Preparation method of high-thermal-conductivity graphene/polyimide-based composite graphite fiber

A high thermal conductivity graphite, polyimide-based technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve weak interaction forces, insignificant effects, and unsatisfactory fiber axial orientation. and other problems, to achieve the effect of increasing steric hindrance, changing types, and improving size and order.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

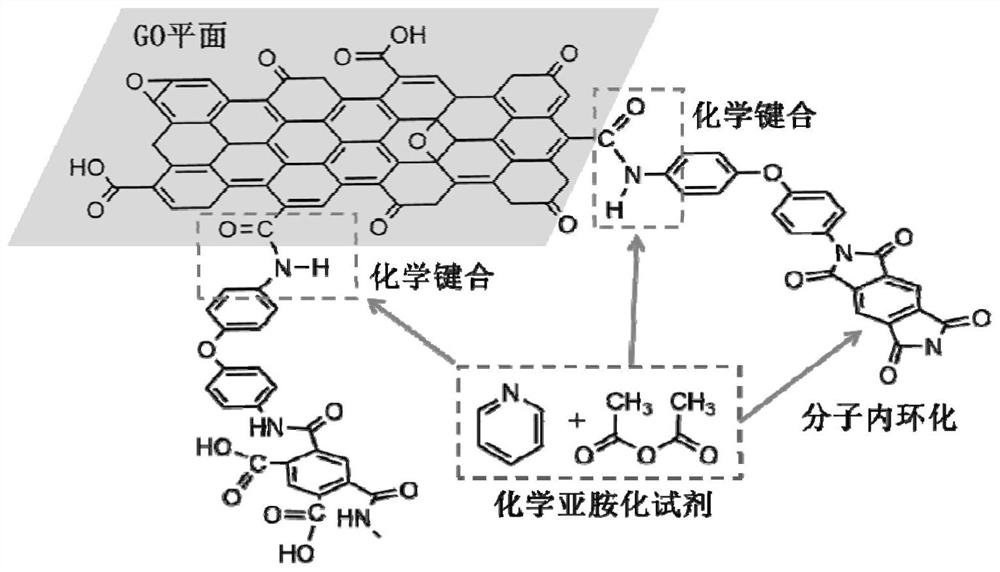

[0033] 1 wt% GO was added to DMF solvent to be fully dissolved by ultrasound, and equimolar amounts of PMDA and ODA were weighed and polymerized in a nitrogen atmosphere at a temperature of 5 °C. ODA was firstly added to DMF, and after complete dissolution, PMDA was added in batches for polymerization, and the reaction was continued for 2 h after all the additions to obtain a GO / PAA solution with a solid content of 10%. A certain amount of acetic anhydride (30 mol% of PAA) and pyridine (the molar ratio of acetic anhydride and pyridine is 4:1) was mixed uniformly, and slowly added dropwise to the above PAA solution for chemical imidization, stirring while adding. After the dropwise addition, the reaction was continued to be stirred for 1 hour, and then left to stand for 24 hours to remove foam.

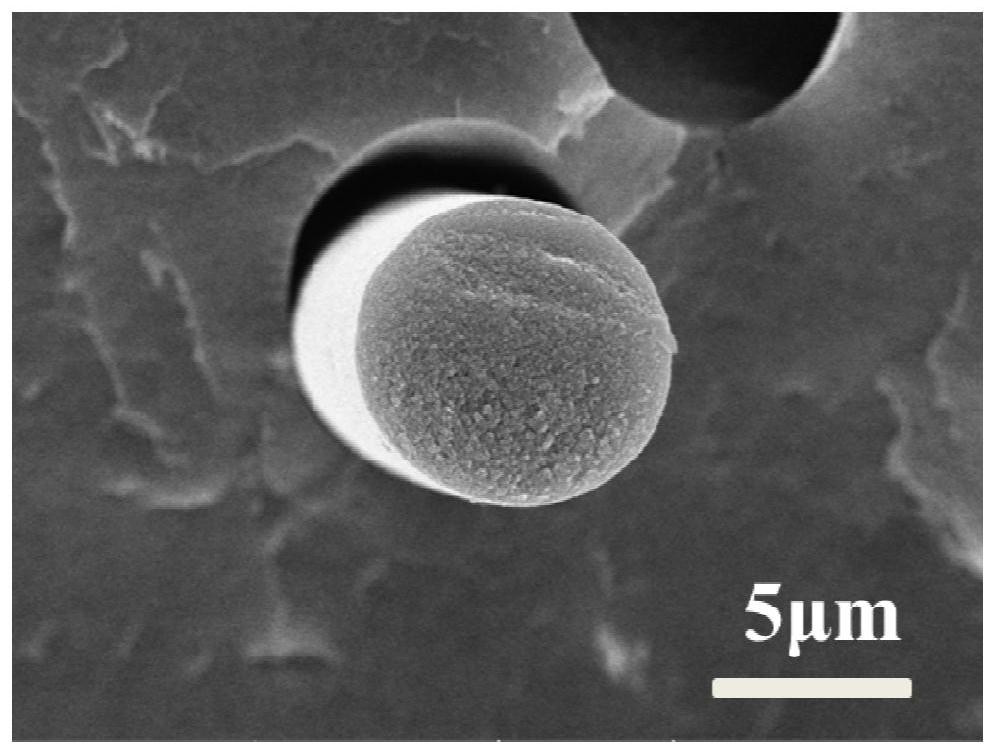

[0034] The above-mentioned GO / PAA-PI spinning solution was subjected to wet spinning. The coagulation bath ratio is V 水 : V 乙醇=9:1, the temperature is 20°C. The spinning solution e...

Embodiment 2

[0038] The amount of GO added was changed to 0.5 wt%, and other conditions were the same as in Example 1, and the average diameter was 10 μm and the thermal conductivity was 730 W m -1 ·K -1 , a high-performance graphite fiber with a tensile strength of 2500 MPa.

Embodiment 3

[0040] The addition amount of acetic anhydride was changed to 10 mol%, and other conditions were the same as in Example 1, to obtain an average diameter of 10 μm and a thermal conductivity of 710 W m -1 ·K -1 , a high-performance graphite fiber with a tensile strength of 2450MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com