Patents

Literature

822results about How to "Neatly stacked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

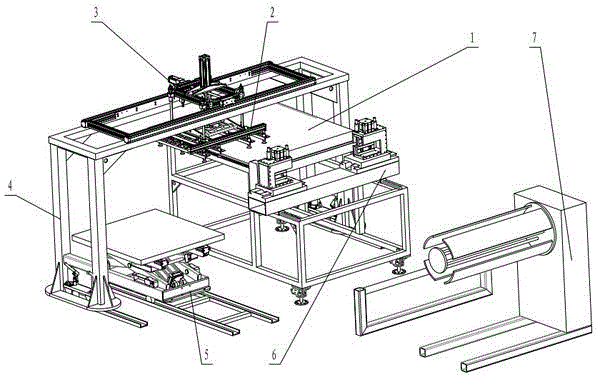

Full-automatic loading-unloading and visual inspection device

ActiveCN106124520AReduce labor intensityImprove efficiencyMaterial analysis by optical meansSortingEngineeringAssembly line

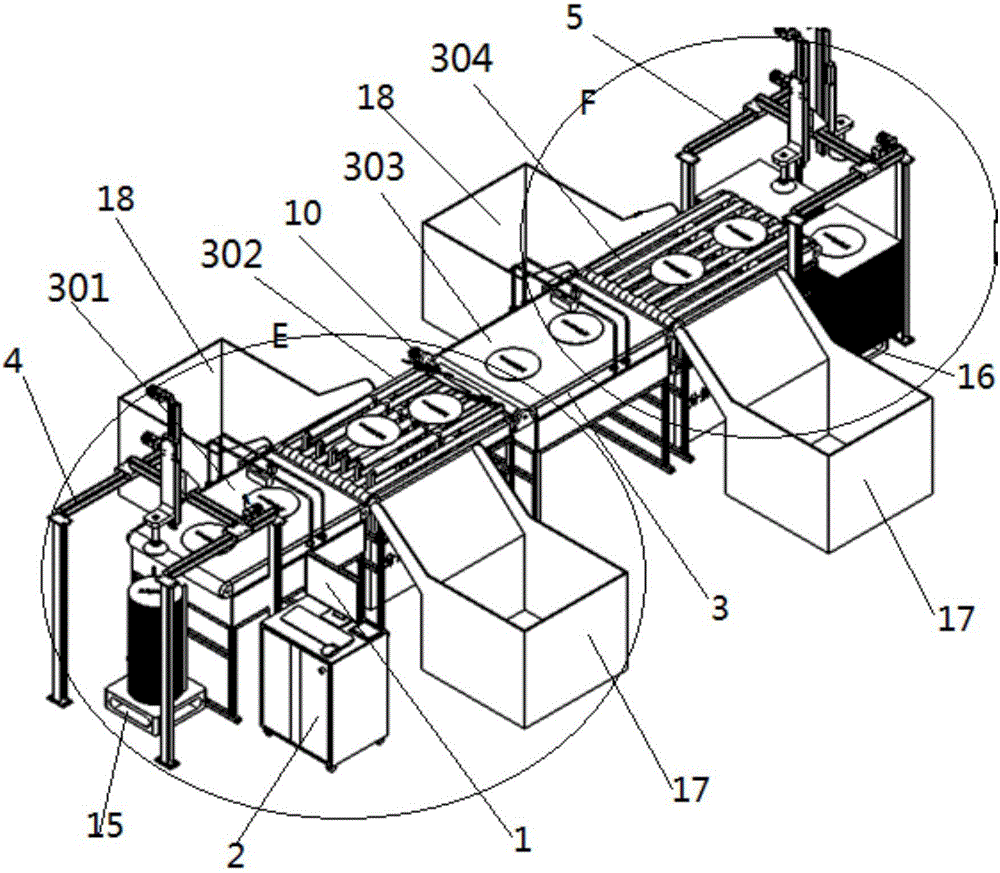

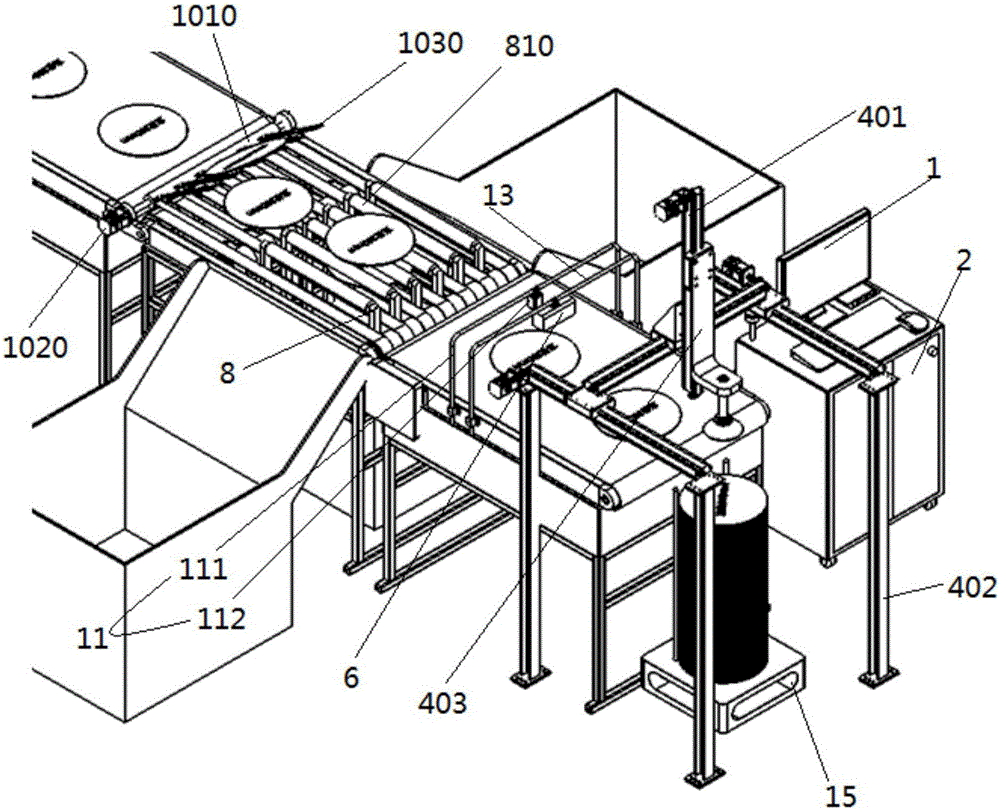

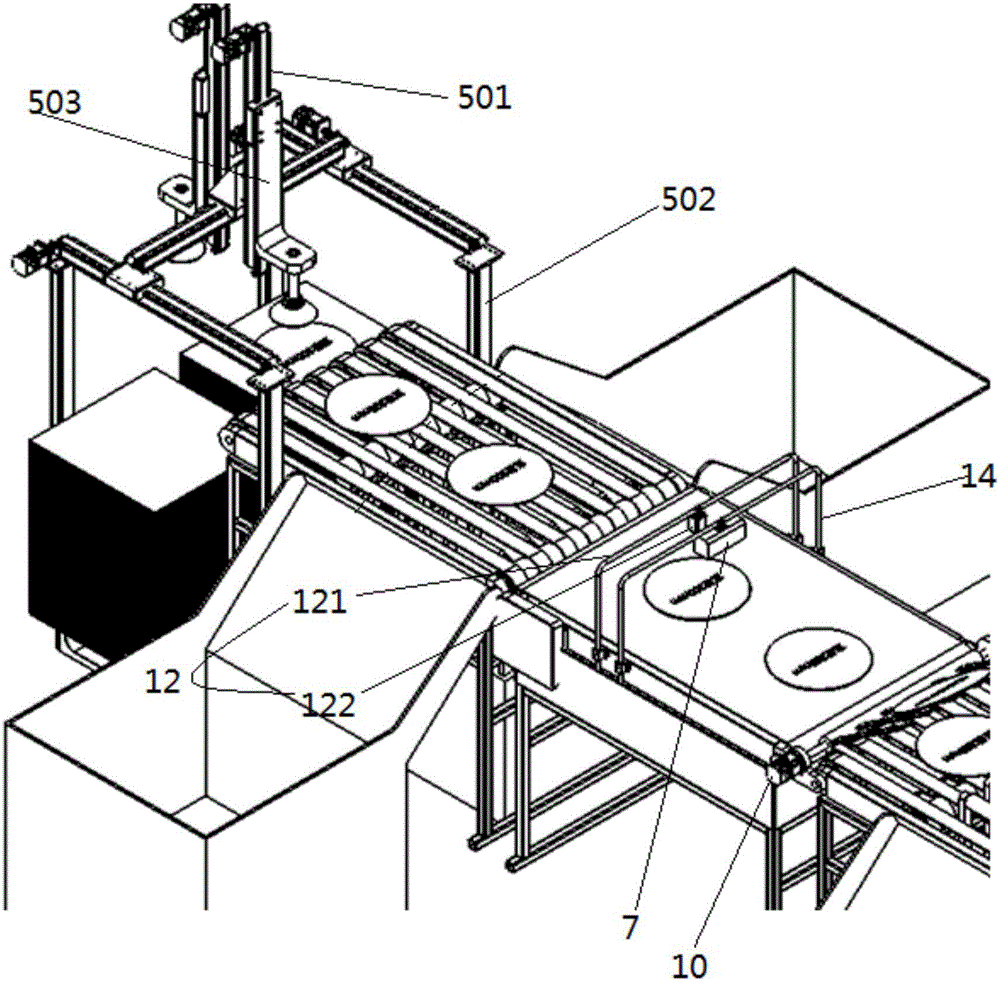

The invention relates to a full-automatic loading-unloading and visual inspection device. The device comprises a combined assembly line, a first image collecting device, a first product conveying device, an overturning device, a second image collecting device, a second product conveying device, an industrial computer, an electric appliance control cabinet, a loading device and an unloading device. The full-automatic loading-unloading and visual inspection device has the beneficial effects that a manual loading-unloading manner is changed into an automatic loading-unloading manner, so that the labor intensity of workers is reduced, and the device is high in efficiency and practical and can be applied to long-term scale production; besides, a manual detection manner is changed into an online automatic detection manner, so that the quality of products with front and back surfaces can be accurately detected, the economic loss of a user caused by manual erroneous judgment can be reduced, the detection efficiency is high, and the detection is accurate and reliable, the online automatic detection is realized, and the 24-hour ceaseless working can be realized; and data can be stored in real time, and the user can analyze the product process according to the detection data, so that the economic benefit of a factory is increased.

Owner:武汉智慧眼智能科技有限公司

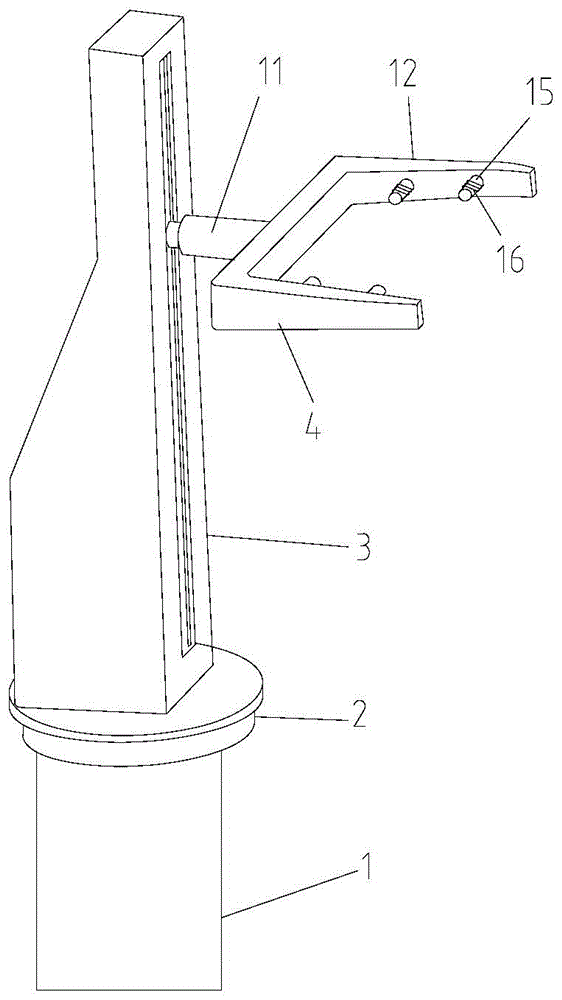

Intelligentized manipulator paw mechanism for piling machine

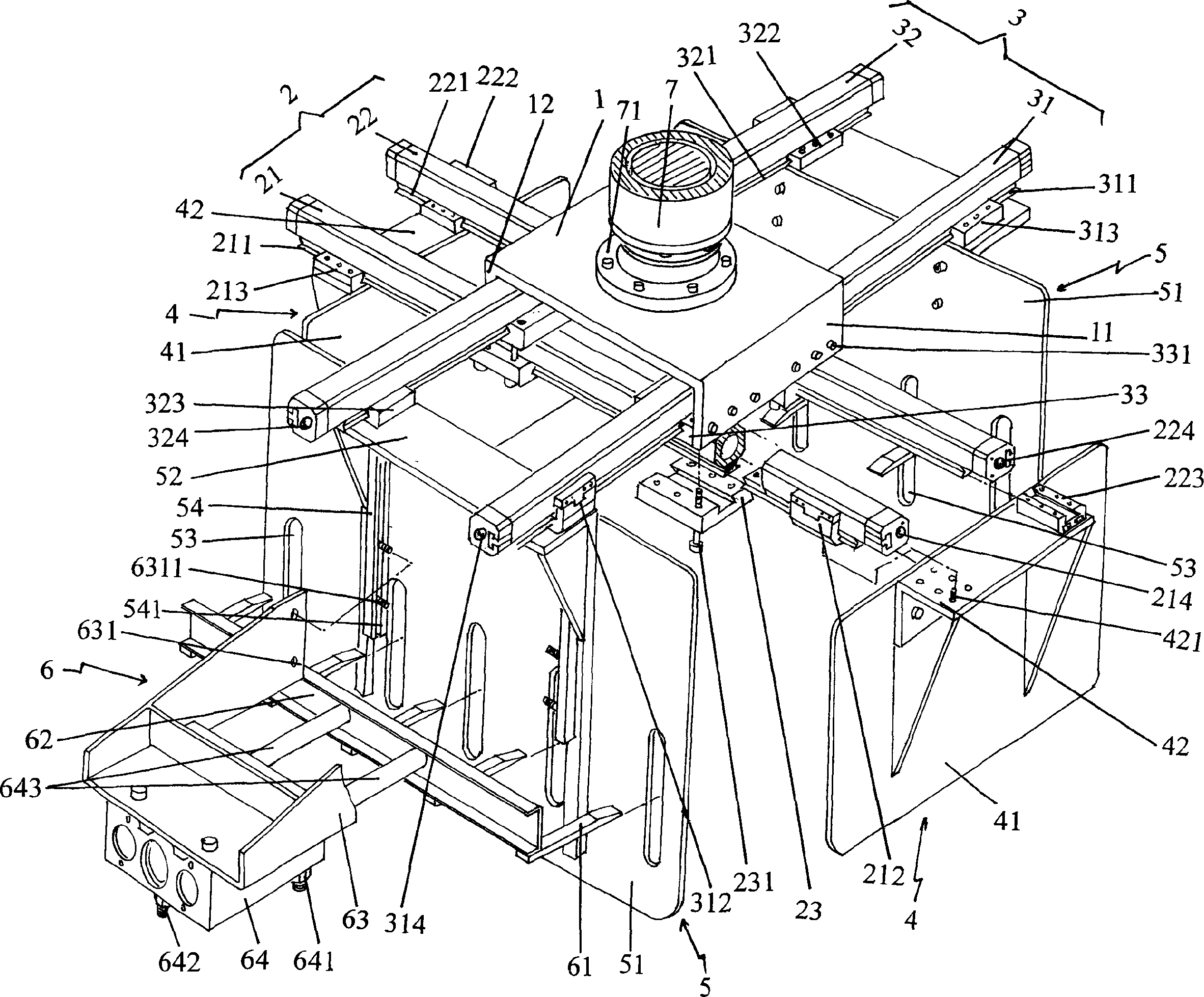

The invention relates to the grip mechanism of an intelligent robot pallet machine, which comprises grip palm coupling with the arm of the intelligent robot, a pair of No.1 and No.2 drive device crossingly fixed on the grip palm, a pair of picking device matching for the case and bag for the clipping and release of all directions, a pair of left and right picking device, a pair of front and back picking device set at the No.1 drive mechanism, a pair of left and right picking device setting on the No.2 drive mechanism, a pair of case and bag backing device, with optional choice of the front and back picking device or left and right picking device. It can reduce the landing height of cases, almost eliminate the gap between cases with neat stacking.

Owner:CHANGSHU SANHE PRECISION MACHINERY & TECH CO LTD

Automatic arranging and stacking device of paper boards

ActiveCN105600556ANeatly stackedEasy to collectPile receiversArticle deliveryCardboardPulp and paper industry

The invention belongs to auxiliary tools of paper board machining equipment, and in particular relates to an automatic arranging and stacking device of paper boards. In order to realize the purpose, the invention provides the following technical scheme: the automatic arranging and stacking device of the paper boards comprises a conveying mechanism and an arranging mechanism; when hard paper boards are forwards fed on a conveyor belt and pass through a pushing plate, the hard paper boards can be pushed to a blocking wall by the pushing plate, so that all the hard paper boards are enabled to be tidily and forwards fed along the blocking wall in turns, and convenience is provided for collection in the next step. According to the automatic arranging and stacking device of the paper boards, disclosed by the invention, each paper board is enabled to only have very small falling difference when each paper board falls from a supporting plate to a support, so that the attitude of the paper boards is enabled not to change greatly during a falling process, and tidy stacking of the paper boards is ensured.

Owner:安徽华艺印刷包装有限公司

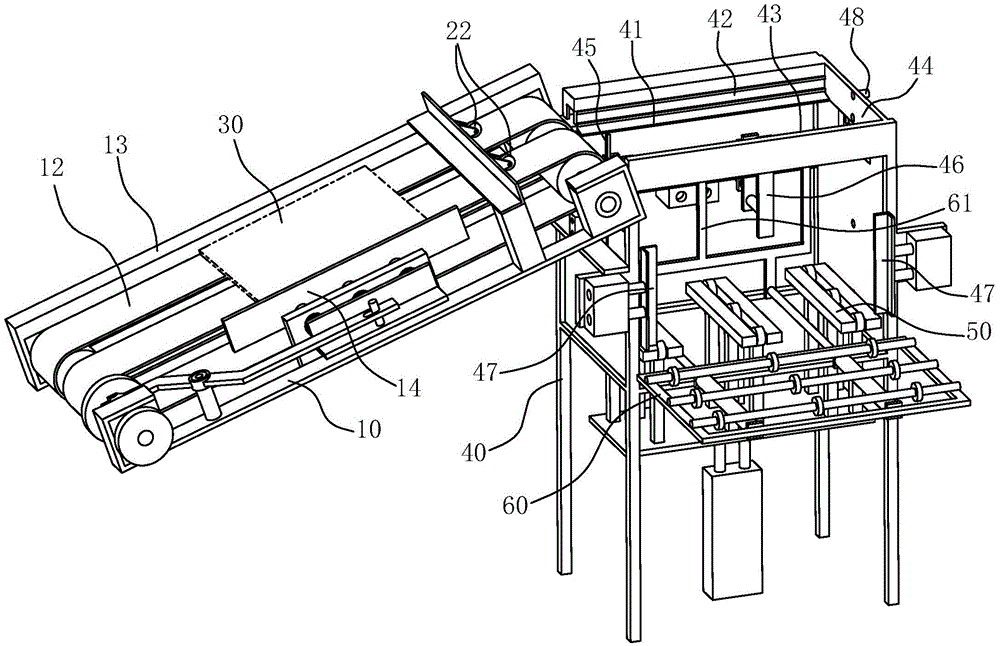

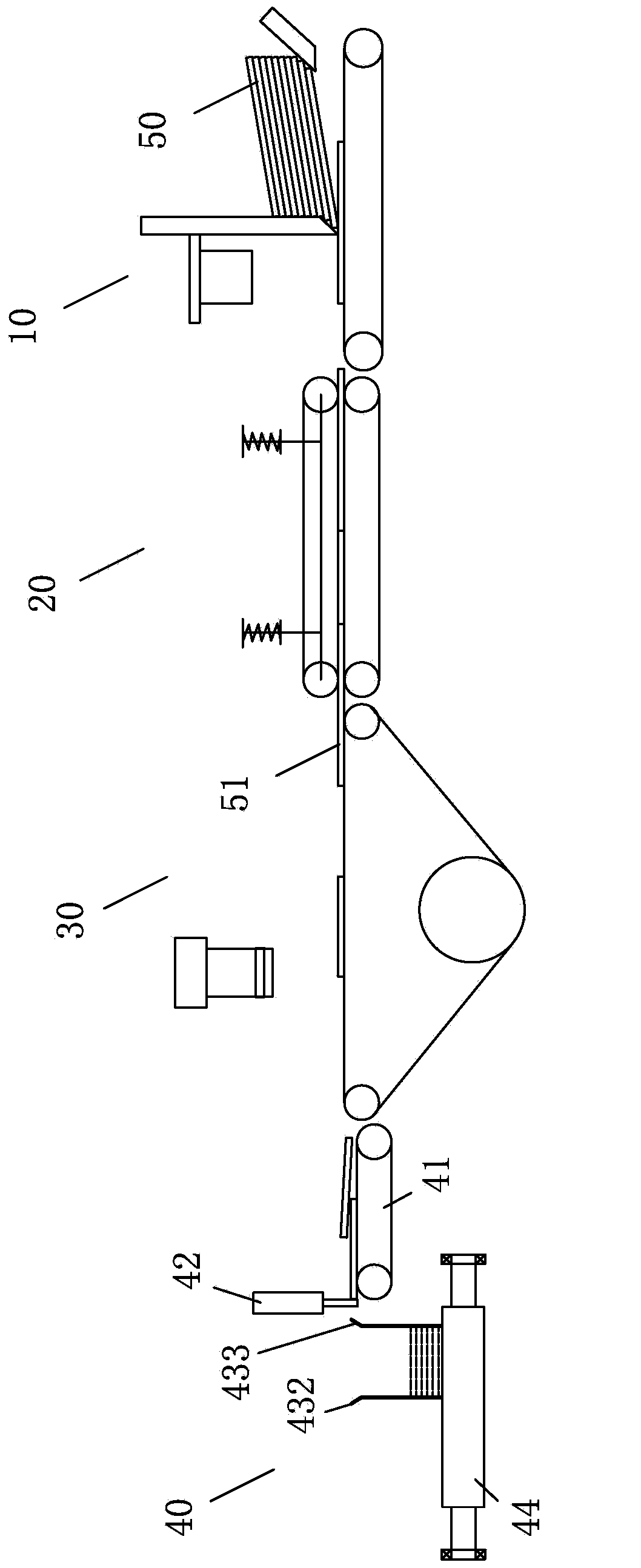

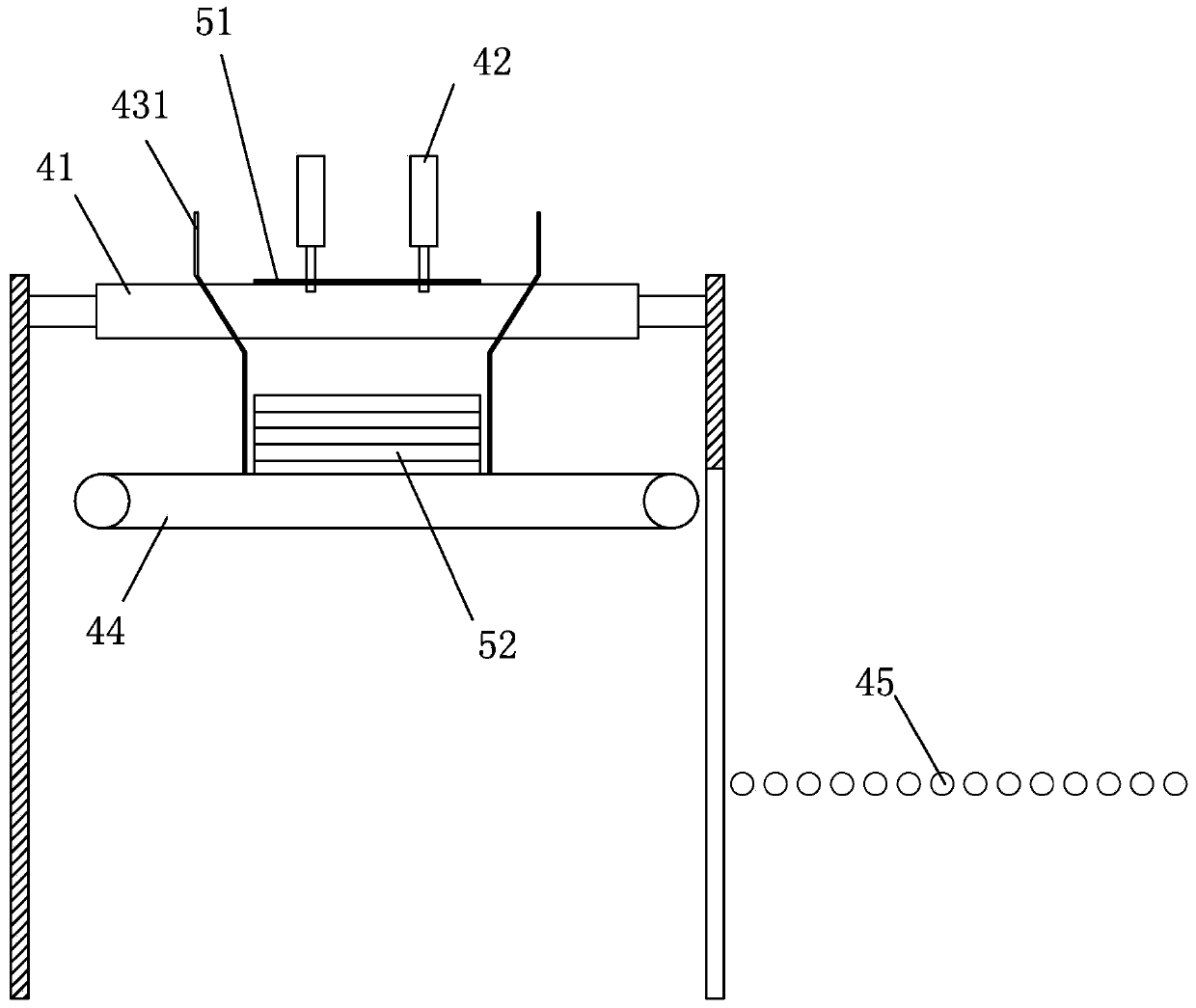

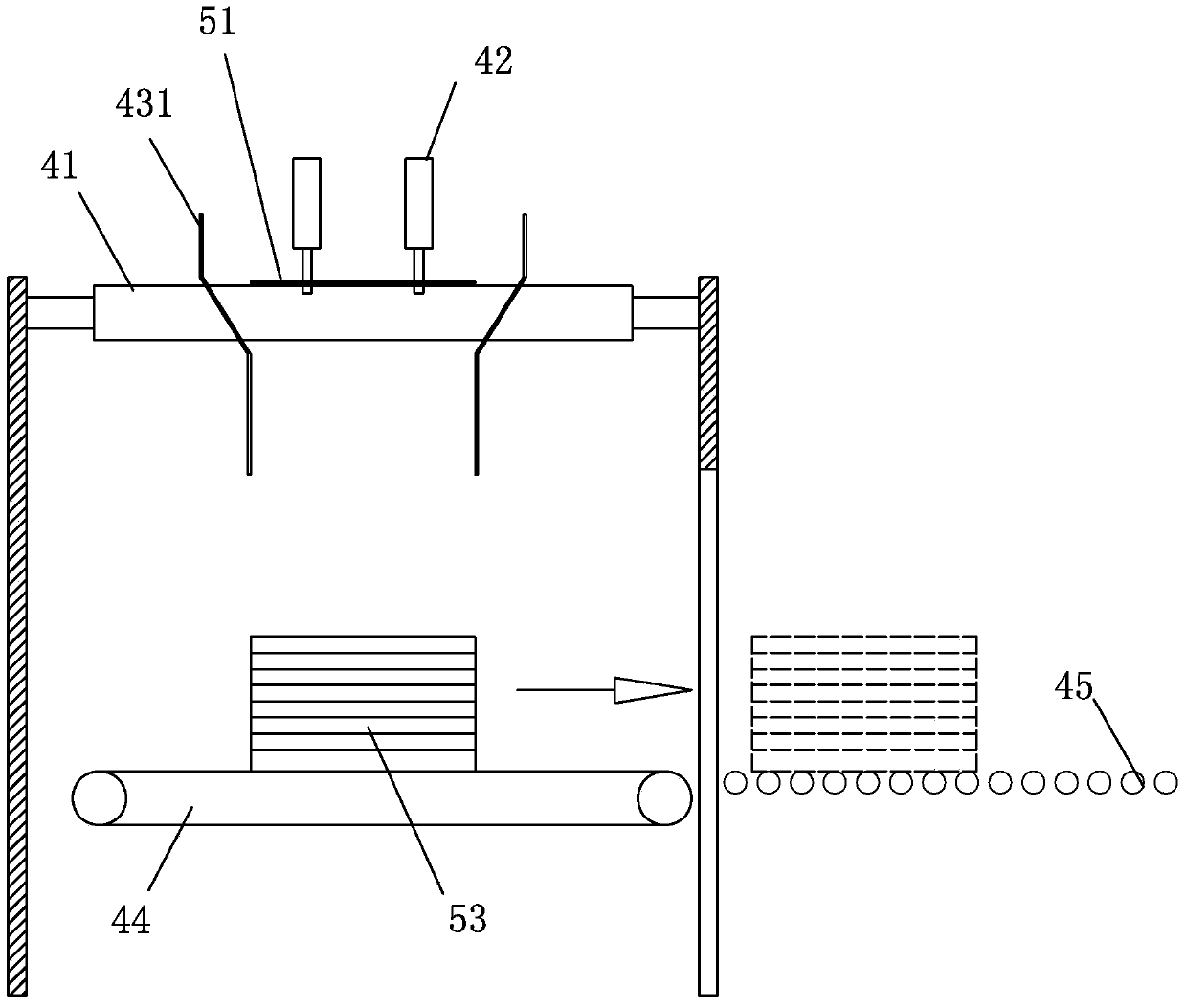

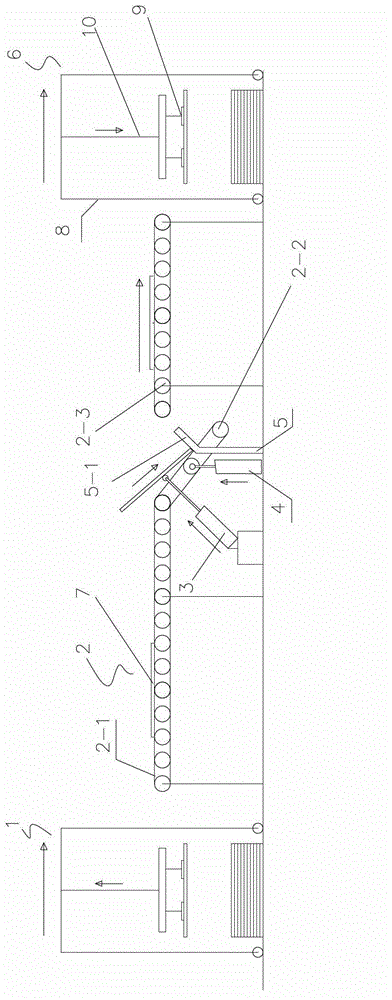

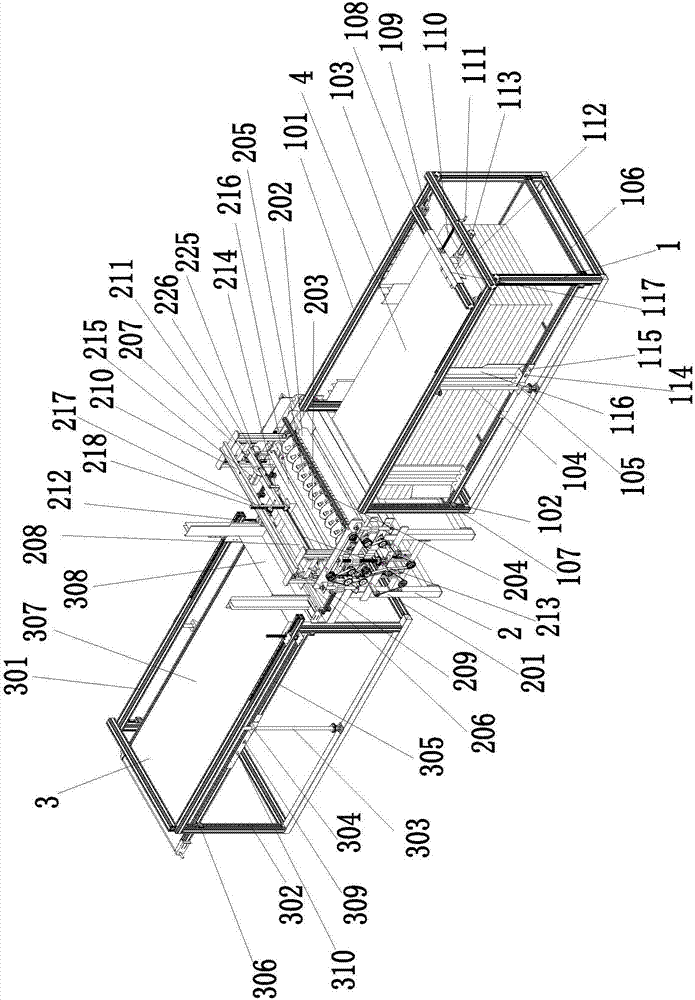

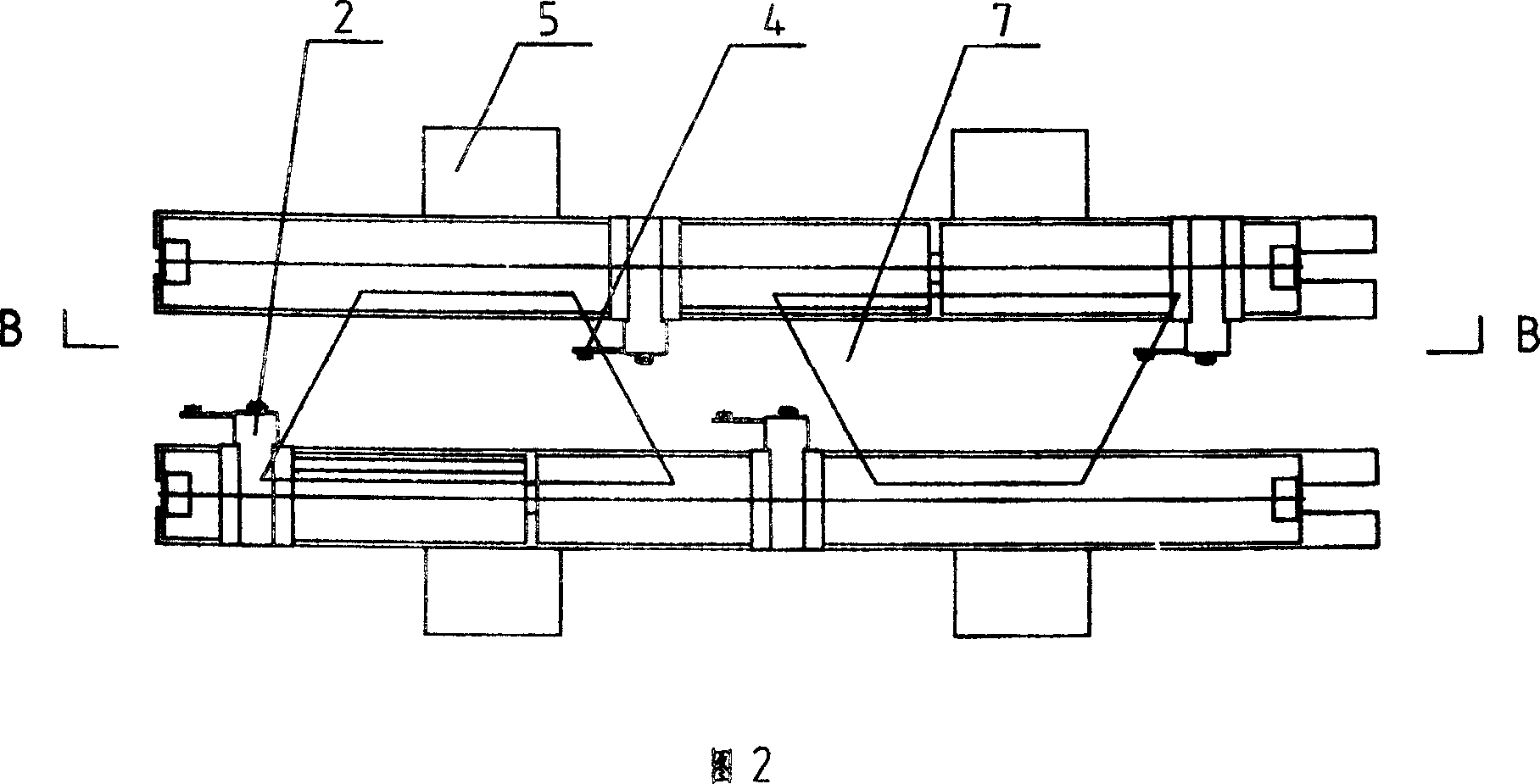

Automatic packaging assembly line and packaging process

ActiveCN104192380ASuitable for quantitative production needsIncrease productivityPackaging machinesProcess engineeringAssembly line

The invention provides an automatic packaging assembly line and a packaging process and belongs to the field of equipment and the process for sorting and packaging square products like ceramic tiles. The automatic packaging assembly line comprises a tile storage machine (1) connected with a finished ceramic tile assembly line. The automatic packaging assembly line is characterized in that the outlet end of the tile storage machine (1) is sequentially provided with a color difference detection device (2), a flatness detector (3), a tile sorting and stacking machine (4), an angle wrapping machine (5), a box filling machine (6), a code spraying and marking machine (7), a box stacking machine (8), a band tying machine (9) and an automatic grabbing machine (10). The packaging process of the automatic packaging assembly line comprises the working procedures of selecting, classifying, color separating, sorting, box filling, band tying, marking, pallet stacking and the like. Seamless joint of the automatic packaging assembly line and a beginning finished product conveyor line is achieved, full-automatic assembly line operation of the working procedures for the finished ceramic tiles can be achieved, the labor cost is greatly reduced, and the work efficiency is improved.

Owner:蔡群龙

Automatic stacking machine for printed matter checkout machine

ActiveCN103803333ANeatly stackedAccurate countPile receiversArticle deliveryLower limitStack machine

The invention discloses an automatic stacking machine for a printed matter checkout machine. The automatic stacking machine comprises a paper collecting and delivering mechanism. A counting sensor is arranged on one side of the paper collecting and delivering mechanism, a turnover paper blocking mechanism and an aligning mechanism are arranged at the output end of the paper collecting and delivering mechanism, a paper supporting mechanism and a paper pushing mechanism are arranged below the aligning mechanism, and a paper storing mechanism is correspondingly arranged on one side of the paper pushing mechanism; the turnover paper blocking mechanism comprises a paper blocking board with a supporting hook arranged at the bottom, the aligning mechanism comprises aligning boards on the left side, the right side, the front side and the right side, the paper supporting mechanism comprises an inching sensor and multiple paper supporting rods which form a paper supporting plane and move vertically, and the paper pushing mechanism comprises multiple paper pushing rods which form a paper pushing plane and move horizontally and linearly; when located at the upper limit position, the paper supporting plane is close to the aligning boards, and then the paper supporting plane is located at the lower limit position, the paper pushing rods can push a stack of printed matters stacked on the paper supporting plane orderly onto the paper storing mechanism. According to the automatic stacking machine, automatic stacking and aligning speeds of small printed matters are high, stacking is orderly, counting is accurate, paper delivery time is short and work efficiency is improved.

Owner:HEBEI TIANYUHENG TECH CO LTD

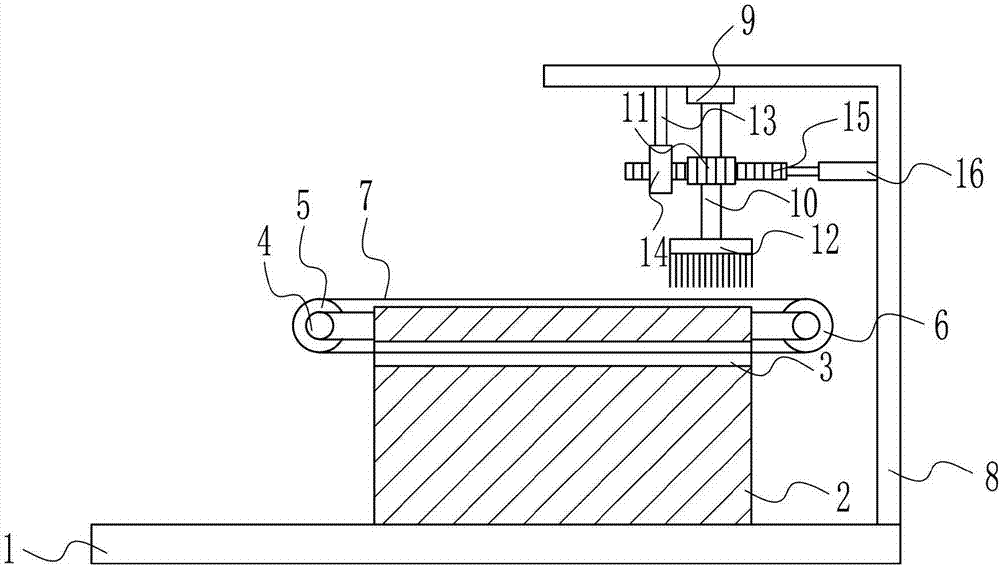

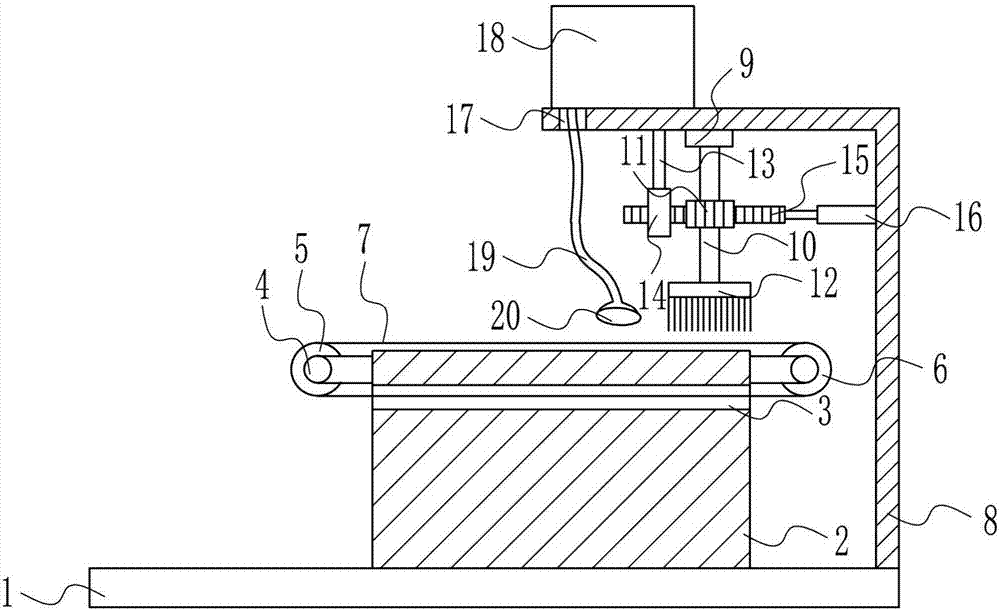

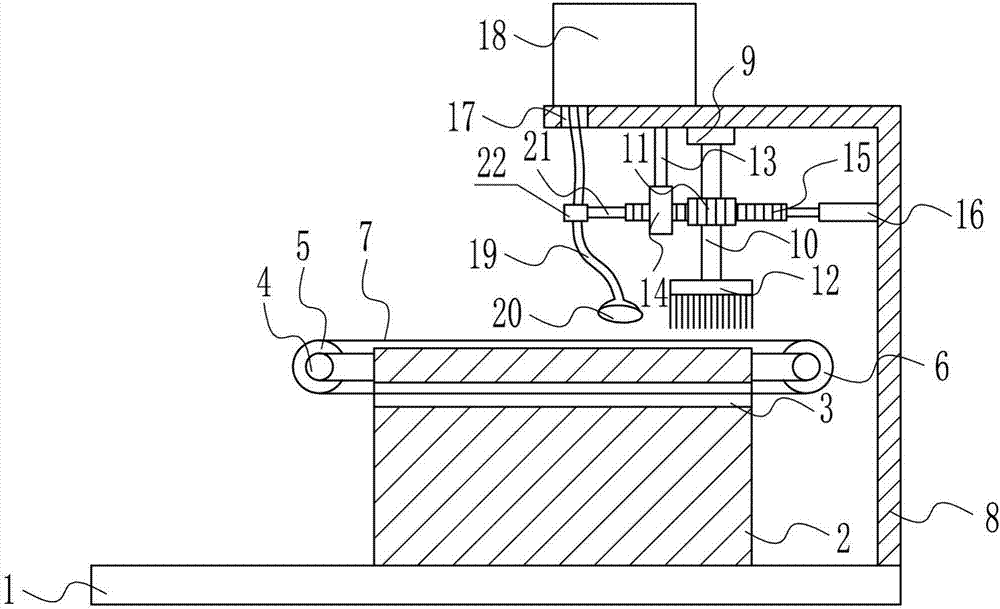

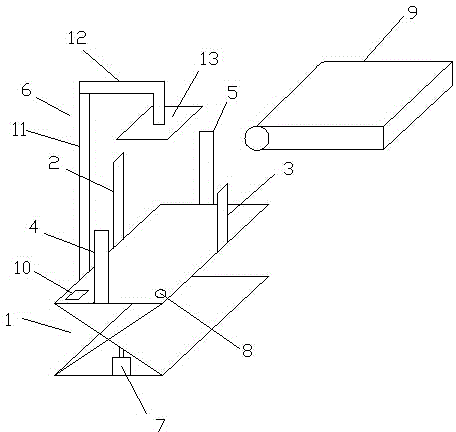

Main board impurity removing device for computer hardware production

InactiveCN106944386AAvoid driftingAvoid inhalationDirt cleaningCleaning using toolsVertical barImpurity

The invention relates to a device for computer hardware production, in particular to a main board impurity removing device for computer hardware production. The technical problem to be solved by the invention is to provide the main board impurity removing device for computer hardware production capable of removing impurities of a main board, improving the quality of the main board and improving the quality of a computer. In order to solve the technical problem, the invention provides the main board impurity removing device for computer hardware production. The device comprises a baseplate, a worktable, a first motor, a first belt wheel, a second belt wheel, a flat belt, a support plate, a bearing base, a rotating shaft, a gear, a brush, a vertical rod and the like; the worktable is arranged at the top of the baseplate; an opening is horizontally formed in the upper part of the worktable; and the first motor is arranged on the left side surface of the worktable. The device enables the brush to alternately rotate forwards and reversely to brush away fine impurities on the main board moving to the left side, and uses a dust sucker for sucking the fine impurities brushed from the main board into through holes by an air sucking pipe and a sucking nozzle.

Owner:汪国栋

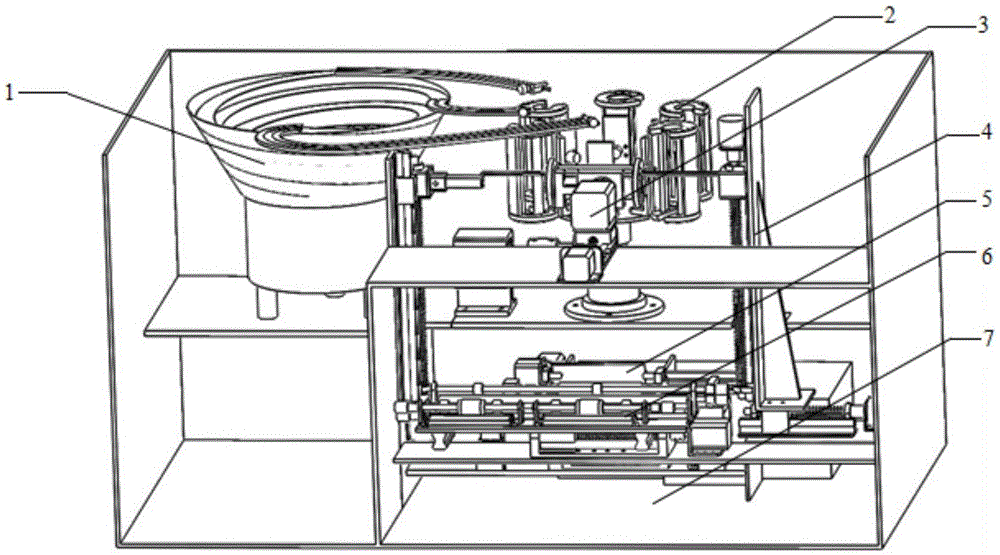

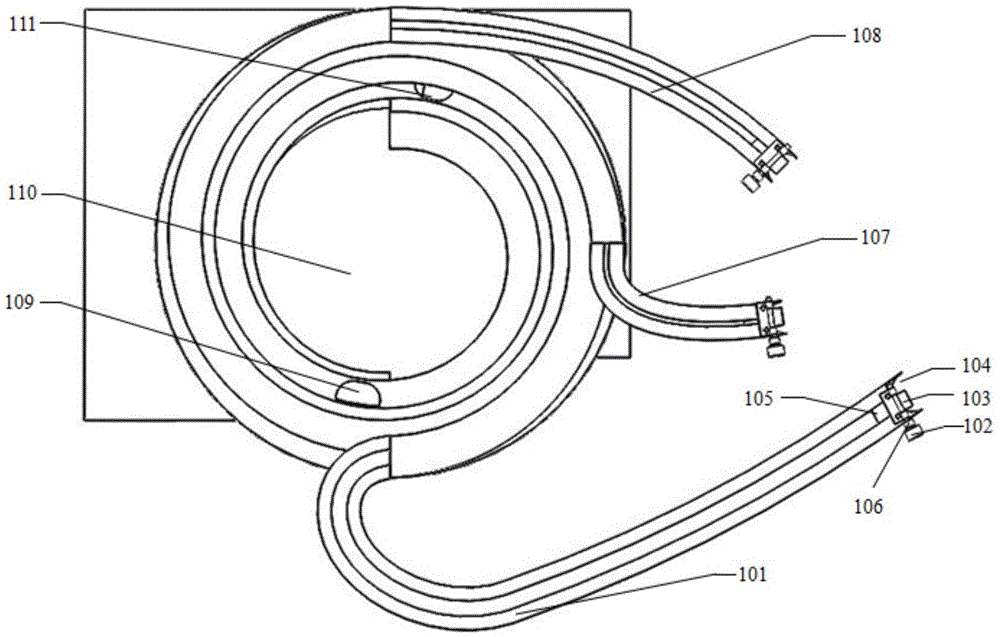

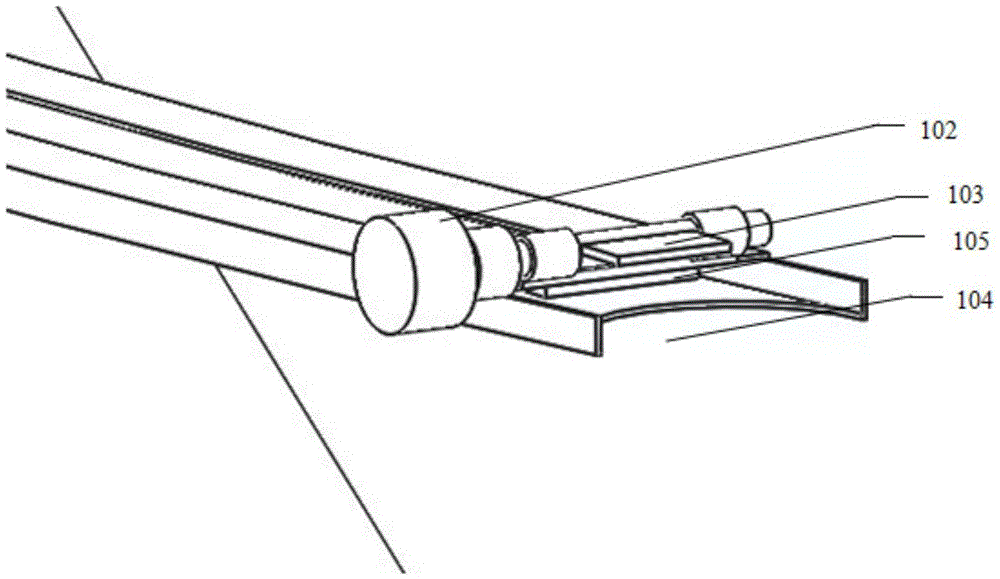

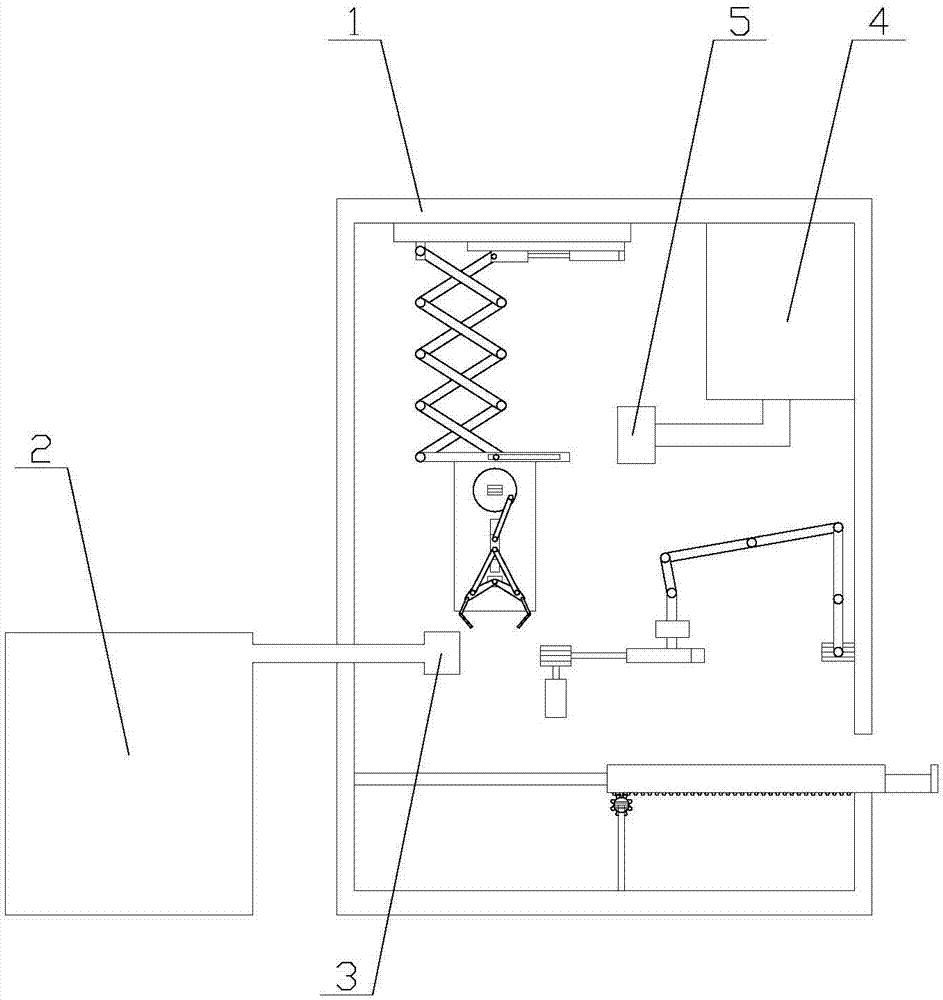

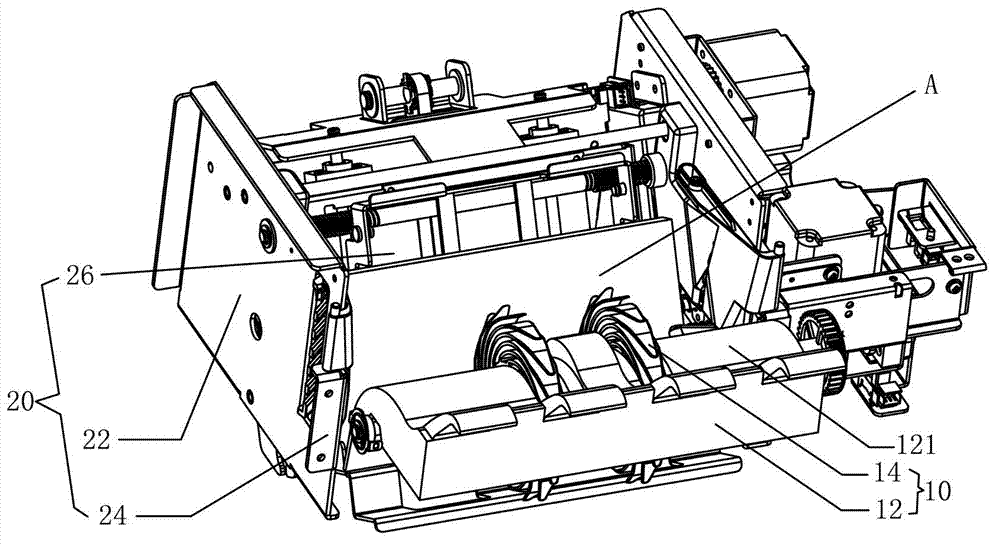

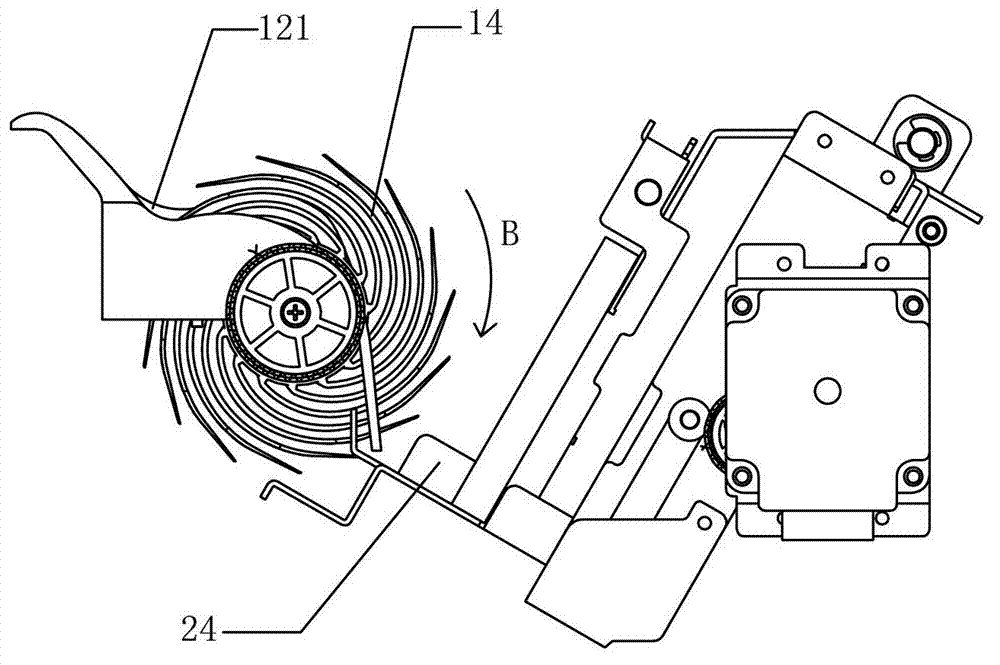

Coin sorting packaging machine

ActiveCN105632010AReduce the chance of tipping and falling out of the coin barrel deviceReduced run-out of the cartridge unitCoin/paper handlersProcess engineeringCoin

The invention discloses a coin sorting packaging machine, comprising a vibration plate sorting mechanism (1); the vibration plate sorting mechanism (1) is successively connected to a coin pushing mechanism and a coin packaging mechanism (5); and the coin packaging mechanism side is provided with a paper feeding mechanism (6). The coin sorting packaging machine has functions of coin sorting, code sorting and packaging, realizes automatic operation, and achieves the goals of high efficiency, reliability, high production efficiency and reducing labor cost.

Owner:WENZHOU UNIVERSITY

Intelligent mechanical equipment based on Internet of Things and used for cleaning cups

ActiveCN107495915AImprove cleanlinessNeatly stackedTableware washing/rinsing machine detailsWater storage tankLiquid storage tank

The invention relates to intelligent mechanical equipment based on Internet of Things and used for cleaning cups. The intelligent mechanical equipment comprises a housing and a liquid storage tank, wherein the housing is internally provided with a moving mechanism, a cleaning mechanism, a transporting mechanism, a water storage tank, a first spray nozzle and a second spray nozzle; the moving mechanism comprises a first motor, a gear, a sliding plate, a rack and a telescopic rod; the cleaning mechanism comprises a second motor, a guide rod, a driving rod, a connecting rod, a first driven rod, a sliding rod, a limiting rod and a cleaning component; the transporting mechanism comprises a lifting component, a capturing component and two translation components; each translation component comprises a fourth motor, an idler wheel, a second sliding chute and two lugs. According to the intelligent mechanical equipment based on Internet of Things and used for cleaning cups, disinfection and cleaning are carried out on the cups through the cleaning mechanism, so that the cleanliness of the cups is guaranteed; the cups are stacked up regularly through the transporting mechanism, so that the space is saved, the utilization rate of the space is improved, and the practicability of the intelligent mechanical equipment is improved.

Owner:南京横溪文化旅游发展有限公司

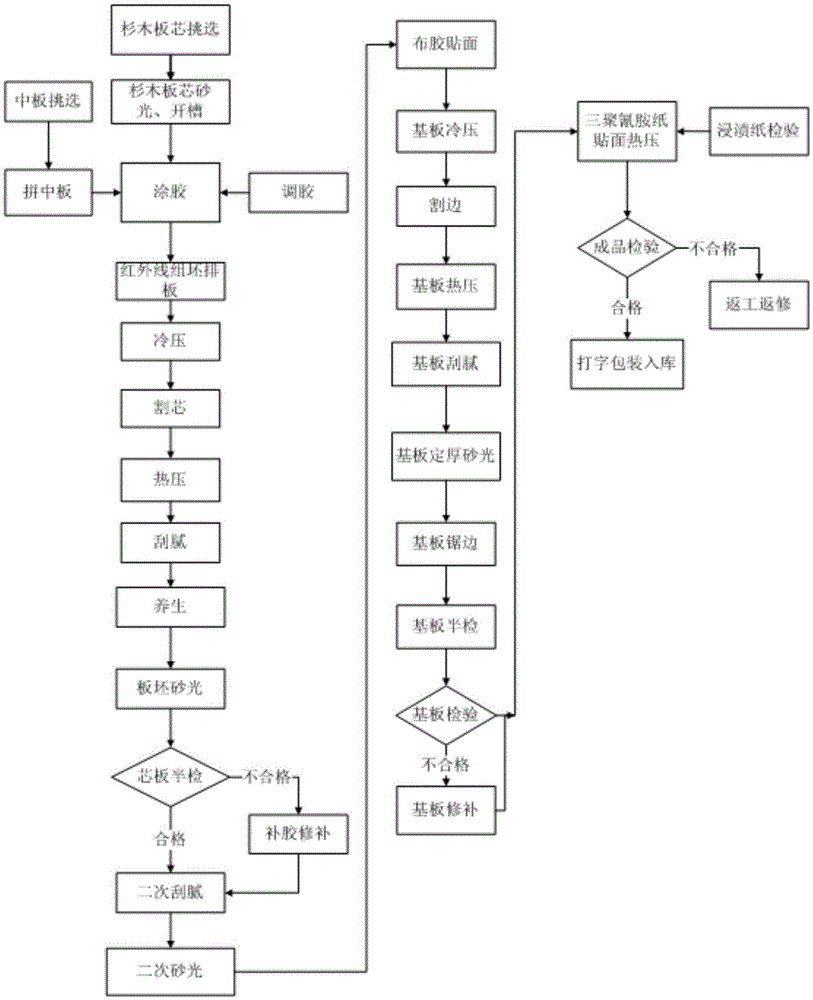

Production process of high-grade fir melamine ecological board

ActiveCN105459221AReduces surface white bloomsReduce defects such as carbonizationOther plywood/veneer working apparatusLaminationInfraredProduct inspection

The invention belongs to the field of board machining and particularly relates to a production process of a high-grade fir melamine ecological board. The process particularly includes the following steps of poplar middle plate selection, poplar middle plate splicing, fir core veneer selection, fir core veneer sanding, fir core veneer slotting, core veneer gluing, infrared ray board arrangement for forming a blank, cold pressing, core cutting, hot pressing, putty application, maintenance, sanding, semi-checking, secondary putty application, secondary sanding, gluing and veneering, base board cold pressing, base board edge cutting, base board hot pressing, base board putty application, base board fixed-thickness sanding, base board edge sawing, base board inspection, repairing, melamine impregnated paper hot pressing and finished product inspection, packaging and warehousing of finished products. The production process has the advantages that fir core veneers are adopted, the hardness, nail-holding ability and static bending strength of the board is improved; eucalyptus middle plates are replaced with poplar middle plates, and the defects that the surface of the finished products is stained and carbonized caused by multiple burrs and scabs on the surfaces of the gum wood are reduced effectively.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

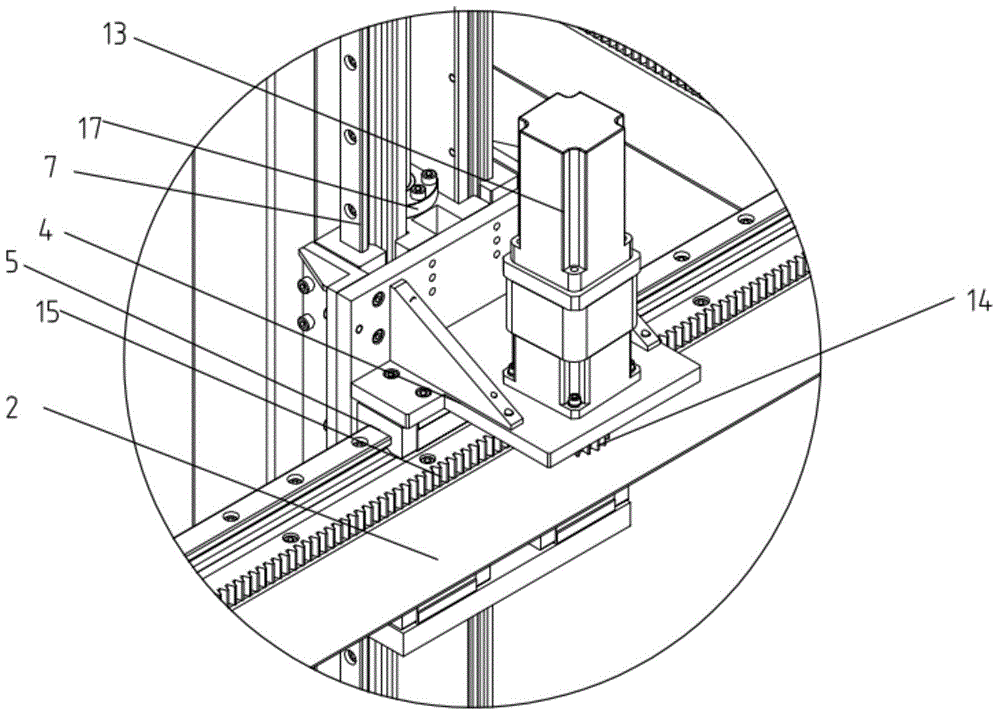

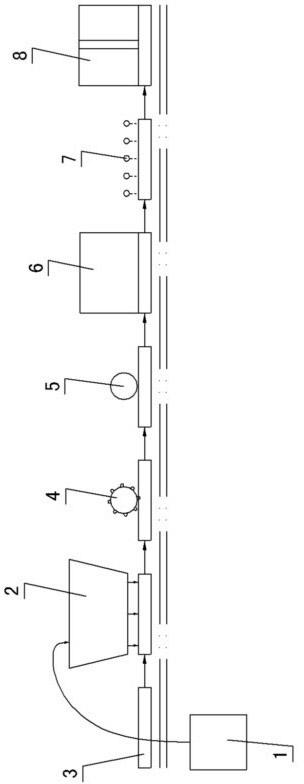

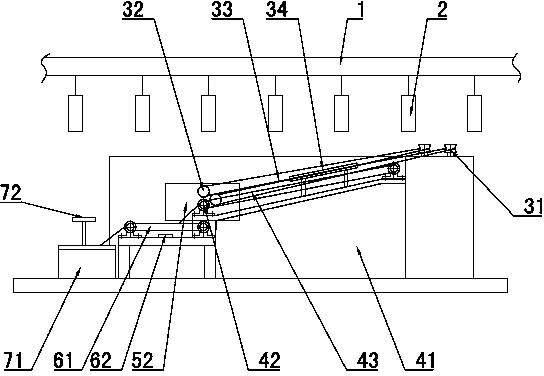

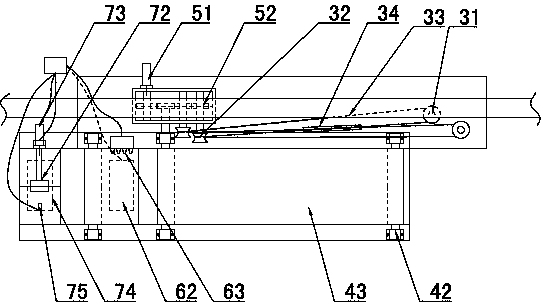

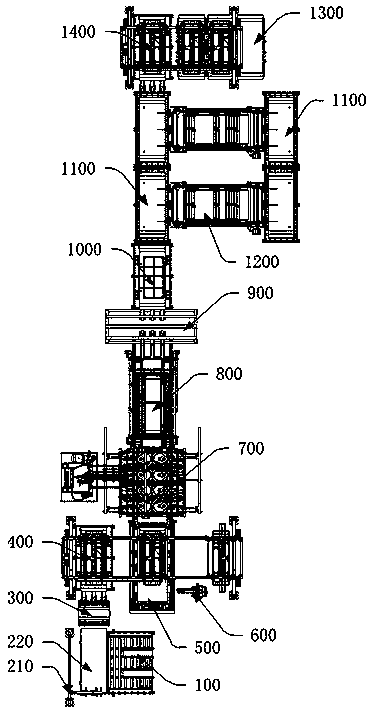

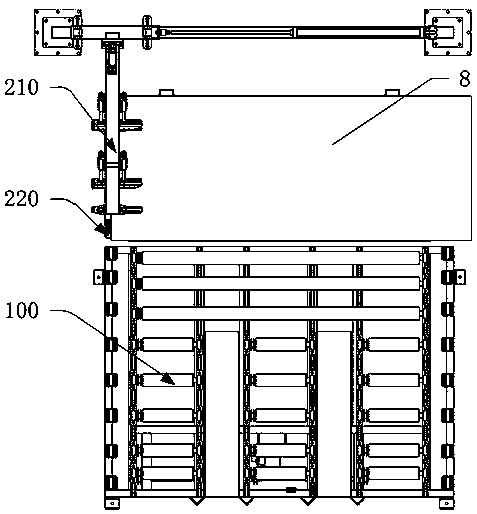

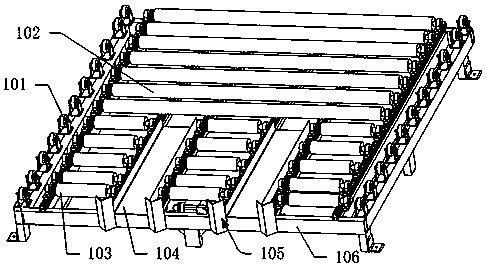

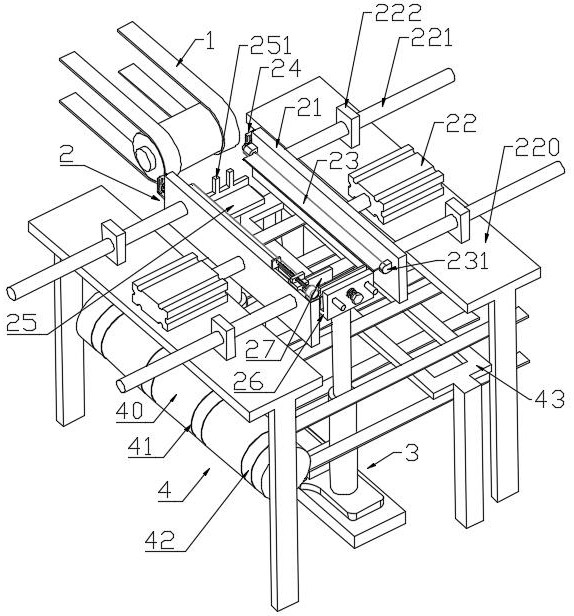

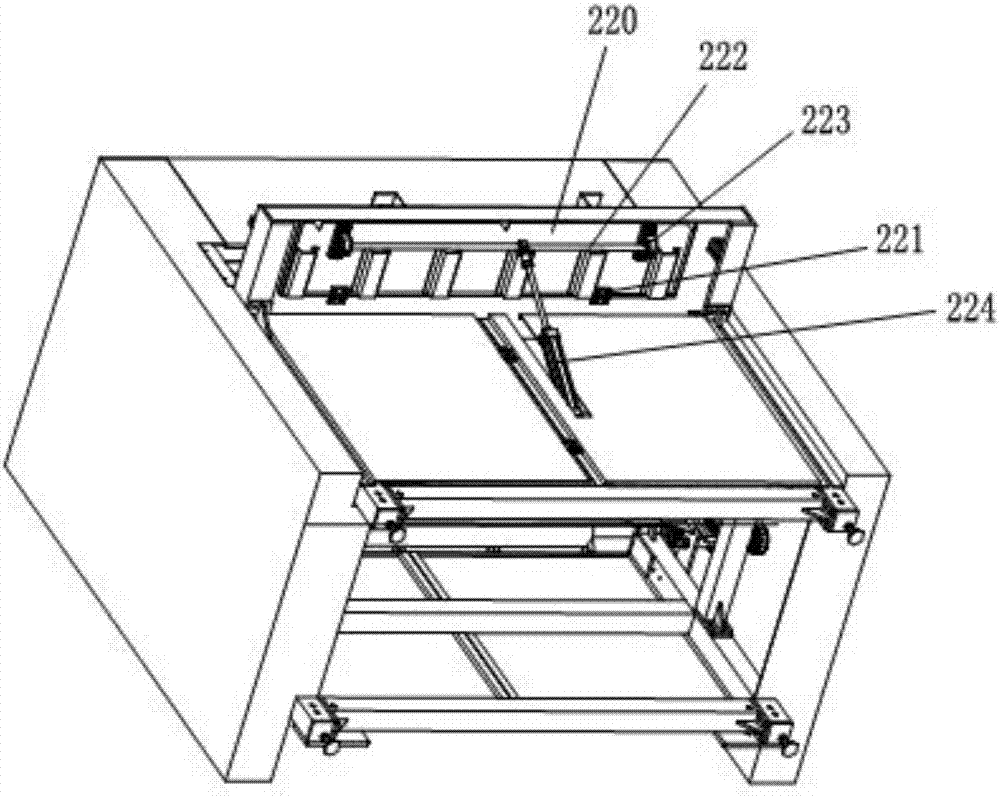

Automatic blanking system for silicon steel sheet stamping production line

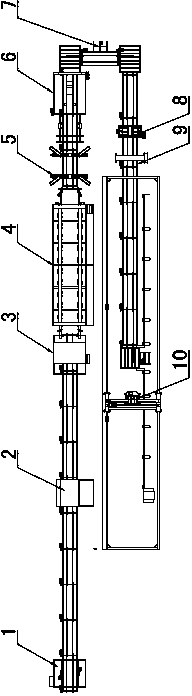

ActiveCN104801624AIngenious structure layoutImprove efficiencyMetal-working feeding devicesPositioning devicesWire cuttingScrap

The invention relates to the field of the automation of a stamping machine, and particularly relates to an automatic blanking system for a silicon steel sheet stamping production line. The automatic blanking system comprises a material collecting system, an adsorption system, a carrying system, a supporting mechanism, a stacking system, a waste cutting system and a waste coiling system; the carrying system is connected with the adsorption system, the carrying system is installed on the supporting mechanism, the stacking system and the material collecting system are arranged below the supporting mechanism, the stacking system and the collection system are arranged in parallel, one end of the collection system is provided with the waste cutting system, and the waste coiling system is arranged by the side of the waste cutting system. The automatic blanking system is ingenious in structure layout, high in efficiency and low in cost; the carrying system has the advantages of high speed, high rigidness, high load capacity and the like and is applicable to different silicon steel sheets in different specifications, the existing stamping machine does not need to be changed, and the automatic blanking system is suitable for automatically modifying various silicon steel sheet production devices.

Owner:DONGFANG ELECTRIC CORP LTD

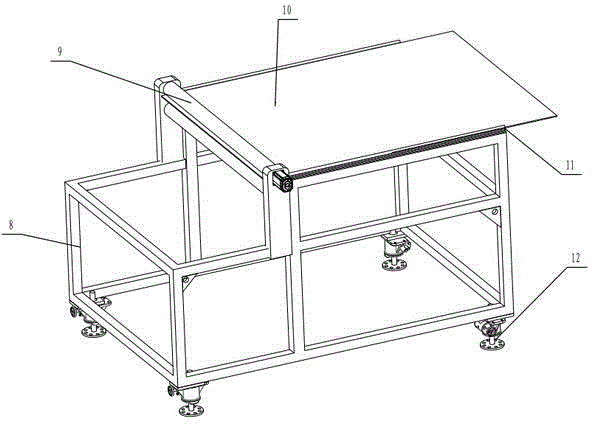

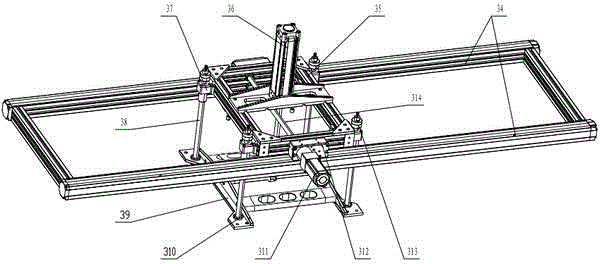

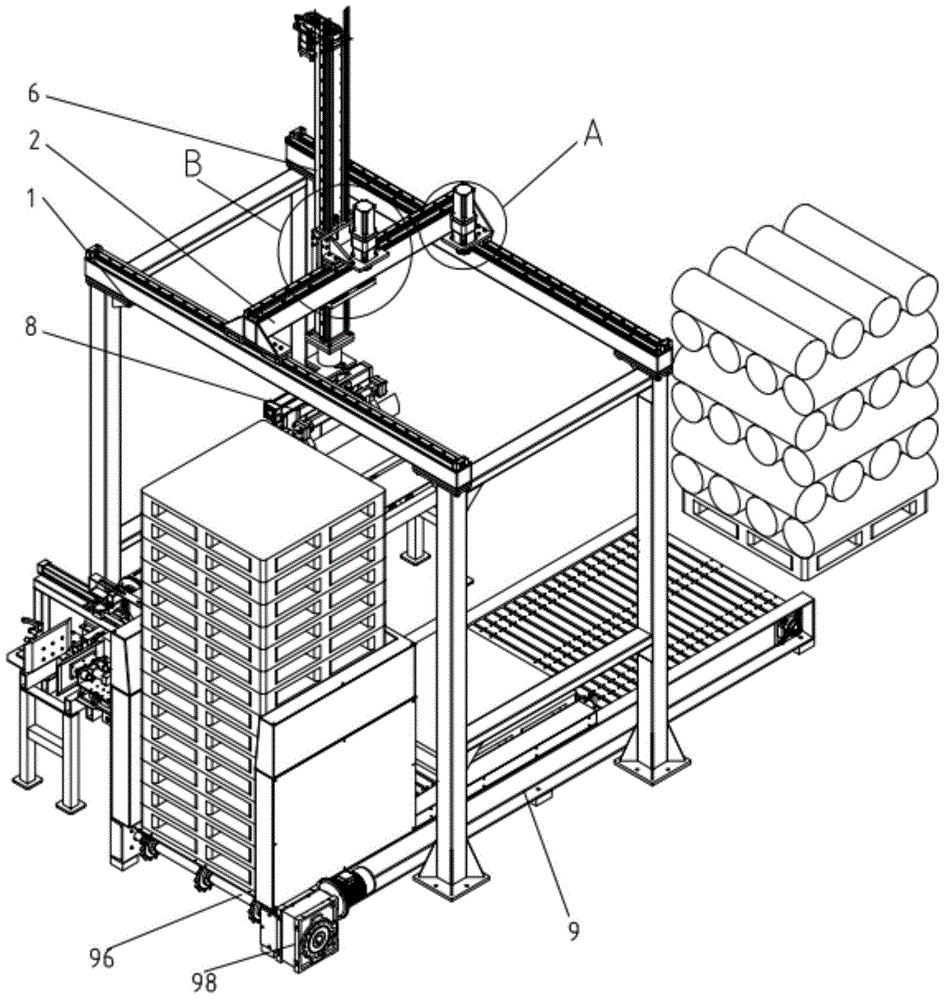

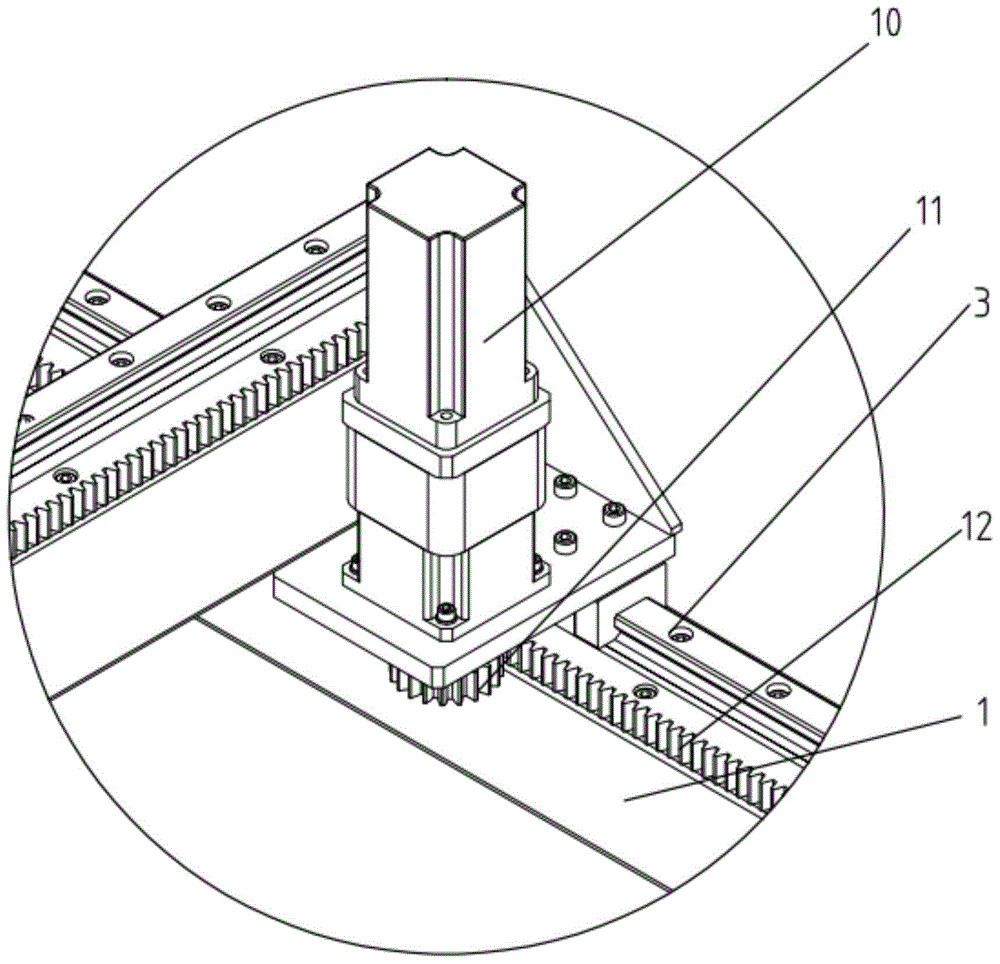

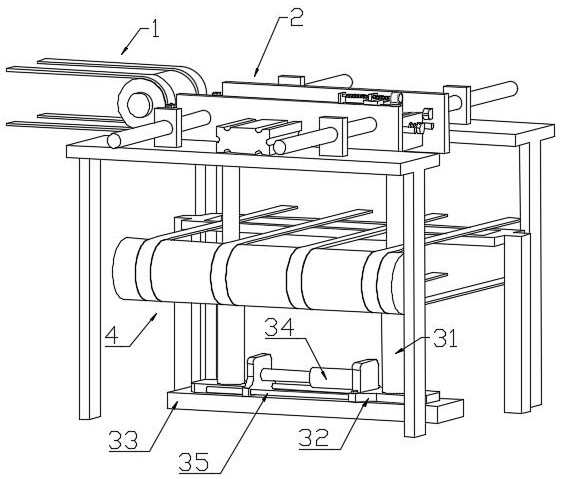

Stacker for clay laths

The invention discloses a stacker for a clay lath. The stacker comprises a frame, an X-direction carling, an X-direction moving device, a Y-direction moving seat, a Y-direction moving device, a Z-direction moving beam, a Z-direction moving device, a gripping apparatus and a transportation support device, wherein the X-direction carling is movably arranged on the frame through a first guide rail slider pair; the X-direction moving device is arranged between the X-direction carling and the frame; the Y-direction moving seat is movably arranged on the X-direction carling through a second guide rail slider pair; the Y-direction moving device is arranged between the Y-direction moving seat and the X-direction carling; the Z-direction moving beam is movably arranged on the Y-direction moving seat through a third guide rail slider pair; the Z-direction moving device is arranged on the Z-direction moving beam and the Y-direction moving seat; the gripping apparatus is arranged on the end of the Z-direction moving beam and is used for clamping the clay lath processed by a clay cutting machine; the transportation support device is arranged on the frame. According to the stacker, automatic stacking of the clay lath produced by the clay cutting machine is implemented, stacking is neater, and the stacking speed is greatly improved.

Owner:HUNAN SLON EQUIP

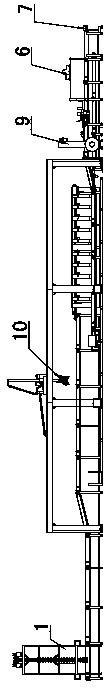

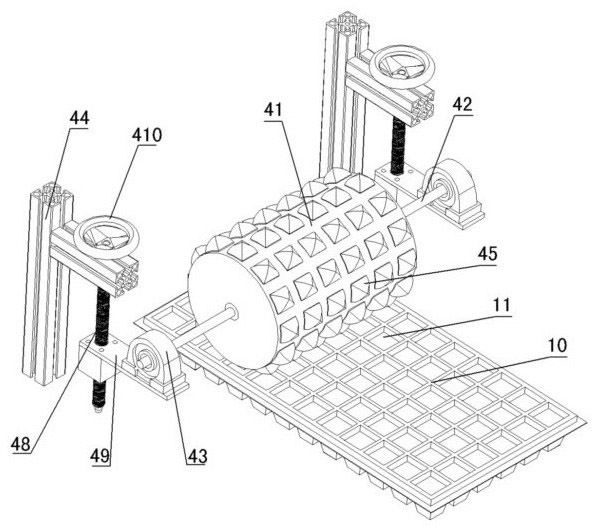

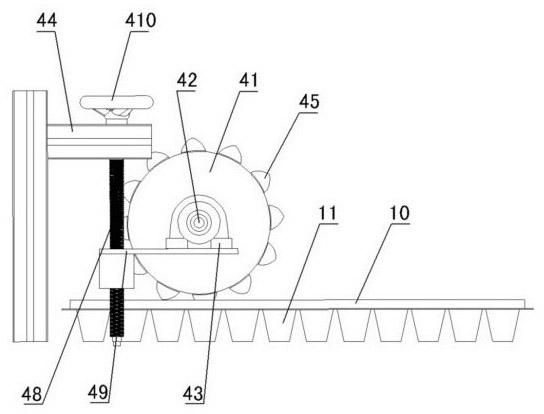

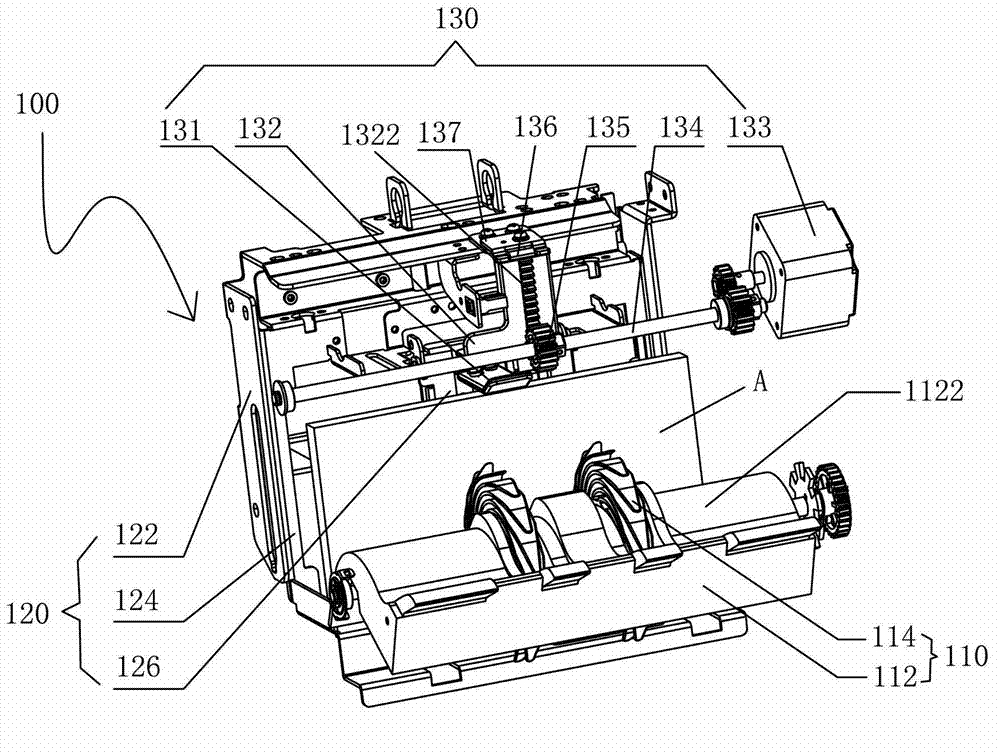

Full-automatic drum-type precision seeding flow line

ActiveCN102550181AEasy to insertAvoid cloggingRegular seed deposition machinesEngineeringProcessing cost

A full--automatic drum-type precision seeding flow line comprises a soil stirring mechanism and a soil loading device and further comprises a seedling-raising disk feeding mechanism, a hole pressing device, a seeding mechanism, an earth covering device, a water spraying device and an outlet disk stacking mechanism which are all mounted on a machine frame. According to the scheme, the hole pressing device is driven with no power, and is high in hole pressing rate and high in efficiency; the seeding mechanism seeds precisely by adopting positive-negative pressure pneumatic type, the processing cost of a seeding drum is low, and the energy consumption is low; the earth covering device adopts a crawler to blank in a rolling manner, earth covering is uniform, and the success rate of seed cultivation is high; and the outlet disk stacking mechanism can stack outlet disks automatically, so that working hours are saved, and the production cost is reduced.

Owner:杭州赛得林智能装备有限公司

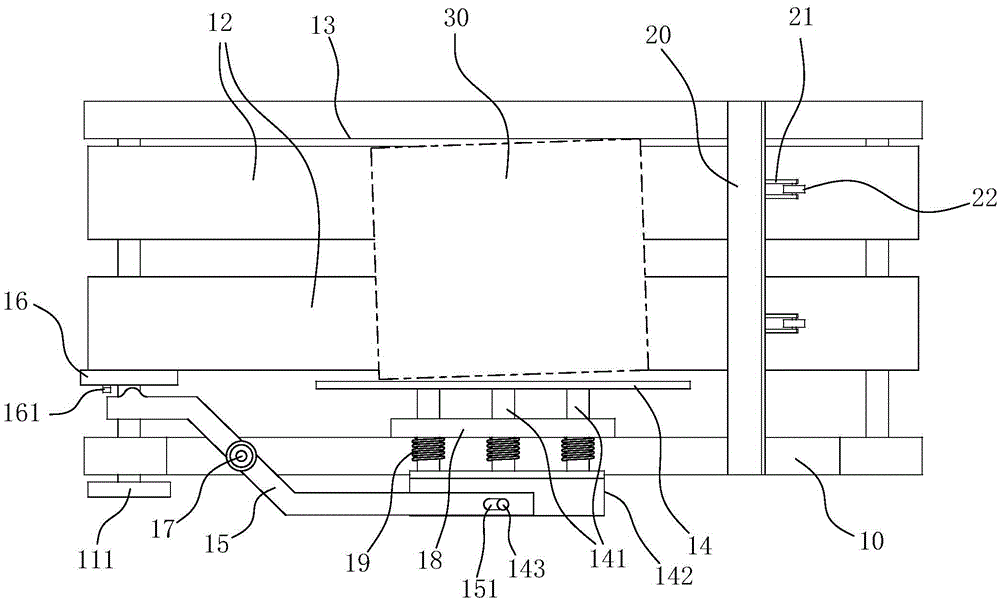

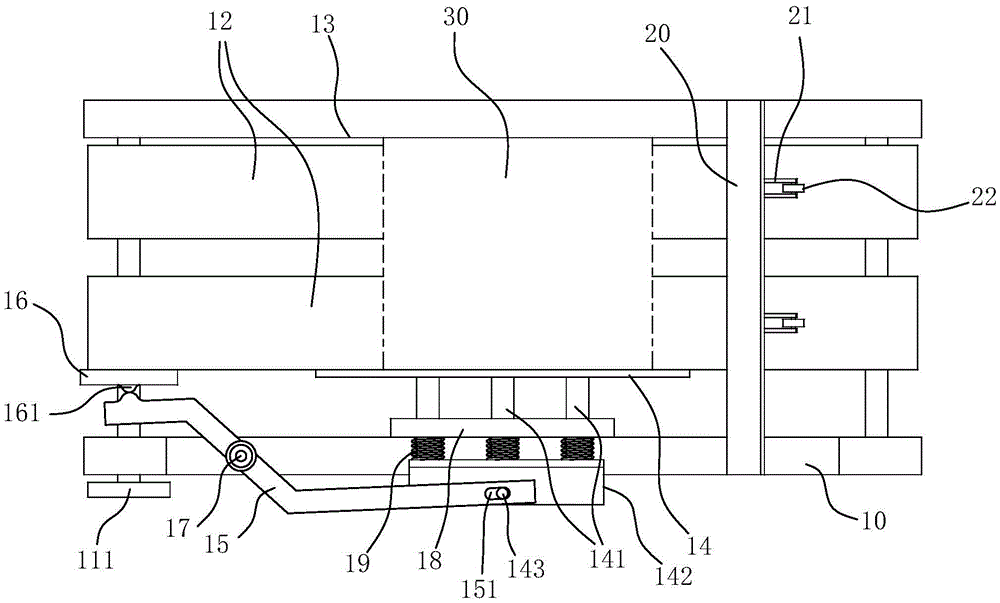

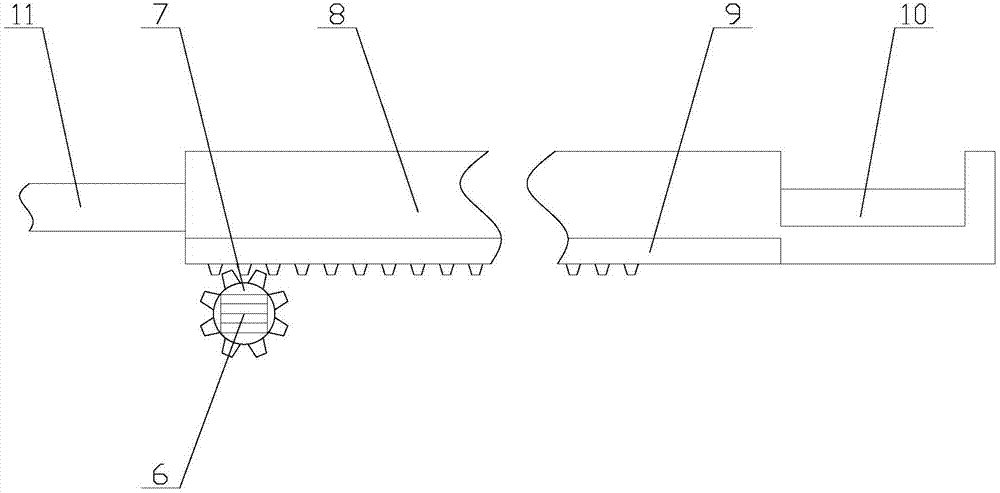

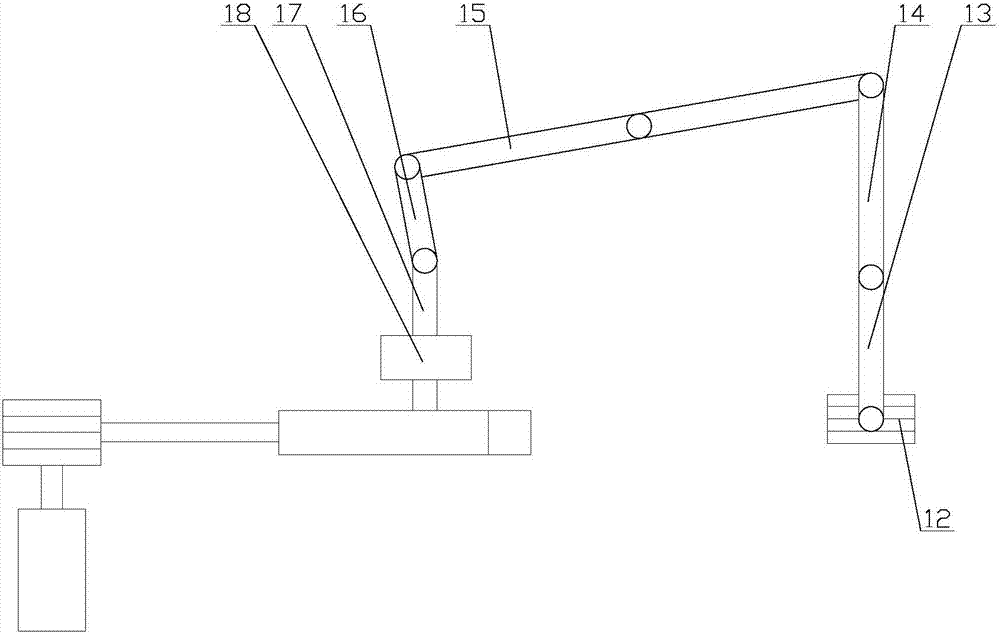

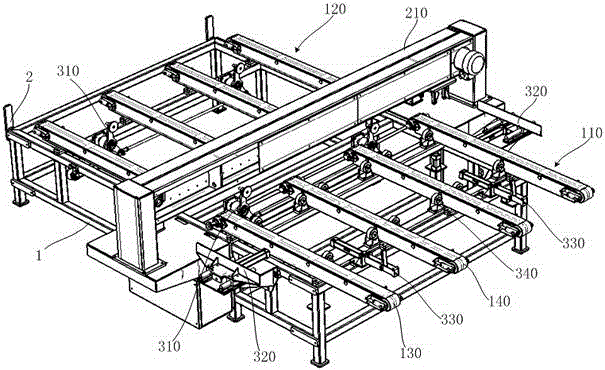

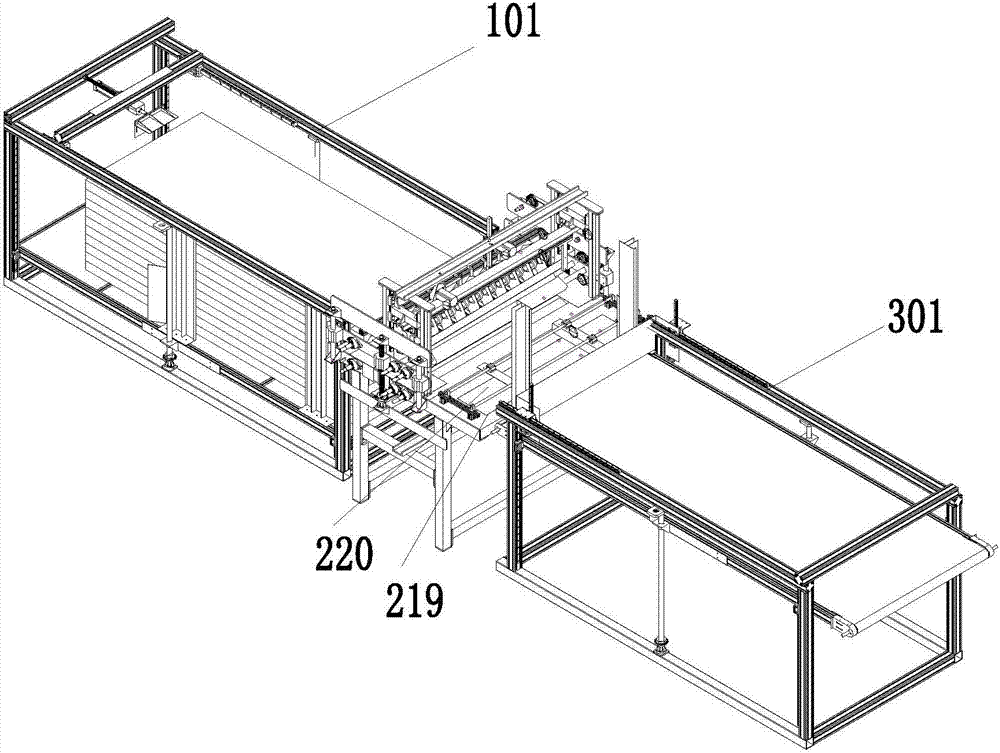

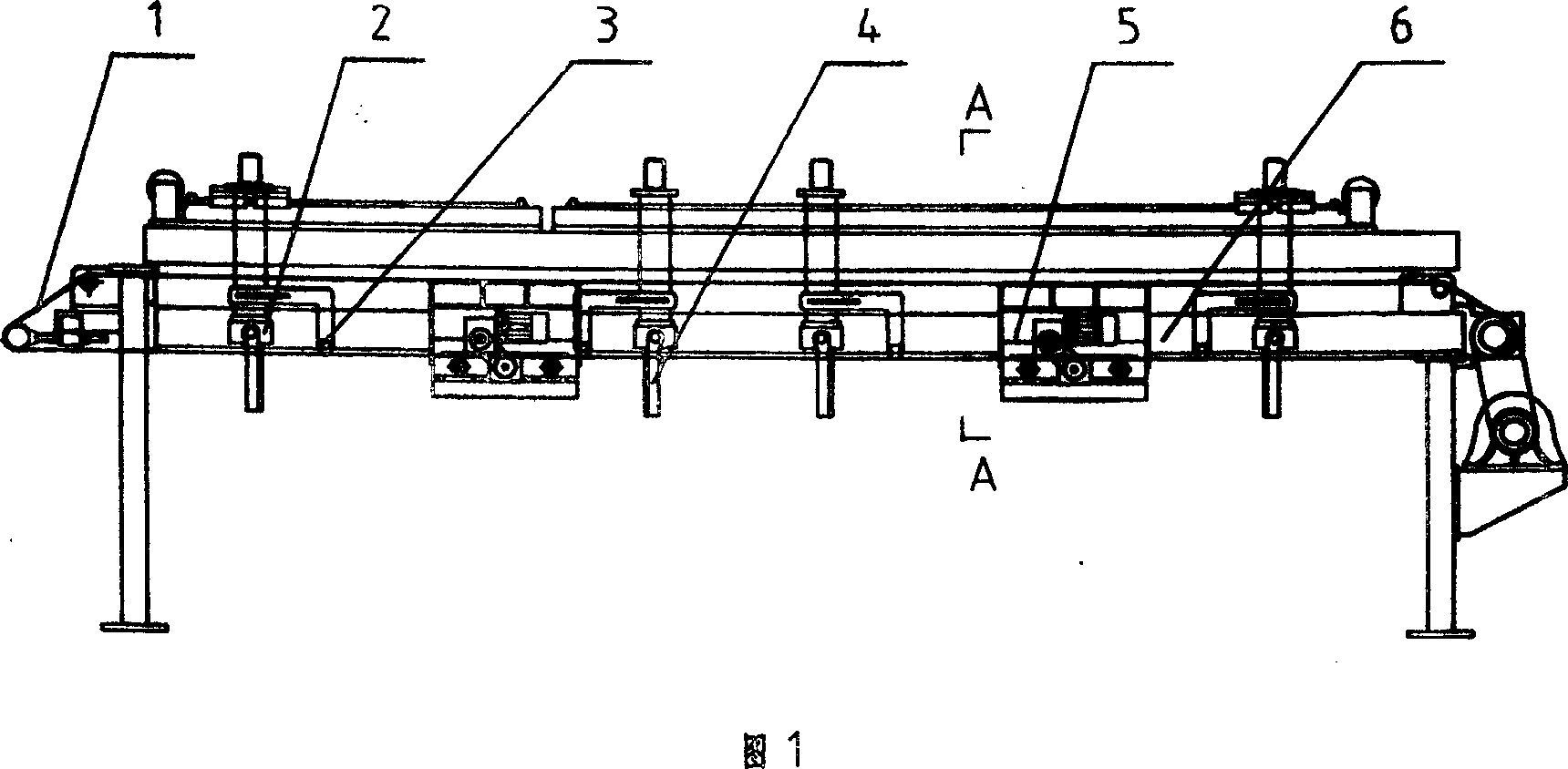

Conveying and trimming assembly used for melamine board, trimming and board discharging assembly and achieving method of conveying and trimming assembly and trimming and board discharging assembly

InactiveCN104444480AReduce labor intensityHigh precisionOther plywood/veneer working apparatusRegistering devicesHeat pressEngineering

The invention discloses a conveying and trimming assembly for a melamine board. The conveying and trimming assembly comprises a bottom frame arranged outside a discharging port of a hot press, a two-section type conveying mechanism arranged on the bottom frame in the discharging direction, a positioning and position adjusting mechanism installed on the bottom frame and used for adjusting the position of a board on the two-section type conveying mechanism to as to conveniently conduct trimming, a trimming mechanism arranged at the sectioned position of the two-section type conveying mechanism in a crossing mode, and a tail-end baffle located at the tail end of the two-section type conveying mechanism. The invention further discloses a trimming and board discharging assembly which comprises the conveying and trimming assembly and a board discharging and carrying mechanism connected with the conveying and trimming assembly. Under the cooperation action of the conveying mechanism and the positioning and position adjusting mechanism, the board obtained after hot pressing is conveyed to a designated position, trimming is conducted on the board through the trimming mechanism, the board is well placed through the board discharging and carrying mechanism, an automatic mechanical device can fully replaced labor force, the labor intensity of workers is greatly lowered, the labor cost is reduced, and the production efficiency is effectively improved.

Owner:李茂华

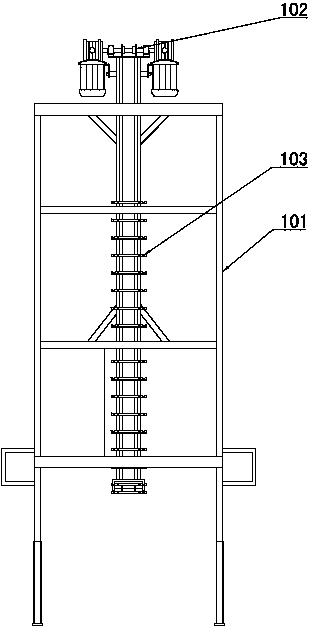

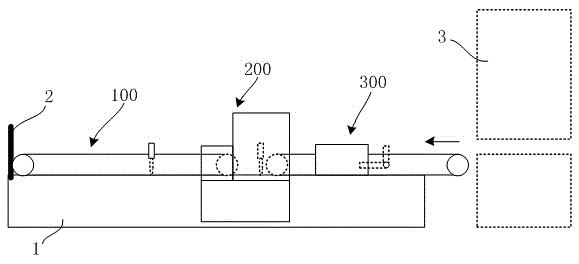

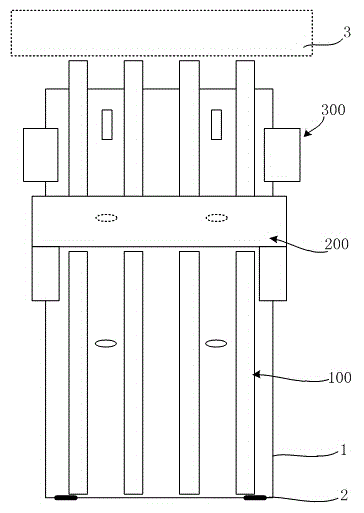

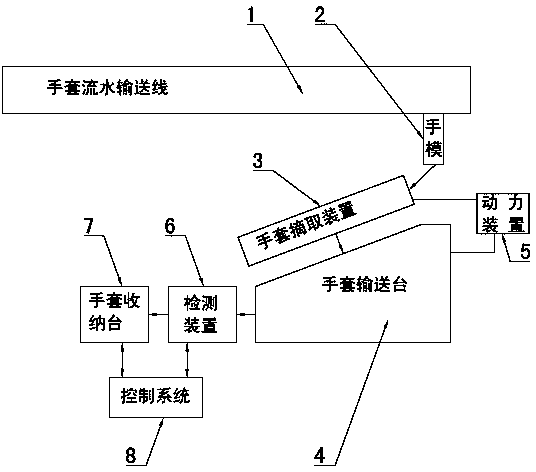

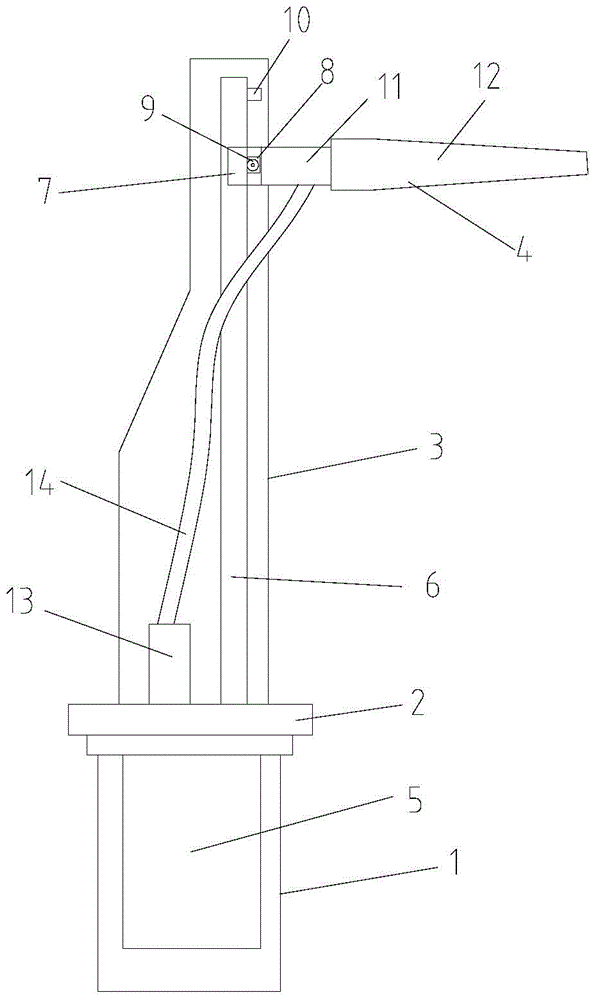

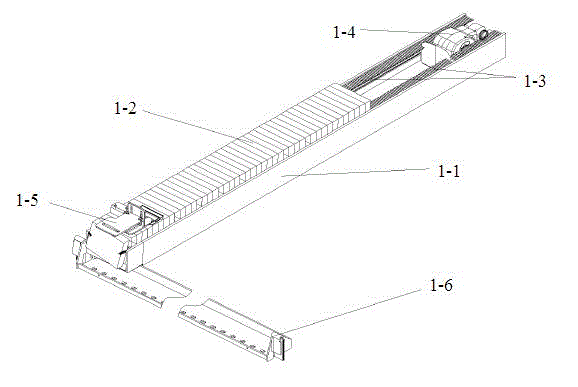

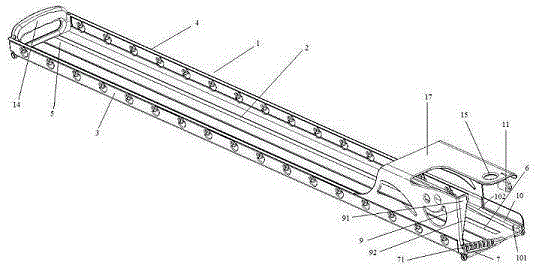

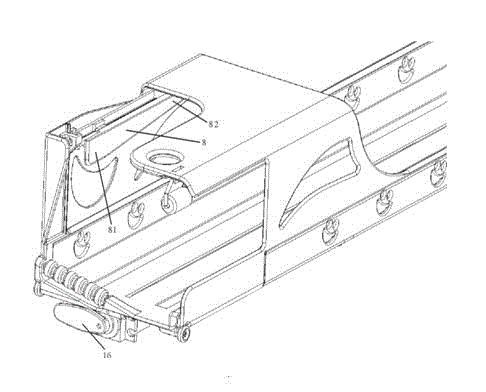

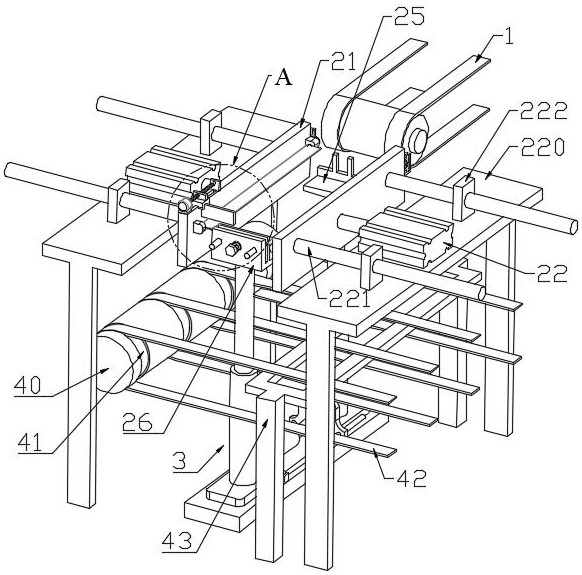

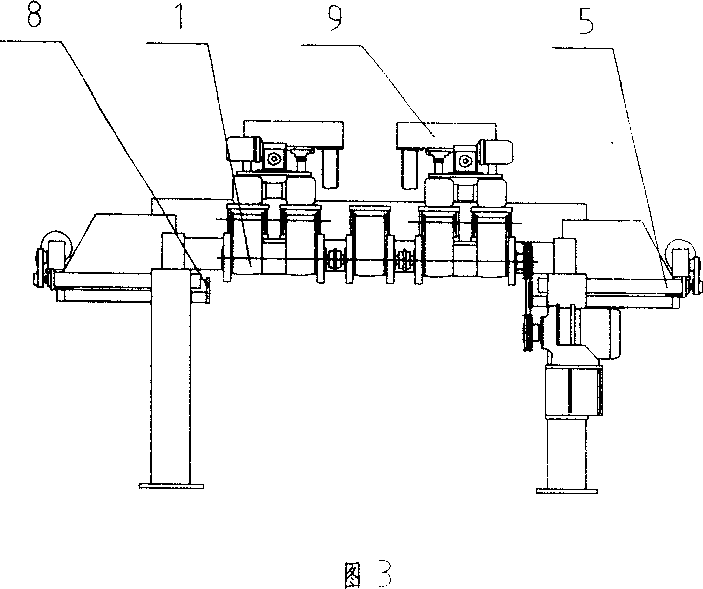

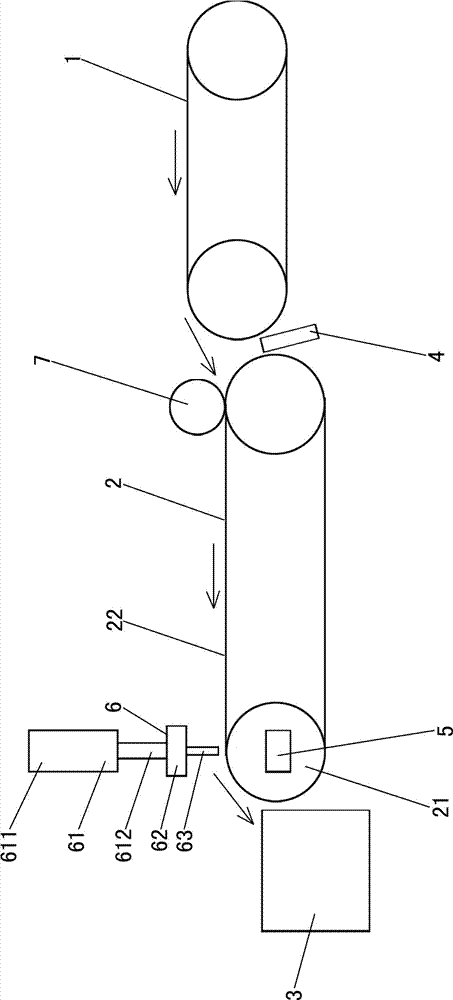

Full-automatic glove counting and stacking machine

The invention provides a full-automatic glove counting and stacking machine, and belongs to the field of production devices of vinyl gloves, butyronitrile gloves and latex gloves. The full-automatic glove counting and stacking machine comprises a glove assembly conveying line (1), a plurality of hand moulds (2) are hung on the lower portion of the glove assembly conveying line (1), and gloves are arranged on the surfaces of the hand moulds (2) in a sleeved mode in the conveying process. The full-automatic glove counting and stacking machine is characterized in that a glove picking device (3) and a power device (5) are arranged below the glove assembly conveying line (1), a glove conveying table (4) with an inclined conveying face is arranged on one sides of the glove picking device (3) and the power device (5), the power device (5) drives the glove conveying table (4) and the glove picking device (3) to work at the same time, a detection device (6) is arranged at the output end of the glove conveying table (4), and the rear portion of the detection device (6) is connected with a glove storing table (7). The full-automatic glove counting and stacking machine is simple in structure, high in efficiency, free of cylinder control, convenient to maintain, and capable of achieving glove picking, detecting, conveying, and stacking functions.

Owner:ZIBO CHENGXUN AUTOMATION EQUIP

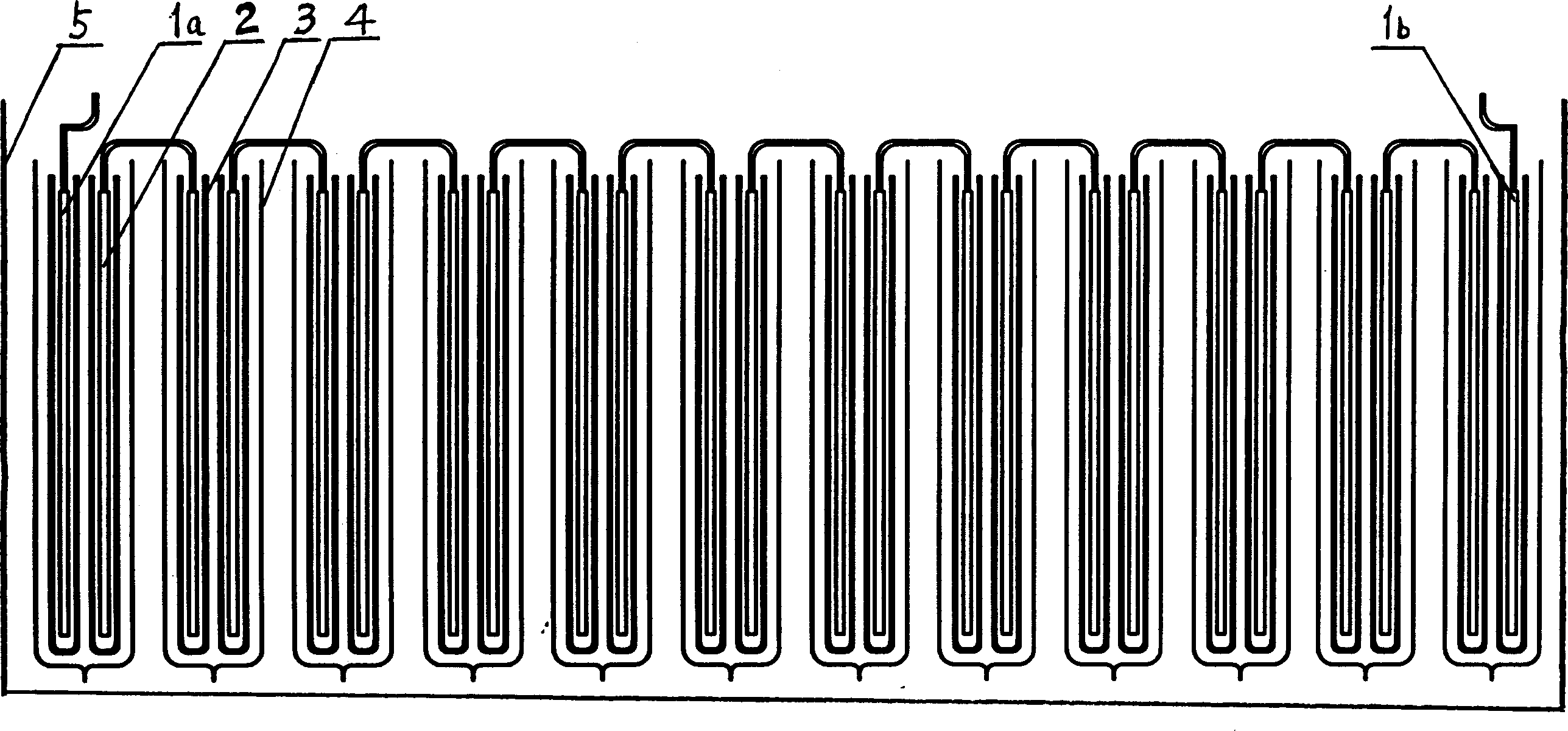

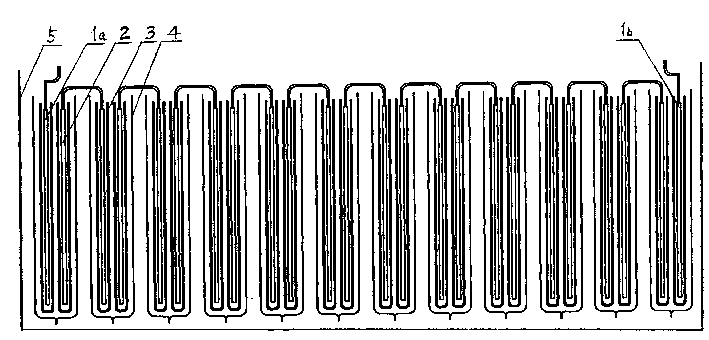

Pole Plate folding type lead-acid accumulator and its preparing method

InactiveCN1458708AReduce volumeReduce weightFinal product manufactureLead-acid accumulators constructionElectrical polarityEngineering

This invention discloses a folded polar plate lead acid battery and its making method, among which the lead wire connecting two plates is folded into u-shape and monopolar and bipolar plates are arranged in the box in sequence according to the matched polarities, a V-shaped diaphragm wraps both sides of each plate, insulation bag sleeve two adjacent polar plates and the diaphragm warapping the polar plates, realizing internal serials connection by lead wires. The lead acid battery has the advantages of small volume, light weight and good power characteristic.

Owner:SHIJI QIANWANG BATTERY TECH CO LTD BEIJING

Workpiece turnover device

The invention relates to a workpiece turnover device. The workpiece turnover device is characterized in that the device comprises a conveying belt mechanism, front and rear translation suction lifting mechanisms and a turnover air cylinder, the conveying belt mechanism is arranged between the front translation suction lifting mechanism and the rear translation suction lifting mechanism, the conveying belt mechanism is composed of a front horizontal conveying section conveying belt, a workpiece turnover section conveying belt and a rear horizontal conveying section conveying belt, the upper end of the workpiece turnover section conveying belt is in a hinged connection with a front horizontal conveying section conveying belt, the middle portion of the workpiece turnover section conveying belt is in a pin connection with a conveying belt lifting air cylinder, and the turnover air cylinder is arranged at the position of the workpiece turnover section conveying belt in an inclined mode. The workpiece turnover device has the advantages that mechanical automation replaces manpower to pack building material plate products, and the products can be neatly packed; the mode that faces of all plates are packed upwards is changed to be a face to face packing mode and a back to back packing mode, the continuous production is achieved, and the plates on a conveying line is turned over once every other piece; the plate surface damage caused by manual handling can be effectively reduced; and the plates can be rapidly turned over, and the work efficiency is improved.

Owner:易科美德(天津)环保建材有限公司

Double-sided synchronous knurling embossed wood veneer production line

PendingCN110315603APrecise positioningChange the manual laying methodPlywood pressesVeneer pressesWood veneerMaterials preparation

The invention discloses a double-sided synchronous knurling embossed wood veneer production line which is capable of automatically finishing knurling embossing of veneers. The production line comprises an industrial personal computer, a longitudinal hot press, a material preparation table, a material discharging table, an automatic plate edge trimmer, an automatic plate airing line, a base material lifting platform arranged at an outlet of the material preparation table, a push plate device arranged above the base material lifting platform, a feeding conveying mechanism arranged at an inlet ofthe longitudinal hot press, a first automatic centering and conveying device arranged at an outlet of the base material lifting platform and arranged one side of the feeding conveying mechanism, a second automatic centering and conveying device arranged at an outlet of the automatic plate airing line and arranged on one side of the discharging table, a paper lifting platform arranged on the otherside of the feeding conveying mechanism, a paper laying manipulator device arranged above the paper lifting platform, a visual system arranged above the paper lifting platform, and a discharging conveying mechanism arranged at an outlet of the longitudinal hot press, wherein an outlet of the discharging conveying mechanism is connected with an inlet of an automatic plate edge trimmer, the automatic plate airing line comprises a plate airing machine and a roller conveyer arranged at an inlet of the plate airing machine, and an outlet of the automatic plate edge trimmer is connected with an inlet of the automatic plate airing line.

Owner:广东英达斯列智能科技有限公司

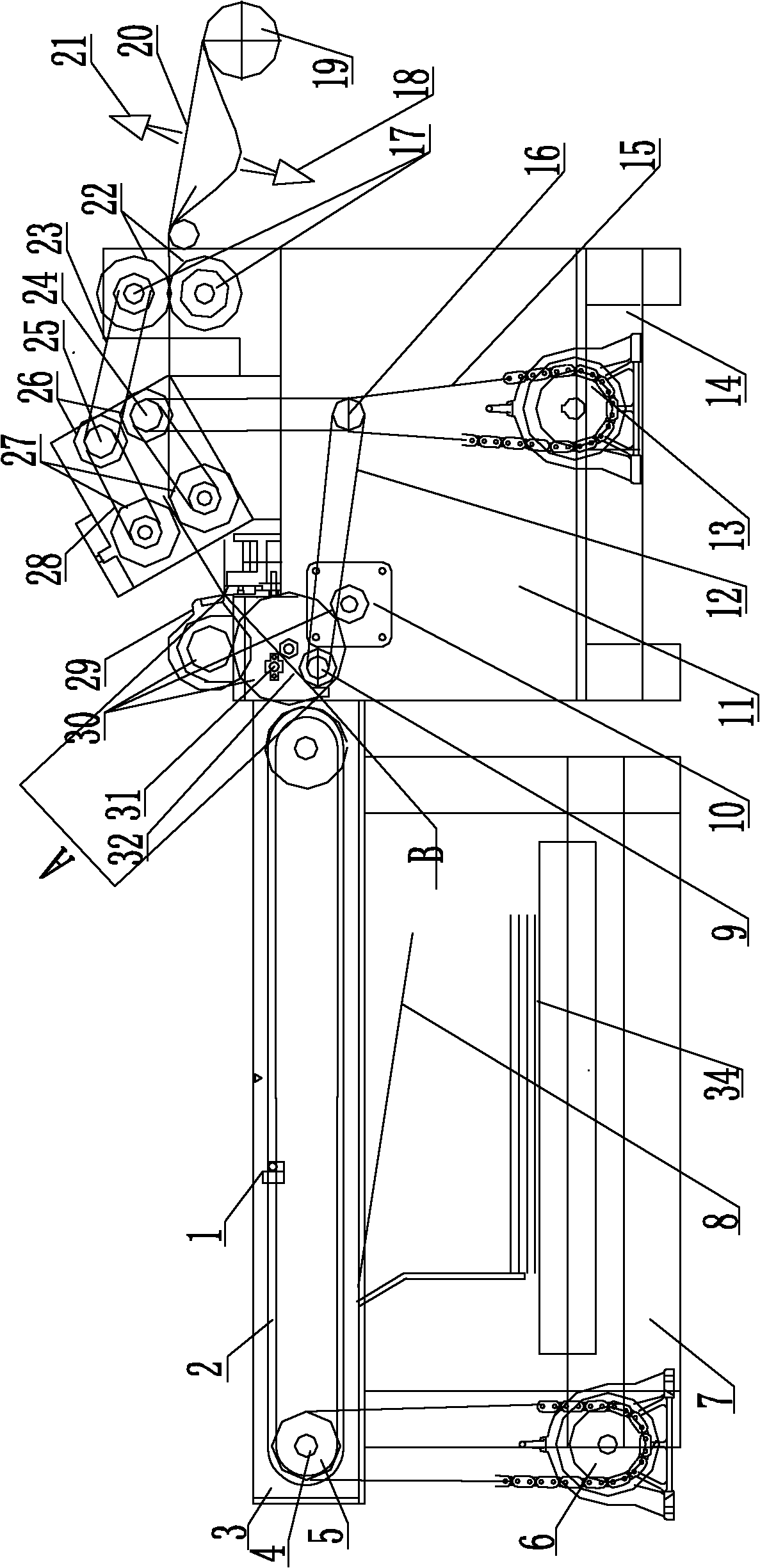

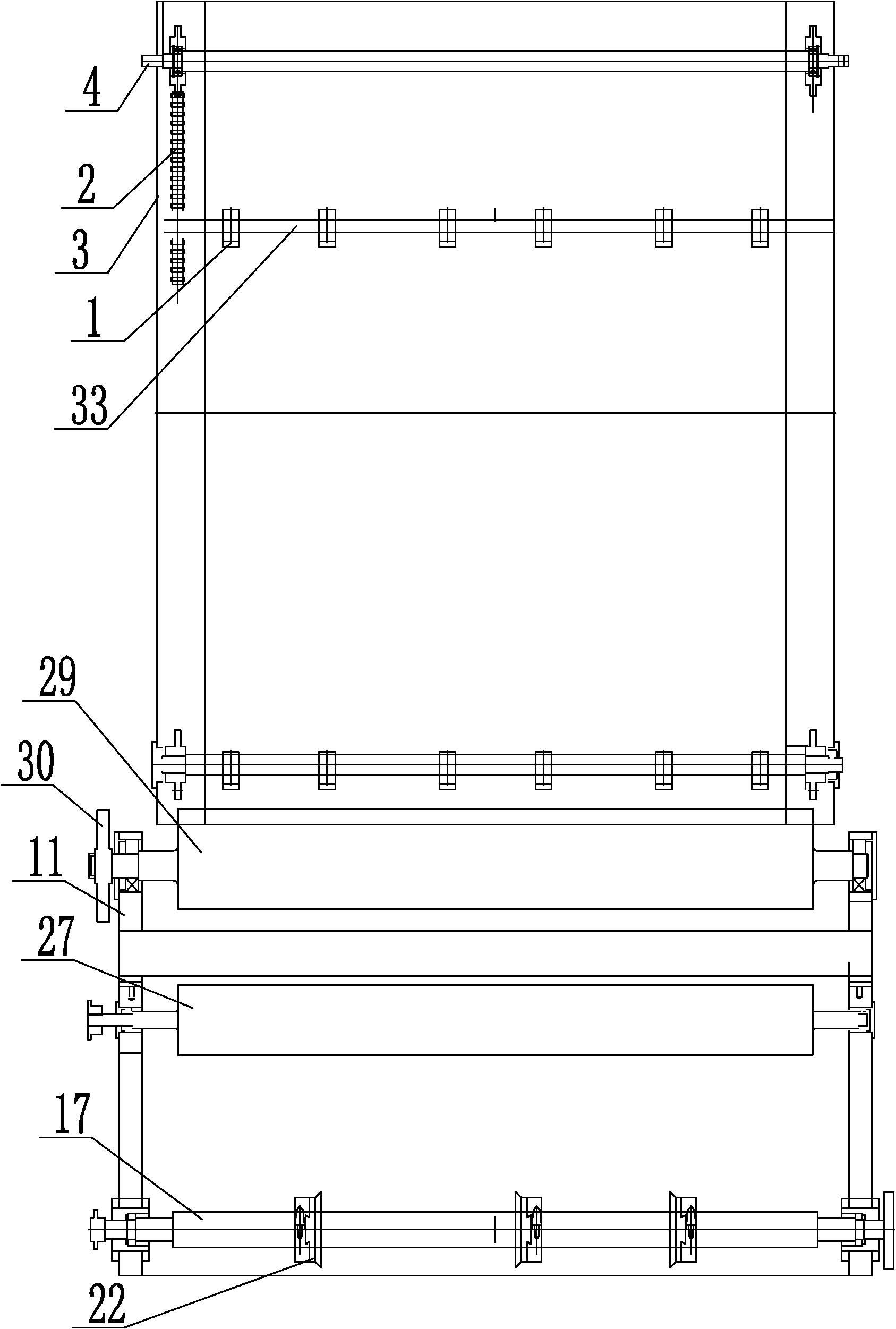

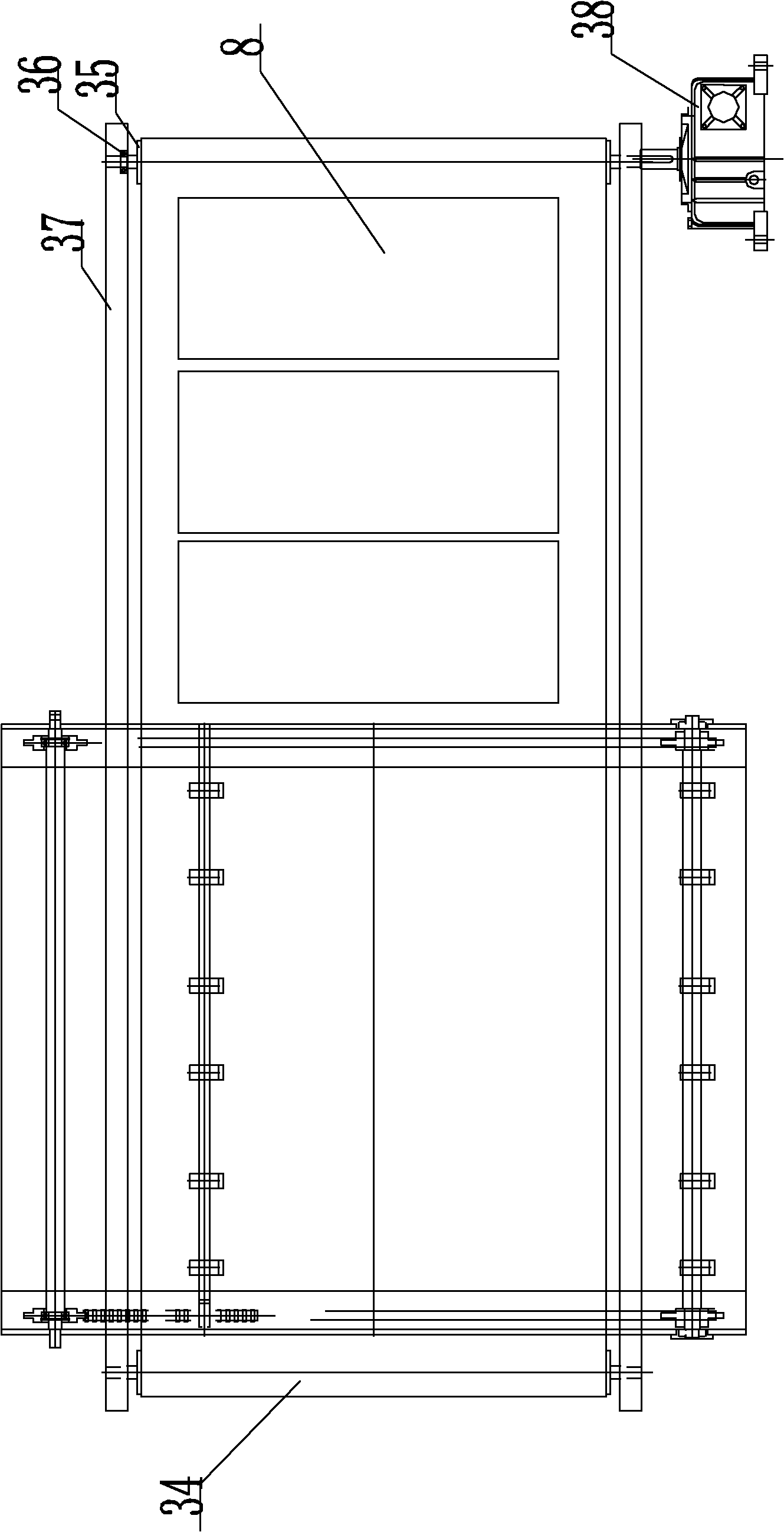

Paper cutting/receiving machine

InactiveCN102060205APrecise cut paper sizeNeatly stackedPile receiversArticle deliveryRolling paperLongitudinal splitting

The invention relates to a paper cutting / receiving machine, which comprises a paper conveying / cutting part, a paper receiving part and a transverse output belt (34), wherein the paper conveying / cutting part comprises a paper cutting foot (14), a paper cutting wallboard (11), a reversing gear (26), a paper drawing shaft (9), a paper pressing strip crossbar (31), a paper pressing strip (32), a round cutter (29), a round cutter gear (30), a servo motor (10), a reversing gear (26), a first short bridge axle (24), a second short bridge axle (25), a chain (28) with a paper conveying rubber roller, a bridge axle (16), a transmission bridge axle variable-frequency motor (13), a transmission paper drawing shaft chain (12), a longitudinal splitting cutter shaft (17), a longitudinal splitting cutter (22), a chain (23) with a longitudinal splitting cutter shaft, an upper photoelectric switch (21) and a lower photoelectric switch (18); and the paper receiving part comprises a paper receiving foot (7), a paper receiving wallboard (3), a seam (1), a seam mounting strip (33), a paper receiving chain (2), a paper receiving chain wheel shaft (4), a paper receiving chain wheel (5) and a transmission paper receiving shaft variable-frequency motor (6). Through the invention, the single-corrugated paper formed by a single-corrugated machine or roll paper is cut off and then automatically stacked.

Owner:赵祖良

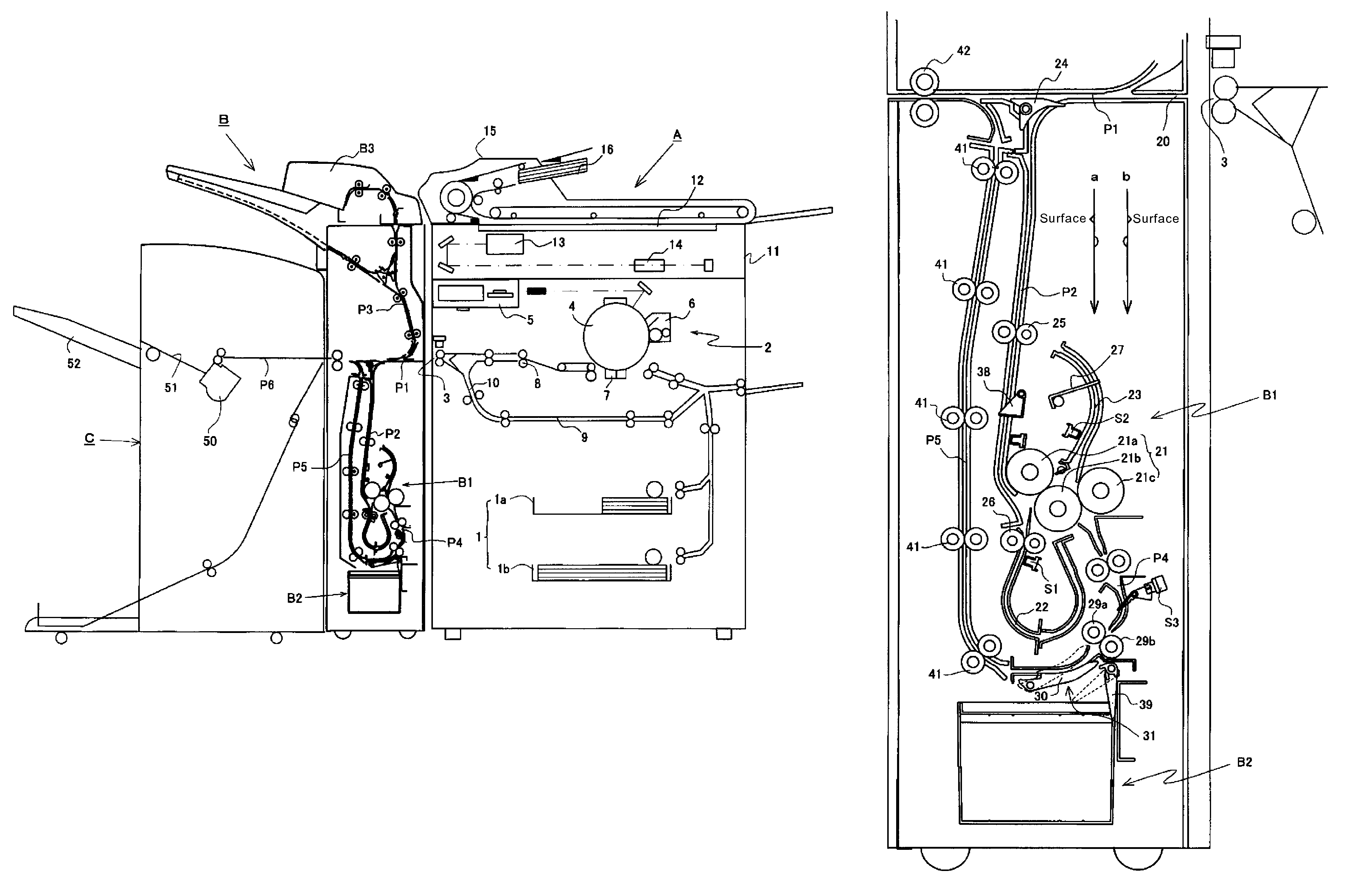

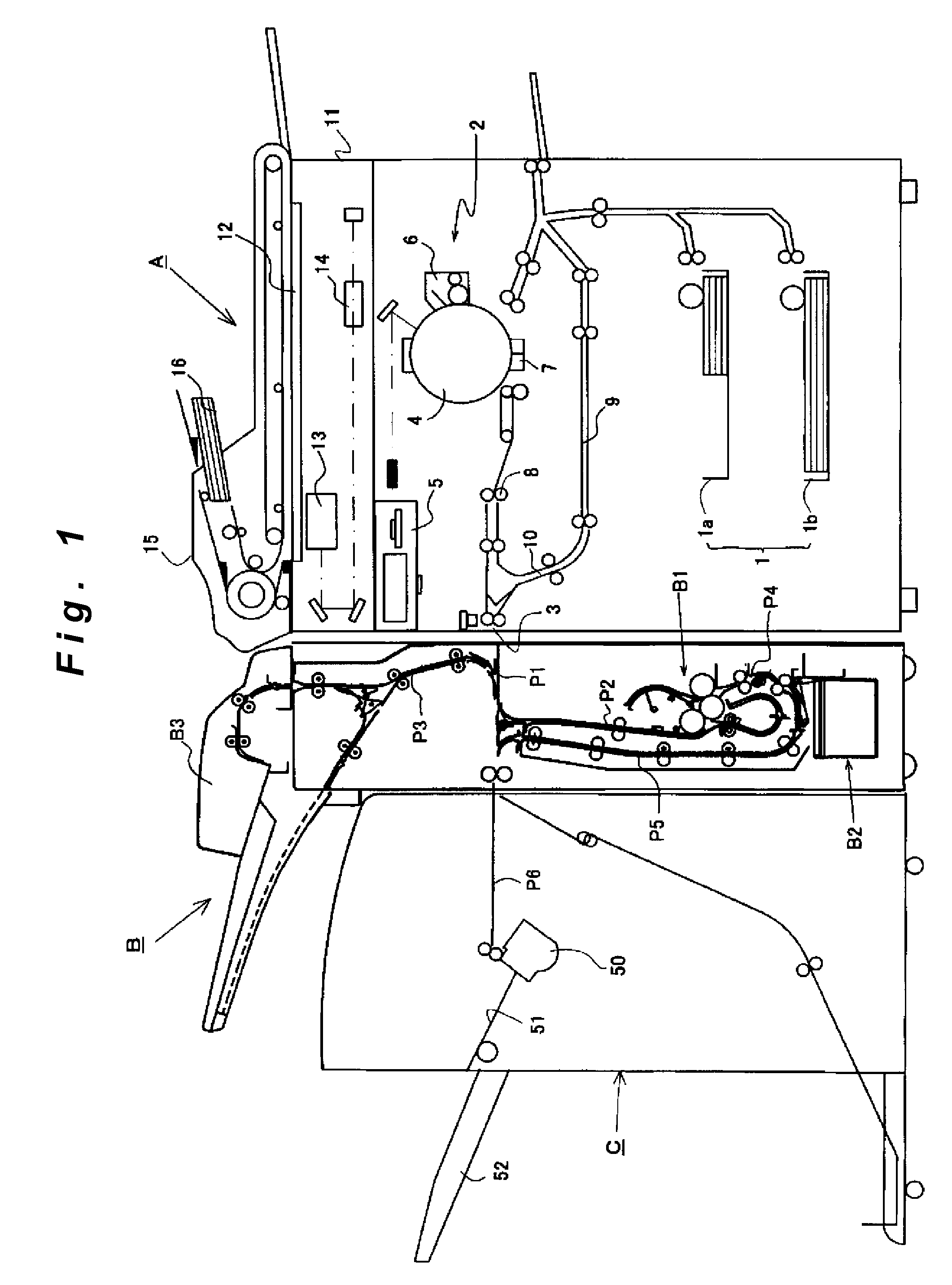

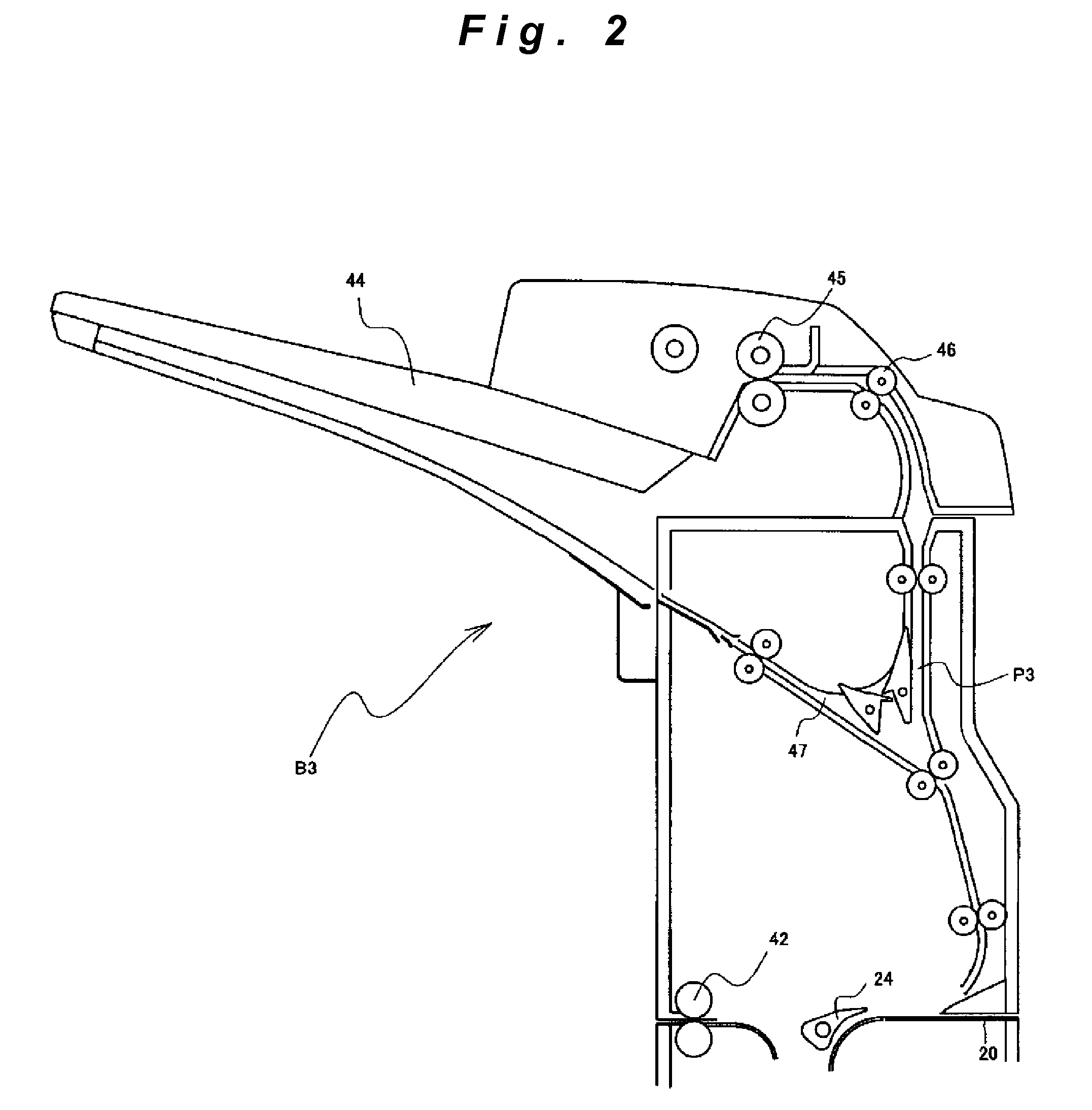

Sheet-folding apparatus and image-forming system equipped with the same

InactiveUS7712732B2Simple structureNeatly stackedFolding thin materialsOffice printingImage formationProcessing element

Sheets after having been sequentially folding-processed are stowed neatly without becoming dog-eared, wrinkled, etc. in the course of being transported to a stacker. A folding process unit folds sequentially fed copy paper or other sheets, and a sheet stacking unit loads / stows sheets from the folding unit. A conveyance device conveying one folding-processed sheet at a time is furnished between the folding unit and the sheet stacking unit. The conveyance device includes a first, upstream conveyance unit conveying sheets from the folding process unit in a direction approximately orthogonal to the sheets' crease(s), and a second, downstream conveyance unit conveying sheets in the orientation of the crease(s). The second conveyance unit is configured with a tray member where sheets are supported one at a time, and is configured so as to sequentially deliver each sheet to the sheet stacking unit along the tray member in the orientation of the crease(s).

Owner:NISCA KK

Tray and device for stablising a tray

Owner:SAFETRAY PRODS

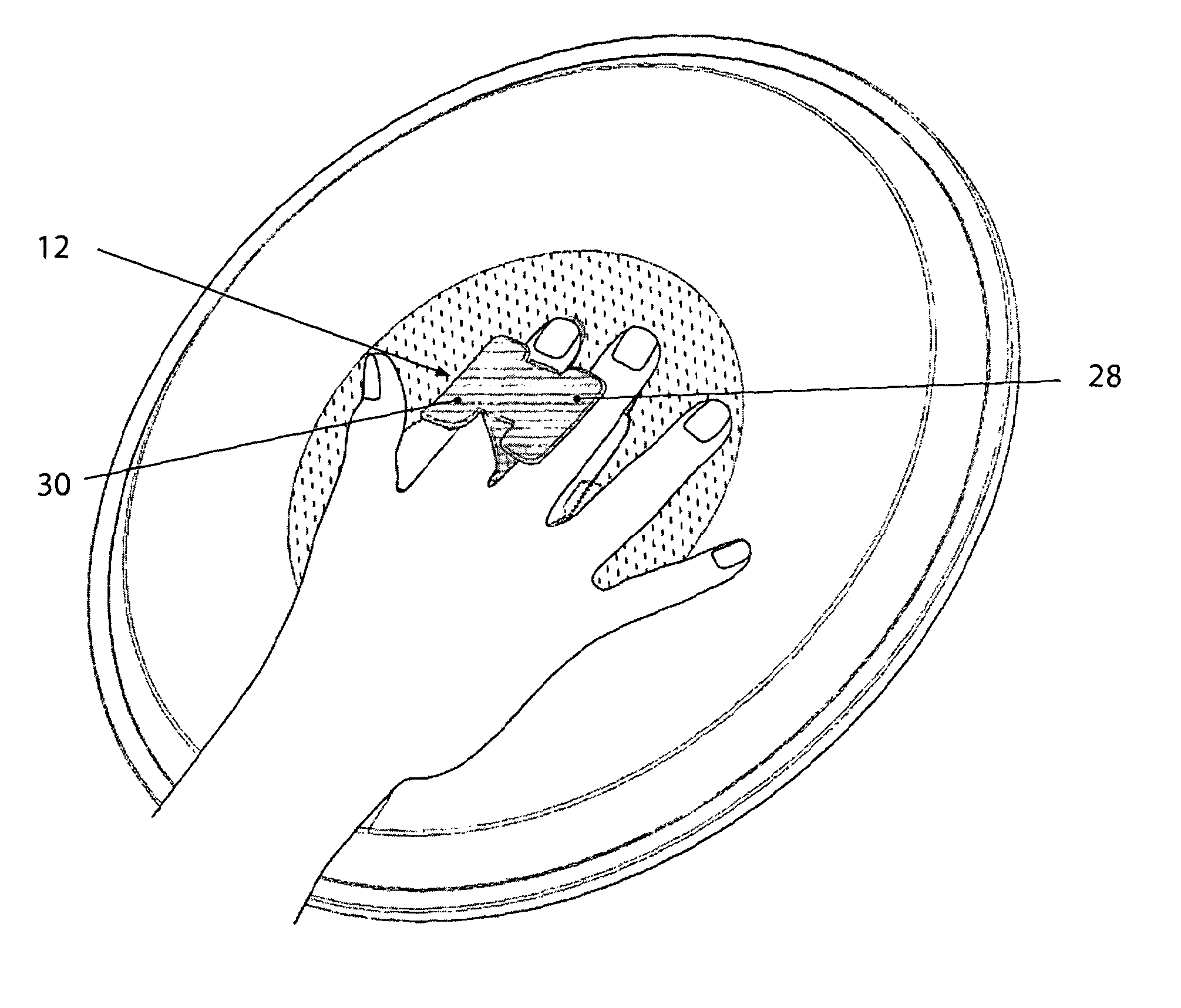

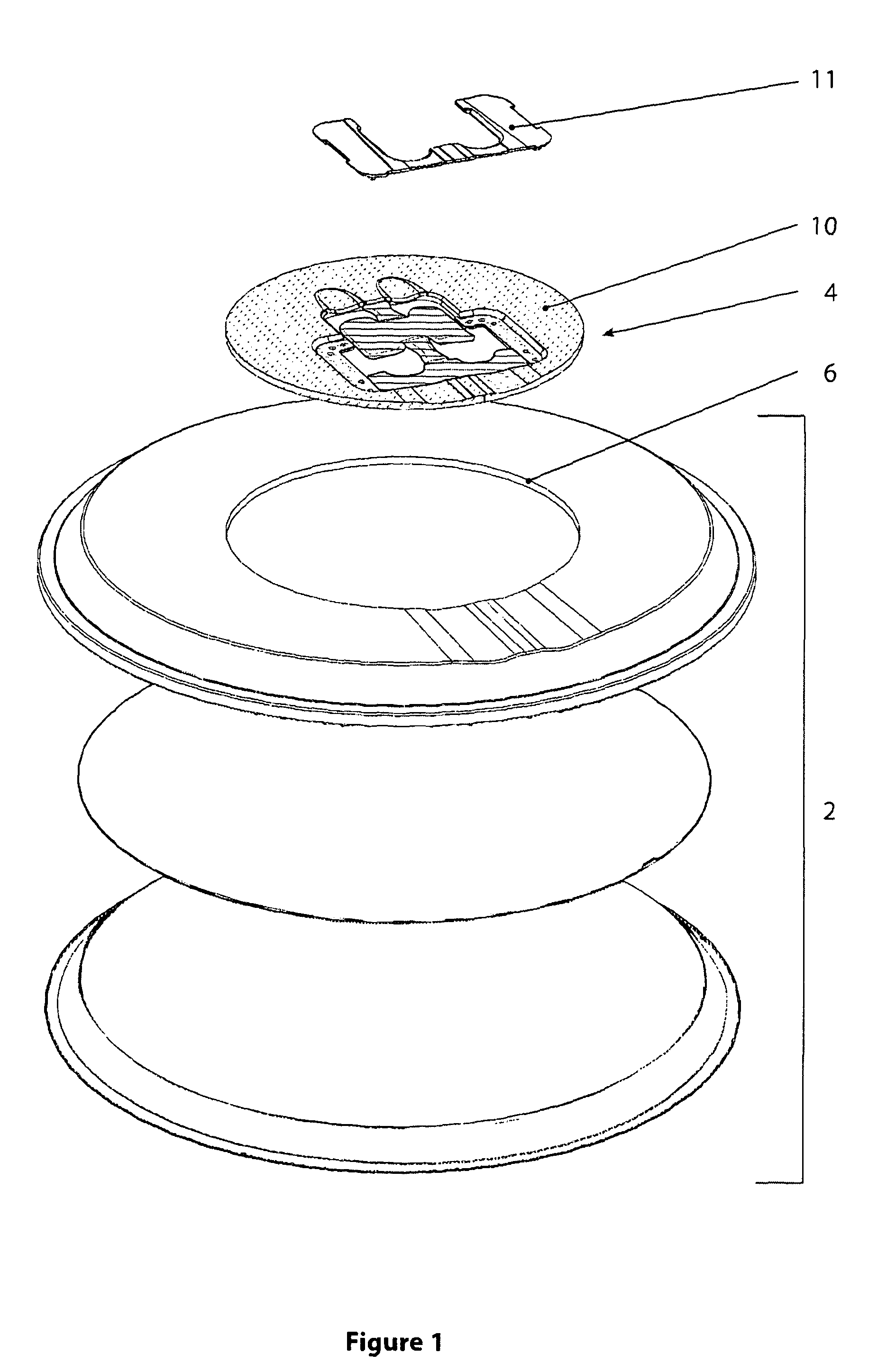

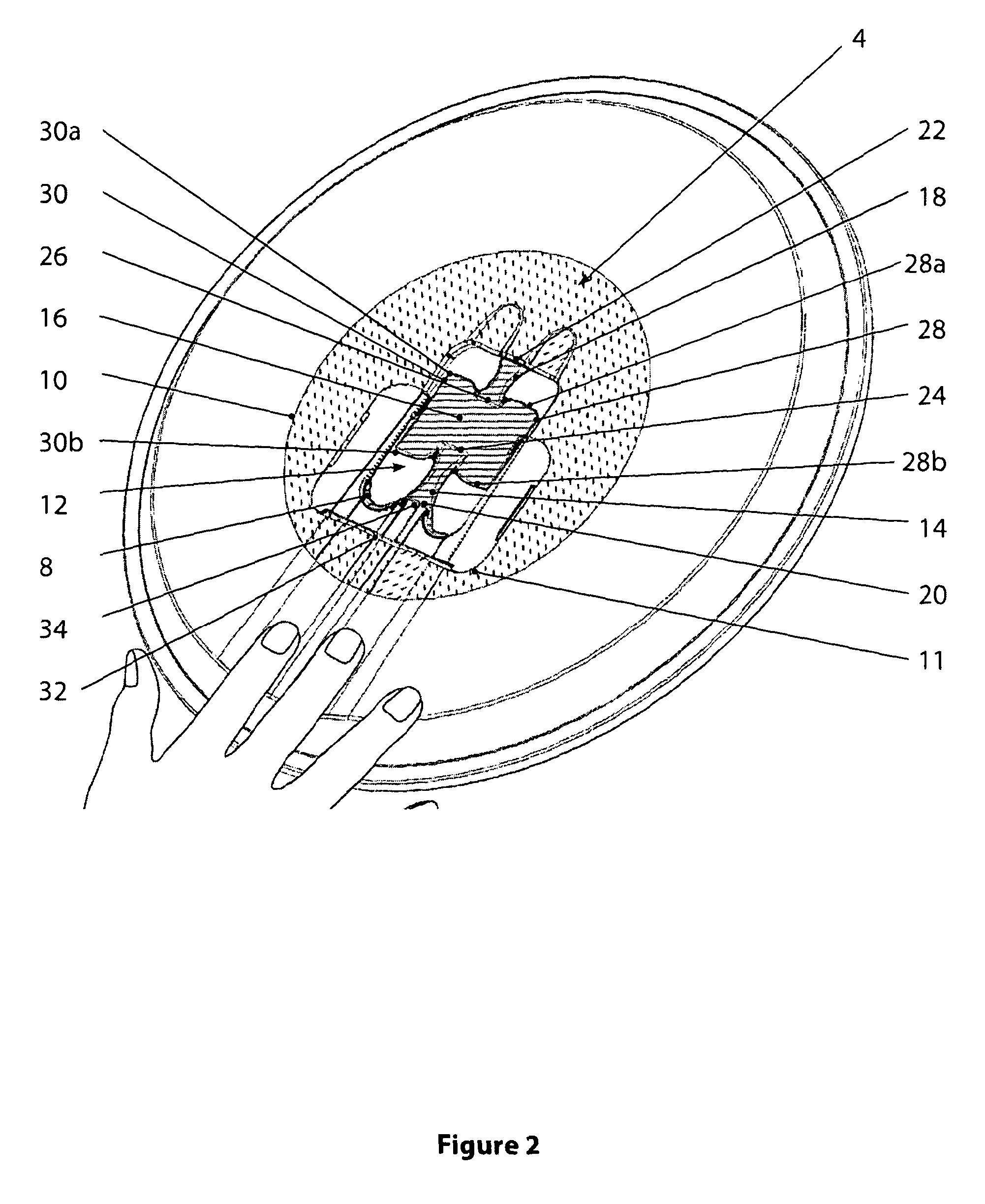

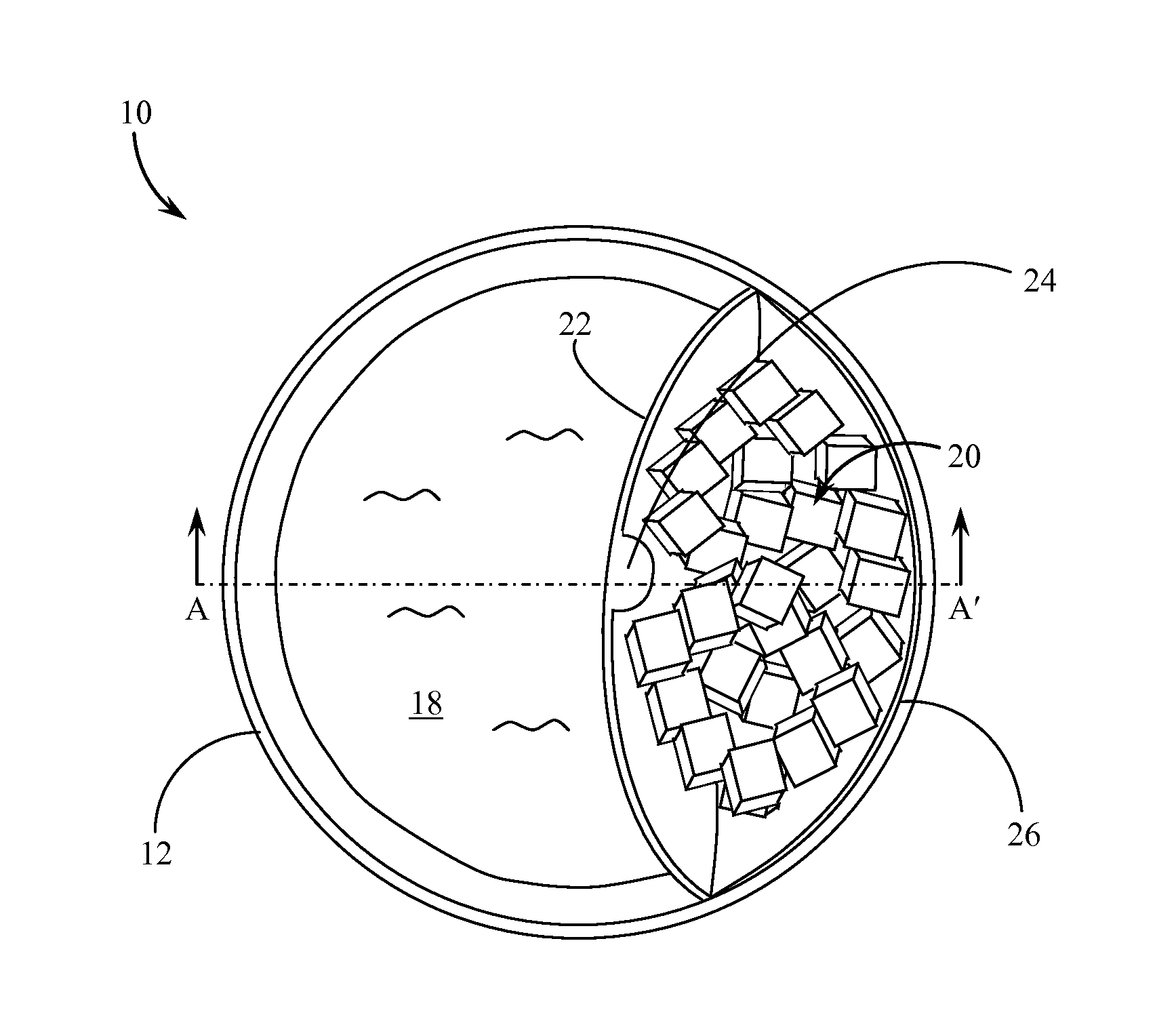

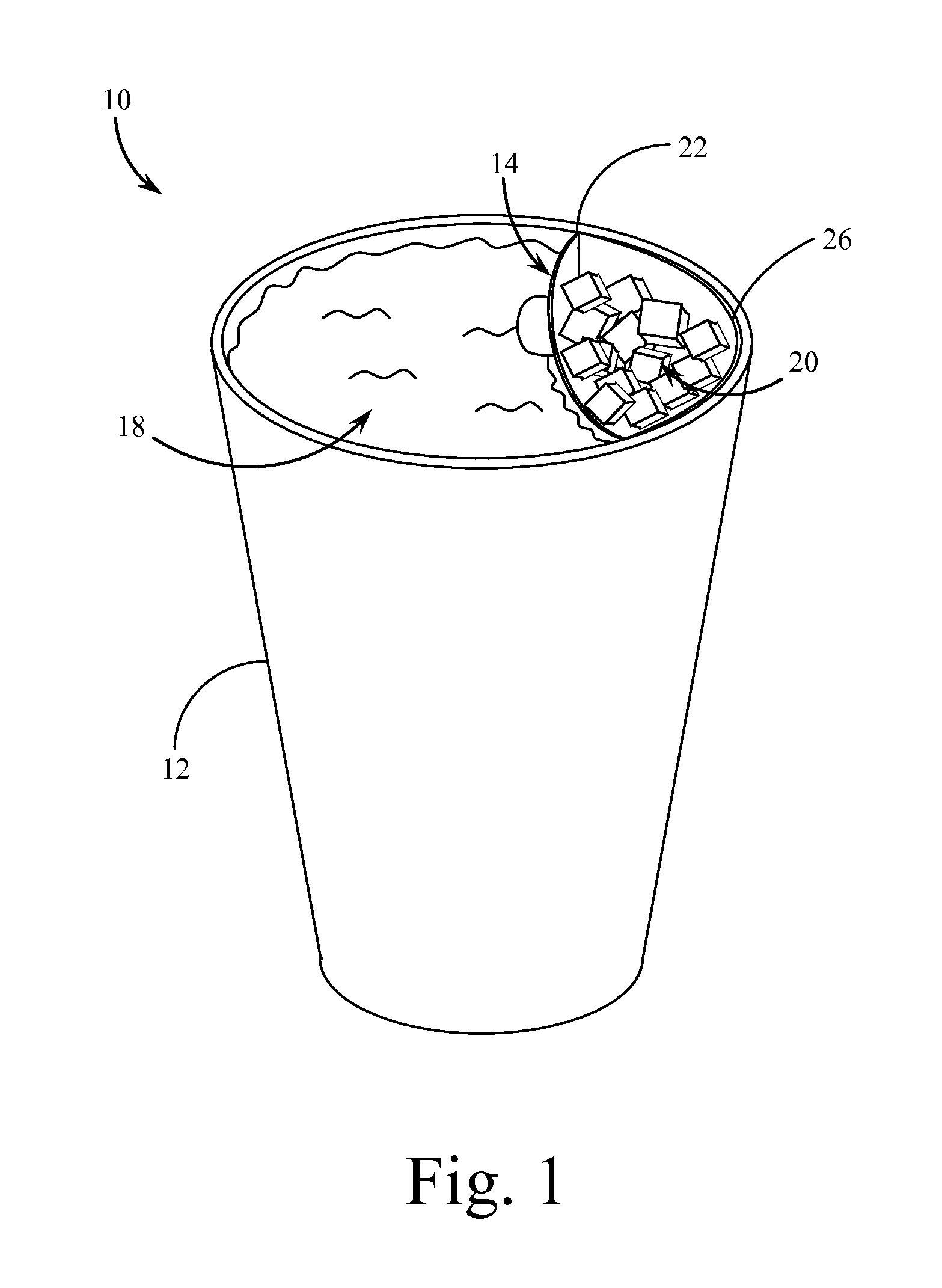

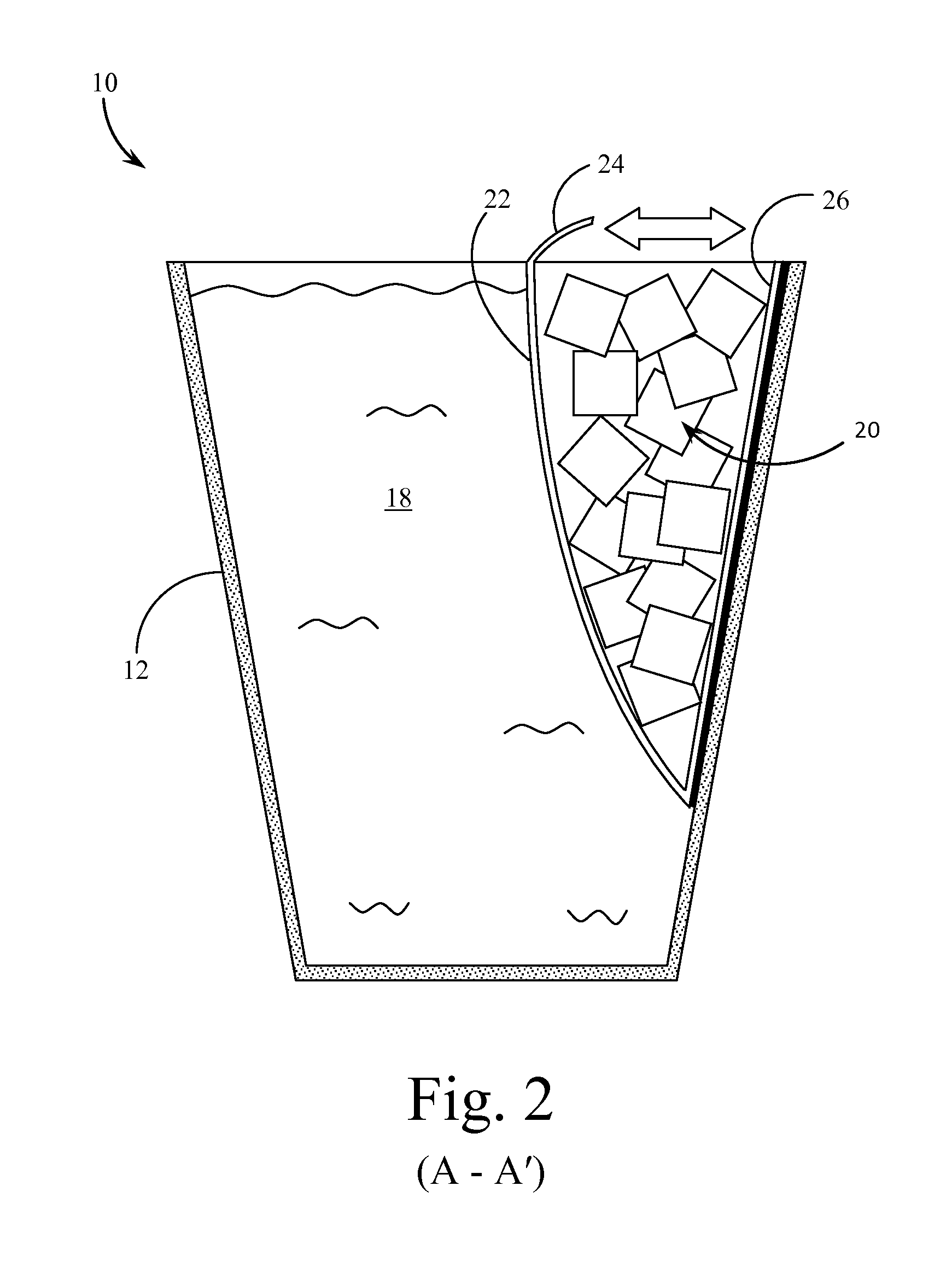

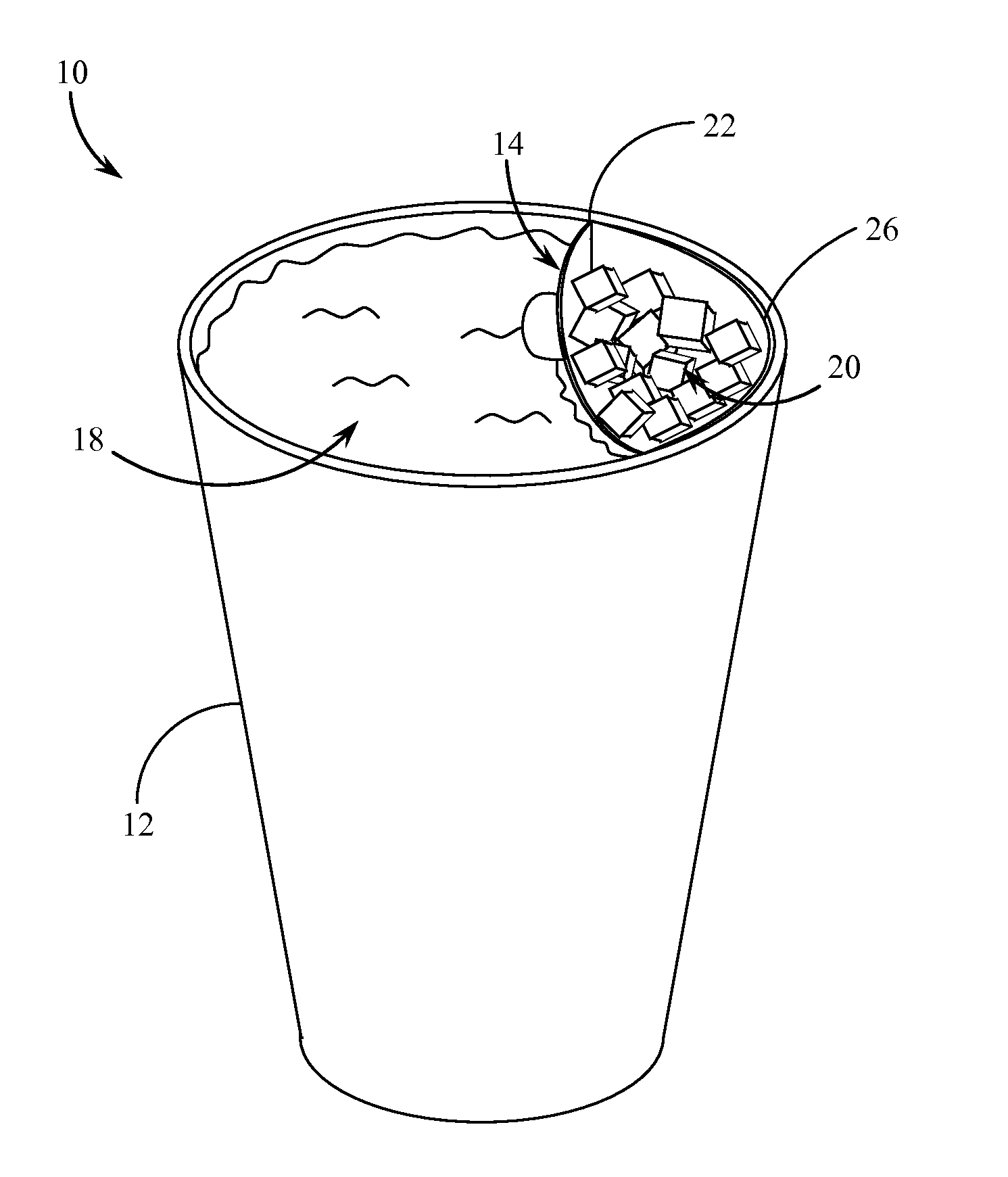

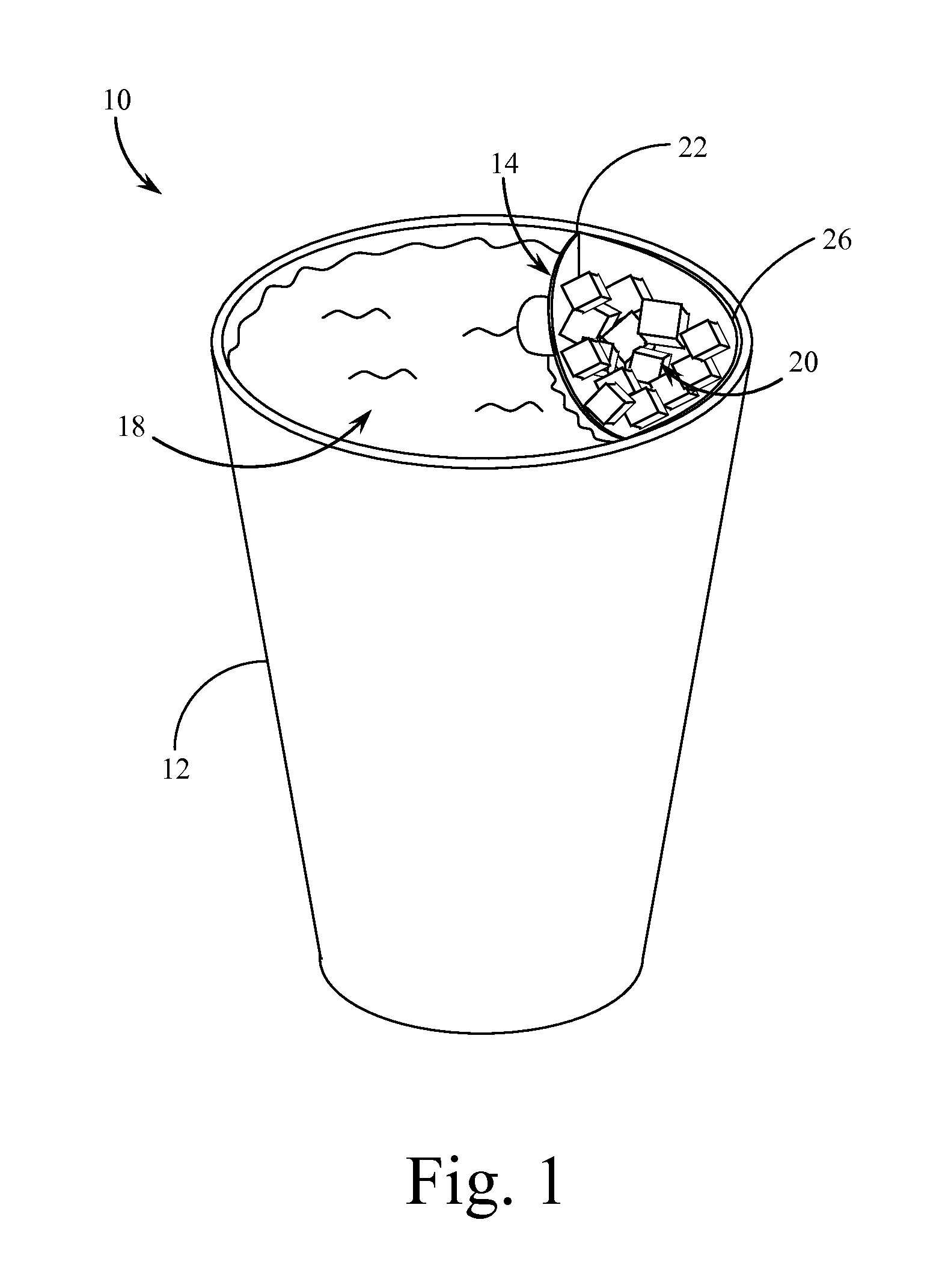

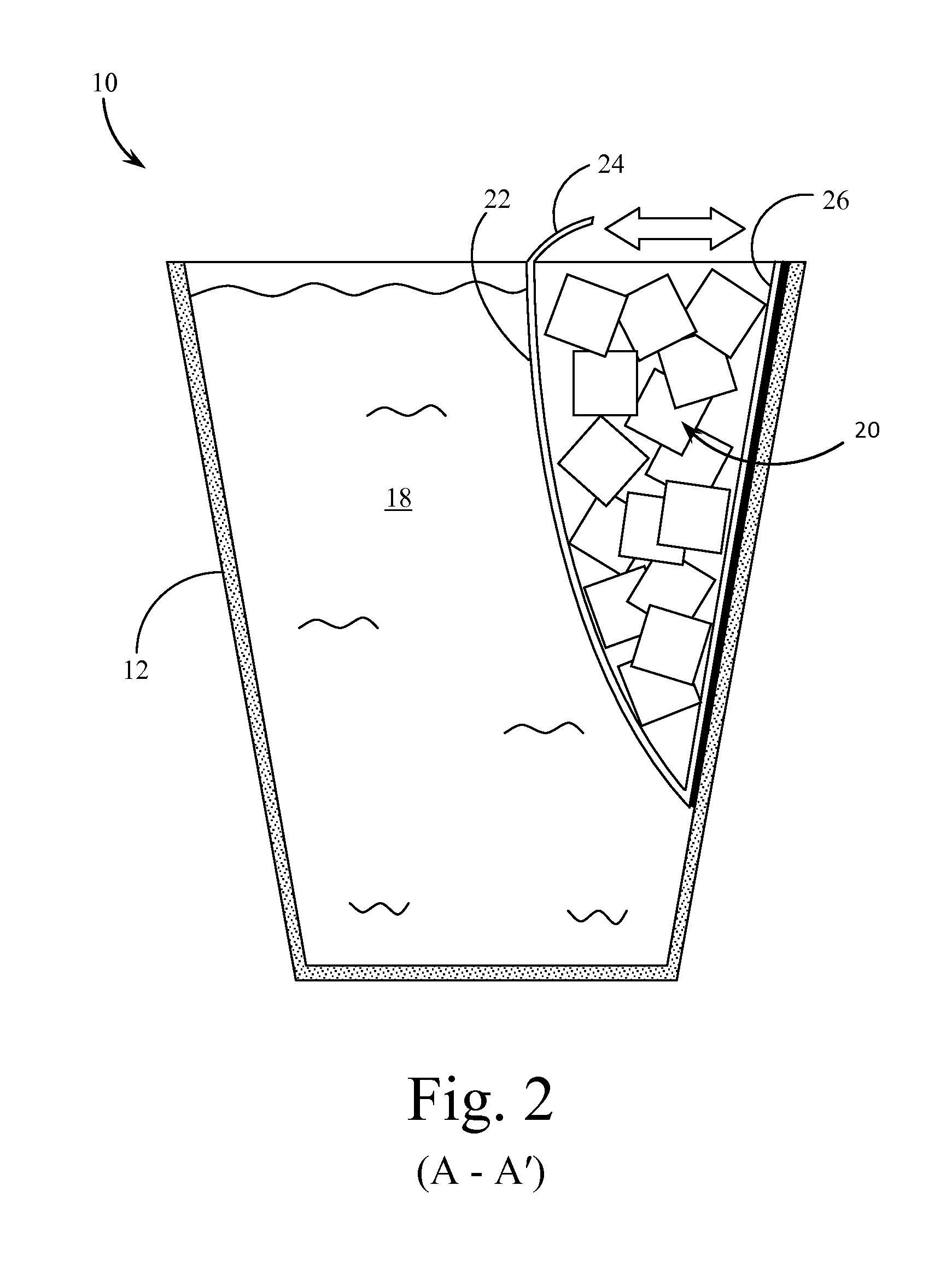

Ice cup

A stackable, self-standing, liquid-tight, disposable drinking cup to keep ice separated from a beverage in the cup to permit cooling without resultant dilution. A collapsible plastic film liner is secured to certain inner cup surfaces to provide a flexible wall for dividing the interior into two separate areas. The liner forms a pocket with an expandable top edge which may be pulled away from the cup body to hold ice. The pocket may be made of one film layer with the edges of the pocket attached to the cup body. Alternatively, the pocket may be made of two layers joined by a heat sealed seam with the film layer next to the cup body attached to the cup wall at least along a portion of the top edge. The container body may be manufactured from conventional materials. Conventional cup dispensers, beverage dispensers, cup lids, and straws may be utilized without modification of design.

Owner:HAYS BARRETT K +1

Ice Cup

ActiveUS20120267378A1Neatly stackedLighting and heating apparatusInternal framesPlastic filmEngineering

A stackable, self-standing, liquid-tight, disposable drinking cup to keep ice separated from a beverage in the cup to permit cooling without resultant dilution. A collapsible plastic film liner is secured to certain inner cup surfaces to provide a flexible wall for dividing the interior into two separate areas. The liner forms a pocket with an expandable top edge which may be pulled away from the cup body to hold ice. The pocket may be made of one film layer with the edges of the pocket attached to the cup body. Alternatively, the pocket may be made of two layers joined by a heat sealed seam with the film layer next to the cup body attached to the cup wall at least along a portion of the top edge. The container body may be manufactured from conventional materials. Conventional cup dispensers, beverage dispensers, cup lids, and straws may be utilized without modification of design.

Owner:HAYS BARRETT K +1

Automatic gripping device

InactiveCN104440929ANeatly stackedPrevent collapseGripping headsStacking articlesHydraulic cylinderGear wheel

The invention relates to the field of automatic gripping devices, in particular to an automatic gripping device. The automatic gripping device comprises a base, a rotary disc, a mechanical claw installation support and a mechanical claw; the automatic gripping device is characterized in that a rotation motor is arranged in the base, an output shaft of the rotation motor is connected with the rotary disc, a sliding rail is arranged inside the mechanical claw installation support, a sliding sleeve matched with the sliding rail is arranged on the sliding rail, threads are arranged on the upper surface of the sliding rail, a motor is arranged inside the upper portion of the sliding sleeve, and the output shaft of the motor is sleeved with a gear matched with the threads on the upper surface of the sliding rail. The mechanical claw comprises an installation rod connected with the sliding sleeve and a claw connected with the installation rod, a movable rod is arranged on the inner side of the U-shaped claw and sleeved with a spring, a hydraulic cylinder enabling the movable rod to stretch out and draw back is arranged inside the claw, an oil cylinder is arranged in the mechanical claw installation support, and a hydraulic pump is arranged on the oil cylinder. By means of the automatic gripping device, wood can be orderly stacked, the functions are complete, and convenience is brought to use.

Owner:常州依丝特纺织服饰有限公司

Bill stacking and sorting device and bill stacking and sorting system

ActiveCN102774683ANeatly stackedEasy to tie actionFunction indicatorsPile receiversElectrical and Electronics engineering

Owner:GRG BAKING EQUIP CO LTD

Drawer type boxed article distributing device

ActiveCN102874535ASimple processSimple structureCoin-freed apparatus detailsStorage devicesCamElectrical and Electronics engineering

The invention discloses a drawer type boxed article distributing device. The device comprises an article storage channel, an article inlet and an article outlet, wherein a bottom plate is arranged in the article storage channel; two sides of the bottom plate are connected with a first partition board and a second partition board; the first partition board and the second partition board extend upwards at the front end of the article storage channel close to the article outlet and are connected with a device for preventing articles from being gathered; and a lower baffle plate for preventing the articles from sliding downwards and a cam for uplifting one end of a first box of articles first are arranged at the article outlet. The drawer type boxed article distributing device has the advantages of simple structure and convenience for operation; and by the drawer type boxed article distributing device, boxed articles can be smoothly taken out of warehouses through the outlet, and the working efficiency is improved. Preferably, a first guide plate and a second guide plate are arranged on the drawer type boxed article distributing device, so that the boxed articles are prevented from being uplifted or sliding towards side wings when sliding in the article storage channel, and can be stacked neatly and taken out of the warehouses uniformly.

Owner:JIANGSU XUNJIE HARNESS TECH

Semiconductor lead frame punch forming product discharging, stacking and transferring device

The invention discloses a semiconductor lead frame punch forming product discharging, stacking and transferring device. The semiconductor lead frame punch forming product discharging, stacking and transferring device comprises a bearing mechanism, a lifting mechanism and a transferring mechanism, wherein the bearing mechanism comprises a pair of spacing-adjustable limiting plates, a first L-shapedbearing plate and a second L-shaped bearing plate, and the first L-shaped bearing plate and the second L-shaped bearing plate are oppositely arranged at an interval between the limiting plates; the lifting mechanism is connected with the first L-shaped bearing plate and the second L-shaped bearing plate and used for driving the first L-shaped bearing plate and the second L-shaped bearing plate toascend and descend; and the conveying direction of the transferring mechanism is perpendicular to the conveying direction of a discharging conveying crawler belt, the transferring mechanism comprisesa rotating roller and a plurality of conveying belts arranged on the rotating roller at intervals, and the first L-shaped bearing plate and the second L-shaped bearing plate are located at the intervals of the pair of adjacent conveying belts correspondingly. According to the device, stamped and formed lead frames can be stacked in order, the influence of a height difference at the moment when adischarged material is separated from a conveying crawler belt on the lead frames is avoided, slow descending stacking is achieved, and the lead frames stacked to the designated height can be conveyedto the rear stage in order after being stacked in order.

Owner:四川富美达微电子有限公司

Full-automatic cutting all-in-one machine for pearl wool

ActiveCN107214750ANeatly stackedSave human effortClimate change adaptationMetal working apparatusIntegrated productionProduction quality

The invention discloses a full-automatic cutting all-in-one machine for pearl wool. The full-automatic cutting all-in-one machine for the pearl wool comprises an automatic feeding mechanism, a transverse and vertical cutting mechanism and a material stacking and discharging mechanism; the automatic feeding mechanism comprises a feeding frame, a feeding lifting mechanism and a feeding lifting machine frame, wherein the pearl wool is stacked on the feeding lifting machine frame, and a feeding push part mechanism and a push plate are arranged on the upper part of the feeding frame; the transverse and vertical cutting mechanism comprises a cutting frame, a conveying guide roller set, a vertical cutting mechanism and a transverse cutting mechanism, wherein the vertical cutting mechanism comprises a rotating shaft and a vertical cutter set, and the transverse cutting mechanism comprises a transverse cutting lifting mechanism, a transverse cutting translation mechanism and a transverse cutter; and the material stacking and discharging mechanism comprises a discharging frame, a discharging lifting mechanism, a discharging lifting machine frame and a conveying belt. The full-automatic cutting all-in-one machine for the pearl wool has the advantages that batching, automatic feeding, cutting and stacking integrated production of the pearl wool can be realized, and therefore the cutting precision can be improved, the material waste can be reduced, and in addition, the production quality and the production efficiency of the pearl wool can be improved.

Owner:杭州华飞包装材料有限公司

Sheel metal stacker

ActiveCN101045505APrecise positioningRealize blankingPile receiversArticle deliveryInductorEngineering

A plate stacking machine for the shaped plates is composed of a moving, locating and plate lowering system consisting of machine frame, parallel two longitudinal beams, driver unit, controller, conveying belt, electromagnetic suction block, and automatic locating block, an automatic lifting-lowering platform, coaxial two horizontal stop blocks under the plate inlets and perpendicular to longitudinal beam, another two stop blocks on said longitudinal beams, and an inductor between said another two stop blocks and connected electrically to said controller.

Owner:JIANGSU YAWEI MACHINE TOOL

Presswork counting and stacking method

The invention provides a presswork counting and stacking method. A counting sensor is arranged between a fast-speed conveying belt and a slow-speed conveying belt; the counting sensor generates a presswork counting signal and conveys the presswork counting signal to a control device; an encoder is arranged on a belt wheel of the slow-speed conveying belt; a presswork stopping mechanism is arranged above the slow-speed conveying belt; when the accumulated value of the presswork counting signal which is transmitted to the control device by a timing sensor is equal to the pre-set value of the presswork quantity, the control device starts to count pulses to the encoder; when the pulse counting numerical value of the encoder is equal to the encoder pulse pre-set value, the presswork stopping mechanism moves and stops a presswork at the back side; a presswork at the front side is moved to a stacking mechanism to finish the counting and stacking process; and the presswork stopping mechanism is reset. According to the presswork counting and stacking method, the transmission speed of the presswork can be slowed through the slow-speed conveying belt, and the impact force on the presswork is reduced so as to be good for sequentially stacking the presswork; and the encoder and the presswork stopping mechanism are arranged, so that the accurate counting on the presswork can be realized.

Owner:YANBIAN CHANGBAISHAN PRINTING

High-accuracy paper catching device

InactiveCN104528445AGood for neat stackingNeatly stackedPile receiversArticle deliveryPulp and paper industry

Owner:NANTONG SITONG FORESTRY MACHINE MFG INSTALLATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com