Patents

Literature

300 results about "Static bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alongside automatic stability control (ESC), other safety features include static bending headlights to provide better illumination of the road through corners, auto cruise control that is designed for convenience and improved fuel economy, and emergency stop signal which automatically flashes the brake lights when the driver brakes heavily.

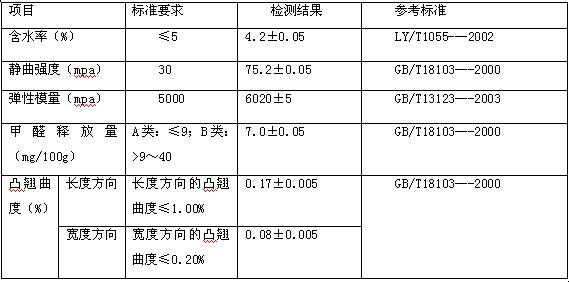

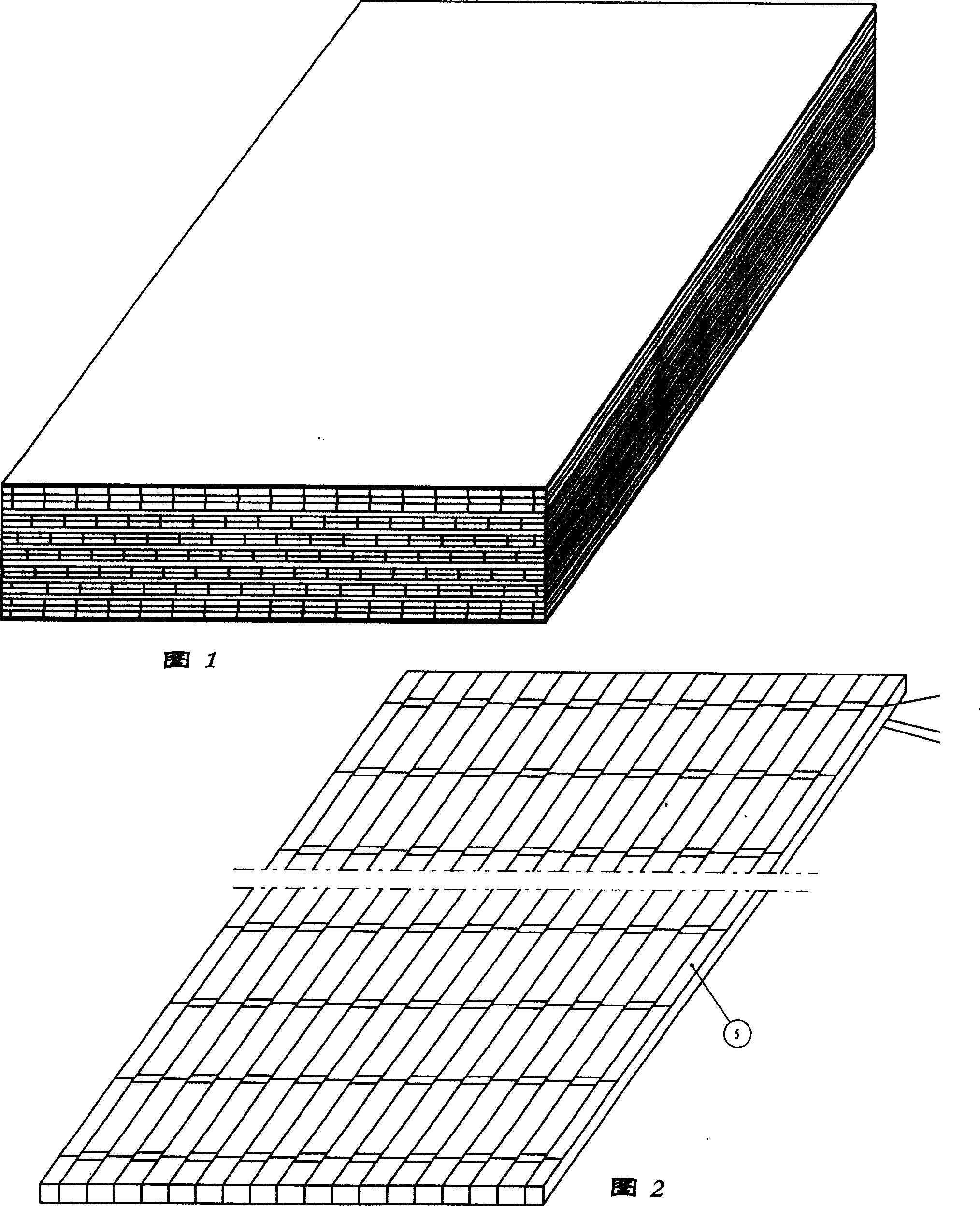

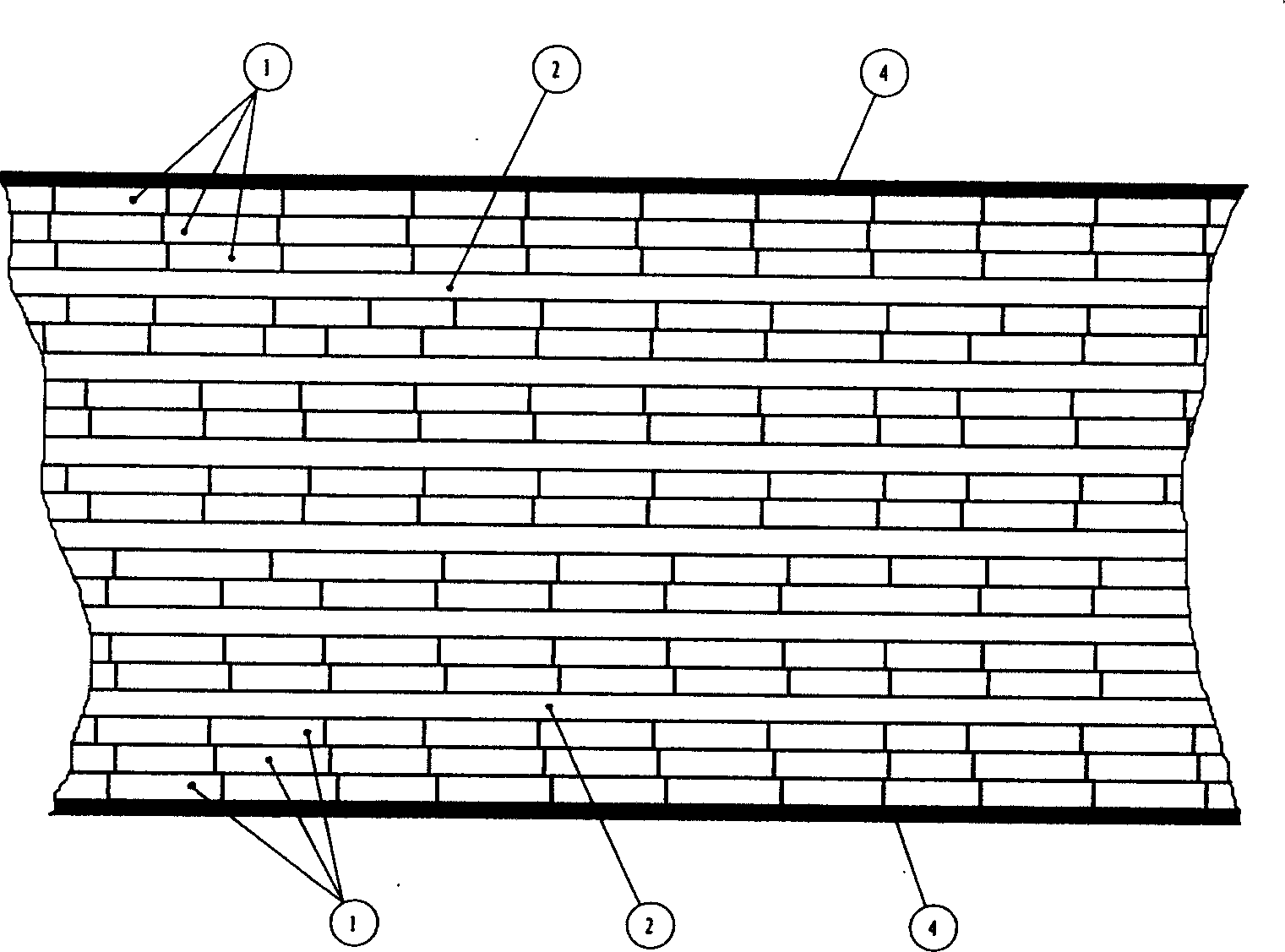

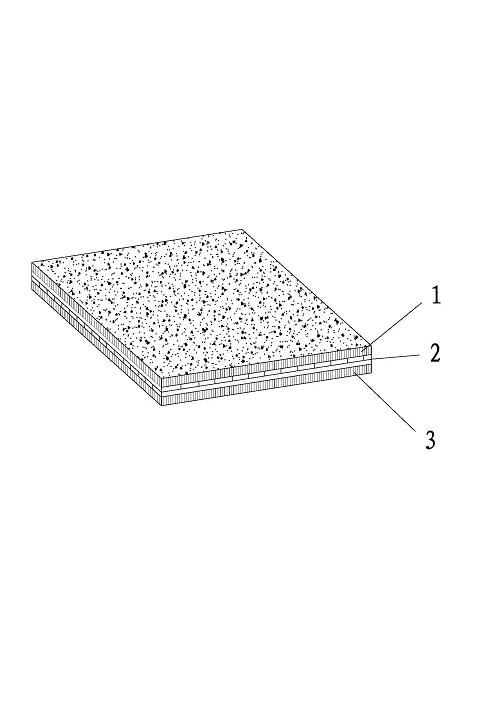

Oriented chipboard and processing technology

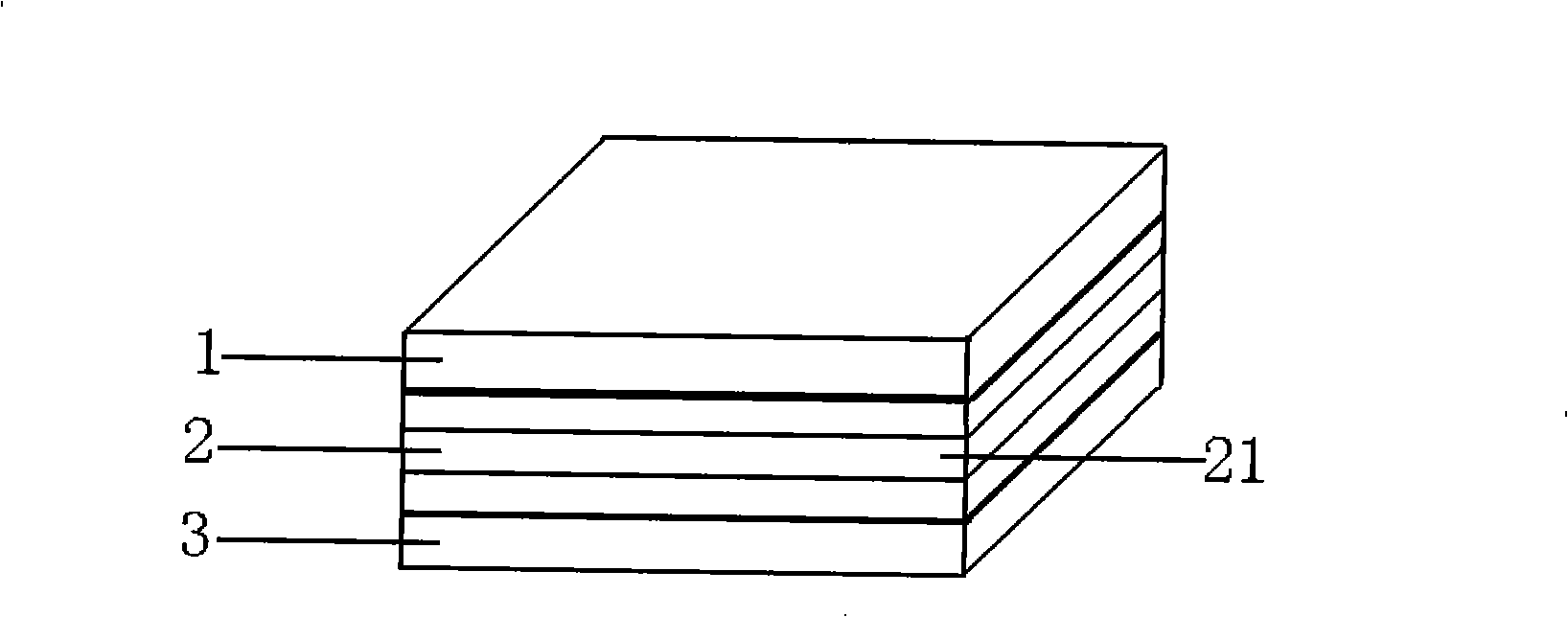

ActiveCN102198684ASave resourcesReduce consumptionWood working apparatusDomestic articlesWood shavingsSurface layer

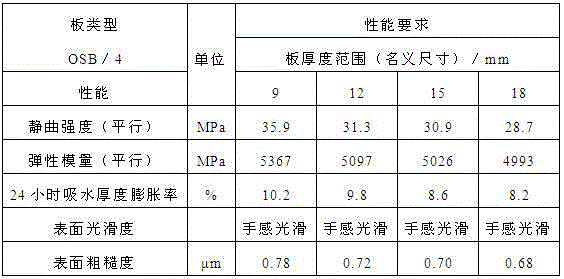

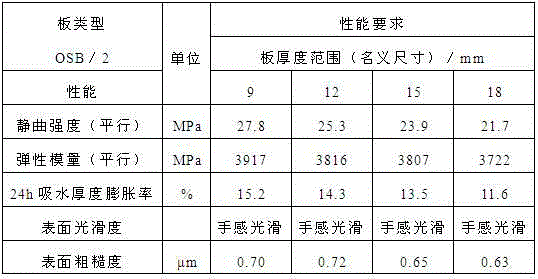

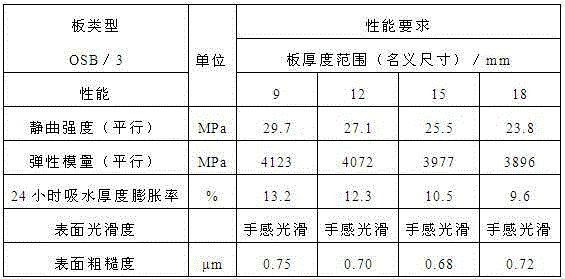

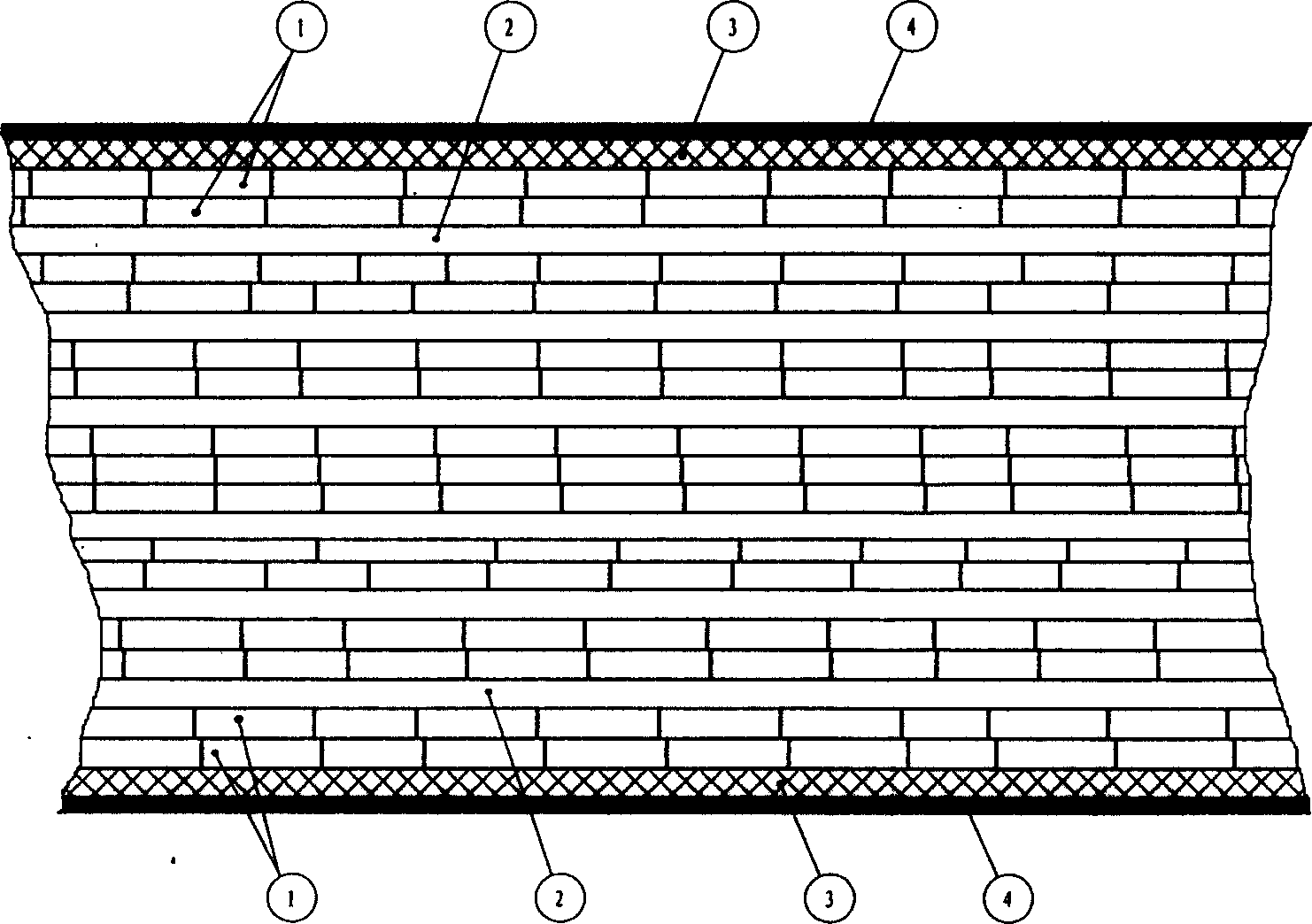

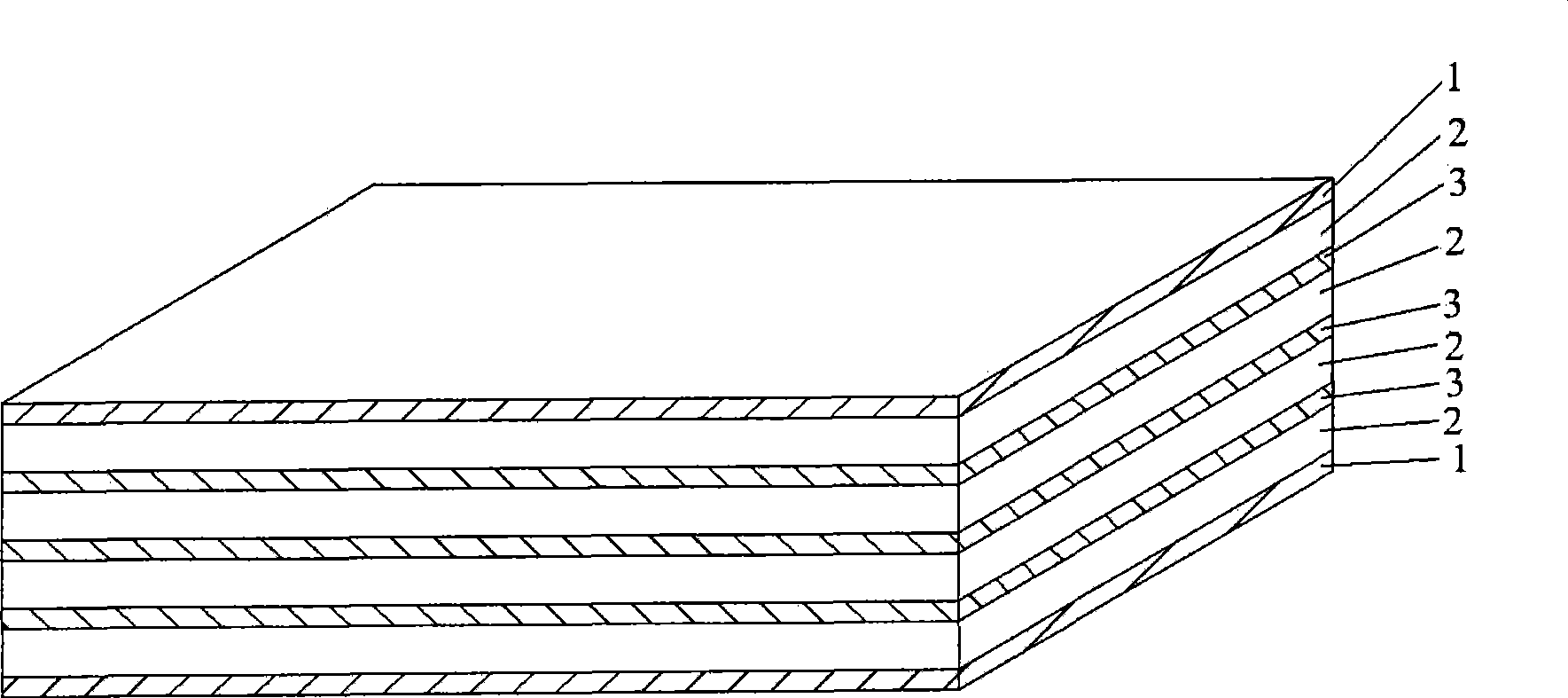

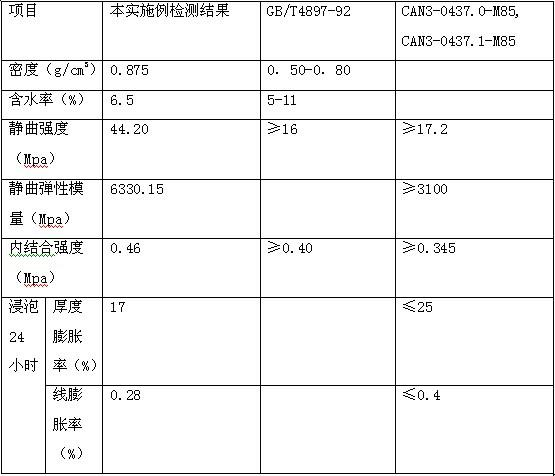

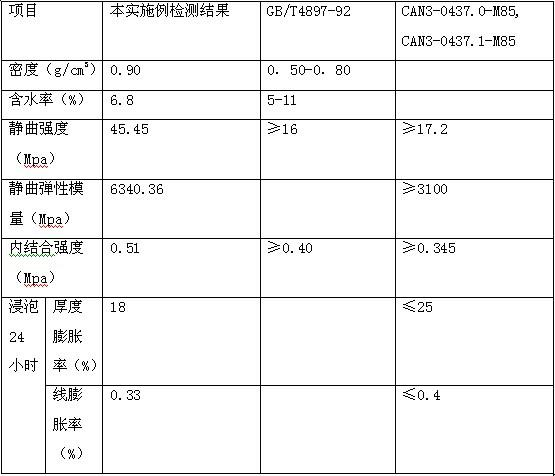

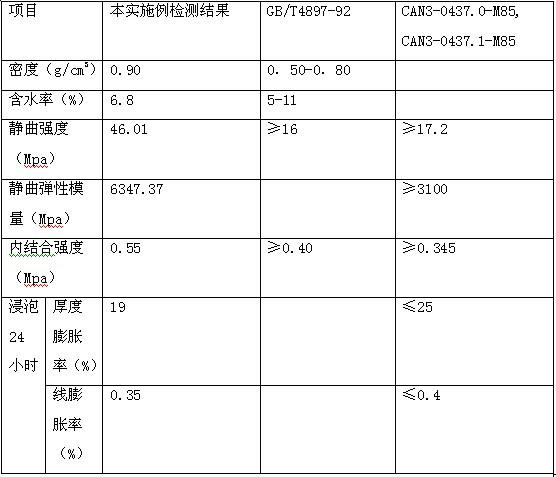

The invention discloses an oriented chipboard and a processing technology. The chipboard is composed of three layers including two surface layers and one intermediate core layer, which are adhered together by adhesives; the processing technology uses rotary cut veneer wastes remained in a plywood production process as raw materials to substitute small-diameter standard materials, so that a large volume of wood is saved, and production cost is saved; and simultaneously, the length of the oriented chipboard can be increased by using the method, consequently, inherent mechanical property indexes of the oriented chipboard can be improved, and the oriented chipboard has higher carrying capacity; the oriented chipboard and the processing technology provided by the invention have the advantages that the rotary cut veneer wastes can be used as the raw materials, so that the large volume of wood is saved, the production cost is saved, the static bending strength and the elastic modulus of the produced oriented chipboard are synchronously increased, and the carrying capacity of the oriented chipboard is greatly improved.

Owner:寿光市鲁丽木业股份有限公司

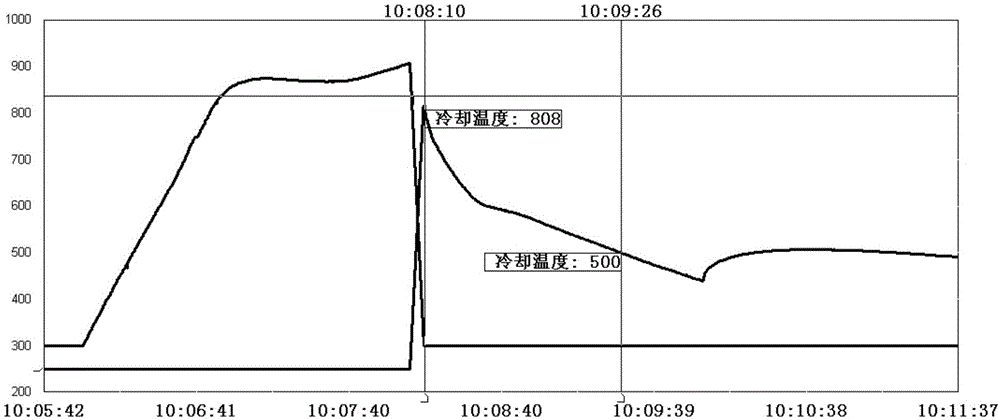

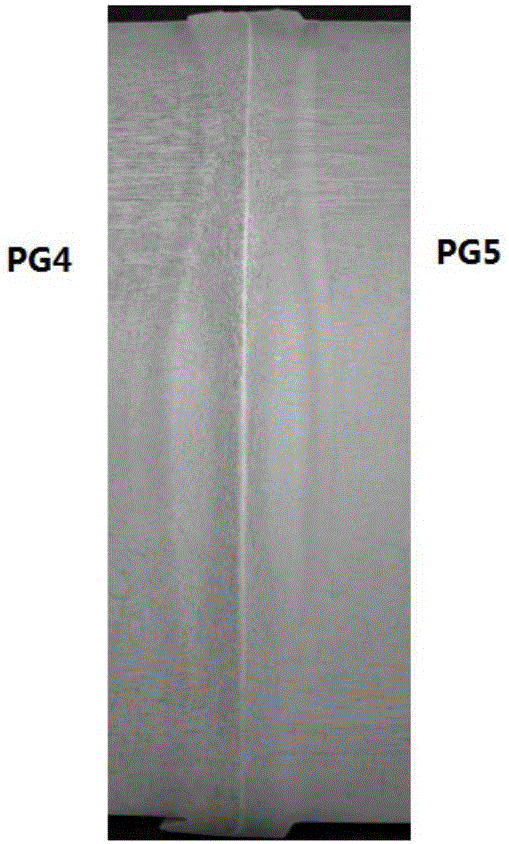

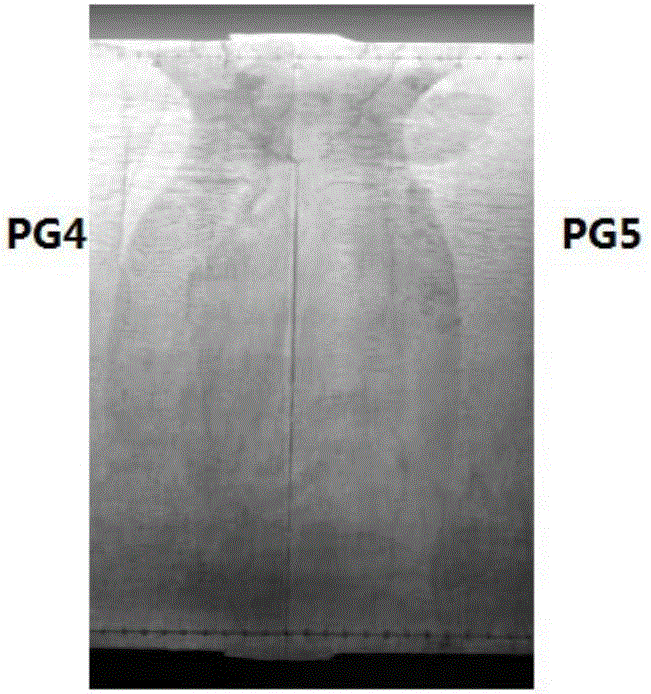

Method for post-weld heat processing of rail welded joint

ActiveCN106544933AGood toughness matchReduce internal defectsFurnace typesRailway track constructionEngineeringTread

The invention relates to the field of rail welding and discloses a method for post-weld heat processing of a rail welded joint. The method comprises the steps that first cooling is conducted to the to-be-cooled rail welded joint obtained through welding till the temperature is lower than 400 DEG C; then, the rail welded joint obtained after the first cooling is heated to a temperature between 860 DEG C and 930 DEG C; and second cooling is then conducted to the rail welded joint till a tread face temperature of the joint is between 410 DEG C and 450 DEG C, wherein the rail welded joint is a welded joint of a 75kg / m hypereutectoid steel rail and a pearlite steel rail. The method disclosed by the invention is used for the post-weld heat processing of the welded joint of the hypereutectoid steel rail and the PG4 heat-processing steel rail; and the heterogeneous rail joint has fewer internal defects and stable welding quality, and can satisfy requirements for passing tests such as a fatigue test, a stretching and impact test and a static bending test.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

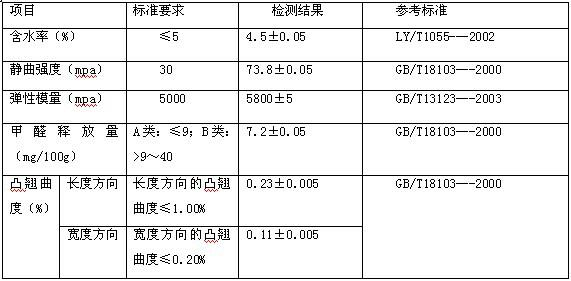

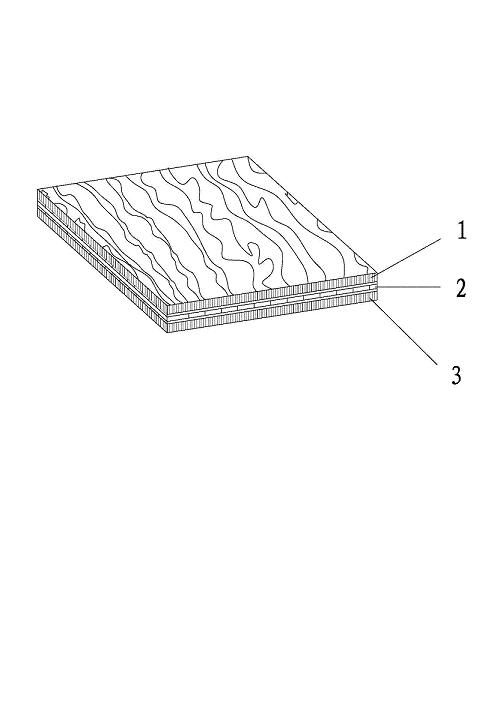

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

High-intensity wood plastic composite board and fabrication method thereof

InactiveCN101708614AEasy to produceHigh strengthWood veneer joiningFlat articlesMechanical propertyWhite oil

The invention relates to a wood plastic composite, in particular to a high-intensity wood plastic composite board and a fabrication method thereof. The method for fabricating the high-intensity wood plastic composite board comprises the following steps: treating nano titanium dioxide with silane coupling agent to obtain modified nano titanium dioxide; mechanically stirring the modified nano titanium dioxide, plastic particles, maleic anhydride grafted plastic particles, calcium stearate and the like, and extruding and pelleting all the materials to obtain modified plastic particles; mechanically stirring the modified plastic particles, wood flour, terpene resin, chopped glass fiber, white oil, antioxidant and the like, and extruding, melt-blending and pelleting all the materials to obtain high-intensity wood plastic composite particles; and finally extruding the high-intensity wood plastic composite particles with a machine to mold the high-intensity wood plastic composite board. The high-intensity wood plastic composite board has extremely wide application range, and is applied to the fields such as transportation, construction, decoration, ornament, municipal works, garden and park, packaging and the like. The high-intensity wood plastic composite board has the advantages of reproducibility, low cost and higher mechanical properties such as static bending strength and the like, thereby being an ideal material for replacing wood. Compared with traditional wood plastic composites, the high-intensity wood plastic composite board has longer service life, and is a novel upgrade product of the present wood plastic composites.

Owner:江苏森诺塑胶科技有限公司

Method for manufacturing bamboo macrofiber composite material

InactiveCN101642923AImprove permeabilityMovement does not affectReed/straw treatmentFlat articlesAdhesiveVolumetric Mass Density

The invention relates to a method for manufacturing a bamboo macrofiber composite material. Bunchy bamboo fibers of which the green and yellow are removed are taken as raw materials and dipped with awater soluble phenol formaldehyde adhesive, and the production steps comprise material preparation (comprising the preparation of bamboo macrofiber reinforcement and a water soluble phenol formaldehyde resin matrix), adhesive dipping, extraction, warm-pressing, curing and post curing. The method has the advantages that: (1) the method has reasonable process, strong production continuity, high efficiency, low energy consumption, and no environmental pollution; (2) the manufactured bamboo macrofiber composite material has no mold and no crack, and has the density between 0.9 and 1.3g / cm<3>, thehardness between 60 and 150MPa, the static bending strength between 140 and 160MPa, the water-absorbing expansion rate between 0.3 and 2 percent, the surface wear resistance between 0.04 and 0.09g / 100r, and the formaldehyde emission between 0.1 and 0.4mg / L; and (3) the invention provides a more positive production technique for reasonably utilizing the bamboo resources, so that the reconstituted bamboo timber application prospect is better.

Owner:仇峰 +1

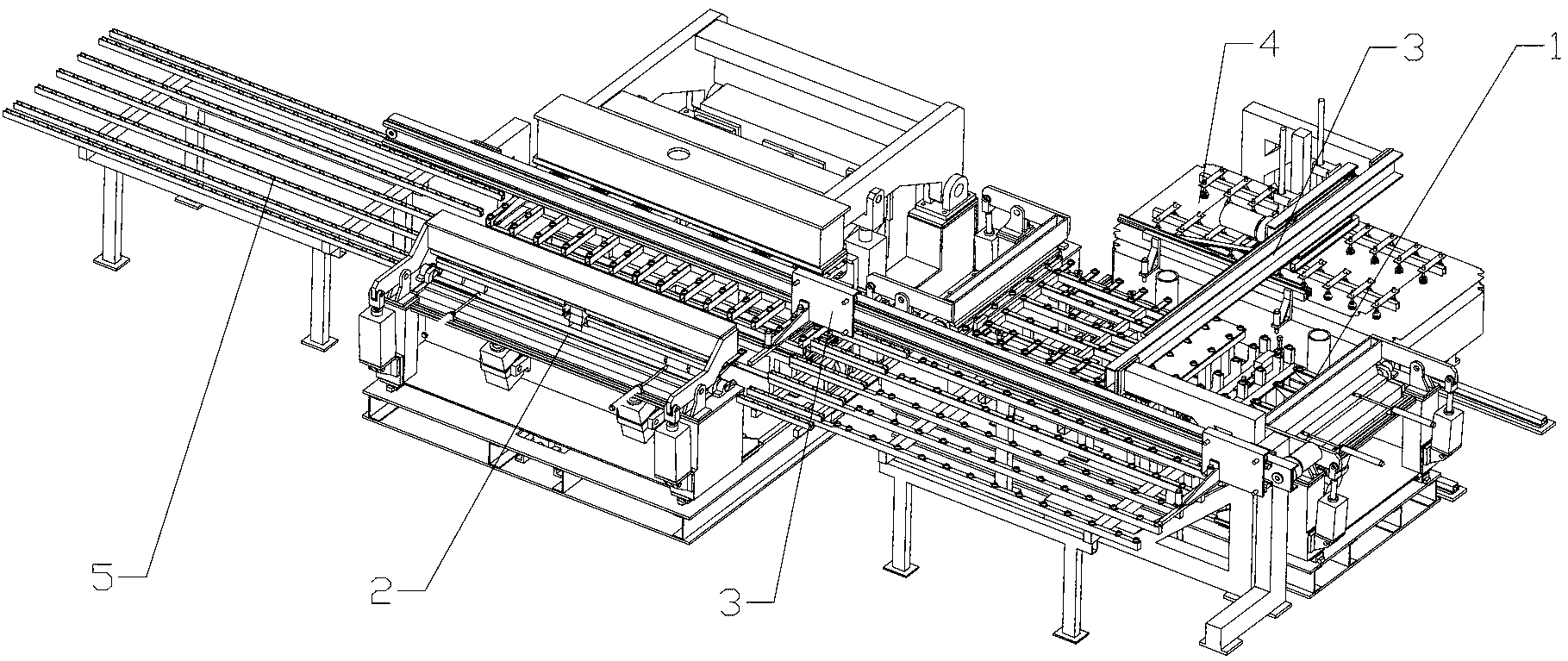

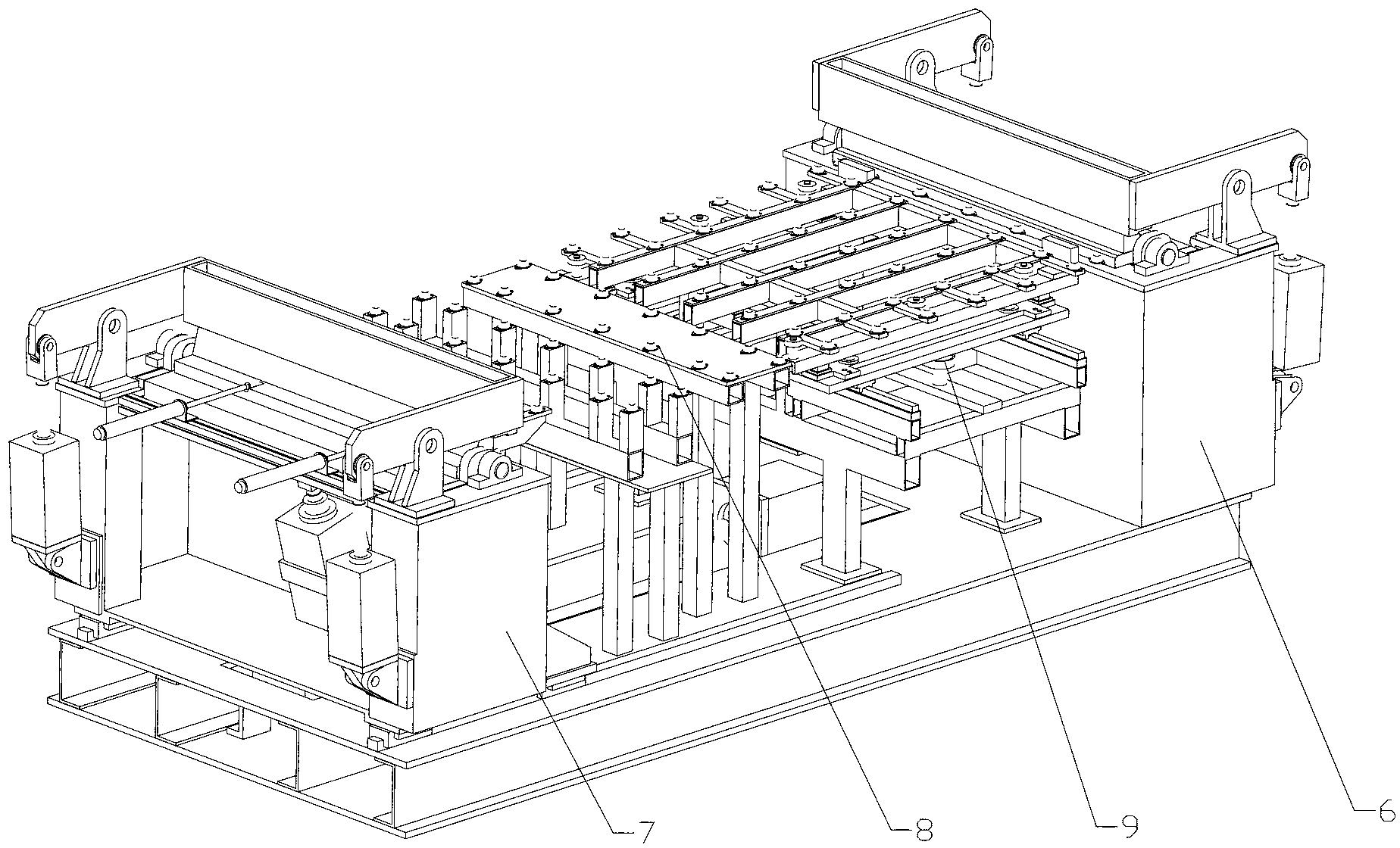

Four-side bending system

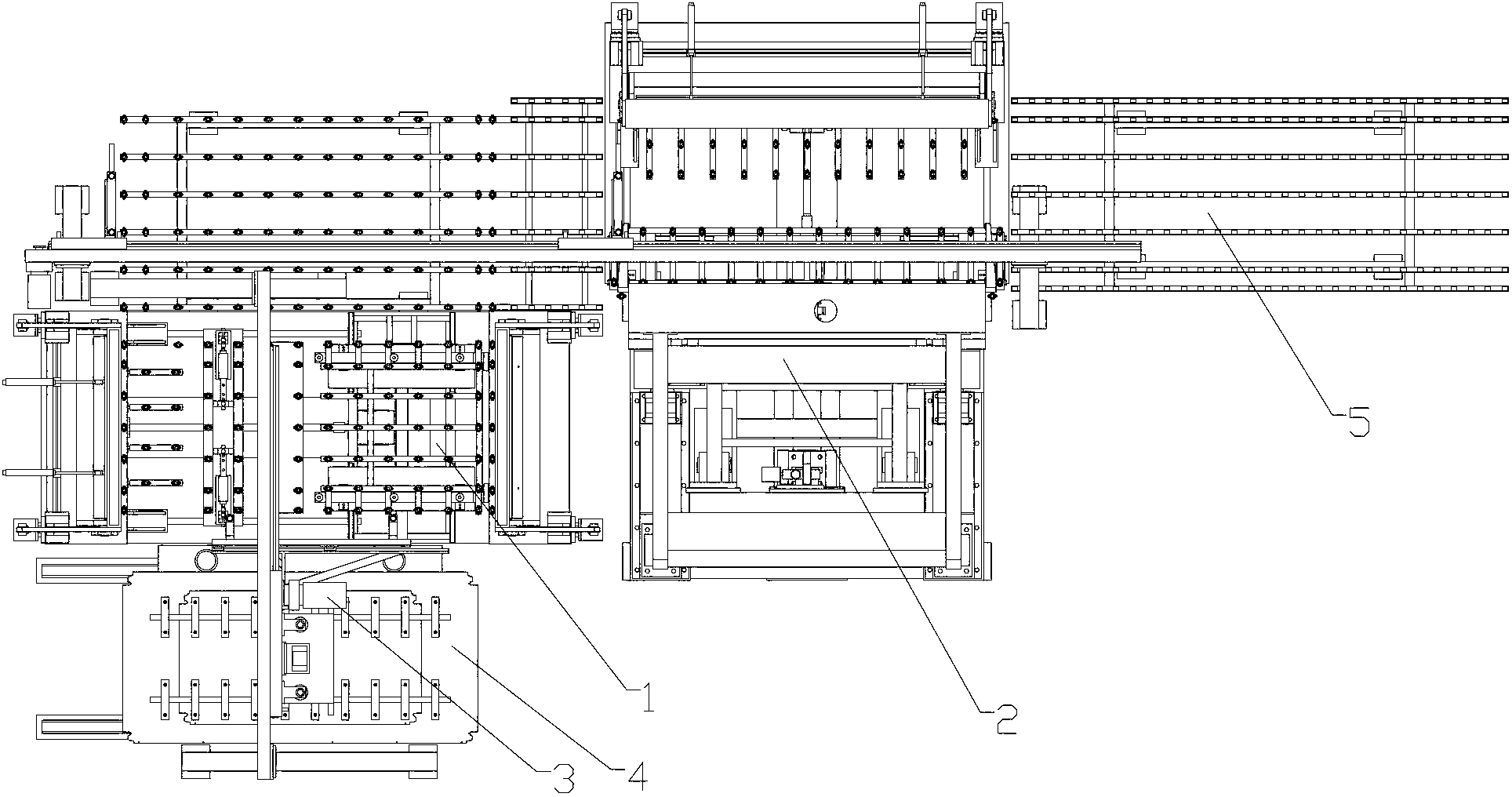

ActiveCN102909244AImprove combination efficiencyEasy to arrange for productionMaterial transferPress brake

The invention relates to a four-side bending system comprising a first bending unit, a second bending unit and a material transferring device, wherein the first bending unit is used for completing the bending work of a group of opposite sides of a material to be bent; the second bending unit is used for completing the bending work of the other group of opposite sides of the material to be bent; and the material transferring device is used for shifting the material according to the process. The first bending unit comprises a first static bending machine, a first movable bending machine, a first working table and a first positioning part, wherein the first static bending machine and the first movable bending machine are oppositely placed on a main frame; and the working table and the positioning part are placed between the first static bending machine and the first movable bending machine. The second bending unit comprises a second static bending machine, a second movable bending machine, a second working table and a second positioning part, wherein the second static bending machine and the second movable bending machine are oppositely placed on the main frame; and the second working table and the second positioning part are placed between the second static bending machine and the second movable bending machine. The four-side bending system is relatively high in production efficiency, relatively low in manufacture cost and simple to maintain and is suitable for various productions.

Owner:YINDU KITCHEN EQUIP

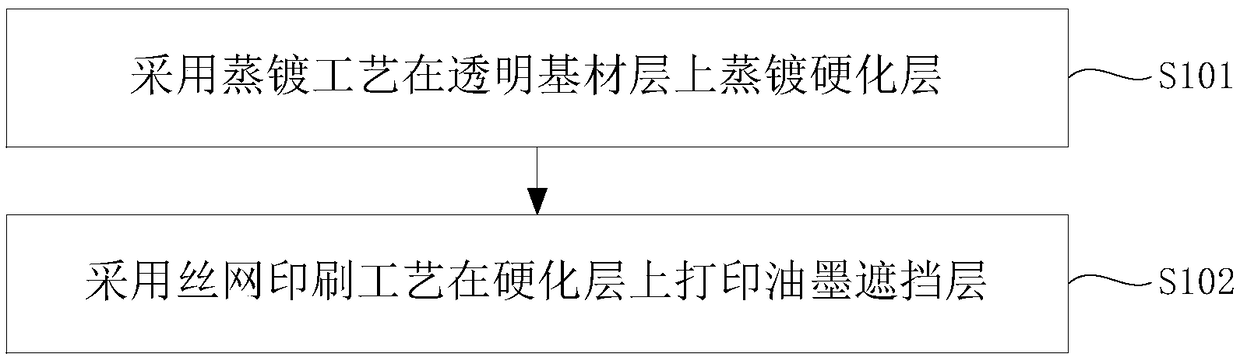

Cover plate, preparation method of cover plate, display panel and display device

PendingCN108831305AImprove bending reliabilityGuaranteed surface hardnessDigital data processing detailsCasings/cabinets/drawers detailsDisplay deviceHardness

The invention relates to the technical field of display, and discloses a cover plate, a preparation method of the cover plate, a display panel and a display device. The bending reliability and deformation recovery reliability of the cover plate are improved. The cover plate comprises a transparent substrate layer and a hardening layer located above the transparent substrate layer, wherein the transparent substrate layer comprises a bent area and a non-bent area; soft hardening materials and rigid hardening materials are alternately arranged on the portion, on the bent area, of the hardening layer; the portion, on the non-bent area, of the hardening layer is provided with a rigid hardening material. In the cover plate, the bent area is provided with the flexible hardening materials so thatthe hardening layer breaking phenomenon cannot occur when the bending radius of the bent area of the cover plate is small, and then the bending reliability of the cover plate can be improved. Meanwhile, the rigid hardening materials of the bent area and the rigid hardening material of the non-bent area are arranged so that the surface hardness of the cover plate can be guaranteed, the cover platecan still restore a flat state after dynamic bending or long-time static bending.

Owner:BOE TECH GRP CO LTD

Method for producing bamboo-wood composite board

ActiveCN102398287AAchieve sustainable developmentShorten the growth cycleWood veneer joiningMaterials scienceStatic bending

The invention relates to a method for producing a building composite rubber plate, in particular to a method for producing a bamboo-wood composite board. The method for producing the bamboo-wood composite board is implemented by the following technical scheme that the method for producing the bamboo-wood composite board comprises the following steps of: (1) preparation of a core board and a surface board; and (2) compounding process of the core board and the surface board. The bamboo-wood composite board prepared by implementing the method disclosed by the invention has the advantages of low buckling deformation and high static bending strength.

Owner:浙江安吉双虎竹木业有限公司

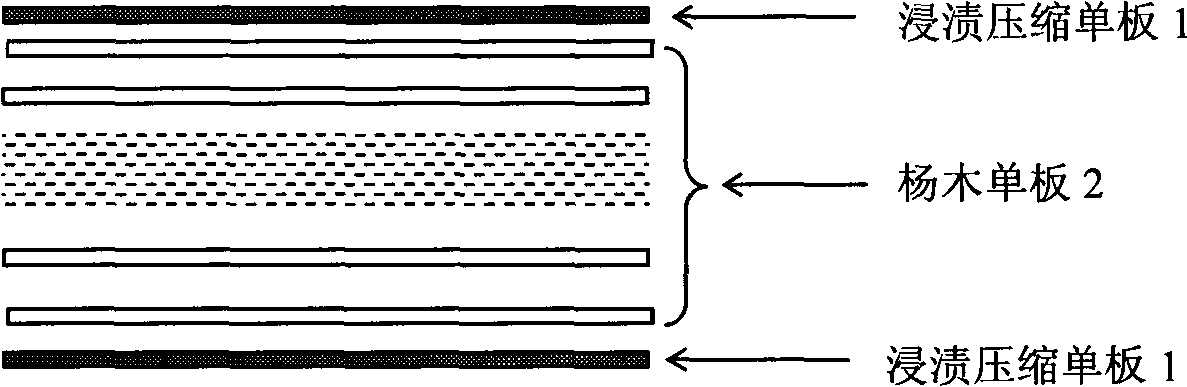

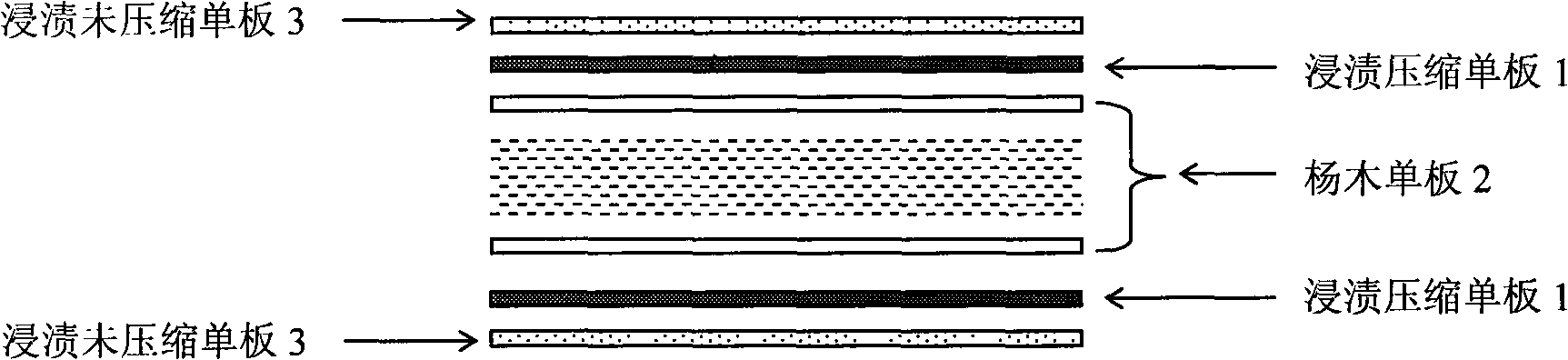

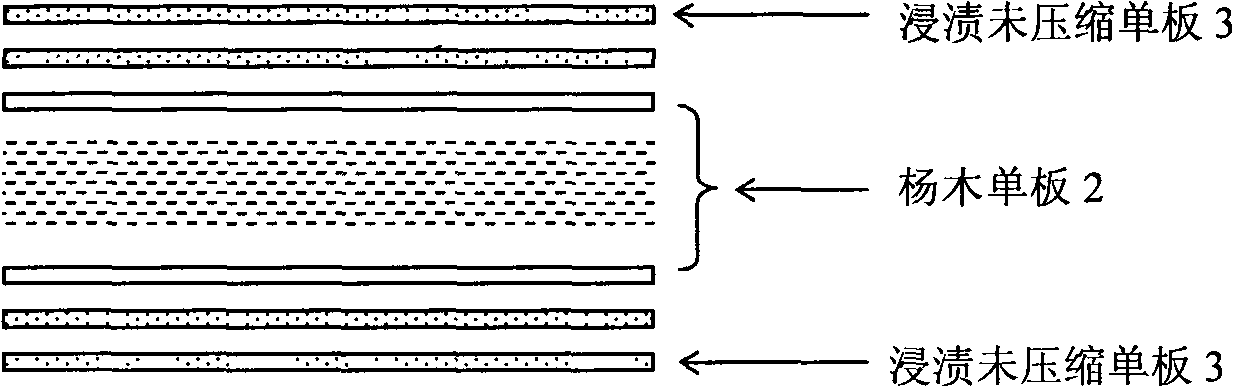

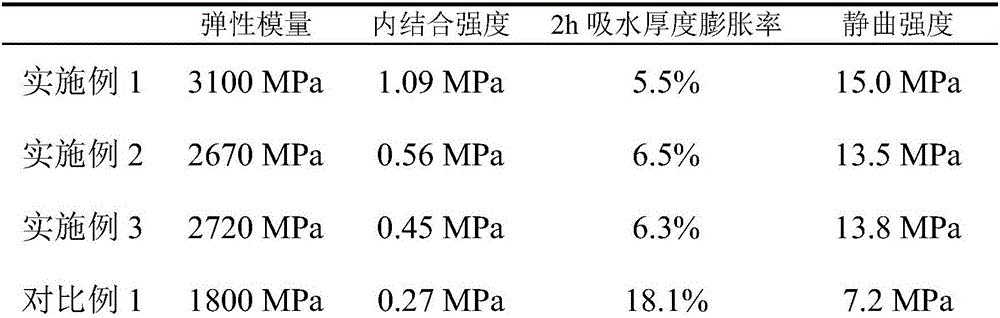

Impregnation densified veneer enhanced laminated veneer lumber and a manufacturing method thereof

ActiveCN102179842AEfficient use ofSave resource loggingWood veneer joiningDomestic articlesEcological environmentEngineering structures

The invention relates to an impregnation densified veneer enhanced laminated veneer lumber and a manufacturing method of the impregnation densified veneer enhanced laminated veneer lumber, the impregnation densified veneer enhanced laminated veneer lumber structurally consists of an impregnation veneer or / and an impregnation densified veneer and a wood veneer, wherein the impregnation veneer or the impregnation densified veneer is used as the surface layer and the subsurface layer of a laminated veneer lumber plate blank or all layers of the plate blank and is used for increasing the modulus of elasticity and the static bending strength of the laminated veneer lumber. The impregnation densified veneer enhanced laminated veneer lumber has the advantages that: a thick veneer made of fast-growing wood is adopted as raw material to manufacture the impregnation densified veneer enhanced laminated veneer lumber, the intension is high, the dimensional stability is good, the physical mechanical property can meet the requirement of structural laminated veneer lumber standard in China, the impregnation densified veneer enhanced laminated veneer lumber can totally replace high-quality solid wood converted timber and can be used in a constructional engineering structure and used as a high class cement concrete framework, heavy electro machinery packing material and the like. The fast-growing wood is utilized effectively and comprehensively, nature timber resources are saved, the ecological environment is protected, the additional value of a product is increased, and the supply and demand contradiction to major diameter class nature timber in domestic market is remitted.

Owner:NANJING FORESTRY UNIV

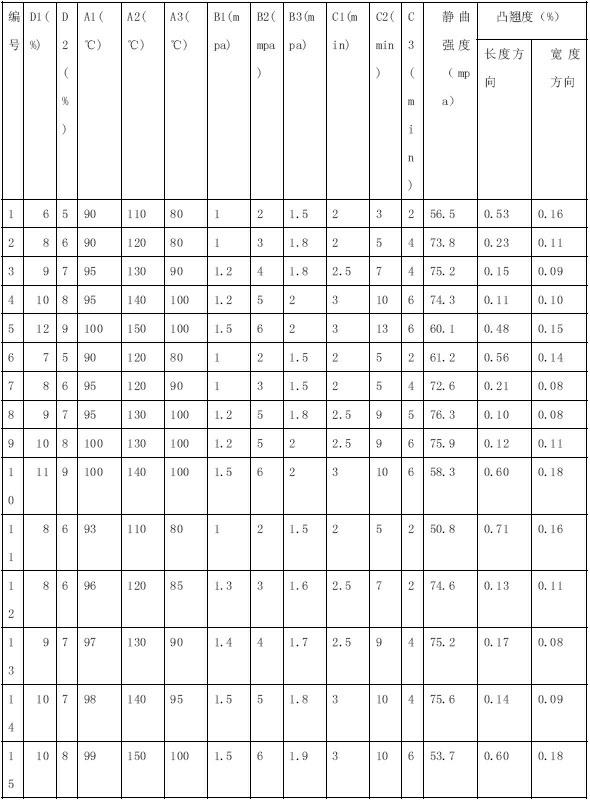

Wood bunch recombining material and producing method thereof

InactiveCN101104286ALow technical requirementsReduce investmentDomestic articlesFlat articlesFiberVolumetric Mass Density

Disclosed is a wood bunch composite lumber, whose cross section is square, round or elliptical shaped, wherein the wood fiber is vertically arranged; the appearance of the cross section is a congregated section of numerous wood bunches, showing the combining color of the natural wood color and the color of the glue; the density is 0.7-1.1g / cm3; the static bending strength is 30-40MPa; the elasticity modulus is 5000 -11000MPa; the nail-holding ability is 1100-2000N. The production of the composite lumber includes the following procedures: material selection, wood-bunch preparation, desiccantion, gluing, measuring, assembling, mould packing, cold pressing, thermal initiated solidification, cooling and mould removal. The composite lumber can be applied directly to the architectural ornament industry, the sawed floor board and the furniture faceplate and so on. The invention has advantages that the raw materials adopted can make comprehensive use of the lumber resources; the material quality of the product is even; the structure and the nature of the lumber can basically be kept unchanged; the lumber is material-saving, stable and easy for secondary production.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Urea formaldehyde resin adhesive medium density fiber board utilizing castor bean stalk as raw material

The invention relates to a urea formaldehyde resin adhesive medium density fiber board utilizing a castor bean stalk as a raw material, which is characterized in that the weight proportion of the solid additive amount of castor bean stalk fiber or castor bean stalk with 8 percent of water content and urea formaldehyde resin adhesive is 86-90 to 14-10. The preparation process comprises the following steps: preparing raw materials; mixing the fiber with adhesive and drying; laying and prepressing; hot pressing; and post processing. The invention has the advantages of low manufacture cost, wood resources saving, ecological environment protection and industrialized production. After urea formaldehyde resin is used as the adhesive and 1.0-1.6 percent of paraffin is added on the basis of the mass of the absolutely dry fiber, all technical indexes of the produced medium density fiber board are as follows: density 0.55-0.85kg / cm3, static bending strength 25-37MPa, elastic modulus 2950-3210MPa,plane tensile strength 0.68-1.0MPa and absorbing water thickness expansion rate 7.32 percent-9.25 percent, and reach the standard of a Chinese fiber board.

Owner:苏州伍得人造板设备有限公司

Soybean-based formaldehydeless adhesive used for chipboards, and application method thereof

ActiveCN105838304ASolve for uniformitySolve the problem of excessive moisture content of wood shavings after sizingNon-macromolecular adhesive additivesProtein adhesivesWood shavingsCross-link

The invention discloses a soybean-based formaldehydeless adhesive used for chipboards, and an application method thereof. The soybean-based formaldehydeless adhesive is prepared from, by weight, 10-30 parts of a soybean derivative, 0.1-1 part of an acidity-alkalinity adjusting agent, 1-30 parts of a cross-linking agent, 0.1-1 part of a mildew inhibitor, 0.1-1 part of a leveling agent, 10-100 parts of water and 5-50 parts of a tackifier. Multi-component adhesive application is adopted to solve the problems of unable adhesive application of commercial soybean adhesives and too high water content of wood shavings after adhesive application, and the tackifier is used to solve the problems of poor initial viscosity of chipboards made by using the soybean adhesives, poor pre-forming property after adhesive application of wood shavings, and low static bending strength and large water absorption thickness swelling rate of boards.

Owner:宁波朝露新材料科技有限公司

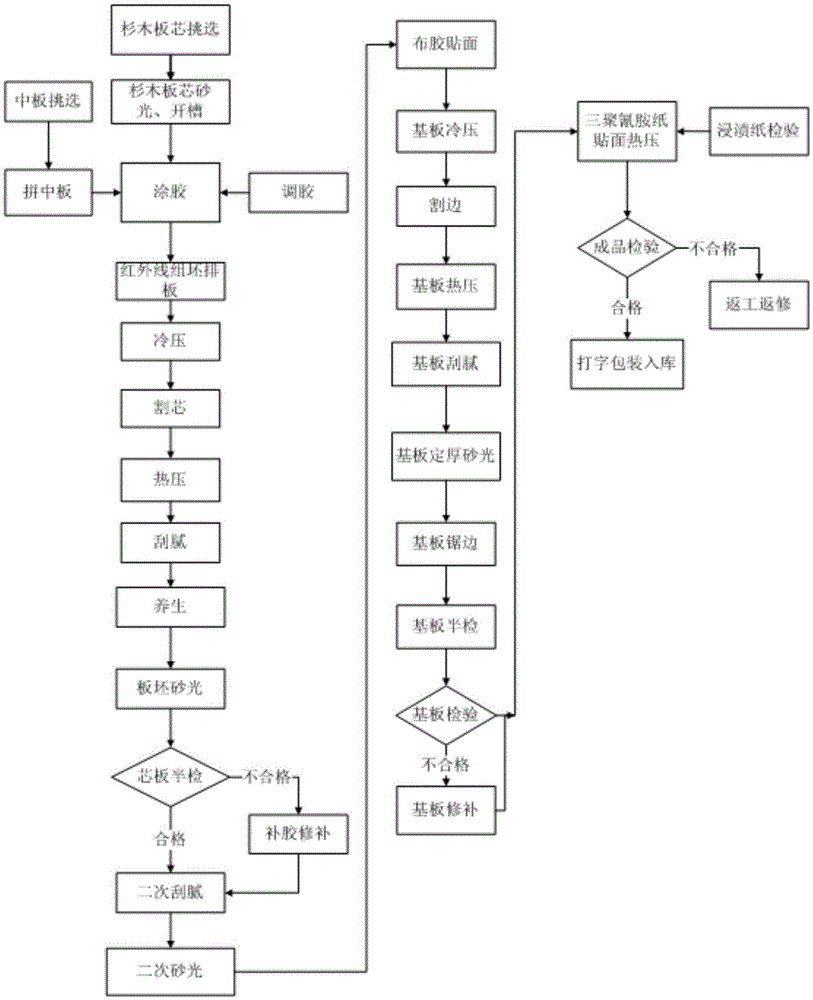

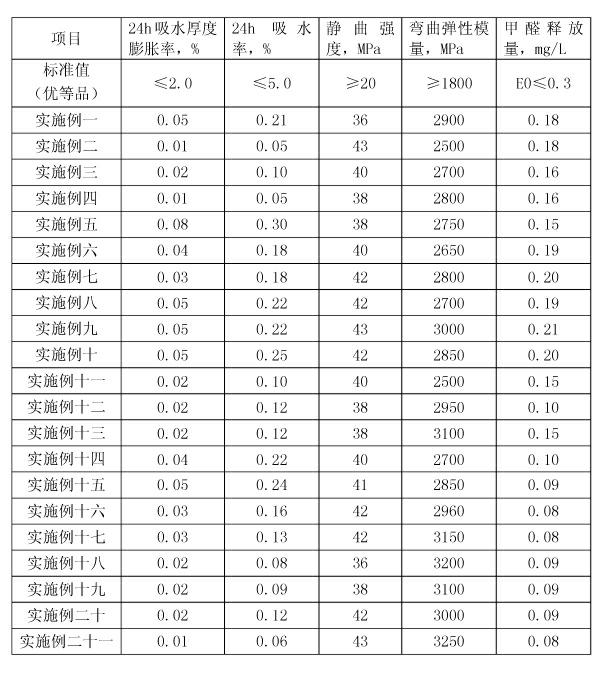

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Zero-carbon high-fiber environment-friendly sheet synthesized by waste circuit board powder and production process thereof

The invention discloses a zero-carbon high-fiber environment-friendly sheet synthesized by waste circuit board powder and a preparation process thereof. The pressing raw materials of the environment-friendly sheet comprise: circuit board recycled powder, wood fiber powder, a cross-linking agent, a waterproofing agent, and carbon filament fiber; the production process of the sheet comprises the following steps of: drying the circuit board recycled powder at a constant temperature; converting high fiber auxiliary materials into wood fiber powder above 80 meshes, drying, and then stirring under 180 DEG C to form carbon fiber powder; adding a processing assistant and blending uniformly again; and feeding materials, paving pressing plates, pressurizing, standing, complementing pressure, and gently decompressing to produce the sheet. The pressure during the production process is controlled so that the sheet is stable in quality and high in intensity; the sheet synthesized by wood fiber powder obtained by recycling crop straw, bamboo and wood saw powder and the like with the waster circuit board powder can be sawn, drilled, processed, and shaped easily; furthermore, the sheet is excellent in waterproof and fireproof performances, and high in static bending strength; and the utilization of waste materials reaches the purposes of environmental protection and low carbon.

Owner:清远炬众节能环保科技有限公司

Low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive and preparation method thereof

ActiveCN103865404AImprove flame retardant and smoke suppression performanceNon-combustibleInorganic adhesivesPolyvinyl alcoholInternal bonding

The invention discloses a low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive and a preparation method thereof. The low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive comprises the following components in parts by weight: 30-50 parts of magnesium oxide, 20-40 parts of magnesium chloride, 30-60 parts of water, 3-8 parts of polyvinyl alcohol, 1-5 parts of trisodium phosphate, 2-7 parts of water glass, 0.08-0.1 part of tartaric acid, 0.5-3 parts of sulfonic acid, 0.05-0.3 part of octylphenol polyvinyl ether and 0.01-0.2 part of sodium carboxymethyl cellulose. The low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive prepared through the method is noninflammable and achieves outstanding flame-retardant smoke-suppressing property on an artificial board. The fire-proof grade of the prepared artificial board achieves A2 grade through testing; the price of the prepared artificial board only accounts for 5% of the price of an isocyanate adhesive and accounts for 50% of the price of an urea-formaldehyde resin adhesive; the internal bonding strength of the produced artificial board achieves 1.05 MPa, the static bending intensity achieves 16.5 MPa, and the 24-hour water absorption thickness expansion ratio is only 1.1%. The low-cost high-strength flame-retardant smoke-suppressing artificial board inorganic adhesive disclosed by the invention can not release any harmful gas and achieves outstanding environmental-friendly property.

Owner:河南恒顺植物纤维板有限公司

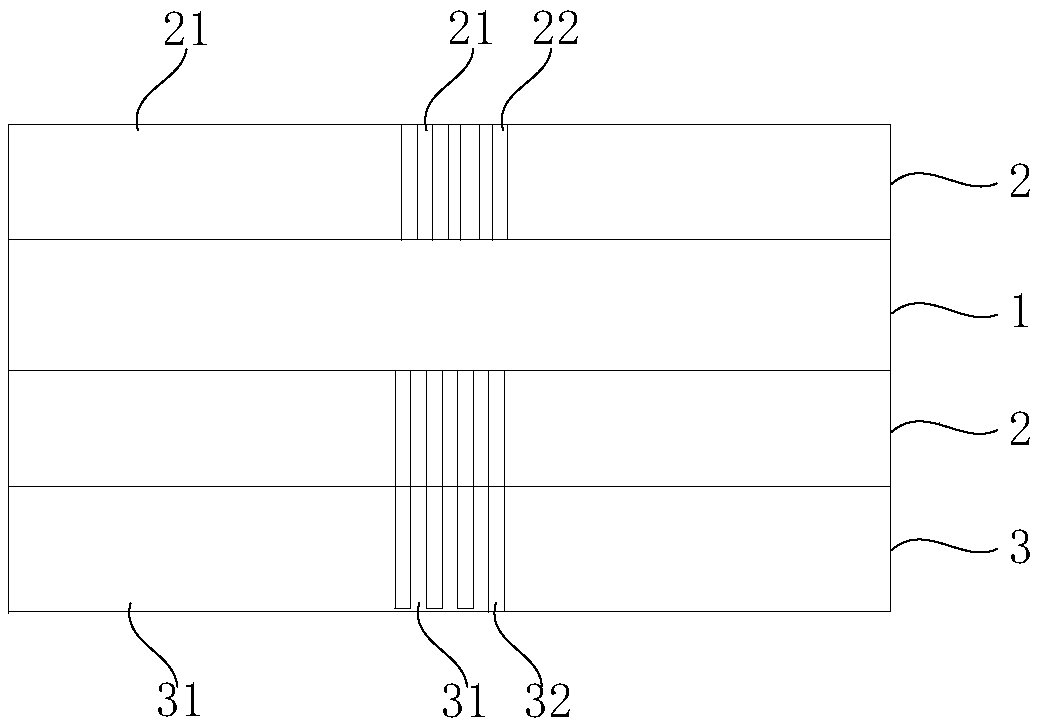

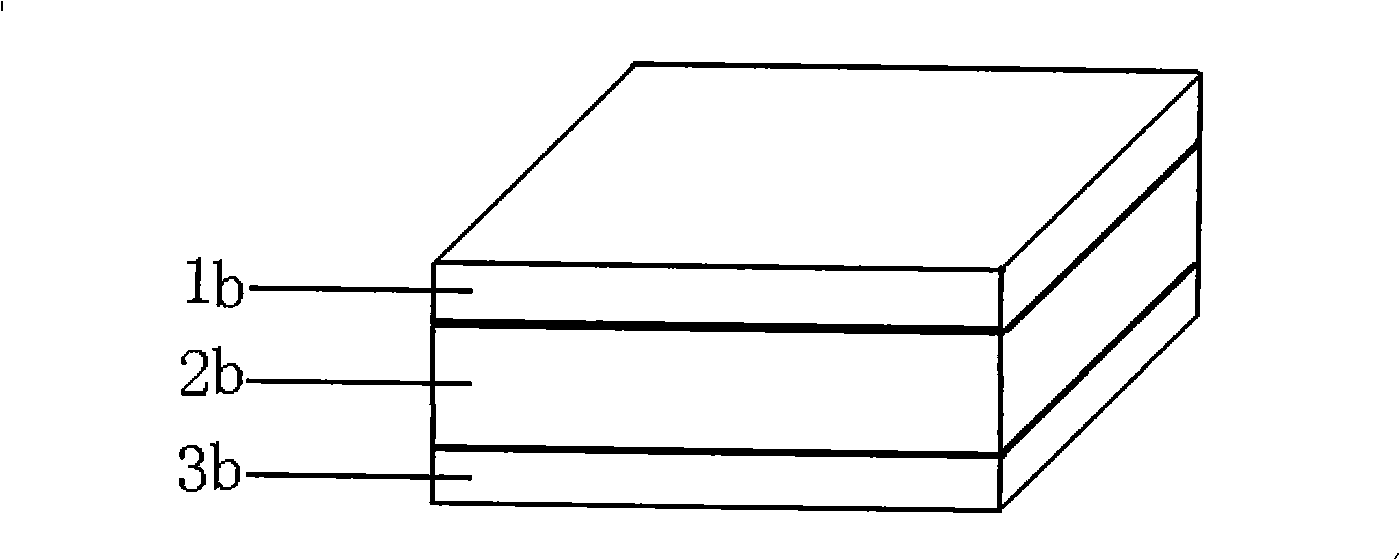

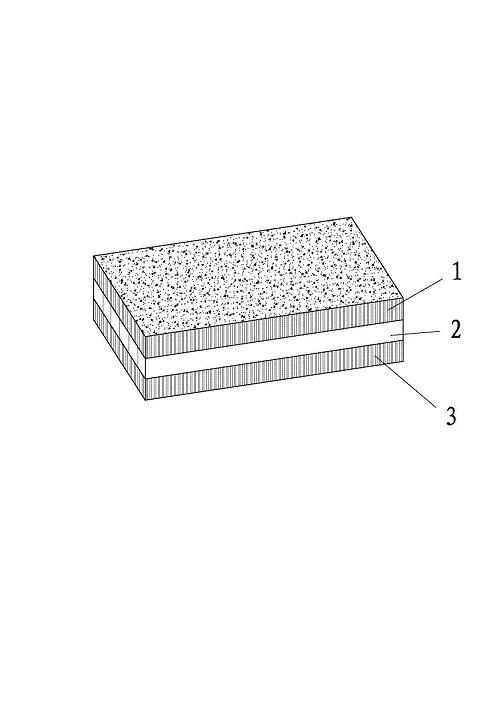

Three-laminated composite board type full-nutritional rice seedling breeding bedding and preparation method thereof

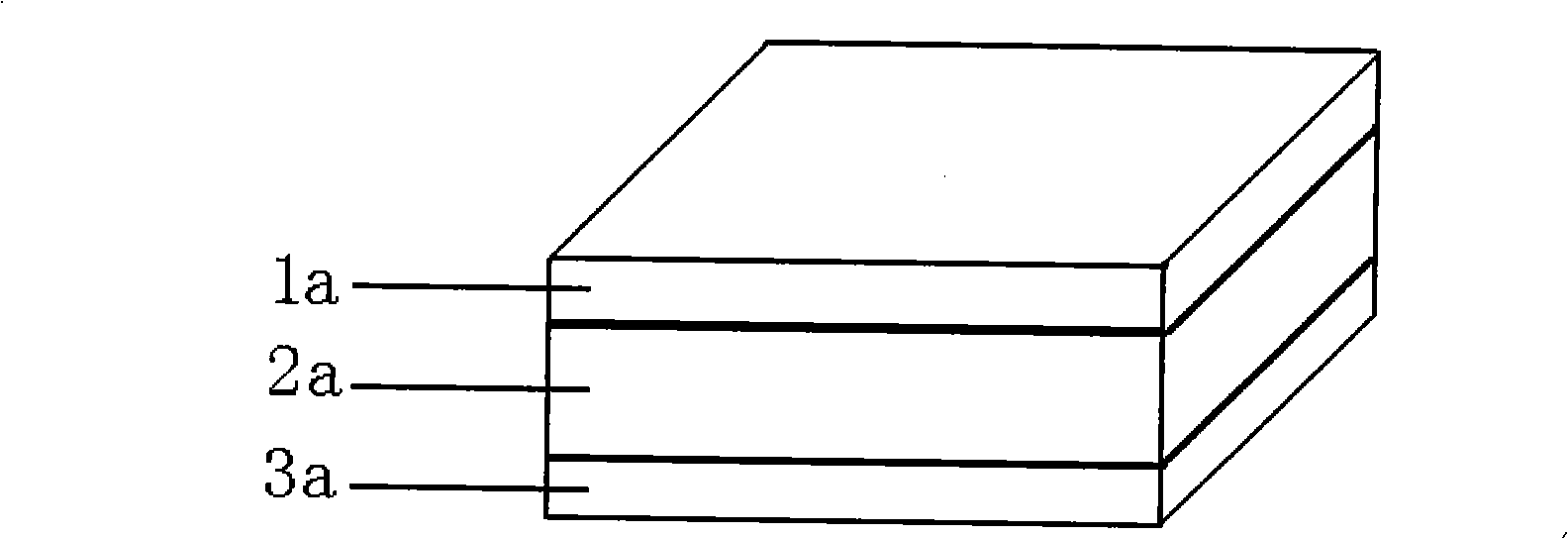

InactiveCN106542909AUniform textureQuality improvementGrowth substratesCulture mediaSurface layerUltimate tensile strength

The invention discloses three-laminated composite board type full-nutritional rice seedling breeding bedding and a preparation method thereof and relates to rice seedling breeding bedding and a preparation method thereof. The problems that existing seedling breeding bedding is poor in water-retaining property, fertilizer efficiency in the later period of seedling breeding is poor, strength is low, and the existing seedling breeding bedding is not suitable for being transported and carried are solved. The seedling breeding bedding is divided into three layers from top to bottom, the middle layer is a core layer, and the surface layers are located on the two sides of the core layer. The preparation method comprises the following steps that (1), straw is cut into sections; (2), steaming and softening are conducted; (3), the straw is ground and kneaded to be in a fiber shape and is dried; (4), mixing is conducted; (5), paving is conducted; and (6), hot-pressing is conducted. According to the three-laminated composite board type full-nutritional rice seedling breeding bedding (as shown in figure 1) produced through the preparation method, when no water is absorbed by the three-laminated composite board type full-nutritional rice seedling breeding bedding, the static bending intensity is 21-22.8 MPa, and the internal bonding strength is 0.35-0.40 MPa; and the three-laminated composite board type full-nutritional rice seedling breeding bedding is high in strength, not prone to breakage or damage and easy to cut and can be manufactured to be in different shapes.

Owner:刘越

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

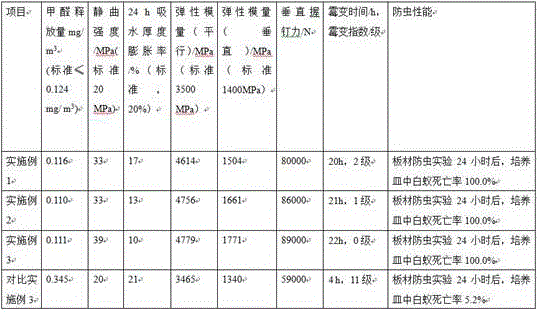

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

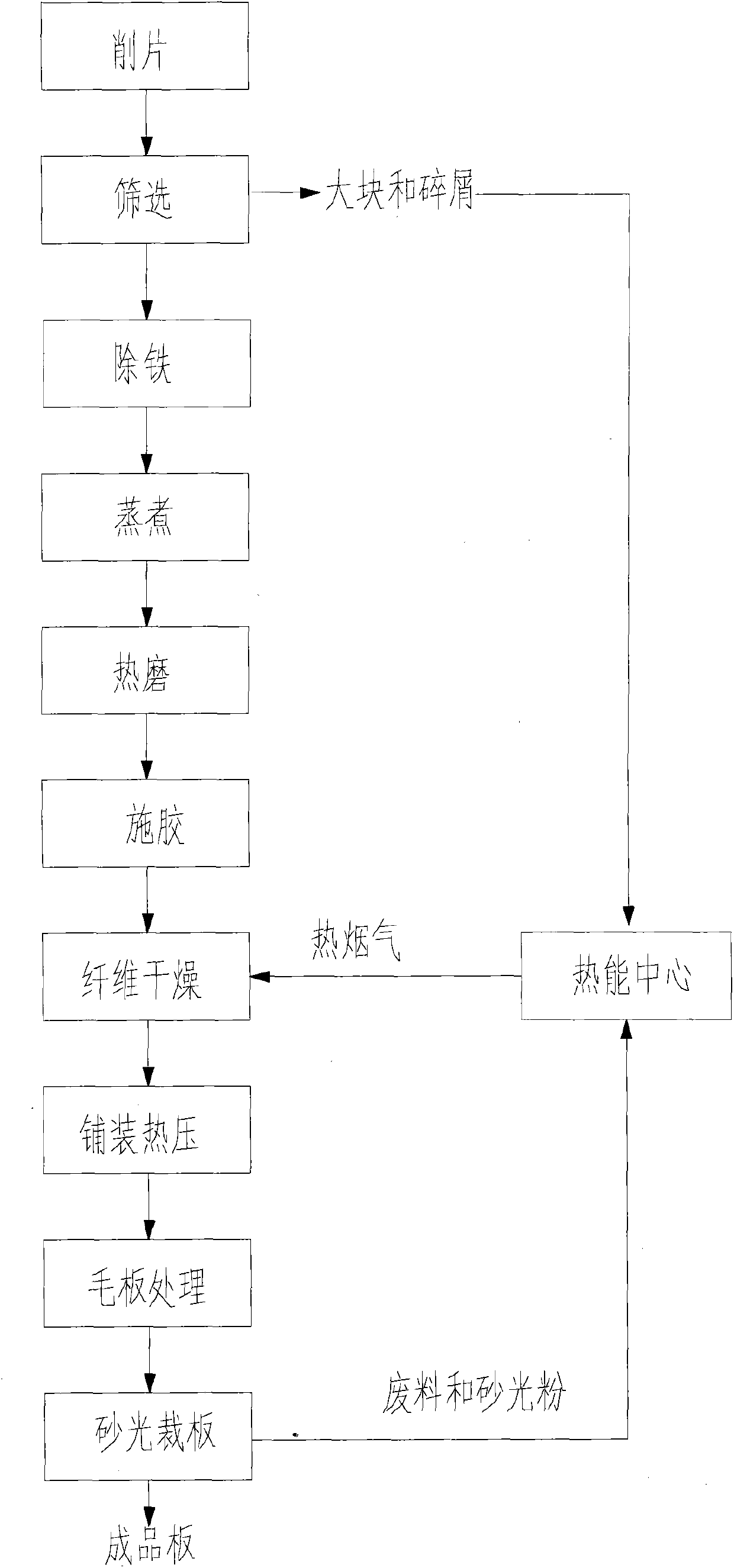

Fiberboard production process for elecampane non-formaldehyde floor base material

InactiveCN103737696AIncrease elasticityHigh strengthDomestic articlesFlat articlesFiberPolyurethane adhesive

The invention provides a fiberboard production process for an elecampane non-formaldehyde floor base material and relates to the technical field of artificial board production. The fiberboard production process comprises the steps of using pines and poplars as raw materials, chipping, screening and deironing, preparing fiber and sizing-drying, laying and hot-pressing, processing rough boards, sanding and cutting the boards and the like, a certain proportion of jasmine or sandalwood and other flavoring agents are added in a waterproof agent adopted in the fiber preparing and sizing-drying step, and an urea-formaldehyde resin adhesive is replaced by a polyurethane adhesive. In the fiberboard production process, a continuous flat pressing technology is adopted, and accordingly the elasticity modulus, static bending intensity and physical and mechanical properties of products are further improved by fully mixing the pines and poplars in certain proportion. The products do not contain formaldehyde and is good in waterproof performance by adopting the polyurethane adhesive to replace the urea-formaldehyde resin adhesive during production of fiberboards for floor base materials. In addition, a certain proportion of jasmine or sandalwood and other flavoring agents are added in the waterproof agent, so that the products have fragrance and have the advantages of being stable in quality, environment-friendly and healthy.

Owner:SHANDONG HEYOU GROUP

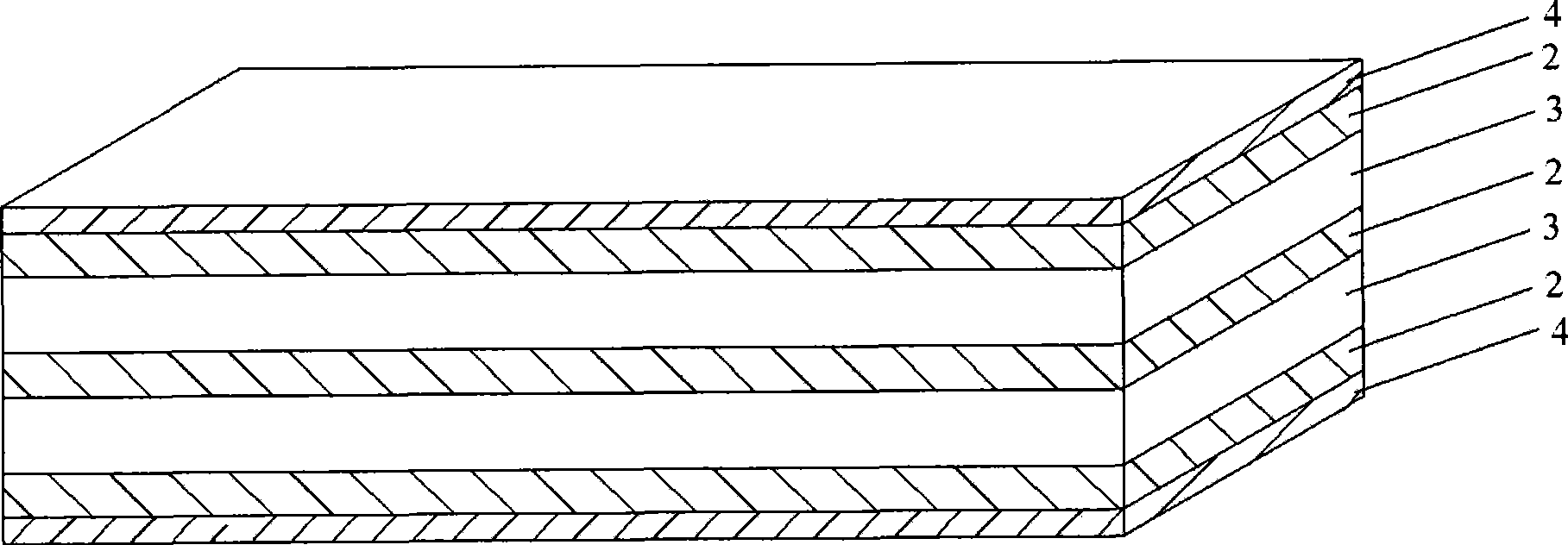

Bamboo and wood alternately arranged composite board and its manufacturing method

InactiveCN1569409AReduce consumptionCane mechanical workingWood veneer joiningEngineeringUltimate tensile strength

The invention discloses a bamboo and wood interface compound board, which includes lengthwise arranged bamboo pieces and transverse arranged wood single boards. The bamboo piece and the single wood boards are compounded together layer by layer from outside in; the external layer is made up of three layers of bamboo pieces, the core layer is made p of single layer wood board and two layers of bamboo pieces. They are also can be compounded: the external layer is one bamboo banquet, the core layer is made up of single layer board and two layers of bamboo pieces, the furthest layer is bamboo piece. The compressing rate is more than 25%, the intensity is more than 21kg / cm2, the static bending modulus is more than 1000kg / cm2, the elastic modulus is more than 100ton / cm2.

Owner:南通新洋环保板业有限公司

Scrimber and manufacturing method thereof

ActiveCN101642924AQuality improvementNo pollution in the processWood treatment detailsDomestic articlesFiberAdhesive

The invention discloses a scrimber and a manufacturing method thereof. The scrimber is prepared by the following steps: taking braches as raw materials, and cutting, peeling and grinding the branchesinto bunchy macrofiber; removing hemicelluloses and pectin; dipping a water soluble phenol formaldehyde adhesive; extracting free phenol and water content of the free phenol in vacuum; warmly pressinginto sections; performing curing; and performing after curing. The physical and mechanical properties of the scrimber are as follows: the density is between 0.9 and 1.3g / cm<3>; the hardness is between 60 and 120MPa; the static bending strength is between 90 and 150MPa; the water-absorbing expansion rate is between 0.3 and 2 percent; and the formaldehyde emission is between 0.1 and 0.4mg / L. The invention has the advantages that: the invention provides a scrimber product with no mold, no crack and no horizontal warpage; the manufacturing method for the scrimber has reasonable process, high efficiency, low energy consumption and no environmental pollution, the production flow has strong continuity and high connection degree, and the scrimber can be produced on a large scale; and the prospectof fully utilizing branch resources is better.

Owner:仇峰

Bamboo wood composite plywood for concrete form panel and manufacturing method thereof

InactiveCN101486208AIncrease profitReduce manufacturing costWood veneer joiningWood layered productsEnvironmental resistanceSurface layer

The invention relates to a bamboo wood composite plywood for a concrete template and a method for manufacturing the same. The bamboo wood composite plywood is provided with a body which is manufactured from a first log rotary cut veneer and a bamboo curtain in alternate arrangement through hot pressing; the body has odd layers; and the first log rotary cut veneer is positioned on the surface layer of the body. The outer side of the body can also be a composite bamboo mat or a veneer. The method for manufacturing the bamboo wood composite plywood comprises the steps of carrying out assembly, prepressing, aging, and hot pressing on the log rotary cut veneer, the bamboo curtain and / or the bamboo mat, and the like. The bamboo wood composite plywood realizes combination of bamboo and the log rotary cut veneer, improves the utilization rate of wood and the bamboo, simultaneously improves the performance greatly, has a more stable structure, and greatly improves bonding strength and transverse static bending strength; and in the manufacturing process, the method does not need to carry out complex gum dipping and other treatment on the bamboo curtain, the bamboo mat, and the like, greatly reduces the use amount of an adhesive, reduces the machining cost, and is favorable for environmental protection.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Method for producing uniform-density bamboo shaving board

InactiveCN102198685ALow costSave on energy costsWood working apparatusFlat articlesEngineeringVolumetric Mass Density

The invention relates to a machining process for an artificial board, in particular to a method for producing a uniform-density bamboo shaving board. The invention is realized through the following technical scheme: the method for producing the uniform-density bamboo shaving board is characterized by sequentially comprising the following steps of: (1) selecting materials; (2) first screening; (3) first drying; (4) second screening; (5) second drying; (6) sizing; (7) hot-pressing; and (8) refrigerating. The uniform-density bamboo shaving board has the advantages of density uniformity, high dimensional stability and high static bending strength.

Owner:浙江安吉强裕人造板有限公司

Whole bamboo high strength composite industrial floor

The invention relates to a full-bamboo and high strength composite industrial floor board, which is characterized in that auxiliary materials (offcut materials of semi-finished products) of bamboos (of any variety), bamboo treetop, bamboo branches, waste trifling and waste strips are adopted to make into medium density (more than 750kg / m<3>) or high density (more than 850kg / m<3>) full-bamboo fiber board for manufacturing the core board by the steps of cleaning, softening, burnishing, adhering by modified urea formaldehyde or modified phenolic resin adhesives, and processing at high temperature and high pressure. As result of long length and good flexibility, the bamboo fibers are crosswise rearranged and adhered during the softening, burnishing, adhering and thermally pressing molding processes, the indexes of static bending strength and elastic modulus of longitudinal and transverse texture, and the shearing force are also increased and the characteristics of the bamboo are optimized. Therefore, the composite industrial floor board is an ideal full-bamboo core board material and improves the comprehensive utilization ratio of the full bamboo (the utilization rate is more than 95 percent).

Owner:葛会龙 +1

Method for manufacturing high intensity plywood for engineering structure by utilizing fast growing wood

InactiveCN103991113AHigh static bending strengthIncrease elasticityWood treatment detailsWood veneer joiningWeather resistanceSingle plate

The invention provides a method for manufacturing high intensity plywood for an engineering structure by utilizing fast growing wood. The method comprises the following steps of (1) single plate rotary cutting, (2) modified liquid preparation, (3) single plate reinforced processing, (4) gluing assembly prepressing, (5) plate blank hot press forming, and (6) veneering or film covering processing. The method for manufacturing the high intensity plywood for the engineering structure by utilizing the fast growing wood has the advantages that firstly modified liquid reinforced processing is carried out on the single plates of the fast growing wood, the intensity of the single plates of each layer is improved to a large extent, the reinforcing degree of the single plates can be adjusted through the weight gain rate of the single plates, and the weight gain rate of the reinforced single plates can be reduced from outside to inside in a graded mode to save cost and fully perform the intensity performance of single plates of all layers; thus, plywood products gain extremely high static bending intensity, elasticity modulus and surface hardness under the condition of a low compression rate, the thickness swelling rate of the products is small, the dimensional stability of the products is good, and reinforcer gives the products good rotproofness and weather resistance at the same time.

Owner:NANJING FORESTRY UNIV +1

Compound enhanced wood-plastic composite plate and preparation method thereof

InactiveCN102732045AEasy to produceThe production is convenient, and the traditional wood-plastic composite material production process is convenientAntioxidantMechanical property

The invention discloses a compound enhanced wood-plastic composite plate and a preparation method thereof. The preparation method comprises the following steps of: diluting vinyltriethoxysilane with tap water; putting wood flour into the above water solution, evenly shaking, and ultrasonically processing with ultrasonic waves to obtain enhanced wood flour; stirring, extruding and pelleting the enhanced wood flour, plastic particles, plastic particles grafted by maleic anhydride, potassium titanate whisker, chopped glass fiber powder and oxidic polyethylene to obtain composite particles; and evenly stirring the composite particles, ethylhexyl stearate, terpene resin and an antioxidant again and then melting, blending and extruding via an extruder to obtain the wood-plastic composite plate. In the invention, the production process is convenient and the production cost is low. The compound enhanced wood-plastic composite plate has the advantages of small dosage of plastic, environmental protection, good ageing resistance and deformation resistance and good buckling deformation resistance; and compared with other wood-plastic composite plates, the mechanical properties such as the static bending intensity, the impact strength and the like are more excellent, the service life is longer, and the application range is wider. The compound enhanced wood-plastic composite plate cannot only be used for making floors, but also can be hung up.

Owner:江苏森诺塑胶科技有限公司

Restored rubber produced hardwood sheet material and method for producing the same

The invention discloses a hard wood board produced by using reclaimed rubber and a preparation method thereof. The hard wood board has the preparation method that the wasted rubber product is desulfurized to produce the reclaimed rubber, and then a kneader is used to make 100 parts weight of reclaimed rubber, 10 to 20 parts of curing agent, 0.3 to 5 parts of curing accelerator, 0.1 to 10 parts of activating agent, 1 to 80 parts of bulk additive, 0.1 to 1.5 parts of anti-aging agent, and 0.1 to 5 parts of plasticizer according to the weight part mixed evenly, then the evenly mixed materials are put to the vulcanizing paste press for pressing and shaping as well as sulfurization, the sulfurization temperature is 140 to 180 DEG C, the pressure is 20 to 40 MPa, and the time is 20 to 60 minutes, finally the required hard wood board is prepared. The hard wood board of the invention has very high static bending intensity and modulus, and can be used as structure material instead of the traditional hard wood, and the hard wood board also has good anti-aging property and long service life.

Owner:浙江绿环橡木有限公司 +1

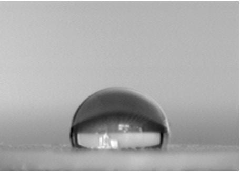

Method for preparing amphiphobic wood/calcium carbonate composite material by biomimetic mineralization in-situ process

InactiveCN101797762AAct as a surface modificationReduce sizeWood impregnation detailsAlcoholChloride

The invention discloses a method for preparing an amphiphobic wood / calcium carbonate composite material by a biomimetic mineralization in-situ process, which relates to a wood composite material preparing method. The method solves the problems of the traditional wood composite material preparing method that the energy consumption is large and the additional surface treatment is singly required to the composite material. The method comprises the following steps of: firstly, preparing a calcium chloride solution and an alcohol solution of an organic amphiphatic surface active agent; mixing the two solutions to obtain a mixing solution; immersing the wood into the mixing solution to impregnate; then, moving the wood into a calcium carbonate solution to impregnate; and finally, drying to obtain the amphiphobic wood / calcium carbonate composite material. The invention has the advantages of simultaneous performance of compounding and surface nature modification, simple operation, no use of expensive equipment, little energy consumption, low cost, static bending strength of the composite material of 80-83Mpa, elasticity modulus of 13500-13600Mpa, and compression strength parallel to grain of 65-68Mpa, and can be used as building structure, indoor decoration, floor and furniture materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

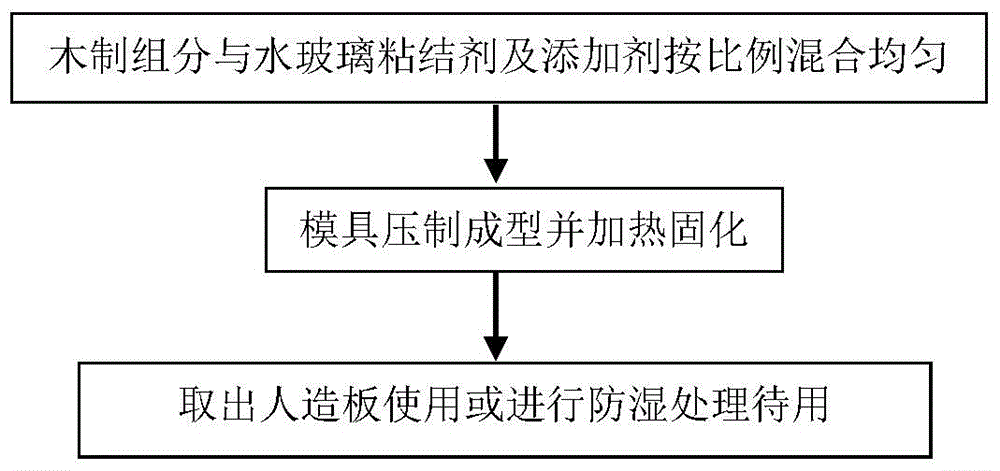

Inorganic binder refractory artificial board material and preparation method thereof

InactiveCN104962099AMeet the requirements of green environmental protectionSatisfy the use effectRefractoryHeat stability

The invention discloses an inorganic binder refractory artificial board material and a preparation method thereof. The inorganic binder refractory artificial board material comprises a wood component and an environment-pollution-free sodium silicate binder, wherein the modulus of the sodium silicate binder is 1.5-3.0. The preparation method comprises the following steps: uniformly mixing the wood component and sodium silicate binder, putting the mixture into a mold, compacting, heating for thermosetting, and demolding to obtain the inorganic binder refractory artificial board. The method can be used for preparing the inorganic binder refractory artificial board which has the advantages of no formaldehyde release, favorable static bending strength, favorable elastic modulus, favorable hydroscopic property, favorable heat stability and favorable fire resistance. The method has the advantages of wide raw material sources and low price.

Owner:HUAZHONG UNIV OF SCI & TECH

Glued bamboo board and preparation method thereof

InactiveCN101885194AHigh surface finishHigh densityWood veneer joiningWood layered productsSurface finishInter layer

The invention relates to a glued bamboo board and a preparation method thereof, in particular to a bamboo board prepared by gluing a restructured bamboo board and a bamboo chip glued board and belongs to the technical field of bamboo development and bamboo board processing. The glued bamboo board comprises an upper layer, a middle layer and a lower layer, wherein the upper layer and the lower layer are restructured bamboo boards; and the bamboo filament arrangement direction of the restructured bamboo boards is vertical to board faces per se. The glued bamboo board of the invention has the advantages of high surface finish, high density, high grade, high overall static bending strength, high compression strength, high impact strength, high surface hardness, low thickness swelling rate of water absorption and high size stability.

Owner:ZHEJIANG XINYUAN BAMBOO PRODS

Method for establishing moisture content gradient of shaving board

ActiveCN103950085AReduce drying energy consumptionGuaranteed drying qualityWood working apparatusFlat articlesWood shavingsSurface layer

The invention discloses a method for establishing a moisture content gradient of a shaving board. The method consists of three technological links, namely drying in levels, respective glue mixing and respective paving. The drying in levels is characterized in that two levels of drying systems are established and a shaving sorting procedure is set up between the first-level drying system and the second-level drying system; the shavings subjected to drying in levels are respectively stored, metered and mixed with glue, and the moisture content difference between shavings in a core layer and shavings on a surface layer are stabilized; after the shavings are metered, the shavings are respectively paved, and the moisture content gradient is finally established on a cross section of a blank of the shaving board. By the moisture content gradient, the moisture on the surface of the blank is quickly vaporized in the heating process, a steam impact effect is generated, the heat transfer speed is improved, the temperature rise speed of the core layer is improved and the aims of shortening hot-pressing time and improving hot-pressing efficiency are finally fulfilled; in addition, by establishing the moisture content gradient of the blank, the performance and the surface quality of the finished shaving board can be obviously improved, the static bending intensity of the board is improved, the made shaving board is more smooth in surface, and the sanding loss of the shaving board is reduced.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com