Decorating mineral slag and desulfurized gypsum composite plate for building

A technology for desulfurization gypsum and building decoration, applied in the field of building decoration boards, can solve problems such as pollution of the environment, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Such as figure 1 Shown is a schematic structural view of the slag desulfurized gypsum composite board for architectural decoration of the present invention. The slag desulfurization gypsum composite board for architectural decoration is made of ground slag powder and calcined desulfurization gypsum as raw materials, adding Glauber's salt, alum, water glass, slaked lime, chopped glass fiber, mixing evenly in proportion, adding water and VAE The emulsion is stirred into a slurry, formed by the flow method, and the slurry is hardened. The slag desulfurization gypsum composite board for architectural decoration of the present invention is made of the following raw materials in parts by weight:

[0022] Slag 100 parts

[0023] Desulfurization gypsum 50 parts

[0024] Glauber's salt 0.5 parts

[0025] 4 parts alum

[0026] 1 part water glass

[0027] 7 parts slaked lime

[0028] 4 parts chopped fiberglass

[0029] 1 part of VAE emulsion;

[0030] The mass ratio of wa...

Embodiment 2

[0035] The wallboard of the present embodiment is basically the same as the first embodiment, and its raw material ratio is:

[0036] Slag 100 parts

[0037] 60 parts of desulfurized gypsum

[0038] Glauber's salt 1.5 parts

[0039] 3 parts alum

[0040] 3 parts water glass

[0041] 6 parts slaked lime

[0042] 3 parts chopped fiberglass

[0043] 2 parts of VAE emulsion;

[0044] The mass ratio of water to material is 0.50.

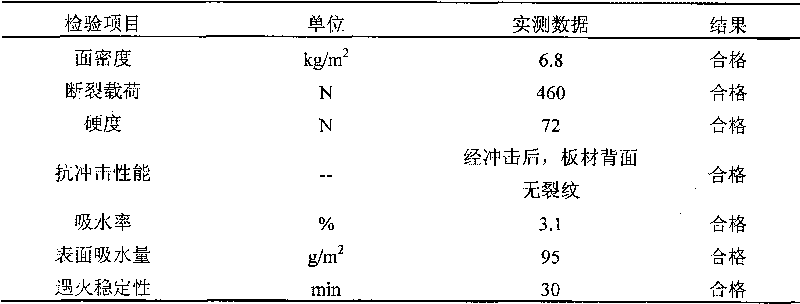

[0045] The size of the slag desulfurized gypsum composite board for architectural decoration is 2100mm×900mm×9.5mm, and the technical performance test results are shown in Table 2.

[0046] Table 2

[0047]

Embodiment 3

[0049] The wallboard of the present embodiment is basically the same as the first embodiment, and its raw material ratio is:

[0050] Slag 100 parts

[0051] Desulfurization gypsum 70 parts

[0052] Glauber's salt 2 parts

[0053] Alum 1.5 parts

[0054] Water glass 4 parts

[0055] 4 parts slaked lime

[0056] 2 parts chopped fiberglass

[0057] 2.5 parts of VAE emulsion;

[0058] The mass ratio of water to material is 0.60.

[0059] The size of the slag desulfurized gypsum composite board for architectural decoration is 2400mm×1200mm×9.5mm, and the technical performance test results are shown in Table 3.

[0060] table 3

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com