Novel solid ecological bamboo board and production process thereof

A solid wood and ecological technology, applied in the direction of wood processing appliances, wood veneer bonding, manufacturing tools, etc., can solve the problem of surface crack resistance, poor cold and heat cycle resistance, poor surface flatness of finished products, and prone to carbonized white flowers. and other problems, to achieve the effect of good surface flatness, reduced production process, and increased use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Combine below Attached picture A detailed description will be made to the specific embodiment of the present invention.

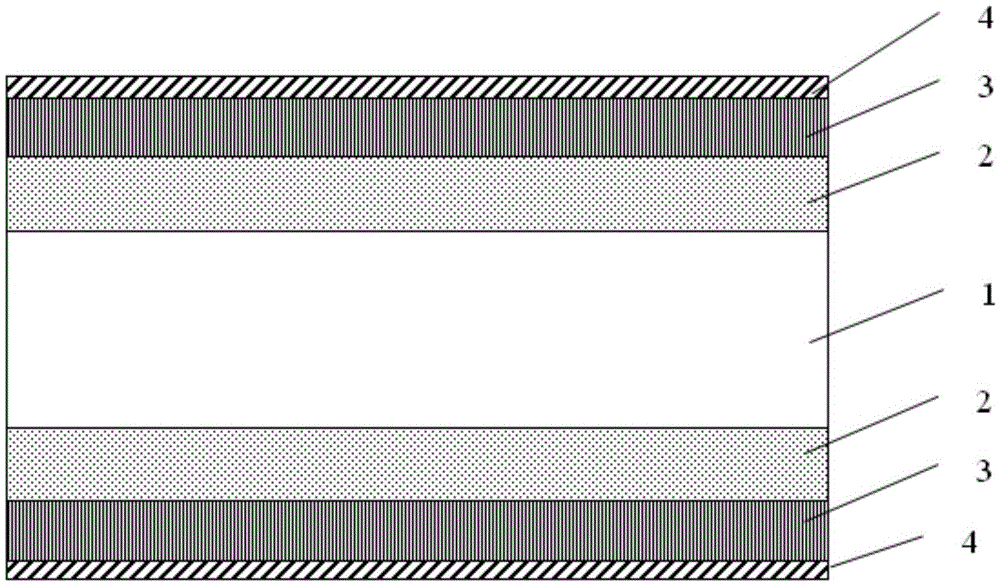

[0041] Such as Figure 1~2 As shown, the present invention provides a new type The specific embodiment of solid wood ecological bamboo plank, the new type The solid wood ecological bamboo board comprises a fir board core 1, a middle board 2, a bamboo fiber board 3 and melamine-impregnated paper 4, the upper and lower surfaces of the fir board core 1 are respectively glued and covered with a middle board 2, and are integrally pressed together to form a slab; The bamboo fiber board 3 is pressed and pasted with melamine-impregnated paper 4 to form a surface layer substrate; the upper and lower surfaces of the slab are respectively coated with surface layer substrates and formed integrally by cold and hot pressing.

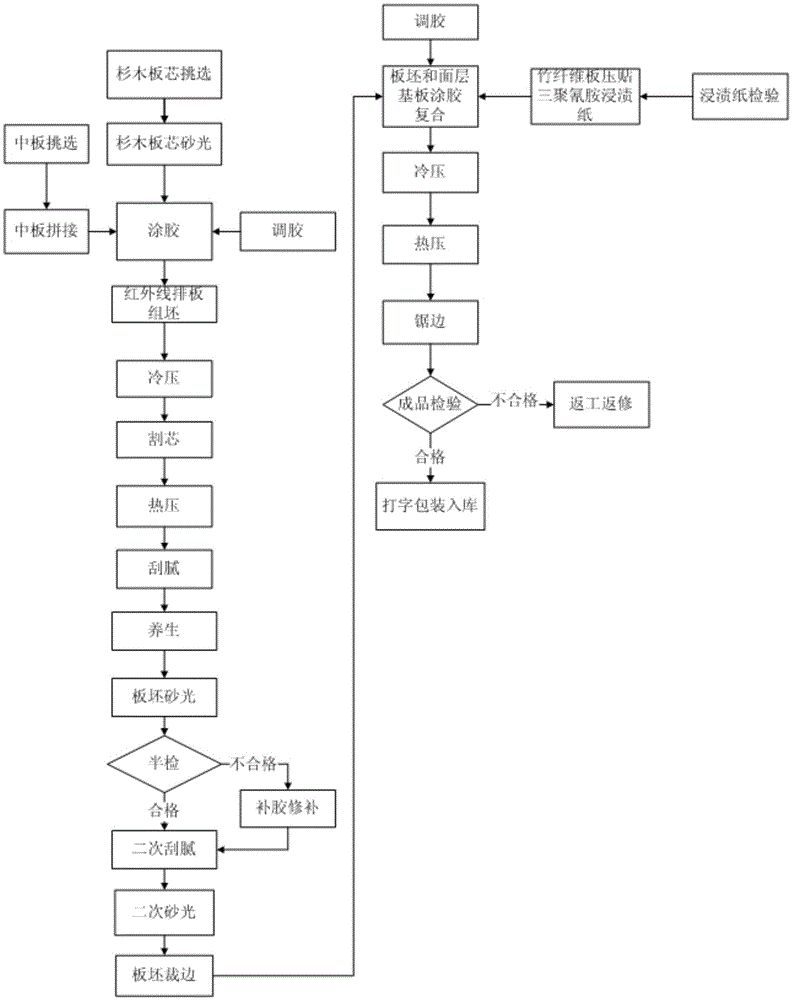

[0042] In addition, the present invention also provides a new type The production process of solid wood ecological bamboo plank comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com