Presswork counting and stacking method

A printing and stacking technology, applied in the field of counting and stacking of printed matter, can solve the problems of slippage, offset, counting error, inability to count accurately, etc., to avoid paper jams and reduce impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

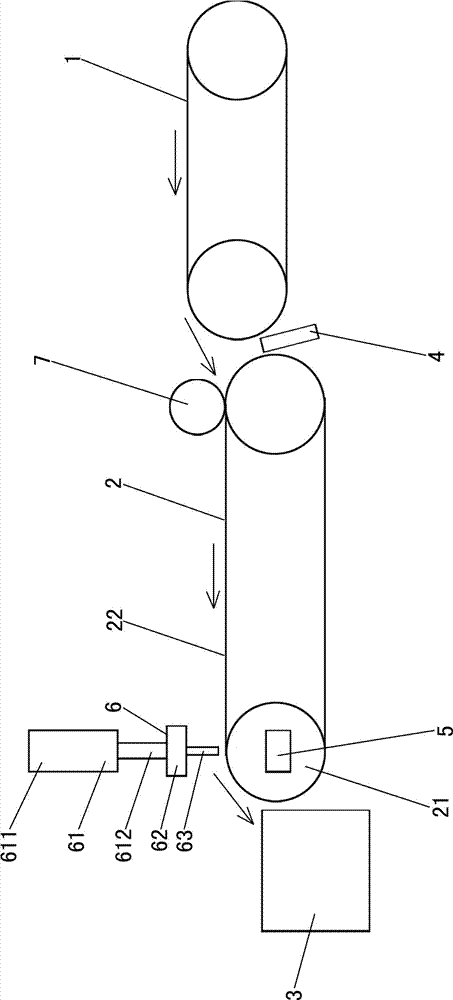

[0020] The printed matter counting and stacking method of the present embodiment adopts figure 1The printed matter counting and stacking device shown is realized. This printed matter counting and stacking device includes a frame, a fast conveyor belt 1, a slow conveyor belt 2, a stacking mechanism 3, a counting sensor 4, an encoder 5, a printed matter blocking mechanism 6 and a control device ( figure 1 The frame and control device are not shown in the frame); the fast conveyor belt 1, the slow conveyor belt 2 and the stacking mechanism 3 are along the printed matter conveying direction (such as figure 1 (shown by the arrows in ) are arranged on the frame in turn; the counting sensor 4 is set between the fast conveyor belt 1 and the slow conveyor belt 2, and the counting sensor 4 is connected to the corresponding input end of the control device; the encoder 5 is installed on the slow conveyor belt 2 On a pulley 21, the printed matter blocking mechanism 6 is located above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com