Method and device for vertically vibrating out single flexible linear material

A single-material, line-type technology, applied in chemical instruments and methods, solid separation, grading, etc., can solve the problems of inability to realize automatic detection and low efficiency, and achieve the effect of liberating labor intensity and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

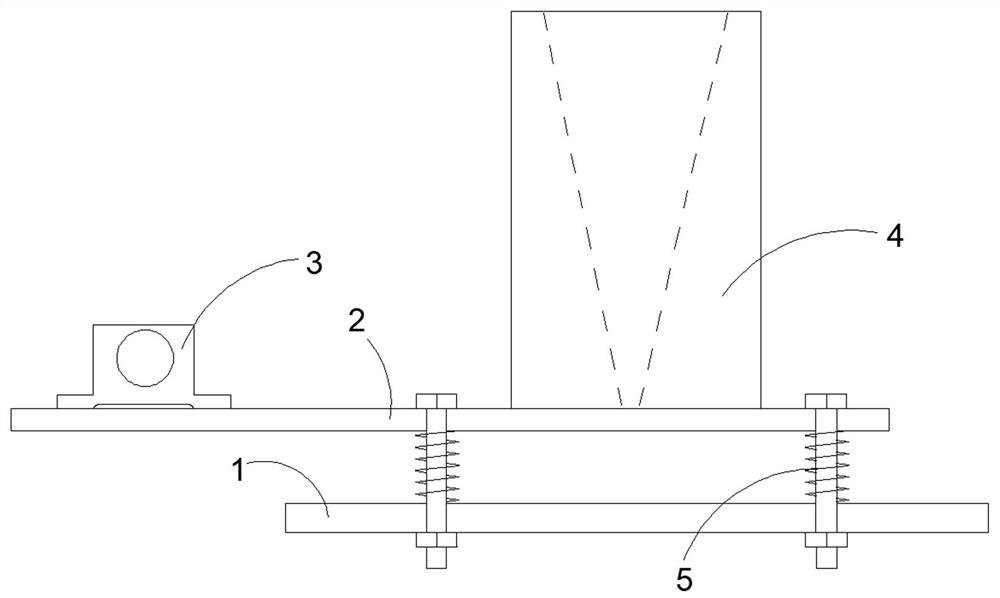

[0014] See attached figure 1 , a method of vertical vibration of a single flexible linear material. The flexible linear material is placed in a tapered funnel with a large top and a small bottom. The smallest hole diameter of the tapered funnel is about larger than the largest diameter of a single flexible linear material. Vibrating up and down and swinging left and right through the conical funnel, single flexible linear materials are continuously discharged from the hole at the bottom of the hopper.

[0015] A device for vibrating a single piece of flexible linear material vertically, including a fixed plate 1, a vibrating plate 2, a vibrator 3, a tapered funnel 4 and a spring 5, the fixed plate 1 and the vibrating plate 2 are connected as a whole through the spring 5, and the A vibrator 3 is fixedly connected to one side of the vibrating plate 2, and a conical funnel 4 is fixedly connected to the vibrating plate 2 on the side away from the vibrating device 3. The smallest h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com