Semiconductor lead frame punch forming product discharging, stacking and transferring device

A technology of lead frame and transfer device, which is applied in the stacking, transportation and packaging of objects, and can solve the problems of unfavorable lean production management, time required, and time increase, so as to avoid damage and scrap, improve stability, and be practical sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

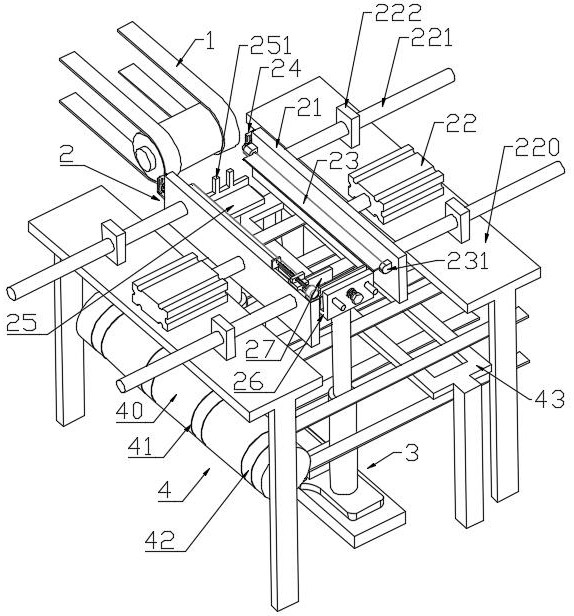

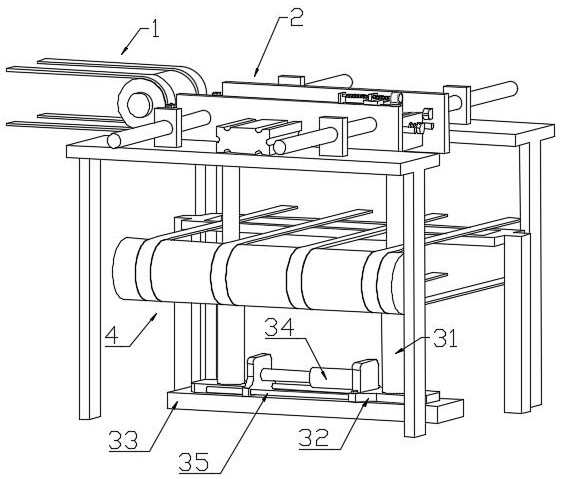

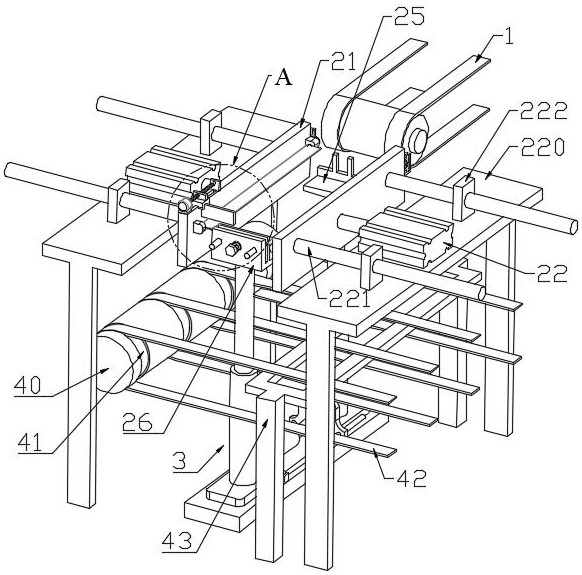

[0032] Such as Figure 1~6 As shown in the example, a semiconductor lead frame stamping and forming product discharge stacking transfer device used in this example is set at the end of the discharge conveyor belt 1 of the lead frame stamping die, including: a carrying mechanism 2, a lifting mechanism 3, and a transfer mechanism 4 Wait.

[0033] The carrying mechanism 2 is used to carry the finished lead frame products conveyed from the discharge conveyor belt 1. The carrying mechanism 2 includes a pair of space-adjustable limit plates 21 and a first L spaced between the limit plates 21 and oppositely arranged. Type bearing plate 25 and the second L-shaped bearing plate 26.

[0034] The lifting mechanism 3 is connected to the first L-shaped loading plate 25 and the second L-shaped loading plate 26 for driving the first L-shaped loading plate 25 and the second L-shaped loading plate 26 to lift.

[0035] The conveying direction of the transfer mechanism 4 is perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com