A gasket automatic sorting machine

A technology of automatic sorting and shims, applied in the direction of conveyor objects, transportation and packaging, and object destacking, etc., can solve the problems of low efficiency, labor-intensive, easy to serialize the wrong number, etc. The effect of high axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

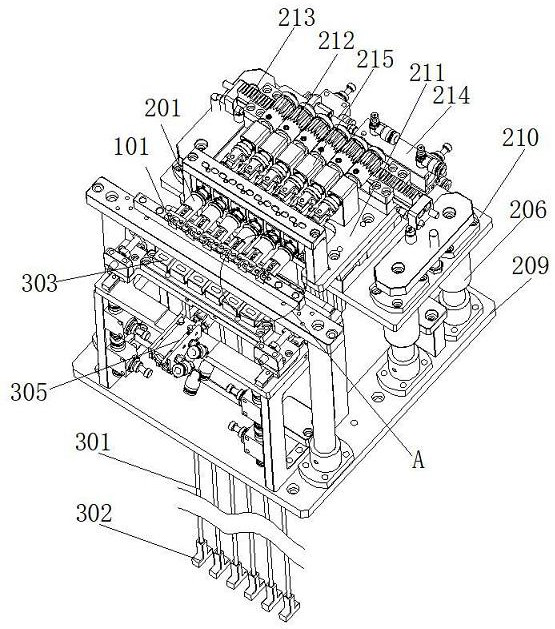

[0028] see Figure 1 to Figure 3 , as shown in the legend therein, an automatic shim sorting machine, comprising:

[0029] A feeding unit, which includes a plurality of feeding ports 101 arranged in sequence along the horizontal X direction and each facing the direction of the horizontal Y axis, and a vibrating plate (not shown in the figure) for automatically sorting and feeding to each feeding port 101;

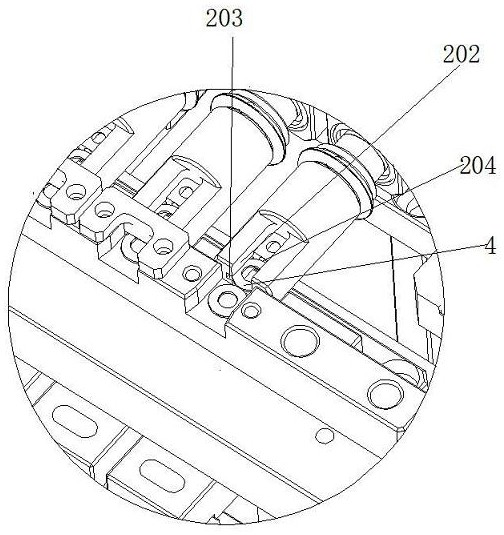

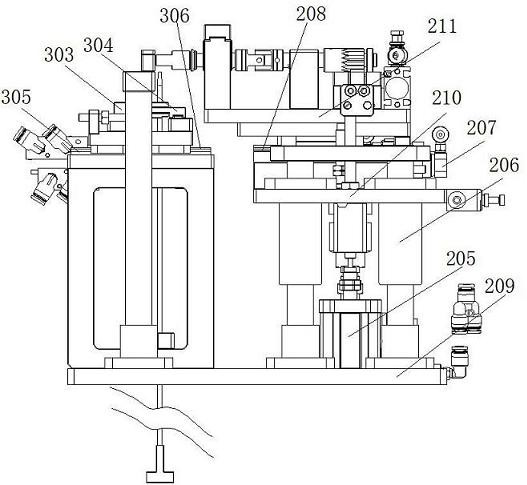

[0030] The material retrieving unit includes a plurality of reclaiming shafts 201 arranged in sequence along the horizontal X-axis direction and each extending along the horizontal Y-axis direction, a lifting device that drives the reclaiming shafts 201 to rise and fall along the vertical Z-axis direction, and drives the reclaiming shafts 201 A translation device that translates along the direction of the horizontal Y-axis. The feeding shaft 201 has a free end facing the feeding port 101. The free end is provided with a U-shaped opening 202 when viewed from above. The two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com