Production process of high-grade fir melamine ecological board

A melamine and production process technology, which is applied in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of easy deformation of the board, low qualified rate of finished products, and many bubble boards, so as to reduce the number of surface burrs, The effect of good gloss and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

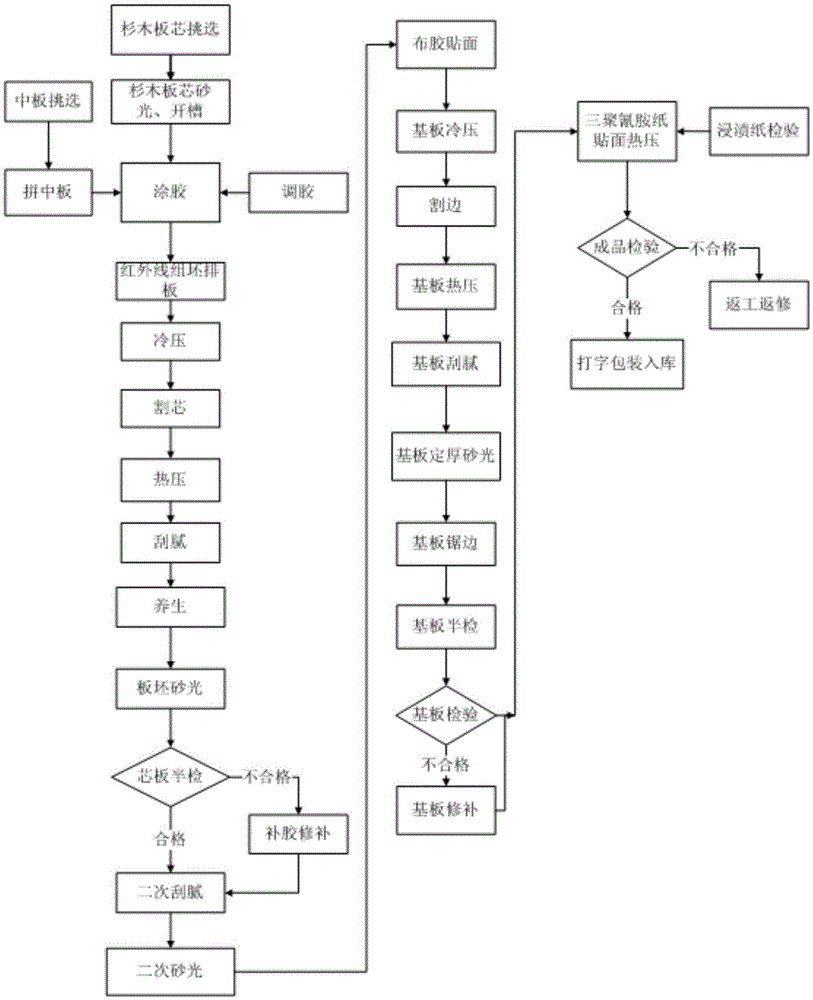

[0044] like figure 1 Shown, provide the specific embodiment of the production technology of a kind of high-grade Chinese fir melamine ecological board, this production technology comprises the steps:

[0045] 1. Poplar mid-board selection: select poplar mid-board with no defects such as cracks, shedding holes, pollution, overlapping, and decay on the surface.

[0046] 2. Splicing of poplar middle boards: splicing poplar middle boards into required size middle boards through hot melt glue and glue line, among which the required size is 2470-2500mm in length and 1250-1300mm in width;

[0047] 3. Selection of fir core boards: select finger-joined fir core boards with good flatness and no surface defects;

[0048] 4. Sanding of fir core board: Sanding the selected fir core board to ensure the flatness of the core board;

[0049]5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com