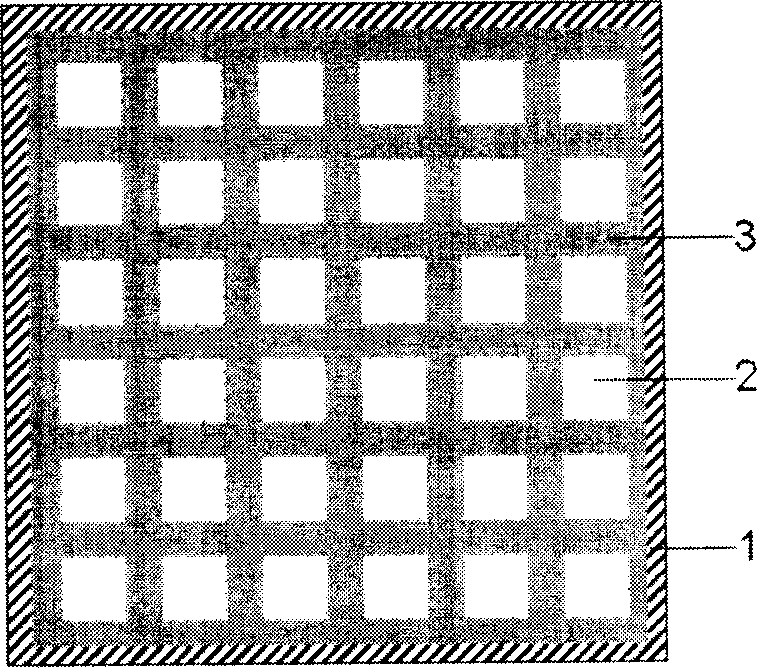

Large-scale thin-wall valve body lost foam casting process

InactiveCN102717031AIncrease stiffnessNot easily deformedFoundry mouldsFoundry coresPolystyrene beadThin walled

The invention relates to a large-scale thin-wall valve body lost foam casting process, comprising the following steps of: (1) pre-foaming polystyrene beads; (2) curing the polystyrene beads; (3) moulding a white mould; (4) drying the white mould; (5) assembling the white mould; (6) brushing lost foam casting fireproof coating on the surface of the obtained white mould; (7) drying the white mould coated with the coating; (8) burying a box and compacting; (9) pouring molten iron; (10) insulating heat after pouring is finished, and then opening the box; and (11) cleaning off redundant anti-deformation ribs, and polishing and levelling by adopting a grinding wheel to obtain a thin-wall valve body. According to the process disclosed by the invention, when the white mould of the valve body is moulded, a cross-shaped rib which can prevent a round hole from deforming is additionally arranged in a flange hole, stiffness of the white mould is increased, deformation can be prevented; a T-shaped rib, an I-shaped rib and a diagonal tie rib are additionally arranged in an inner cavity of a square hole after assembling and adhesive bonding, an anti-deformation rib for a square opening is additionally arranged outside the square opening, and therefore deformation of the white mould after assembling is effectively overcome. When a casting is cleaned, the anti-deformation ribs inside and outside are removed, thus deformation of a workpiece is avoided and rejection rate is reduced.

Owner:SHANXI MOFAN MACHINERY MFG

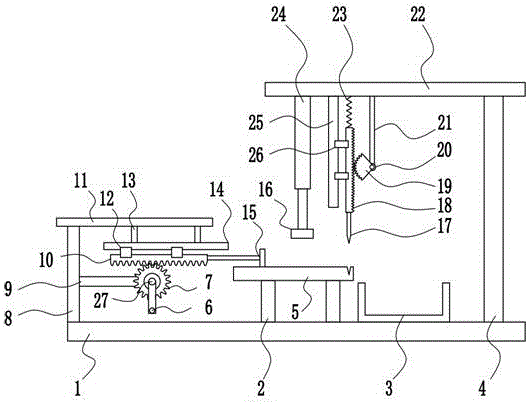

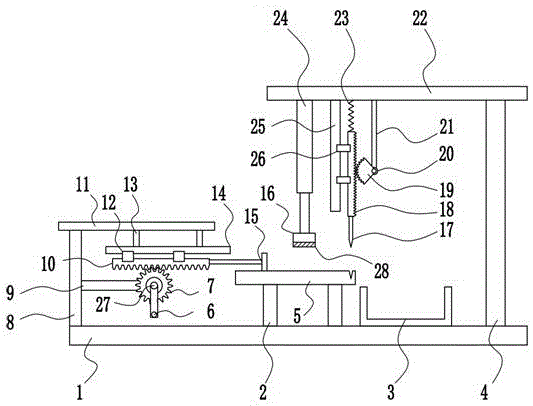

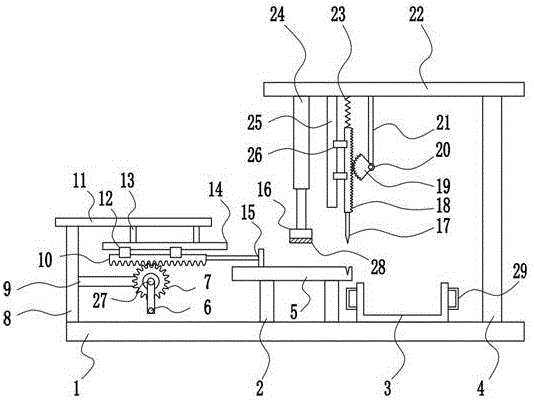

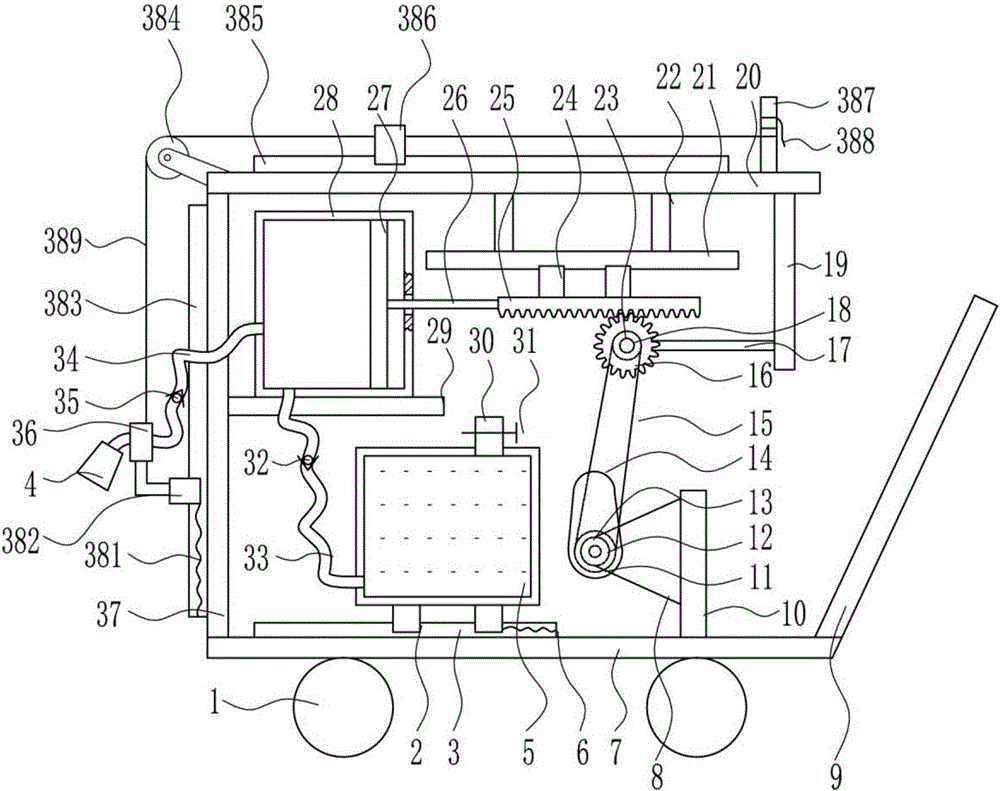

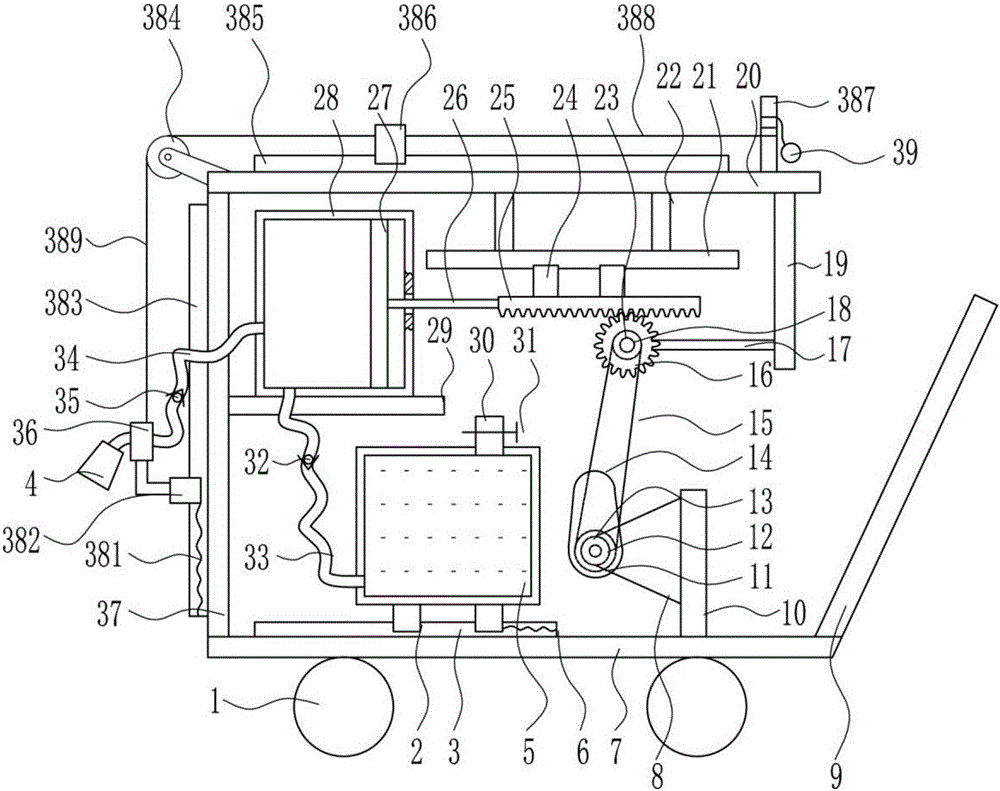

Foamed plastic dicer

The invention relates to a dicer, in particular to a foamed plastic dicer, and aims to provide the foamed plastic dicer which is convenient to operate, high in dicing efficiency and uniform in dicing. In order to solve the technical problem, the foamed plastic dicer comprises a bottom plate, supporting rods, a collecting frame, a right rack, an operating table, a rocking handle, a circular gear, a left rack, a bearing block, a first rack, a fixing plate, a first slider and the like; the supporting rods are symmetrically welded to the left and the right of the middle of the top of the bottom plate; the upper ends of the supporting rods are welded with the operating table, the right rack is welded on the right side of the top of the bottom plate, a top plate is welded at the upper end of the right rack, and the left side of the bottom of the top plate is connected with an electric push rod by a bolt. A rotating motor drives a fan-shaped gear to rotate, the fan-shaped gear drives a second rack to move vertically, the second rack drives a blade to move vertically, and the blade dices foamed plastic.

Owner:WUXI TONGXIN PLASTIC PROD

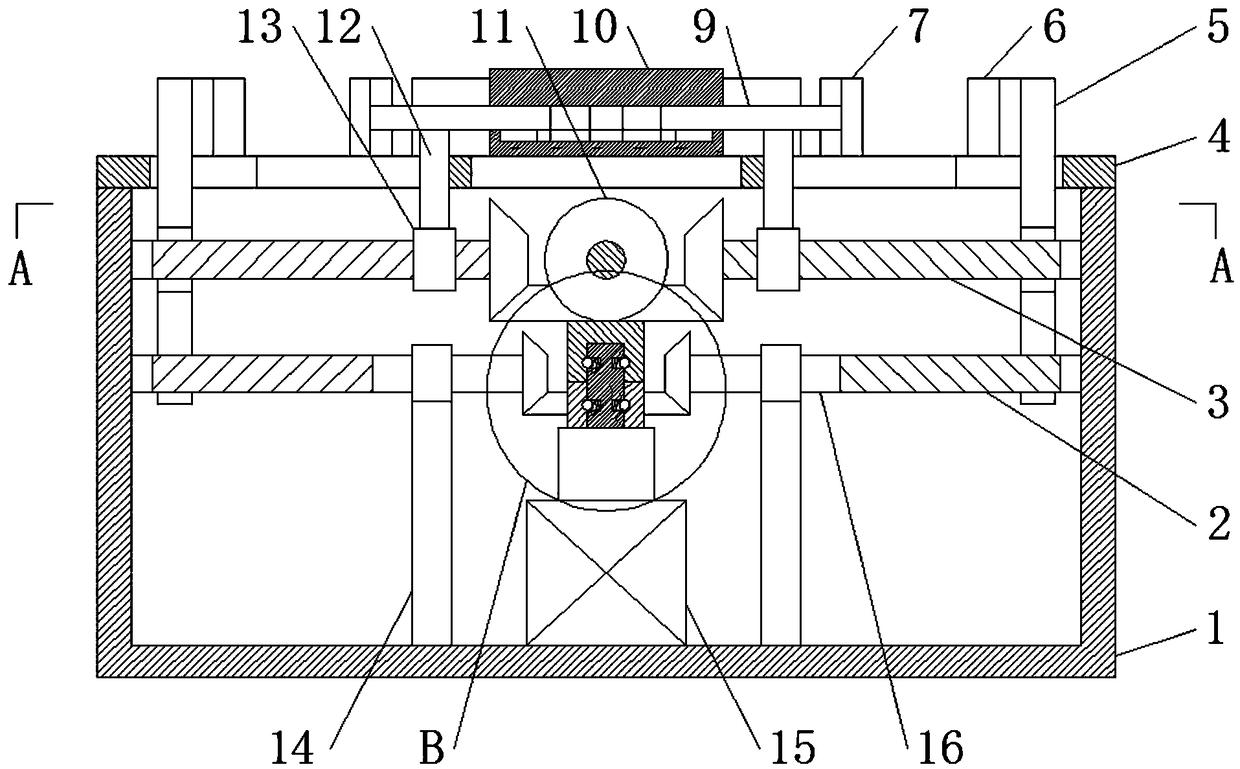

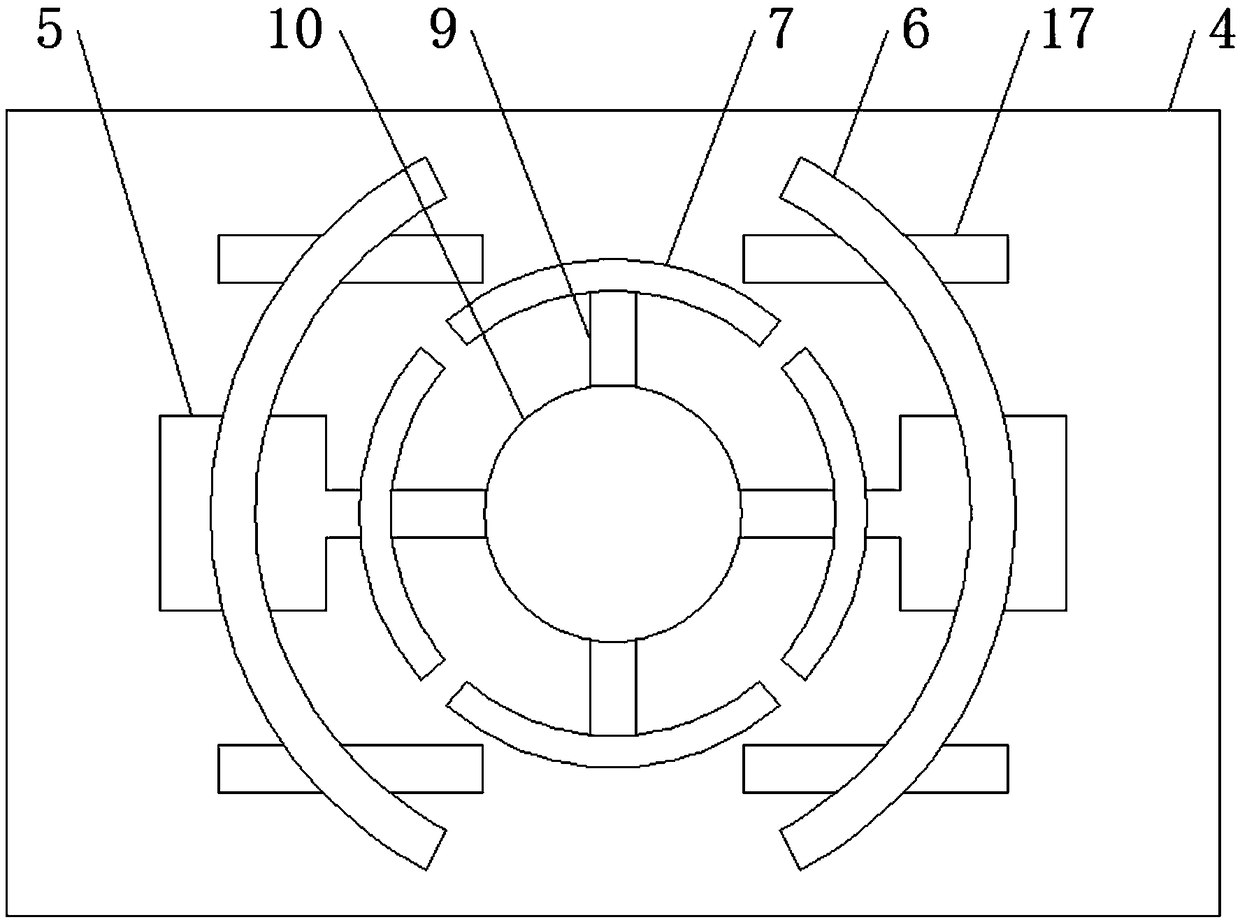

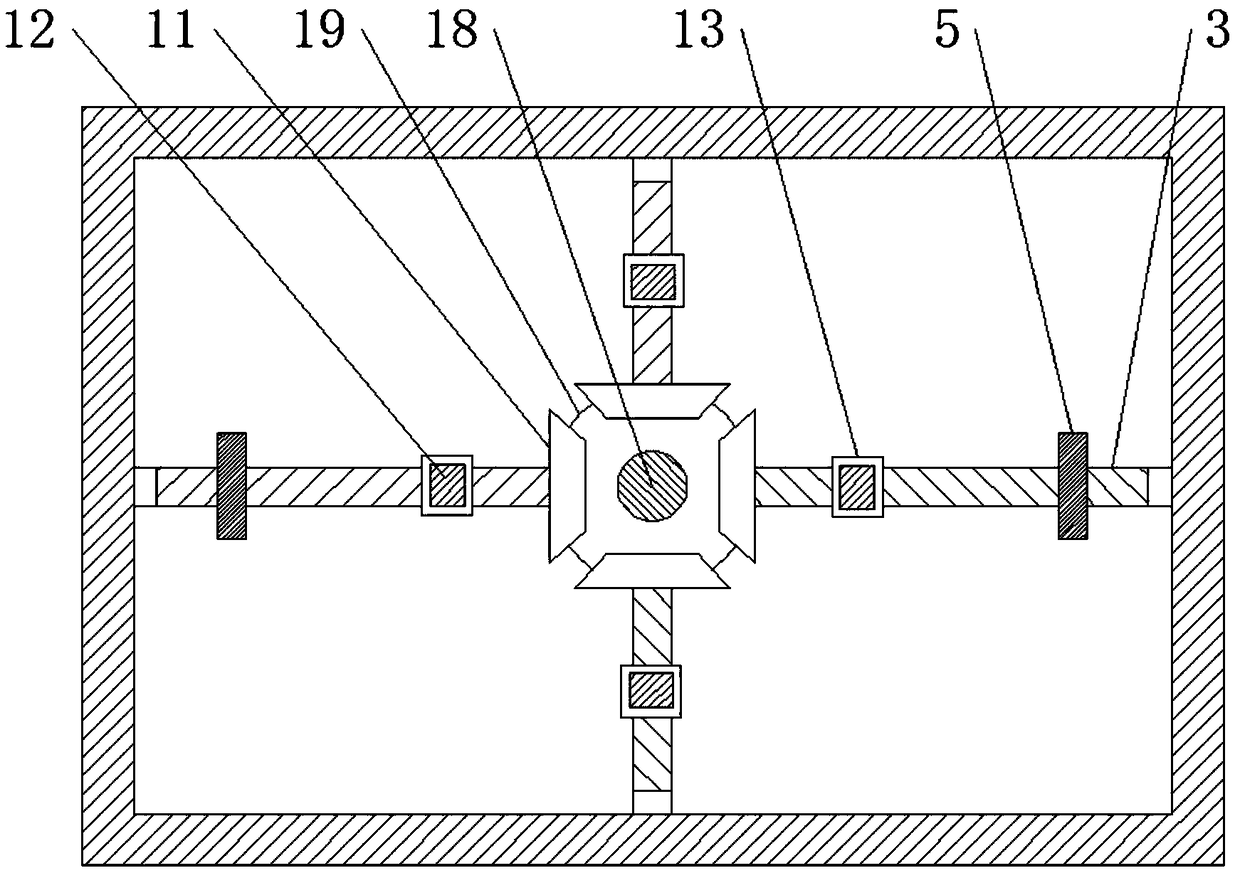

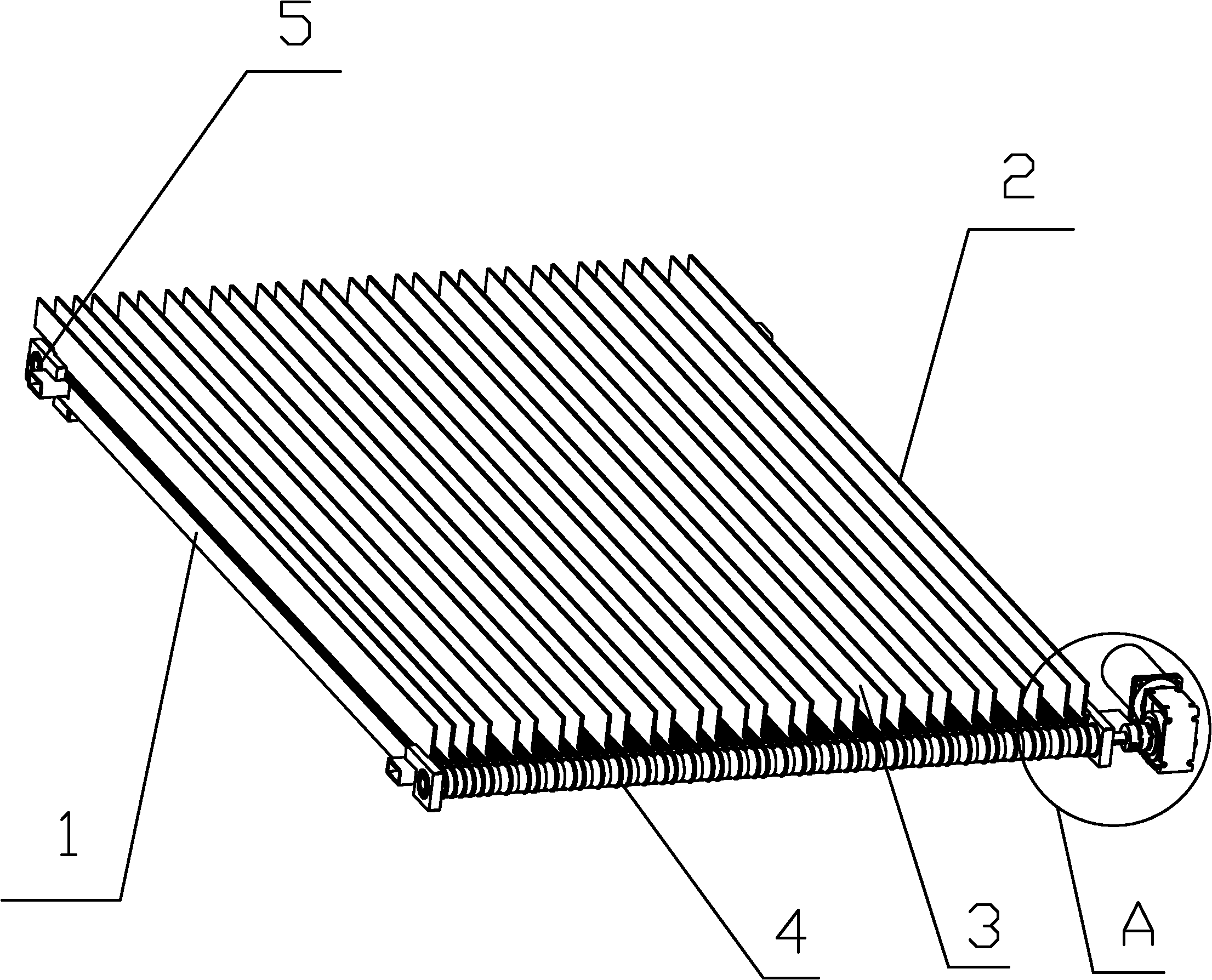

Adjustable positioning milling fixture with uniform clamping force

ActiveCN109158908AIncrease the bearing areaNot easily deformedPositioning apparatusMetal-working holdersEngineeringMachining

The invention relates to the technical field of motor machining, and discloses an adjustable positioning milling fixture with uniform clamping force. The milling fixture comprises a mounting table, the top of the mounting table is fixedly connected with a connecting block, four evenly distributed sliding holes are formed in the side wall of the connecting block, the four sliding holes communicate,sliding rods are in sliding connection to the inner walls of the four sliding holes, the ends, located in the connecting block, of the four sliding rods are fixedly connected with limiting blocks, limiting grooves are formed in the inner walls of the four sliding holes, the four limiting blocks are in sliding connection with the inner walls of the four limiting grooves, the ends, outside the connecting block, of the four sliding rods are fixedly connected with a first arc clamping plate, and a transmission box is fixedly connected to the bottom of the mounting table. According to the adjustable positioning milling fixture with uniform clamping force, a motor shell is sleeved with the position between a first clamping plate and a second clamping plate, the side wall stress area of the motor shell is increased, clamping force is transmitted by two opposite directions, and when the motor shell is clamped, the shell is not prone to deforming.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

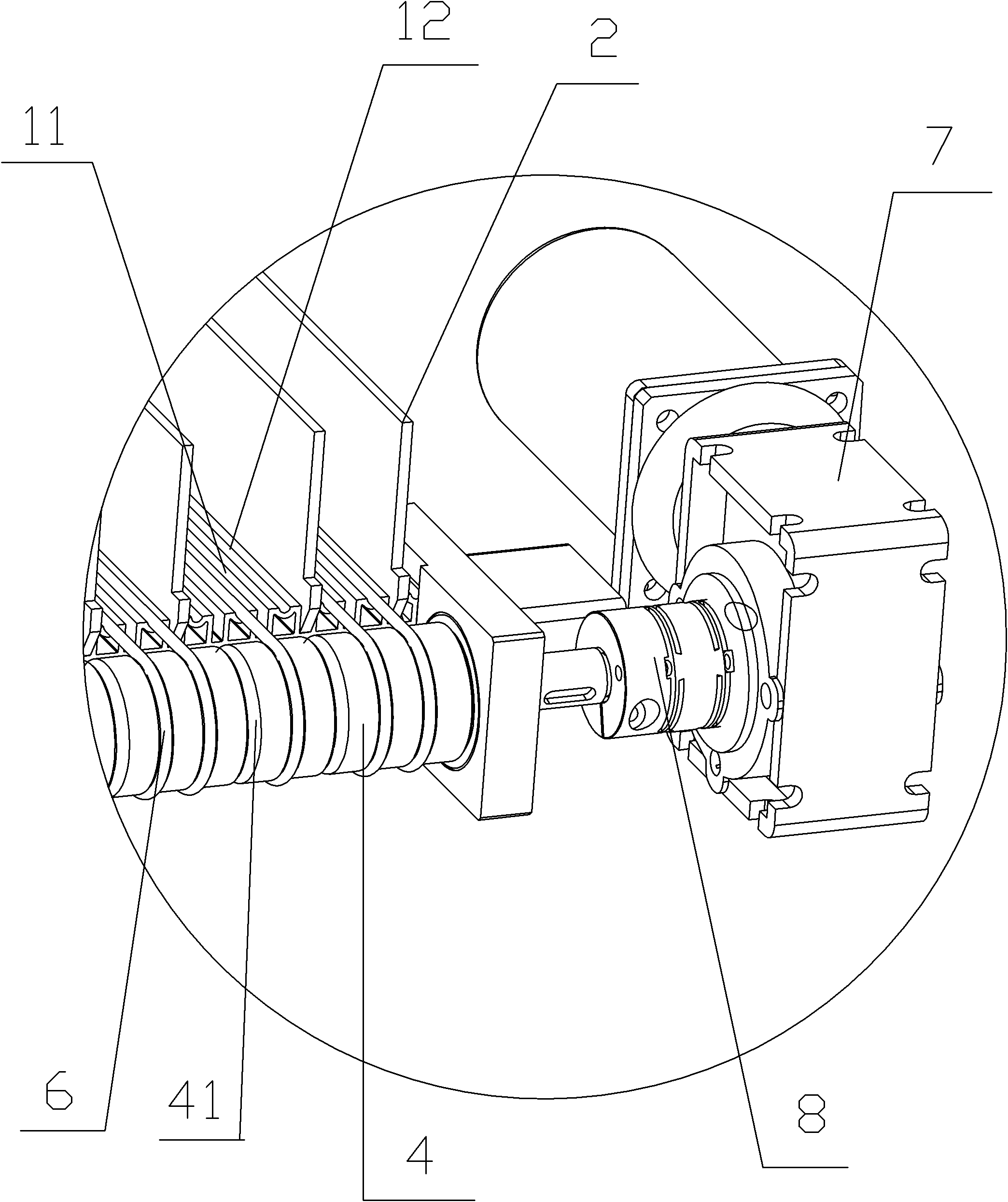

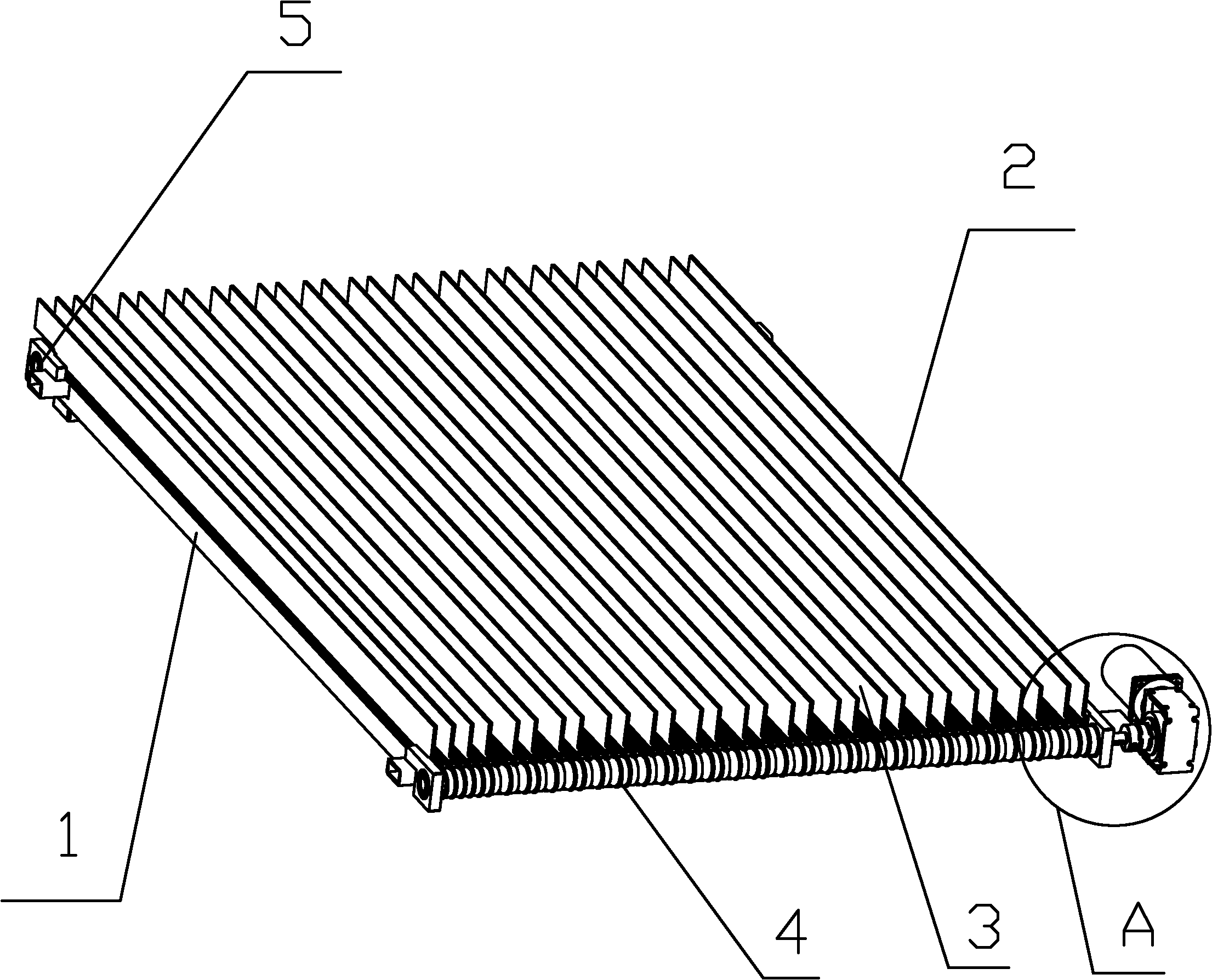

Medicine discharging mechanism of medicine storing device

The invention relates to a medicine discharging mechanism of a medicine storing device, comprising a medicine tank bottom board, a plurality of partition boards, a driving wheel shaft, a driven shaft, a plurality of belts and a motor, wherein the medicine tank bottom board is arranged inside the medicine storing device; the partition boards are arranged on the medicine storing device tank bottom board to form a plurality of medicine slide tanks together with the medicine tank bottom board; the driving wheel shaft and the driven shaft are respectively arranged at both ends of the medicine tank bottom board and are respectively vertical toperpendicularly to the medicine slide tank; the belts are sheathed on the driving wheel shaft and the driven wheel shaft; and the motor is connected with the driving wheel shaft. The medicine discharging mechanism adopts the motor to drive the driving wheel shaft to realize that the belts drives medicine tanks boxes to discharge medicine, can adjust the width of the medicine slide tanks through adjusting the positions of the partition boards according to the volumes and the weights of the medicine tanks and simultaneously adjust the driving power through adjusting the number of the belts in the medicine slide tanks, thereby realizing that the medicine tanks boxes with different volumes, heights and weights can smoothly discharge the medicine.

Owner:朱桂荣

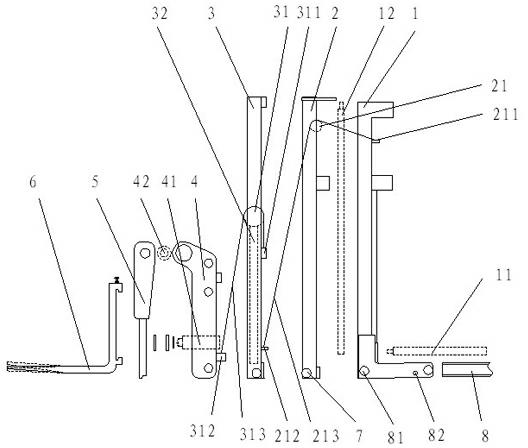

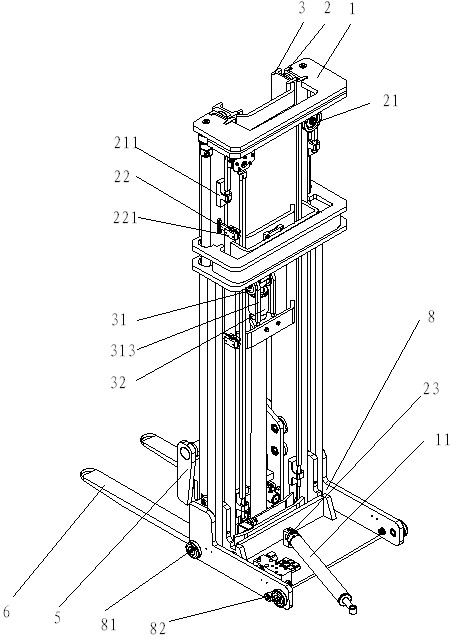

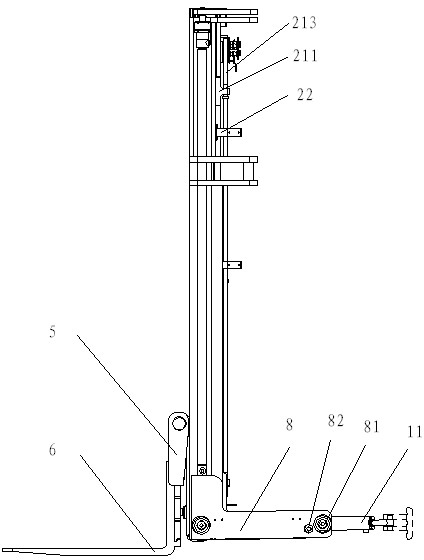

Forklift mast

The invention relates to a forklift mast and discloses a three-level forklift mast. The forklift mast comprises an outer mast (1), a middle mast (2) and an inner mast (3), the outer mast (1), the middle mast (2), the inner mast (3), a carriage (4) and a fork carrier (5) are sequentially connected, a first chain (213) winds around a first sprocket (21), two ends of the first chain (213) are fixed on a first chain fixing block (211) and a second chain fixing block (212), a second chain (313) winds around a second sprocket (31), and two ends of the second chain (313) are fixed on a third chain fixing block (311) and a fourth chain fixing block (312). According to the technical scheme, the forklift mast is high in strength, is not easy to deform when in use and high in stability and safety when in loading, friction is reduced by brass graphite blocks and the service life of the forklift mast is longer.

Owner:ZHEJIANG EP EQUIP

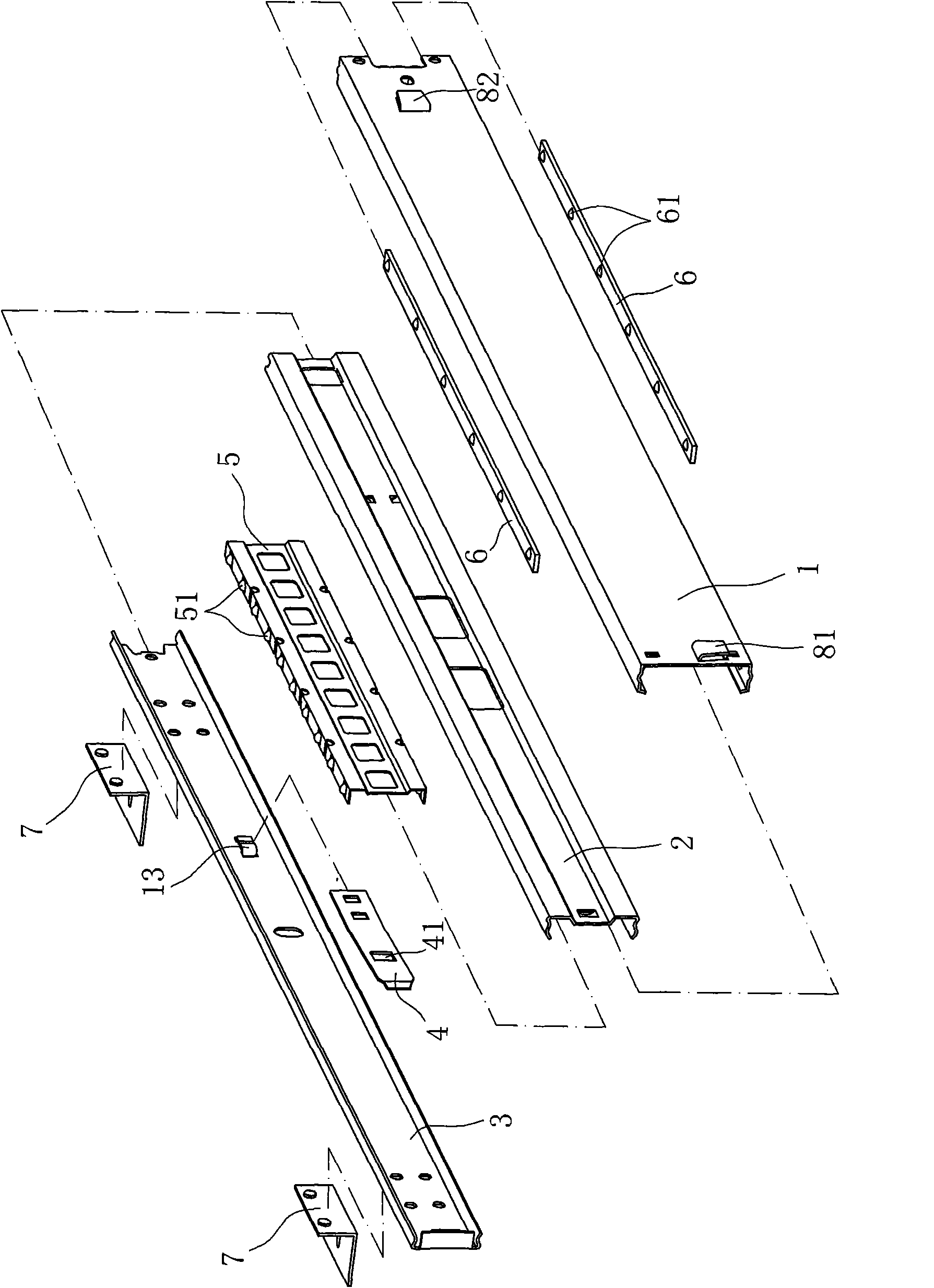

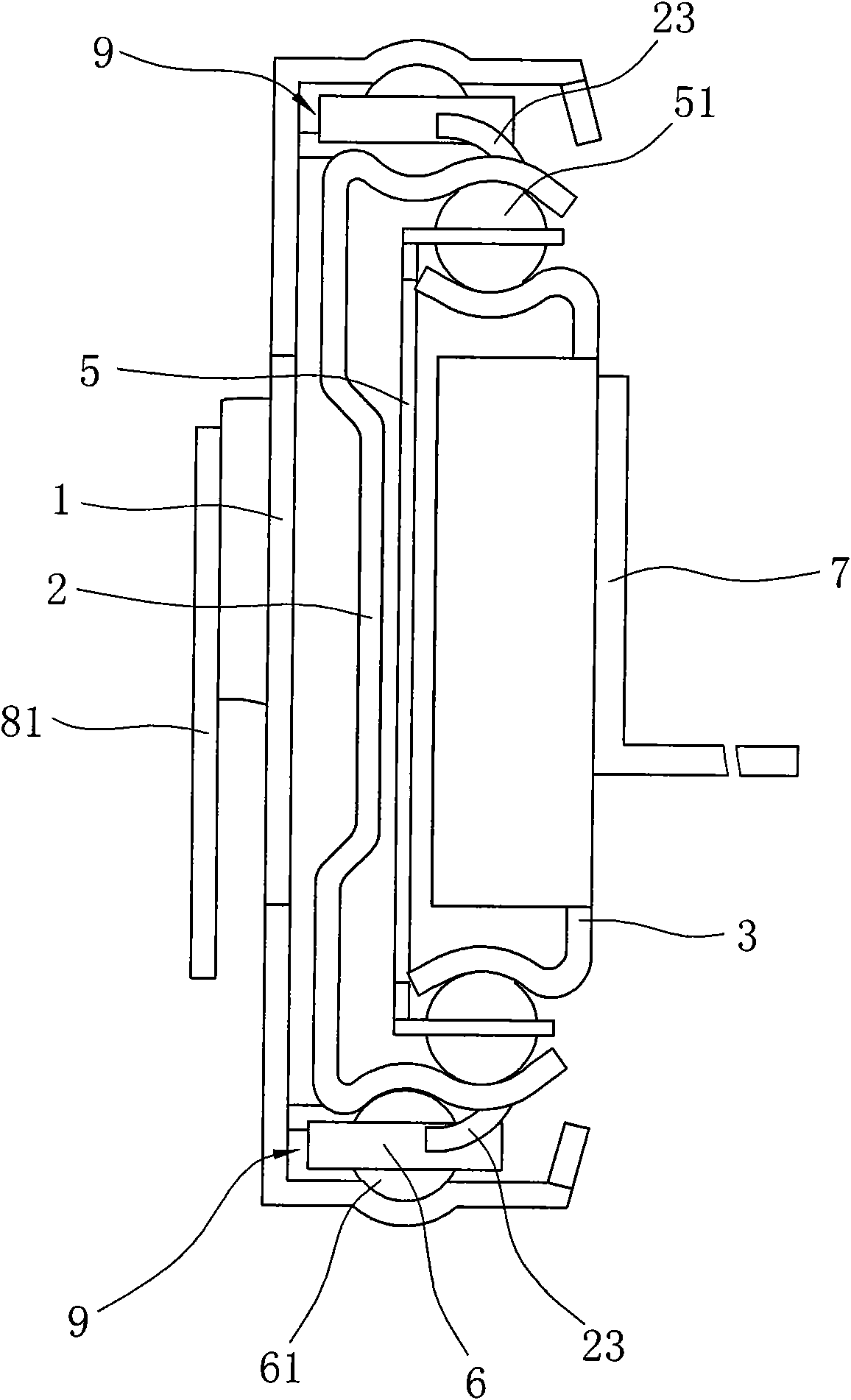

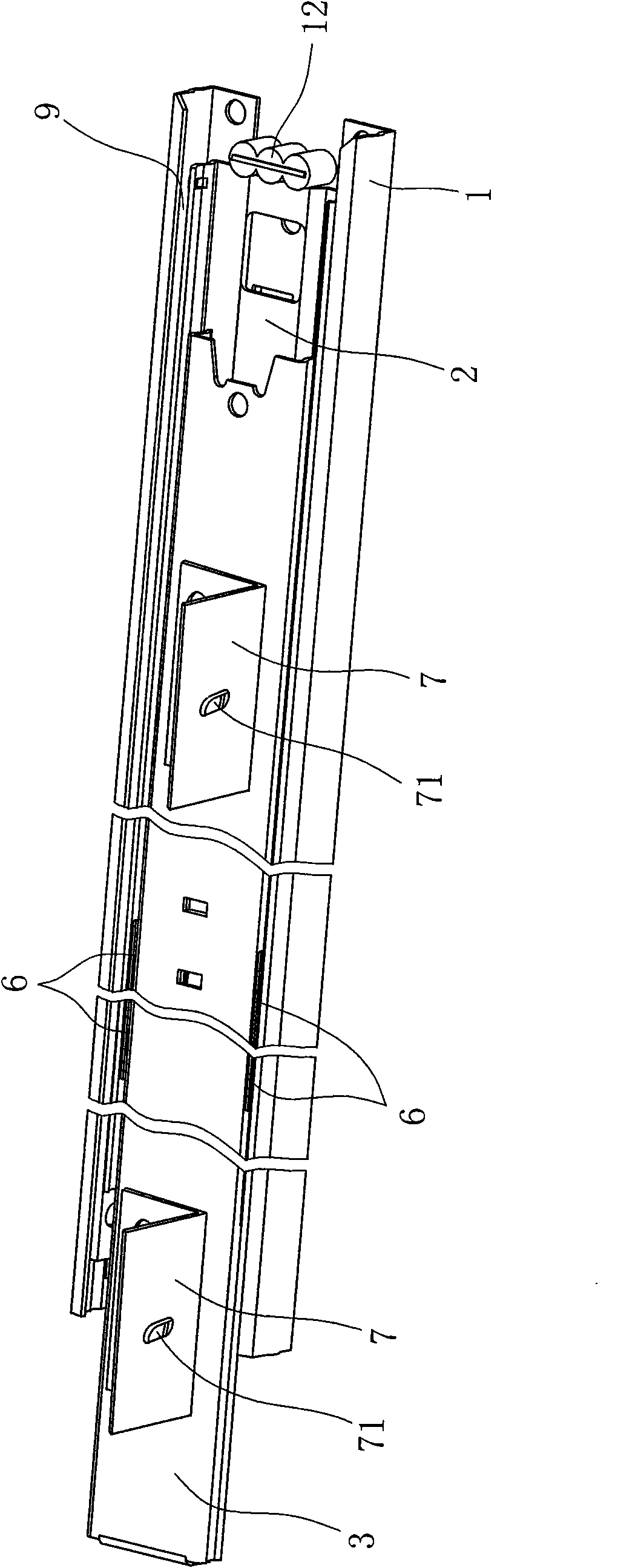

Detachable drawer slide

The invention provides a detachable drawer slide, comprising a supporting seat, an outer slide, an inner slide and a locking mechanism. The drawer slide is characterized in that the locking mechanism comprises a reed; wherein one end of the reed is a fixed end connected with a web plate of the inner slide, while the other end is an elastic movable end which is raised towards one side of the outer slide; the movable end is provided with a through hole; the outer slide is provided with a stop lug raising towards the reed on the web plate; the stop lug can be received in the through hole to prevent the inner slide from separating from the outer slide. Compared with the prior art, the drawer slide uses the reed instead of the prior elastic strip structure to ensure that the drawer can be separated from the slide only through lightly pressing the elastic movable end of the reed by the first finger, is in accordance with the characteristic of finger force application of a human body, and has the advantages of easy and convenient operation; and the finger need not put into the groove of the outer slide, and can not adhere to stains on the slide. The drawer slide is sanitary and clean for use, has uneasily deformed metal reed, long service life, and safer and more reliable limit.

Owner:朱建华

Method for producing automotive rear shelf

The invention relates to a method for producing an automotive rear shelf. The method is characterized by comprising the following steps of: (1) heating: hanging polypropylene sheets in a two-layer drying oven and heating, wherein the temperature of an upper-layer drying oven of the two-layer drying oven is between 240 and 260 DEG C; the temperature of a lower-layer drying oven of the two-layer drying oven is between 325 and 345 DEG C; and the heating time is 85 to 95 seconds; (2) pressing and forming: laying a fabric on two layers of PP sheets flatly, and pressing and forming the fabric in a die to obtain a half-finished product, wherein the pressure during pressing and forming is 70 to 90kg / cm<2>, and the forming time is 60 to 70 seconds; (3) cooling and shaping: cooling and shaping the half-finished product at the normal temperature, wherein the cooling time is 30 to 50 seconds; (4) installing accessories: installing the accessories on the half-finished product to obtain an automotive rear shelf finished product; and (5) examining and packing, wherein the fabric is a non-woven fabric, and the PP sheets are PP wood powder sheets with glue. The method ensures the performance indexes of light weight, high strength, difficult contraction distortion and the like of a rear shelf, greatly reduces the weight of the rear shelf, and meets the requirement for lightweight vehicle design; and as the material has a double-layer wood powder sheet structure, the product is fuller.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

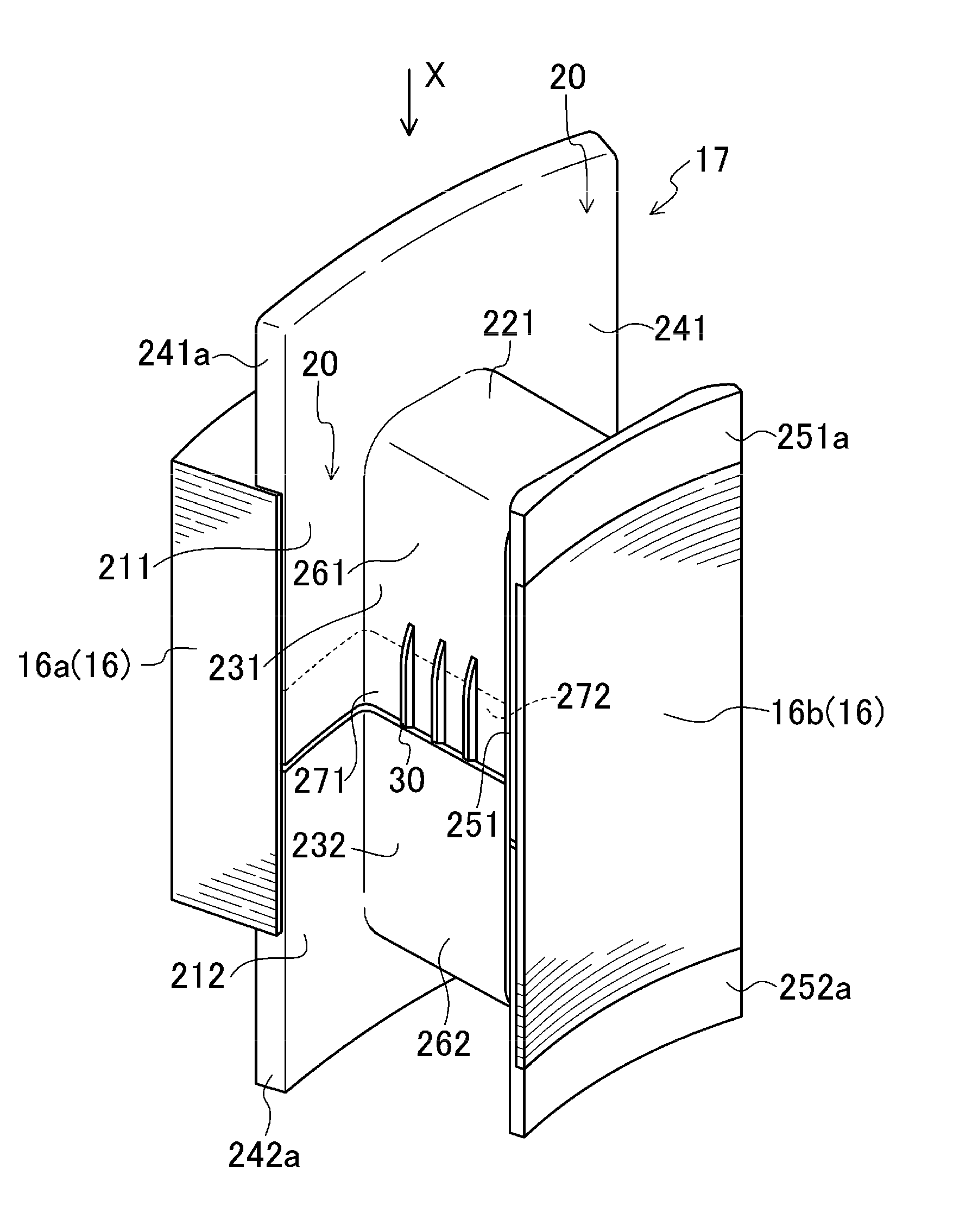

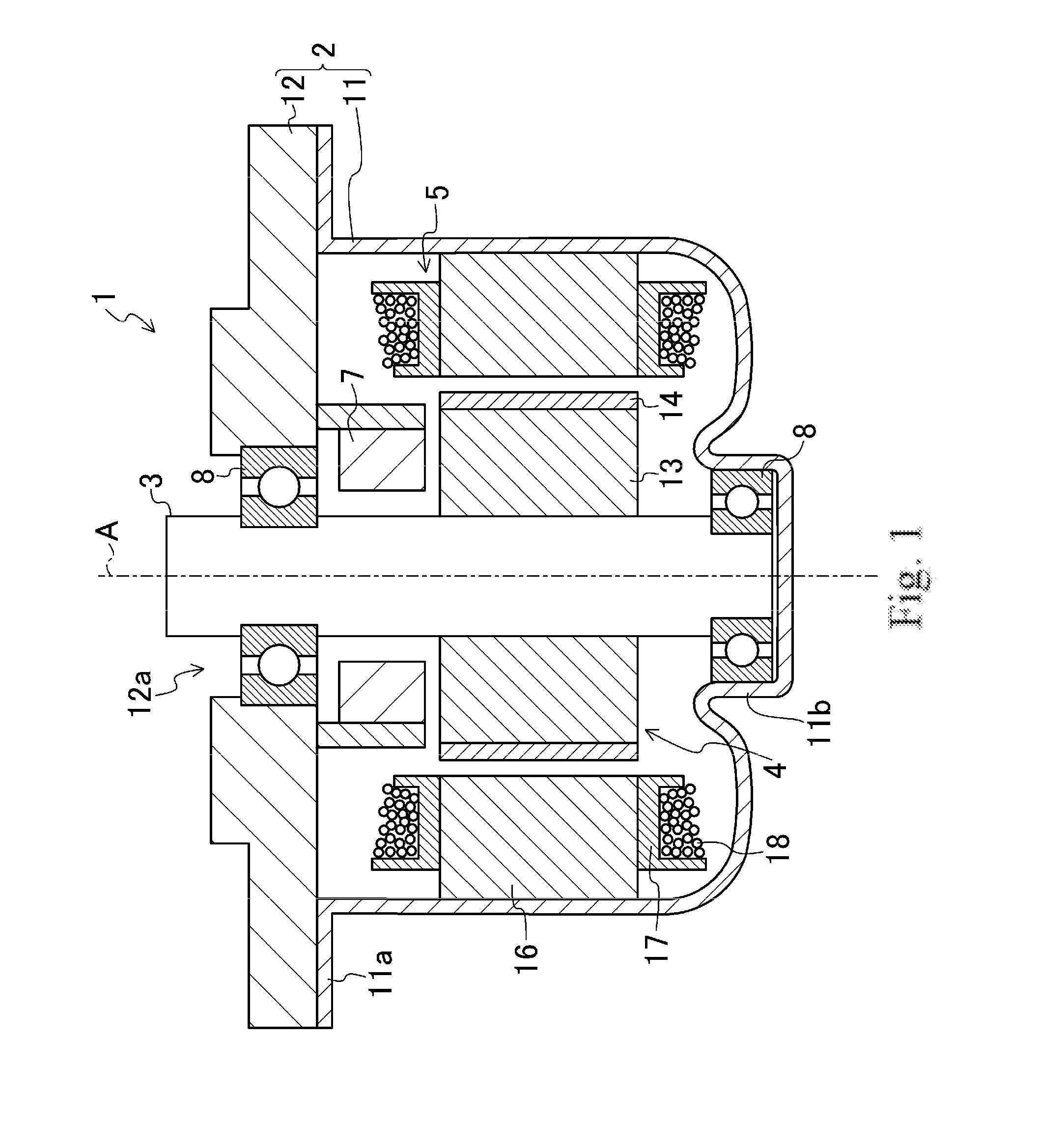

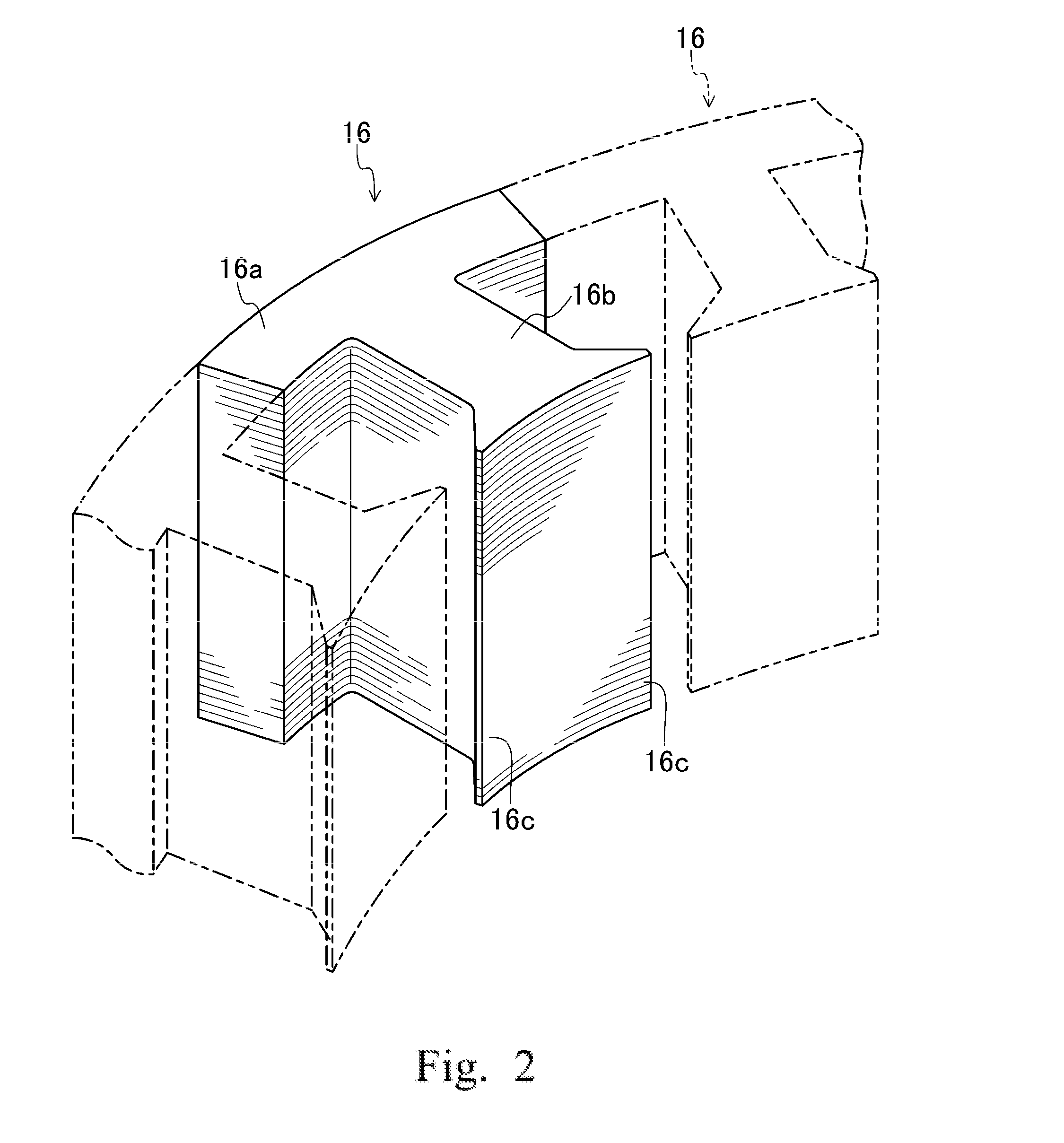

Armature and motor including armature

ActiveUS20130221770A1Not easily deformedStably held in constant shapeWindings insulation shape/form/constructionMagnetic circuit characterised by insulating materialsEngineeringElectric motor

Owner:NIDEC CORP

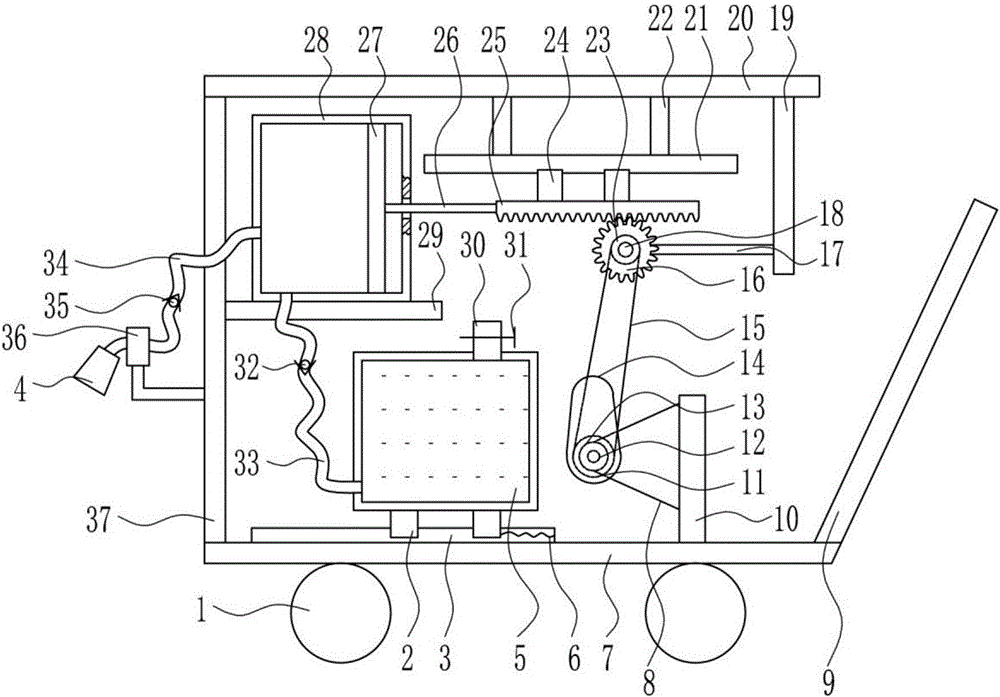

Landscaping lawn pest breeding prevention pesticide spraying device

The invention relates to a pesticide spraying device, particularly to a landscaping lawn pest breeding prevention pesticide spraying device. The landscaping lawn pest breeding prevention pesticide spraying device solves the technical problem of providing the landscaping lawn pest breeding prevention pesticide spraying device, which is low in worker load, capable of re-mixing prepared pesticides and free in adjustment of height of a spray nozzle. The landscaping lawn pest breeding prevention pesticide spraying device comprises wheels, a first sliding block, a first sliding rail, the spray nozzle, a case, a first spring, a bottom plate, a mounting plate, a push handle, a mounting plate, a large belt pulley, a rotating shaft, a bearing block and the like. The left end of the top of the bottom plate is welded with a left frame, and the lower portion of the left of the left frame is welded with a fixing sleeve. According to the landscaping lawn pest breeding prevention pesticide spraying device, case is continuously moved in a cross direction through the side-to-side movement of the piston.

Owner:聂正香

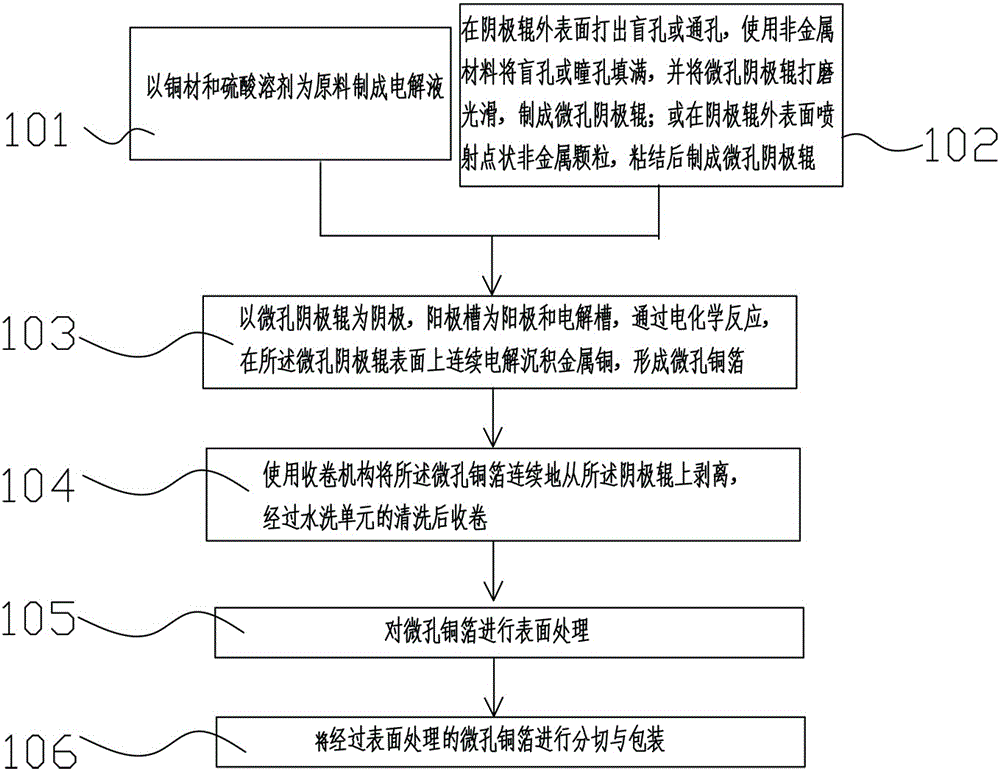

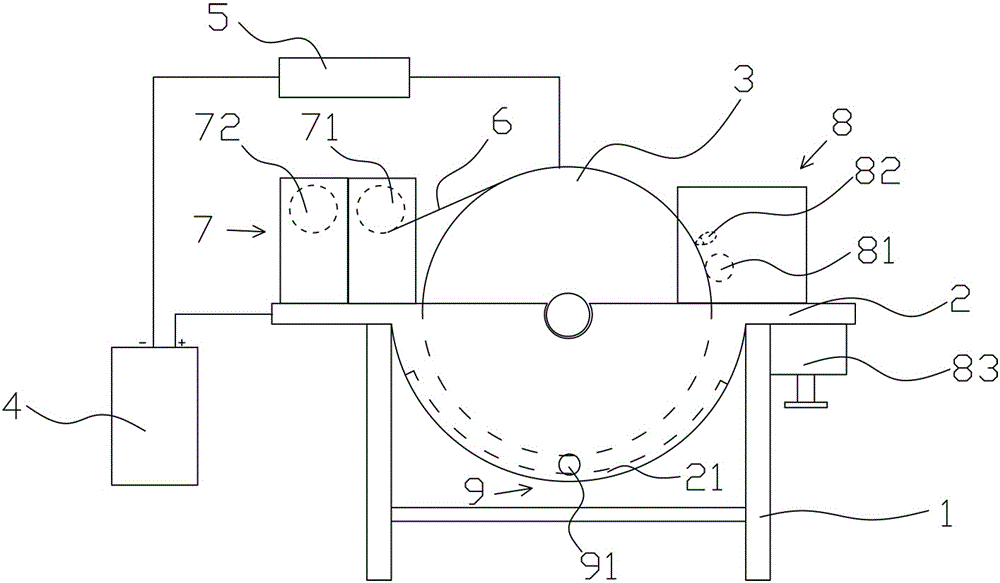

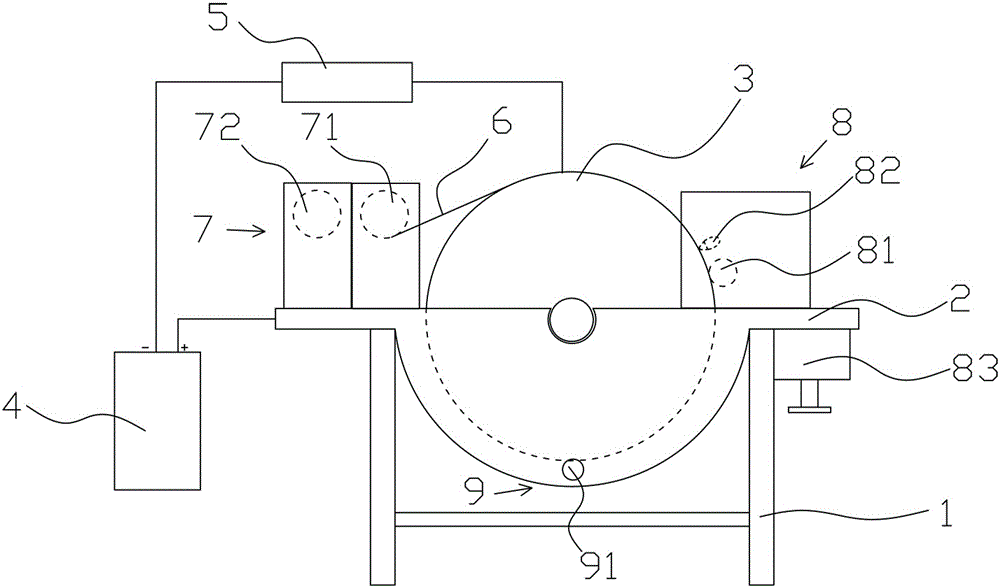

Production method of microporous copper foil, microporous copper foil and production device thereof

InactiveCN104993153AAppropriate thicknessNot easily deformedElectrode carriers/collectorsElectroforming processesIonElectrochemical response

The invention provides a production method of a microporous copper foil, a microporous copper foil and a production device thereof. The production method comprises the following steps: taking a solution containing copper ions as an electrolyte, taking a prefabricated microporous cathode roll as a cathode, taking an anode cell as an anode, continuously electrolyzing depositing metal copper on the surface of the microporous cathode roll to form a microporous copper foil, wherein the microporous cathode roll is a cathode roll with a plurality of nonmetal dotted articles on a surface, contacting the electrolyte, of the cathode roll. The production device comprises a stander, wherein the stander is provided with the anode cell, the anode cell is connected with an anode of a power source by virtue of a copper bar, a cathode roll connected with a cathode of the power source is arranged above the anode cell, and the cathode roll is a microporous cathode roll. The microporous copper foil produced by adopting the production method is suitable for the smearing of a smearing machine, so that a cathode material is unlikely to drop; the microporous copper foil has advantages of being appropriate in thickness and not prone to deform and damage.

Owner:SHENZHEN XINYUREN TECH

Waterborne extinction polyurethane resin and preparation method thereof

The invention discloses a water-based matting polyurethane resin and a preparation method thereof, comprising macromolecular polyols, hydrophilic diols, small molecule diols, diisocyanates, catalysts, salt-forming agents, amine chain extenders, and deionized water , Thickener. The preparation includes the following steps: step a: add macromolecular diol into the reaction kettle, and vacuum dehydrate at 100°C for 1 hour; step b: add co-solvent, diisocyanate, small molecular polyol and hydrophilic diol; step c: React at 70-90°C for 3-6 hours; Step d: After adding triethylamine to form a salt, add deionized water to emulsify into an emulsion while stirring; Step e: Add amine chain extender; Step f: Add thickener to adjust Viscosity: The prepared water-based polyurethane resin has a high matting degree, no additional matting powder is needed, and the obtained matting coating film is good in abrasion resistance and scratch resistance.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

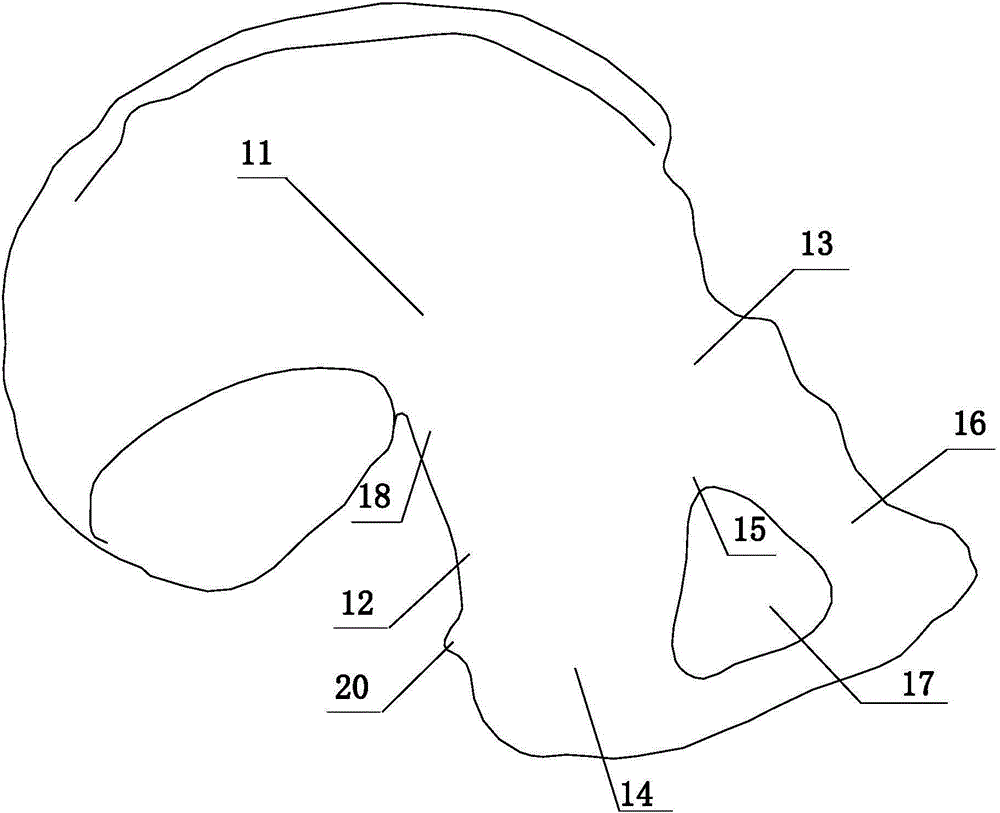

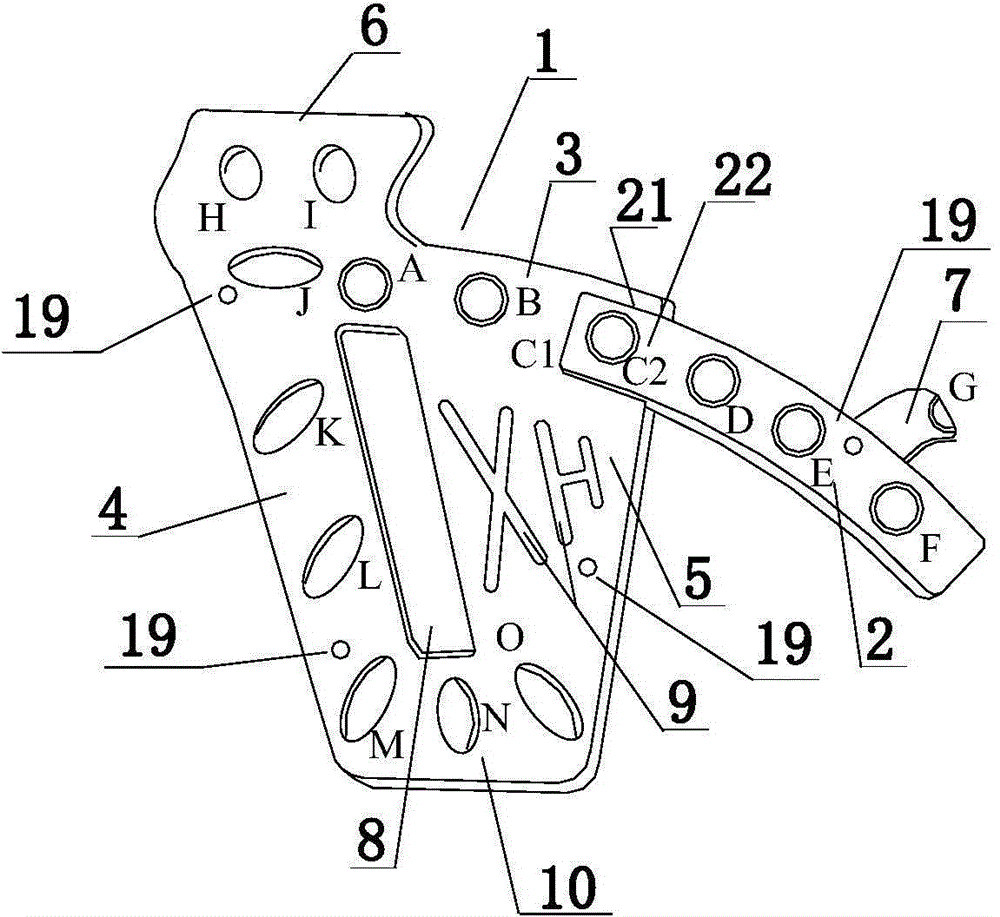

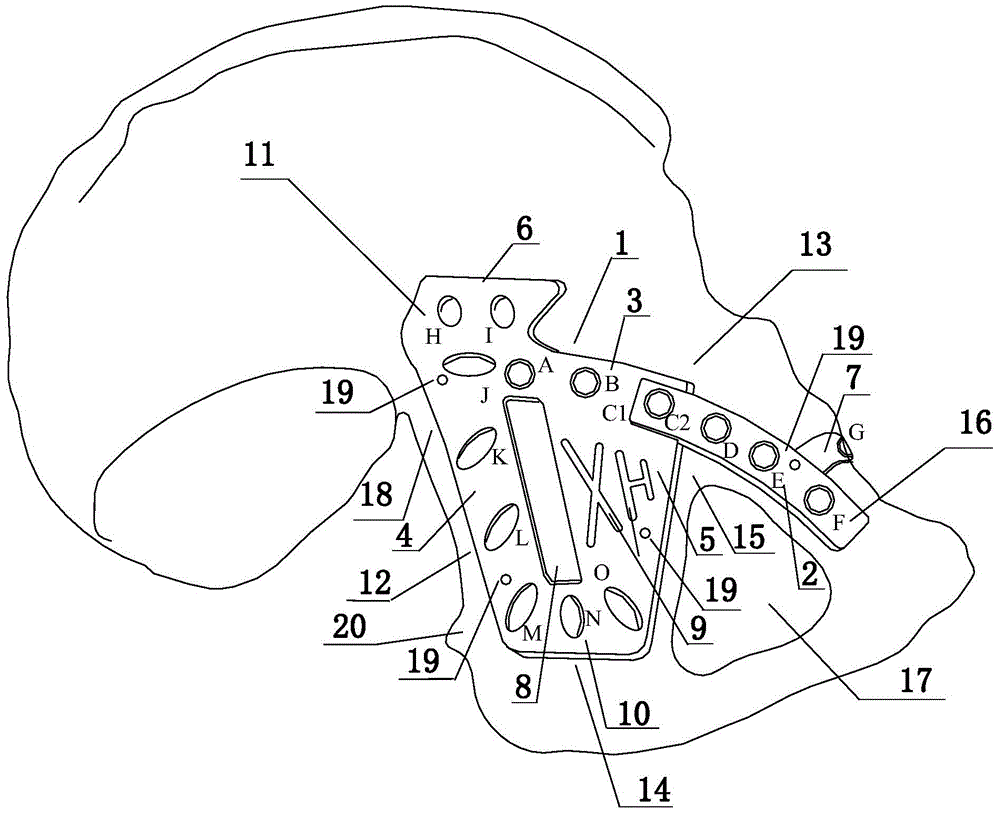

Fixing device for fractures of anterior column, posterior column and square area of acetabulum and method

InactiveCN104644255ANot easily deformedReduce traumatic arthritisBone platesSteel platesFossa iliaca

The invention discloses a fixing device for fractures of an anterior column, a posterior column and a square area of an acetabulum and a use method thereof. The fixing device comprises a trapezoid main board and a pubic auxiliary board; the integral shape of the trapezoid main board and the pubic auxiliary board is matched with anatomical structures of the insides of the anterior column and the posterior column of the acetabulum and the square area of the acetabulum; an arcus marginalis steel plate positioned at an ilium arcus marginalis is arranged at the upper part of the trapezoid main board; a posterior column steel plate is arranged at one side edge of the trapezoid main board; after being crossed, the posterior column steel plate and the arcus marginalis steel plate are bent and extend towards the fossa iliaca to form a posterior column side wall; an ischium steel plate is arranged at the lower part of the trapezoid main board; a square area baffle is arranged among the arcus marginalis steel plate, the posterior column steel plate and the ischium steel plate; the pubic auxiliary board is matched with an anatomical structure of the inside of the superior pubic ramus, is bent near a pubic tubercle and extends towards the upper surface of the superior pubic ramus to form a pubic side wall; the trapezoid main board and the pubic auxiliary board are provided with a plurality of screw holes. By using the fixing device, the acetabulum fractures can be stably reduced and fixed and quality of fracture reduction and internal fixation is improved.

Owner:郭晓东

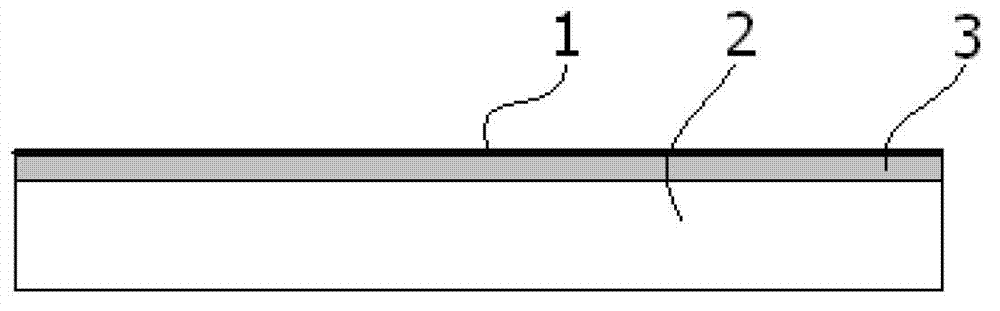

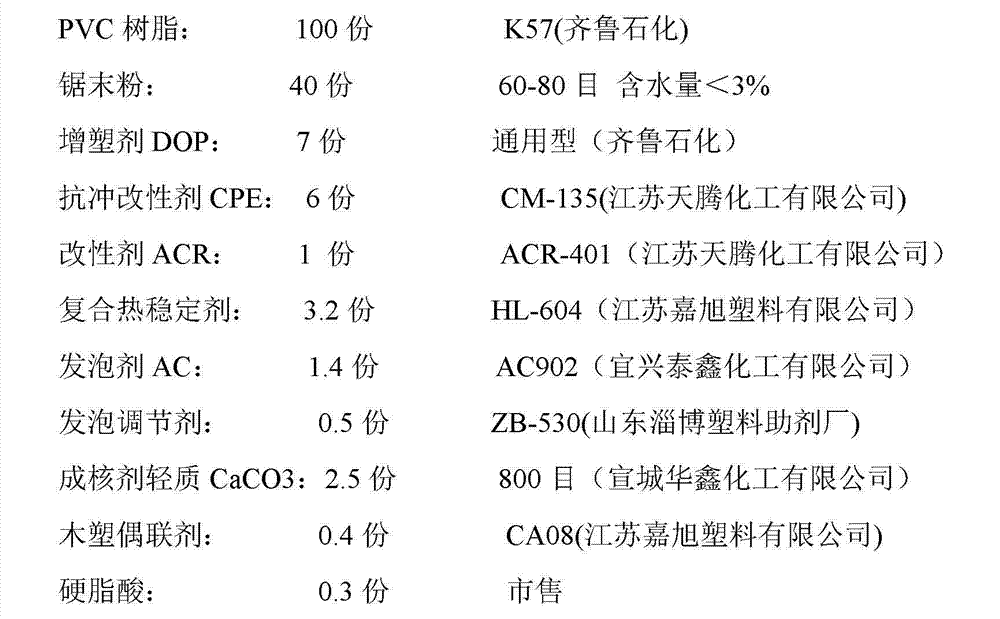

High-wear-resistant wood-plastic composite floor and preparation method thereof

ActiveCN102758518ANot easily deformedEasy to prepareSynthetic resin layered productsLaminationWear resistantSolid wood

The invention discloses a high-wear-resistant wood-plastic composite floor and a preparation method thereof. The high-wear-resistant wood-plastic composite floor sequentially comprises a wear-resistant layer, a solid wood face and a wood-plastic composite base material, wherein the wear-resistant layer is wear-resistant aluminium oxide paper. The high-wear-resistant wood-plastic composite floor disclosed by the invention has the characteristics of high wear resistance, environmental protection, economization, uneasy deformation, insect prevention and moth proofing and the like.

Owner:江苏辛巴地板有限公司

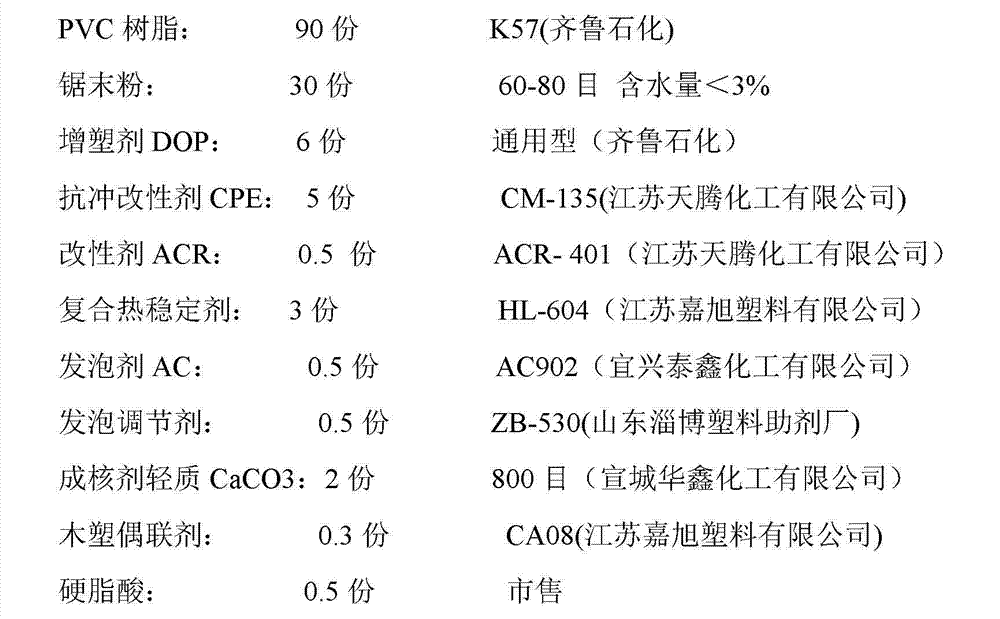

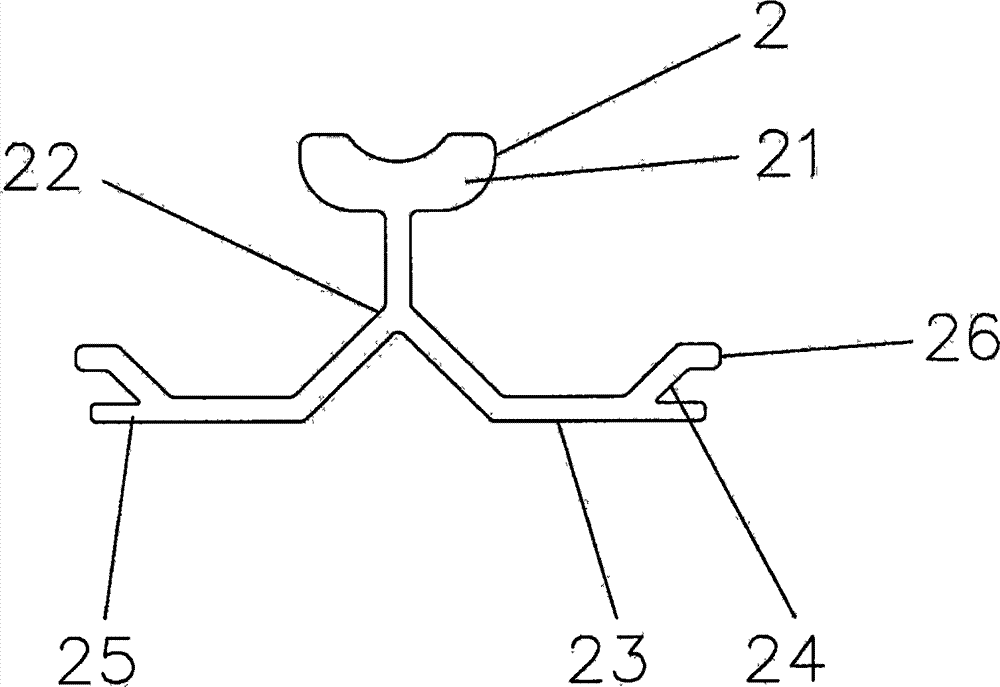

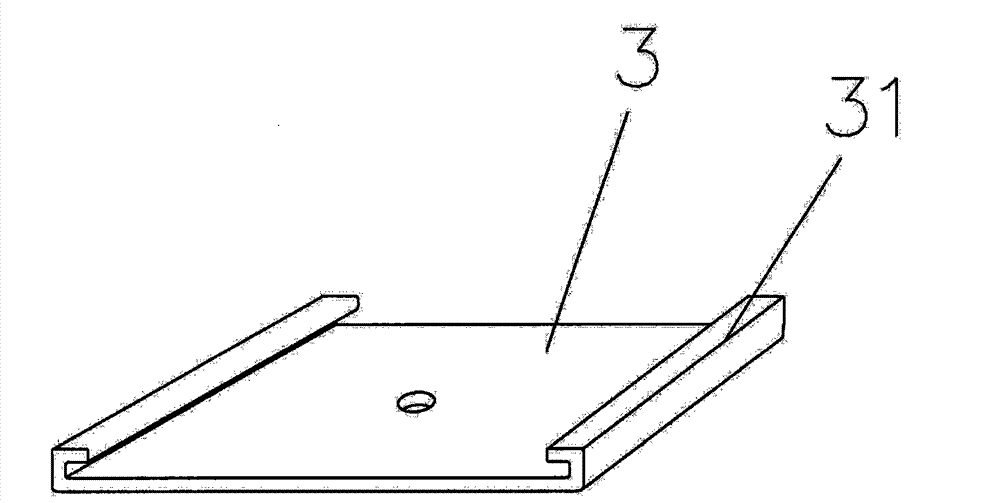

Double-hook lock flooring

The invention relates to double-hook lock flooring. The double-hook lock flooring comprises a flooring body, and symmetric mortise grooves are formed in the two sides of the flooring body; symmetric clamping grooves are formed in the bottom of the flooring body, and 45-degree chamfers are arranged on the edge of the bottom of the flooring body; adjacent floor bodies are connected through a connecting clamping buckle, and tongues matched with the mortise grooves of the two floor bodies are arranged at the top end of the connecting clamping buckle; the connecting clamping buckle is matched with the chamfers through a Y-shaped connecting rod, and the tail end of the connecting rod is connected with barbs matched with the clamping grooves through transverse rods; and the bottom ends of the barbs are provided with protrusions connected with a floor fastener in a clamped manner, and the floor fastener is connected with a keel through a clamping buckle. The structure is suitable for multi-layer wooden flooring, and the flooring can be automatically locked, can expand and contract freely under the affects of environment, and are not prone to deformation. The double-hook lock flooring can be easily mounted or dismounted without damage, and can be repeatedly utilized. By using the double-hook lock flooring, resources are greatly saved, the cost is saved, and paving is firmer.

Owner:徐小团

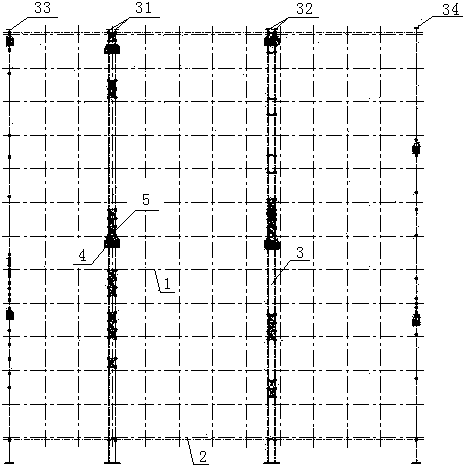

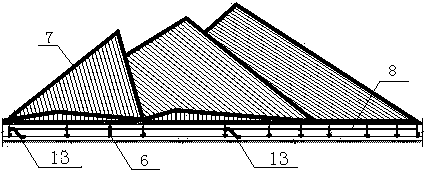

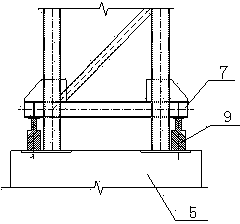

Overall sliding construction method for large-span special-shaped space grid pipe truss

The invention relates to the field of steel structure monolithic architecture construction, in particular to an overall sliding construction method for a large-span special-shaped space grid pipe truss. The method is characterized by comprising the following steps that 1, a truss erecting field is determined; 2, a trestle type Bailey frame is erected in a foundation trench, and a concrete strip foundation is laid outside the foundation trench; 3, four parallel rails are laid; 4, spliced supporting frames and sliding supporting frames are arranged; 5, the truss is erected through a hoist; 6, vertical and horizontal unloading operating is carried out on the erected truss; 7, the sliding supporting frames are connected with ejectors; 8, synchronous control devices are arranged between the ejectors; 9, the ejectors are started, and the sliding supporting frames are made to synchronously slide to the target position; 10, the sliding supporting frames are dismounted, and a truss support is mounted. Through the steps, the large-span special-shaped space grid pipe truss can be mounted in a sliding mode, the truss is stressed evenly in the sliding mounting process, and deformation is not prone to being caused.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD

Production method of vehicular coat and hat rack

InactiveCN101357612AReduce weightNot easily deformedRacks dispositionEnvironmental resistanceWork in process

The invention relates to a method for manufacturing a coatrack of an automobile, which pertains to the technical field of automobile interior trim parts; the method comprises the steps: a natural fiberboard is taken as a board body of the coatrack; press forming, cool setting, fabric attaching, die cutting and accessory mounting are carried out to the board body of the coatrack. The board body is claimed as a finished product after passing the examination. The method of the invention achieves the performance indexes of a coatrack assembly, such as heat resistance, light weight, high strength, low contractility and low deformability and reaches the Grade 3 of the international leading level, thereby reducing the weight of the coatrack and meeting the design requirement of light weight of the whole automobile; the process adopts the double-oven suspension heating and molding line production, with stable technique; a semi-automatic assembling fixture is adopted in the installation, thereby ensuring safe accuracy and improving working efficiency. No semi-manufactured goods accumulate during the course so that the manufacturing cost can be saved. No harmful substance is generated in the whole production process so that the coatrack produced by the method of the invention is environment-friendly.

Owner:WUXI GISSING AUTO PARTS CO LTD

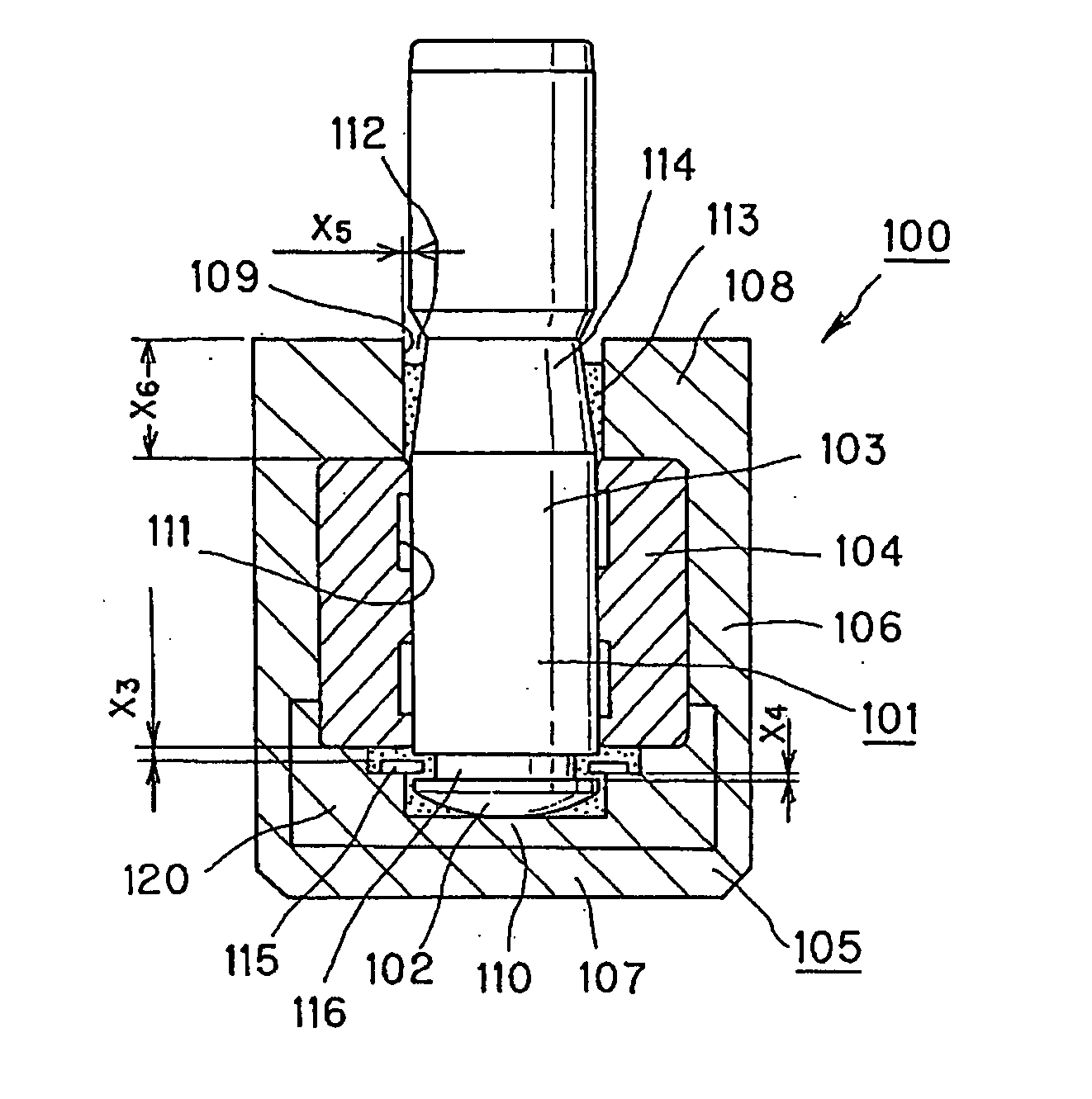

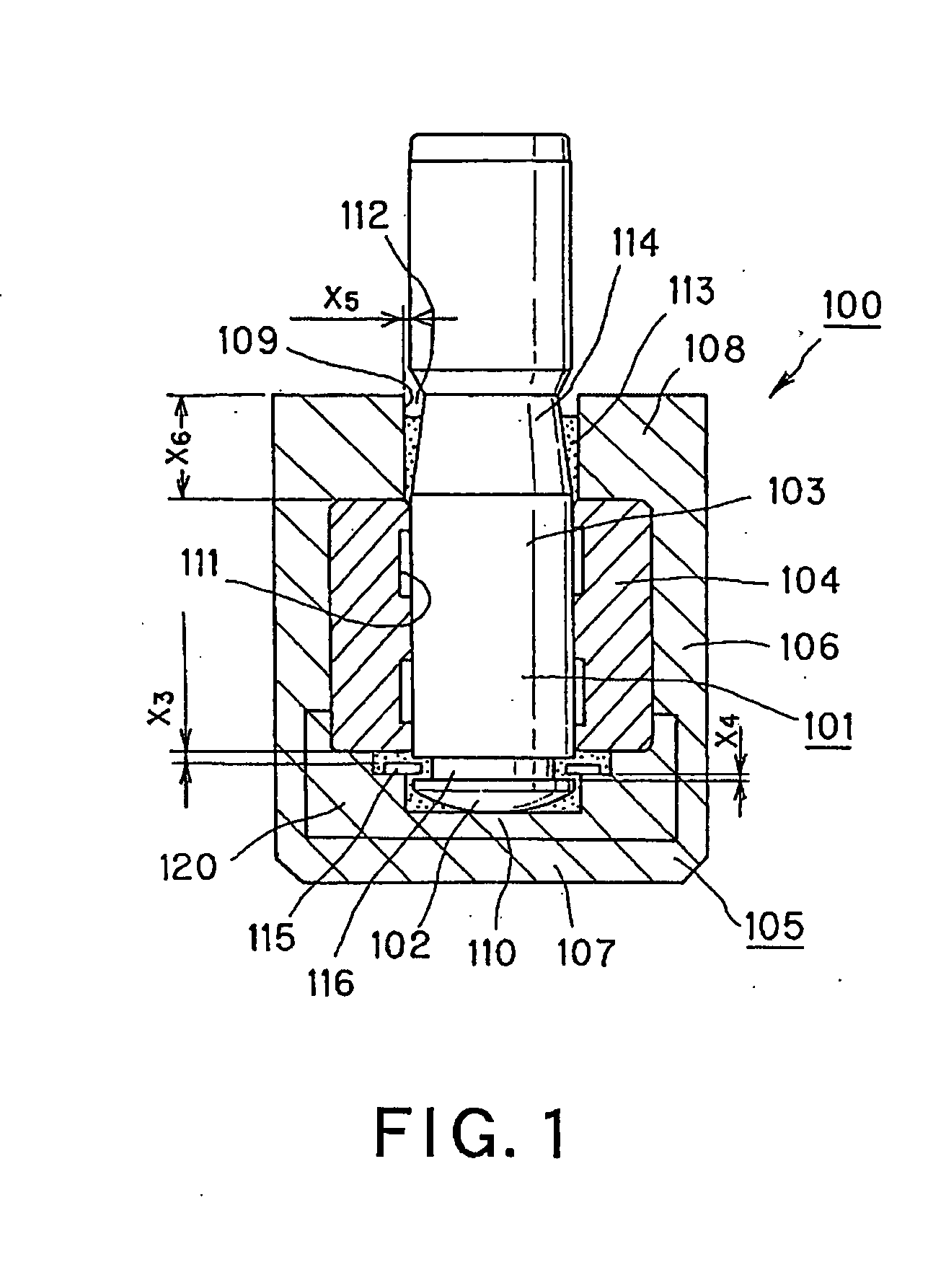

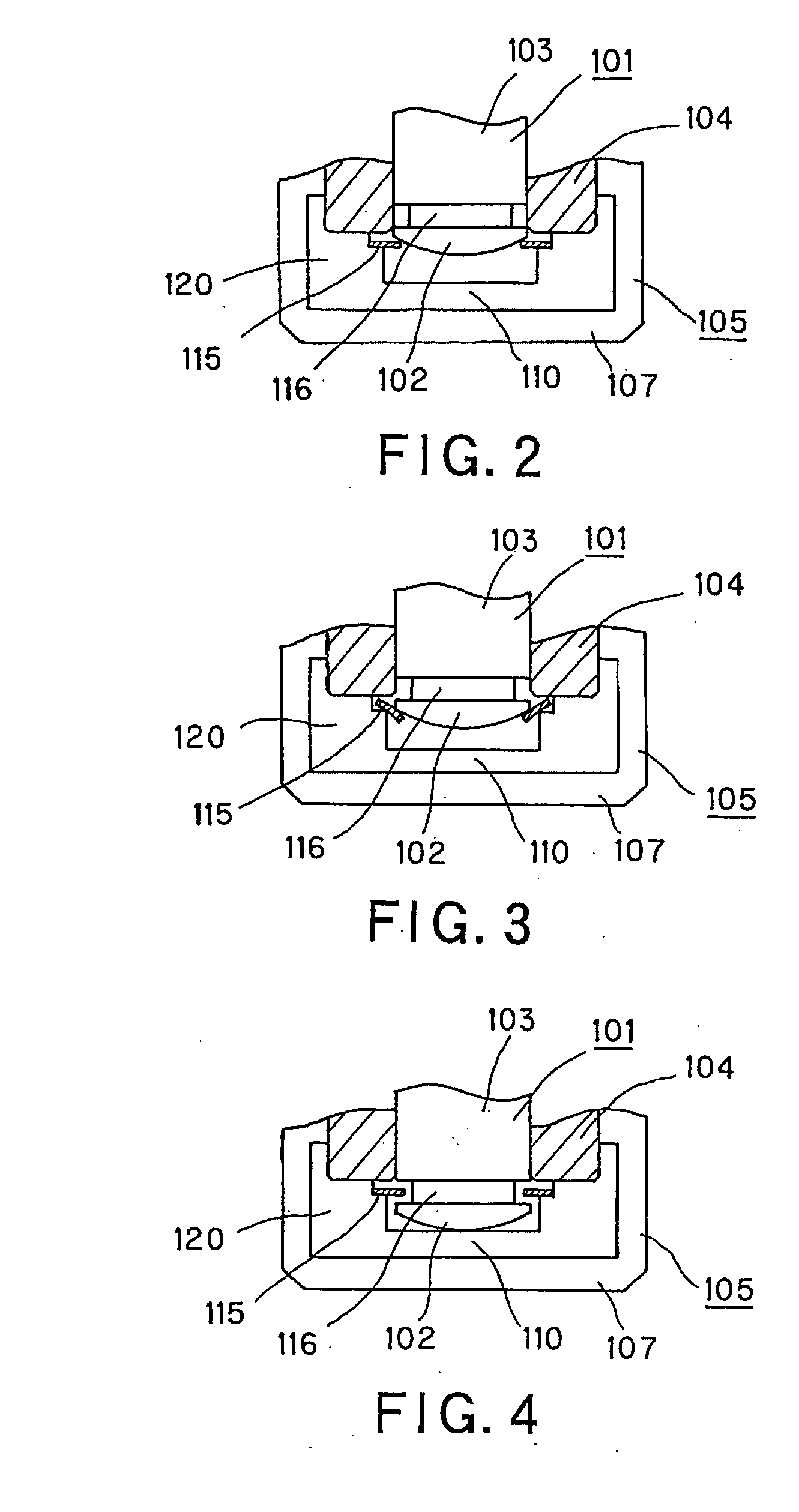

Bearing unit, and motor and electronic apparatus having the bearing unit

InactiveUS20050220379A1Reduce sizeNot easily deformedSliding contact bearingsMechanical energy handlingBearing surfaceLubrication

The bearing unit of the present invention has: a shaft; a radial bearing which supports the shaft in a circumferential direction of the shaft; a thrust bearing which supports an end of the shaft in a thrust direction of the shaft; a housing having a closed structure except for a shaft insertion hole in which the shaft is inserted, with the radial bearing and the thrust bearing being provided inside the housing; a stopper member which prevents the shaft from being pulled out of the radial bearing; and viscous liquid filled in the housing. The stopper member is made of an elastic member which is elastically deformed only in the radial direction and is hardly deformed in the axial direction. Hence, the shaft is prevented from being pulled out from the housing, and shortage of the lubrication oil around bearing surfaces is prevented from being caused by lifting of the shaft.

Owner:SONY CORP

Longitudinal shearing splitting disc blade and manufacturing method thereof

ActiveCN104923849AGood wear resistance and toughnessNot easily deformedShearing toolsQuenchingEngineering

The invention discloses a longitudinal shearing splitting disc blade and a manufacturing method thereof, and belongs to the technical field of tool machining. The longitudinal shearing splitting disc blade comprises a mounting hole and a cutting edge, the surface roughness of the cutting edge is 0.2, the thickness of the cutting edge is 12+ / -0.002 mm, and the diameter of the outer circle of the longitudinal shearing splitting disc blade ranges from 500 mm to 700 mm. Material components for manufacturing the disc blade comprise, by mass, 1.15 percent to 1.40 percent of C, 0.40 percent to 0.65 percent of Mn, 0.32 percent to 0.40 percent of Si, 5.00 percent to 7.50 percent of Cr, 1.50 percent to 2.50 percent of W, 1.40 percent to 1.65 percent of V, 0.40 percent to 0.60 percent of Mo, 0.40 percent to 0.50 percent of Ni, S smaller than or equal to 0.020 percent, P smaller than or equal to 0.027 percent and the balance Fe. In the annealing and heat treatment process, heating speed is strictly controlled, and the longitudinal shearing splitting disc blade is obtained through quenching by adopting quenching liquid with special components. The longitudinal shearing splitting disc blade has the advantages of being good in tenacity and wear resistance, not likely to deform in the machining process, low in defective percentage and the like.

Owner:安徽华天机械股份有限公司

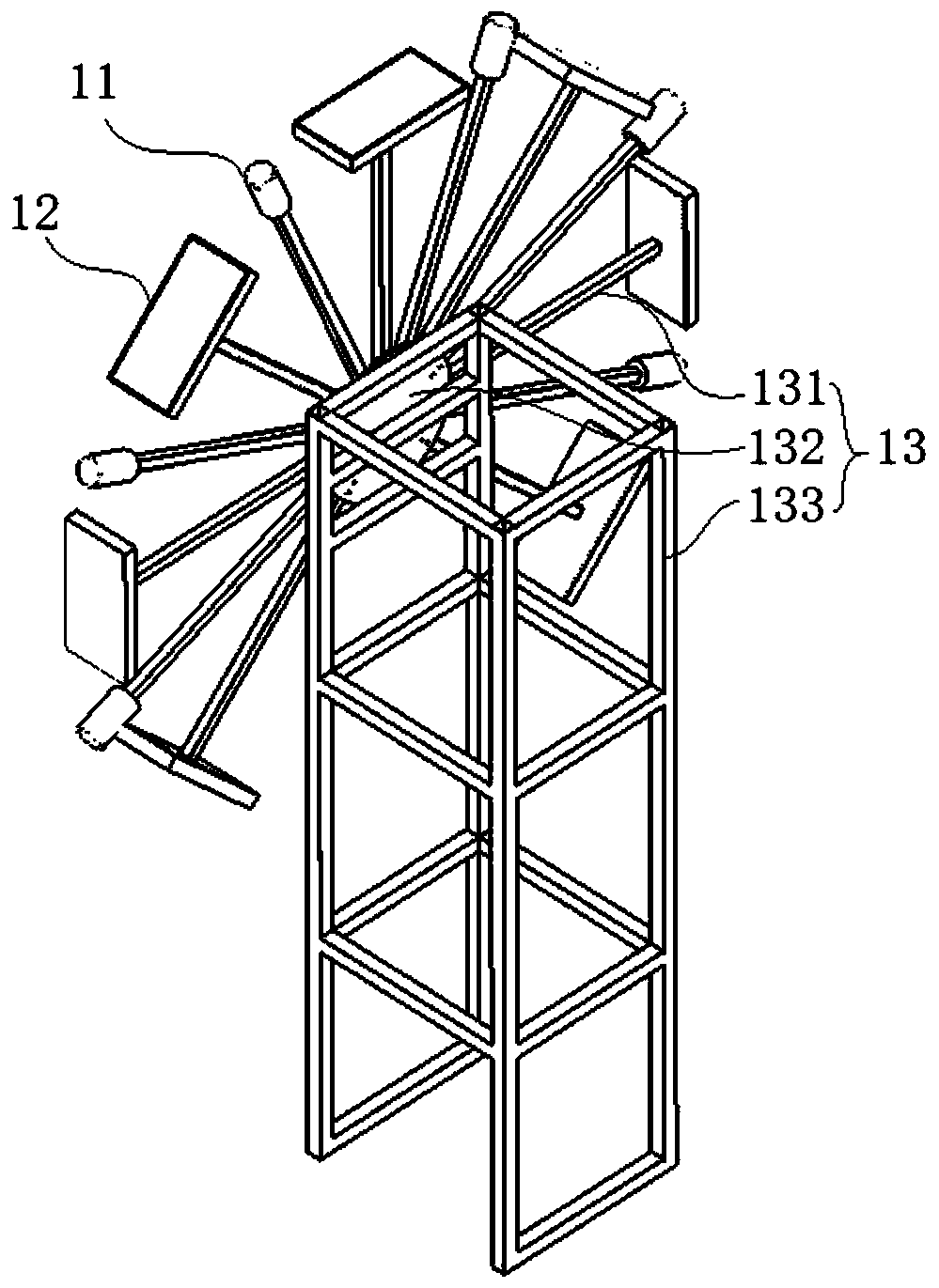

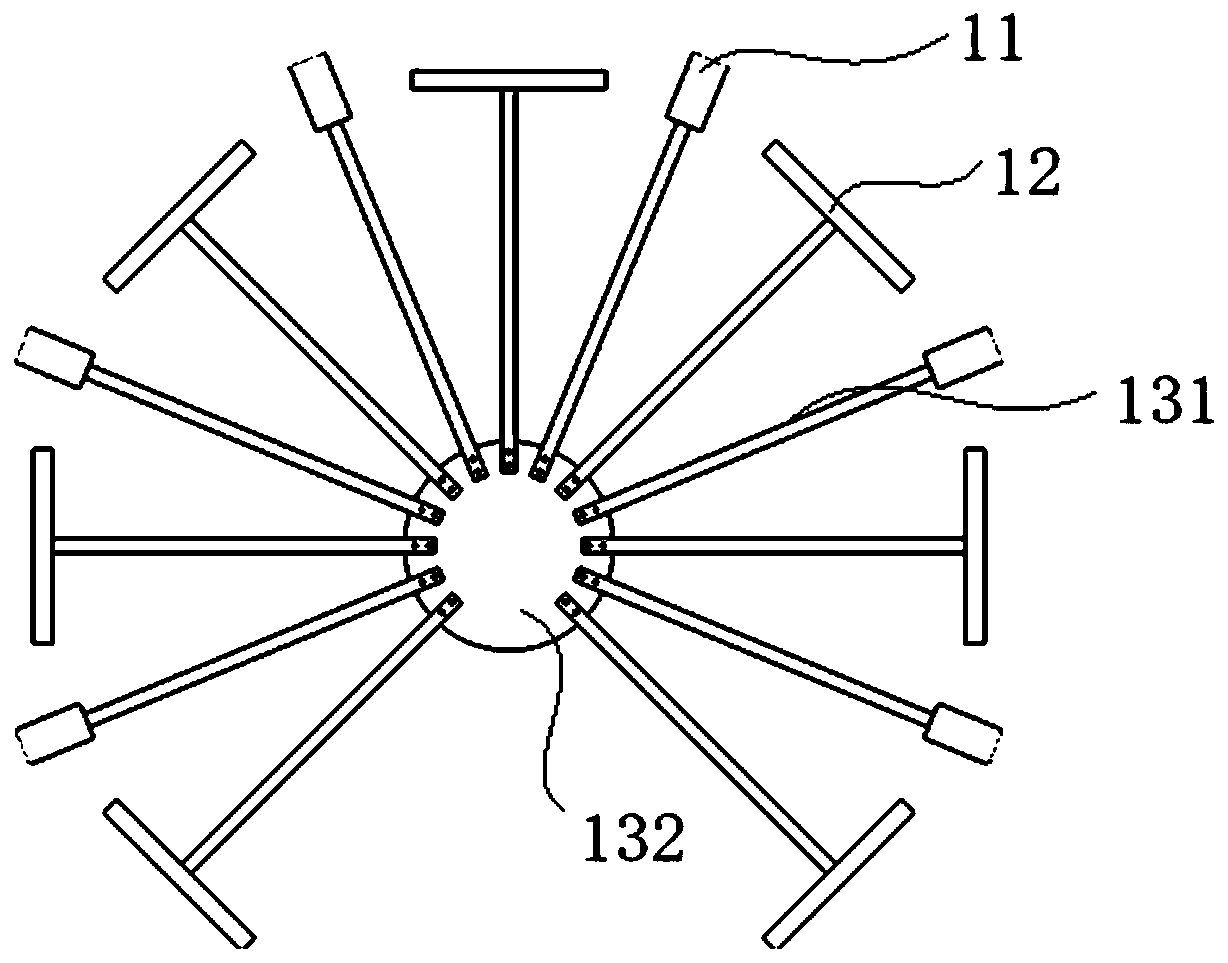

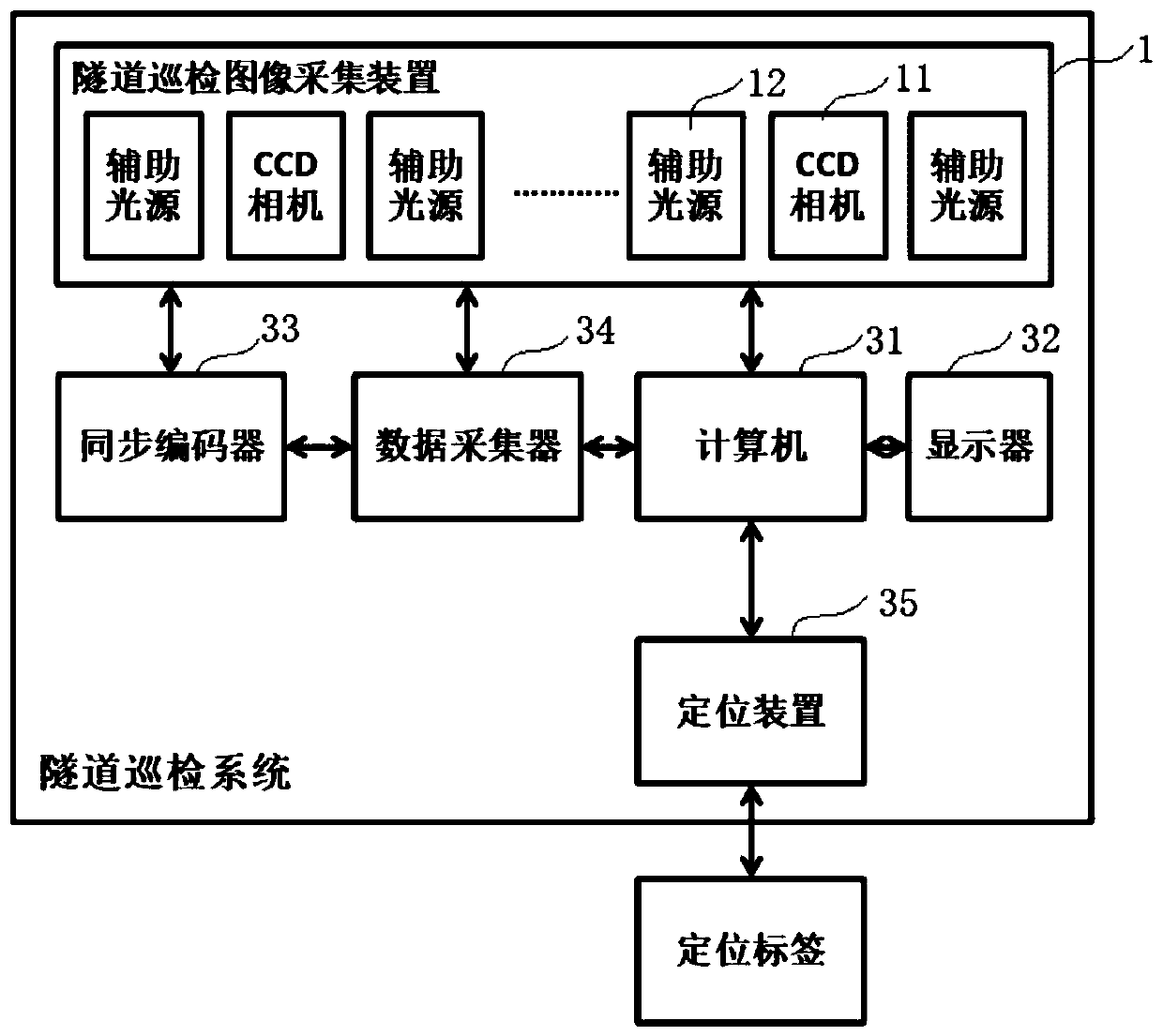

Tunnel inspection image acquisition device and tunnel inspection system

PendingCN110487816ANot easily deformedReduce difficultyMining devicesOptically investigating flaws/contaminationPhysicsWork status

The invention discloses a tunnel inspection image acquisition device and s tunnel inspection system. The tunnel inspection image acquisition device comprises a plurality of CD cameras, a plurality ofauxiliary light sources, and a fixed bracket, wherein the CD cameras and the auxiliary light sources are fixed on the fixed bracket, and fixing positions of the plurality of CCD cameras are arranged on the same circular ring; in a working state, the center of the circular ring is arranged at the circle center of a tunnel so as to ensure that the distances from the plurality of CCD cameras to a tunnel inner lining are identical, and the overall photographic angle of the plurality of CCD cameras cover the range of the tunnel inner lining. According to the tunnel inspection system, the tunnel inspection image acquisition device is arranged on a flaw detection mobile platform and cooperates with a computer, a display, a synchronous encoder and a data collector to perform synchronous photographing, disease identification, real-time stitching and display of the tunnel. The tunnel inspection image acquisition device and the tunnel inspection system have the technical features of wide detection range, fast detection speed and high timeliness.

Owner:SHANGHAI ORIENTAL MARITIME ENG TECH CO LTD

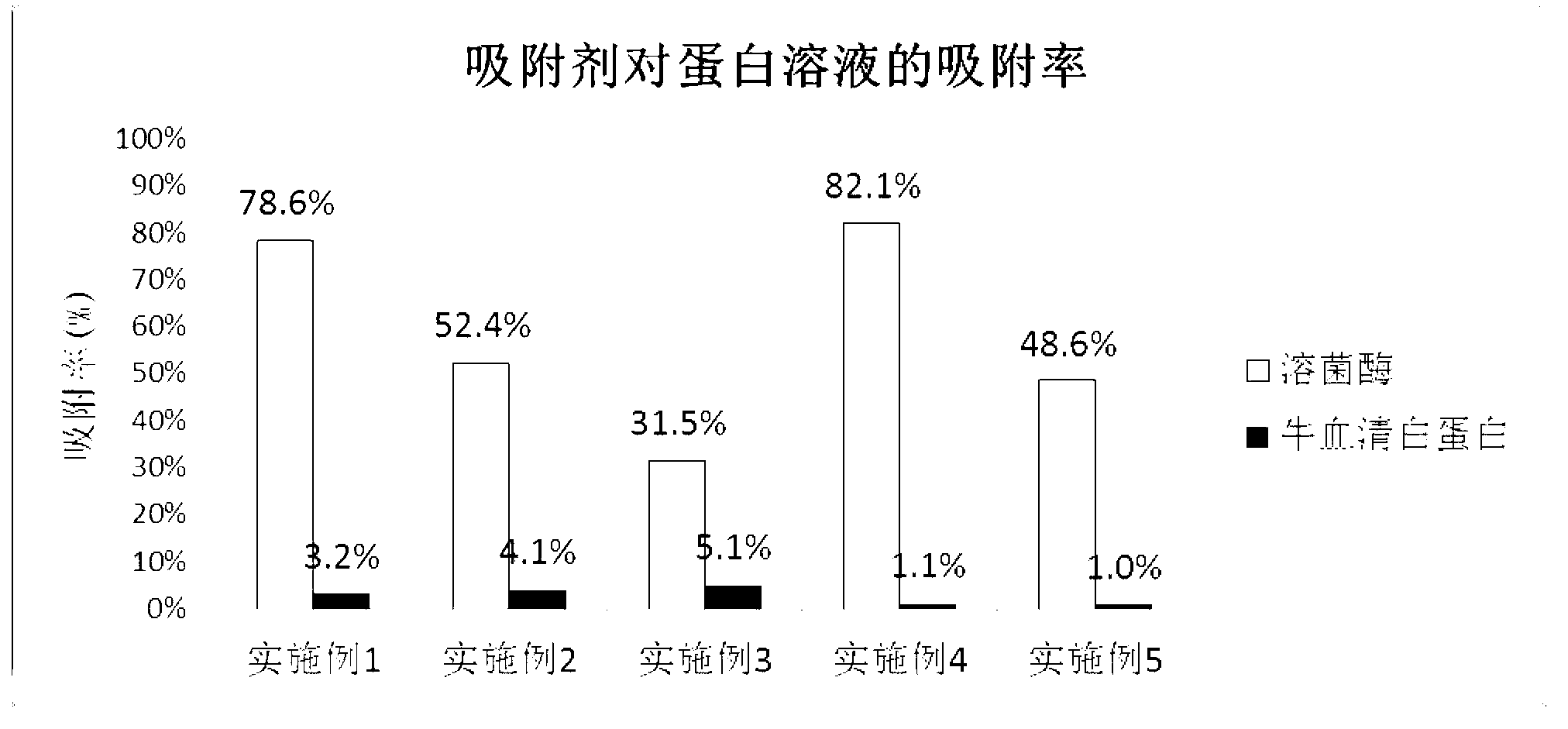

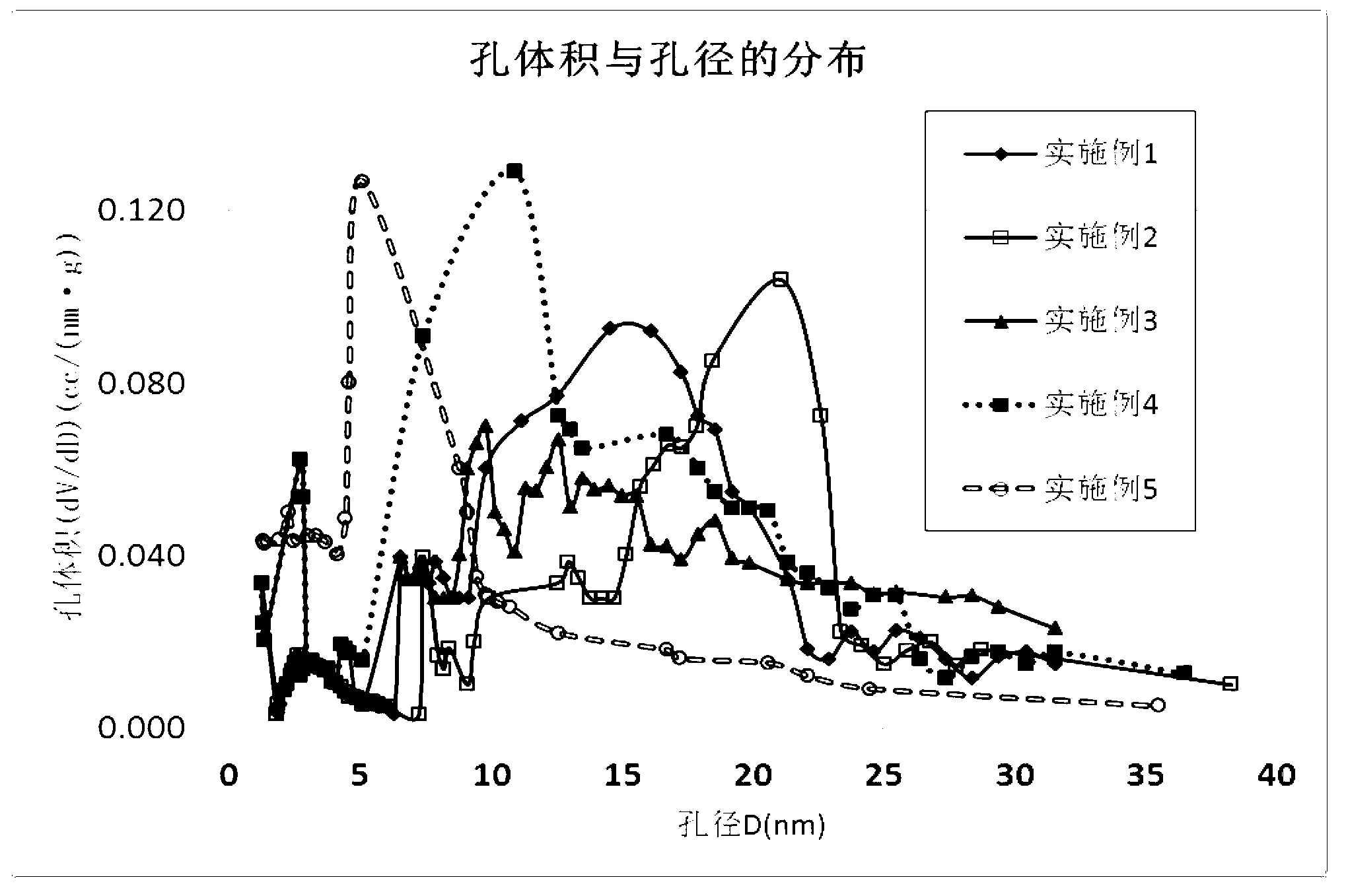

Porous cellulose microsphere adsorbent used for blood perfusion and preparation method thereof

ActiveCN102794161ANot easy to swellNot easily deformedOther chemical processesOther blood circulation devicesChemistryCellulose

The invention relates to a porous cellulose microsphere adsorbent used for blood perfusion and a preparation method thereof. According to the porous cellulose microsphere adsorbent, the grain sizes of prepared porous cellulose microspheres are 0.1-2mm, the inner hole sizes of the porous cellulose microspheres are mainly distributed in a range of 5nm-40nm, the specific surface area is 400-1,000m<2> / g, and the operating pressure capable of being resisted is 7-15bar. The preparation method is characterized by comprising the following steps of: obtaining the porous cellulose microspheres by utilizing an inverse suspension system, and then obtaining the porous cellulose microspheres capable of resisting the operating pressure of 7-15bar through cross linking, wherein the porous cellulose microspheres can be used as a carrier of a biomedical material or used as an adsorbent material for the blood perfusion.

Owner:重庆希尔康血液净化器材研发有限公司

Belt pulley powder metallurgy formulation and process

ActiveCN104759614ANot easily deformedReduce use noiseTurbinesOther manufacturing equipments/toolsPowder metallurgyNickel

The invention discloses a belt pulley powder metallurgy formulation. The belt pulley powder metallurgy formulation is composed of the following ingredients (mass percentage): 0.3-0.7% of graphite, 1.5-2.5% of copper powder, 0.6-1.0% of zinc stearate, 0.1-0.3% of sulphur, 0.3-1.5% of nickel powder, 0.3-1.0% of molybdenum powder, and the rest is iron powder; the invention further discloses a process for preparing the belt pulley powder metallurgy formulation. The process comprises the following steps of mixing materials, pressing, sintering, cooling, shaping, removing oil, blasting sands, and blackening. In the formulation and the method, the formulation is reasonable, the belt pulley is proper in hardness, the process is simplified, the production efficiency is high and the production cost is low.

Owner:ANHUI HENGJUN POWDER METALLURGY TECH

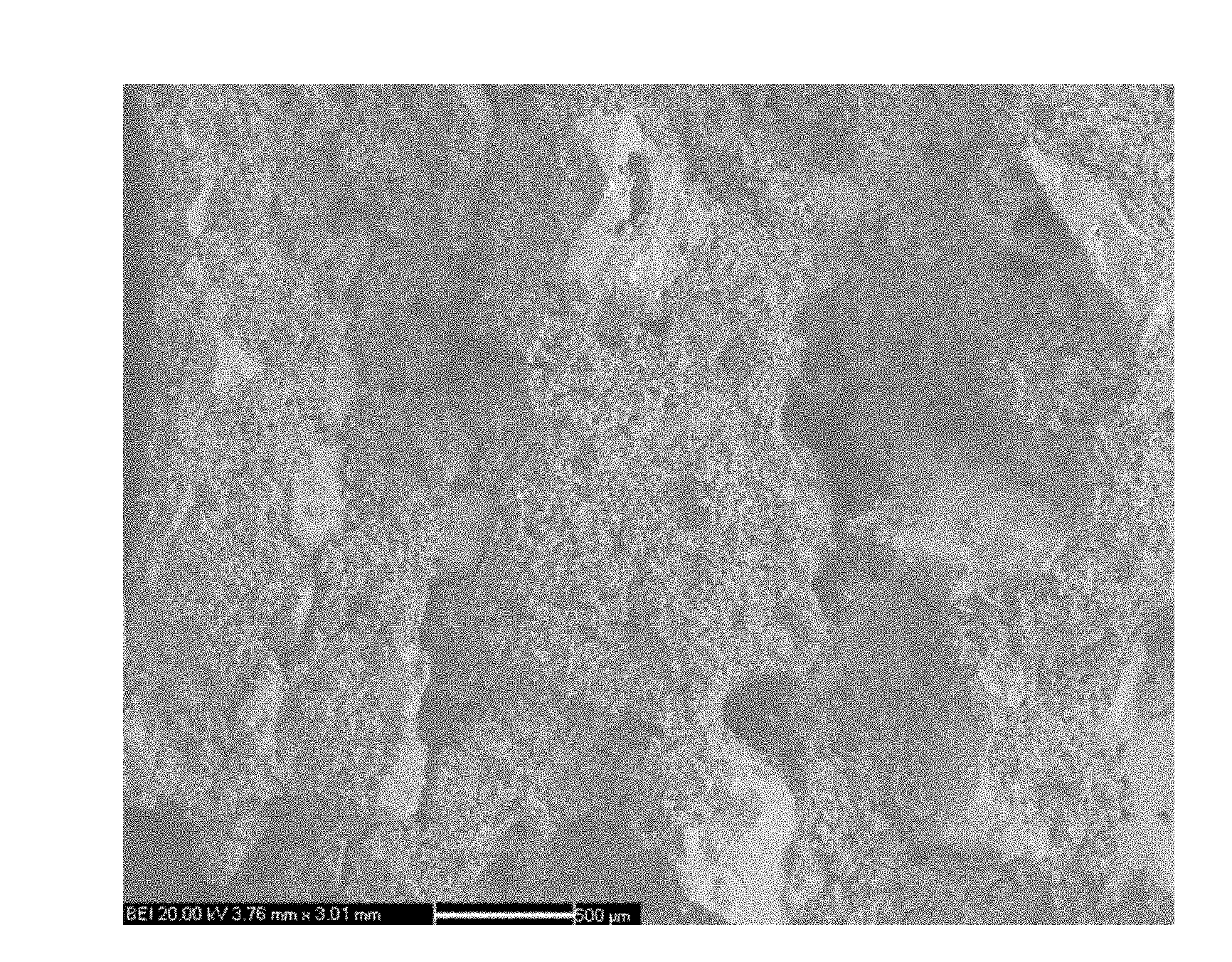

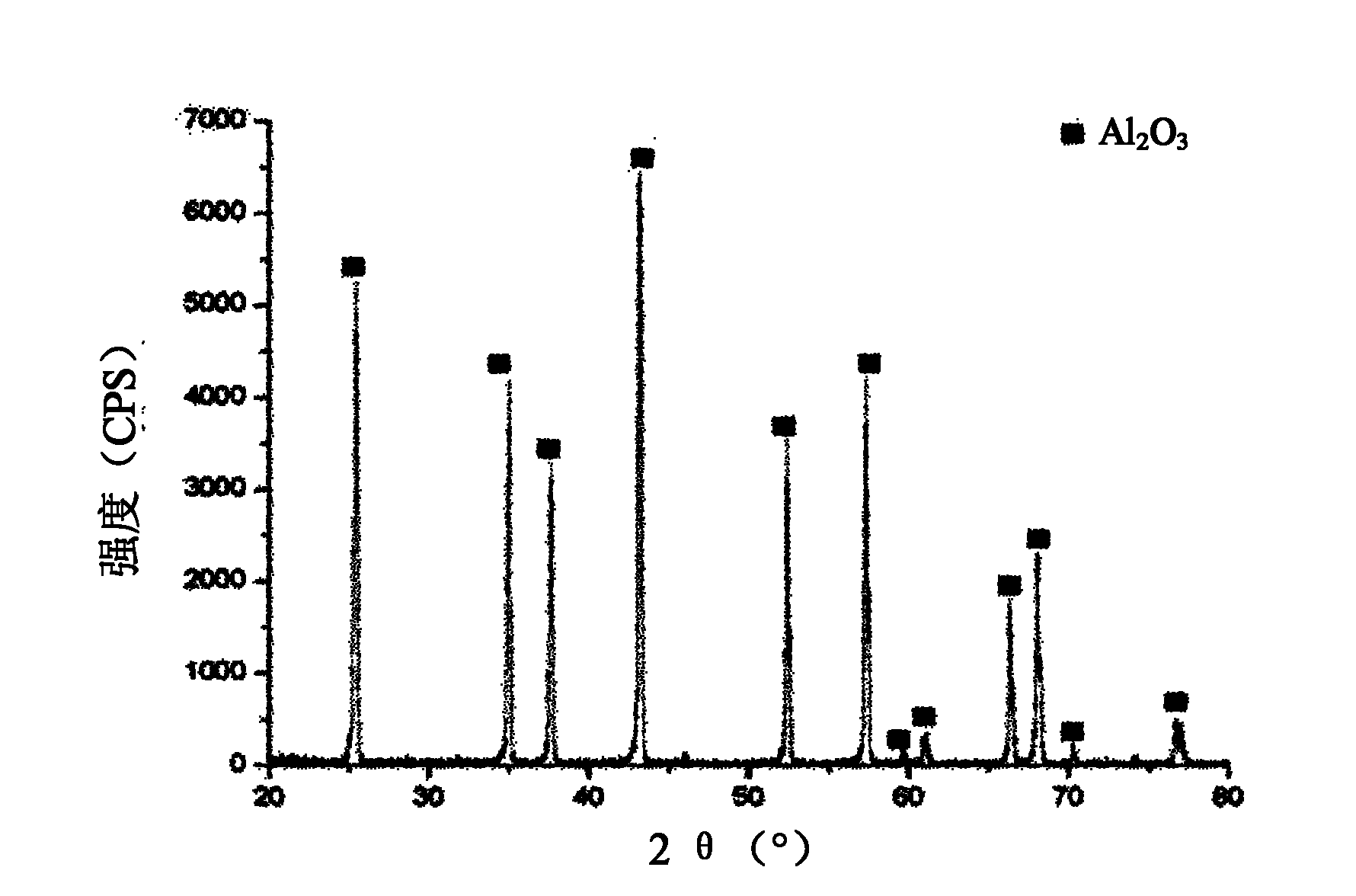

Aluminasol bonded alumina mould case and manufacturing method thereof

ActiveCN102029353AHigh dimensional accuracyNot easily deformedFoundry mouldsFoundry coresDefoaming AgentsScanning electron microscope

The invention discloses an aluminasol bonded alumina mould case and a manufacturing method thereof. The slurry of the alumina mould case comprises aluminasol, alumina powder, a mineralizing agent, a dispersing agent, a defoaming agent and a moisturizing agent. In the invention, the alumina mould case is manufactured by using a molten mould precision casting process. The aluminasol bonded alumina mould case of the invention fully utilizes the characteristics of the two materials of aluminasol and alumina at low temperature and high temperature, the morphology of the section of the manufacturedmould case is observed under a scanning electron microscope, and the section has obvious layering structure. The layering structure occurred in the aluminasol bonded alumina mould case is caused by different particle sizes of alumina sands connecting two adjacent layers of the slurry, which is beneficial to interlayer bonding. Thus, the strength of the mould case is increased, the air permeability of the mould case is also increased, and thus, the mould case has enough strength and air permeability when the mould case is used at high temperature.

Owner:BEIHANG UNIV

Production method of ecology homestead wood floor

InactiveCN101337367AGood stabilityNot easily deformedWood working apparatusWear resistantEnvironmental resistance

The invention discloses a method for producing ecological homestead solid wood flooring. The method comprises the steps of taking a reinforced plate as a base material; slicing; grooving; sealing edges; sanding; filling putty; priming; printing decorative designs; applying primer and finishing coat, etc. The ecological homestead solid wood flooring has the advantages of good stability, less possibility of deformation, clear texture, the same effect as solid wood flooring, strong paint surface adhesive force, wear-resistant flooring surface and good shock resistance. The ecological homestead solid wood flooring maintains the artistic and environment-friendly characteristics of the solid wood flooring, protects precious wood resource, greatly reduces production cost and creates the concept of the regeneration of solid wood flooring.

Owner:浙江永吉木业有限公司

Water dispersion type emulsion of crylic acid, preparation method and usage

InactiveCN1563123ANot easily deformedLow costIon-exchange process apparatusFibre treatmentIonIon exchange

The invention relates to a water dispersible type polyacrylic emulsion whose emulsoid surface has functional group, its preparation method and application. Said emulsion is made up by using (by weight portion) acrylic acid 100, butyl acrylate 180-400, methyl methacrylate 80-160, vinyl acetate 10-20, acrylonitrile 0-10, deionized water 250-780 and radical initiator 0.5-3 through the processes of reaction and polymerization. Its preparation method includes the following steps: firstly, using 1 / 3-2 / 5 of mixed monomer, making pre-emulsification, regulating pH value to 4-6, heating to 74-83 deg.C, making partial radical initiator produce initiation reaction, then drop-adding residual mixed monomer, at same time adding initiator to make reaction. Said polyacrylic emulsion only has need of coating, it can make the reactive acrylic resin into reactive film adhered to and covered over the surface of carrier so as to form the material with ion-exchange function. Its ion-exchange performance is not influenced by arrier property.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

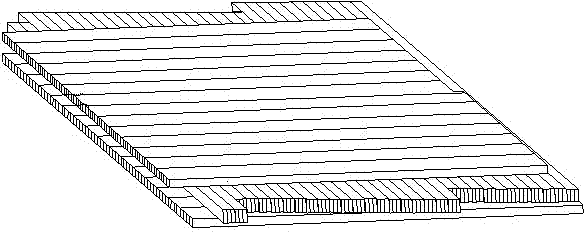

Vertical recombined hot-pressed plywood and its production method

InactiveCN102294713ANot easily deformedNot easy to delaminate and degummingWood veneer joiningWood layered productsEngineeringHot press

Vertical recombined hot-pressed plywood and its production method, the core layer of the plywood is a plurality of single layers superimposed and pasted together, and the single layers are all composed of side-by-side long strips pasted together, and the long strips are cut along the longitudinal direction. Formed by plywood, the veneer layers of the long strips in a single layer are all perpendicular to the surface layer and the bottom layer, and the angles between the strips in adjacent single layers are α, 0°

Owner:陈琳

Vibration dust-removal type cloth bag dust remover

InactiveCN108499255AImprove the effectNot easily deformedDispersed particle filtrationEngineeringVibration motor

Owner:JIANGSU LINGFULONG ENVIRONMENTAL ENG CO LTD

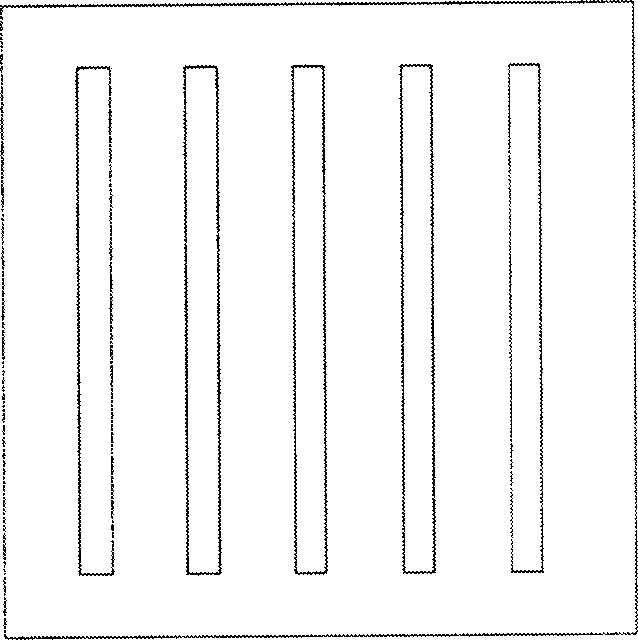

Vaporization coating template and application thereof

ActiveCN1865486ASimple structureNot easily deformedVacuum evaporation coatingSputtering coatingCeramicMetal

The invention discloses a formwork in the deposition technology and using method of RGB preparing patterned full-color display organic electroluminescent element, which comprises the following parts: limit formwork base plate and barrier, wherein the base plate material is selected from glass, metal or ceramics; the barrier material is selected from metal, magnetic material. The invention is simple to manufacture and operate as well as clean, which isn't easy to deform.

Owner:BEIJING VISIONOX TECH

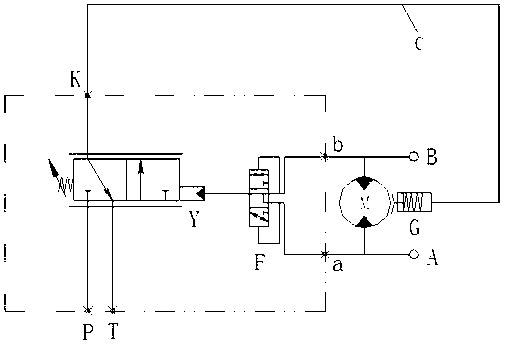

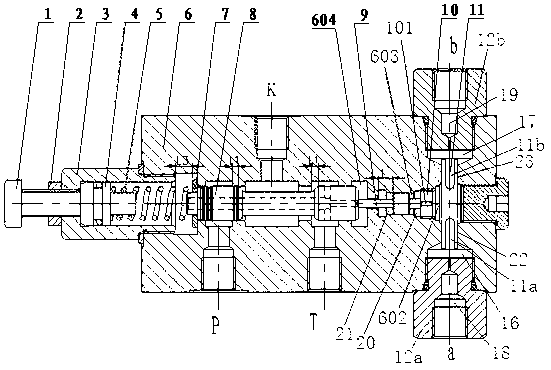

Shuttle valve, shuttle valve driving type device, winding drum brake cylinder control loop and crane

ActiveCN102889398ANot easily deformedReliable performanceMultiple way valvesHoisting equipmentsDrum brakeOil pressure

The invention relates to a shuttle valve which comprises a valve rod type valve core (11), when the output end of the shuttle valve is communicated with one of a first input end and a second input end; and one end face of the valve core and an inner wall surface, which is corresponding to one end of a valve cavity form an end face seal, and the periphery surface of the valve core (11) and an inner periphery surface of the valve cavity corresponding to one section form a cylindrical surface sealing, and an output end and the other one of the first input end and the second input end are mutually closed through the end face seal and the cylindrical surface seal. In addition, the invention also provides a shuttle valve driving type device comprising the shuttle valve, a winding drum brake cylinder control loop and a crane. The shuttle valve provided by the invention adopts a unique valve rod type valve core, the double seal is formed in a shuttle valve working process through an end face seal and the cylindrical surface seal, and the shuttle valve is capable of effectively working in a hydraulic system with relatively higher oil pressure; and the shuttle valve can effectively receive impaction and is not easy to transform, the service performance is reliable, the sealing property is relatively better, and the service life of the products is observably prolonged.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC

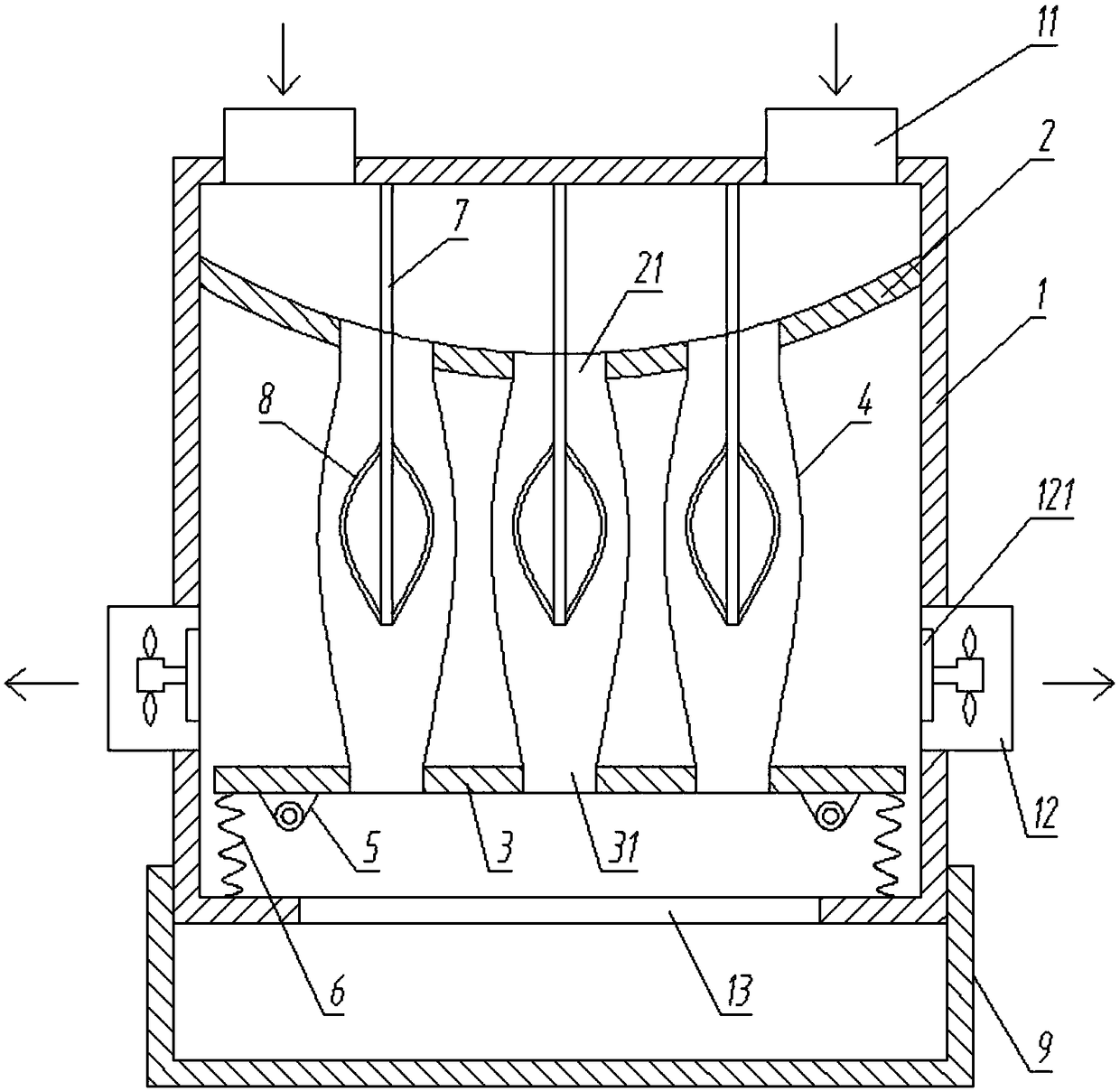

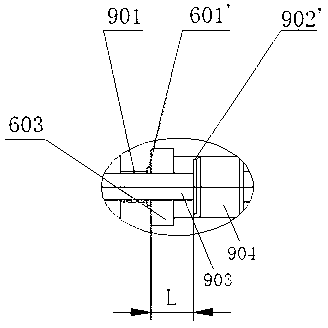

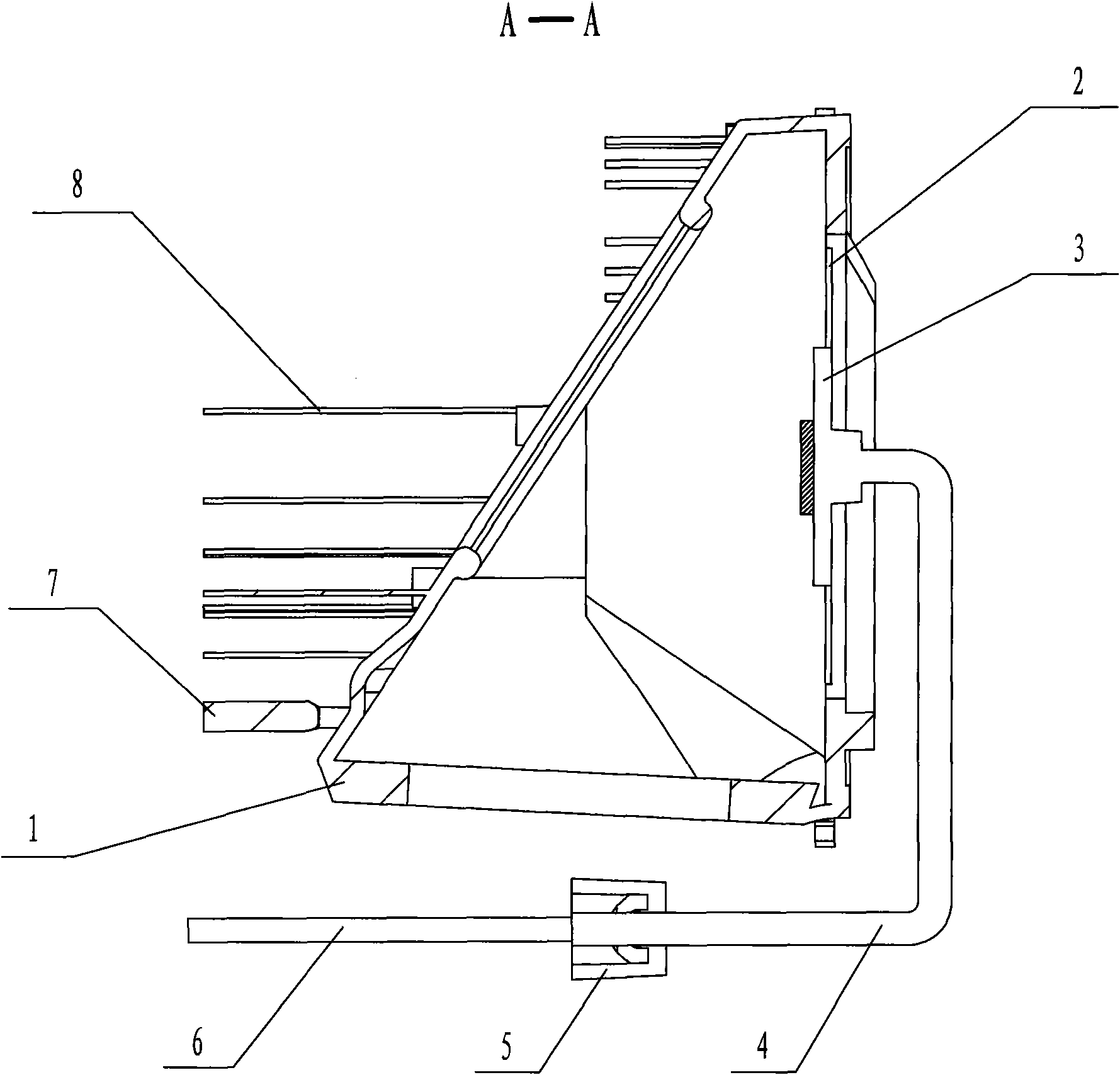

Method for casting cabin casts of aerogenerators

The invention discloses a method for casting cabin casts of aerogenerators, comprising the steps of mould manufacture, the manufacture of sand moulds and moulding by pouring. During the manufacture of sand moulds, a bottom pouring type pouring system is adopted; an ingate II (2) is arranged in a round hole of a main bearing on the bottom surface of a cast mould cavity; an outer sprue is a quantitative ladle stopper pouring sprue; the ratio of cross-sectional areas of a sprue I to a side runner to a sprue II to an ingate I to the ingate II is (0.20 to 0.80) to (1.80 to 2.60) to 1 to (4.0 to 6.0) to (2 to 4); during the moulding by pouring, the taphole temperature of iron liquor is from 1430 DEG C to 1500 DEG C; the magnesium explosion time is from 1.20 seconds to 4.50 seconds; the pouring temperature is controlled from 1275 DEG C to 1370 DEG C; the pouring time is from 30 seconds to 70 seconds; and then a cast (1) is obtained. Compared with the prior art, the method ensures that a large cast is not easy to deform or to produce a shrinkage hole, shrinkage porosity or entrapped slag, and the rate of finished products is high.

Owner:宁波日星铸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com