High-wear-resistant wood-plastic composite floor and preparation method thereof

A composite floor, high wear-resistant technology, applied in the field of decoration materials, can solve the problems of poor texture of reinforced composite floor, formaldehyde-containing and unenvironmental protection, etc., and achieve the effect of low cost, simple preparation method, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

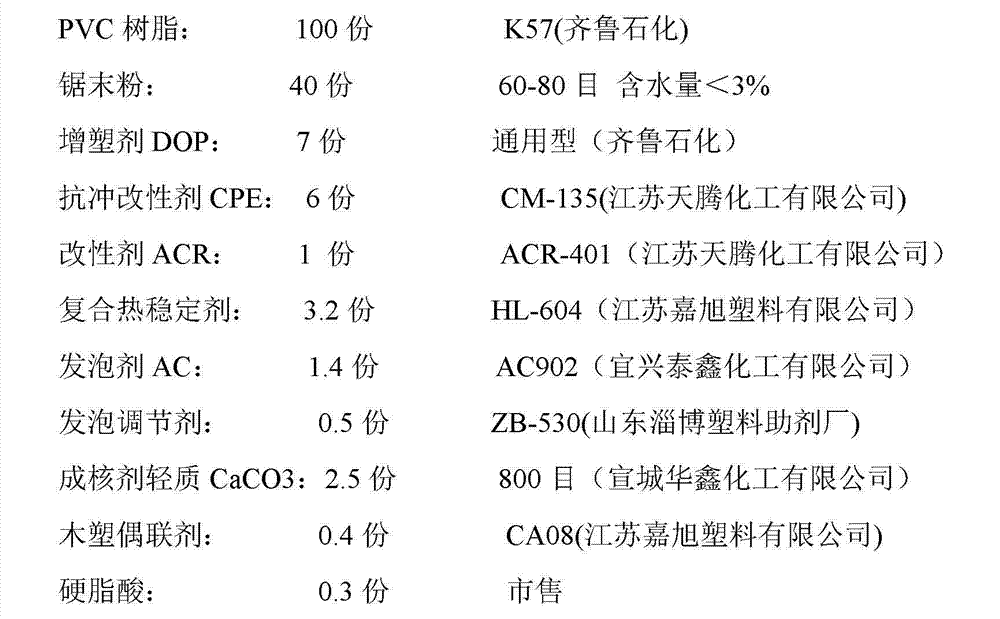

[0022] Example 1 Preparation of wood-plastic composite substrate

[0023] Weigh the following components in proportion:

[0024]

[0025] The sawdust powder is first stirred and dried (open) in a high-speed mixer (preheating temperature 102°C) for 12 minutes, so that the moisture content of the sawdust powder is less than 0.3%, and then slowly add metered broken wood-plastic coupling agent for modification , stirring time is 3-5 minutes. Add respectively PVC resin, plasticizer, impact modifier CPE, modifier ACR, composite thermal stabilizer, foam regulator, blowing agent AC, nucleating agent and stearic acid according to the weight parts and continue stirring for 6 Minutes, then the discharge is transferred to the storage tank, and then the mixture is added to the conical twin-screw extruder production line for extrusion to produce plastic-wood composite substrates. Among them, the twin-screw extrusion production line has different functions and the temperature settings a...

Embodiment 2

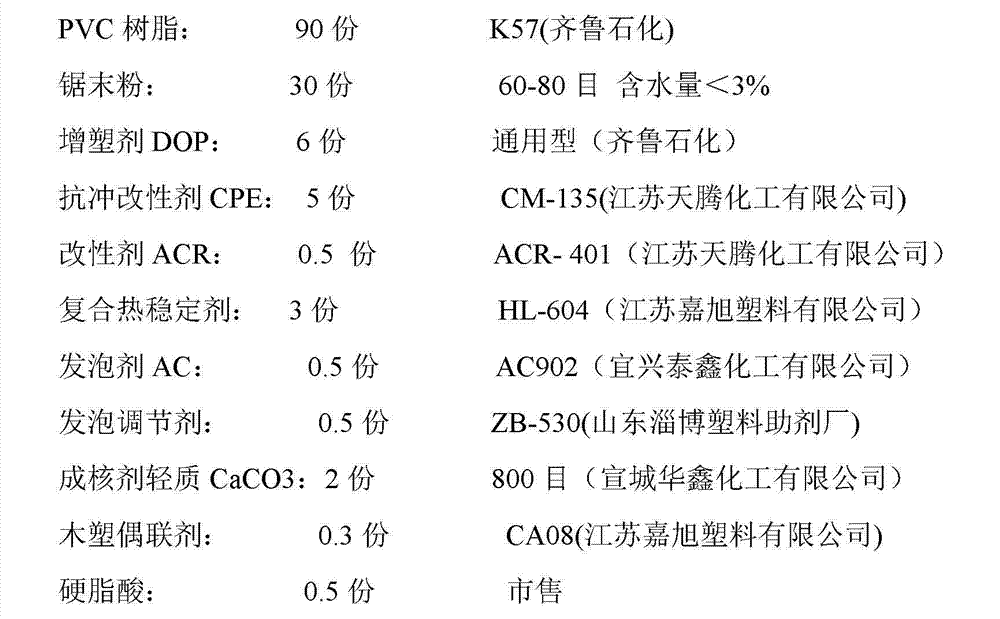

[0028] Embodiment 2 prepares plastic-wood composite substrate

[0029] Weigh the following components in proportion:

[0030]

[0031] The sawdust powder is first stirred and dried (open) in a high-speed mixer (preheating temperature 102°C) for 12 minutes, so that the moisture content of the sawdust powder is less than 0.3%, and then slowly add metered broken wood-plastic coupling agent for modification , stirring time is 3-5 minutes. Add respectively PVC resin, plasticizer, impact modifier CPE, modifier ACR, composite thermal stabilizer, foam regulator, blowing agent AC, nucleating agent and stearic acid according to the weight parts and continue stirring for 6 Minutes, then the discharge is transferred to the storage tank, and then the mixture is added to the conical twin-screw extruder production line for extrusion to produce plastic-wood composite substrates. Among them, the twin-screw extrusion production line has different functions and the temperature settings are ...

Embodiment 3

[0034] Embodiment 3 prepares plastic-wood composite substrate

[0035] Weigh the following components in proportion:

[0036]

[0037]

[0038] The sawdust powder is first stirred and dried (open) in a high-speed mixer (preheating temperature 102°C) for 12 minutes, so that the moisture content of the sawdust powder is less than 0.3%, and then slowly add metered broken wood-plastic coupling agent for modification , stirring time is 3-5 minutes. Add respectively PVC resin, plasticizer, impact modifier CPE, modifier ACR, composite thermal stabilizer, foam regulator, blowing agent AC, nucleating agent and stearic acid according to the weight parts and continue stirring for 6 Minutes, then the discharge is transferred to the storage tank, and then the mixture is added to the conical twin-screw extruder production line for extrusion to produce plastic-wood composite substrates. Among them, the twin-screw extrusion production line has different functions and the temperature s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com