A chemical fiber dryer feed auxiliary device

An auxiliary device, dryer technology, applied in the direction of drying, drying solid materials, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

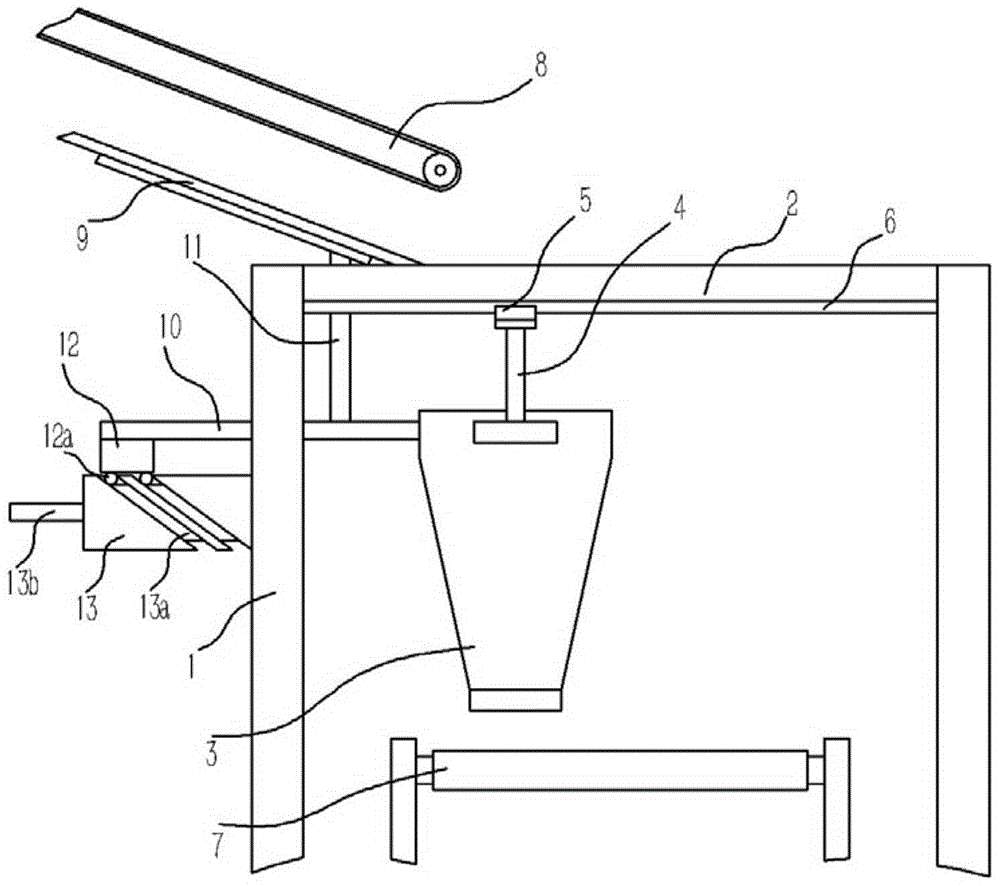

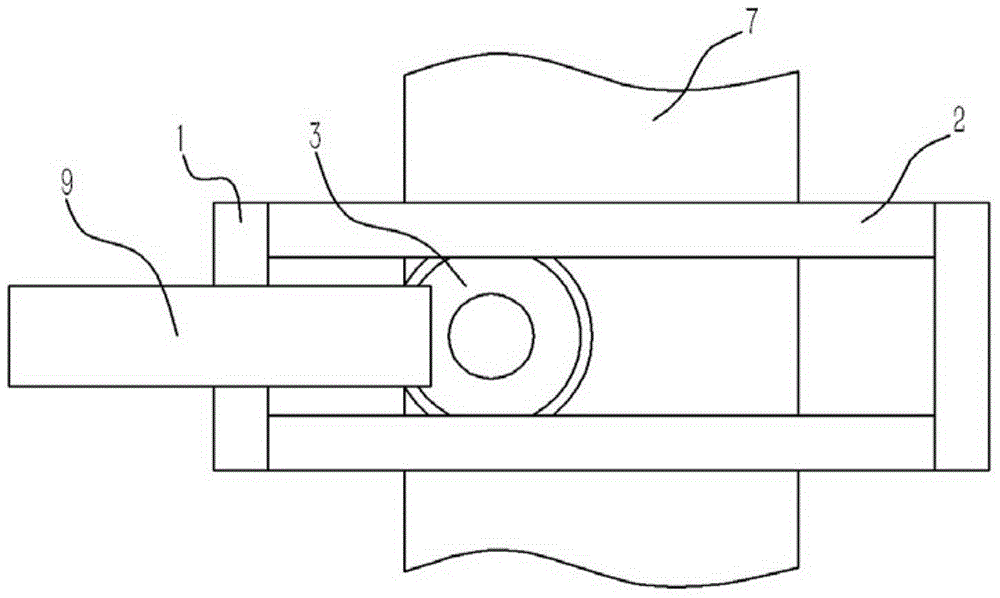

[0014] Example: see figure 1 , 2 As shown, a feeding auxiliary device for a chemical fiber dryer includes two support columns 1, two beams 2 fixed on the front and back sides of the support column 1, and a conical hopper 3, which is fixed on the side wall of the upper end of the conical hopper 3 There is a group of mounting brackets 4, the upper end of the mounting bracket 4 is fixed with a slider 5, the slider 5 is inserted and sleeved on the guide rail 6, and the guide rail 6 is fixed on the lower bottom surface of the beam 2; the side wall of the tapered hopper 3 is fixed The cross bar 10, the other end of the cross bar 10 is fixed on the mounting block 12 through the support column 1, the support column 1 is hinged with a cylinder 13, and the cylinder 13 is formed with an inclined annular groove 13a, the annular groove 13a A ball 12a is built in, and the ball 12a is hinged on the mounting block 12; the guide plate bracket 11 is fixed on the cross bar 10, and the guide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com