Novel cloth folding machine

A cloth folding machine, a new type of technology, applied in the field of cloth folding machines, can solve the problems of increasing the labor intensity of personnel, and achieve the effect of increasing uniformity and uniform stacking of cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

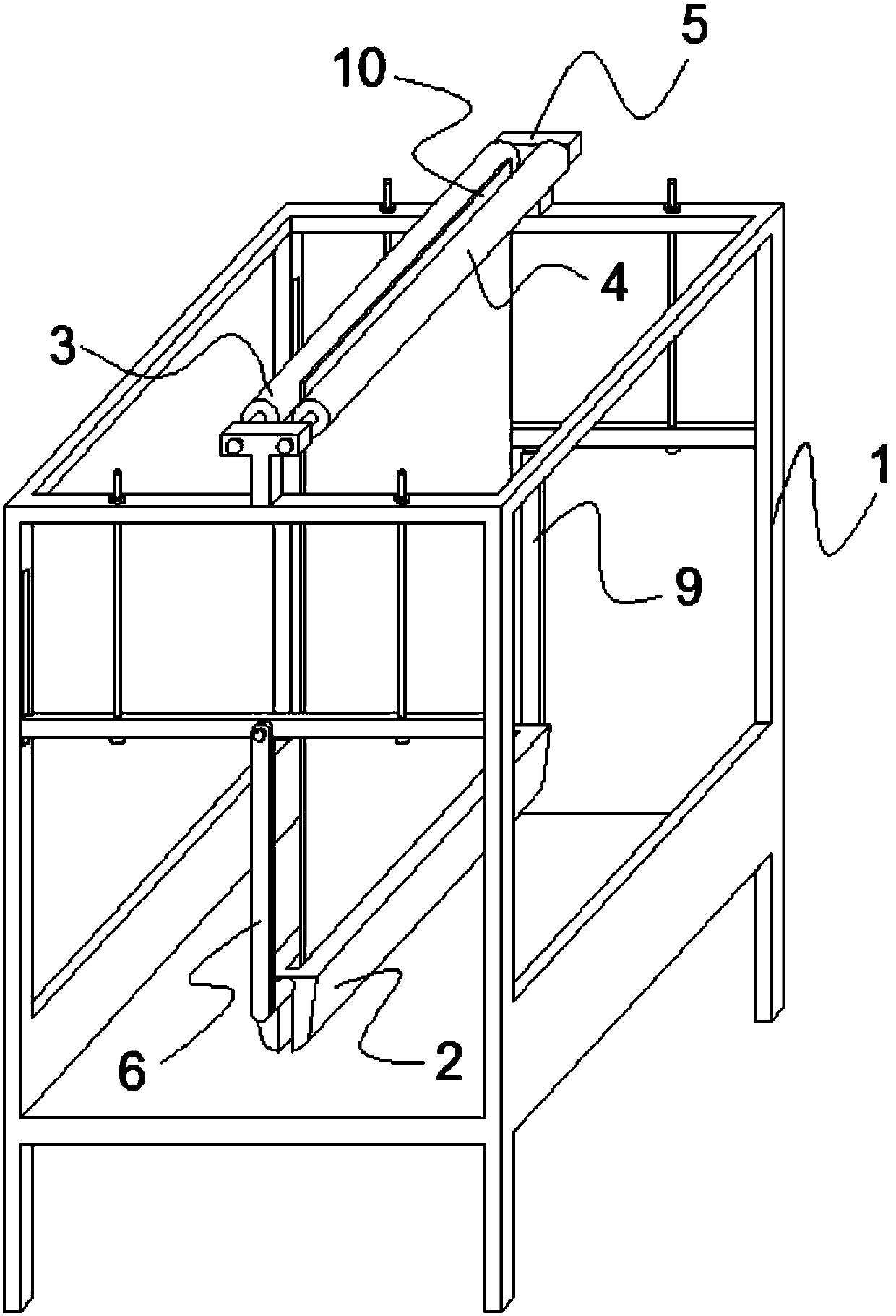

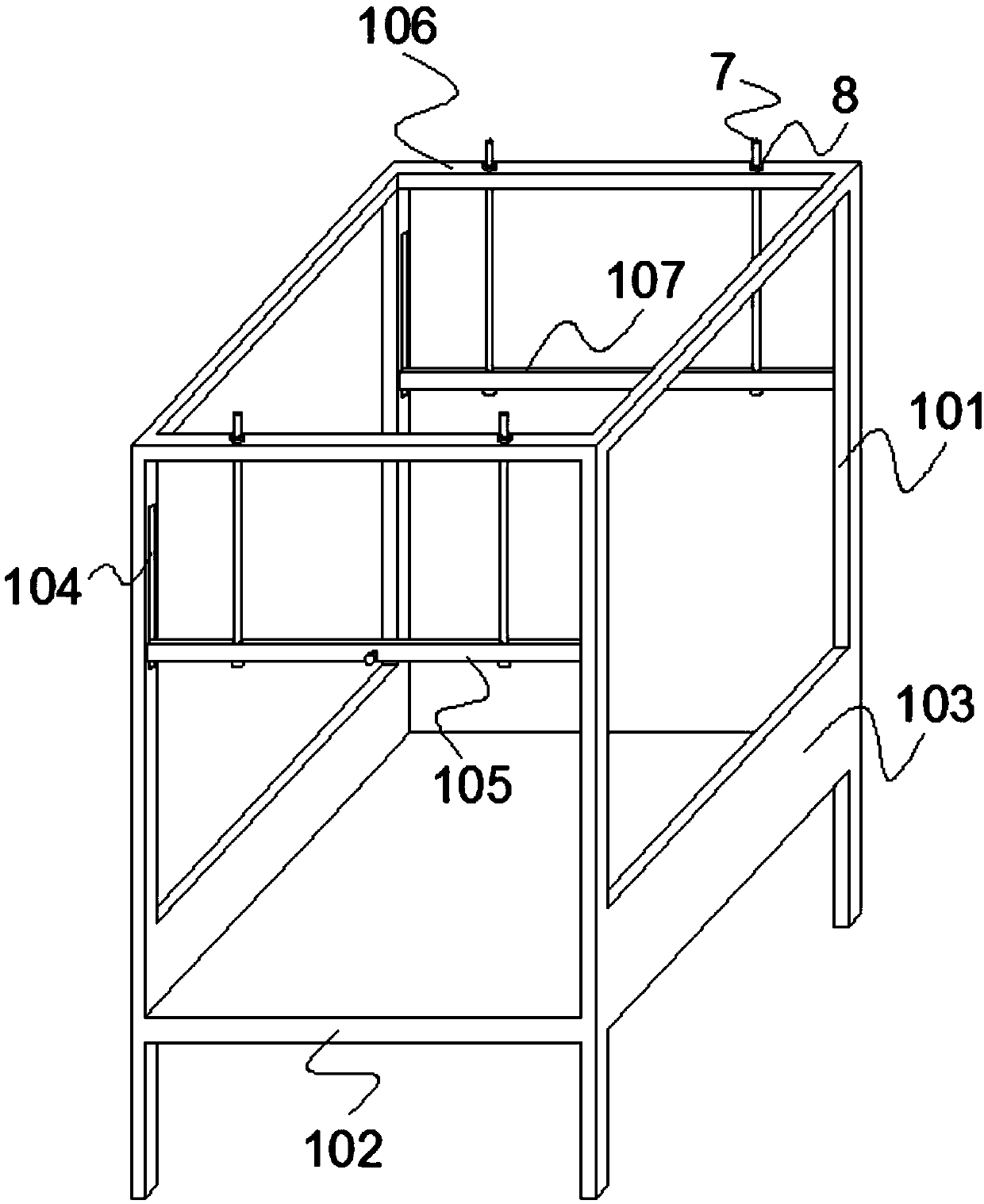

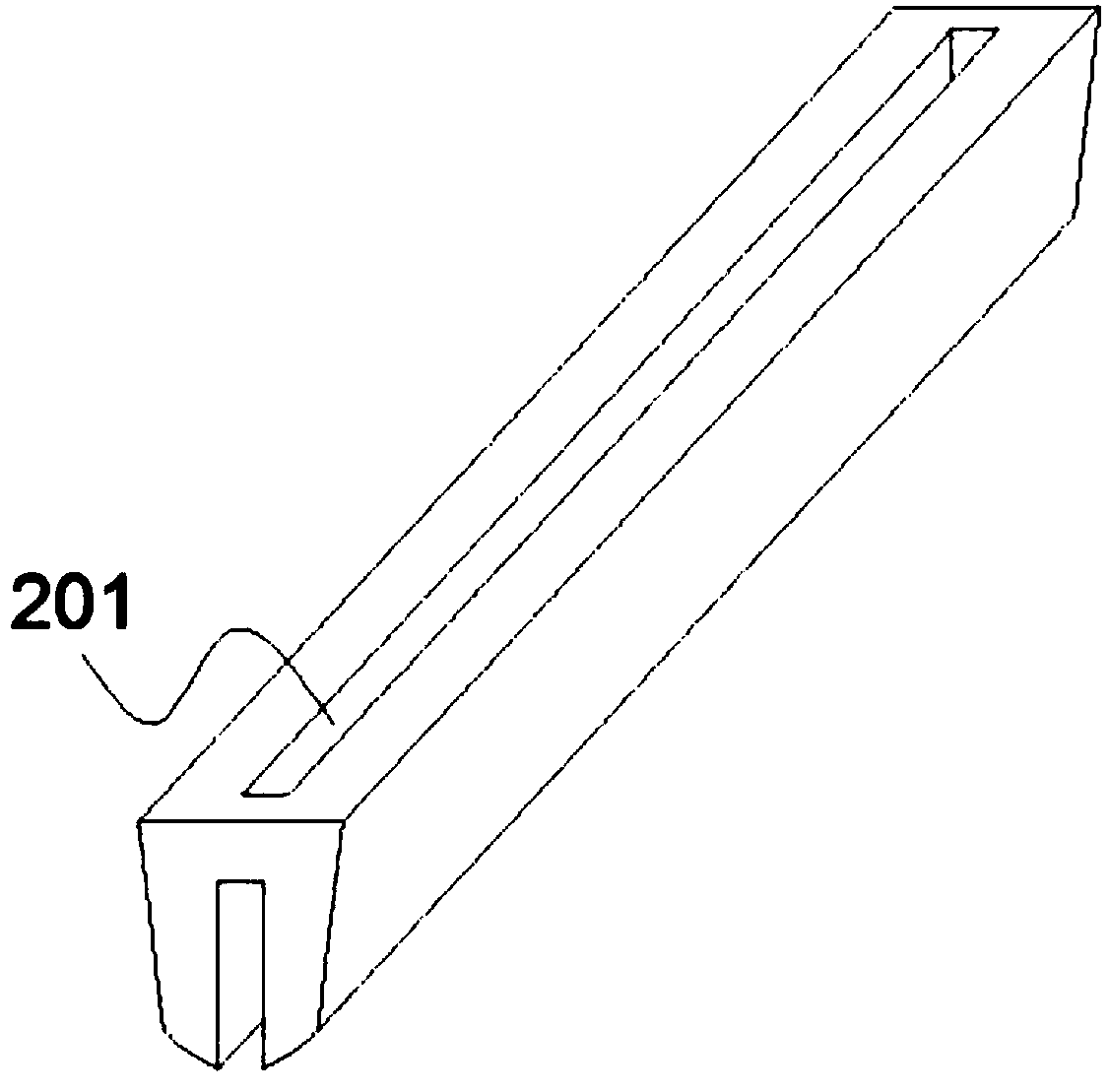

[0014] like figure 1 and figure 2 As shown, the new type of cloth stacking machine provided in this embodiment includes a bracket 1 and a cloth guide roller set arranged above the bracket 1. The bracket 1 includes a rectangular frame 106 at the top and four vertical frames connected below the corners of the rectangular frame 106. The rod 101, the front beam and the rear beam of the rectangular frame 106 are provided with a T-shaped table 5. The cloth guide roller group includes a first cloth guide roller 3 and a second cloth guide roller 4. The first cloth guide roller 3 and the second cloth guide roller The cloth guide rollers 4 are arranged side by side between the T-shaped table 5 on the front beam and the rear beam, and the cloth 10 is guided down from between the first cloth guide roller 3 and the second cloth guide roller 4 .

[0015] The lower part of the support 1 is provided with a cloth carrying table 102, the four corners of the cloth carrying table 102 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com