A fully automatic packaging line for fabrics

A fully automatic, assembly line technology, applied in packaging, transportation packaging, transportation and packaging, etc., to achieve the effect of tight fit, stable transition, and convenient circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

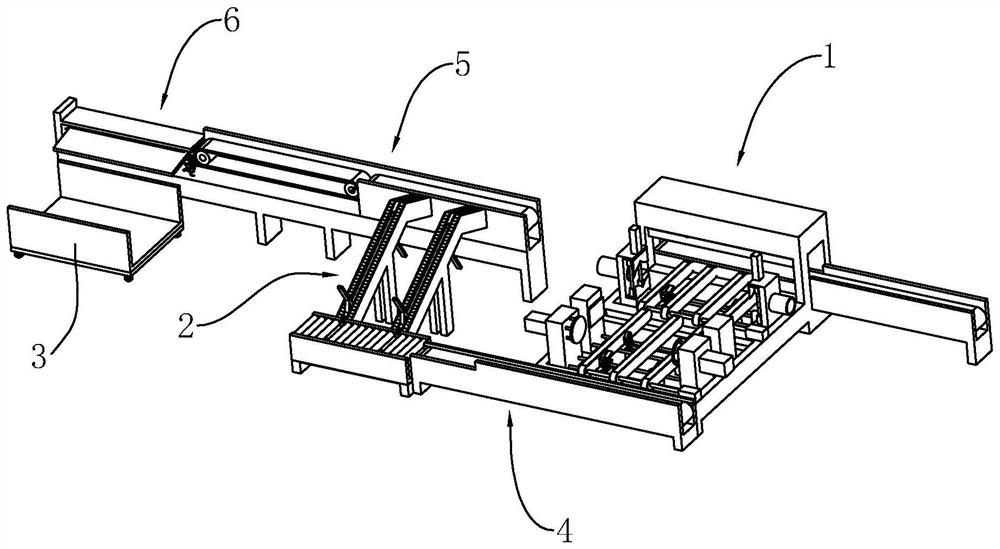

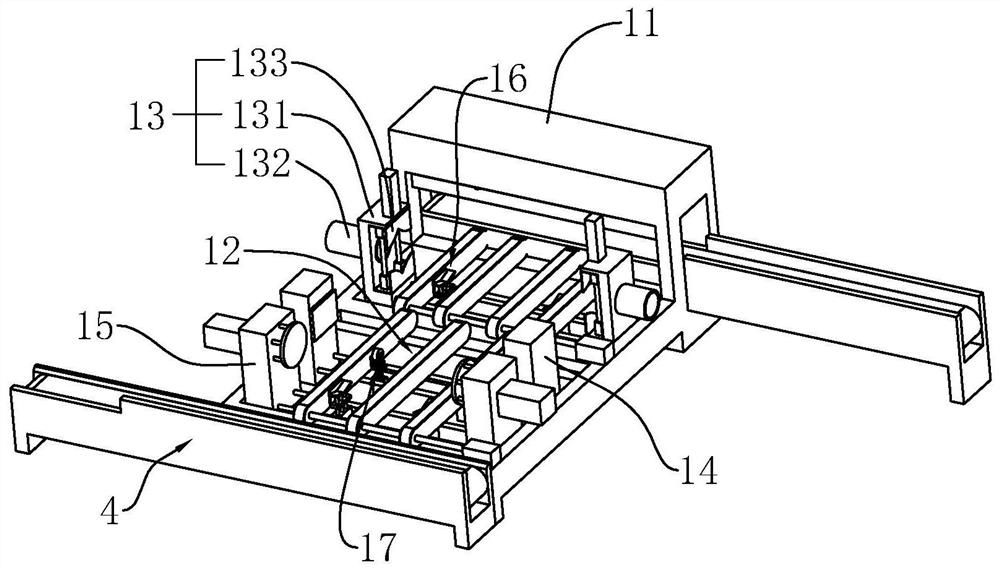

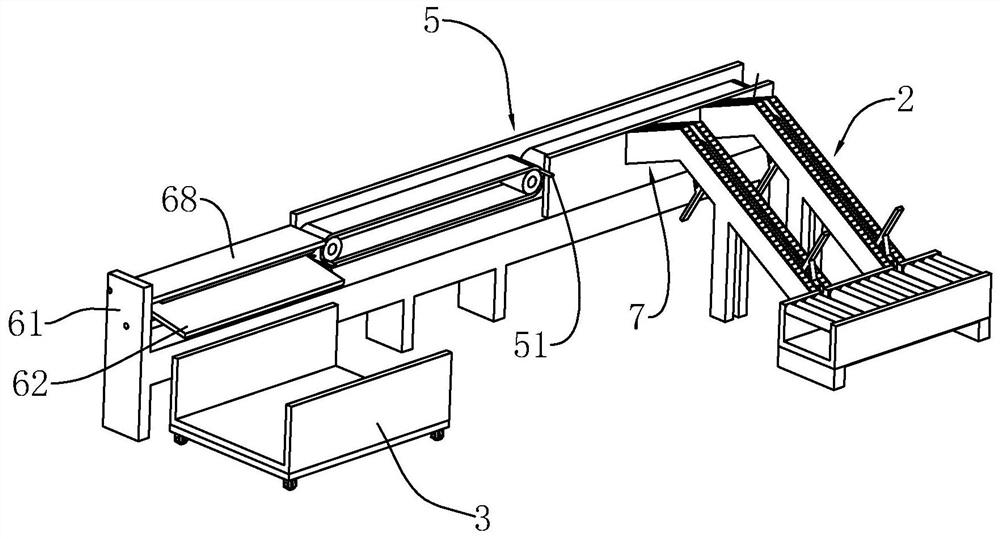

[0035] refer to figure 1 , which is a fully automatic cloth packaging line disclosed in the present invention, is provided with a packaging mechanism 1, a first conveyor belt 4, a lifting mechanism 2, a second conveyor belt 5, an unloading mechanism 6 and a storage vehicle 3 in sequence along the transportation direction of the cloth, Wherein the packaging mechanism 1 and the first conveyor belt 4 are all directly arranged on the ground, and the second conveyor belt 5 and the unloading mechanism 6 are installed at a position higher than the ground so as to use the gravity of the cloth for blanking, and generally speaking To reduce space occupation, it will be installed on the wall. Lifting mechanism 2 is just the equipment that cloth is moved from the first conveyor belt 4 close to the ground side to the second conveyor belt 5 arranged above the ground.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com