Full-automatic agitating machine for edible fungi mixture

A kind of mixed material and fully automatic technology, which is applied in the direction of bioreactor/fermenter combination, special-purpose bioreactor/fermenter, biochemical equipment, etc., and can solve the problems of affecting operations, difficulty in restocking, and difficulty in meeting quality requirements, etc. problems, to achieve the effect of uniform mixing, uniform material turning, and labor intensity liberation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

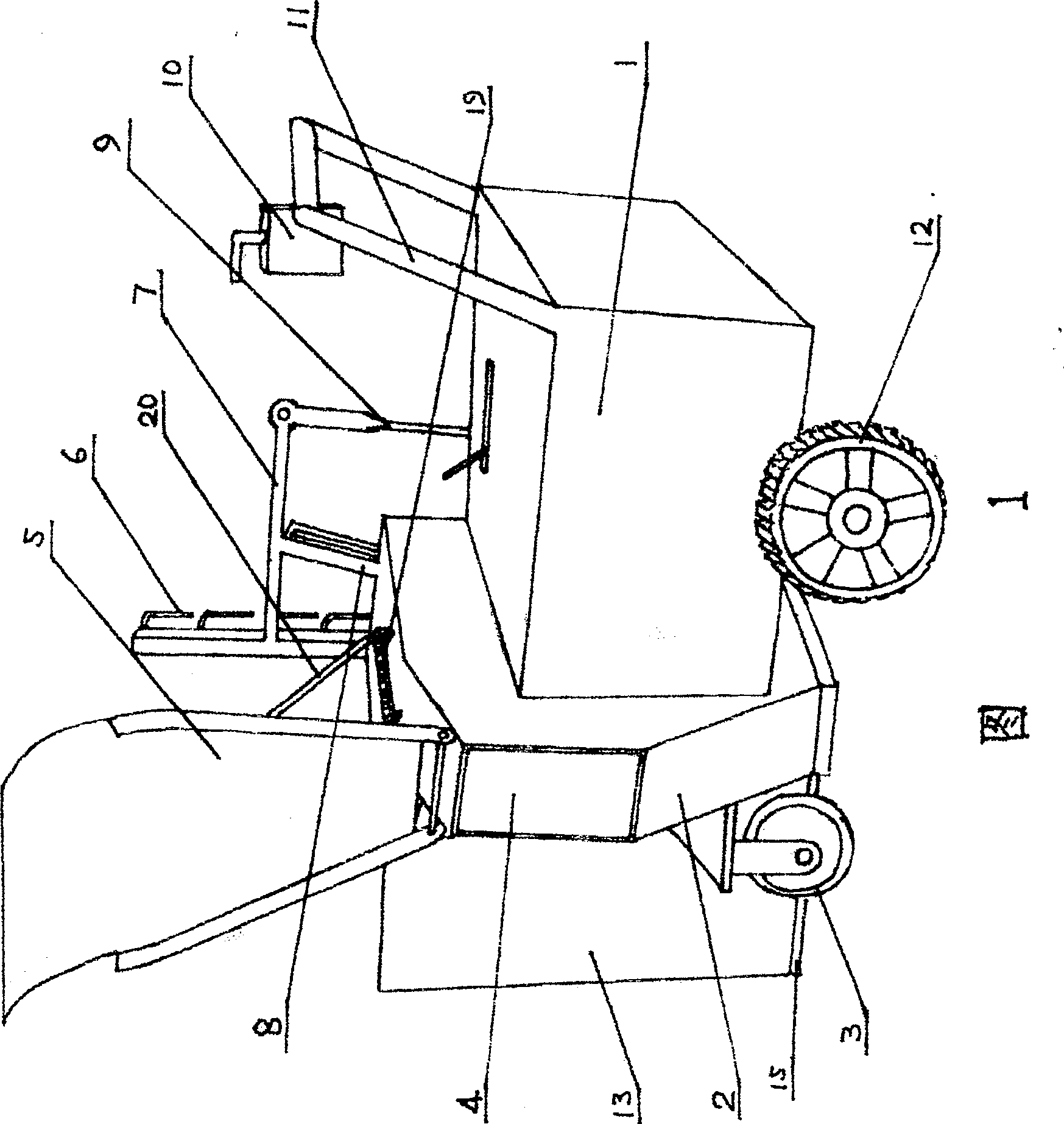

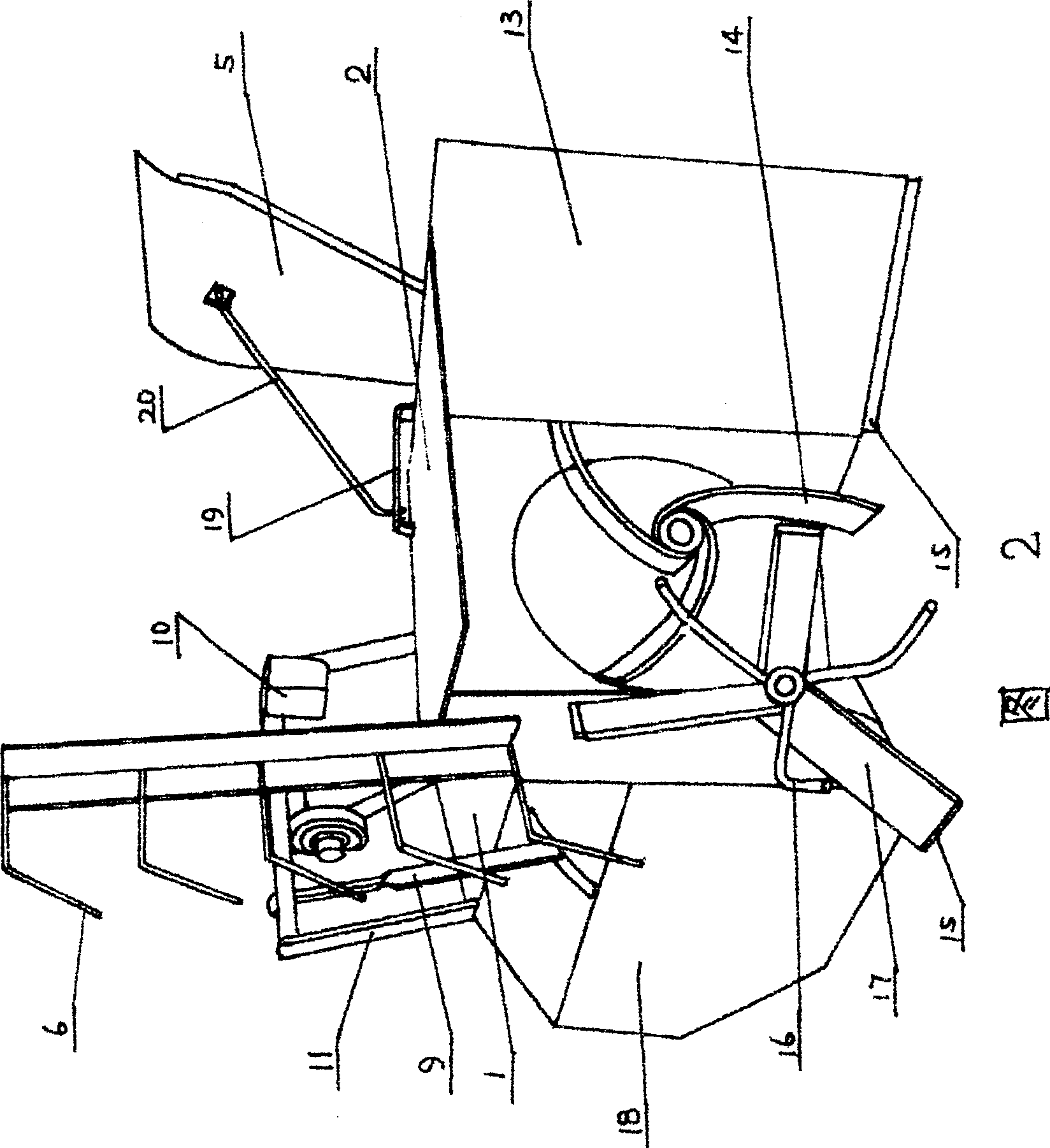

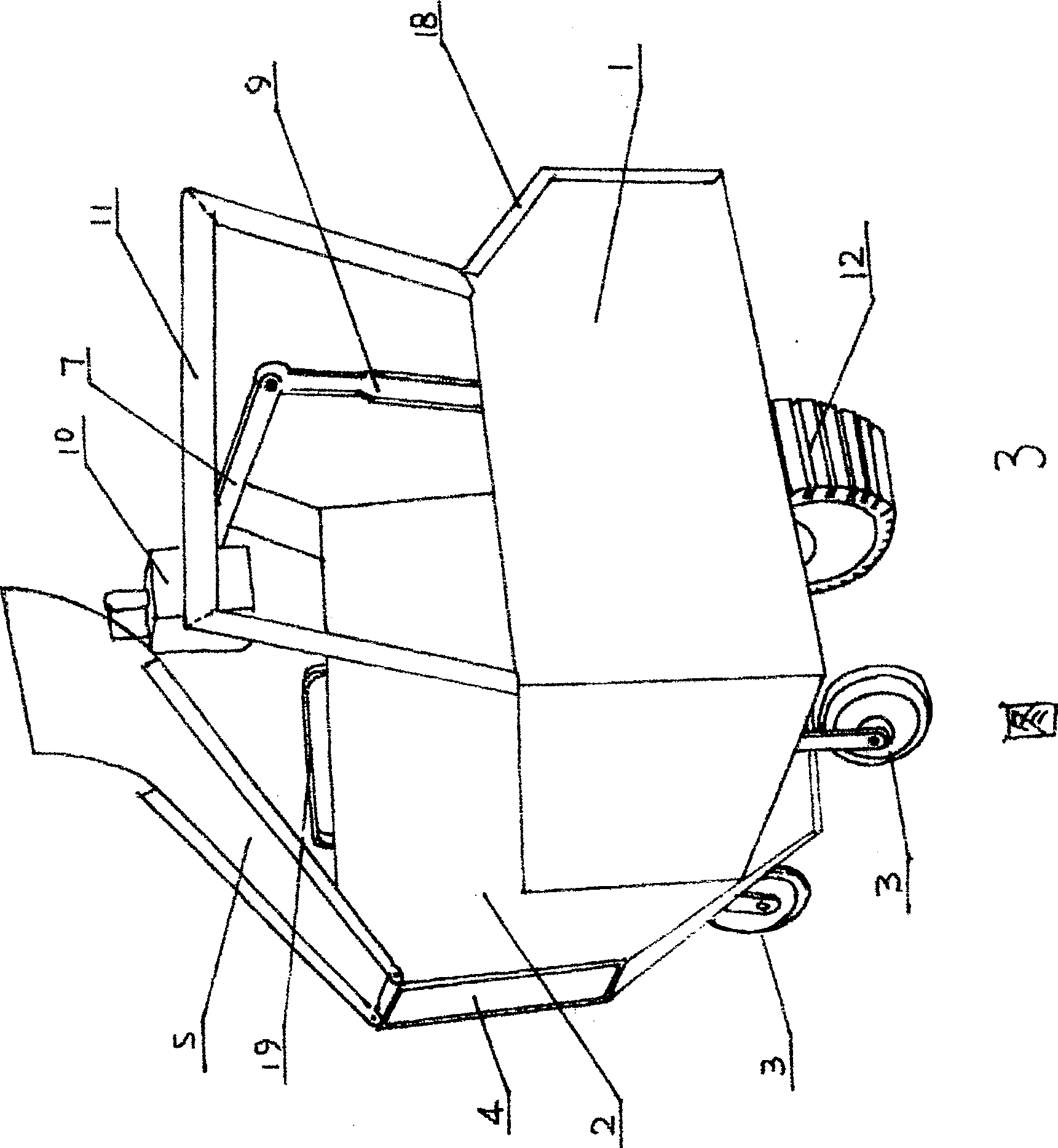

[0013] Please refer to Figure 1 and Figure 2, this implementation is a structure suitable for use on hard ground. There is a box-type main body 1 in the figure, the front end of main body 1 is fixedly connected with material box 2, and the lower end of main body 1 is provided with and is arranged on both sides by the drive wheel 12 that is connected with rotating shaft, and the upper rear end angle of main body 1 is fixed There is a hand push frame 11 and a switch 10 fixed on the hand push frame 11, and a baffle plate 18 for retaining material is fixed on the right side of the main body 1 (with the hand pushing direction as the front); A pull bar 9 that can move up and down is produced, and the pull bar 9 is connected to a horizontal connecting rod 7 by a hinge. 4 shifting forks 6 are fixed; a discharge opening 4 is arranged above an end surface of the left side of the feed box 2, and a movable baffle plate 5 is fixed on the upper window of the discharge opening 4, and the top...

Embodiment 2

[0015] Please refer to Fig. 1, Fig. 2 and Fig. 3, there is a box-type main body 1 among the figure, the front end of main body 1 is fixedly connected with material box 2, and the center of the lower end of main body 1 is provided with a driving wheel 12 connected with it by the rotating shaft and the left side A driven wheel 21 in the same row, a hand push frame 11 and a switch 10 fixed on the hand push frame 11 are fixed on the upper rear end corner of the main body 1, and the right side of the main body 1 (with the hand push direction as the front) is fixed There is a baffle plate 18 for retaining material; the main body 1 raises a pull rod 9 that can move up and down in the middle of the baffle plate 18, and the pull rod 9 is connected to a horizontal connecting rod 7 through a hinge, and the middle of the connecting rod 7 is fixed on the material box 2 The right upper end bracket 8 is used as a fixed support point, and the head of the connecting rod 7 is fixed with 4 shifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com