Patents

Literature

136results about How to "Moth proof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin and the like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

Foam cement insulation board containing industrial solid waste and preparation method thereof

he invention relates to a foam cement insulation board and a preparation method thereof, and provides a foam cement insulation board containing industrial solid wastes and a preparation method thereof. The foam cement insulation board is composed of a mixture A and a mixture B. The mixture A comprises 55-65% of cement, 10-20% of gypsum powder, 8 -15% of hydrogen peroxide,3-4% of a flocculant, 1-2% of a water reducing agent, 1-2% of a coagulant, 2-3% of a cement waterproof agent, 1-2% of lithium carbonate, 1-2% of fiber, and 1-2% of solid master batch. The mixture B comprises 35-47% of a base material, 35-39% of a magnesium chloride solution, 10-15% of magnesium oxide, 2-5% of a binding agent, 2-3% of industrial hydrogen peroxide, 1-2% of lanthanide rare earth and 5-7% of an additive. The Foam cement insulation board provided by the invention has advantages of fireproof, waterproof, light weight, compressive and flexural resistance and high strength, and effectively utilizes industrial solid waste, facilitates environmental protection, and truly realizes turning wastes into treasures.

Owner:ZHENJIANG ZHONGRUI ENERGY SAVING TECH

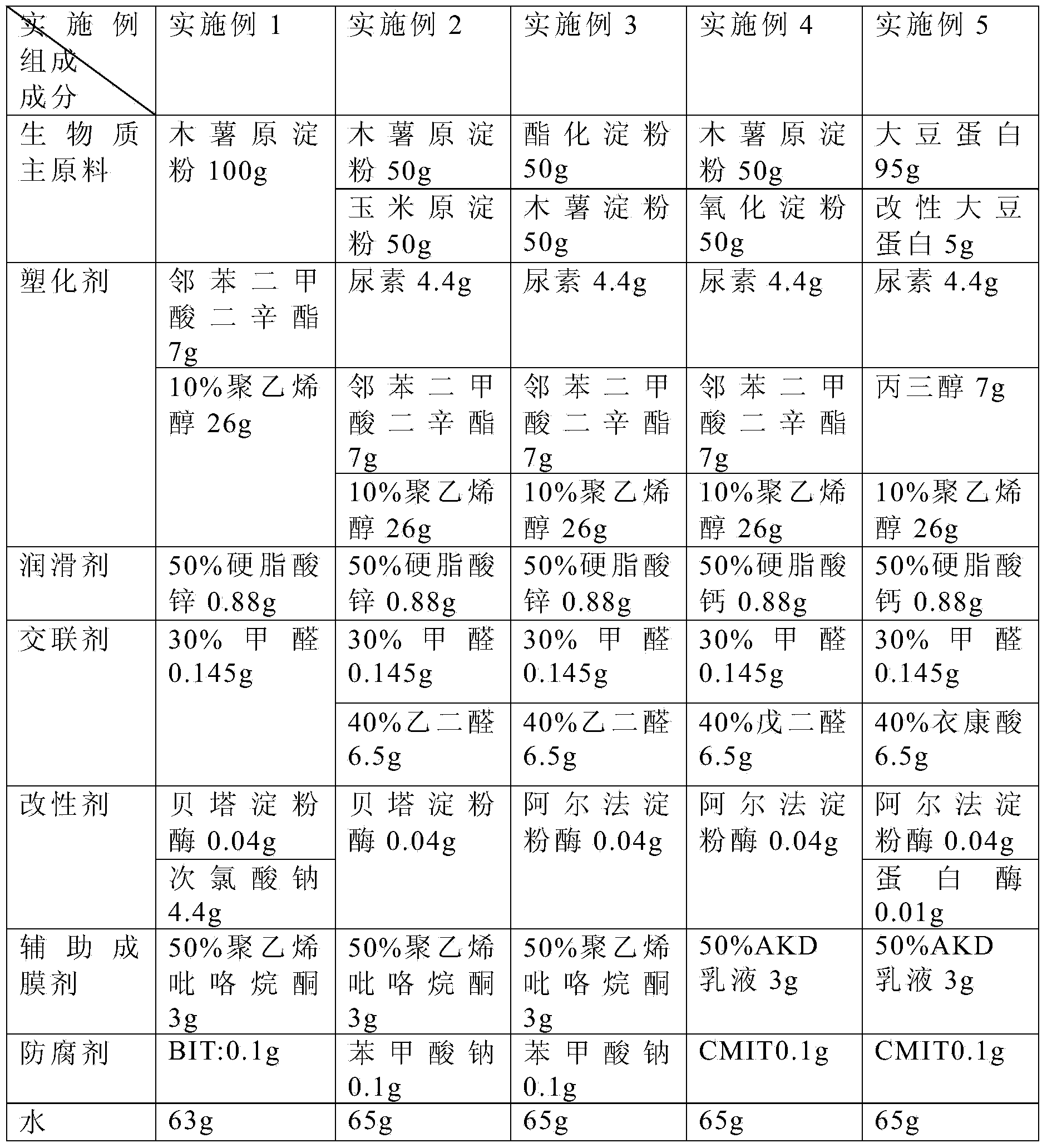

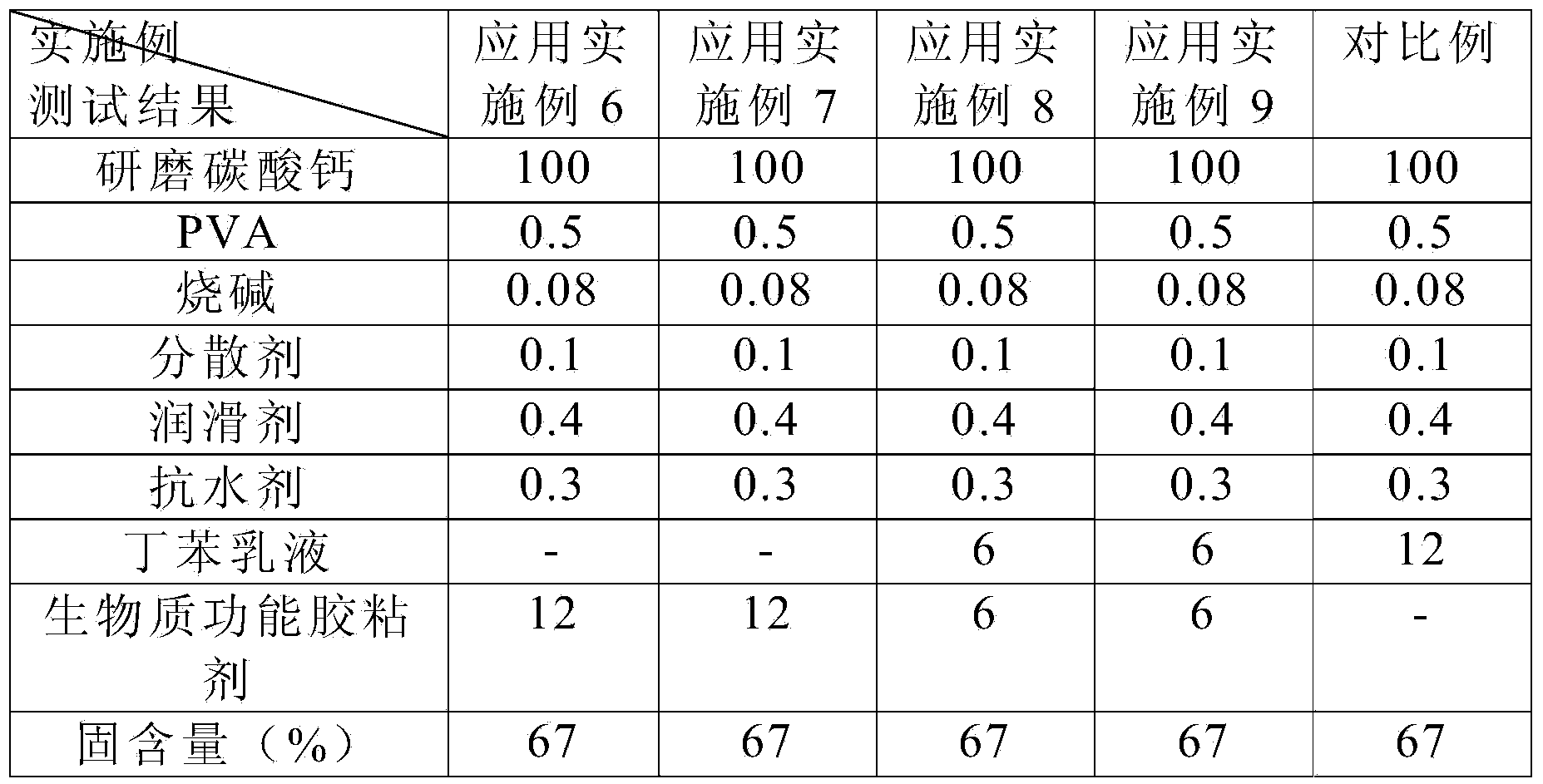

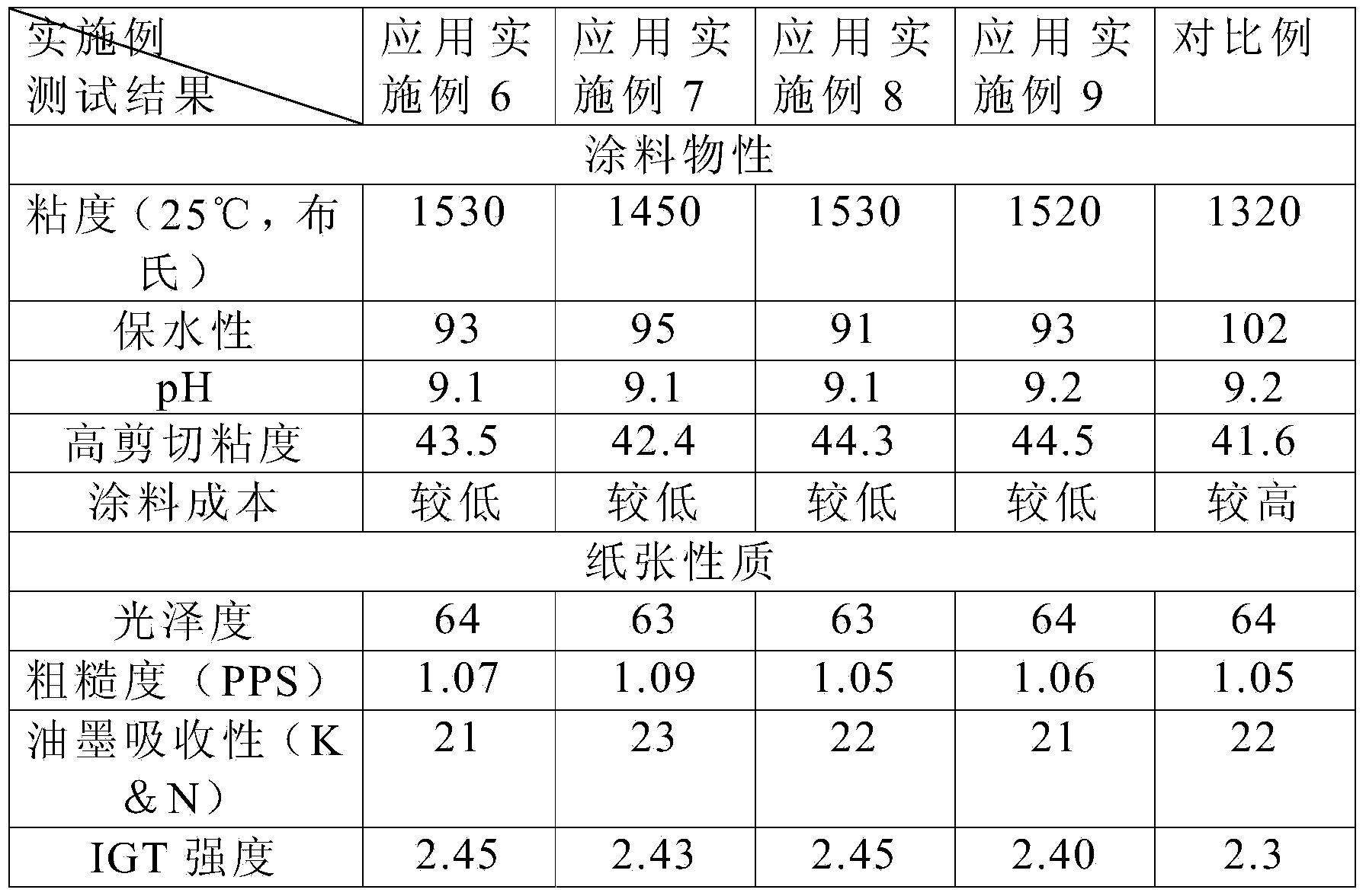

Starch based biomass functional adhesive and preparation method thereof

InactiveCN104164199AReduce manufacturing costHigh economic valueNon-macromolecular adhesive additivesProtein adhesivesAdhesivePlasticizer

The invention relates to a starch based biomass functional adhesive and a preparation method thereof, and is particularly applied to the field of papermaking. The biomass functional adhesive comprises the following components: 30-45% of a biomass main raw material, 5.5-22.5% of a plasticizer, 0.55-3.5% of a lubricant, 0.55-5.5% of a crosslinking agent, 0.01-5.5% of a modifier, 0.55-5.5% of an auxiliary film-forming agent, 0.1-0.55% of a preservative, 0.01-5.5% of a pH regulator and the balance of water. The preparation method is as follows: adding the biomass main raw material, the modifier and the water into a reaction kettle, heating to 60 to 100 DEG C for reaction; performing digestive treatment; adding the lubricant, the plasticizer and the crosslinking agent for reaction at 60 to 90 DEG C, then adding the preservative, adding the pH regulator and the auxiliary film-forming agent, mixing, discharging and filtering to obtain the biomass functional adhesive. The biomass functional adhesive has low cost and excellent adhesive performance.

Owner:NINGBO JIAHUA NEW MATERIAL TECH CO LTD

Wood-plastic composite material and prepration method thereof

The invention discloses a wood-plastic composite material and a preparation method thereof, and the wood-plastic composite material comprises the following raw materials according to the mixing ratio by parts by weight: 30-80 parts of modified fiber powder; 15-80 parts of plastics; 2-10 parts of phase solvent; 2-10 parts of lubricant; 0-10 parts of stabilizer; 0.2-1.0 part of antioxidant; 5-15 parts of filler; and 2-20 parts of flame retardant. Lignin is utilized for modifying fiber powder, then composition with the plastics is carried out, and a finished-product material is formed by extrusion. The preparation method can solve the problems of the compatibility of wood fibers with the thermoplastic plastics, the surface treatment technology of the raw materials by utilizing the lignin andthe like, realize the comprehensive utilization of the lignin and the waste plastics, be capable of replacing wood, increase the additional value of the lignin and solve the utilization problem of the lignin wastes. The manufactured wood-plastic composite material can significantly improve the mechanical performance, the tensile strength, the flexural strength and the impact resistance, and realize the industrial production of high-performance products, such as construction materials.

Owner:BEIJING FORESTRY UNIVERSITY

Aerated concrete wall material containing river silt and preparation method thereof

ActiveCN102910889AFireproofWaterproofCeramic shaping apparatusCeramicwareCompressive resistanceAluminium powder

The invention relates to an aerated concrete wall material and a preparation method thereof, in particular to an aerated concrete wall material containing river silt and a preparation method thereof. The aerated concrete wall material comprises the following main components in percentage by weight: 60-75% of river silt, 1-10% of cement, 13-28% of lime, 1-2% of gypsum powder, 6-10% of aluminum powder and 2-11% of foam stabilizing agent, and the sum of weight percentages of the components is 100%. In the invention, river silt dug out by regulating the Yangtze River can be effectively utilized, energy is saved, emission is reduced, the ecological environment is protected, and the processed aerated concrete wall material also has high compressive strength and high bending strength.

Owner:HUAHONG GROUP YIXING HUAHONG NEW WALL BUILDING MATERIALS

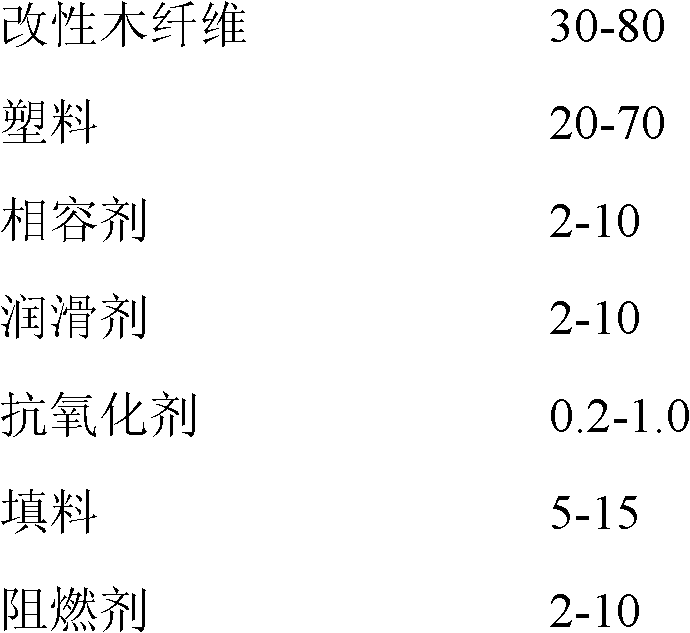

Wood plastic composite and preparation method thereof

InactiveCN102304290AImprove mechanical propertiesReduce consumptionRaw material divisionThermoplasticForest industry

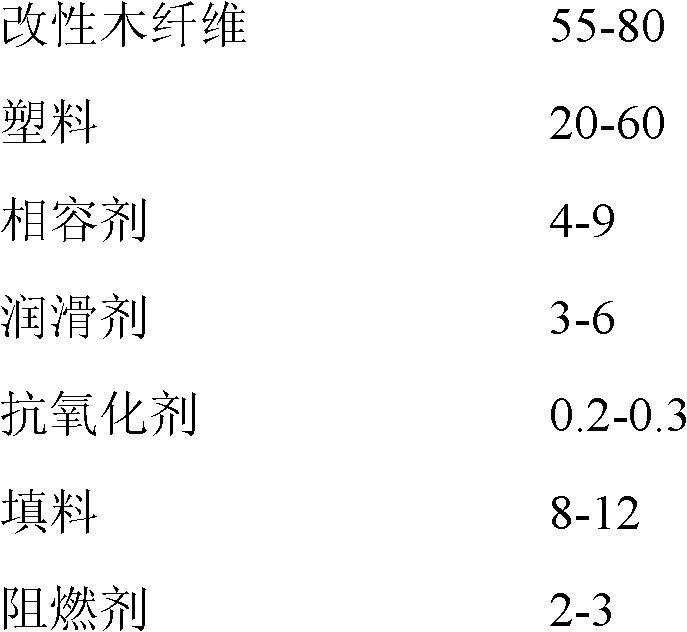

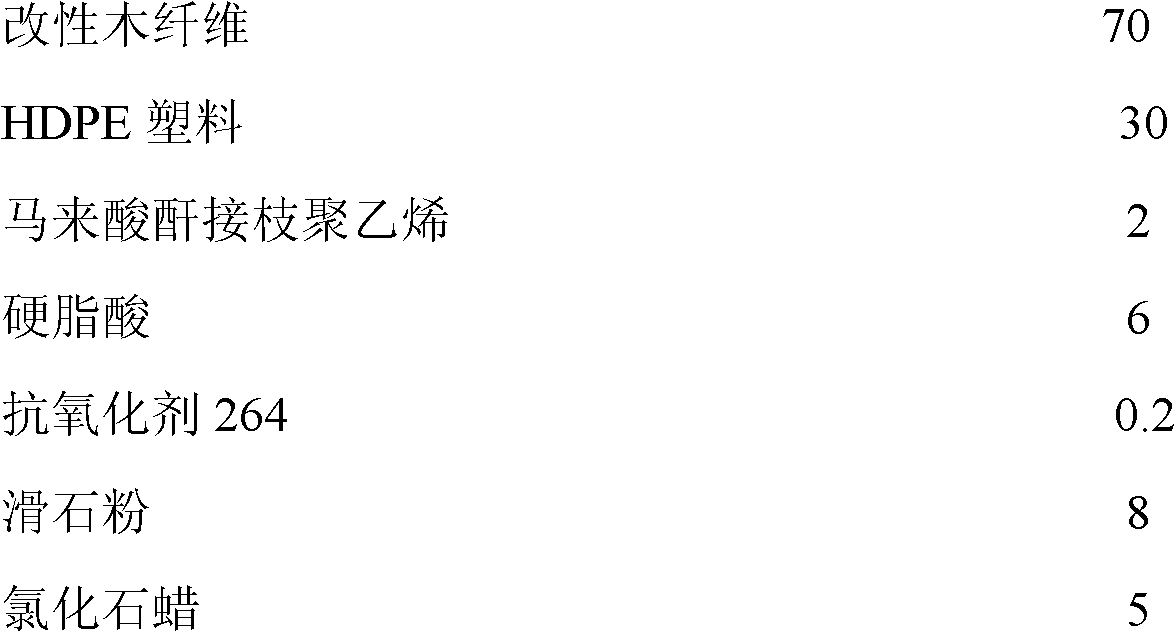

The invention discloses a wood plastic composite and a preparation method thereof. The wood plastic composite comprises the following raw materials according to parts by weight: 30-80 parts of modified wood fiber, 20-70 parts of plastic, 2-10 parts of compatilizer, 2-10 parts of lubricant, 0.2-1.0 part of antioxidant, 5-15 parts of filler and 2-10 parts of fire retardant. 'forestry three waste' wood wastes are prepared onto modified wood fibers with an explosion treatment method, wherein the modified wood fibers are mutually separated, and eh surface of the modified wood fibers is covered with lignin; then the modified wood fiber is compounded with plastic; and the product is extruded to form finished product material. According to the wood plastic composite, the technical problems of poor compatibility of wood fiber and thermoplastic plastics can be solved to realize the purpose of comprehensively utilizing the 'forestry three waste' wood and plastic, the wood can be omitted, and the additional value of the forest residue is increased. The wood plastic composite manufactured with the preparation method has high mechanical property, and strong tensile strength, bending strength and impact strength of composite material, and the industrial production of high-performance products, such as building engineering materials, can be realized.

Owner:BEIJING FORESTRY UNIVERSITY

Ink-absorbing quick-drying painting canvas

ActiveCN103741481AImprove antioxidant capacityNot easy to fadeFibre treatmentChemistryEconomic shortage

The invention discloses an ink-absorbing quick-drying painting canvas. The preparation method of the canvas comprises the following steps: (1) painting gel resin on the surface of fabric, drying in an oven with a temperature of 100 to 120 DEG C so as to obtain a gel resin layer; (2) painting prime paint on the gel resin layer, drying in an oven with a temperature of 90 to 100 DEG C so as to obtain a prime paint layer; (3) painting surface paint on the prime paint layer, drying in an oven with a temperature of 70 to 85 DEG C so as to obtain a surface paint layer, wherein during this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute; (4) painting ink-absorbing quick-drying paint on the surface paint layer, drying in an oven with a temperature of 70 to 85 DEG C, wherein in this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute. The ink-absorbing quick-drying painting canvas preserves the unique wash-painting effect of raw Xuan paper, overcomes the inherent shortages of raw Xuan paper, thus enlarges the application range and increases the collection value of wash paintings.

Owner:沭阳凤凰画材有限公司

High-strength magnesian coal ash clinker-free cement

The invention relates to high-strength magnesian coal ash clinker-free cement, which comprises the following raw materials in part by weight: 100 parts of coal ash, 30 to 40 parts of light roasting magnesium oxide, 10 to 15 parts of magnesium sulfate heptahydrate, 2 to 4 parts of calcium sulfate, ferrous sulfate or aluminum sulfate, 0.5 to 1.0 part of phosphoric acid and 50 to 100 parts of water. The high-strength magnesian coal ash clinker-free cement has the advantages that a large amount of coal ash is utilized, and produced wastes are used as production raw materials and are put into use, so that environmental pollution is reduced; and the product is long in service life and high in board strength, and is widely applied to wallboards, suspended ceilings, decorative materials and furniture.

Owner:湖北兆驰新材料有限公司

Autoclaved aerated concrete building block containing industrial solid waste and preparation method thereof

ActiveCN102786320AFireproofWaterproofSolid waste managementCeramicwareCompressive resistanceEnvironmental engineering

The invention relates to an autoclaved aerated concrete building block and a preparation method thereof, in particular to an autoclaved aerated concrete building block containing industrial solid waste and a preparation method thereof. The autoclaved aerated concrete building block containing industrial solid waste comprises, by weight percent, 35%-47% of base material, 35%-39% of magnesium chloride solution, 10%-15% of magnesium oxide, 2%-5% of binder, 2%-3% of industrial hydrogen peroxide, 1%-2% of lanthanide rare earth, and 5%-7% of additive. The autoclaved aerated concrete building block has the advantages of fire prevention, water proofing, moth prevention, lightness, crush resistance, bending resistance, high strength, moss avoidance and the like. The proportion of the materials determines the water proofing and moth prevention. The fire prevention meets the standard (class A) of nonflammable materials. The crush resistance is larger than 53Mpa. The bending resistance is larger than 80Mpa. In addition, the industrial solid waste is effectively utilized, wastes are utilized, environment is protected, and the wastes are turned into wealth.

Owner:HUAHONG GROUP YIXING HUAHONG NEW WALL BUILDING MATERIALS

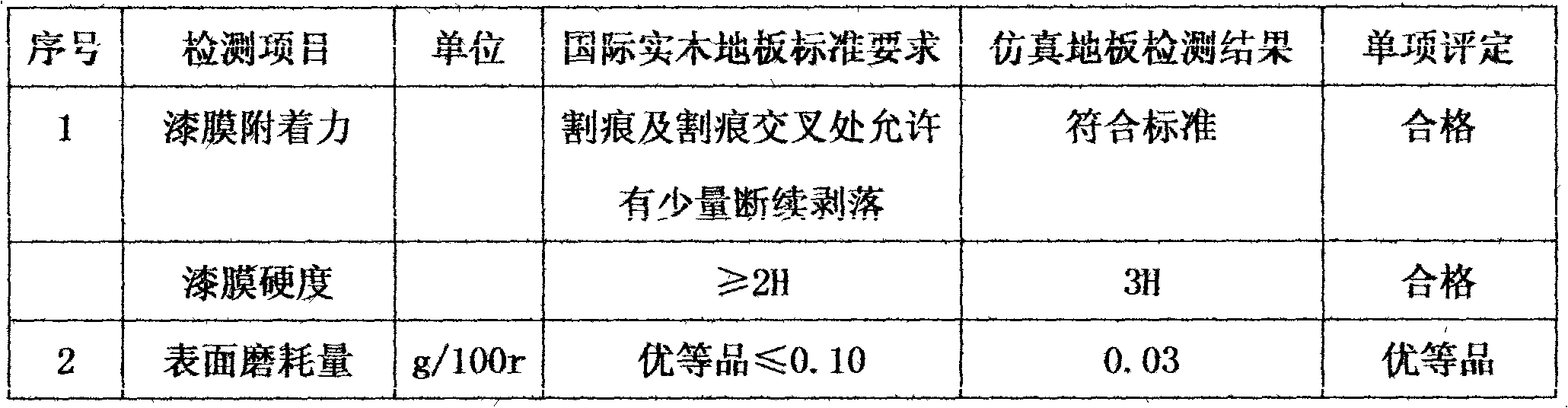

High-wear-resistant wood-plastic composite floor and preparation method thereof

ActiveCN102758518ANot easily deformedEasy to prepareSynthetic resin layered productsLaminationWear resistantSolid wood

The invention discloses a high-wear-resistant wood-plastic composite floor and a preparation method thereof. The high-wear-resistant wood-plastic composite floor sequentially comprises a wear-resistant layer, a solid wood face and a wood-plastic composite base material, wherein the wear-resistant layer is wear-resistant aluminium oxide paper. The high-wear-resistant wood-plastic composite floor disclosed by the invention has the characteristics of high wear resistance, environmental protection, economization, uneasy deformation, insect prevention and moth proofing and the like.

Owner:江苏辛巴地板有限公司

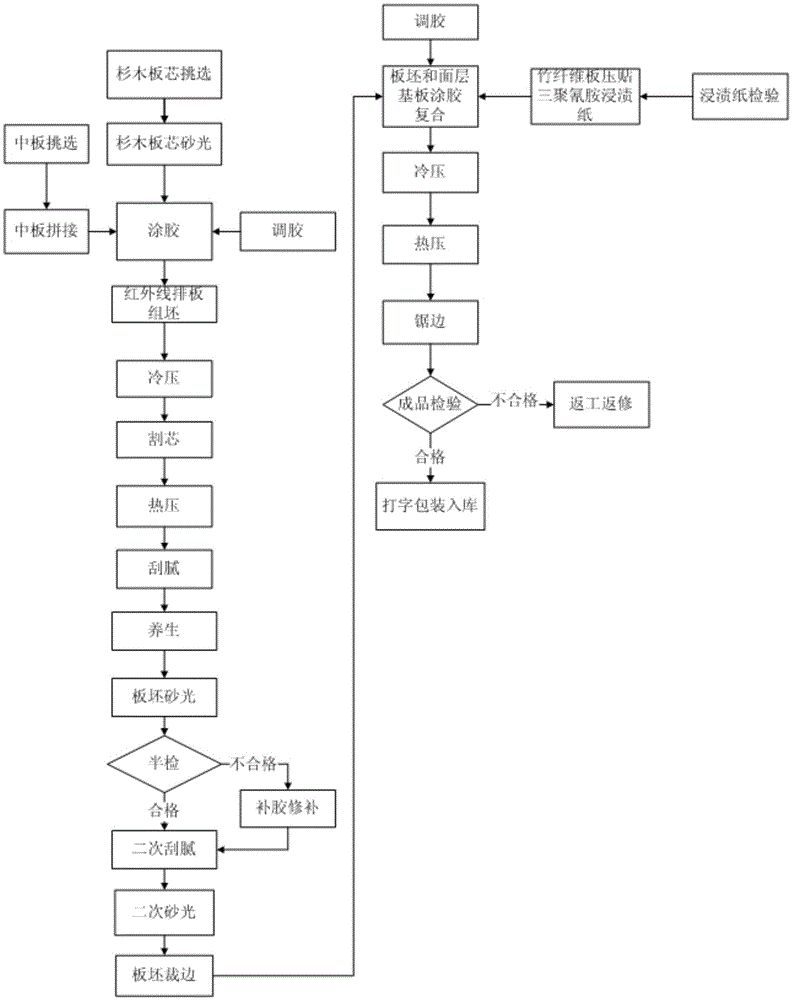

Novel solid ecological bamboo board and production process thereof

InactiveCN105415457AThe process is simple and reasonableShort production processOther plywood/veneer working apparatusWood veneer joiningEnvironmentally friendlySolid wood

The invention belongs to the field of board machining and provides a novel solid ecological bamboo board and a production process thereof. The novel solid ecological bamboo board comprises a cedarwood board core, middle boards, bamboo fiber boards and melamine impregnated paper. The upper surface and the lower surface of the cedarwood board core are covered with the middle boards through gluing and integrally pressed to form a board blank; the melamine impregnated paper is stuck to the bamboo fiber boards in a pressed mode to integrally form surface-layer substrates; the upper surface and the lower surface of the board blank are gelatinized and coated with the surface-layer substrates and integrally formed through hot pressing to obtain a finished product. The novel solid ecological bamboo board and the production process thereof have the advantages that 1, a novel assembly structure is adopted, and the hardness, nail-holding ability, static bending strength and surface evenness of the board are greatly improved; and 2, the bamboo fiber boards are adopted for the surface-layer substrates, the fracturing resistance and the thermocycling resistance of melamine ecological boards are greatly improved, and thus the melamine ecological board can meet the all-weather all-region using requirement; besides, the finished product is low in formaldehyde content, economical, environmentally friendly, and the advantages of water resistance, mould resistance, inflaming retarding, moth resistance and the like are achieved at the same time.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Method for manufacturing half-dry mold-pressed honeycomb carboards

InactiveCN102108655AReduce weightStress resistantSpecial paperPaper/cardboardZero emissionMachinability

The invention discloses a method for manufacturing half-dry mold-pressed honeycomb carboards, which comprises the following steps of: (1) preparing starch glue; (2) preparing mixed pulp; and (3) processing honeycomb carboards. In the method for manufacturing the half-dry mold-pressed honeycomb carboards, waste carboard paper, agricultural stalks, waste textiles and the like can be recycled. In the manufacturing method, the total solid content in the mixed pulp is about 50 percent; compared with a wet processing method, the method has the characteristics of energy conservation and water conservation; and compared with a thermosetting processing method, the method has the characteristics of no aldehydes, zero emission, no toxin, no pollution and the like. The honeycomb carboards processed by the method have the characteristics of light weight, strong compressive resistance, waterproofness, moistureproofness, rot resistance, anti-mildew, anti-moth, and fumigation-free moth removal, have excellent processability such as capacity of being sawed, nailed and glued and the like, and can be widely applied to products such as heavy duty pallets, heavy duty packing boxes, light walls, decorative boards, furniture and the like.

Owner:TIANJIN MINGTANG ENVIRONMENTAL PROTECTION TECH

Stone plastic floor

InactiveCN103642148AImprove waterproof and moisture-proof performanceGuaranteed StrengthFlooringWear resistantEngineering

The invention provides a stone plastic floor with environmental protection and wear resistant performances, beauty and low cost, thereby solving many problems existed in stone and wood floor. The prepared floor contains PVC material, therefore the product has good waterproof and moistureproof performances, and the skid resistance is improved compared to common stone floor; the invention combines calcium powder and PVC, thereby keeping floor strength and simultaneously increasing floor toughness without fracture; simultaneously, waste heat extruded by an extruder is used for carrying out coating, and the coating effect is good, and the wear resistance of the present invention is improved; the floor prepared by the material has environmental protection effect without pollution. The sheet material provided by the invention not only can be used for floor, but also can be used for furniture, interior wall and exterior wall decoration materials, etc. with insect preventing, deformation preventing and other performances.

Owner:孔祥利

Simulated marble slab and production method thereof

InactiveCN102700205AHard textureImprove wear resistanceNatural patternsSynthetic resin layered productsBuilding materialSubstrate surface

The invention relates to a marble slab, in particular to an artificial simulated marble slab and a production method of the artificial simulated marble slab. The invention aims to overcome defects of natural marble and provide the simulated marble slab which has low price, is light, is easy to pave, has no harm and pollution and can replace the natural marble. The simulated marble slab comprises a substrate layer. A priming paint layer, a marble pattern layer and a finish layer are sequentially arranged on the positive face of the substrate layer from bottom to top. The invention also aims to provide a production method of the simulated marble slab, which comprises the following steps of: selecting a substrate; tailoring the selected substrate to a required size; tenoning on tailored substrate; coating priming paint on the positive surface of the substrate; spraying natural marble patterns on the surface coated with the priming paint of the substrate; and coating finish on the surface sprayed with the natural marble patterns of the substrate. The simulated marble slab provided by the invention can be widely applied in multiple industries such as building material, advertisement, furniture, decoration and the like.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

Raw bamboo protective agent and processing technology thereof

InactiveCN102687729APlay a role in long-term protectionMoth proofBiocidePest repellentsPunchingMethyl carbamate

The invention discloses an insect-resistant, corrosion-resistant, and mildew-resistant raw bamboo protective agent which comprises the following components: ammoniacal copper quaternary, N-2-benzimidazolyl methyl carbamate, and a penetrating agent, and also discloses processing technology of the raw bamboo protective agent, which comprises the following steps: performing bamboo joint punching processing of a fresh felled raw bamboo, naturally drying; putting the raw bamboo into a pressure impregnation tank, closing the tank door, turning on a vacuum pump to vacuumizing the impregnation tank; adding the raw bamboo protective agent till the impregnation tank is filled up with the vacuum pump being turned on; turning off the vacuum pump, turning on a pressure pump till the raw bamboo protective agent becomes saturated in the raw bamboo; releasing the pressure, discharging the protective agent in the impregnation tank. The purpose of the invention is to provide the raw bamboo protective agent which can simultaneously provide insect-resistant, corrosion-resistant, and mildew-resistant effects for raw bamboos, and also to provide the processing technology of the raw bamboo protective agent, which allows the protective agent to completely penetrate into the raw bamboo and thus to reach the effect of long-term raw bamboo protection without environment problems.

Owner:SOUTHWEST FORESTRY UNIVERSITY +1

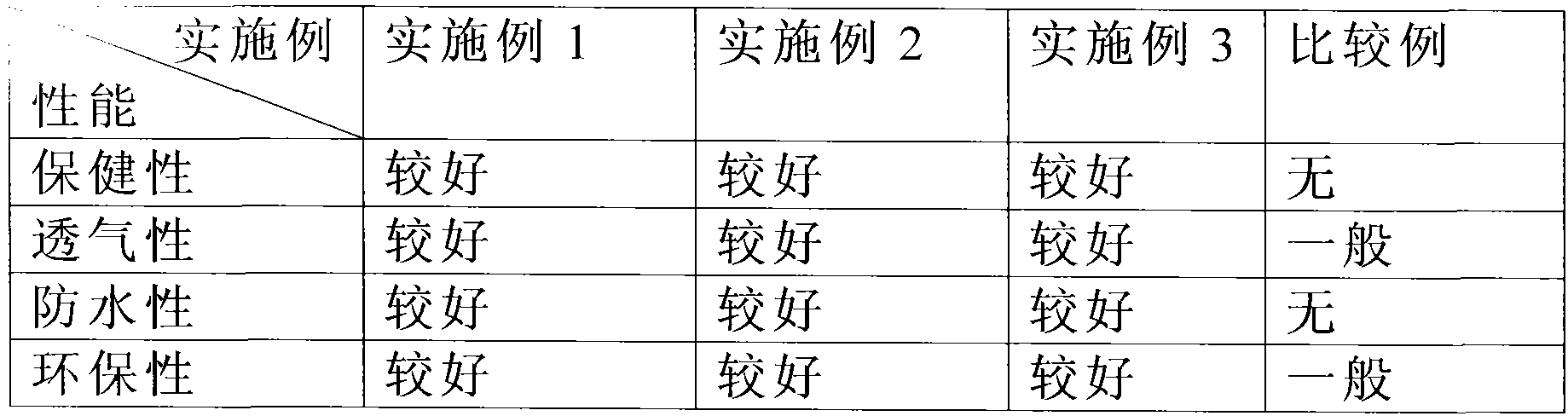

Water wash cotton for bedding and clothing and production technology thereof

The invention discloses a bedding-clothing water washed cotton and its producing process, and its characteristic: it contains the components in weight percent: cotton and hair fibers 20%-80% and other fibers 80%-20%. It includes the working procedures made in sequence: screening, degreasing, bleaching, high-temperature sterilizing, UV sterilizing, mixing, combing, paving net, and thermal-setting. The beneficial effects: it is a novel heat-preserving material developed by using cotton, hair, and other fibers; it has the functions: heath, moth prevention, moisture transmission, waste wash resistance, good model maintenance, comfort, etc. The product has wide application range, the thin-type low-g weight material can be used to make air-conditioner water-wash bedding for the summer, and fashionable dresses and overskirts, etc; the thick-type high-g weight material can be used to make heat-preserving bedding for the winter, heat-preserving cotton-padded clothes, sleeping bags, cushions, etc.

Owner:王洪云

Environment protective and flame retardant decorative material and preparation process thereof

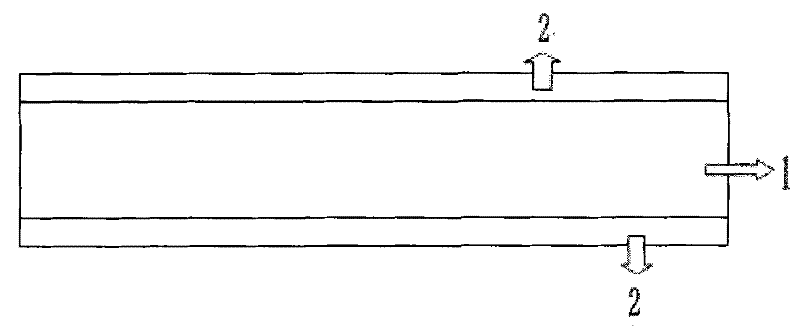

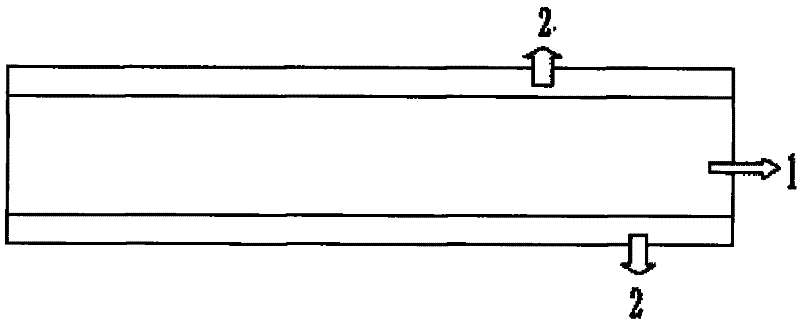

InactiveCN101775882AHigh strengthFlame-resistant and fire-resistantCovering/liningsCeramic shaping apparatusGlass fiberFiberglass mesh

The invention relates to the technical field of decorative and building material, in particular to environment protective and flame retardant decorative material and a preparation process thereof; the decorative material of the invention sequentially comprises a first fabric paste layer, a first glass fiber mesh layer, a main material layer, a second glass fiber mesh layer and a second fabric paste layer from up to down, and is characterized by comprising the following components by weight percentage: 55.0 to 75.0 percent of filler, 22.0 to 32.0 percent of binder, 3.8 to 4.8 percent of hardener, 0.05 to 1.0 percent of glass fiber mesh, and 5.5 to 8.0 percent of fabric; the decorative material of the invention has the advantages of fire retardance and fireproofing, environment protection, waterproofing, insect resistance, light weight, pressure and bending resistance, high strength and the like; and the invention does not contain formaldehyde and benzene, satisfies the environment protective requirements, and can be used for floor slabs, floor, various deck plats, templates, trays, wood, vertical columns and the like.

Owner:王春莉

Simulated wood board and production method thereof

InactiveCN102535813AStable materialNo pollution in the processCovering/liningsDecorative surface effectsPublic placeEngineering

The invention relates to a wood board, in particular to an artificial simulated wood board and a production method thereof. The simulated wood board aims to overcome shortcomings of natural wood, is waterproof, moisture-proof, insect-proof, mothproof, anti-crack, harmless and pollution-free, does not deform, and can replace the natural wood. The simulated wood board comprises a base material layer, and a primer layer, a pattern layer made of marble and a finish layer are successively arranged at the front of the base material layer from bottom to top. The invention further provides the production method of the simulated wood board. The production method comprises following steps: selecting a base material; cutting the selected base material into a base material with the required dimension; arranging tenon fasteners on the cut base material; coating primer on the front of the base material; printing textures of natural wood on the surface of the base material coated with the primer; and coating finish on the surface of the base material printed with the textures of the natural wood. The simulated wood board can be paved on floors of various humid environments and public places, and completely overcomes shortcomings that various wood floors are expanded when wetted and are contracted when dried.

Owner:GUANGZHOU GUANGYANG FU BULGARI HOME MATERIAL

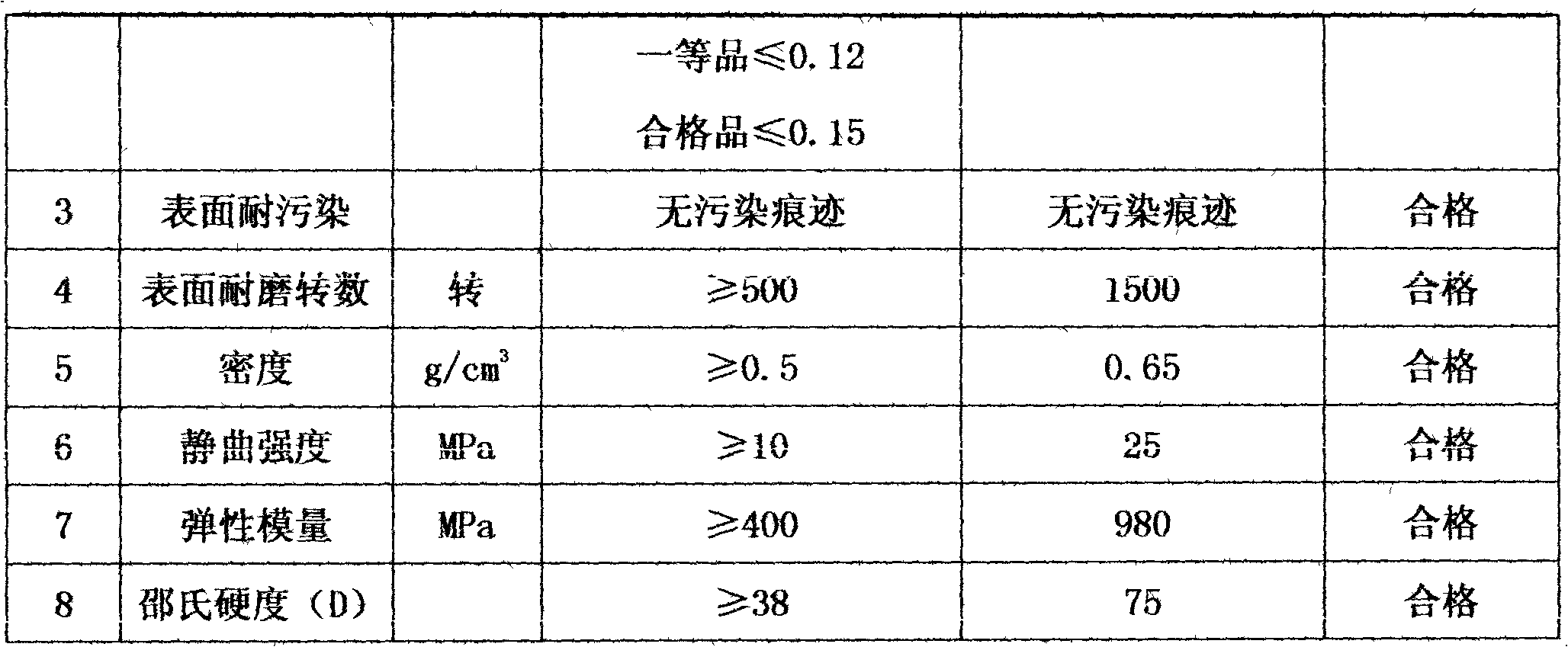

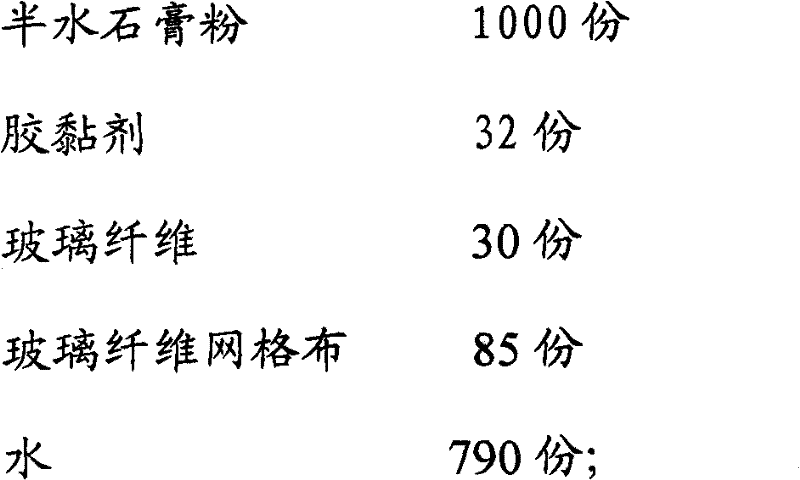

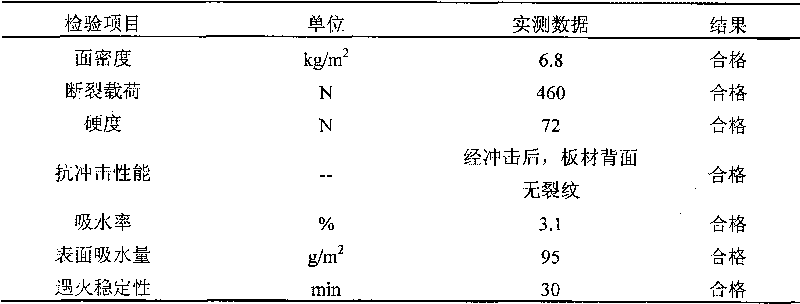

A mothproof and fireproof glass fiber surface gypsum board and preparation method thereof

The invention discloses a mothproof and fireproof glass fiber surface gypsum board and a preparation method thereof. Including the intermediate base layer made of gypsum cementitious material, the glass fiber surface formed by coating the outer side of the intermediate base layer with glass fiber mesh, and the contents of each component are parts by weight during batching: 1000 parts of hemihydrate gypsum powder; 30-35 parts; 20-45 parts of glass fiber; 75-90 parts of glass fiber mesh cloth; Moth-proof, fire-proof performance is higher than paper-faced gypsum board, belongs to Class A non-combustible material, and has better waterproof performance. It can be widely used in the fields of construction and decoration.

Owner:SHANDONG BAIER BUILDING MATERIAL CO LTD

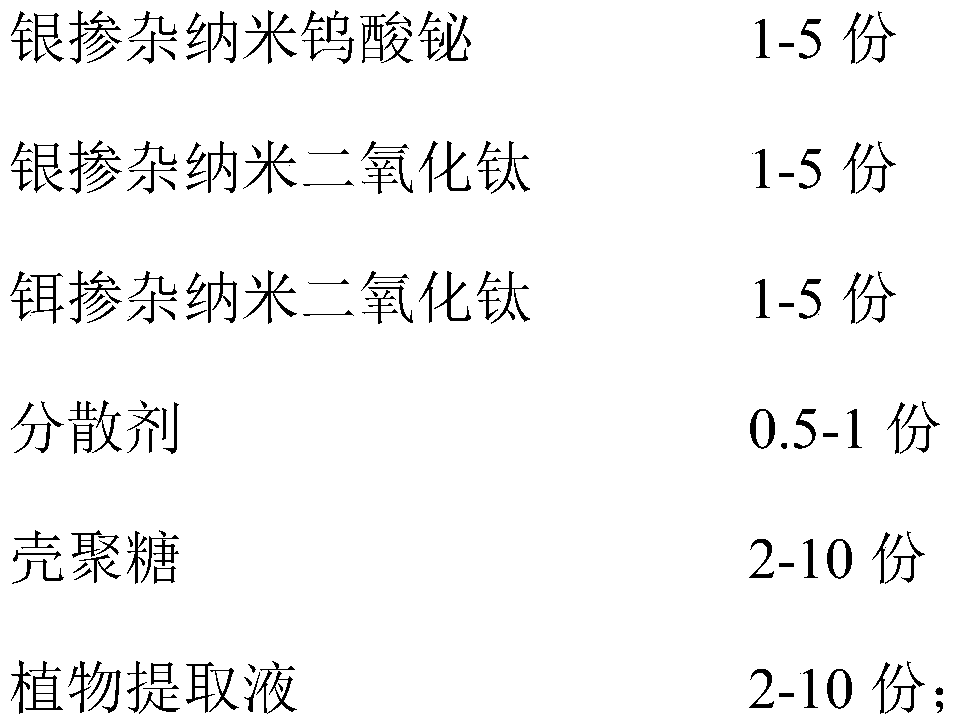

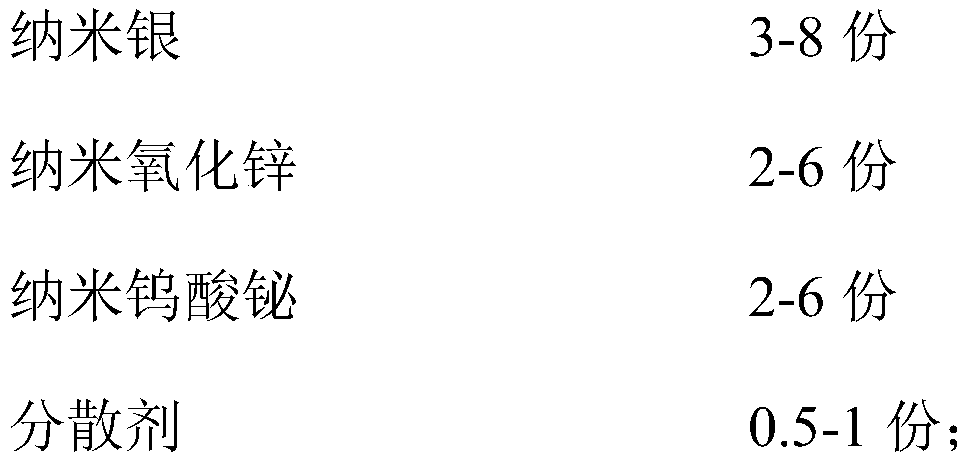

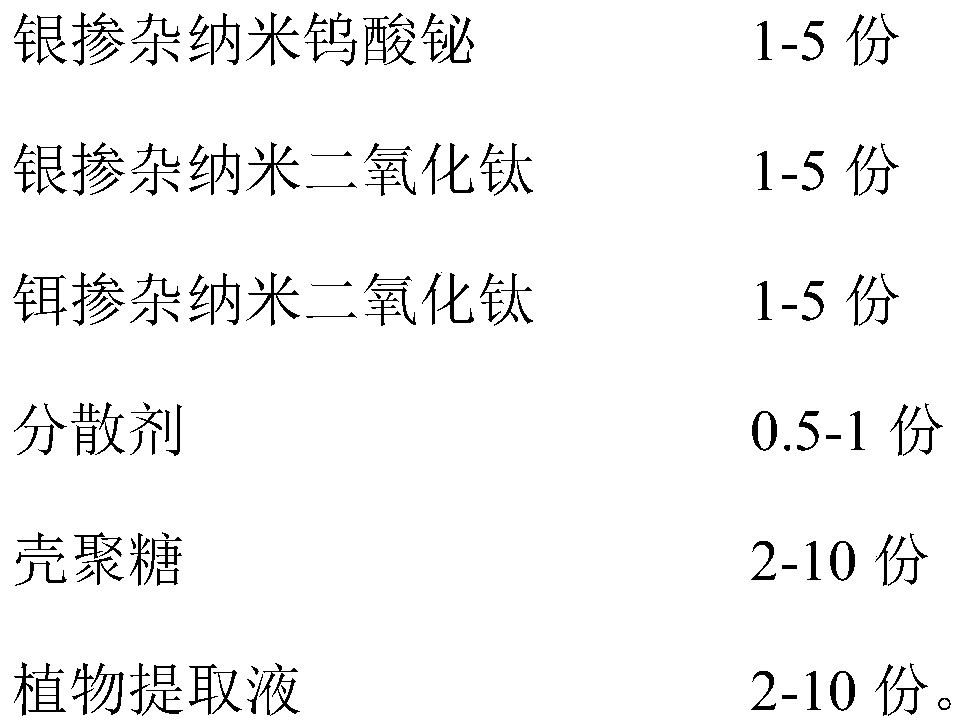

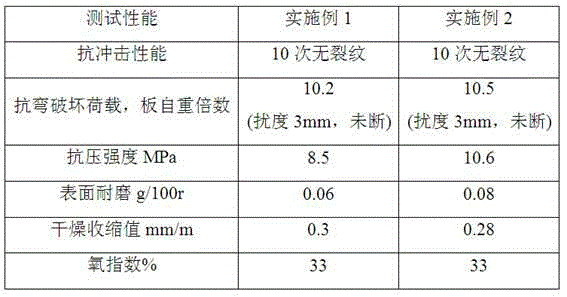

Anti-bacterial, anti-mite and anti-viral finishing agent, plush shell fabric and preparation method and application of plush shell fabric

ActiveCN111411510AImprove antibacterial propertiesImprove antibacterial, anti-mite and anti-virus effectsBiochemical fibre treatmentBiotechnologyEscherichia coli

The invention provides an anti-bacterial, anti-mite and anti-viral finishing agent, a plush shell fabric and a preparation method and application of the plush shell fabric. The anti-bacterial, anti-mite and anti-viral finishing agent includes a metal-ion-doped photocatalyst, a plant extract, chitosan and a dispersing agent, and the plush shell fabric functionally treats a fabric in the after-treatment process through the anti-bacterial and anti-viral finishing agent. Metal ions, the photocatalyst, the plant extract and the chitosan in the anti-bacterial, anti-mite and anti-viral finishing agent synergistically cooperate, the anti-bacterial ratio of the plush shell fabric against bacteria such as escherichia coli, staphylococcus aureus and candida albicans can be increased, the resistance of the plush shell fabric to viruses such as H1N1 and H3N2 is improved, the mould-proof grade of the shell fabric is zero, and the shell fabric has a good expelling effect on mites and can be widely applied to manufacturing of plush toys, clothing, woollen blankets, plush mats, plush four-piece suits and the like.

Owner:同曦集团有限公司

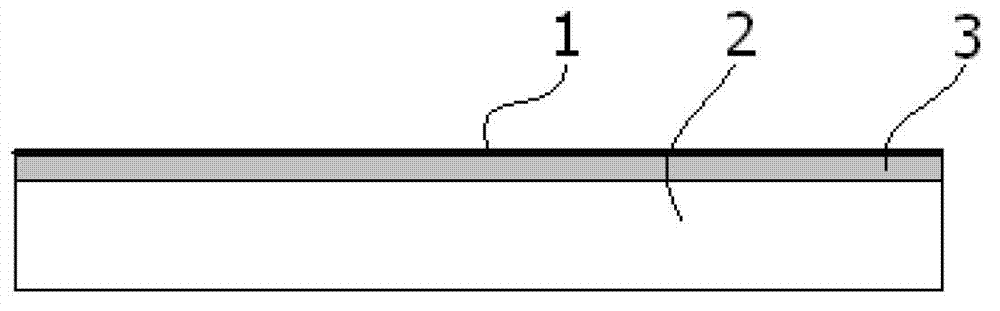

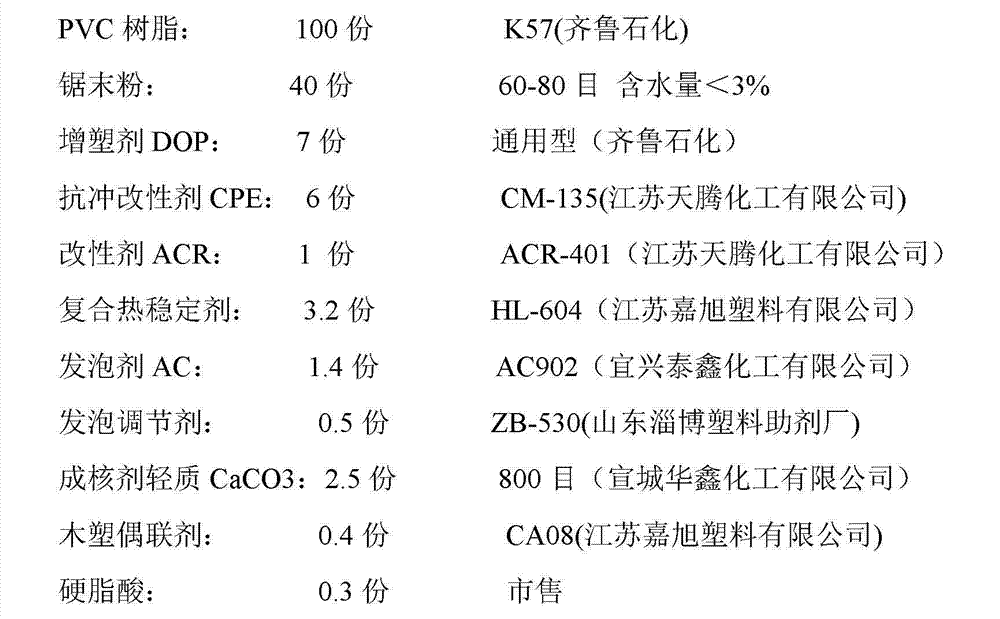

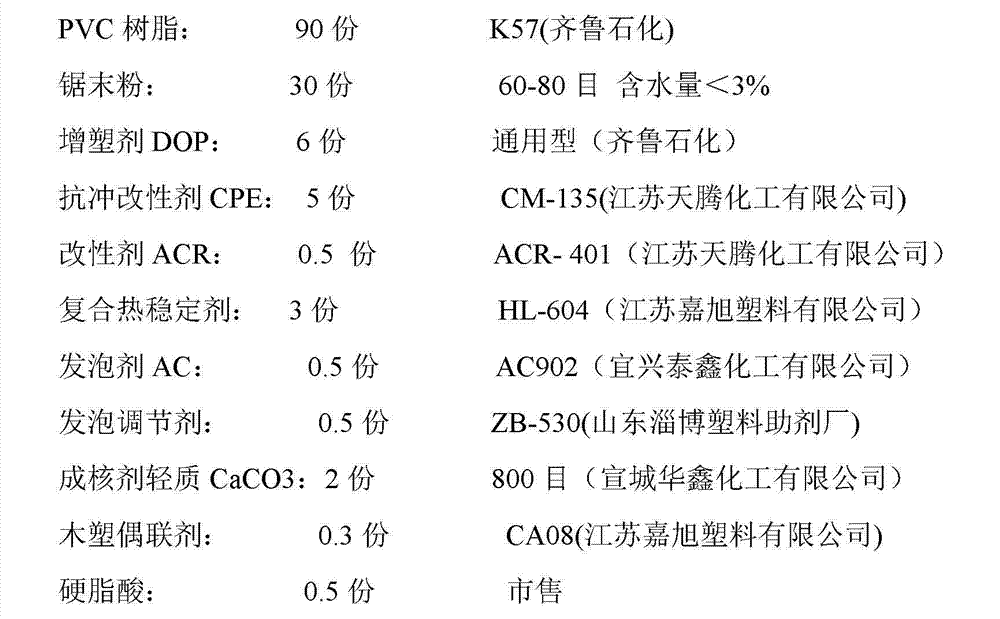

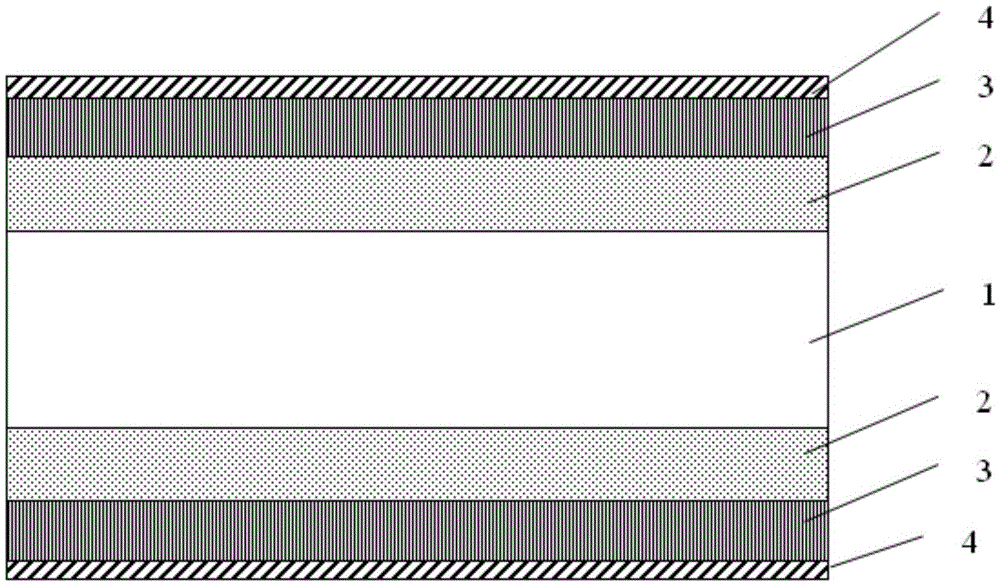

Wood-plastic floorboard and manufacturing method

The invention provides a wood-plastic floorboard and its manufacturing method. The wood-plastic floorboard contains at least two layers of PVC-based wood-plastic composites. The product provided by the invention has advantages of ageing resistance, wear resistance, environmental protection, high strength, good waterproofness, insect resistance and the like, and is not easy to deform. The manufacturing technology is simple, has low cost and is beneficial to popularization and application.

Owner:MEIHUA IND

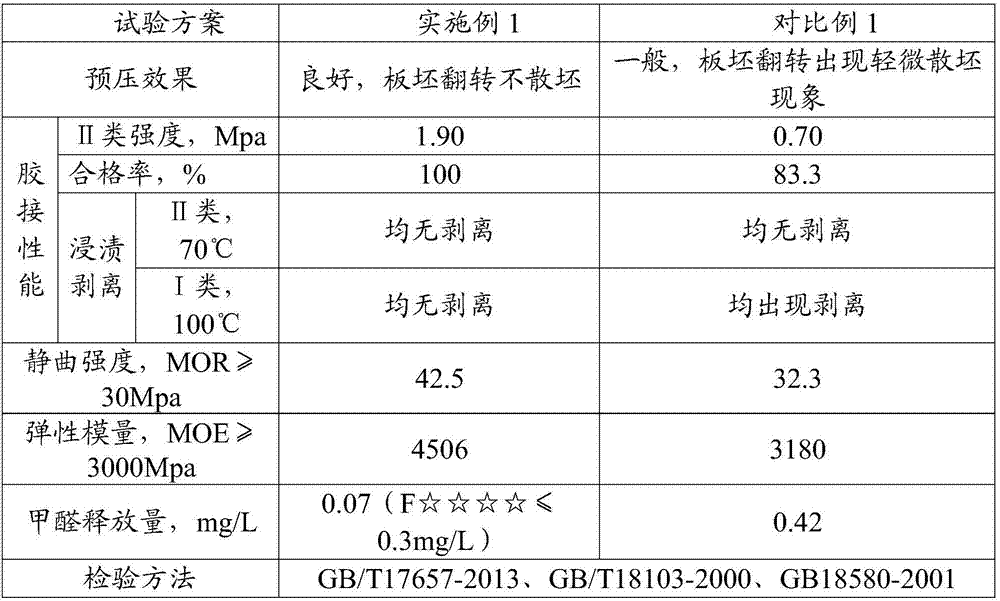

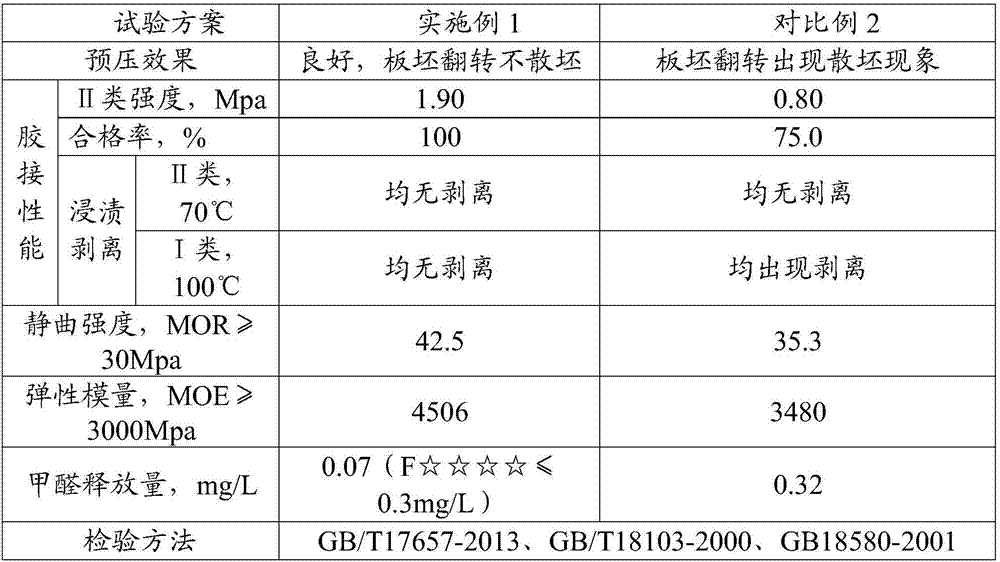

E0-level melamine modified urea formaldehyde resin adhesive

ActiveCN106883366AImprove water resistanceReduce free formaldehydeNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesResin adhesiveParquetina

The invention discloses a preparation method of E0-level melamine modified urea formaldehyde resin. The E0-level melamine modified urea formaldehyde resin is prepared by the following steps of feeding urea by three batches, and feeding melamine by three batches. The invention also discloses the E0-level melamine modified urea formaldehyde resin and an E0-level melamine modified urea formaldehyde resin adhesive. The method has the advantages that the distribution of the internal molecular structure of the urea formaldehyde resin is changed by the multi-batch feeding type, the prepared resin is added into an adhesive mixer, a formaldehyde removing agent, a reinforcing agent, an acid curing agent and industrial flour are stirred until all the components are uniformly mixed, so as to obtain a mixed adhesive, and the obtained mixed adhesive is applied into the production of parquets; the hot pressing cycle can be shortened, the hot pressing time is shortened from conventional 70-79s / mm to 30-35s / mm under the condition of no change of pressure and temperature parameters, and the utilization rate and production efficiency of a hot press are greatly improved; the release amount of formaldehyde in the prepared plate reaches superE0 level.

Owner:广州市长安粘胶制造有限公司

Process of producing hung board for outer wall

InactiveCN101066612AThe production process is simple to operateFireproofSolid waste managementMixing operation control apparatusHalogenLacquer

The present invention relates to production of composite plate, and is process of producing hung board for outer wall. The technological process includes the steps of compounding MgCl2 solution, mixing the slurry, feeding formwork, stirring the slurry, loading the slurring, rolling, cutting, setting onto shelf, curing, soaking and sunning to eliminate halogen, cutting, spraying bottom paint, etc. The production process is simple, and the produced hung board is fireproof, waterproof, mothproof, light, high in strength and has other advantages.

Owner:林启红

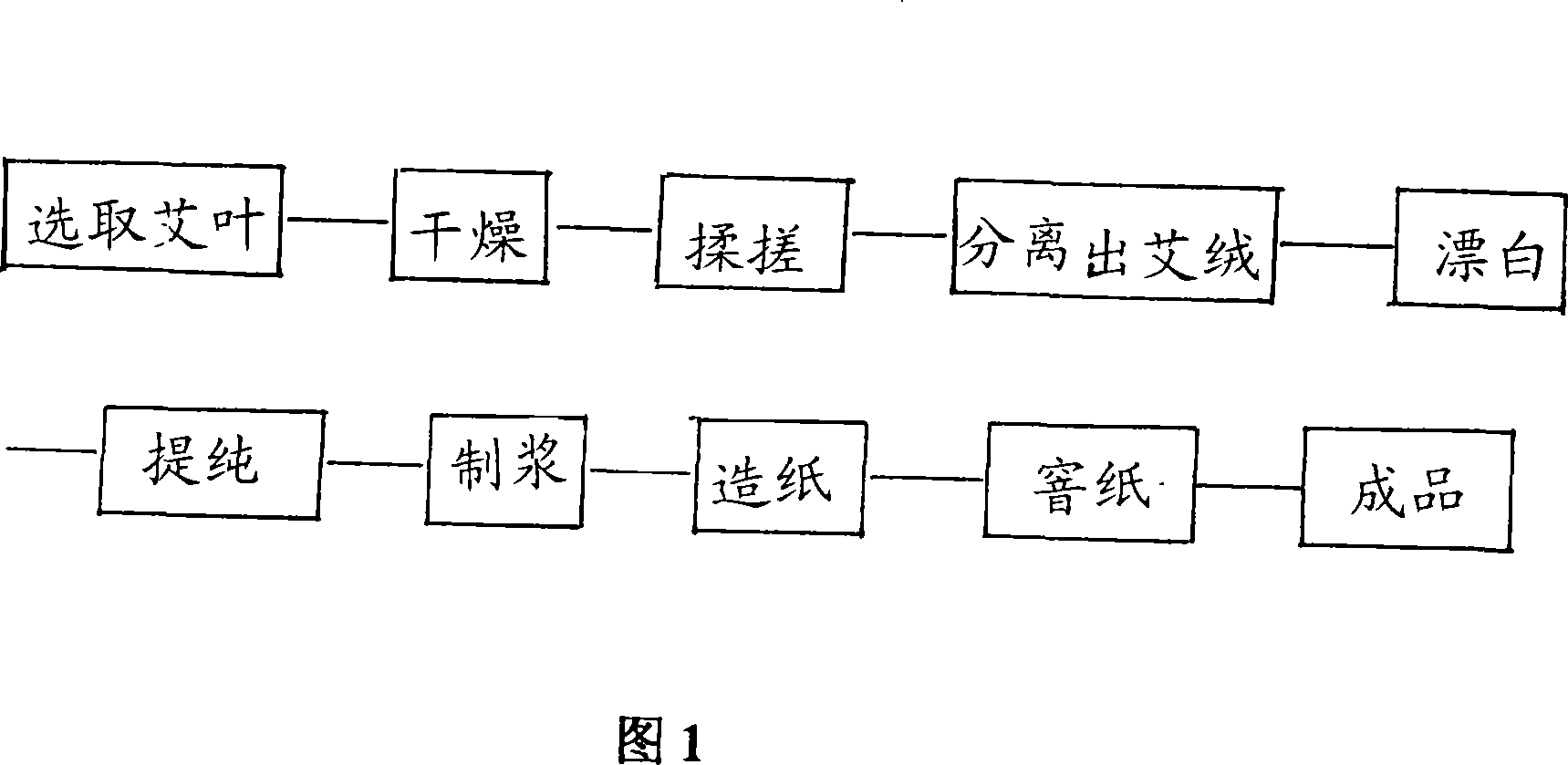

Process for manufacturing argyi leaf functional paper

InactiveCN101135123AImprove separation rateHigh purityVegetable material additionNon-woody plant/crop pulpPapermaking

The present invention relates to papermaking technology, and is especially functional moxa leaf paper making process. The present invention features that the functional moxa leaf paper is made with moxa leaf as material and through one improved papermaking process including the steps of sorting moxa leaf, drying, kneading, separating, bleaching, purifying, making pulp, making paper and scenting paper. The functional moxa leaf paper is applied for painting and calligraphy, as wall paper, in decoration, etc, and has the features of long preservation period, environment friendship and functional function.

Owner:河南绿莹艾草制药有限公司

Health care mat for infants and manufacturing method thereof

InactiveCN103405088APowerful insecticidePromote circulationNervous disorderImmunological disordersTraditional medicineSemen

The invention provides a health care mat for infants and belongs to the technical field of textile processing. The health care mat for infants is of a three-layer double-side structure, a front side layer and a back side layer are both a simulation rattan mat body, and a middle health care layer is formed by evenly mixing and flattening 100 parts of Chinese herbal medicine and 5-40 parts of natural rubber cement by weight. The Chinese herbal medicine of the health care layer includes the following raw materials by weight: 1 part to 10 parts of bamboo charcoal, 1 part to 10 parts of jasmine flower, 20-35 parts of negundo chastetree fruit, 10-30 parts of semen cassiae, 10-30 parts of lavender and 10-20 parts of mint. The manufacturing method includes manufacturing the simulation rattan mat bodies, taking the Chinese herbal medicine according to the prescription, drying and breaking the Chinese herbal medicine, mixing the dried and broken Chinese herbal medicine with the natural rubber cement to obtain the health care layer, evenly coating the natural rubber cement on the bottom face of one simulation rattan mat body, laying the health care layer, then laying the other simulation rattan mat body and conducting clipping and edge wrapping to obtain a finished product of the health care mat for the infants. The health care mat is good in health care effect and low in cost.

Owner:NINGBO YINZHOU LIMING ARTS & CRAFTS

Decorating mineral slag and desulfurized gypsum composite plate for building

InactiveCN101734901ALight weightWith heat insulationCovering/liningsSolid waste managementGlass fiberMass ratio

The invention belongs to the technical field of building decorating materials and relates to a building decorating plate produced by using mineral slag and desulfurized gypsum as main raw materials. The decorating mineral slag and desulfurized gypsum composite plate for a building is prepared from the following raw materials in percentage by weight: 100 parts of mineral slag, 50 to 80 parts of desulfurized gypsum, 0.5 to 3 parts of salt cake, 0.5 to 4 parts of alum, 1 to 5 parts of water glass, 2 to 7 parts of lime hydrate, 1 to 4 parts of chopped glass fiber and 1 to 3 parts of VAE latex, and the mass ratio of the water to the raw materials is 0.40-0.70. The decorating mineral slag and desulfurized gypsum composite plate for the building has the characteristics of light weight, heat insulation, sound insulation, fire resistance, water resistance, worm resistance, breathing function and the like, has the advantages of low production cost, energy conservation and environment friendliness, and is a green and environment-friendly building decorating material.

Owner:UNIV OF JINAN

Producing and processing method for flue sheet material prepared by mixing straws

InactiveCN102674790AWith thermal insulationLubriciousSolid waste managementEcological environmentAdditional values

The invention provides a producing and processing method for flue sheet material prepared by mixing straws, and relates to flue sheet material for floor. The flue sheet material has the advantages of resisting fire and flaming, resisting moisture and mildew, and resisting insects and moth, and is good in waterproof property and high-temperature-resistant, is capable of being sawed and planed, is endurable, simple in production process, safe and convenient to operate, and high in production efficiency, thus being novel flue sheet material. Straws of rice and wheat are utilized as main raw material of the flue sheet, thus reducing pollution of burning the straws of rice and wheat to the environment, being low in cost, changing wastes into valuables, being high in additional value, lowering the manufacturing cost of the flue sheet, protecting the ecological environment, benefiting the country and people, and making contributions for creating economic and low-carbon society for China.

Owner:YANCHENG JINMA NEW ENVIRONMENT FRIENDLY BUILDING MATERIALS MFG

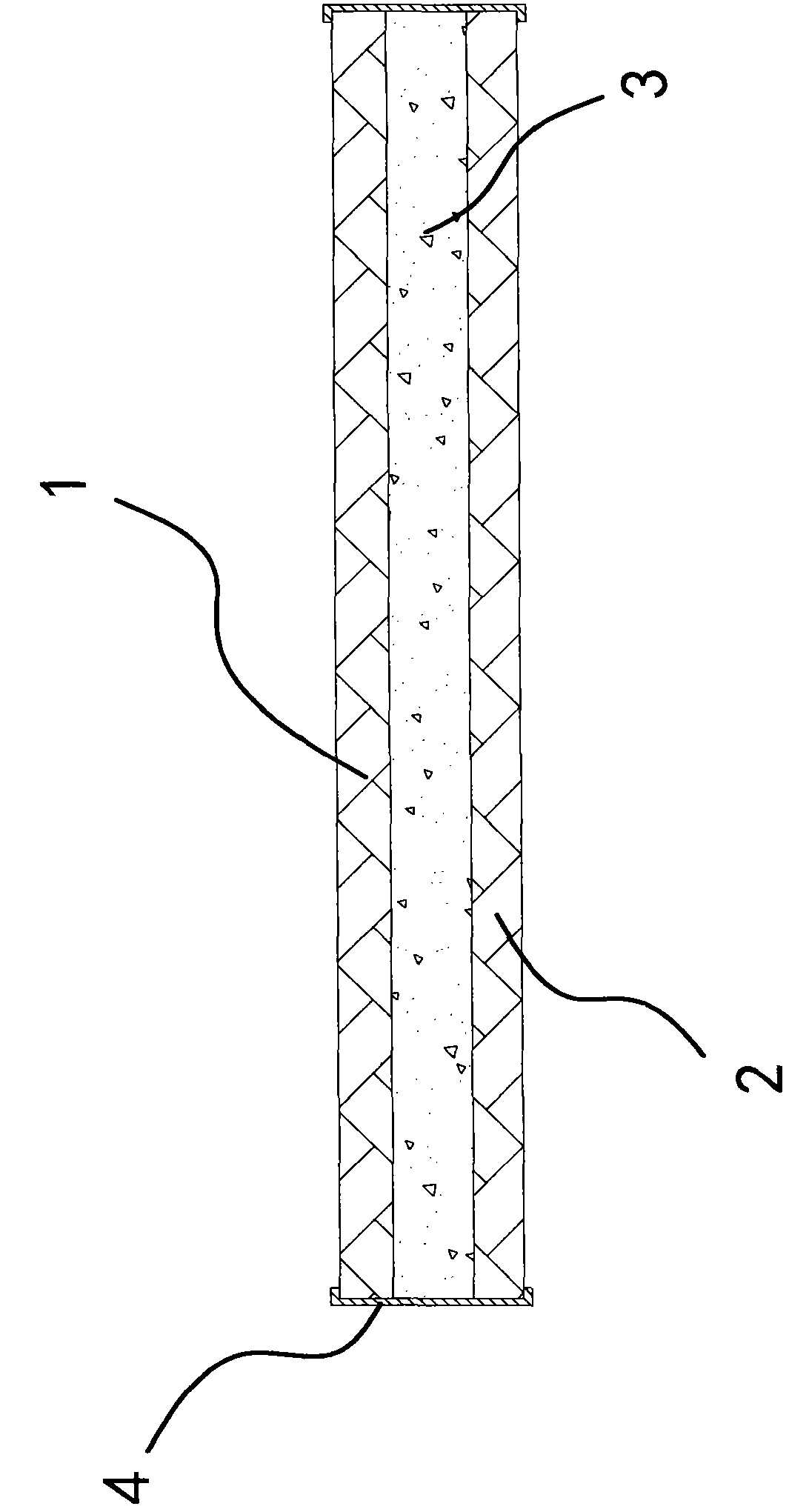

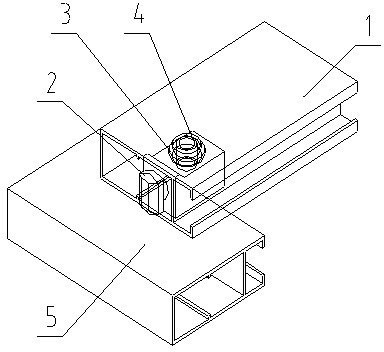

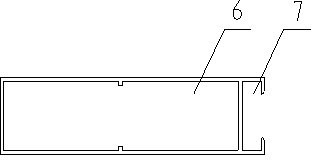

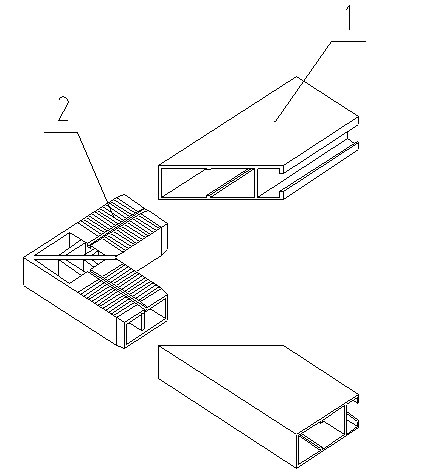

Border direct-splicing connection structure of all-aluminum furniture cabinet

The invention relates to a border direct-splicing connection structure of an all-aluminum furniture cabinet, which comprises a border I (1) and a border II (5), wherein the border I (1) and the border II (5) are made of the same sectional bars. Each sectional bar comprises a cavity (6), and a clamping groove (7) is arranged on the outer wall on the right side of the cavity (6). A connecting part (2) comprises a clamping seat (2.1), a connecting portion (2.2) is arranged on the left lateral face of the clamping seat (2.1), and a clamping head (2.3) is arranged on the connecting portion (2.2). The clamping seat (2.1) of the connecting part (2) is arranged in the cavity (6) of the border I (1) and fixedly connected with the border I (1), and the clamping head (2.3) of the connecting part (2) is arranged in the clamping groove (7) of the border II (5). The border direct-splicing connection structure of the all-aluminum furniture cabinet can be used for producing safe and environment-friendly all-aluminum furniture, the formaldehyde does not exceed the standard, and the furniture is fireproof, waterproof and capable of being recycled and is not damaged by worms.

Owner:江苏嘉斯顿船舶装备科技有限公司

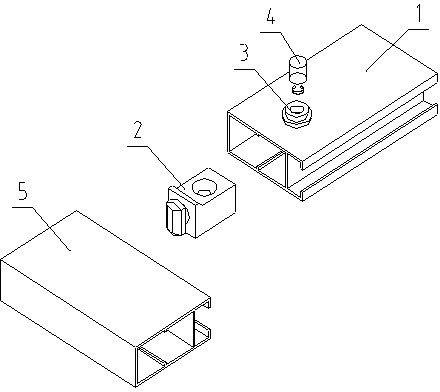

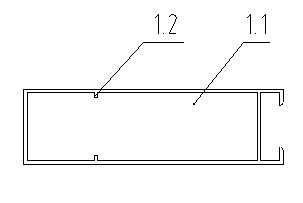

Connecting structure for corner brace and frame of all-aluminum furniture cabinet

InactiveCN102606585AExtended service lifeThere is no problem of excessive formaldehydeFurniture joiningReusabilityMechanical engineering

The invention relates to a connecting structure for a corner brace and a frame of an all-aluminum furniture cabinet. The connecting structure comprises the frame (1) and the corner brace (2), the frame (1) comprises a belly cavity (1.1), convex ribs (1.2) are arranged on the upper inner wall and the lower inner wall of the belly cavity (1.1), the corner brace (2) comprises a corner brace body (2.1) with a 90-degree corner, clamp grooves (2.2) are arranged on the front sides and the rear sides of two corner brace wings of the corner brace body (2.1), saw teeth (2.3) are arranged on two sides of each clamp groove (2.2), the two corner brace wings of the corner brace body (2.1) are inserted into the belly cavity (1.1) of the frame (1), and the convex ribs (1.2) are matched with the clamp grooves (2.2). The connecting structure for the corner brace and the frame of the all-aluminum furniture cabinet can be used for producing safe, environment-friendly and green all-aluminum furniture which is free of the problem of formaldehyde exceeding and has the advantages of water and fire proofing, moth prevention, reusability, long service life and the like.

Owner:江苏嘉斯顿家俱有限公司

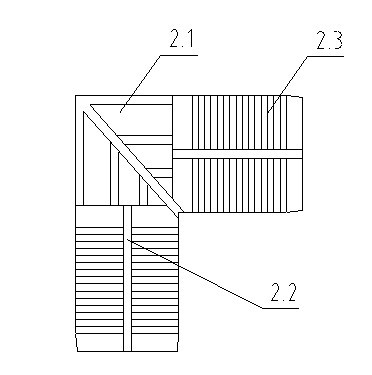

Environment-friendly multifunctional composite artificial board

InactiveCN104369235ASimple structureReasonable designFireproof paintsAntifouling/underwater paintsAdhesiveSodium phosphates

The invention discloses an environment-friendly multifunctional composite artificial board. The artificial board comprises a surface layer, a middle layer and a bottom layer. The surface layer and the middle layer are bonded together through an adhesive layer, and the middle layer and the bottom layer are bonded together through an adhesive layer. The upper surface of the surface layer and the lower surface of the bottom layer are each coated with a functional protection coating. The adhesive layers are formed by inorganic phosphate adhesives which comprise the raw constituents of sodium phosphate, titanium dioxide powder, nano-silica, spinel particles, tourmaline powder, magnesium oxide and zinc oxide. The artificial board has the advantages that the structure is simple, and design is reasonable; the inorganic phosphate adhesives are adopted for both manufacturing of the board and bonding of the board layers, so that the problems that an artificial board generates poisonous and harmful gas and pollutes the environment are solved fundamentally; the artificial board has water resistance, flame resistance, antibacterial properties, worm damage resistance and the like; the artificial board is good in durability and use safety and long in service life.

Owner:SUZHOU YIAIFU CHEM MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com